Liebherr LHM 120 User Manual

Mobile Harbour Crane |

LHM 120 |

|

|

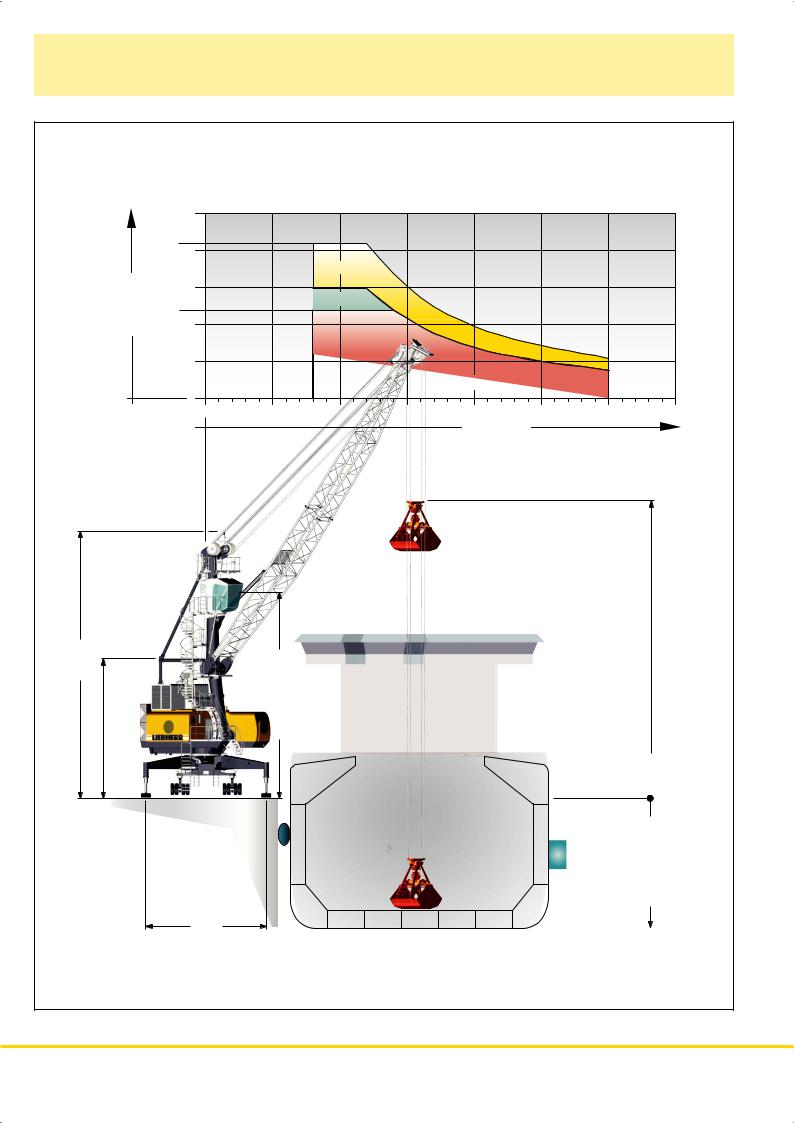

Main dimensions

Bulk operation

|

|

Load diagram |

|

|

|

|

|

|

|

||

|

|

|

|

50 |

|

|

|

|

|

|

|

|

|

|

|

42 40 |

|

|

|

|

|

|

|

|

|

|

(t) |

|

|

on the ropes |

|

|

|

|

|

|

|

|

30 |

|

|

|

|

|

|

|

|

|

|

|

Capacity |

|

motor grab |

|

|

|

|

|

|

|

|

|

24 |

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

||

|

|

|

20 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

10 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

4-rope grab |

|

|

|

|

|

|

|

0 |

|

|

|

|

25 |

30 |

35 |

|

|

|

|

0 |

5 |

10 |

15 |

20 |

|||

|

|

|

|

|

|

|

|

Outreach (m) |

|

|

|

|

19.6 m |

Boom fulcrum |

10.1 m |

|

Eye level 15.2 m |

|

|

|

|

|

Above quay max. 34 m (depending on grab) |

|

|

|

|

|

|

Coastal Bulk Carrier |

|

|

Below quay 13 m |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

9 m |

|

|

|

|

|

|

|

2 |

LHM 120 |

|

|

|

|

|

|

|

|

|

|

Bulk operation

Maximum crane capacity 42 t

|

Hook operation |

Grab operation |

||

Outreach |

on the ropes |

4-rope grab |

|

motor grab |

|

||||

(m) |

(t) |

(t) |

|

(t) |

8-11 |

42.0 |

24.0 |

|

30.0 |

12 |

42.0 |

24.0 |

|

29.9 |

13 |

37.7 |

24.0 |

|

26.8 |

14 |

33.8 |

24.0 |

|

24.1 |

15 |

30.5 |

21.7 |

|

21.7 |

16 |

27.5 |

19.6 |

|

19.6 |

17 |

25.1 |

17.8 |

|

17.8 |

18 |

23.0 |

16.3 |

|

16.3 |

19 |

21.2 |

15.0 |

|

15.0 |

20 |

19.6 |

13.9 |

|

13.9 |

21 |

18.2 |

13.0 |

|

13.0 |

22 |

17.1 |

12.2 |

|

12.2 |

23 |

16.1 |

11.5 |

|

11.5 |

24 |

15.2 |

10.8 |

|

10.8 |

25 |

14.4 |

10.2 |

|

10.2 |

26 |

13.7 |

9.7 |

|

9.7 |

27 |

13.0 |

9.2 |

|

9.2 |

28 |

12.3 |

8.7 |

|

8.7 |

29 |

11.6 |

8.3 |

|

8.3 |

30 |

11.0 |

7.8 |

|

7.8 |

|

|

|

|

|

Weight ramshorn hook 1.5 t

Weight rotator 1.5 t

Professional bulk handling – Turnover up to 550 t per hour

The powerful hydrostatic transmission and advanced Liebherr electronics ensure short, productive working cycles during bulk handling.

•During grab operation, hoisting, slewing, and luffing are driven simultaneously at maximized speed to achieve the highest (possible) turnover.

•During grab filling, features such as automatic lowering and hoisting guarantee the optimum filling level of the grab.

•The slack rope monitoring system ensures extended lifetime of the ropes and increases operational safety.

•Reverse power is returned to the drive process through closed loop hydraulics which results in reduced fuel consumption.

•The Cycoptronic® anti-sway system automatically compensates for all rotational swing, transverse and longitudinal sway of the load at maximum speeds.

•To provide safe and stress-free working conditions for the operator, Liebherr offers the Cycoptronic® including teach-in® feature, a semi-automatic system, which pilots the crane from the vessel hatch to the quay without any sway. Especially for bulk operation into hoppers, the teachin® system increases turnover and ensures consistent turnover rates during the entire ship unloading.

•Liebherr technology is absolutely resistant to all types of dust and dirt due to the closed hydraulic system and an electronic system which is military proven and tested.

•The airflow needed for cooling hydraulic and engine systems is routed external from the main machinery house. This helps keep the engine room clean and free of debris.

LHM 120 3

Loading...

Loading...