Liebherr LB 16 User Manual

Rotary drilling rigs LB series

Efficient in every application

The conception of the Liebherr rotary drilling rigs (LB series) is based on Liebherr’s many years of experience with deep foundation applications and considers even the heaviest demands, which are nowadays made on modern rotary drilling rigs.

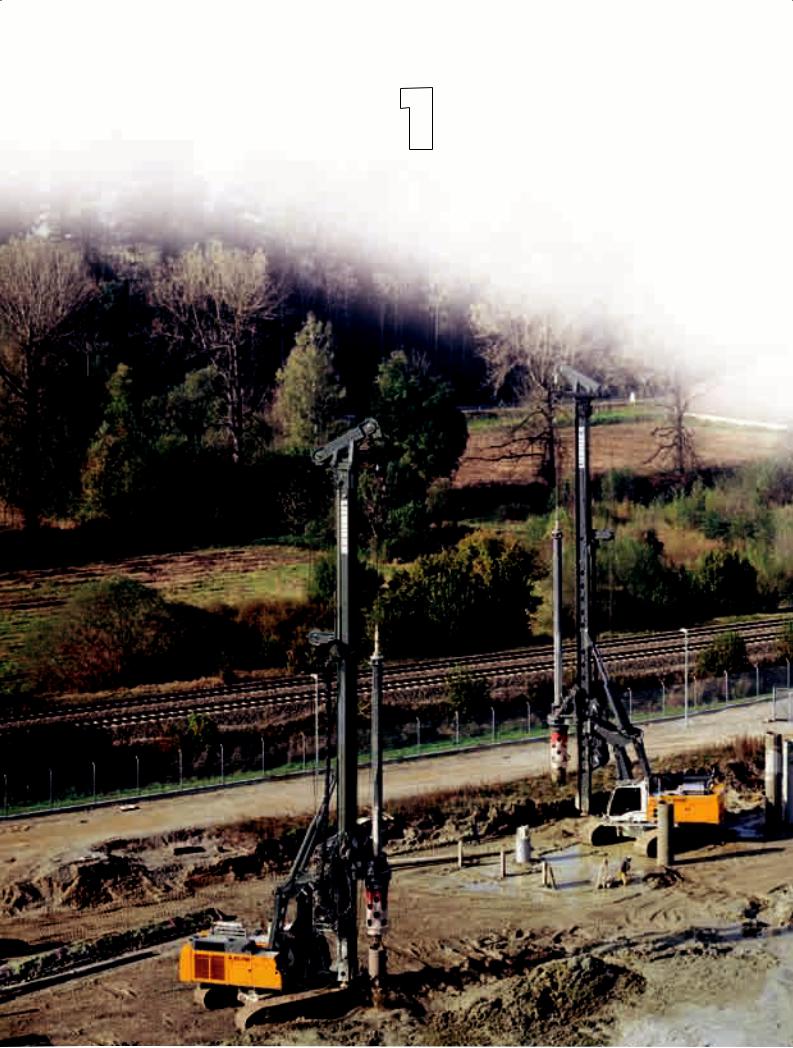

1Success through leading technology

Liebherr rotary drilling rigs achieve an excellent level of performance in every situation due to leading technology developed in-house. This includes

the powerful drive technology, the solid leader design, the electronic control and the reliable machine and process data recording system. Thus, Liebherr defines new standards for rotary drilling rigs.

2

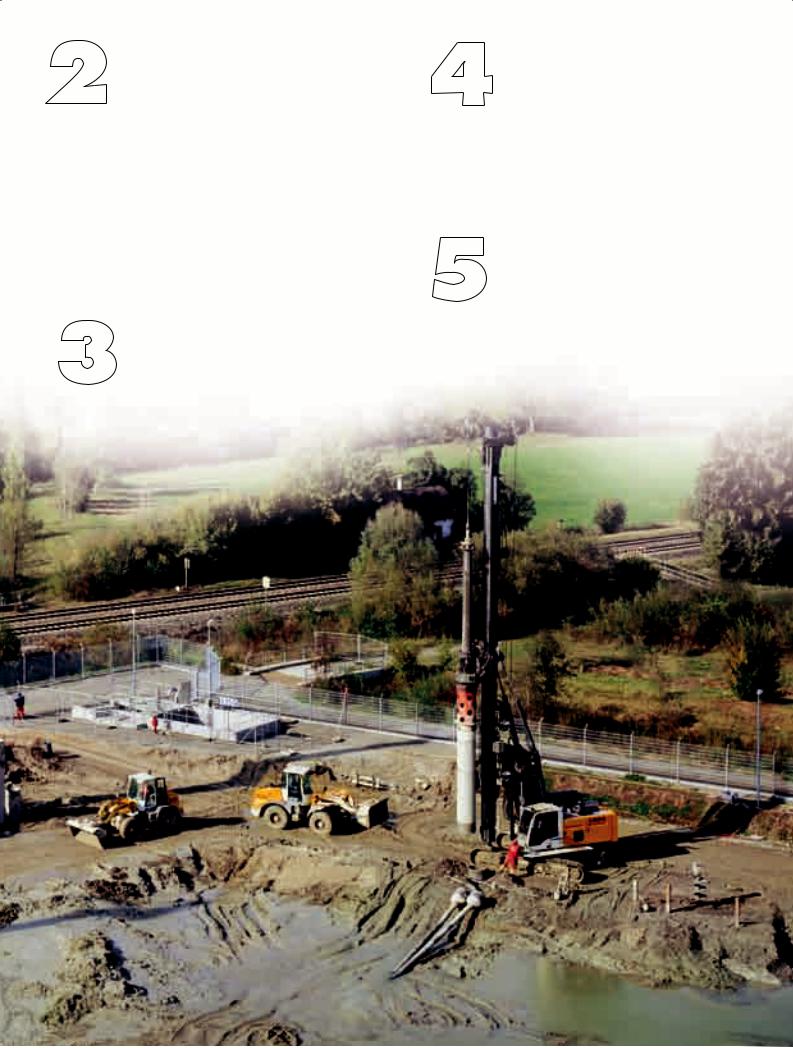

2Performance and flexibility through innovation

Liebherr rotary drilling rigs offer a wide range of possible applications.

No existing standard concept was used for their development. The steel structure of the uppercarriage was newly designed to meet with the requirements. Many innovations from Liebherr's many years of experience with deep foundation applications were incorporated and all requirements for best performance were uncompromisingly fulfilled. Reliable Liebherr components as well as proven Liebherr technology were used to ensure the high quality and longevity of the drilling rigs.

3Cost-effective operation

Economical transportation, quick and easy assembly as well as extremely low operating costs are decisive advantages of Liebherr rotary

drilling rigs.

4Higher productivity through better comfort

The ergonomically designed cab provides the operator with an unlimited view of the operating area. The standard equipment of the Liebherr

rotary drilling rigs includes numerous innovative technical features ensuring ease of operation for the operator and thus maintaining his efficiency.

5Reliable service

Thanks to low maintenance requirements, the possibility of remote diagnosis, quick assistance on site and an efficient spare

parts supply, Liebherr guarantees the permanent availability of its products. For qualified service of the machines as well as comprehensive training of operating and maintenance personnel, state-of-the-art repair and training centres are available at the works in Nenzing as well as at other locations.

3

4

1Success through leading technology

Thanks to the extremely robust leader and the parallel kinematics Liebherr rotary drilling rigs are enormously versatile and ideal for precise work. The rope crowd system featuring exceptionally high pull and push forces significantly enhances the rigs' performance. The Litronic control system does not only include programs for the application of the various drilling methods but also provides the operator with information on service requirements and possible defaults. The process data recording and evaluation systems are available as additional equipment. The reliable Liebherr diesel engines offer sufficient power and are particularly energy-saving.

5

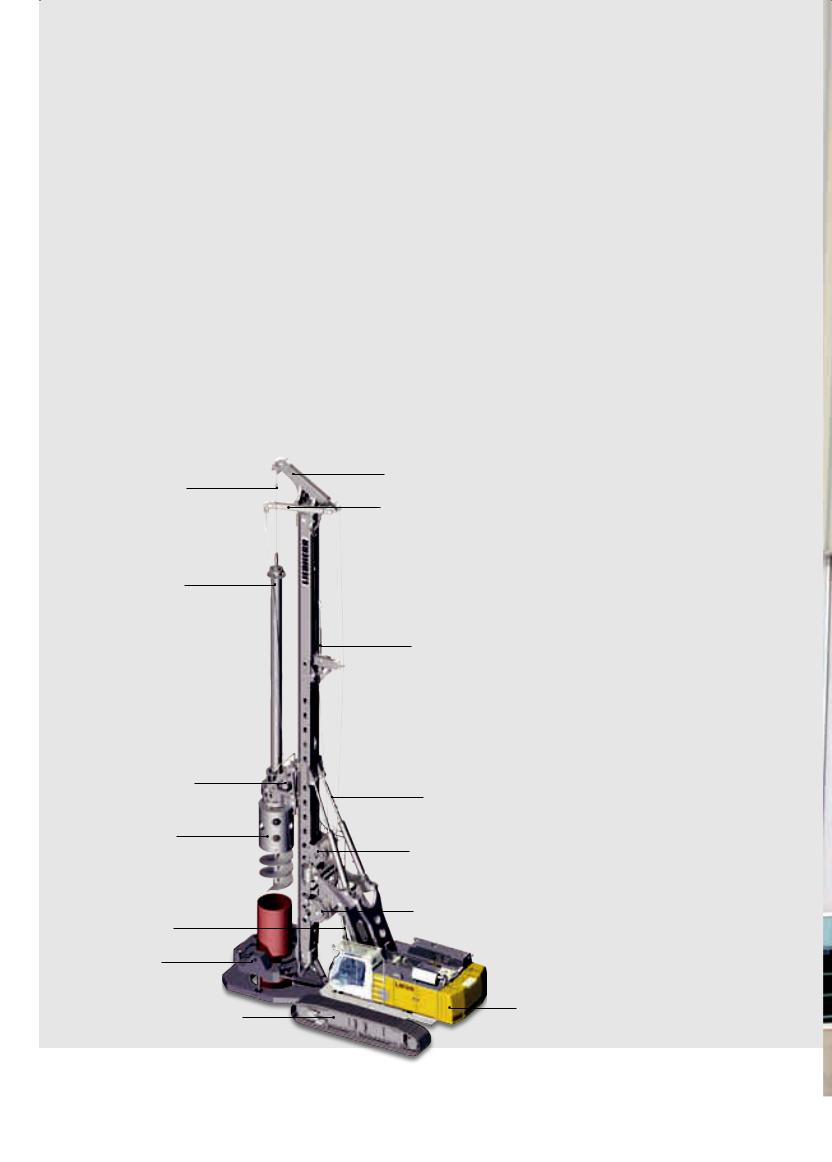

Convincing leader concept

The higher the utilization of a drilling rig, the more profitable is its operation. Therefore the kinematics and leaders of Liebherr rotary drilling rigs are designed for a wide variety of applications.

More stability for maximum precision

The parallel kinematics, which is exclusively applied in the Liebherr rotary drilling rigs, provides the unit with outstanding stability and high alignment forces. It only allows for minimum deformation and thus guarantees maximum precision, e.g. when installing foundation piles by drilling. Decisive advantages are due to the functions of radius adjustment without inclination adjustment and radius adjustment without rope movement. The latter is possible because all winches are mounted on the leader. Moreover, the rig has a larger operating area without repositioning the undercarriage.

Box design reinforces the leader

Since the leader is built in an especially rigid box design with a large cross section, it can absorb very high pull forces and torques. Thanks to this robust design deformations are reduced to a minimum and lower surface pressure is achieved leading to less wear and a longer service-life.

Rope crowd system for increased crowd force

For drilling operations the crowd force of the rig is of vital importance. Due to the high pull force of the LB rigs cased boreholes of greater length can be produced without casing oscillators. This saves time and money. Using the standard rope crowd system the rotary drive can travel over the complete leader length, thus allowing installation of longer casings. This saves time when connecting the pipes.

Kelly rope

Kelly bar

Rotary drive

Casing driver

Radius adjustment

Casing oscillator

Undercarriage

Leader top for Kelly rope

Leader top for auxiliary rope

Tensioning cylinder for the crowd rope

Leader inclination device

Crowd winch

Kelly winch

Uppercarriage

6

7

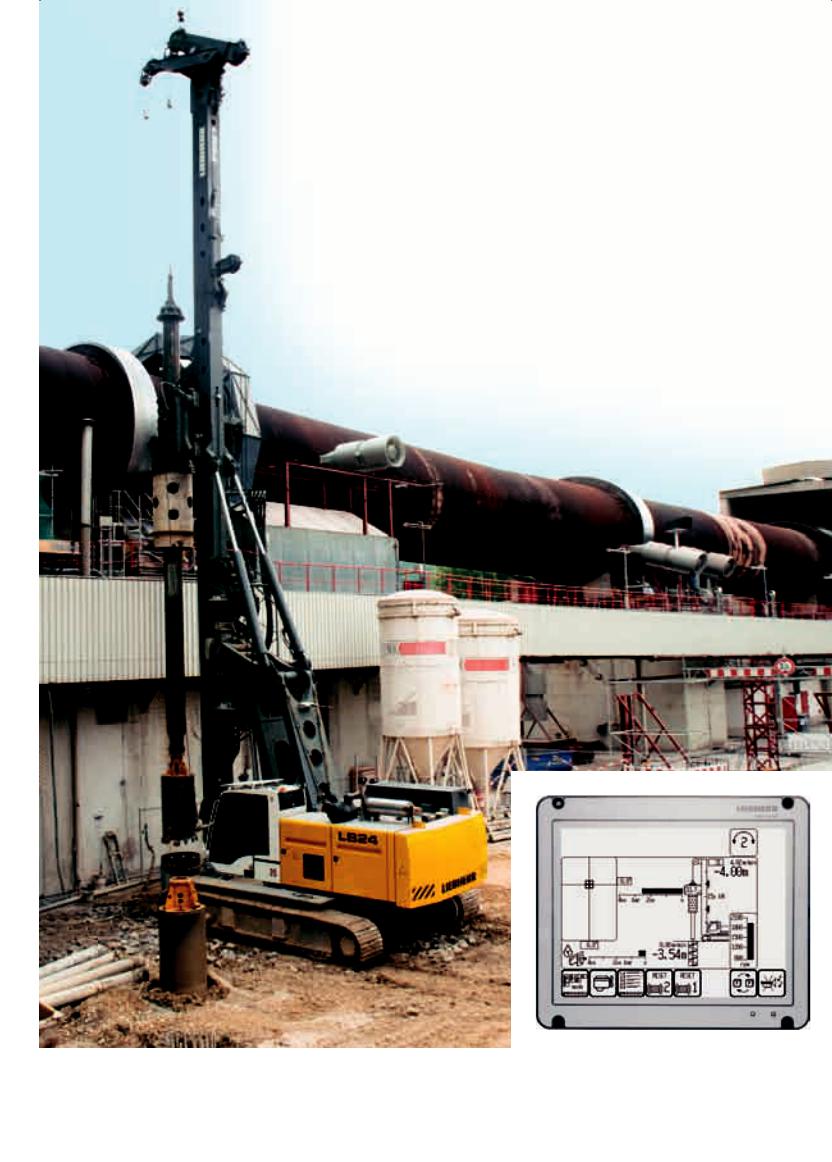

Electronic control

The core of the Liebherr rotary drilling rigs is the Litronic control system. Developed and manufactured by Liebherr, this comprehensive system encompasses all control and monitoring functions and is designed for extreme environmental conditions in tough assignments.

Operating comfort and information through Litronic

The Litronic control is based on a CAN-Bus system of the latest generation. All information required for the current rig operation such as information on the type of application, machine data, warnings and failure indications are displayed on the large touch screen. This allows optimum diagnosis and early detection and prevention of more serious defects.

High precision machine control

The electro-hydraulic proportional control enables several movements to be carried out simultaneously and with utmost precision. As a special operating comfort all leader functions can be controlled either via the additional control panel or via joystick. Thus, excellent positioning is provided in all fields of application.

8

9

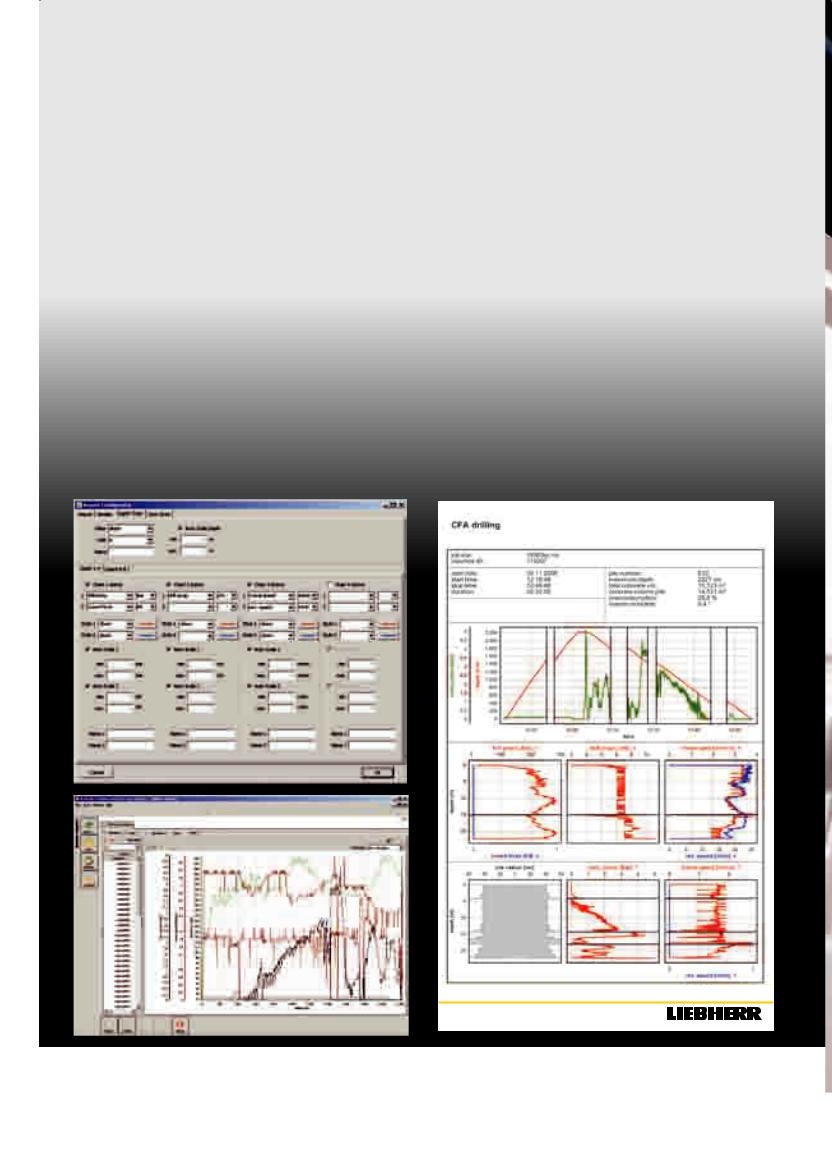

Electronic evaluation

A modem for remote diagnosis as well as a process data recording system for documentation of the work carried out and a process data reporting software for evaluating the recorded data are available as cartridge.

Quality assurance through process data recording (PDE)

The process data is constantly measured during the working process. External sensors can also be connected to the system. Measurement data relevant to the working process is displayed on the monitor in the cab. The operator can then control all processes and, if necessary, correct them. The data is stored by the system and can be transferred to a computer using a CompactFlash card. Via GSM modem the data can be transferred.

Evaluation and visualisation through process data reporting (PDR)

The Liebherr software for process data reporting allows to further process the data on a PC, where they are directly stored, sorted and visualised. Thus, customer-specific evaluations can easily and quickly be created.

10

11

Loading...

Loading...