Liebherr R 936 User Manual

Crawler excavator |

R 936 |

||

|

|

|

|

|

|

|

|

|

|

|

|

Operating Weight: 30,550 – 34,750 kg |

|||

Engine Output: |

160 kW / 218 HP |

||

Bucket Capacity: |

1.00 – 2.20 m³ |

||

R 936

Operating Weight: 30,550 – 34,750 kg

Engine Output: |

160 kW / 218 HP |

Bucket Capacity: |

0.70 – 2.20 m³ |

2 R 936 Litronic

Comfort

In the cab the driver can look forward to a workplace designed in accordance with the very latest findings in ergonomic science, with emphasis on comfort and ease of operation. The optimised arrangement of the hydraulic hoses means that the driver has en even wider field of vision, and the heating and climate control system fitted as standard means pleasant working conditions inside, whatever the weather. Liebherr crawler excavators are also particularly easy to service – maintenance tasks can be carried out easily and rapidly at readily accessible service points.

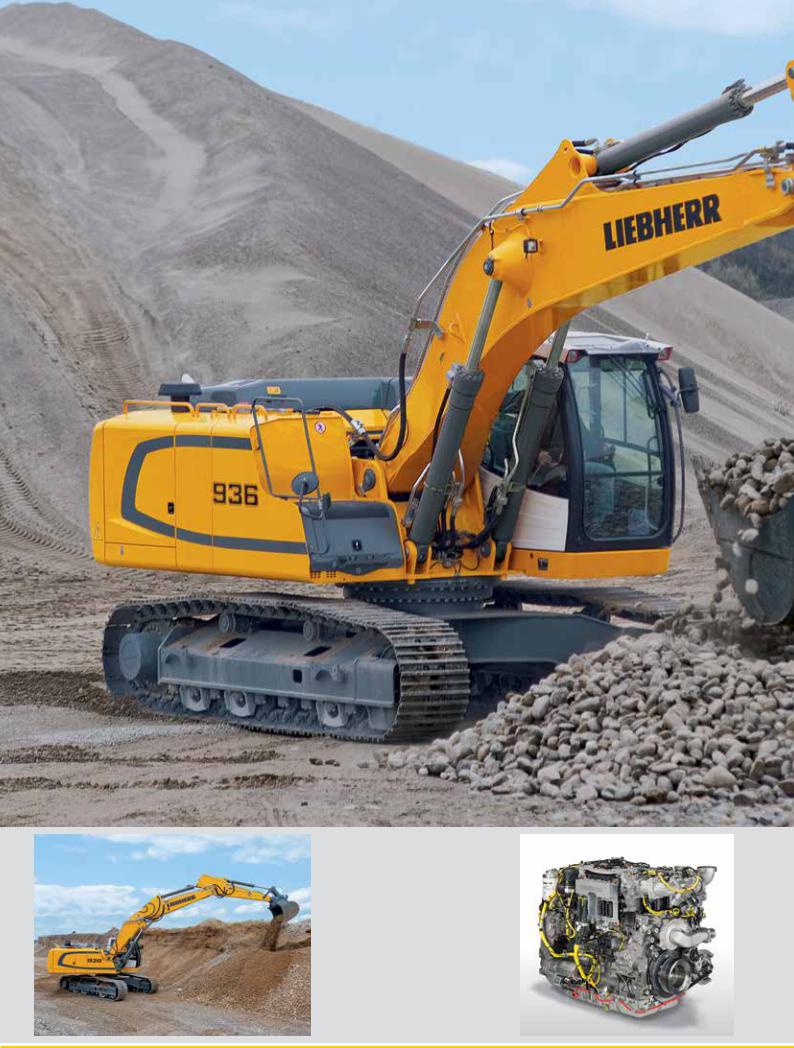

Performance

Thanks to its innovative Advanced excavator system technology, the R 936 crawler excavator has performance features that are truly unique. Characteristic elements of this system technology include the particularly effective and energy-efficient Positive Control twincircuit hydraulic system, which was specifically designed for machines with a high level of superimposed functions and operational movements. The electronic pump control arrangement sets this technology apart, creating a new standard for performance and quantity control that entirely matches the operator’s needs.

Reliability

Liebherr provides customers with solutions that lead the way for the future, solutions for maximum equipment reliability and availability, solutions which satisfy the most extreme demands for performance and quality. With more than 50 years experience in the construction of hydraulic excavators, we have an advantage in design and consultation that clearly sets us apart.

Economy

Crawler excavators from Liebherr guarantee maximum productivity. The optimum interplay of hydraulics and electronics means that individual movements and superimposed movements alike can be carried out particularly efficiently. And, perhaps last but by no means least, the perfect harmonisation of all the components means that energy expenditure during operation can be kept to an absolute minimum.

R 936 Litronic 3

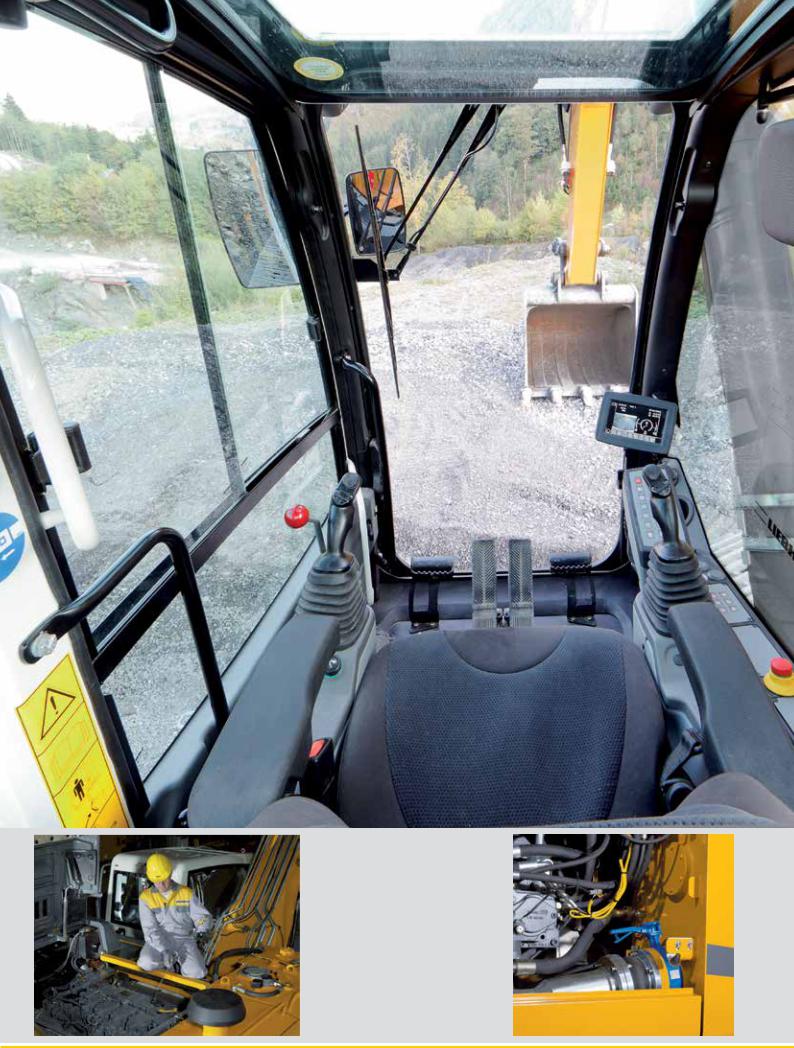

Extremely maintenance-friendly

•All maintenance points are easily accessible

•Daily routine servicing work can be carried out very rapidly, reliably, and in comfort

•The R 936 comes as standard with a fully-automatic central lubrication system

4 R 936 Litronic

Comfort

In the cab the driver can look forward to a workplace designed in accordance with the very latest findings in ergonomic science, with the emphasis on comfort and ease of operation. The optimised arrangement of the hydraulic hoses means that the driver has en even wider field of vision, and the heating and climate control system fitted as standard means pleasant working conditions inside, whatever the weather. Liebherr crawler excavators are also particularly easy to service

– maintenance tasks can be carried out easily and rapidly at readily accessible service points.

Safe work – with a clear layout

A pleasant workplace |

The entirely new design of the cab provides plenty |

|

of room, and creates a pleasant sense of space. |

|

Cab windows in the front, the roof, and on the right |

|

are made of break-resistant two-pane safety glass. |

|

The front windscreen is a two-part design and can |

|

be completely retracted. The cab meets ROPS re- |

|

quirements, providing the driver with even more |

|

protection. |

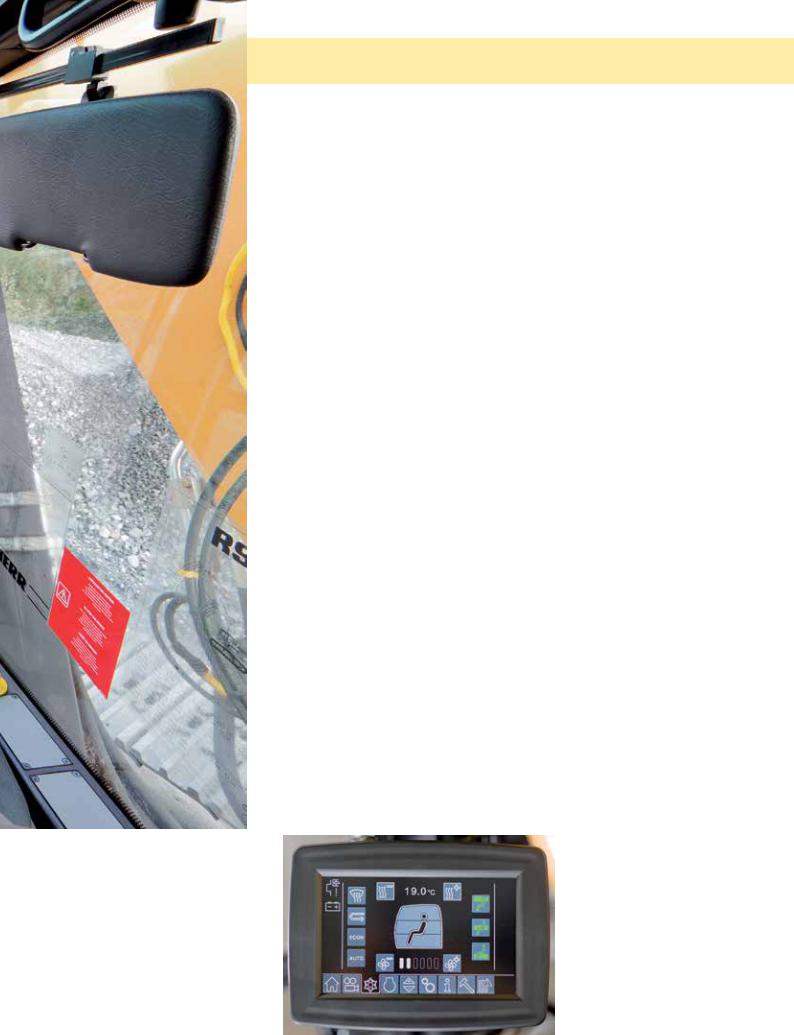

High-resolution |

The 7-inch high-resolution colour display can be |

colour display |

operated as a touch-screen system. Thanks to its |

|

high resolution, the video-style display reproduces |

|

the image from the rear area monitoring camera |

|

in the best possible quality. It comes with versatile |

|

adjustment, control, and monitoring capabilities, and |

|

is designed to be glare-free. |

Wide camera field |

The reversing camera for the R 936, fitted as stand- |

of vision |

ard, provides a wide-ranging view of the area be- |

|

hind the machine. |

Fully automatic |

The climate control system has more than 12 ad- |

climate control system |

justable nozzles for individual control of air flow, and |

|

can be operated via the display. |

Minimal noise |

The new cab on the Liebherr crawler excavator meets |

and vibration |

the standards for noise emissions and whole-body |

|

vibrations, which makes work a pleasure. |

Hydraulic reservoir stop valve |

|

Touch-screen display |

|

||

• Easy and quick interruption of the oil |

|

• 7-inch touch-screen |

circuit between hydraulic reservoir |

|

with colour display |

and hydraulic system |

|

• Wide range of adjustment, check, |

|

|

|

• No drainage of fluid necessary |

|

and monitoring possibilities |

for service or repair work on |

|

• Tough, reliable design |

the hydraulic system |

|

|

|

(sealing tightness class IP 65) |

|

|

|

|

|

|

• Video capacity with high resolution, |

|

|

reproduces the image from the rear |

|

|

area monitor camera in best possible |

|

|

quality |

|

|

|

|

|

|

|

|

|

R 936 Litronic 5

Spare parts service

•Any spare parts required are available within 24 hours – worldwide. And that means high operational readiness of the machines, wherever, whenever

•Over 80,000 spare parts in stock at all times

6 R 936 Litronic

Reliability

Liebherr provides customers with solutions that lead the way for the future, solutions for maximum equipment reliability and availability, solutions which satisfy the most extreme demands for performance and quality. With more than 50 years experience in the construction of hydraulic excavators, we have an advantage in design and consultation that clearly sets us apart.

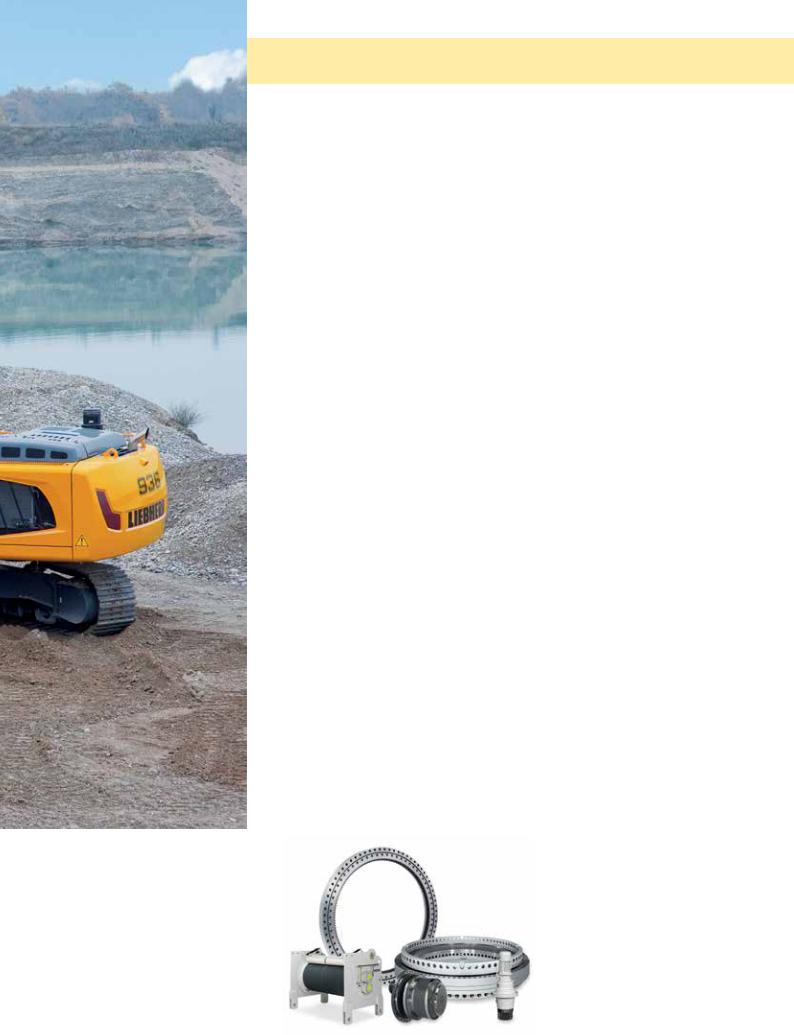

High stability undercarriage

Better force distribution The undercarriage concept leads to increased performance with improved service life. Thanks to the connection of the middle section being extended as far as the ends of the chassis beams, known as the X-design, the forces are better distributed, which increases the service life of the undercarriage.

Technology with perspective

Quality right down |

The at-a-glance layout of the hydraulic, lubrication, |

to the last detail |

and electricity lines makes for optimum functional |

|

reliability and maximum availability of the unit. Best |

|

possible corrosion protection is guaranteed thanks |

|

to components and modules being finalpainted and |

|

surface treated before assembly. |

Perfect optimisation |

Individual components of the drive train, manufac- |

|

tured in-house, such as diesel engine, traction drive, |

|

rotary actuators, operating pump and hydraulic |

|

cylinder are perfectly optimised with one another. |

|

As components of a total system designed for long |

|

operational life, they guarantee maximum possible |

|

reliability. |

Safety of functionality

Safety of functionality |

The cab is equipped with an integrated roll-over |

ROPS cab structure |

protection system (ROPS) in accordance with |

|

ISO 12117-2, guaranteeing driver safety in any |

|

situation. |

Automatic control |

The operator can entirely focus on his job, be- |

of functionality |

cause the integrated on-board electronic continu- |

|

ously performs a comparison with pre-determined |

|

target data. Eventual deviations from the target |

|

parameters are shown on the display. |

LiDAT data transfer system |

|

Key technologies – |

|

||

• Complete fleet management, |

|

Made by Liebherr |

|

• Perfect matching of the components |

|

all from one source |

|

|

|

to construction machine operations |

|

• Optimized economical performance of |

|

|

|

• Engine, hydraulic pumps, transfer |

|

the machine park thanks to detailed |

|

|

|

gears, travel drives, slewing drives, |

|

view of the distribution of operating |

|

|

|

slewing rings, and electronic compo- |

|

states and times |

|

|

|

nents – all from the same source |

|

• Reports on capacity commitment and |

|

|

|

• Main steel components, such as |

|

the use of the machine park can be |

|

|

|

undercarriage, equipment modules, |

|

called up daily via the Web portal |

|

|

|

and slewing superstructure, all |

|

• Precise location of the machine |

|

|

|

designed by Liebherr |

|

|

|

|

• Regional delimitation and fixed down- |

|

|

times increase safety and reliability |

|

|

|

|

|

|

|

|

R 936 Litronic 7

Wide range of operational possibilities

•Large number of equipment variants

•Versatile selection of undercarriage variants

•Broad operational spectrum,

from earthmoving, to grading work, to demolition

8 R 936 Litronic

Loading...

Loading...