Leica 150, 150M, 250M User Manual [ru]

Sprinter 150/150M/250M

User Manual

Sprinter_01

Version 1.0

EN, JA, ZH, KO, RU, PL, HU,

EL, CZ, TR, SR

User Manual

Руководство пользователя

Instrukcja obsługi Használati utasítás

Εγχειρίδιο χρήσης

Uživatelská příručka

Kullanma Kılavuzu

Корисничко упутство

EN

JA

ZH

KO

RU

PL

HU

EL

CZ

TR

SR

EN User Manual (English)

DEFR 1. Introduction

Purchase

ES |

Congratulations on the purchase of a new Leica Geosystems elec- |

||

IT |

tronic level. It is designed to make levelling works easier and |

||

PT |

quicker on any construction site. |

||

Product |

|

||

NL |

This manual contains important safety direc- |

||

tions as well as instructions for setting up the |

|||

NO |

|||

product and operating it. Refer to "12. Safety |

|||

SV |

Directions" for further information. |

||

Read carefully through the User Manual before you use the |

|||

FI |

product. |

|

|

DA |

Product identification |

|

|

The model and the serial number of your product are indicated on |

|||

|

the type plate. |

|

|

|

Enter the model and serial number in your manual and always refer |

||

|

to this information when you need to contact your agency or Leica |

||

|

Geosystems authorized service workshop. |

||

|

Type: ____________ |

Serial no.: ____________ |

|

|

Validity of this manual |

|

|

|

This manual is valid for Sprinter 150/150M/250M. |

||

)Sections only valid for Sprinter 150M/250M are marked accordingly with an asterisk (*).

Trademarks

All trademarks are the property of their respective owners.

Available documentation

Name |

Description |

Sprinter |

All instructions required in order to operate the |

150/150M/ |

product to a basic level are contained in this User |

250M User |

Manual. Provides an overview of the system together |

Manual |

with technical data and safety directions. |

Symbols

The symbols used in this Manual have the following meanings:

DANGERIndicates an imminently hazardous situation which, if not avoided, will result in death or serious injury.

WARNINGIndicates a potentially hazardous situation or an unintended use which, if not avoided, could result in death or serious injury.

CAUTIONIndicates a potentially hazardous situation or an unintended use which, if not avoided, may result in minor or moderate injury

and / or appreciable material, financial and environmental damage.

)Important paragraphs which must be adhered to in practice as they enable the product to be used in a technically correct and efficient manner.

Introduction |

1 |

Sprinter 150/150M/250M - 1.0.0en |

Table of Contents |

|

|

1. |

Introduction ..................................................................... |

1 |

2. |

Instrument Components.................................................. |

2 |

3. |

Measurement Preparations............................................. |

3 |

4. |

User Interface.................................................................. |

4 |

5. |

Set of Characters ............................................................ |

9 |

6. |

Operation ........................................................................ |

9 |

7. |

Data Transfer DataLoader* ........................................... |

15 |

8. |

Check & Adjust.............................................................. |

16 |

9. |

Error Messages............................................................. |

18 |

10. |

Operation Messages ..................................................... |

19 |

11. |

Care and Transport ....................................................... |

21 |

12. |

Safety Directions ........................................................... |

22 |

13. |

Technical Data .............................................................. |

29 |

14. |

International Warranty, Software |

|

|

Licence Agreement ....................................................... |

32 |

15. |

Index ............................................................................. |

33 |

2.Instrument Components

|

|

d |

|

|

e |

|

|

f |

a |

|

g |

|

h |

|

|

|

|

b |

|

i |

c |

|

|

|

j |

|

Sprinter 01 |

|

|

|

|

|

a) Horizontal fine motion screw |

f) |

Handle |

b) Battery compartment incl. phone |

g) Eyepiece |

|

jab interface for USB cable |

h) LCD display |

|

c) Circular level |

i) |

Base plate |

d) Gunsight |

j) |

Levelling foot- |

e) Focusing knob |

|

screw |

Container Contents

Sprinter, batteries (4x), allen key, user manual, strap, CD-ROM* (incl. DataLoader), USB cable*.

EN

DE

FR

ES

IT

PT

NL

NO

SV

FI

DA

Instrument Components |

2 |

Sprinter 150/150M/250M - 1.0.0en |

EN

DE

FR ES

IT

PT

NL

NO

SV

FI

DA

Accessories

Tripod, aluminum staff (region dependant), fibre glass staff (to achieve 0.7 mm accuracy with Sprinter 250M). (Optional: sunshade, 4 rechargeable batteries and charger)

3.Measurement Preparations

3.1 Change Battery

Insert 4 AA dry cells according to the positive and negative signs as indicated on the holder.

)Always replace with a complete battery set! )Do not use old and new batteries together.

)Always replace with a complete battery set! )Do not use old and new batteries together.

)Do not use batteries from different manufacturers or batteries of different types.

3.2 Set-up Instrument

3.2 Set-up Instrument

Levelling

•Set up the tripod. Extend the legs to a suitable length and ensure that the tripod head is approximately level. Tread the tripod shoes firmly into the ground to ensure stability.

•Mount the instrument on the tripod by screwing the tripod screw onto the base of the instrument.

•Use the three levelling foot screws to center the circular bubble in order to level the instrument.

Eyepiece Adjustment

Point the telescope to a uniform light surface such as a wall or a piece of paper. Turn the eyepiece until the cross hairs are sharp or distinct.

Target Image Focusing

Use the gunsight to aim the objective lens at the staff. Turn the horizontal fine motion screw until the staff is nearly centered in the field of view and then turn the focusing knob to focus on the staff. Ensure that staff image and reticle are sharp or distinct.

Power ON

The instrument is ready to measure.

)Technical hints:

• First check and adjust the electronic and optical line-of-sight errors, then the circular level on the instrument and then the staff: before starting work in the field, after long storage periods, after long transportation.

• Keep the optics clean. Dirt or condensation on the optics can limit measurements.

• Before starting work, let the instrument adjust to the ambient temperature (approx. 2 minutes per °C of temperature difference).

• Avoid measuring through window panes.

• Staff sections have to be fully extended and properly secured.

• Touching the upper third of the tripod, can damp vibrations at the instrument due to wind.

• Use the lens hood to cover the objective when backlight disturbs.

• Evenly illuminate the measuring area of the staff with a flashlight or spotlight in darkness.

Measurement Preparations |

3 |

Sprinter 150/150M/250M - 1.0.0en |

4.User Interface

|

EN |

c f |

DE |

|

FR |

|

ES |

b

a

Sprinter_08

|

|

ESC |

IT |

|

|

|

PT |

|

|

|

NL |

|

|

|

NO |

|

d |

e |

SV |

Sprinter_09 |

FI |

||

|

|

|

DA |

|

Key |

|

Symbol |

|

1st level functions |

|

2nd level functions |

|

|||

|

|

|

|

|

|||||||

|

a) On/Off |

|

|

|

|

|

|

Power On or Off switch |

|

NONE |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

b) MEAS |

|

|

|

|

|

|

Measuring trigger key |

|

Press and hold for 3 seconds to start and stop tracking measurement / |

|

|

|

|

|

|

|

|

|

|

|

timer measurement* |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

c) Height / |

|

|

|

|

|

|

Alternating between Height and |

|

Cursor up (in Menu / Settings mode), Switch between intermediate sight |

|

|

Distance |

|

|

|

|

|

|

Distance display |

|

I and foresight F in line leveling program BIF* |

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

User Interface |

4 |

Sprinter 150/150M/250M - 1.0.0en |

|

|

|

Key |

|

Symbol |

|

1st level functions |

|

|

|

|

|

|

|

2nd level functions |

|

|||||||||||||||||||

|

EN |

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||||||

|

DE |

|

d) dH |

|

|

|

|

|

|

Height Difference and Elevation meas- |

|

Cursor down (in Menu / Settings mode) |

|

||||||||||||||||||||||

|

FR |

|

|

|

|

|

|

|

|

|

|

urement |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

ES |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

e) MENU |

|

|

|

|

|

|

Activation and Selection of settings |

|

|

|

|

|

|

|

ENTER key for confirmation purpose |

|

|||||||||||||||||

|

IT |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

PT |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

f) Backlight |

|

|

|

|

|

|

LCD backlight illumination |

|

|

|

|

|

|

|

ESC key to decline termination of program / application or to exit setting |

|

|||||||||||||||||

|

NL |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(in Menu / Settings mode) |

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

NO |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Modes |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

SV |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

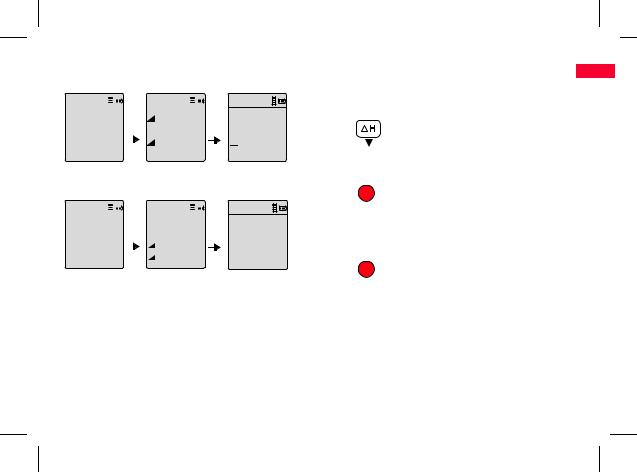

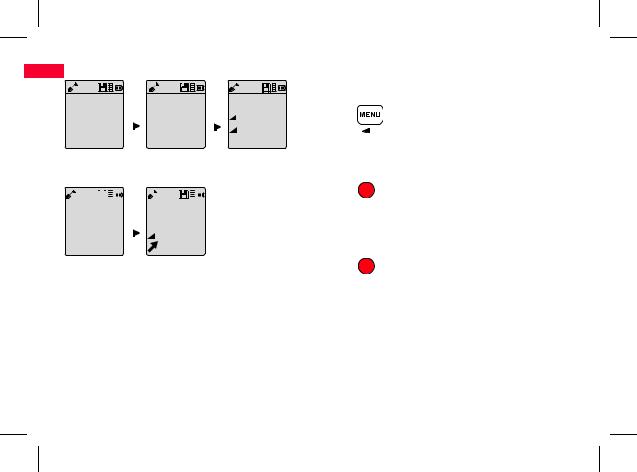

Measurement Mode |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

BF line levelling * |

|

||||||

|

|

|

MEAS |

|

|

|

|

B |

F |

B |

F |

|

|

|

|

|

|

|

|

|

|||||||||||||||

|

FI |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

MENU |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

BFFB line levelling * |

|

|||

|

DA |

|

|

MENU |

|

|

|

|

|

|

B |

FFB |

B |

F |

FB BF |

F |

B BFF |

B |

BFFB |

|

|||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Adjustment Mode |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

BIF line levelling * |

|

|||||

|

|

|

|

ADJ |

|

|

|

|

B |

IF |

B |

I |

F |

|

BI |

F |

|

|

|

|

|

||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Tracking |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Cut & Fill * |

|

|||

|

|

|

|

TRK |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Settings |

|

|

|

dH |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Height Difference |

|

||||||||

|

|

|

|

SET |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Measurement interval / timer acti- |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

vated * |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

User Interface |

5 |

Sprinter 150/150M/250M - 1.0.0en |

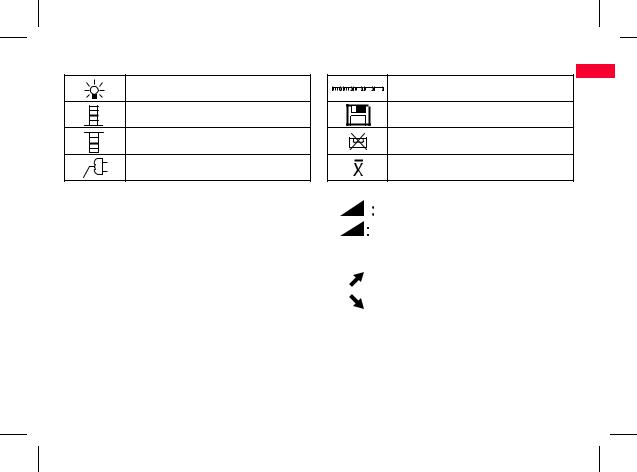

Icons

LCD backlight ON

Upright staff measuring mode

Inverted staff measuring mode

External power connected *

Measurement and Data Display Symbols

Battery icon at various capacities

Data stored to internal memory *

Tilt warning OFF

Measurement averaging activated

PtID: / RfID: |

Point ID * / Reference Benchmark ID * |

|

|

|

|

|

|

|

Measured staff height |

|

|

|

|

|

|

|

|

|

|

BM: |

Benchmark elevation |

|

|

|

|

|

|

|

Measured distance |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

dH: |

Height Difference |

|

|

|

|

|

|

|

Mean height difference in BFFB * |

|

|

dH: |

|||||||

|

|

|

|

|

|||||

Elv: |

Elevation |

|

|

|

|

|

|

|

Fill / raise height to reach design elevation * |

|

|

|

|

|

|

|

|

|

|

D.Elv: |

Design Elevation * |

|

|

|

|

|

|

|

Cut / lower height to reach design elevation * |

|

|

|

|

|

|

|

|

|

|

EN

DE

FR

ES

IT

PT

NL

NO

SV

FI

DA

User Interface |

6 |

Sprinter 150/150M/250M - 1.0.0en |

EN

DE

FR

ES

IT

PT

NL

NO

SV

FI

DA

Menu Setting |

|

|

|

|

|

|

|

||

Menus |

Selections (sub-selections) |

Descriptions |

||

1. |

Program* |

Line Levelling (BIF, BF, BFFB) |

Select line levelling method. |

|

|

|

|

|

Sighting and measurement sequence in line levelling is indicated with |

|

|

|

|

)highlighted 'alphabet' of the respective line levelling icons. |

|

|

Cut |

& Fill |

Cut & Fill application. |

2. |

Intermediate |

ON / OFF |

|

Enable / disable Intermediate Sight in BIF line levelling. |

|

Sight* |

|

|

|

3.Input PtID* Input user point ID.

4.Input BM Input Reference Benchmark elevation.

5.Input D.ELV* Input design elevation in Cut & Fill application.

6. |

Data |

View Data |

Viewing recorded data / deleting of a recorded data by pressing ENTER key. |

|

Manager* |

Download Data (GSI / ASCII) |

Transferring of recorded data to PC via RS232, in GSI-8 or ASCII format. |

|

|

Delete All Data |

Deleting of all recorded data in the on-board / internal memory. |

7. |

Recording* |

Memory |

Measurement recorded to on-board / internal memory. |

|

|

|

In line levelling application, recording mode has to be set prior to first |

|

|

|

)backsight measurement. |

|

|

Off |

Measurement not stored. |

|

|

Ext |

Measurement recorded to external device in GSI-8 format via RS232 cable. |

8. |

Adjustment |

Adjustment program. |

|

9. |

Inverse Staff |

ON [Inverted], OFF [Upright], AUTO |

Recognition mode setting of staff orientation. |

|

|

[Auto recognition of staff orientation] |

|

User Interface |

7 |

Sprinter 150/150M/250M - 1.0.0en |

Menus |

Selections (sub-selections) |

Descriptions |

10.Settings |

Contrast (10 levels) |

LCD display contrast setting. |

|

Unit (M, Int. ft, US ft, Ft in 1/16 inch) |

Unit setting. |

|

AutoOff (ON 15 min. / OFF) |

ON 15 min., instrument will be switched off about 15 minutes after the last key |

|

|

press. OFF, the instrument will not auto switch off. |

|

Rounding (Standard / Precise) |

Minimum reading display setting. |

|

|

In metric: |

|

|

• Standard = 0.001m for height and 0.01m for distance |

|

|

• Precise = 0.0001 m for height and 0.001m for distance |

|

|

In Ft (Int. and US ft): |

|

|

• Standard = 0.01 ft for height and 0.1 ft for distance |

|

|

• Precise = 0.001 ft for height and 0.01 ft for distance |

|

|

In Ft in 1/16 inch: |

|

|

• Precise & Standard = ft-inch-1/16 inch for height and distance |

|

Beep (ON / OFF) |

Trigger key acoustic signal setting. |

|

RS232* (Baudrate: 1200, 2400, 4800, |

Communication settings for RS232 interface. |

|

9600, 19200, 38400; Parity: None, Odd, |

|

|

Even; Stop Bit: 1, 2; Data Bit: 7, 8) |

|

|

Tilt Warning (ON / OFF) |

Electronic tilt warning setting. |

|

Backlight (ON / OFF) |

Backlight setting. |

|

Averaging |

Input number of measurement for averaging of measurements. |

|

Language (List of interface language |

Interface language setting. |

|

selections) |

|

|

Timer* |

Input measurement time interval 00 hr: 00 min (applicable to Ht / Dist application |

|

|

only). |

|

|

Press height / distance or dH or backlight or menu key. A message "stop |

|

|

)Tracking" will be displayed. |

EN

DE

FR

ES

IT

PT

NL

NO

SV

FI

DA

User Interface |

8 |

Sprinter 150/150M/250M - 1.0.0en |

EN 5. Set of Characters

DE Benchmark Elevation (BM), Design Elevation* (D.Elv)

BM and Design elevation numeric input consists of 0 ~ 9, space, FR decimal, Ft in 1/16 inch separator, the "+" and "-" signs.

ES Point ID* (PtID)

Point ID alphanumeric input consists of a ~ z, 0 ~ 9 and space.

IT Accepting character in the existing value

PT If there is no change for any particular character in the existing entry field, press ENTER key to accept the old entry.

NL Clearing all the existing entry field

Highlight the first entry field with "SPACE" character and press NO ENTER key to clear the entire last input value.

SV To discard entry

Press ESC key to discard entry and restore old value.

FI Point ID increment

DA Point ID will be automatically incremented by 1from the last point ID, if point ID input field is not updated manually.

6.Operation

Height and Distance measurement (electronic)

Example of an electronic measurement:

)Always aim at the center of bar code staff and focus the staff image for accurate measurement.

6.1 Height and Distance Measurement

MEAS

|

: _ _ _ _ _ |

|

|

: >>>> |

|

|

|

|

: |

1.235m |

||||||

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

: _ _ _ _ _ |

|

|

|

|

: >>>> |

|

|

|

: |

5.68m |

||||

|

|

|

|

|

|

|||||||||||

Measurement |

|

Measuring in |

Measurement with |

|||||||||||||

Standby Mode |

|

progress |

height and distance |

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Step |

Key |

|

|

Description |

|

|

|

|

|

||||||

1. |

|

|

|

Press to switch on the instrument, Leica logo |

||||||||||||

|

|

|

|

|

|

|

is displayed follow by the default measure- |

|||||||||

|

|

|

|

|

|

|

ment standby mode. |

|

|

|

|

|

||||

2. |

|

|

|

Aim at staff and focus. Lightly trigger the |

||||||||||||

|

|

|

|

|

|

|

measurement key to activate measurement. |

|||||||||

3. |

|

|

|

Height and distance measurement is |

||||||||||||

|

|

|

|

|

|

|

displayed. |

|

|

|

|

|

||||

Set of Characters |

9 |

Sprinter 150/150M/250M - 1.0.0en |

6.2Height Difference and Reduced Level Measurement (internal Memory not active)

dH |

|

|

|

|

|

|

|

|

|

MEAS |

|

|

|

|

||||||

BM: |

100.038m |

|

|

|

|

|

|

|

|

: |

>>>> |

|

|

|

||||||

|

|

|

|

|

||||||||||||||||

MeasReference |

|

|

|

|

|

|

: >>>> |

|

|

|

||||||||||

To change BM & RflD |

|

|

|

|

|

|

|

|||||||||||||

goto nenue |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Measure to Bench- |

Measuring in |

|||||||||||||||||||

mark with prompt |

progress |

|||||||||||||||||||

message |

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

dH |

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

MEAS |

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Meas.Target ! |

|

Elv: |

|

|

|

|

||||||||||||||

|

dH: |

|

|

|

|

|||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

: |

>>>> |

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

: |

>>>> |

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

Prompt message |

Measuring in |

|||||||||||||||||||

measure to target |

progress |

|||||||||||||||||||

dH

: 1.235m

: 1.235m

: 5.68m

: 5.68m

Measurement to Benchmark displayed

dH

Elv: 99.138m dH: - 0.900m  : 2.135 m

: 2.135 m  : 31.11 m

: 31.11 m

Measurement to target displayed

Step |

Key/Screen |

Description |

1. |

|

Press key to start height difference and |

|

|

reduced level function. |

|

|

|

2. |

|

A message "Meas. Reference" with input |

|

|

reduced level is displayed. |

3. |

|

Press measuring key to initiate measurement |

|

|

with respect to the Reference staff / Bench- |

|

|

mark. |

4. |

|

Reference height and distance measurement |

|

|

is displayed; follow by a message "Meas. |

|

|

Target!" prompted. |

5. |

|

Again, press measure key to start measure- |

|

|

ment with reference to target point. |

|

|

|

6. |

|

The following results are displayed accord- |

|

|

ingly;- target reduced level (RL), target height |

|

|

difference (dH) with respect to the reference |

|

|

staff, height and distance of target point. |

EN

DE

FR

ES

IT

PT

NL

NO

SV

FI

DA

Operation |

10 |

Sprinter 150/150M/250M - 1.0.0en |

EN 6.3 Cut & Fill Measurement* (internal Memory active)

DE

|

RfID: |

BM1 |

|

RfID: |

BM1 |

|

RfID : |

|

|||

FR |

|

BM1 |

|||||||||

BM: |

100.038m |

|

BM: |

100.038m |

|

||||||

|

|

|

|

|

: |

1.235m |

|||||

ES |

D.Elv: |

0.000m |

|

D.Elv: |

100.500m |

|

|

|

|||

|

|

||||||||||

|

Meas Reference |

|

Meas Reference |

|

: |

5.68m |

|||||

|

|

|

|||||||||

IT |

Change RfID, BM & |

|

Change RfID, BM & |

|

|

|

|

|

|

||

D.Elv goto menu |

|

D.Elv goto menu |

|

|

|

|

|

|

|||

PT |

Measure to Bench- |

Go to menu update |

Measurement to |

||||||||||||||||||

|

mark with prompt |

Design Elevation |

Benchmark |

||||||||||||||||||

NL |

|||||||||||||||||||||

|

message |

|

|

|

|

|

|

|

|

|

displayed |

||||||||||

|

|

|

|

|

|

|

|

|

|

||||||||||||

NO |

|

|

|

|

|

|

|

|

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

SV |

|

|

|

|

|

|

|

|

|

|

|

PtID: |

SLAB 1 |

|

|||||||

|

|

Meas.Target ! |

Elv.: |

99.563m |

|

||||||||||||||||

FI |

|

||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

: |

1.710 m |

|

|||||

DA |

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0.937 m |

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

Prompt message |

Measurement to |

|

||||||||||||||||||

|

measure to target |

target displayed |

|

||||||||||||||||||

Step |

Key/Screen |

Description |

||

1. |

|

|

|

Press Menu key and select Cut & Fill applica- |

|

|

|

|

tion in the Program sub-menu. |

|

|

|

|

|

|

|

|

|

|

2. |

|

|

|

A message "Meas. Reference" with input |

|

|

|

|

Benchmark reduced level value and Design |

|

|

|

|

Elevation is displayed. |

3. |

|

|

|

Press measuring key to initiate measurement |

|

|

|

|

with respect to the Reference staff / Bench- |

|

|

|

|

mark. |

4. |

|

|

|

Reference height and distance measurement |

|

|

|

|

is displayed; follow by a message "Meas. |

|

|

|

|

Target!" prompted. |

5. |

|

|

|

Again, press measure key to start measure- |

|

|

|

|

ment to target point. |

|

|

|

|

|

6. |

|

|

|

The following results are displayed accord- |

|

|

|

|

inglytarget reduced level (RL) / Elevation, |

|

|

|

|

height of target point and cut / fill value at |

|

|

|

|

target point with respect to the Design |

|

|

|

|

reduced level / Design Elevation. |

Operation |

11 |

Sprinter 150/150M/250M - 1.0.0en |

6.4 BIF Line Levelling Measurement* (internal Memory active) |

|

|

EN |

|

B I F |

|

B I F |

|

B I F |

|

B I F |

|

B I F |

|

DE |

|

|

|

|

|

|

FR |

||||||

PtlD : |

1 |

PtlD : |

1 |

PtID: |

2 |

PtID: |

RD1 |

PtID: |

RD1 |

||

ES |

|||||||||||

Elv: |

120.000m |

: |

1.417m |

Elv: |

_ _ _ _ _m |

Elv: |

_ _ _ _ _m |

Elv: |

119.317m |

||

Meas to backsight |

: |

28.35 m |

: _ _ _ _ _m |

: _ _ _ _ _m |

: |

2.100m |

IT |

||||

: _ _ _ _ _m |

: _ _ _ _ _m |

: |

30.617m |

||||||||

To change Elv & PtID |

|

Accept |

|||||||||

goto menu |

|

|

B I F/ Menu |

|

B I F/ Menu |

|

Accept |

PT |

|||

|

|

|

|

|

|||||||

Measure to backsight with |

Backsight measurement |

Measure to foresight with |

Go to menu set "Interme- |

Intermediate sight |

|

|

NL |

||||||

prompt message |

displayed with prompt |

prompt message |

diate Sight" to ON OR |

measurement |

||

|

message |

|

press Height & Distance |

displayed with |

|

|

|

|

NO |

||||

|

|

|

key, measure to interme- |

prompt message |

|

|

|

|

|

diate sight |

|

SV |

B I F |

B I F |

B I F |

FI |

B I F |

PtID: |

|

|

RD2 |

|

PtID: |

2 |

|

|

|

PtID: |

2 |

|

|

|

PtlD : |

2 |

DA |

|||||||||||||

Elv: _ _ _ _ _m |

Elv: _ _ _ _ _m |

Elv: |

119.894m |

|

|

|

: _ _ _ _ _m |

|||||||||||||||||||||||

|

|

: _ _ _ _ _m |

|

|

|

|

: _ _ _ _ _m |

|

|

|

|

: |

1.523m |

|

|

|

|

|

: _ _ _ _ _m |

|||||||||||

|

|

: _ _ _ _ _m |

|

|

: _ _ _ _ _m |

|

|

: |

30.76m |

|

|

|

||||||||||||||||||

|

|

|

|

|

|

|

|

|

||||||||||||||||||||||

|

|

|

B |

|

F/ Menu |

|

|

|

B |

|

F/ Menu |

|

|

|

Accept |

|

|

|

Meas / Menu |

|||||||||||

|

|

|

I |

|

|

|

I |

|

|

|

||||||||||||||||||||

Measure |

|

to next interme- |

Go to |

menu set "Interme- |

Foresight measurement |

Measure to backsight of |

||||||||||||||||||||||||

diate sight with prompt |

diate Sight" to OFF OR |

displayed with prompt |

next change point with |

|||||||||||||||||||||||||||

message |

press Height & Distance |

message |

prompt message |

|||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

key, measure to foresight |

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

Operation |

12 |

Sprinter 150/150M/250M - 1.0.0en |

EN

DE

FR

ES

IT

PT

NL

NO

SV

FI

DA

Step |

Key/Screen |

Description |

||||||

1. |

|

|

|

|

|

|

|

Initialize the BIF method. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2. |

|

|

|

|

|

|

|

Initiate measurement to Benchmark. |

|

|

|

|

|

|

|

|

|

3. |

|

|

|

|

|

|

|

Backsight measurement displayed. |

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

4. |

|

|

|

|

|

|

|

To start 'Intermediate sight' measurement, |

|

|

|

|

|

|

|

|

go to menu set 'Intermediate Sight' to ON |

|

|

|

|

|

|

|

|

or press Height & Distance key. |

|

|

|

|

|

|

|

|

|

5. |

|

|

|

|

|

|

|

Intermediate sight measurement |

|

|

|

|

|

|

|

|

displayed. |

|

|

|

|

|

|

|

|

|

6. |

|

|

|

|

|

|

|

Go to menu set 'Intermediate Sight' to OFF |

|

|

|

|

|

|

|

|

or press Height & Distance key, then |

|

|

|

|

|

|

|

|

measure to the foresight staff. |

|

|

|

|

|

|

|

|

|

7. |

|

|

|

|

|

|

|

Foresight measurement displayed. |

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

8. |

|

|

|

|

|

|

|

System refreshes a standby display for |

|

|

|

|

|

|

|

|

measurement to the backsight of next |

|

|

|

|

|

|

|

|

change point. |

6.5 BF Line Levelling Measurement*

Step |

Key/Screen |

Description |

|||||||

1. |

|

|

|

|

|

|

|

|

Initialize the BF method |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2. |

|

|

|

|

|

|

|

|

Initiate measurement to Benchmark |

|

|

|

|

|

|

|

|

|

|

3. |

|

|

|

|

|

|

|

|

Backsight measurement displayed. |

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

4. |

|

|

|

|

|

|

|

|

Measure to the foresight staff. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

5. |

|

|

|

|

|

|

|

|

Foresight measurement displayed. |

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

6. |

|

|

|

|

|

|

|

|

System refreshes a standby display for |

|

|

|

|

|

|

|

|

|

measurement to the backsight of next |

|

|

|

|

|

|

|

|

|

change point. |

Operation |

13 |

Sprinter 150/150M/250M - 1.0.0en |

6.6BFFB Line Levelling Measurement*

Step |

Key/Screen |

Description |

|||||||

1. |

|

|

|

|

|

|

|

|

Initialize the BFFB method. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2. |

|

|

|

|

|

|

|

|

Initiate measurement to Benchmark. |

|

|

|

|

|

|

|

|

|

|

3. |

|

|

|

|

|

|

|

|

Backsight measurement displayed. |

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

4. |

|

|

|

|

|

|

|

|

Measurement to foresight. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

5. |

|

|

|

|

|

|

|

|

Foresight measurement displayed. |

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

6. |

|

|

|

|

|

|

|

|

Measure to the foresight staff (second |

|

|

|

|

|

|

|

|

|

sighting). |

|

|

|

|

|

|

|

|

|

|

7. |

|

|

|

|

|

|

|

|

Foresight (second sighting) measure- |

|

|

|

|

|

|

|

|

|

ment displayed. |

|

|

|

|

|

|

|

|

|

|

8. |

|

|

|

|

|

|

|

|

Measure to the backsight staff (second |

|

|

|

|

|

|

|

|

|

sighting). |

|

|

|

|

|

|

|

|

|

|

Step |

Key/Screen |

Description |

|||

9. |

|

|

|

|

Backsight (second sighting) measure- |

|

|

|

|

|

ment displayed. |

|

|

|

|

|

|

10. |

|

|

|

|

System displays current 'Change Point' |

|

|

|

|

|

measurement report. Press ENTER key |

|

|

|

|

|

to accept the result. |

11. |

|

|

|

|

System refreshes a standby display for |

|

|

|

|

|

measurement to the backsight of next |

|

|

|

|

|

change point. |

)Mean (average) of height difference in double-

sighting of backsight and foresight for BFFB line dH levelling method.

6.7 Timer Measurement*

Set measurement time interval 00 hr:00 min in Menu\Settings\Timer. Press and hold measuring key for 3 seconds to start timer measurement, Timer icon will be shown at the top left of LCD display to indicate current measurement mode. To stop timer measurement, press and hold measuring key for 3 seconds.

EN

DE

FR

ES

IT

PT

NL

NO

SV

FI

DA

Operation |

14 |

Sprinter 150/150M/250M - 1.0.0en |

EN 7. Data Transfer DataLoader*

DE

FR

ES

IT

PT

NL

NO

SV

FI

DA

1.Double left click on the Sprinter_Dataloader .exe setup launcher (by default, the DataLoader will be installed in C: \ Program files \ Leica-Geosystems).

2.Connect the USB cable with phone jab to the connector port (which is located in the battery compartment of the instrument) and USB jab to the USB port at the PC.

3.Power On the instrument, wait for the double beeps and USB icon will be shown on the LCD of the instrument.

4.Start the DataLoader from default C: \ Program files \ LeicaGeosystems.

5.Left click on 'USB Connect' button in the DataLoader and all info relevant to instrument will be displayed.

6.Left click on 'Data Listing' / 'Field Book' button in the Data

Export window to download the data from the instrument to PC in Window Ms-Excel ®.

)For further DataLoader details and RS232 data transfer instructions please refer to the Sprinter CD-ROM*.

Data Transfer DataLoader* |

15 |

Sprinter 150/150M/250M - 1.0.0en |

8.Check & Adjust

8.1 Electronic Collimation Adjustment

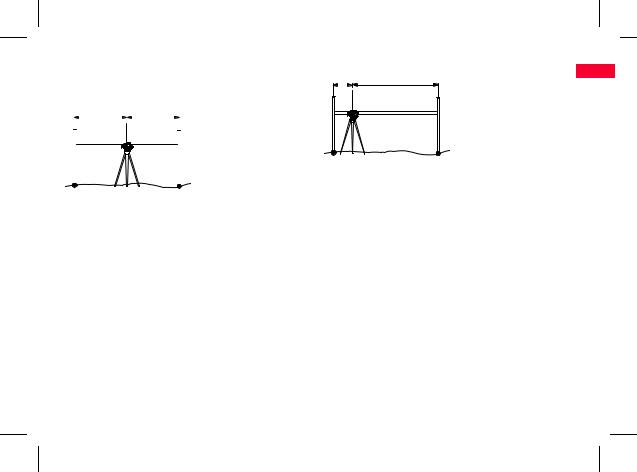

A ~15m |

|

|

~15m B |

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

To activate "Adjustment" program, go to Menu\Adjustment. Step 1: Aim at Staff A and press MEAS key. Measurement display, press ENTER key to accept.

Step 2: Aim at Staff B and press MEAS key. Measurement display, press ENTER key to accept.

Now shift the Sprinter towards staff A and set it up at about 3 m to staff A.

A ~3m |

~27m |

B |

Step 3: Aim at Staff B and press MEAS key. Measurement display, press ENTER key to accept.

Step 4: Aim at Staff A and press MEAS key. Measurement display, press ENTER key to accept.

The new electronic collimation error is displayed. To accept new correction, press ENTER key, otherwise press ESC key to decline adjustment result.

)Opticalreticle. collimation error can be corrected by adjusting the

EN

DE

FR

ES

IT

PT

NL

NO

SV

FI

DA

Check & Adjust |

16 |

Sprinter 150/150M/250M - 1.0.0en |

EN 8.2 |

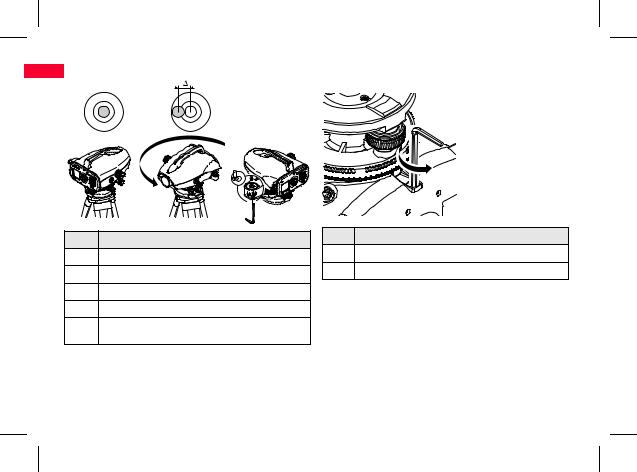

Circular Level |

|

|

DE |

|

|

|

FR |

|

|

|

ES |

3. |

|

|

IT |

1. |

2. |

|

PT |

|||

|

|||

|

|

||

NL |

|

|

|

NO |

|

|

|

SV |

|

4. |

|

r_18 |

|

||

FI |

|

|

|

DA Step |

Description |

|

|

1. |

Level instrument. |

|

|

2. |

Turn instrument by 180°. |

|

|

3. |

Center bubble if it extends beyond the centering circle. |

||

4. |

Correct half of the error with the Allen key. |

||

|

Repeat steps 1 to 4 until the circular level bubble is |

||

) centered at any random telescope pointing. |

|||

8.3Optical Collimation / Reticle Adjustment

Step Description

1.Turn Allen key until design value is reached.

2.Check collimation.

If the collimation error exceeds 3 mm over 60 m distance, the collimation needs to be adjusted.

Check & Adjust |

17 |

Sprinter 150/150M/250M - 1.0.0en |

9.Error Messages

No. |

Error message |

Counter measure / causes |

E99 |

System Error, Contact |

Hardware faults or file errors or adjustment errors or setting errors rendering instrument not working prop- |

|

Services ! |

erly. |

E100 |

Low Battery ! |

Change to new or freshly charged batteries. |

E101 |

Point No. Not Incre- |

Change the PtID. Max. PtID is 99999999 and do not end any 8 characters string with an alphabet char- |

|

mented! |

acter. |

E102 |

Too Bright ! |

Darken staff or reduce lighting on staff or shade the objective telescope. |

E103 |

Too Dark ! |

Light up staff uniformly. |

E104 |

No Staff ! |

Check targeting. |

E105 |

Invalid Entry! |

Check the entry / input. |

E106 |

Out Of Level ! |

Level the instrument. |

E107 |

Memory Full! |

Set internal memory to OFF and continue measurement without recording OR download stored data to |

|

|

an external device and continue measurement with internal memory ON after deleting all recorded data |

|

|

in the internal memory. |

E108 |

Data File Error ! |

Data file error. |

E109 |

Low Memory! |

Prepare to download data to external device, in order to continue further measurement with recording ON |

|

|

after deleting all recorded data in the internal memory. |

E110 |

Target Too Close ! |

Move staff or instrument further apart. |

E111 |

Target Too far ! |

Move staff or instrument closer together. |

E112 |

Too Cold ! |

Stop working, external temperature is outside the instrument operating temperature. |

E113 |

Too Hot ! |

Stop working, external temperature is outside the instrument operating temperature. |

EN

DE

FR

ES

IT

PT

NL

NO

SV

FI

DA

Error Messages |

18 |

Sprinter 150/150M/250M - 1.0.0en |

|

EN |

No. |

Error message |

Counter measure / causes |

|

DE |

E114 |

Invalid Measurement ! |

Make another measurement. If further measurement proved to be futile, check staff position and Inverse |

|

FR |

|

|

Staff setting, check the lighting condition at the staff and stray light, check focusing and targeting, check |

|

|

|

if sufficient length of barcode in the field of view. |

|

|

ES |

E115 |

Temperature Sensor |

Cover the objective telescope with a hand and switch ON the instrument. Hardware communication failed. |

|

IT |

|

Error ! |

|

|

E116 |

Adjustment Error ! |

Carry out the adjustment with guided steps, make sure instrument is level and staff is truly vertical in |

|

|

PT |

|

|

normal position. Collimation is out of correction range. |

|

NL |

E117 |

BM Change Not Allowed! |

Exit to default measurement mode by pressing HEIGHT/DISTANCE key, and change the Benchmark |

|

NO |

|

|

elevation in the INPUT BM menu mode. |

|

E119 |

Staff Blocked |

Not enough barcode length for measurement. |

|

|

SV |

E120 |

Image sensor Error! |

Contact services. |

|

FI |

E121 |

Adjustment Inverse Staff |

Check the staff orientation and staff setting. |

|

|

Not Allowed! |

|

|

|

DA |

|

|

|

|

|

|

|

|

|

E123 |

PtID Change Not Allowed |

Exit the message by pressing ESC key. |

|

|

|

|

|

|

10. Operation Messages

Operation message |

Counter measure / remark |

Start Tracking! |

Tracking mode starts. |

Stop Tracking! |

Tracking mode stops. |

Tracking Hold! |

Press measure key for 3 seconds to restart tracking mode. Tracking will hold after 10 unsuccessful meas- |

|

urements. |

Abort Measurement! |

Current measuring process is terminated. |

Downloading Data! |

Downloading of data from the internal memory to an external device is in progress. |

Operation Messages |

19 |

Sprinter 150/150M/250M - 1.0.0en |

|

|

|

|

Operation message |

Counter measure / remark |

EN |

|

Download Completed! |

System is successfully downloaded the internal memory data to an external device. |

DE |

|

No Data In Memory! |

No data is stored in the internal memory. |

FR |

|

Delete. Are You Sure? |

Questionnaire prompted user to confirm the deletion of a data (in View Data mode) / all the data (in Delete |

|

|

ES |

|

||

|

All Data mode) in the internal memory. |

|

|

Data Deleted! |

System confirmation a data or all the data in the internal memory is deleted. |

IT |

|

Can't Delete! |

Reference Benchmark and line levelling measurement not allowed to be deleted by single data deletion method. |

PT |

|

Change BM. Are You Sure? |

Question to prompt user if changing of Reference Benchmark elevation to confirm. |

|

|

NL |

|

||

Change Design Elevation. Are |

Question to prompt user if changing of Design elevation to confirm. |

|

|

|

|

||

You Sure? |

|

NO |

|

Wait! File System Clean Up! |

Cleaning up of temporary files/system files. |

SV |

|

Shut Down! |

System is switching OFF. |

|

|

FI |

|

||

Sand Clock Icon |

Please wait! System task is in progress. |

|

|

DA |

|

||

|

|

|

|

Meas Target |

Aim to target staff and press measuring button. |

|

|

|

|

|

|

Setting... |

System parameter setting in progress. |

|

|

Change Point not completed! Quit |

Prompt message to quit application during line levelling process. Complete current line levelling change point |

|

|

Application? |

measurements, then leave the application program. Pressing ENTER key to quit application; otherwise, |

|

|

|

press ESC key to return to current application. |

|

|

Quit This Application? |

Prompt message to quit current application, pressing ENTER key to quit application; otherwise, press ESC |

|

|

|

key to return to current application. |

|

|

Operation Messages |

20 |

Sprinter 150/150M/250M - 1.0.0en |

EN 11. Care and Transport

DE 11.1 Transport

FR Transport in the field

When transporting the equipment in the field, always make sure ES that you

IT • either carry the product in its original transport container,

• or carry the tripod with its legs splayed across your shoulder, PT keeping the attached product upright.

Transport in a road vehicle

NL Never carry the product loose in a road vehicle, as it can be affected NO by shock and vibration. Always carry the product in its transport

container and secure it.

SV Shipping

FI When transporting the product by rail, air or sea, always use the complete original Leica Geosystems packaging, transport container

DA and cardboard box, or its equivalent, to protect against shock and vibration.

Shipping, transport of batteries

When transporting or shipping batteries, the person in charge of the product must ensure that the applicable national and international rules and regulations are observed. Before transportation or shipping, contact your local passenger or freight transport company.

Field adjustment

After transport inspect the field adjustment parameters given in this user manual before using the product.

11.2 Storage

Product

Respect the temperature limits when storing the equipment, particularly in summer if the equipment is inside a vehicle. Refer to "13. Technical Data" for information about temperature limits.

Field adjustment

After long periods of storage inspect the field adjustment parameters given in this user manual before using the product.

If the equipment is to be stored for a long time, remove the alkaline batteries from the product in order to avoid the danger of leakage.

11.3 Cleaning and Drying

Product and Accessories

•Blow dust off lenses.

•Never touch the glass with your fingers.

•Use only a clean, soft, lint-free cloth for cleaning. If necessary, moisten the cloth with water or pure alcohol.

Do not use other liquids; these may attack the polymer components.

Damp products

Dry the product, the transport container, the foam inserts and the accessories at a temperature not greater than +40°C / +104°F and clean them. Do not repack until everything is completely dry.

Care and Transport |

21 |

Sprinter 150/150M/250M - 1.0.0en |

12. Safety Directions

12.1 General Introduction

Description

The following directions should enable the person responsible for the product, and the person who actually uses the equipment, to anticipate and avoid operational hazards.

The person responsible for the product must ensure that all users understand these directions and adhere to them.

12.2 Intended Use

Permitted use

•Measuring distances.

•Recording measurements.

•Electronic and optical height measurements to a staff.

•Optical height readings.

•Optical distance measuring with stadia readings.

•Data communication with external appliances.

Adverse use

•Use of the product without instruction.

•Use outside of the intended limits.

•Disabling safety systems.

•Removal of hazard notices.

•Opening the product using tools, for example screwdriver, unless this is specifically permitted for certain functions.

•Modification or conversion of the product.

•Use after misappropriation.

•Use of products with obviously recognizable damages or defects.

•Use with accessories from other manufacturers without the prior explicit approval of Leica Geosystems.

•Inadequate safeguards at the working site, for example when measuring on roads.

•Aiming directly into the sun.

WARNINGAdverse use can lead to injury, malfunction and damage. It is the task of the person responsible for the equipment to inform the user about hazards and how to counteract them. The product is not to be operated until the user has been instructed on how to work with it.

12.3 Limits of Use

Environment

Suitable for use in an atmosphere appropriate for permanent human habitation: not suitable for use in aggressive or explosive environments.

DANGERLocal safety authorities and safety experts must be contacted before working in hazardous areas, or in close proximity to electrical installations or similar situations by the person in charge of the product.

12.4 Responsibilities

Manufacturer of the product

Leica Geosystems AG, CH-9435 Heerbrugg, hereinafter referred to as Leica Geosystems, is responsible for supplying the product, including the user manual and original accessories, in a completely safe condition.

EN

DE

FR

ES

IT

PT

NL

NO

SV

FI

DA

Safety Directions |

22 |

Sprinter 150/150M/250M - 1.0.0en |

EN

DE

FR

ES

IT

PT

NL

NO

SV

FI

DA

Manufacturers of non Leica Geosystems accessories

The manufacturers of non Leica Geosystems accessories for the product are responsible for developing, implementing and communicating safety concepts for their products, and are also responsible for the effectiveness of those safety concepts in combination with the Leica Geosystems product.

Person in charge of the product

The person in charge of the product has the following duties:

•To understand the safety instructions on the product and the instructions in the user manual.

•To be familiar with local regulations relating to safety and accident prevention.

•To inform Leica Geosystems immediately if the product and the application becomes unsafe.

WARNINGThe person responsible for the product must ensure that it is used in accordance with the instructions. This person is also accountable for the training and the deployment of personnel who use the product and for the safety of the equipment in use.

12.5 Hazards of Use

WARNINGThe absence of instruction, or the inadequate imparting of instruction, can lead to incorrect or adverse use, and can give rise to accidents with far-reaching human, material, financial and environmental consequences.

Precautions:

All users must follow the safety directions given by the manufacturer and the directions of the person responsible for the product.

CAUTIONWatch out for erroneous measurement results if the product has been dropped or has been misused, modified, stored for long periods or transported.

Precautions:

Periodically carry out test measurements and perform the field adjustments indicated in the user manual, particularly after the product has been subjected to abnormal use and before and after important measurements.

DANGERBecause of the risk of electrocution, it is very dangerous to use staffs in the vicinity of electrical installations such as power cables or electrical railways.

Precautions:

Keep at a safe distance from electrical installations. If it is essential to work in this environment, first contact the safety authorities responsible for the electrical installations and follow their instructions.

CAUTIONStrong magnetic fields in the immediate vicinity (e.g. transformers, melting furnaces...) may influence the compensator and lead to measuring errors.

Safety Directions |

23 |

Sprinter 150/150M/250M - 1.0.0en |

Precautions:

When measuring near strong magnetic fields, check results for plausibility.

CAUTIONBe careful when pointing the product towards the sun, because the telescope functions as a magnifying glass and can injure your eyes and/or cause damage inside the product.

Precautions:

Do not point the product directly at the sun.

WARNINGDuring dynamic applications, for example stakeout procedures there is a danger of accidents occurring if the user does not pay attention to the environmental conditions around, for example obstacles, excavations or traffic.

Precautions:

The person responsible for the product must make all users fully aware of the existing dangers.

WARNINGInadequate securing of the working site can lead to dangerous situations, for example in traffic, on building sites, and at industrial installations.

Precautions:

Always ensure that the working site is adequately secured. Adhere to the regulations governing safety and accident prevention and road traffic.

WARNINGIf computers intended for use indoors are used in the field there is a danger of electric shock.

Precautions:

Adhere to the instructions given by the computer manufacturer with regard to field use in conjunction with Leica Geosystems products.

CAUTIONIf the accessories used with the product are not properly secured and the product is subjected to mechanical shock, for example blows or falling, the product may be damaged or people may sustain injury.

Precautions:

When setting-up the product, make sure that the accessories are correctly adapted, fitted, secured, and locked in position.

Avoid subjecting the product to mechanical stress.

CAUTIONWhen using a vertical staff supported by one brace there is always the danger of falling, for example by wind gusts and therefore danger of damage to equipment and danger of personal injuries.

Precautions:

Never leave a vertical staff supported by a brace unsupervised (person at the staff).

WARNINGIf the product is used with accessories, for example masts, staffs, poles, you may increase the risk of being struck by lightning.

Precautions:

Do not use the product in a thunderstorm.

EN

DE

FR

ES

IT

PT

NL

NO

SV

FI

DA

Safety Directions |

24 |

Sprinter 150/150M/250M - 1.0.0en |

EN

DE

FR

ES

IT

PT

NL

NO

SV

FI

DA

CAUTIONDuring the operation of the product there is a hazard of squeezing extremities or entanglement of hairs and/or clothes by rotating parts.

Precautions:

Keep a safe distance of the rotating parts.

WARNINGIf you open the product, either of the following actions may cause you to receive an electric shock.

•Touching live components

•Using the product after incorrect attempts were made to carry

out repairs.

Precautions:

Do not open the product. Only Leica Geosystems authorized service workshops are entitled to repair these products.

WARNINGBatteries not recommended by Leica Geosystems may be damaged if charged or discharged. They may burn and explode.

Precautions:

Only charge and discharge batteries recommended by Leica Geosystems.

WARNINGUsing a battery charger not recommended by Leica Geosystems can destroy the batteries. This can cause fire or explosions.

Precautions:

Only use chargers recommended by Leica Geosystems to charge the batteries.

CAUTIONDuring the transport, shipping or disposal of batteries it is possible for inappropriate mechanical influences to constitute a fire hazard.

Precautions:

Before shipping the product or disposing of it, discharge the batteries by running the product until they are flat.

When transporting or shipping batteries, the person in charge of the product must ensure that the applicable national and international rules and regulations are observed. Before transportation or shipping contact your local passenger or freight transport company.

WARNINGHigh mechanical stress, high ambient temperatures or immersion into fluids can cause leackage, fire or explosions of the batteries.

Precautions:

Protect the batteries from mechanical influences and high ambient temperatures. Do not drop or immerse batteries into fluids.

WARNINGShort circuited battery terminals can overheat and cause injury or fire, for example by storing or transporting in pockets if battery terminals come in contact with jewellery, keys, metallized paper or other metals.

Precautions:

Make sure that the battery terminals do not come into contact with metallic objects.

Safety Directions |

25 |

Sprinter 150/150M/250M - 1.0.0en |

CAUTIONLong term storage may reduce lifetime or damage the battery.

Precautions:

During long term storage, maintain battery life by periodic recharge.

WARNINGIf the product is improperly disposed of, the following can happen:

•If polymer parts are burnt, poisonous gases are produced which may impair health.

•If batteries are damaged or are heated strongly, they can explode and cause poisoning, burning, corrosion or environmental contamination.

•By disposing of the product irresponsibly you may enable unauthorized persons to use it in contravention of the regulations,

exposing themselves and third parties to the risk of severe injury and rendering the environment liable to contamination.

Precautions:

The product must not be disposed with household

waste.

Dispose of the product appropriately in accordance with the national regulations in force in your country.

Always prevent access to the product by unauthorized

personnel.

Product specific treatment and waste management information can be downloaded from the Leica Geosystems home page at http://

www.leica-geosystems.com/treatment or received from your Leica Geosystems dealer.

WARNING

Only Leica Geosystems authorized service workshops are

entitled to repair these products.

12.6 Electromagnetic Compatibility EMC

Description

The term Electromagnetic Compatibility is taken to mean the capability of the product to function smoothly in an environment where electromagnetic radiation and electrostatic discharges are present, and without causing electromagnetic disturbances to other equipment.

WARNINGElectromagnetic radiation can cause disturbances in other equipment.