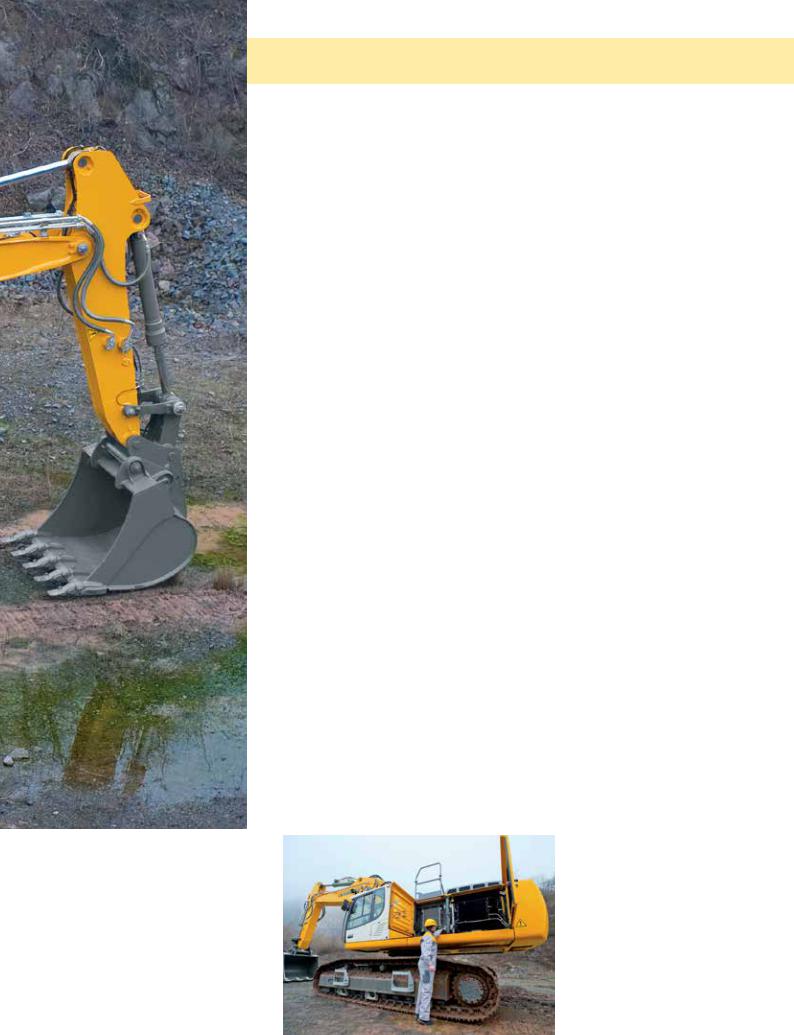

Liebherr R 956 User Manual

Crawler Excavator |

R 956 |

||

|

|

|

|

|

|

|

|

|

|

|

|

Operating Weight with Backhoe Attachment: |

49,600 – 57,100 kg |

||

Operating Weight with Shovel Attachment: |

55,650 – 56,200 kg |

||

Engine Output: |

240 kW / 326 HP |

||

Bucket Capacity: |

1.25 – 3.30 m³ |

||

Shovel Capacity: |

|

3.10 m³ |

|

R 956

Operating Weight with Backhoe Attachment: |

49,600 – 57,100 kg |

|

Operating Weight with Shovel Attachment: |

55,650 – 56,200 kg |

|

Engine Output: |

240 kW / 326 |

HP |

Bucket Capacity: |

1.25 – 3.30 |

m³ |

Shovel Capacity: |

3.10 |

m³ |

2 R 956 Litronic

Performance

Responsive and precise, the R 956 crawler excavators allow you to perform a large number of mass excavation tasks in earthmoving sites or in quarries. Thanks to their tested hydraulic design and their various work modes, Liebherr excavators will always be there to satisfy your needs.

Reliability

Engineered for difficult operating conditions, the R 956 crawler excavators were designed to meet a list of specifications resulting from our customer’s requirements.

Comfort

The new, more spacious operator’s cab provides the operator with a quiet working environment. What’s more, the ergonomics, visibility and soundproofing have been improved for increased comfort.

Profitability

The raw performance amounts to maximum effective working hours. These excavators allow you to target essential operations and reduce operating costs in order to obtain the best return on investment.

R 956 Litronic 3

Liebherr Engine

•New Stage 3B / Tier 4i engine

•Designed specifically for construction applications

•Liebherr Common Rail Injection system with three times less load losses than a conventional Common Rail system

•Automatic fuel-saving idling system

•Two-stage turbocharging with intercooler, for increased power at low revs and reduced fuel consumption

4 R 956 Litronic

Performances

Responsive and precise, the R 956 crawler excavators allow you to perform a large number of mass excavation tasks in earthmoving sites or in quarries. Thanks to their tested hydraulic design and their various work modes, Liebherr excavators will always be there to satisfy your needs.

Technology serving productivity

Liebherr Integration |

All the major components are designed and man- |

|

ufactured within the Liebherr group. This includes |

|

components such as the heat engine, hydraulic |

|

pumps, electronic components (injection mapping, |

|

hydraulic control, control console) and of course the |

|

essential mechanical elements including cylinders, |

|

the slewing ring and work tools, resulting in an over- |

|

all increase in productivity. |

Regeneration Plus |

The „Regeneration Plus“ function allows for the |

|

accelerated lowering of the boom, reduced losses |

|

of pressure and an improved work cycle. The opti- |

|

mization and combination of the „zero-pressure |

|

lowering of the boom“ and „Regeneration plus“ |

|

functions, together with the increased power of |

|

the hydraulics, provide increased performance and |

|

lower consumption. |

Power and speed

Increased |

Thanks to their kinematics and hydraulic power, the |

break-out force |

R 956 crawler excavators develop increased break- |

|

out and digging forces. The generously sized cyl- |

|

inders allow you to increase the break-out perfor- |

|

mance in hard materials. |

Faster cycles |

The mechanical link between the rotation engine |

|

and slewing ring gives the machine a high torque |

|

and swing speed, thus improving your operating |

|

cycles. |

Choice of work mode |

|

Floating Boom Function |

|

||

The different work modes offered allow you to adapt the power |

|

• Increased hydraulic flow for the |

of the excavator to the application |

|

other cylinders (stick and/or bucket |

E Mode - Economy: for economical and ecologically-friendly |

|

for example) |

|

|

|

operation. Minor restriction of power without affecting the load |

|

• More power available, making it easier |

lifting and excavating capacities. Highly recommended for light |

|

to extract materials and reduce work |

and moderate working conditions |

|

cycle times |

P Mode - Power: for high excavation capacities and difficult |

|

• Increased service life when a hydraulic |

applications. Pump flow and power are not limited |

|

hammer is used |

S Mode - Sensitivity: for precision jobs and loading of materials. |

|

|

The pump flow and power are restricted to attain optimal sensitivity |

|

|

P+ Mode - Full Power: especially designed for increased power; |

|

|

only recommended for extreme applications |

|

|

|

|

|

R 956 Litronic 5

Liebherr particle filter

•Designed and manufactured by Liebherr, it eliminates more than 99% (VERT certification) of fine particle emissions

•Active regeneration of the particle filter, causing no interruption to the operator and without reducing the machine’s performance

•The central module (filter unit) is removable and easily accessible for maintenance

6 R 956 Litronic

Reliability

Engineered for difficult operating conditions, the R 956 crawler excavators were designed to meet a list of specifications resulting from our customer’s requirements.

Fully-tested strength

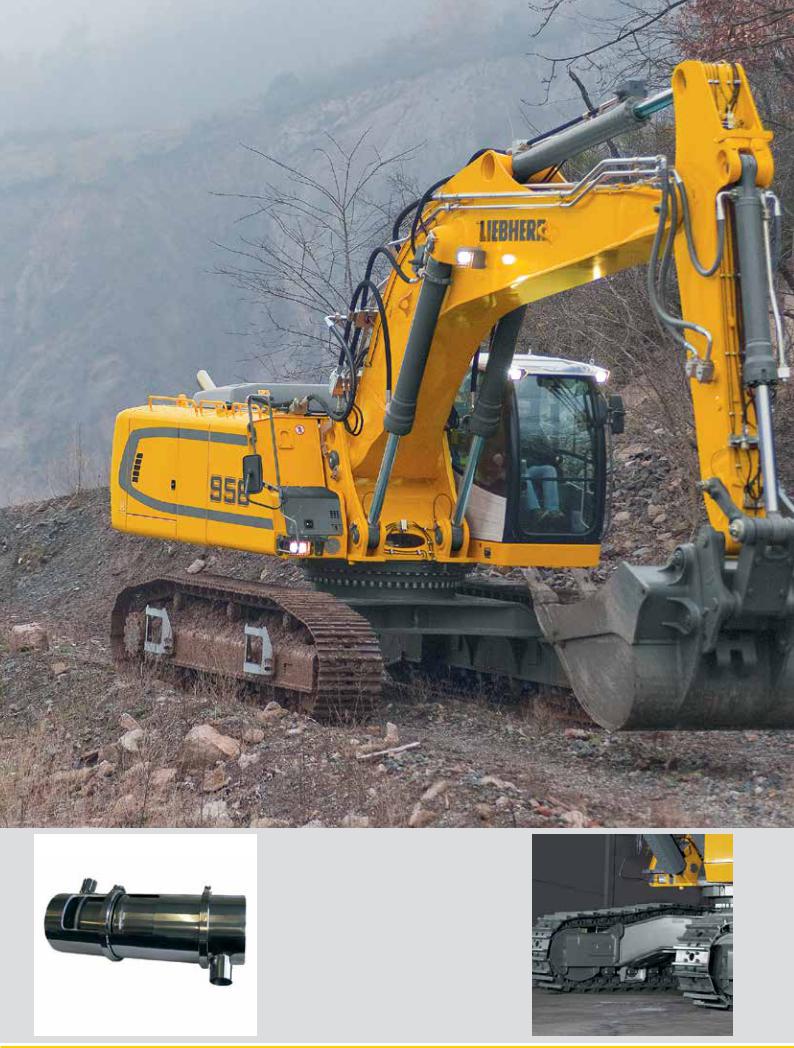

Improved and reinforced With an X-shaped design and an increased slew-

undercarriage |

ing ring diameter, this new undercarriage is char- |

|

acterized by an even distribution of stresses over |

|

the whole structure. This results in increased per- |

|

formance, greater load properties and an increased |

|

service life. |

Safe travel |

The integration of 3 guiding guards per track as |

|

standard significantly reduces the risk of tracks |

|

coming off. In addition, track pins and bearings are |

|

lubricated for life, which reduces both maintenance |

|

tasks and down time. |

Strengthened |

The uppercarriage has been reinforced with heavier |

uppercarriage |

steel to ensure increased strength. The HD boom |

|

and stick are standard - improving resistance to the |

|

impact of materials. Similarly, the system of cast |

|

and welded housings on the boom allows for an |

|

improved distribution of stresses. |

Quality serving safety

Finest details |

The hydraulic, electric and lubrication lines are laid |

|

out to ensure optimum operating safety and maxi- |

|

mum availability. The finish paint applied before |

|

assembly and the appropriate surface treatment of |

|

the components guarantee maximum protection |

|

against corrosion. The integration of the rear camera |

|

in the counter weight elegantly highlights the overall |

|

perception of quality, safety and reliability. |

ROPS cab structure |

The cab is equipped with an integrated roll over |

|

protection system (ROPS), pursuant to standard |

|

ISO 12117-2. |

Undercarriage |

|

Key components developed by Liebherr |

|

||

• New design for increased life and |

|

• Perfect harmonization of the machine |

improved distribution of forces |

|

elements, designed specifically for |

• Linear slope between the upper plate of |

|

earthmoving and quarry applications |

|

• Engine, hydraulic pumps, transfer box, |

|

the central section and the track carriers |

|

|

for constant cleaning |

|

transmission, rotating mechanism, slewing |

• Easy and safe transport thanks |

|

ring, cylinders and electronic components |

|

are designed and manufactured by Liebherr |

|

to integrated securing hooks |

|

|

|

• Purpose built options such as special at- |

|

• 3 types of undercarriage available, |

|

|

|

tachment lengths |

|

including one with a variable gauge |

|

|

|

• Specific tools and custom protection can |

|

for an accurate configuration to suit |

|

|

the jobsite requirements |

|

be added at the factory |

|

|

|

|

|

|

|

|

|

R 956 Litronic 7

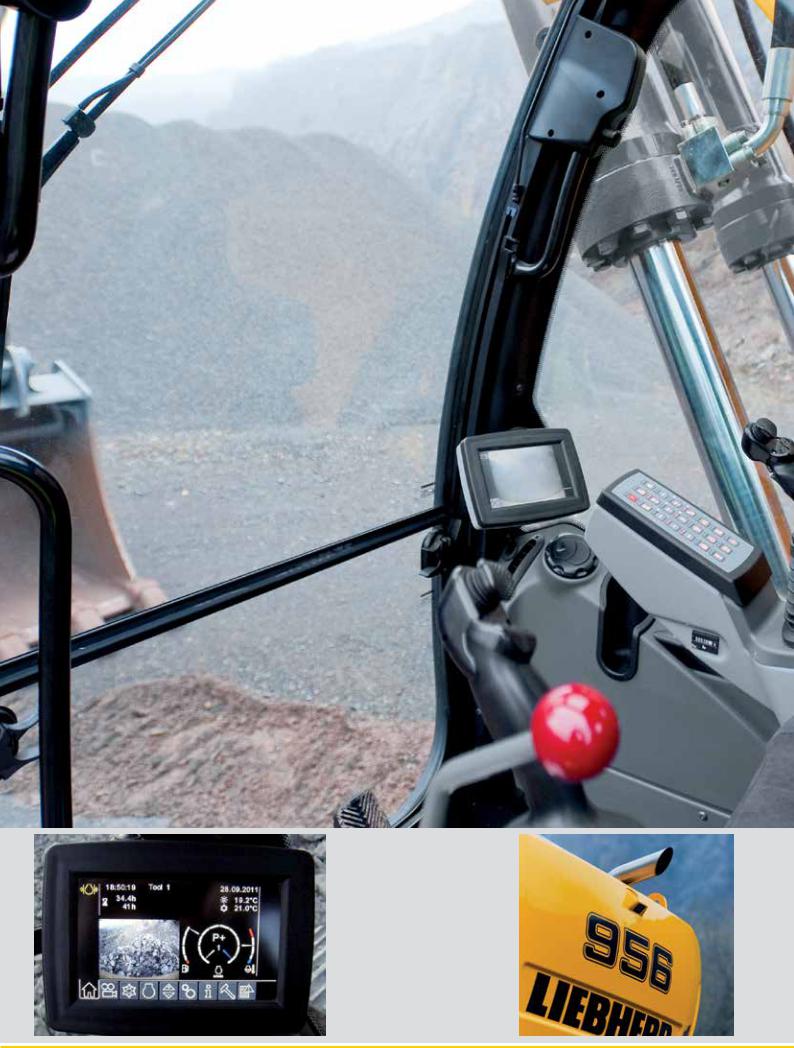

Control screen

•7’’ color touchscreen

•Several setting, control and surveillance options

•Robust and reliable design (Ingress Protection Rating IP65)

•Compatible high resolution video for displaying the rear camera image

8 R 956 Litronic

Comfort

The new, more spacious operator’s cab provides the operator with a tranquil working environment. What’s more, the ergonomics, visibility and soundproofing have been improved for increased comfort.

It’s just about feeling good

A spacious and ergo- |

The cab offers a generous space for maximum com- |

nomic work station |

fort. Equipped, among other things, with a pneu- |

|

matic seat with heater as standard (optional with air- |

|

conditioning), controls connected to the seat and |

|

high-performance automatic air-conditioning, the |

|

cab creates a pleasant working environment. All the |

|

controls are precisely laid out in an intuitive manner |

|

for greater responsiveness and concentration while |

|

working. The cab is mounted on viscoelastic studs |

|

for significantly lower vibration. |

Fully automatic |

The automatic air-conditioning with touchscreen |

air-conditioning |

controls has several ventilation outlets for optimum |

|

ambient air in the cab. |

High resolution |

The color touchscreen is a true human-machine |

color touchscreen |

interface for controlling several comfort functions, |

|

such as the radio, and more operational functions, |

|

such as work modes, tool types and even the |

|

backup camera. |

A cab that’s easy |

The possibility of working in a clean environment |

to look after |

was an important objective in the design of the cab. |

|

It is particularly easy to maintain thanks to elements |

|

such as a keyboard with soft touch comfort keys |

|

and an easily accessible cab air filter. |

Heightened visibility

•Rear camera integrated in the counterweight as standard, for rear visibility and heightened operating safety

•Optimized design of the whole uppercarriage providing the operator with an improved field of vision

•Retractable laminated glass roof panel

Joystick

•Sensitive joystick with proximity switch

(controlled by approach of the operator’s hand) for greater responsiveness when resuming operations

•Proportional ergonomic control for heightened job precision

R 956 Litronic 9

Liebherr tools

•Wide range of tools suitable for every type of application

•Tools designed for maximum productivity and durability

•Shape of buckets designed to assist the filling and stability of bulky materials during the transport stages

•Hydraulic quick coupler system

10 R 956 Litronic

Profitability

The raw performance amounts to maximum effective working hours. These excavators allow you to target essential operations and reduce operating costs in order to obtain the best return on investment.

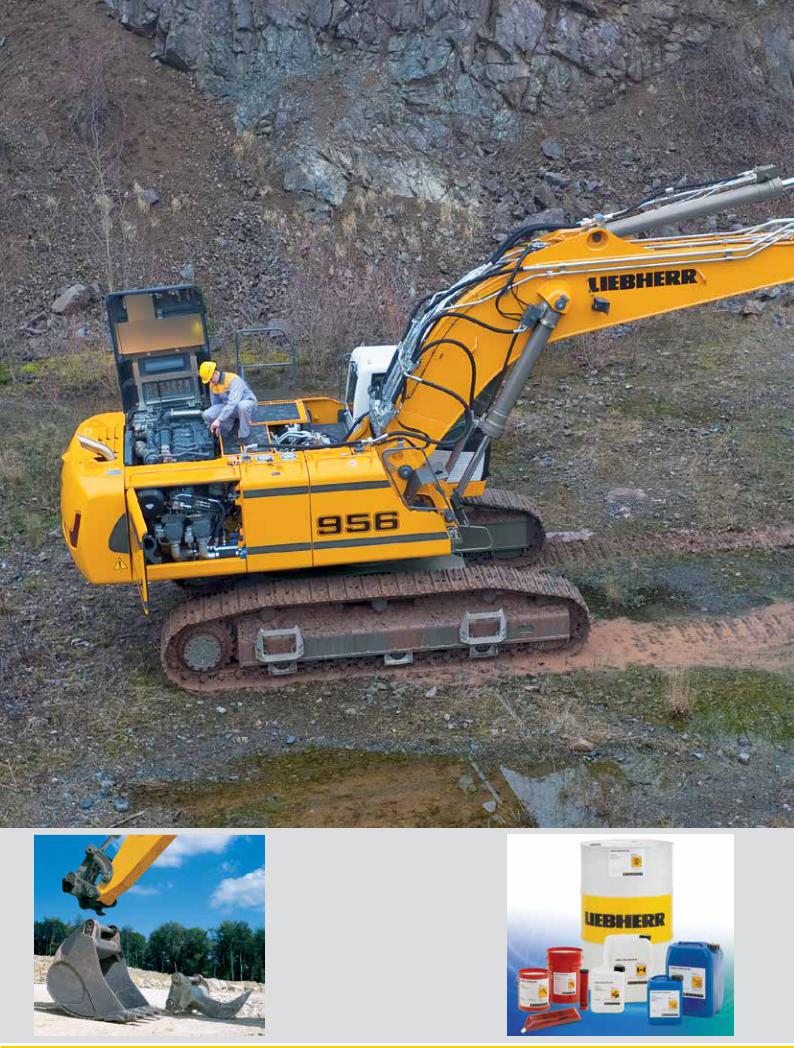

The best choice

Low operating costs Thanks to its high technology and its innovation, the Liebherr France Company increases the performance of its machines while reducing their fuel consumption. Examples of this are the new diesel engine, automatic idling, electronic engine speed sensing control, Regeneration Plus function and the hydrostatic cooling system (fans operate only when necessary). Consequently, the reduced fuel consumption means less pollution.

LiDAT fleet and machine To improve your machine management, Liebherr park management tool has developed its own data transmission system using the GPRS network. This system allows you to instantly know the position of your excavator via a web interface. Thanks to data transmission, the LIDAT system developed and manufactured by

Liebherr keeps you informed about fuel consumption, number of service hours or machine faults, just to name a few. LIDAT allows you to be proactive and more responsive: organizing and maintaining your fleet for increased productivity.

Liebherr-Service

An excellent after-sales The after-sales services can be customized to suit service and respond to your specific needs. Several programs, such as ReMan, ReBuilt and Repair provide the perfect, economical solution, always including the manufacturer’s quality and guarantee. A team of technicians, specialized to intervene on your machines, has all the latest-generation diagnostic tools, for a reduced down time of the machine. By following your chosen maintenance program, you

will also obtain a higher resale price.

Liebherr lubricants |

|

Maintenance |

|

||

• Complete range of lubricants and |

|

• Automatic centralized lubrication as |

coolants for your Liebherr engines |

|

standard for regular lubrication of criti- |

• Special service with product spe- |

|

cal points and reduced machine down |

|

times accurate lubrication for cutting |

|

cialists available to listen to and |

|

|

|

costs and increasing the service life of |

|

advise you |

|

|

|

the elements |

|

|

|

|

|

|

• Hydraulic tank shutoff valve for easily |

|

|

and quickly cutting off the hydraulic |

|

|

circuit: complete drainage not required |

|

|

if it is necessary to repair the system |

|

|

|

|

|

|

|

|

|

R 956 Litronic 11

R 956 Backhoe –

Experience Progress

Visibility

•Rear camera integrated in the counterweight

•Two boom-mounted lights - standard

•Optimized design of the whole uppercarriage providing the operator with a better field of vision

Automatic centralized lubrication - standard

•Reduced maintenance time

•Longer service life thanks to better lubrication

Undercarriage

•Robust structure thanks to the X-shaped profile

•Improved self-cleaning capacity

•Special heat treatment for low wear and tear of drive sprockets

•3 types of undercarriage available, including a variable gauge one

•3 guiding guards per track - standard

12 R 956 Litronic

Loading...

Loading...