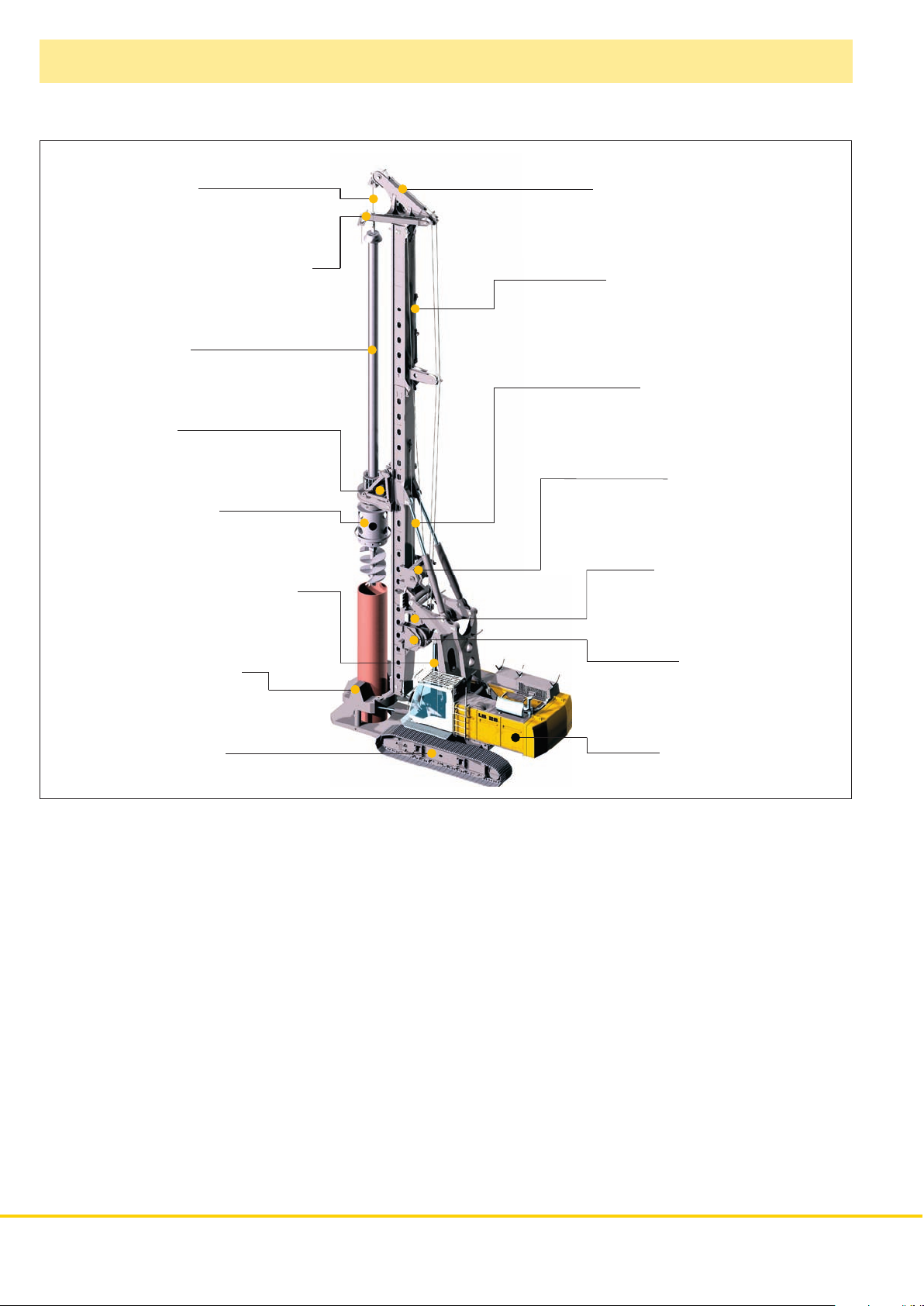

Technical data

Drilling rig

LB 28

Concept and characteristics

Kelly rope

Leader top for Kelly rope

Leader top for auxiliary rope

Auxiliary winch

Kelly bar

Inclination device

Tensioning cylinder for

crowd system

Rotary

Kelly winch

Casing oscillator

Undercarriage

Radius adjustment device

Uppercarriage

Crowd winch

Casing driver

• High engine output with automatic engine speed

control

• Controlled entirely from cab

• Sturdy and solid rig design

• Solid parallel kinematics on the basic machine

• High pull and push forces

• High torque

• Completely self-rigging (no auxiliary machines

required)

• Large range of working tools (all common drilling

works can be performed)

• Stepless leader inclination 5° forward - 15° backward

depending on type of equipment

• Automatic vertical alignment

• High alignment forces

• Simultaneous control of several movements via

Load-sensing multi-circuit hydraulics

• Quick change of rotaries possible through quick

connection

• Equipment design according to latest European

regulations and standards

• All components designed to fulfill the requirements

of a drilling rig

• High manufacturing quality through quality control by

the PDE-system

2 LB 28

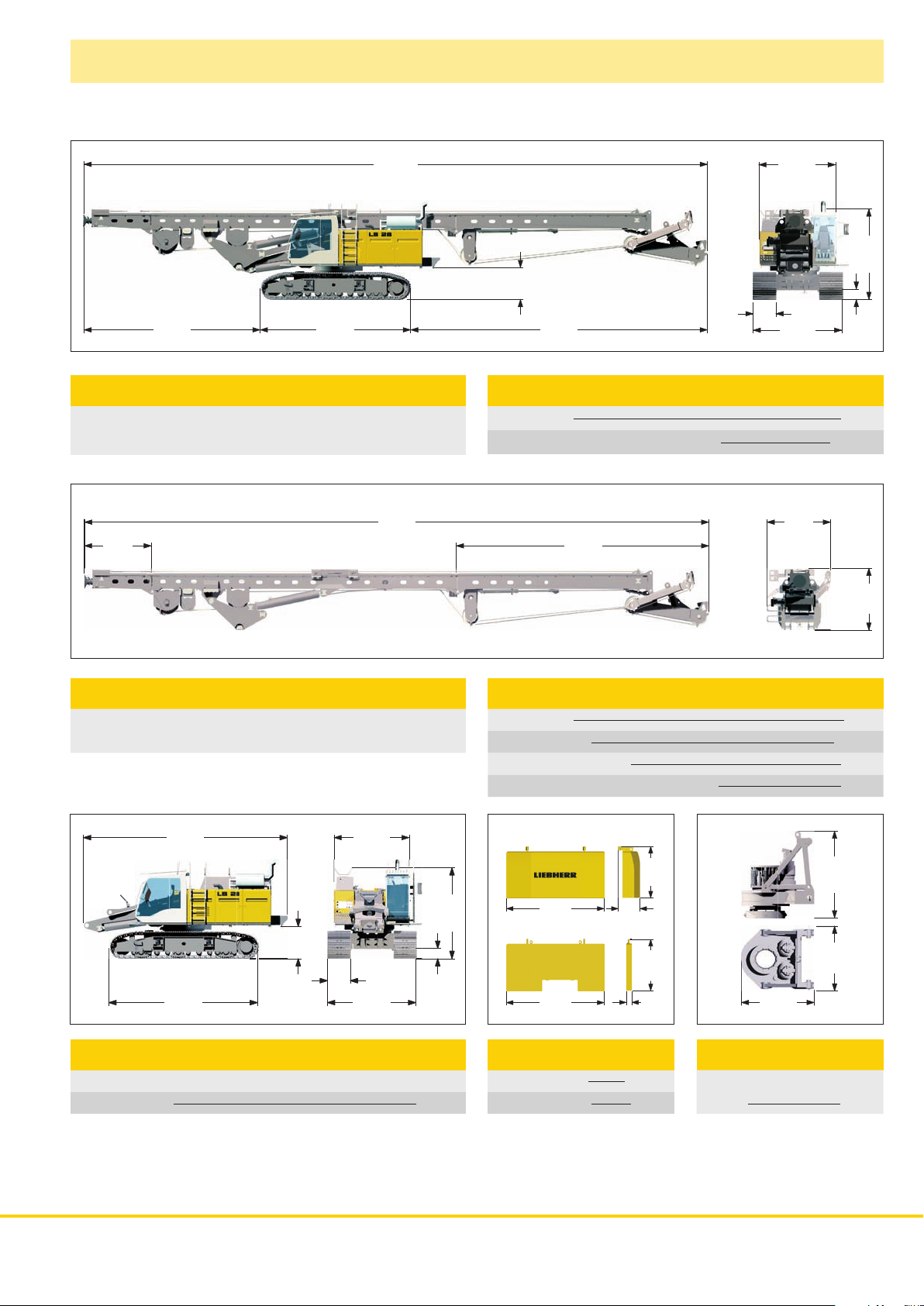

Transport dimensions and weights

6990

5895 12100

24985

900

3500

3000

405

3600

1260

Transport with leader

includes the basic machine (ready for operation) with leader, without

working tools (such as rotary, Kelly bar etc.) and without counterweight.

24985

2640

Transport leader

includes the leader without working tools

(such as rotary, Kelly bar etc.).

8070

3000

Dimensions and weights

Leader length 22 m

Weight complete without counterweight

10305

68.2 t

2610

Dimensions and weights

Leader length 22 m

Weight complete

Lower part of the leader

Upper part of the leader with leader top

Counterweight I

24.2 t

1.5 t

4.6 t

2460

1260

900

5895

3500

Transport basic machine

ready for operation, without counterweight.

Transport weight

Weights can vary with the nal con guration of the machine.

44.0 t

3600

405

3000

Counterweight II

3000

660

170

Weights

Counterweight I 10.2 t

Counterweight II

5.2 t

1550

1565

1840

Rotary

Transport weight

BA 280

2465

1760

6.7 t

LB 28 3

Dimensions

Basic machine LB 28

615

25965

5°

15°

5°

5°

1100

4215

5465 4200

R 4265

5895

Technical data

Total height 25.96 m

Max. pull, leader on ground

Max. torque 286 kNm

Stepless rig inclination adjustment

Lateral inclination

Forward inclination 5°

Backward inclination 15°

400 kN

± 5°

900

4700

Operating weight

Total weight with 800 mm 3–web shoes 95.0 t

Total weight with 900 mm 3–web shoes 95.6 t

The operating weight includes the basic machine LB 28 (with rotary

and Kelly bar MD 28/3/30) and 15.3 t counterweight.

4 LB 28

Technical description

Engine

Power rating according to ISO 9249, 350 kW (469 hp) at 1900 rpm

Engine type Liebherr D 846 A7

Fuel tank 700 l capacity with continuous level

indicator and reserve warning

Engine complies with NRMM exhaust certication EPA/CARB Tier 3

and 97/68 EC Stage III.

Hydraulic system

The main pumps are operated by a distributor gearbox. A xial piston

displacement pumps work in open circuits supplying oil only when

needed (ow control on demand).

The hydraulic pressure peaks are absorbed by the integrated

automatic pressure compensation, which relieves the pump and

saves fuel.

Pumps for working tools 2x 350 l/min

Separate pump for kinematics 180 l/min

Hydraulic oil tank 800 l

Max. working pressure 350 bar

The cleaning of the hydraulic oils occurs via an electronically

monitored pressure and return lter.

Any clogging is shown on the display in the cab.

The use of synthetic environmentally friendly oil is also possible.

Control

The control system – developed and manufactured by Liebherr – is

designed to withstand extreme temperatures and the many heavy–

duty construction tasks for which this machine has been designed.

Complete machine operating data are displayed on a high resolution

monitor screen. A GSM modem allows for remote inquiry of machine

data and error indications. To ensure clarity of the information on

display, different levels of data are shown in enlarged lettering and

symbols.

Control and monitoring of the sensors are also handled by this high

technology system. Error indications are automatically displayed on

the monitor in clear text. The machine is equipped with proportional

control for all movements, which can be carried out simultaneously.

Two joysticks are required for operation. Pedal control can be

changed to hand control.

Options :

PDE : Process data recording

Kelly winch with freewheeling

Line pull (effective) 250 kN

Rope diameter 34 mm

Max. line speed 0-79 m/min

Auxiliary winch

Line pull (effective) 100 kN

Rope diameter 20 mm

Drum diameter 400 mm

Max. line speed 0-89 m/min

Crawlers

Propulsion through axial piston motor, hydraulically released spring

loaded multi–disc brake, maintenance free crawler tracks, hydraulic

chain tensioning device.

Drive speed 0 – 1.9 km/h

Track force 622 kN

Width of 3-web track shoes 900 mm

Swing

Consists of triple-row roller bearing with external teeth and two

swing drives, xed axial piston hydraulic motor, spring loaded and

hydraulically released multi– disc holding brake, planetary gearbox

and pinion. Selector for 3 speed ranges to increase swing precision.

Swing speed from 0 – 2 rpm is continuously variable.

Rope crowd system

Crowd force push/pull 400/400 kN

Line pull (effective) 200 kN

Rope diameter 28 mm

Travel 18.5 m

Max. line speed 0-74 m/min

The winches are noted for compact, easily mounted design.

Propulsion is via a maintenance-free planetar y gearbox in oil bath.

Load support by the hydraulic system; additional safety factor by

a spring–loaded, multi–disc holding brake. All line pull values are

effective values. The efciency factor of approx. 25% has already

been deducted.

Noise emission

Noise emissions correspond with 2000/14/EC directive on noise

emission by equipment used outdoors.

LB 28 5

Rotary BA 280 with shock absorber

Gearbox frame

Drive motors

Kelly bar

Shock absorber

Gearbox

Cardanic joint

Casing driver

350

300

250

200

150

100

Torque [kNm]

50

0

0 10 20 30 40 50 60

BA280

Speed [rpm]

Gear 1

Gear 2

• 2-stage-gear drive for flexible adaptation to soil conditions

• Due to stepless speed control via joystick optimum and precise

alignment and rock drilling is possible even at low speed levels;

it is not required to preselect an operating mode

• Kelly shock absorber and rubber bearing relieve the material and

reduce noise emission

• Thanks to the Kelly shock absorber the Kelly bar is guided at

greater length

• Various drive adapters provide compatibility with other systems

6 LB 28

Kelly drilling

A

1900

X

Technical data

Drilling drive - torque 1

Drilling drive - speed

Drilling drive - torque

Drilling drive - speed

st

gear 286 kNm

st

1

gear 30 rpm

nd

2

gear 148 kNm

nd

2

gear 59 rpm

Performance data

Max. drilling diameter* 1900 mm uncased

Max. drilling diameter* 1500 mm cased

*) Other drilling diameters available on request.

Other Kelly bars available on request.

When using a casing oscillator, value X has to be reduced

by 1500 mm.

Display for Kelly drilling

Kelly bars

A X Drilling

depth

(mm) (mm) (m) (t) (mm)

MD 28/3/24 9880 11500 22 5.0 419

MD 28/3/27 10880 10500 25 5.45 419

MD 28/3/30 11880 9500 28 5.9 419

MD 28/3/33 12880 8500 31 6.35 419

MD 28/3/36 13880 7500 34 6.8 419

MD 28/4/36 11450 9900 34 7.25 419

MD 28/4/42 12950 8400 40 8.1 419

MD 28/4/48 14450 6900 46 8.95 419

MD 28/4/54 15950 5400 52 9.8 419

Weight Kelly Ø

LB 28 7

Continuous fl ight auger drilling

Auger with auger guide

Technical data

Drilling drive - torque 1

Drilling drive - speed

Drilling drive - torque

Drilling drive - speed

1

2

2

st

gear 286 kNm

st

gear 30 rpm

nd

gear 148 kNm

nd

gear 59 rpm

Display for continuous ight auger drilling

Performance data

Drilling depth with auger cleaner* 16.5 m

Drilling depth without auger cleaner*

Drilling depth with 8 m Kelly extension,

without auger cleaner

Max. pull force (crowd winch and Kelly winch)

Max. push force (weight of rotar y and auger to be added)

Max. drilling diameter**

*) Without Kelly extension

**) Other drilling diameters available on request.

17.8 m

25.8 m

900 kN

200 kN

1000 mm

8 LB 28

Double rotary drilling

Model DBA 200

Technical data

2

2

1

st

st

nd

nd

st

st

nd

nd

Drilling drive I - torque 1

Drilling drive I - speed 1

Drilling drive I - torque

Drilling drive I - speed 2

Drilling drive II - torque

Drilling drive II - speed 1

Drilling drive II - torque

Drilling drive II - speed 2

Max. drilling diameter*

Max. drilling depth

Max. pull force

*) Other drilling diameters available on request.

Display for double rotary drilling

gear 195 kNm

gear 9 rpm

gear 97 kNm

gear 18 rpm

gear 103 kNm

gear 17 rpm

gear 51 kNm

gear 34 rpm

620 mm

17.8 m

900 kN

LB 28 9

Twin mix equipment

Model DMA 35

Technical data

Drilling drive - torque 1

Drilling drive - torque 2

Drilling drive - speed

Drilling drive - speed 2

Max. drilling depth

Max. diameter*

*) Other diameters available on request

st

gear 35 kNm

nd

gear 17.5 kNm

st

1

gear 55 rpm

nd

gear 111 rpm

17.8 m

700 mm

Display for soil mixing

10 LB 28

Process data recording system - PDE

PDE® colour monitor

for visualization of the PDE

®

data

in the operator's cab

Process data report software

SCULI PDR

PC provided

by the customer

CompactFlash

memory card

External sensors

Printer

Standard

Optional

PDE

®

pile number

12A/23

0 5 10 45 bar

3040506070

5.5 m

5.0 m

4.5 m

4.0 m

3.5 m

Ø60cm

10%

3.78 m

ABC

59%

®

(additional equipment)

The Liebherr process data recording system PDE® constantly records the relevant process data

during the working process.

Recordings management - The recordings generated by the PDE® system can be imported and managed

in SCULI PDR. The data can be impor ted directly from the CompactFlash card or via the Liebherr telematics

system LiDAT. Certain recordings, e.g. for a particular day or jobsite, can be found using lter functions.

Viewing data - The data in each record is displayed tabularly. Combining several recordings provides

results, for example, regarding the total concrete consumption or the average depth. Furthermore, a diagram

editor is available for quick analysis.

Generating reports - A vital element of SCULI PDR is the report generator, which allows for the generation

of individual repor ts. These can be printed out directly or stored as pdf les. In the process the size, colour,

line thickness or even the desired logo can be con gured. Moreover, the reports can be displayed in different languages, e.g. in English and in the national language.

Depending on the application the recorded and processed data are displayed on the PDE® touchscreen in the operator‘s cab, e.g. in the form

of an online cast-in-place pile.

At the same time the PDE® is operated using this touchscreen. The operator can enter various details (e.g. jobsite name, pile number, etc.)

and star t and stop recordings. A recording of ever y star t-stop cycle carried out in the PDE® is established on a CompactFlash memory card.

The PDE® can be con gured in a number of ways, e.g. for the connection of external sensors, for the generation of a simple protocol as graphic le and/or for a printout directly in the operator‘s cab.

Process data reporting - PDR (additional equipment)

Comprehensive data evaluation and generation of reports on a PC is possible using the software

SCULI PDR.

CFA Drilling

job site:

machine ID:

start date:

start time:

stop time:

duration:

motorway

1155xx

05.11.2008

12:16:48

12:48:48

00:32:00

pile number:

maximum depth:

total concrete vol.:

concrete volume pile:

overconsumption:

maximum incline:

E02

2227 cm

15,123 m³

14,531 m³

29,8 %

0,4 °

LB 28 11

Liebherr-Werk Nenzing GmbH

P.O. Box 10, A-6710 Nenzing/Austria

Tel.: +43 50809 41-473

Fax: +43 50809 41-499

crawler.crane@liebherr.com

www.liebherr.com

LB 28 – 10351286 – 03/2010 Subject to change without notice.

Loading...

Loading...