Liebherr LTM 1220-5.2 User Manual

Mobile crane |

LTM 1220-5.2 |

Product advantages |

|

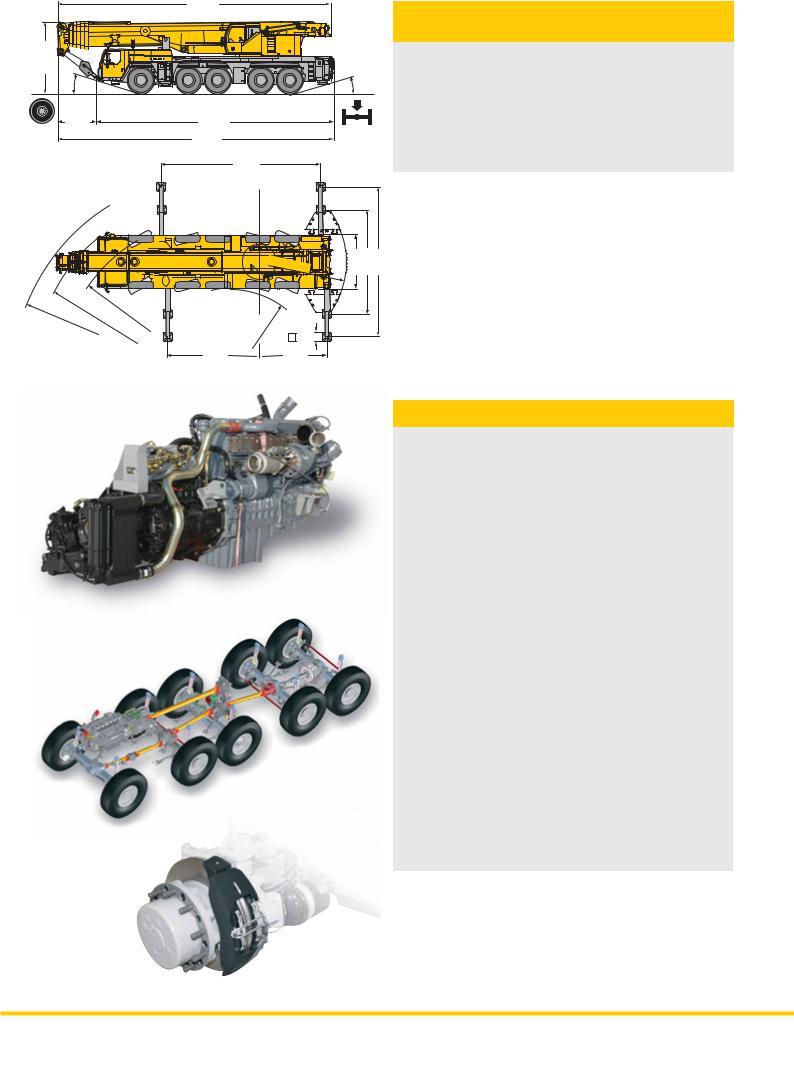

Max. load capacity: 220 t

Max. height under hook: 101 m

Max. radius: 88 m

40000

15323 |

Compact, maneuverable and |

|

|

|

weight-optimized |

|

|

|

• Overall length 15.52 m, carrier length 13.3 m |

|

|

|

|

• Large overhang angles of up to 20° |

|

20° |

|

17° |

• Smallest turning radius of 11.01 m with all-wheel steering |

|

16.00 R 25 12 t |

12 t 12 t |

12 t 12 t |

• Rear counterweight radius only 4.85 m |

|

• 60 t total weight (axle load 5 x 12 t) |

||||

|

|

|

||

2219 |

13298 |

|

• Choice of 3 tyre sizes |

|

|

15517 |

|

14.00 R 25 carrier width 3 m |

|

|

|

16.00 R 25 carrier width 3 m |

||

|

|

|

8899 |

20.5 R 25 carrier width 3.1 m |

|

R

=

R |

= |

|

12070 |

||

|

R |

|

= |

9560 |

|

|

11010 |

|

|

|

R |

|

|

=4850 |

|

= |

5450 |

R |

600 |

|

|

|

5104  3795

3795

3000 |

5500 |

8300 |

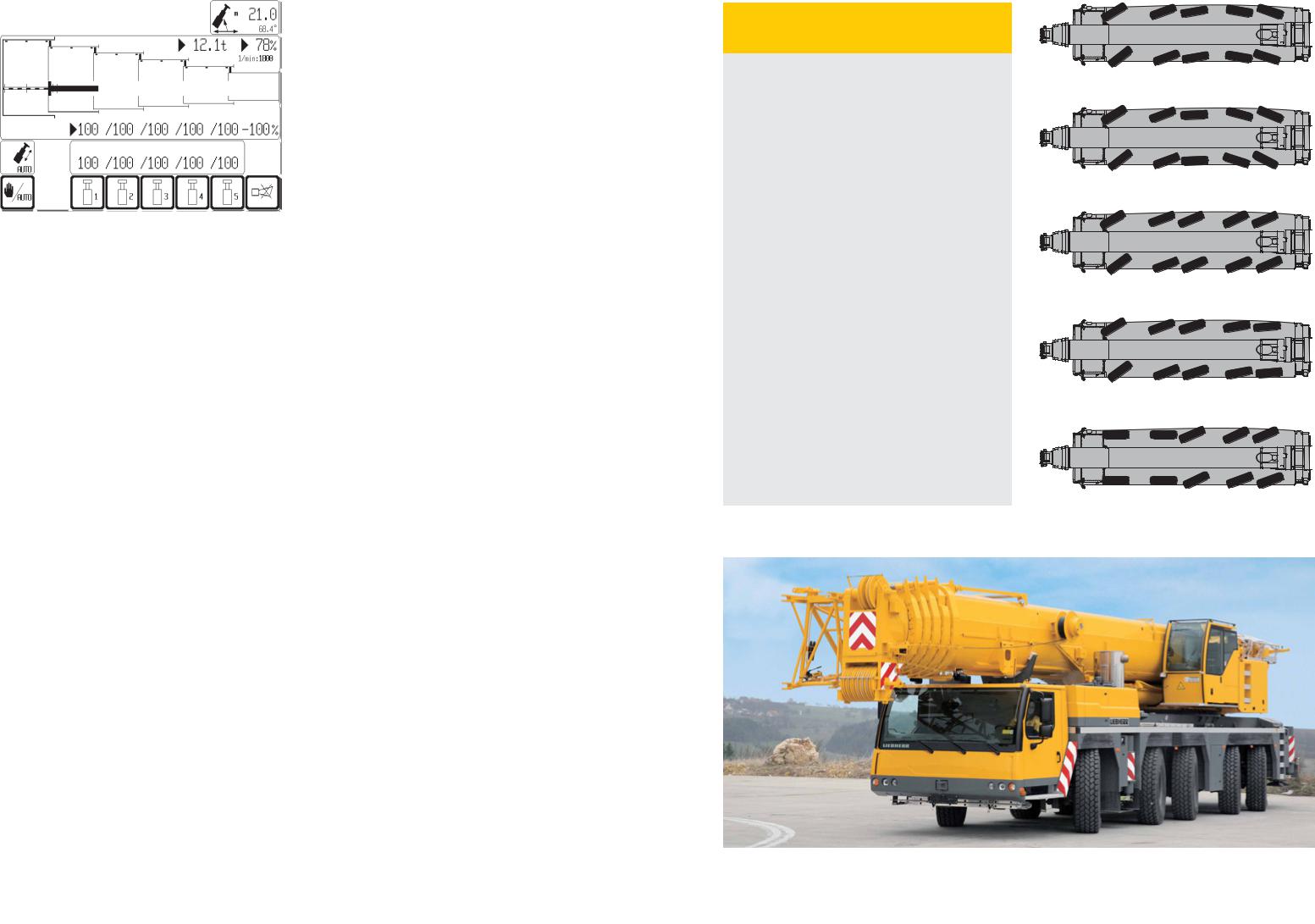

Modern drive concept

•Powerful, 6-cylinder Liebherr turbo-charged diesel engine type D846 A7, 370 kW/503 hp, exhaust gas emissions correspond to the directives 97/68/EC Stage 3 and EPA/CARB Tier 3, robust and reliable, modern and electronically-controlled engine management

•ZF power shift gear with automated AS-TRONIC control system. ZF intarder fitted directly to the gear unit, 12 forward and 2 reverse gears, automated control, reduced fuel consumption due to a high number of gears

•2-stage, robust transfer case with lockable transfer differential, creeping speed 0.78 km/h

•Drive 10 x 6, axles 2, 4 and 5 driven

•Drive 10 x 8 (optional), axles 2, 4 and 5 driven, axle 1 can be activated for off-road displacement

•Weight-optimized, robust, low-maintenance axles, perfect track keeping and lateral stability due to special arrangement of the steering knuckles; maintenance-free axle struts, steel and rubber mounted

•Maintenance-free drive shafts; quick and easy fitting due to 70° diagonal toothing

•Hydropneumatic ”Niveaumatik” suspension, programcontrolled for ”setting crane on outriggers”, ”crane displacement with equipment” and "crane displacement on the road", suspension travel +150/-150 mm

•Lateral force released and maintenance-free suspension rams, piston rods protected against damage

by synthetic pipes

•Sustained-action brakes:

Engine brake as exhaust retarder with Liebherr additional brake system (ZBS), intarder on gear, optional Telma-type eddy current brake

•Service brake:

All axles fitted with air disc brakes, high braking performance, long maintenance intervals, rapid-change brake linings

2 |

LTM 1220-5.2 |

Variable steering concept with

„active rear-axle steering“

Axles 3, 4 and 5 set up as „active rear-axle steering, 5 steering methods are preselectable by fixed programs (P):

P1: On-road steering

Axles 1 and 2 are steered mechanically with hydraulic assistance by the steering wheel. Axles 3, 4 and 5 are steered „actively“ speed-dependent, subject to the cramp of the front axles, and over 30 km/h, axles 3 and 4 are set to straight displacement and fixed, from 60 km/h, axle 5 is fixed equally to straight displacement. The change of the steering angle in accordance with the speed, results in a precise and stable driving quality during higher speeds, tyre abrasion is reduced and the maneuverability clearly improved.

P2: All-wheel steering

Axles 3, 4 and 5, dependent on the steering angle of axle 1 are cramped by means of the steering wheel so that the smallest turning radii can be performed.

P3: Crab steering

Axles 3, 4 and 5 are cramped into the same direction as axles 1 and 2 by means of the steering wheel.

P4: Steering without swerving

Axles 3, 4 and 5 are cramped in accordance with axle 1 so that no swerve out of the rear of the carrier takes place.

P5: Independent rear-axle steering

Axles 1 and 2 are cramped by the steering wheel, axles 3, 4 and 5 steered independent of the cramp of axles 1 and 2 by momentary-contact buttons, whereby the cramp of axle 3 is adapted to the required situation.

• A failure in the rear-axle steering makes it ineffective and the rear axles are set to straight displacement by the centering rams

• Two independent hydraulic circuits with wheeland enginedriven hydraulic pump, thus maximum safety standard

•Two independent control processors (by existing E/A modules) and diversified sensoriel system

•Entire know-how of the „active rear-axle steering“ by Liebherr

|

|

|

|

|

|

|

|

|

LTM 1220-5.2 |

3 |

|

Setting crane on outriggers – quick, convenient and safe

• Variable support basis 700

• Variable support basis 700

outriggers retracted

outriggers retracted

Support basis 5.5 m x 8.9 m Support basis 8.3 m x 8.9 m

•Fix-mounted supporting pads with splash guard

•Supporting ram travel of up to 700 mm

•Level control of the outriggers, all-automatic push-button crane levelling during the supporting procedure

•2 x 9° lateral inclination of crane and crane superstructure

•Control panels at either side of the carrier with membrane keyboard and electronic inclination indicator, push-buttons for ENGINE/START/STOP and speed control are illuminated and lockable

• Operation of the outrigger system in accordance with accident-prevention legislation

• Illumination of the supporting area by 4 incorporated projectors

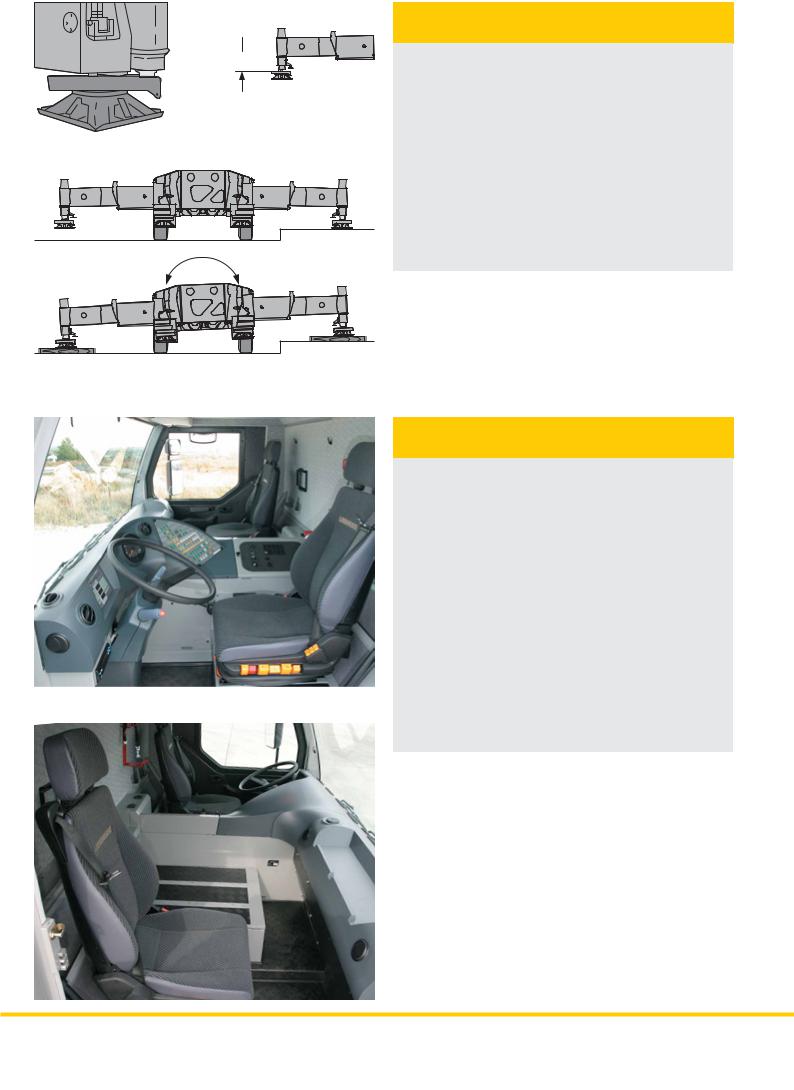

Comfortable driver’s cab of high functionality

•Modern, comfortable driver’s cab of high functionality and convincing design, corrosion-resistant, sheet steel version, cataphoretic dip-primed, front mounted on rubber shock absorbers, rear cushioned hydraulically, internal sound and heat absorbing panelling

•Safety glass all-round, greenish tinted front and side windows for heat absorption, electric window lifters

•Arrangement of the control elements and displays according to ergonomical aspects for safe and convenient handling during continuous operation

•Digital display and keyboard units interconnected with the functional blocks by data bus technology

•Driver’s seat cushioned pneumatically, with pneumatic lumber support, headrest

•Steering wheel adjustable in height and inclination

•Heatable and electrically adjustable rear mirrors

•Safety belts for driver and co-driver

•3 windscreen wipers with automatic wipe/wash system and intermittent control

•Delayed switch-off of the interior lights

•Various racks and stackers

•Radio preparation

4 |

LTM 1220-5.2 |

Loading...

Loading...