Liebherr LTM 1160-5.1 User Manual

Mobile crane

Product advantages

Max. load capacity: 160 t

Max. height under hook: 95 m

Max. radius: 70 m

LTM 1160-5.1

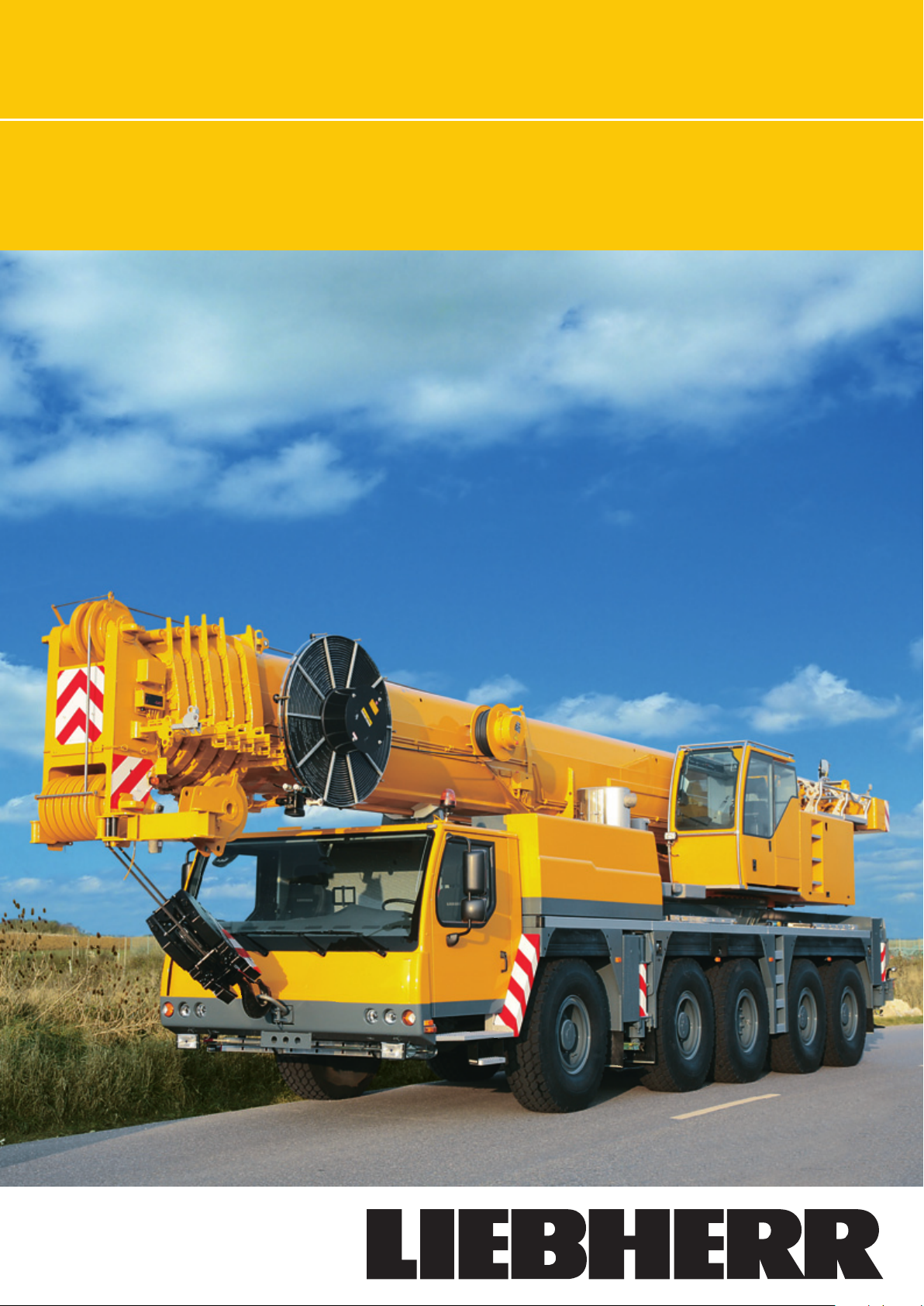

4000

21°

16.00 R 25

2394

15020

12 t 12 t 12 t 12 t 12 t

12346

14740

31364823

26°

Compact, maneuverable

and weight-optimized

• Overall length 15.02 m, chassis length 12.35 m

• Large overhang angle of up to 26°

• Minimum turning-circle radius 10.6 m with all-wheel steering

• Rear ballast radius only 4.22 m

• 60 t gross weight, incl. 6.5 t ballast, 10 x 8 driveline,

16-inch tires, 26 t hook block (axle load 5 x 12 t)

• 3 optional tire sizes

14.00 R 25 (vehicle width 3 m)

16.00 R 25 (vehicle width 3 m)

20.5 R 25 (vehicle width 3.1 m)

R = 10600

R = 11800

R = 12300

R = 4220

R = 5100

7984

5310

7500

5000

3000

600

34964488

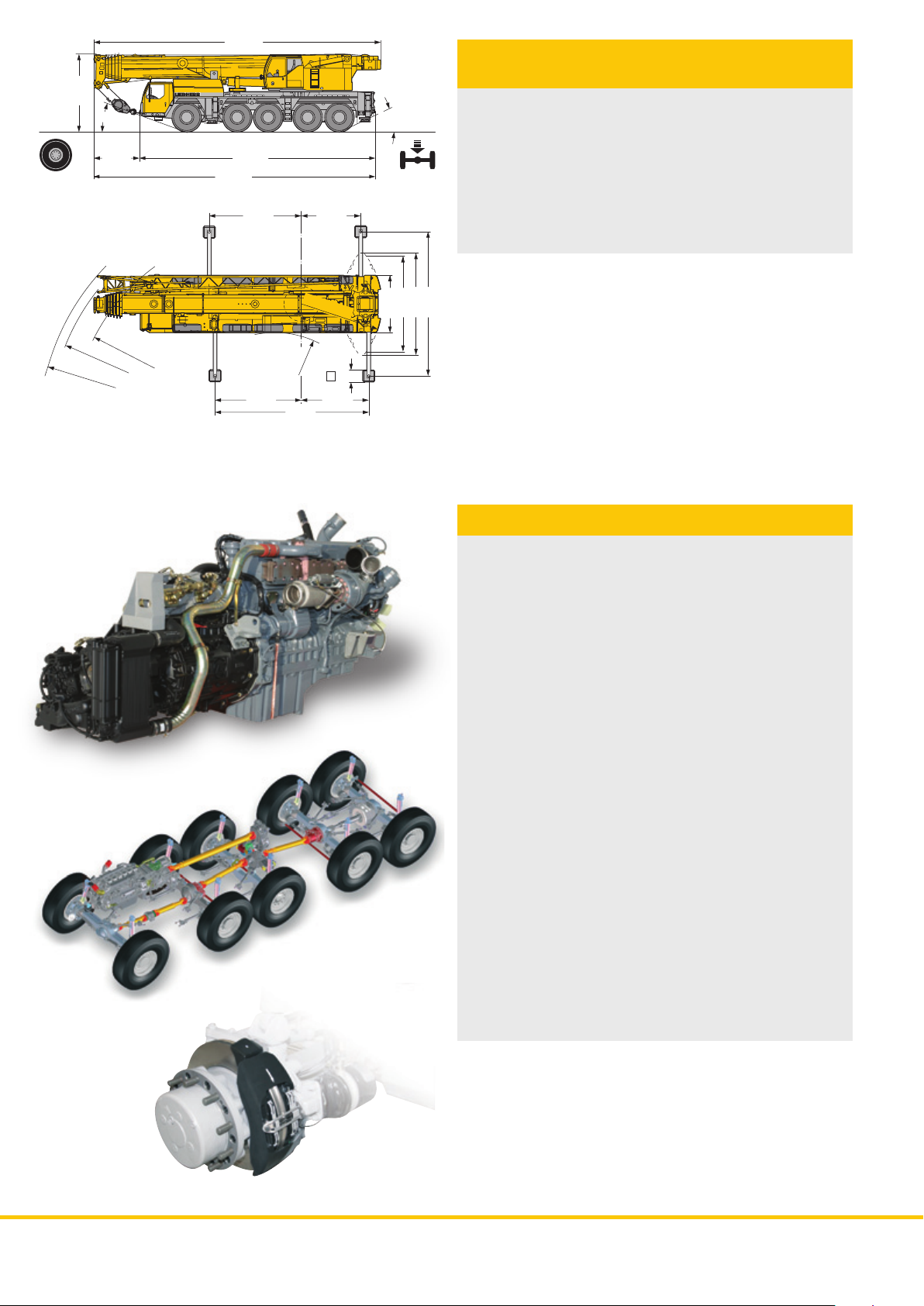

Modern drive concept

• Powerful, 6-cylinder Liebherr Type D846 A7 turbocharged

diesel engine, 370 kW/503 hp, exhaust emissions comply

with 97/68/EC Stage 3 and EPA/CARB Tier 3; robust and

reliable, with modern, electronic engine management

• ZF AS-TRONIC automated manual shift gearbox; ZF Intarder

fitted directly to gearbox; 12 forward and 2 reverse gears,

automated gear shift, high number of gear ratios helps to

reduce fuel consumption

• Robust 2-stage transfer box with lockable differential,

creep speed 0.78 km/h

• Drive 10 x 6: axles 2, 4 and 5 driven

• Drive 10 x 8 (optional): axles 2, 4 and 5 driven,

axle 1 can be engaged for off-road travel

• Robust, low-maintenance weight-optimized axles, special

arrangement of the maintenance-free suspension control

arms for excellent directional and lateral stability, steel and

rubber locating bushings

• Maintenance-free propeller shafts; easy and quick fitting

due to 70° degree cross-splines

• “Niveaumatik” hydropneumatic suspension, programcontrolled for raising crane onto outrigger supports, crane

travel with equipment and on-road crane travel; suspension

travel +150/-150 mm

• Maintenance-free suspension rams free from lateral forces,

piston rods protected against damage by plastic tubes

• Retarders:

Exhaust brake with additional Liebherr brake system (ZBS),

Intarder integrated in gearbox, Telma eddy current brake

(optional)

• Service brake:

All axles fitted with air-operated disc brakes, high braking

performance, extended maintenance intervals, rapid brake

pad renewal

LTM 1160-5.1 LTM 1160-5.1

Variable steering concept

with „active rear-wheel

steering“

Axles 3, 4 and 5 incorporated into active rear-wheel steering

system; 5 steering methods can be preselected as fixed

programs (P):

P1: On-road steering

Axles 1 and 2 are steered mechanically from the steering

wheel, with hydraulic power assistance. Axles 3, 4 and 5 are

steered actively by a speed-dependent method according to

the front wheel lock angle. Above 30 km/h, axles 3 and 4 are

returned to the straight-ahead position and fixed. Above

60 km/h, axle 5 is also fixed in the straight-ahead position.

The change in steering lock angle according to road speed

results in precise, stable driving road behavior at higher speeds,

reduced tire abrasion and much-improved maneuverability

P2: All-wheel steering

Axles 3, 4 and 5, depending on the wheel lock angle of axle 1,

are turned by means of the steering wheel so that the smallest

turning-circle radius can be obtained

P3: Crabwise steering

Axles 3, 4 and 5 are turned into the same direction as axles 1

and 2 by means of the steering wheel

P4: Steering without superstructure

projection when turning

Axles 3, 4 and 5 are turned in accordance with the wheel lock

angle at axle 1, so that the rear of the vehicle does not project

when cornering

P5: Independent rear-axle steering

Axles 1 and 2 are turned by the steering wheel, axles 3, 4 and 5

are steered independent of the lock angle at 1 and 2 by

pushbuttons; at the same time the lock angle at axle 3 is

adapted to suit the actual situation

• A failure in the rear-axle steering shuts it down; the rear axles

are set to the straight-ahead position by centering rams

• Two independent hydraulic circuits with wheel-driven

and engine-driven hydraulic pumps for the maximum

level of safety

• Two independent control processors (by way of existing

input/output modules) and diversified sensor system

• The entire know-how for the active rear-wheel steering

comes from Liebherr

310

700

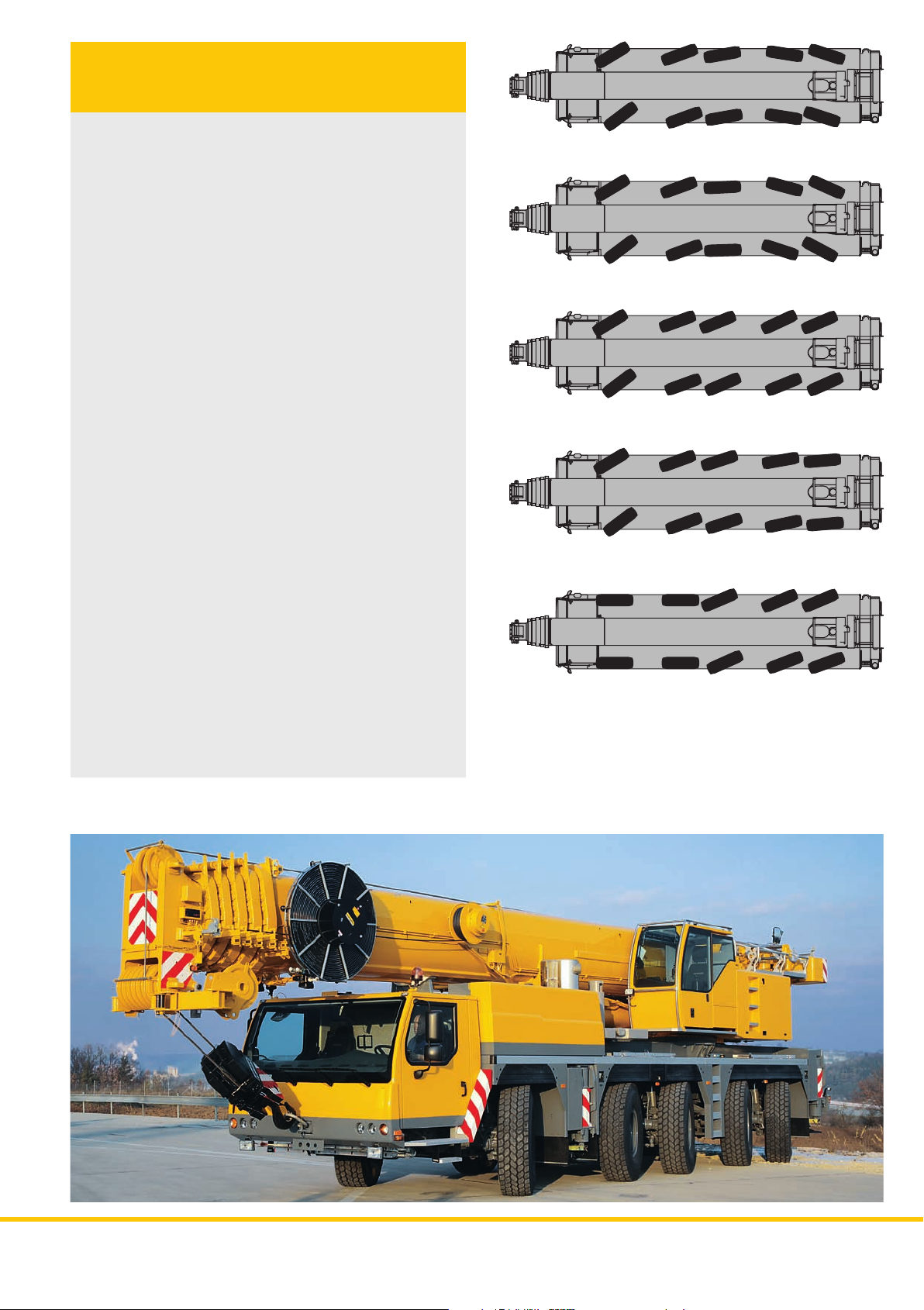

Supporting crane on outriggers –

quick, convenient and safe

• Variable support base width

Outriggers retracted

Support base area 5.0 m x 7.9 m

Support base area 7.5 m x 7.9 m

• Fixed support pads with splash guard

for protection against dirt

• Support jack extension range up to 700 mm

• Self-leveling of the outriggers, fully-automatic leveling of the

crane by pushbutton during the supporting procedure

•2 x 9° lateral inclination of crane chassis and superstructure

• Control panels at either side of the chassis with foil-covered

keyboard and electronic angle indicator, pushbuttons for

ENGINE/START/STOP and speed control are illuminated

and lockable

• Operation of the outrigger system in accordance with the

accident prevention regulations

• Illumination of the support area by 4 built-in lights

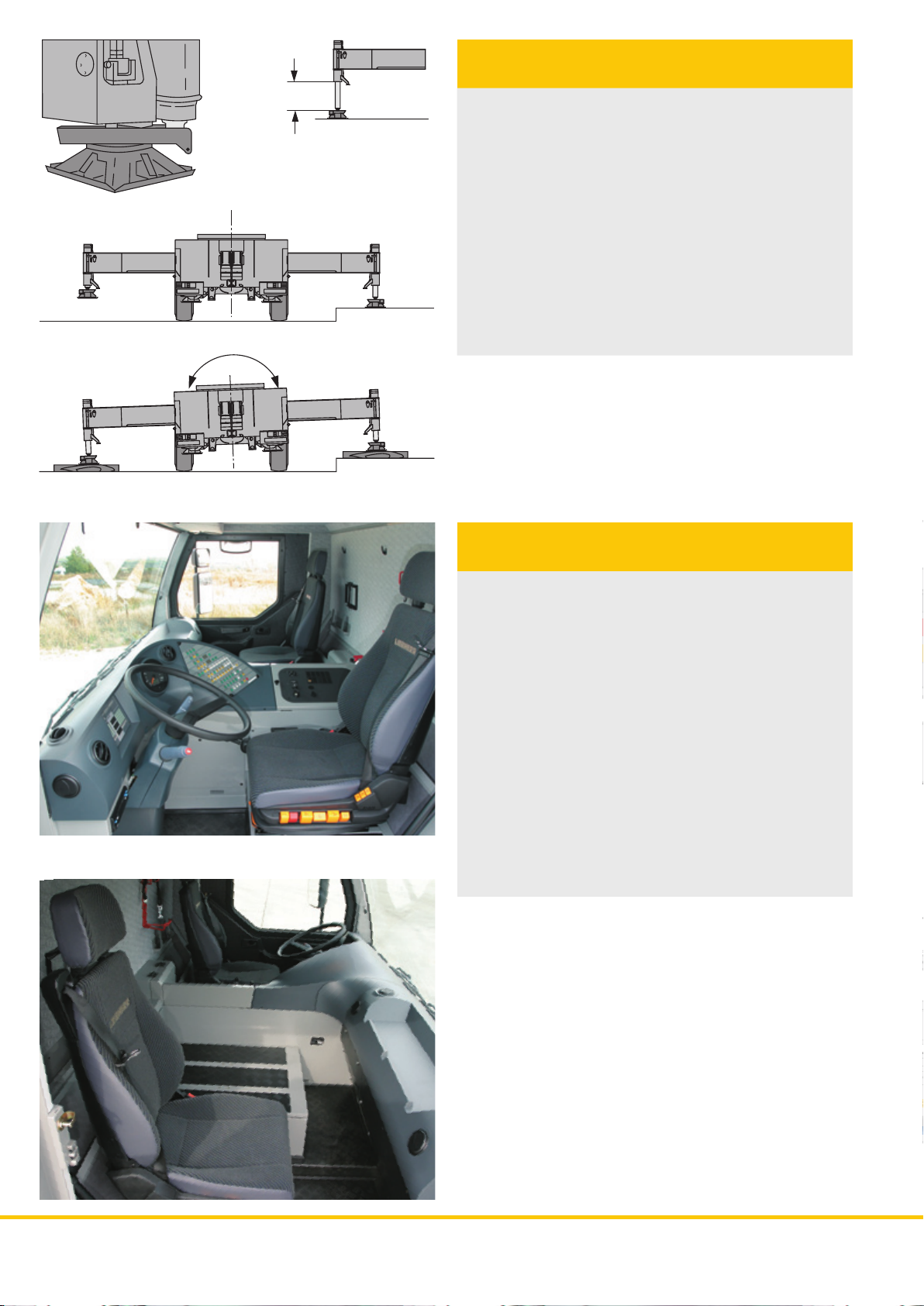

Comfortable, highly efficient

operator’s cab

• Modern, comfortable operator’s cab of highly efficient,

convincing design, corrosion-resistant sheet steel

construction, cataphoretic dip-primer coating, resilient rubber

front mountings, hydraulic damping at rear, sound and heat

absorbent interior paneling

• Safety glass all-round, sunproof green-tinted windshield and

side windows for heat absorption, electric window lifters

• Ergonomically correct arrangement of controls and displays

for safe and convenient handling for long periods

• Digital display and key-panel units interconnected with the

functional blocks by data bus technology

• Air-sprung driver’s seat with pneumatic lumbar

support and head restraint

• Steering wheel adjustable for height and angle

• Heated, electrically adjustable outside mirrors

• Seat belts for driver and co-driver

• 3 windshield wipers with automatic wipe/wash system and

intermittent-wipe setting

• Delayed switch-off of interior lighting

• Various storage shelves and compartments

• Preparation for radio

LTM 1160-5.1 LTM 1160-5.1

Loading...

Loading...