Page 1

Operation and Safety Manual

®

Original Instructions - Keep this manual with the machine at all times.

Model(s)

1532R

1932R

ANSI

AS/NZS

P/N - 3121744

October 20, 2017

Page 2

NOTES:

Page 3

FOREWORD

FOREWORD

This manual is a very important tool! Keep it with the machine at all times.

The purpose of this manual is to provide owners, users, operators, lessors, and lessees with the precautions and operating procedures essential for the safe and proper machine operation for its intended purpose.

Due to continuous product improvements, JLG Industries, Inc. reserves the right to make specification changes without prior notification. Contact JLG Industries, Inc. for updated information.

3121744 – JLG Lift – a

Page 4

SAFETY ALERT SYMBOLS AND SAFETY SIGNAL WORDS

NOTICE

SAFETY ALERT SYMBOLS AND SAFETY SIGNAL WORDS

This is the Safety Alert Symbol. It is used to alert you to the potential personal

injury hazards. Obey all safety messages that follow this symbol to avoid possible injury or death.

INDICATES AN IMMINENTLY HAZARDOUS SITUATION. IF NOT AVOIDED, WILL

RESULT IN SERIOUS INJURY OR DEATH. THIS DECAL WILL HAVE A RED BACKGROUND.

INDICATES A POTENTIALITY HAZARDOUS SITUATION. IF NOT AVOIDED,

COULD

RESULT IN SERIOUS INJURY OR DEATH. THIS DECAL WILL HAVE AN

ORANGE BACKGROUND.

b – JLG Lift – 3121744

INDICATES A POTENTIALITY HAZARDOUS SITUATION. IF NOT AVOIDED, MAY

RESULT IN MINOR OR MODERATE INJURY. IT MAY ALSO ALERT AGAINST

UNSAFE PRACTICES. THIS DECAL WILL HAVE A YELLOW BACKGROUND.

INDICATES INFORMATION OR A COMPANY POLICY THAT RELATES DIRECTLY

OR INDIRECTLY TO THE SAFETY OF PERSONNEL OR PROTECTION OF PROPERTY.

Page 5

THIS PRODUCT MUST COMPLY WITH ALL SAFETY RELATED BULLETINS. CON-

NOTICE

NOTICE

TACT JLG INDUSTRIES, INC. OR THE LOCAL AUTHORIZED JLG REPRESENTATIVE FOR INFORMATION REGARDING SAFETY RELATED BULLETINS WHICH

MAY HAVE BEEN ISSUED FOR THIS PRODUCT.

JLG INDUSTRIES, INC. SENDS SAFETY RELATED BULLETINS TO THE OWNER OF

RECORD OF THIS MACHINE. CONTACT JLG INDUSTRIES, INC. TO ENSURE THAT

THE CURRENT OWNER RECORDS ARE UPDATED AND ACCURATE.

JLG INDUSTRIES, INC. MUST BE NOTIFIED IMMEDIATELY IN ALL INSTANCES

WHERE JLG PRODUCTS HAVE BEEN INVOLVED IN AN ACCIDENT INVOLVING

BODILY INJURY OR DEATH OF PERSONNEL OR WHEN SUBSTANTIAL DAMAGE

HAS OCCURRED TO PERSONAL PROPERTY OR THE JLG PRODUCT.

SAFETY ALERT SYMBOLS AND SAFETY SIGNAL WORDS

For:

• Accident Reporting

• Product Safety Publica-

tions

• Current Owner Updates

• Questions Regarding

Product Safety

• Standards and Regulations

Compliance Information

• Questions Regarding Special

Product Applications

• Questions Regarding Product Modifications

Contact:

Product Safety and Reliability Department

JLG Industries, Inc.

13224 Fountainhead Plaza

Hagerstown, MD 21742

USA

or Your Local JLG Office

(See addresses on manual rear cover)

In USA:

Toll Free: 877-JLG-SAFE (877-554-7233)

Outside USA:

Phone: 240-420-2661

E-mail: ProductSafety@JLG.com

3121744 – JLG Lift – c

Page 6

REVISION LOG

Original Issue of Manual. . . . . . . . . . . . . . . . . . . . . July 14, 2016

Manual Revised . . . . . . . . . . . . . . . . . . . . . . . . . . . . . August 18, 2016

Manual Revised . . . . . . . . . . . . . . . . . . . . . . . . . . . . . September 27, 2016

Manual Revised . . . . . . . . . . . . . . . . . . . . . . . . . . . . . January 30, 2017

Manual Revised . . . . . . . . . . . . . . . . . . . . . . . . . . . . . February 21, 2017

Manual Revised . . . . . . . . . . . . . . . . . . . . . . . . . . . . . October 20, 2017

REVISION LOG

d – JLG Lift – 3121744

Page 7

TABLE OF CONTENTS

SECTION - PARAGRAPH, SUBJECT PAGE SECTION - PARAGRAPH, SUBJECT PAGE

FOREWORD. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A

SAFETY ALERT SYMBOLS AND SAFETY SIGNAL WORDS . . . . . B

Contact: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C

In USA: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C

Outside USA:. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C

REVISION LOG . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D

SECTION - 1 - SAFETY PRECAUTIONS

1.1 GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

1.2 PRE-OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

Operator Training and Knowledge. . . . . . . . . . . . . . . . . . . . . .1-2

Workplace Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

Machine Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

1.3 OPERATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

Trip and Fall Hazards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-5

Electrocution Hazards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-6

Tipping Hazards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-7

Crushing and Collision Hazards. . . . . . . . . . . . . . . . . . . . . . . . .1-9

1.4 TOWING, LIFTING, AND HAULING. . . . . . . . . . . . . . . . . . . . . . . 1-11

1.5 MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

Maintenance Hazards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

Battery Hazards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

SECTION - 2 - USER RESPONSIBILITIES, MACHINE PREPARATION

AND INSPECTION

2.1 PERSONNEL TRAINING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

Operator Training. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

Training Supervision . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

Operator Responsibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

2.2 PREPARATION, INSPECTION, AND MAINTENANCE . . . . . . . . .2-2

2.3 PRE-START INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

2.4 DAILY WALK-AROUND INSPECTION . . . . . . . . . . . . . . . . . . . . . .2-7

2.5 FUNCTION CHECK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-9

SECTION - 3 - MACHINE CONTROLS, INDICATORS AND OPERATION

3.1 GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

3.2 DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

3.3 OPERATING CHARACTERISTICS AND LIMITATIONS . . . . . . . .3-2

General. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

Placards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

3.4 PLATFORM LOADING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

3.5 MACHINE CONTROL LOCATIONS . . . . . . . . . . . . . . . . . . . . . . . . .3-3

3.6 BATTERY CHARGING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-4

3.7 GROUND CONTROL STATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-5

Ground/Platform/OFF Key Selector Switch . . . . . . . . . . . . . .3-6

Platform Lift/Lower Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-6

Inverter ON/OFF Switch (If Equipped). . . . . . . . . . . . . . . . . . .3-6

3121744 – JLG Lift – i

Page 8

TABLE OF CONTENTS

SECTION - PARAGRAPH, SUBJECT PAGE SECTION - PARAGRAPH, SUBJECT PAGE

Ground Emergency Stop Switch. . . . . . . . . . . . . . . . . . . . . . . . 3-6

Hourmeter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-7

Overload Indicator (If LSS Equipped) . . . . . . . . . . . . . . . . . . .3-7

MDI-Indicator - (If Equipped) . . . . . . . . . . . . . . . . . . . . . . . . . . .3-7

3.8 PLATFORM MANUAL DESCENT CONTROL . . . . . . . . . . . . . . . .3-9

3.9 PLATFORM CONTROL STATION. . . . . . . . . . . . . . . . . . . . . . . . . .3-10

Platform Emergency Stop Switch. . . . . . . . . . . . . . . . . . . . . .3-12

Lift/Drive Select. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-12

Forward/Reverse/Lift/Lower Direction Decal. . . . . . . . . . .3-12

Drive/Lift/Steer Joystick Control . . . . . . . . . . . . . . . . . . . . . . .3-13

Steering And Traveling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-13

Steering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-14

Traveling Forward and Reverse. . . . . . . . . . . . . . . . . . . . . . . .3-14

Raising And Lowering Platform. . . . . . . . . . . . . . . . . . . . . . . .3-14

Arm Guards (If Equipped) . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-16

Overload Indicator (LSS) (If Equipped) . . . . . . . . . . . . . . . . .3-16

Tilt Indicator Warning Light and Alarm . . . . . . . . . . . . . . . .3-16

Horn . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-16

Battery Charge Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-17

System Fault Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-17

Alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-17

Indoor-Zone A/Outdoor-Zone B Operation Indicator . . .3-17

Indoor-Zone A/Outdoor-Zone B Operation Mode

Switch. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-17

Outdoor/Indoor Operation Indicator . . . . . . . . . . . . . . . . . .3-18

Outdoor/Indoor Operation Mode Switch . . . . . . . . . . . . . . 3-18

3.10 PLATFORM EXTENSION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-19

3.11 PLATFORM RAILS - FOLD-DOWN PROCEDURE -

(IF EQUIPPED) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-20

3.12 PARKING AND STOWING MACHINE. . . . . . . . . . . . . . . . . . . . . .3-22

3.13 MACHINE LIFTING AND TIE DOWN . . . . . . . . . . . . . . . . . . . . . .3-23

Lifting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-23

Tie Down. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-24

3.14 TOWING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-26

Hydraulic Brake Release. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-26

SECTION - 4 - EMERGENCY PROCEDURES

4.1 GENERAL INFORMATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.2 EMERGENCY OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Operator Unable to Control Machine . . . . . . . . . . . . . . . . . . .4-1

Platform Caught Overhead. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Righting of Tipped Machine. . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.3 PLATFORM MANUAL DESCENT. . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

4.4 INCIDENT NOTIFICATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

SECTION - 5 - GENERAL SPECIFICATIONS AND MAINTENANCE

5.1 INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

Other Publications Available Specific to this Machine:. . . 5-1

5.2 OPERATING SPECIFICATIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Platform Capacities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

ii – JLG Lift – 3121744

Page 9

TABLE OF CONTENTS

SECTION - PARAGRAPH, SUBJECT PAGE SECTION - PARAGRAPH, SUBJECT PAGE

Machine Dimensional Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-5

Tires . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-5

Batteries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-5

Electrical System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-6

5.3 CRITICAL STABILITY WEIGHTS . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-7

5.4 LUBRICATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-7

Lubrication Capacities. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-7

Hydraulic Oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-7

Lubrication Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-8

5.5 OPERATOR MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-9

Scissor Arm - Safety Prop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-9

Hydraulic Oil Check Procedure . . . . . . . . . . . . . . . . . . . . . . . 5-10

Delta-Q - Battery Charger. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-12

Green Power - Battery Charger - (China Only) . . . . . . . . . 5-12

Eagle Performance - Battery Charger. . . . . . . . . . . . . . . . . . 5-13

Battery Maintenance and Safety Practices. . . . . . . . . . . . . 5-14

Battery Quick-Disconnect (If Equipped)5-14

Tire Wear and Damage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-15

Wheel and Tire Replacement . . . . . . . . . . . . . . . . . . . . . . . . . 5-15

Wheel Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-16

5.6 SUPPLEMENTAL INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . 5-17

5.7 DECAL INSTALLATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-18

5.8 DIAGNOSTIC TROUBLE CODES (DTC). . . . . . . . . . . . . . . . . . . . 5-21

SECTION - 6 - INSPECTION AND REPAIR LOG

3121744 – JLG Lift – iii

Page 10

TABLE OF CONTENTS

SECTION - PARAGRAPH, SUBJECT PAGE SECTION - PARAGRAPH, SUBJECT PAGE

LIST OF FIGURES

2-1. Daily Walk-Around Inspection . . . . . . . . . . . . . . . . . . . . . . . . 2-8

3-1. Location of Machine Controls. . . . . . . . . . . . . . . . . . . . . . . . . 3-3

3-2. Ground Control Station. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-5

3-3. MDI Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-8

3-4. Location of Manual Descent Control . . . . . . . . . . . . . . . . . .3-9

3-5. Platform Control Station. . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-10

3-6. Platform Control Station. . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-11

3-7. Grade and Sideslope Definition . . . . . . . . . . . . . . . . . . . . . .3-15

3-8. Platform Deck Extension . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-19

3-9. Platform Rails - Fold Down Sequence . . . . . . . . . . . . . . . .3-21

3-10. Securing Control Station to Platform. . . . . . . . . . . . . . . . .3-22

3-11. Fork Lift Pockets - Location . . . . . . . . . . . . . . . . . . . . . . . . . .3-23

3-12. Lifting Machine Using Spreader Bar and

Lift Lug Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-24

3-13. Tie Down and Lift Lug Locations . . . . . . . . . . . . . . . . . . . . .3-25

3-14. Hydraulic Brakes - Manual Disengage. . . . . . . . . . . . . . . .3-26

4-1. Location of Manual Descent Control . . . . . . . . . . . . . . . . . .4-2

5-1. Scissor Arm - Safety Prop . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-10

5-2. Hydraulic Oil Check Procedure. . . . . . . . . . . . . . . . . . . . . . .5-11

5-3. Hydraulic Oil Fill Procedure . . . . . . . . . . . . . . . . . . . . . . . . . .5-11

5-4. Battery Fluid Level. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-14

5-5. Wheel Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-16

5-6. 1532R/1932R - Machine Decal Installation. . . . . . . . . . . .5-18

LIST OF TABLES

1-1 Minimum Approach Distances (M.A.D.) . . . . . . . . . . . . . . .1-7

1-2 Beaufort Scale (For Reference Only) . . . . . . . . . . . . . . . . . . .1-8

2-1 Inspection and Maintenance Table. . . . . . . . . . . . . . . . . . . .2-3

2-2 High Drive Cutback Height . . . . . . . . . . . . . . . . . . . . . . . . . .2-10

2-3 Tilt Activation Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-10

5-1 Operating Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-2

5-2 Platform Capacities. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-4

5-3 Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-5

5-4 Tire Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-5

5-5 OEM Battery Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

5-6 Battery Charger Specifications . . . . . . . . . . . . . . . . . . . . . . . .5-6

5-7 Critical Stability Weights. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-7

5-8 Capacities. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-7

5-9 Hydraulic Oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-7

5-10 Lubrication Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

5-11 Hydraulic Oil Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . .5-8

5-12 1532R/1932R - Machine Decal Installation Chart. . . . . .5-19

5-13 Diagnostic Trouble Codes (DTC) . . . . . . . . . . . . . . . . . . . . .5-22

6-1 Inspection and Repair Log . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-1

iv – JLG Lift – 3121744

Page 11

SECTION 1. SAFETY PRECAUTIONS

SECTION 1 - SAFETY PRECAUTIONS

1.1 GENERAL

This section outlines the necessary precautions for proper

and safe machine usage and maintenance. In order to promote proper machine usage, it is mandatory that a daily

routine is established based on the content of this manual.

A maintenance program, using the information provided

in this manual and the Service and Maintenance Manual,

must also be established by a qualified person and must

be followed to ensure that the machine is safe to operate.

The owner/user/operator/lessor/lessee of the machine

must not accept operating responsibility until this manual

has been read, training is accomplished, and operation of

the machine has been completed under the supervision of

an experienced and qualified operator.

These sections contain the responsibilities of the owner,

user, operator, lessor, and lessee concerning safety, training, inspection, maintenance, application, and operation.If

there are any questions with regard to safety, training,

inspection, maintenance, application, and operation,

please contact JLG Industries, Inc. (“JLG”).

FAILURE TO COMPLY WITH THE SAFETY PRECAUTIONS LISTED IN THIS MANUAL COULD RESULT IN MACHINE DAMAGE, PROPERTY DAMAGE, PERSONAL

INJURY OR DEATH.

3121744 – JLG Lift – 1-1

Page 12

SECTION 1 - SAFETY PRECAUTIONS

1.2 PRE-OPERATION

Operator Training and Knowledge

• The Operation and Safety Manual must be read and understood in its entirety before operating the machine. For clarification, questions, or additional information regarding any

portions of this manual, contact JLG Industries, Inc.

• An operator must not accept operating responsibilities

until adequate training has been given by competent and

authorized persons.

• Allow only those authorized and qualified personnel to

operate the machine who have demonstrated that they

understand the safe and proper operation and maintenance of the unit.

• Read, understand, and obey all DANGERS, WARNINGS, CAUTIONS, and operating instructions on the machine and in

this manual.

• Ensure that the machine is to be used in a manner which is

within the scope of its intended application as determined

by JLG.

• All operating personnel must be familiar with the emergency controls and emergency operation of the machine as

specified in this manual.

• Read, understand, and obey all applicable employer, local,

and governmental regulations as they pertain to your utilization and application of the machine.

Workplace Inspection

• Precautions to avoid all hazards in the work area must be

taken by the user before and during operation of the

machine.

• Do not operate or raise the platform from a position on

trucks, trailers, railway cars, floating vessels, scaffolds or

other equipment unless the application is approved in writing by JLG.

• Before operation, check work area for overhead hazards

such as electric lines, bridge cranes, and other potential

overhead obstructions.

• Check floor surfaces for holes, bumps, drop-offs, obstructions, debris, concealed holes, and other potential hazards.

1-2 – JLG Lift – 3121744

Page 13

SECTION 1 - SAFETY PRECAUTIONS

• Check the work area for hazardous locations. Do not operate the machine in hazardous environments unless

approved for that purpose by JLG.

• Ensure that the ground conditions are adequate to support

the maximum tire load indicated on the tire load decals

located on the chassis adjacent to each wheel.

• This machine can be operated in nominal ambient temperatures of 0

mize operation outside of this temperature range.

o

F to 104o F (-20o C to 40o C). Consult JLG to opti-

Machine Inspection

• Do not operate this machine until the inspections and functional checks have been performed as specified in Section 2

of this manual.

• Do not operate this machine until it has been serviced and

maintained according to the maintenance and inspection

requirements as specified in the machine’s Service and

Maintenance Manual.

• Ensure all safety devices are operating properly. Modification of these devices is a safety violation.

MODIFICATION OR ALTERATION OF AN AERIAL WORK PLATFORM SHALL BE

MADE ONLY WITH PRIOR WRITTEN PERMISSION FROM THE MANUFACTURER.

• Do not operate any machine on which the safety or instruction placards or decals are missing or illegible.

• Check the machine for modifications to original components. Ensure that any modifications have been approved

by JLG.

• Avoid accumulation of debris on platform deck. Keep mud,

oil, grease, and other slippery substances from footwear

and platform deck.

3121744 – JLG Lift – 1-3

Page 14

SECTION 1 - SAFETY PRECAUTIONS

1.3 OPERATION

General

• Machine operation requires your full attention. Bring the

machine to a full stop before using any device, i.e. cell

phones, two-way radios, etc. that will distract your attention

from safely operating the machine.

• Do not use the machine for any purpose other than positioning personnel, their tools, and equipment.

• Before operation, the user must be familiar with the

machine capabilities and operating characteristics of all

functions.

• Never operate a malfunctioning machine. If a malfunction

occurs, shut down the machine. Remove the unit from service and notify the proper authorities.

• Do not remove, modify, or disable any safety devices.

• Never slam a control switch or lever through neutral to an

opposite direction. Always return switch to neutral and stop

before moving the switch to the next function. Operate

controls with slow and even pressure.

• Do not allow personnel to tamper with or operate the

machine from the ground with personnel in the platform,

except in an emergency.

• Do not carry materials directly on platform railing unless

approved by JLG.

• When two or more persons are in the platform, the operator

shall be responsible for all machine operations.

• Always ensure that power tools are properly stowed and

never left hanging by their cord from the platform work

area.

• Do not assist a stuck or disabled machine by pushing or

pulling except by pulling at the chassis tie-down lugs.

• Fully lower platform and shut off all power before leaving

machine.

• Remove all rings, watches, and jewelry when operating

machine. Do not wear loose fitting clothing or long hair

unrestrained which may become caught or entangled in

equipment.

• Persons under the influence of drugs or alcohol or who are

subject to seizures, dizziness or loss of physical control must

not operate this machine.

1-4 – JLG Lift – 3121744

Page 15

SECTION 1 - SAFETY PRECAUTIONS

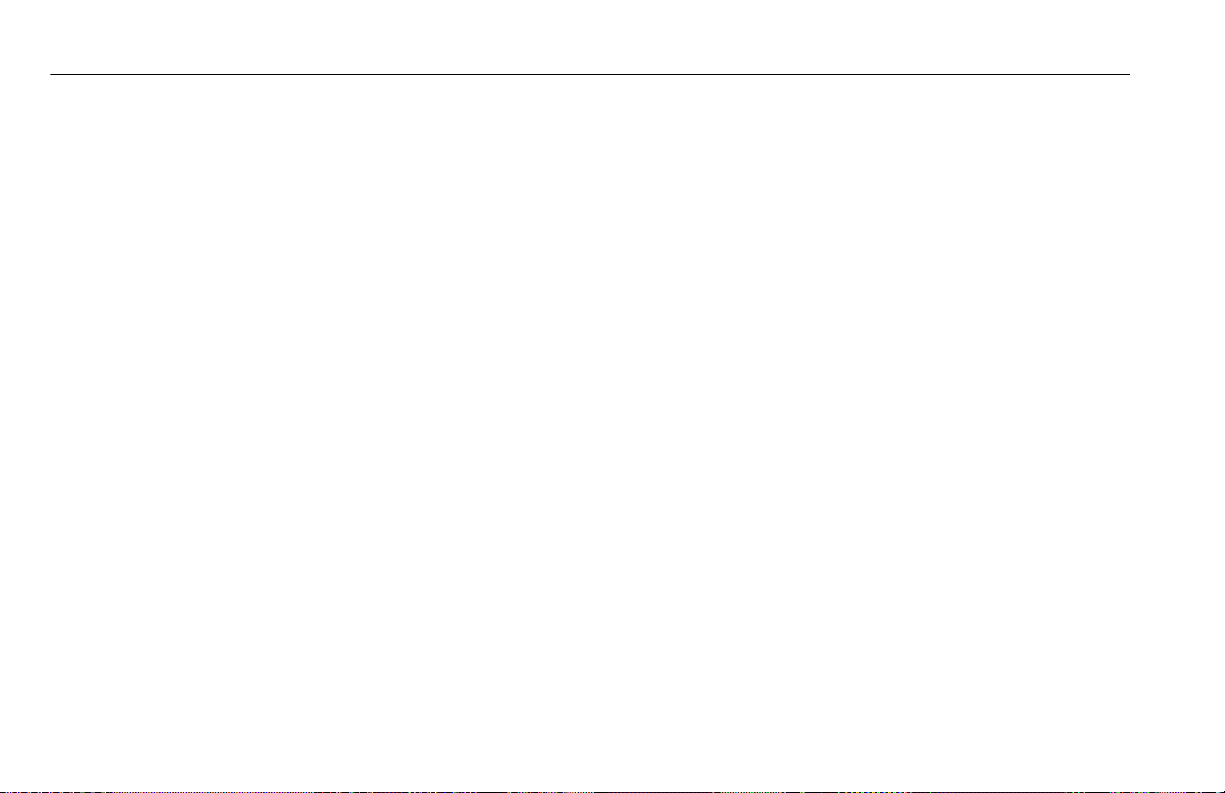

Trip and Fall Hazards

• Prior to operation, ensure all gates and rails are fastened

and secured in their proper position.

• JLG Industries, Inc. recommends that all persons in the platform wear a full body harness with a lanyard attached to an

authorized lanyard anchorage point while operating this

machine. For further information regarding fall protection

requirements on JLG products, contact JLG Industries, Inc.

• Identify the designated lanyard anchorage point(s) at the

platform and securely attach the lanyard. Attach only one

(1) lanyard per lanyard anchorage point.

• Enter and exit only through gate area. Use extreme caution

when entering or leaving platform. Ensure that the platform

assembly is fully lowered. Face the machine when entering

or leaving the platform. Always maintain “three point contact” with the machine, using two hands and one foot or

two feet and one hand at all times during entry and exit.

.

• Keep both feet firmly positioned on the platform floor at all

times. Never position ladders, boxes, steps, planks, or similar items on unit to provide additional reach for any purpose.

• Never use the scissor arm assembly to gain access to or

leave the platform.

• Keep oil, mud, and slippery substances cleaned from footwear and the platform floor.

3121744 – JLG Lift – 1-5

Page 16

SECTION 1 - SAFETY PRECAUTIONS

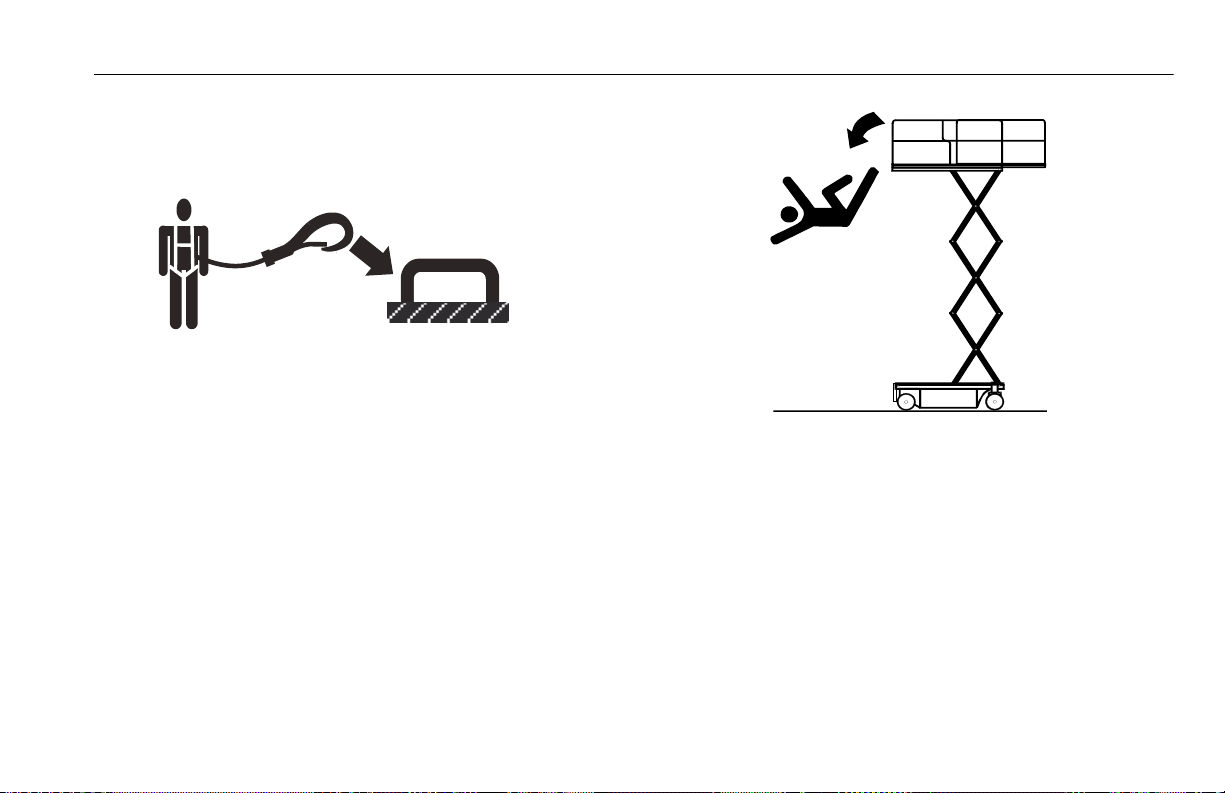

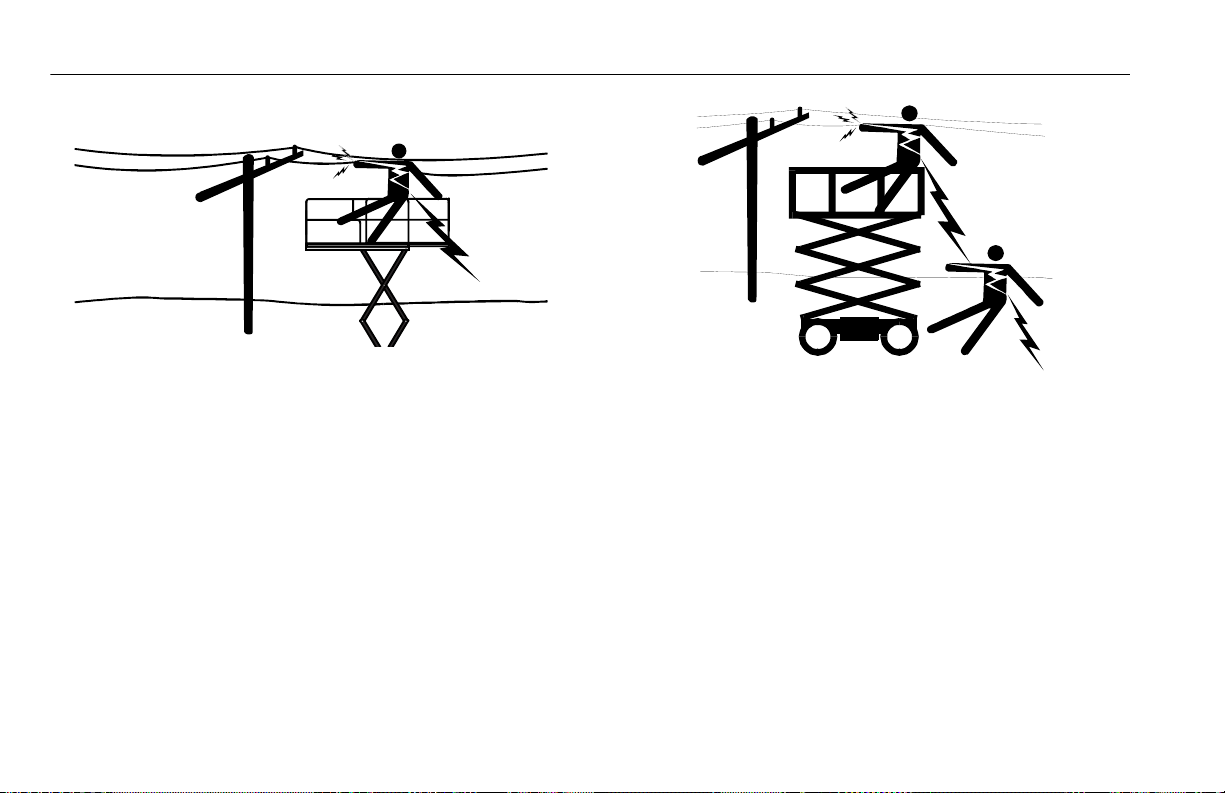

Electrocution Hazards

• This machine is not insulated and does not provide protection from contact or proximity to electrical current.

• Maintain distance from electrical lines, apparatus, or any

energized (exposed or insulated) parts according to the

Minimum Approach Distance (MAD) as shown in Table 1-1.

• Allow for machine movement and electrical line swaying.

• Maintain a clearance of at least 10 ft. (3m) between any part

of the machine and its occupants, their tools, and their

equipment from any electrical line or apparatus carrying up

to 50,000 volts. One foot additional clearance is required for

every additional 30,000 volts or less.

1-6 – JLG Lift – 3121744

• The minimum approach distance may be reduced if insulat-

ing barriers are installed to prevent contact, and the barriers are rated for the voltage of the line being guarded.

These barriers shall not be part of (or attached to) the

machine. The minimum approach distance shall be reduced

to a distance within the designed working dimensions of

the insulating barrier. This determination shall be made by

a qualified person in accordance with the employer, local,

or governmental requirements for work practices near

energized equipment.

Page 17

DO NOT MANEUVER MACHINE OR PERSONNEL INSIDE PROHIBITED ZONE (MAD).

ASSUME ALL ELECTRICAL PARTS AND WIRING ARE ENERGIZED UNLESS KNOWN OTHERWISE.

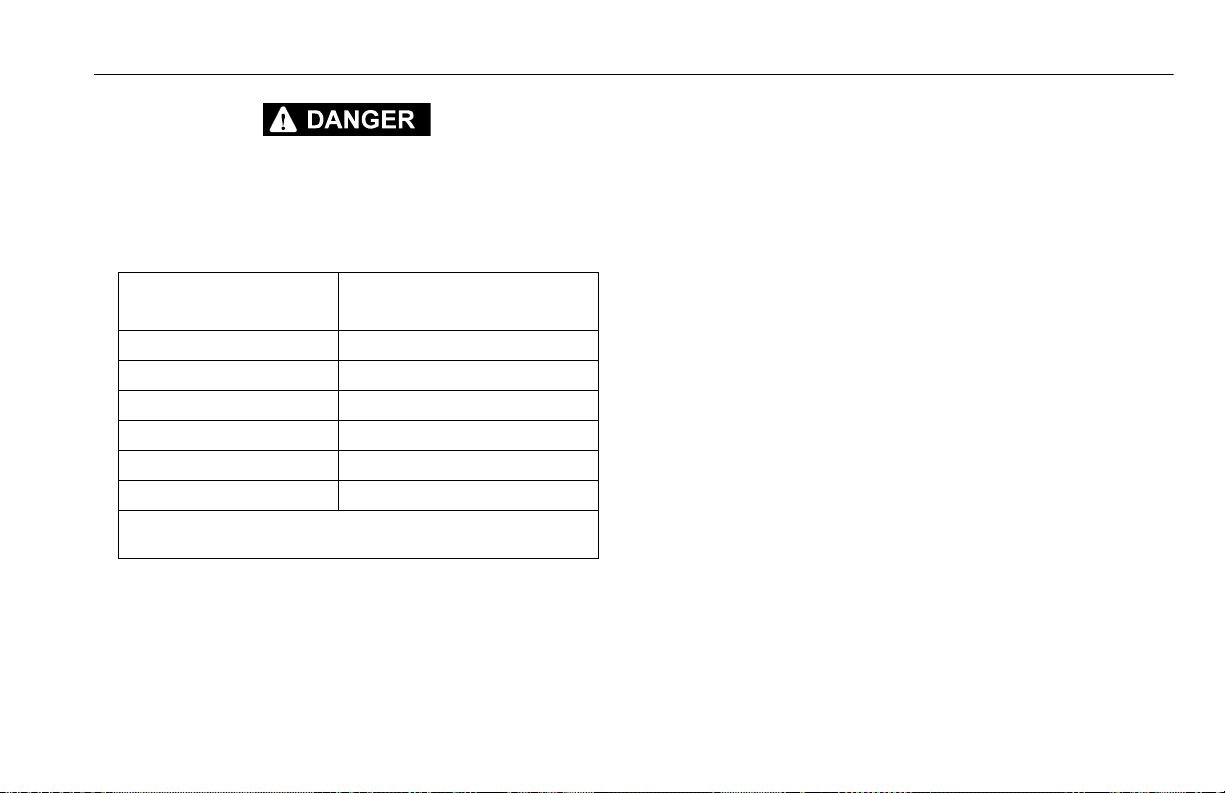

Table 1-1. Minimum Approach Distances (M.A.D.)

VOLTAGE RANGE

(Phase to Phase)

MINIMUM APPROACH DISTANCE

in Feet (Meters)

0 to 50 KV 10 (3)

Over 50KV to 200 KV 15 (5)

Over 200 KV to 350 KV 20 (6)

Over 350 KV to 500 KV 25 (8)

Over 500 KV to 750 KV 35 (11)

Over 750 KV to 1000 KV 45 (14)

NOTE: This requirement shall apply except where employer, local or govern-

mental regulations are more stringent.

SECTION 1 - SAFETY PRECAUTIONS

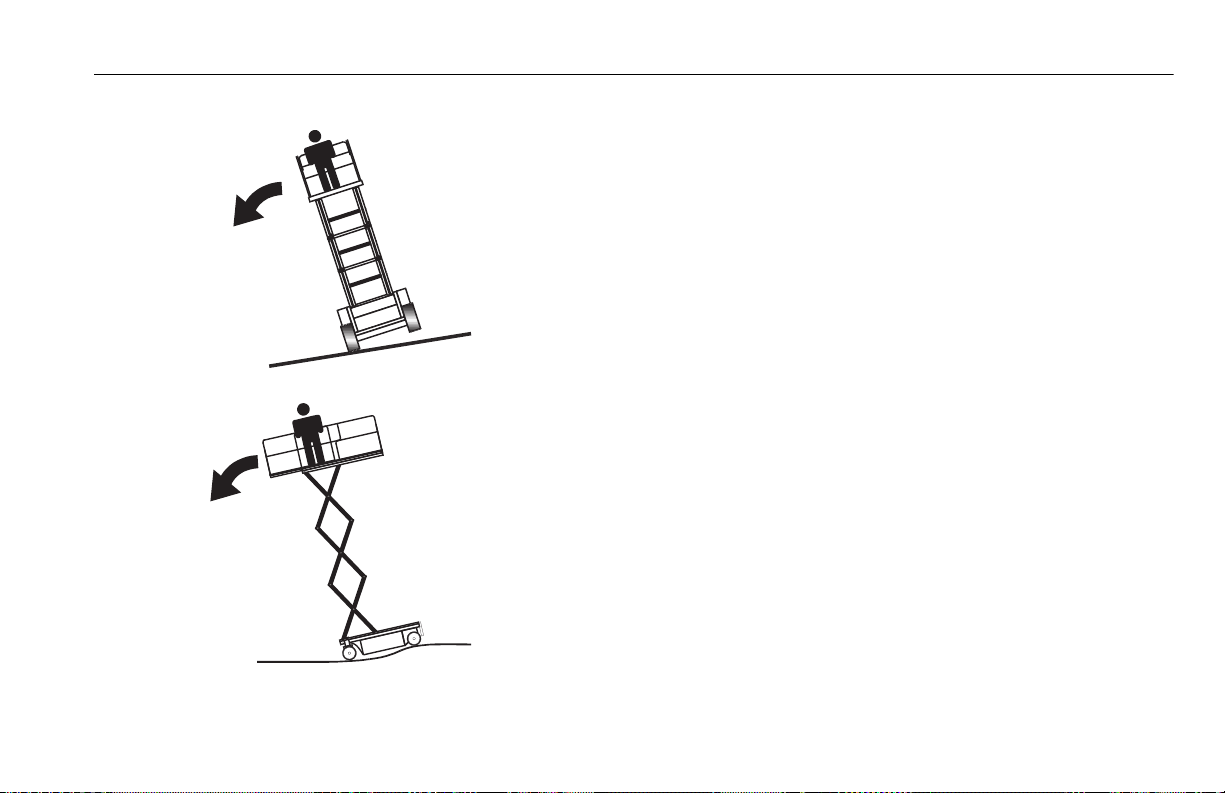

Tipping Hazards

• Ensure that the ground conditions are adequate to support

the maximum tire load indicated on the tire load decals

located on the chassis adjacent to each wheel. Do not travel

on unsupported surfaces.

• The user must be familiar with the driving surface before

driving. Do not exceed the allowable sideslope and grade

while driving.

• Do not elevate platform or drive with platform elevated

while on or near a sloping, uneven, or soft surface. Ensure

machine is positioned on a firm, level and smooth surface

before elevating platform or driving with the platform in

the elevated position.

• Before driving on floors, bridges, trucks, and other surfaces,

check allowable capacity of the surfaces.

• Never exceed the maximum work load as specified on the

platform. Keep all loads within the confines of the platform,

unless authorized by JLG.

• Keep the chassis of the machine a minimum of 2 ft. (0.6m)

from holes, bumps, drop-offs, obstructions, debris, concealed holes, and other potential hazards at the ground

level.

• Do not operate the machine when wind conditions exceed

specifications shown in Section 5, Table 5-2 or as shown on

the capacity placard on the platform billboard.

3121744 – JLG Lift – 1-7

Page 18

SECTION 1 - SAFETY PRECAUTIONS

DO NOT OPERATE THE MACHINE WHEN WIND CONDITIONS EXCEED SPECIFICATIONS SHOWN IN SECTION 5, TABLE 5-2 OR AS SHOWN ON THE CAPACITY PLACARD ON THE PLATFORM BILLBOARD.

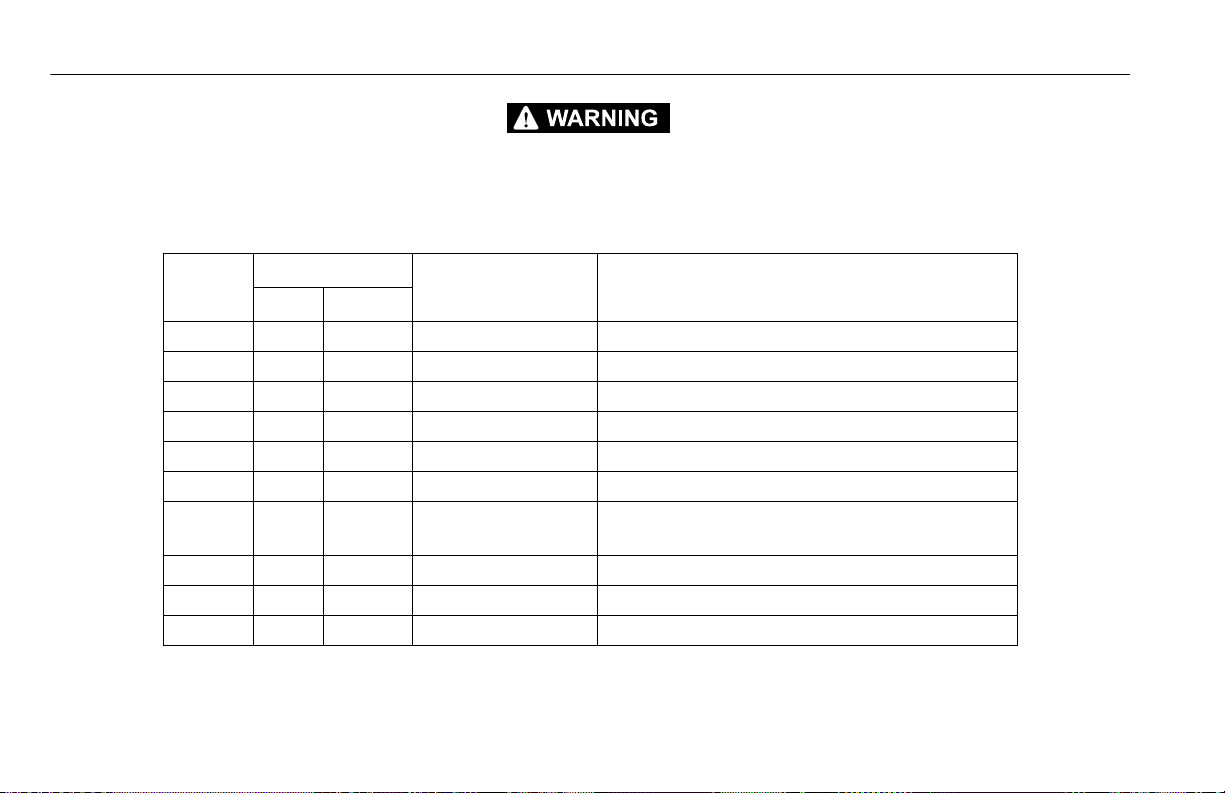

Table 1-2. Beaufort Scale (For Reference Only)

BEAUFORT

NUMBER

WIND SPEED

DESCRIPTION LAND CONDITIONS

mph m/s

0 0 0-0.2 Calm Calm. Smoke rises vertically.

1 1-3 0.3-1.5 Light air Wind motion visible in smoke.

2 4-7 1.6-3.3 Light breeze Wind felt on exposed skin. Leaves rustle.

3 8-12 3.4-5.4 Gentle breeze Leaves and smaller twigs in constant motion.

4 13-18 5.5-7.9 Moderate breeze Dust and loose paper raised. Small branches begin to move.

5 19-24 8.0-10.7 Fresh breeze Smaller trees sway.

6 25-31 10.8-13.8 Strong breeze Large branches in motion. Flags waving near horizontal. Umbrella

use becomes difficult.

7 32-38 13.9-17.1 Near Gale/Moderate Gale Whole trees in motion. Effort needed to walk against the wind.

8 39-46 17.2-20.7 Fresh Gale Twigs broken from trees. Cars veer on road.

9 47-54 20.8-24.4 Strong Gale Light structure damage.

1-8 – JLG Lift – 3121744

Page 19

SECTION 1 - SAFETY PRECAUTIONS

• Never attempt to use the machine as a crane. Do not tie-off

machine to any adjacent structure. Never attach wire, cable,

or any similar items to platform.

• Do not cover the platform sides or carry large surface-area

items in the platform when operating outdoors. The addition of such items increases the exposed wind area of the

machine.

• Do not increase the platform size with unauthorized deck

extensions or attachments.

• If the scissor arm assembly or platform is caught so that one

or more wheels are off the ground, all persons must be

removed before attempting to free the machine. Use

cranes, forklift trucks, or other appropriate equipment to

stabilize machine and remove personnel.

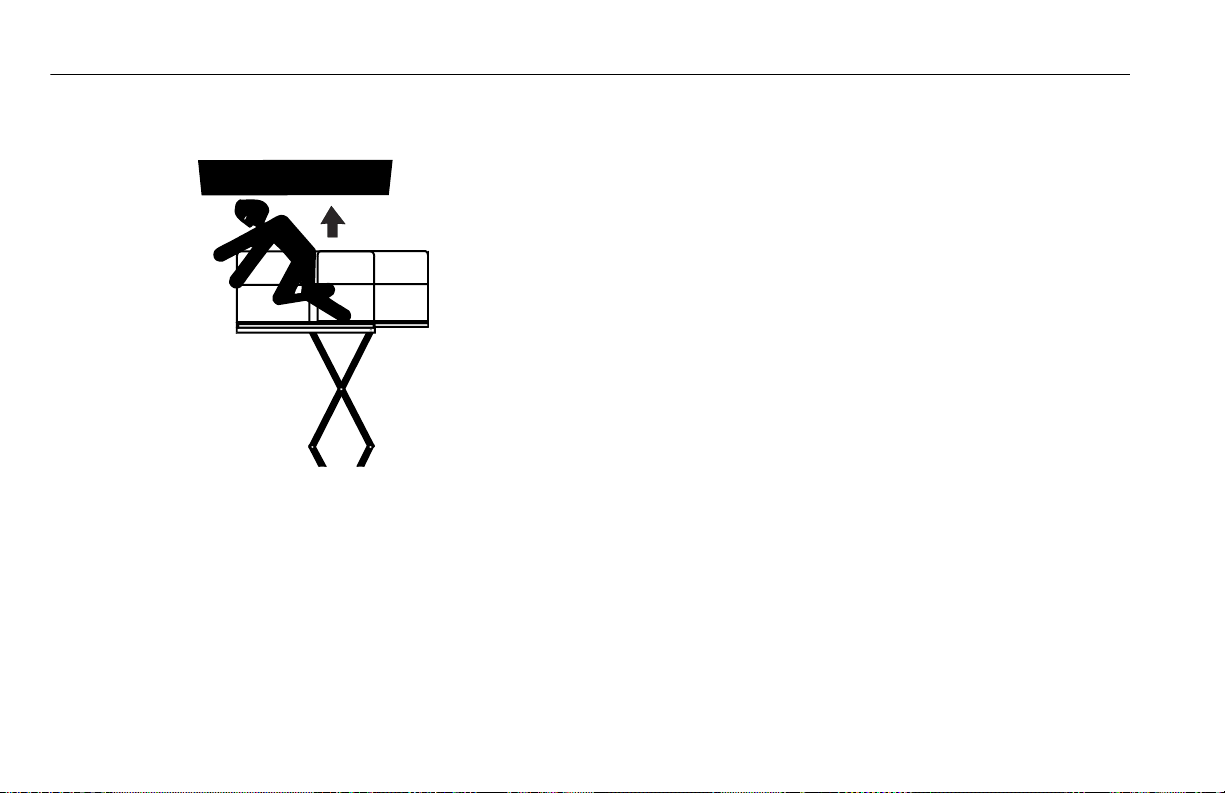

Crushing and Collision Hazards

• Approved head gear must be worn by all operating and

ground personnel.

• Keep hands and limbs out of the scissor arm assembly during operation and when elevated without safety prop

engaged.

• Watch for obstructions around machine and overhead

when driving. Check clearances above, on sides, and bottom of platform when lifting or lowering platform.

3121744 – JLG Lift – 1-9

Page 20

SECTION 1 - SAFETY PRECAUTIONS

• During operation, keep all body parts inside platform railing.

• Always post a lookout when driving in areas where vision is

obstructed.

• Keep non-operating personnel at least 6 ft. (1.8m) away

from machine during all operations.

• Under all travel conditions, the operator must limit travel

speed according to conditions of ground surface, congestion, visibility, slope, location of personnel, and other factors.

• Be aware of stopping distances in all drive speeds. When

driving in high speed, switch to low speed before stopping.

Travel grades in low speed only.

• Do not use high speed drive in restricted or close quarters

or when driving in reverse.

• Exercise extreme caution at all times to prevent obstacles

from striking or interfering with operating controls and persons in the platform.

• Ensure that operators of other overhead and floor level

machines are aware of the aerial work platform’s presence.

Disconnect power to overhead cranes. Barricade floor area

if necessary.

• Do not operate over ground personnel. Warn personnel not

to work, stand, or walk under a raised platform. Position

barricades on floor as necessary.

1-10 – JLG Lift – 3121744

Page 21

SECTION 1 - SAFETY PRECAUTIONS

1.4 TOWING, LIFTING, AND HAULING

• Never allow personnel in platform while towing, lifting, or

hauling.

• This machine should not be towed, except in the event of

emergency, malfunction, power failure, or loading/unloading. Refer to emergency towing procedures.

• Ensure platform is fully retracted and completely empty of

tools prior to towing, lifting or hauling.

• When lifting machine with a forklift, position forks only at

designated areas of the machine. Lift with a forklift of adequate capacity.

• Refer to Section 3 for lifting information.

1.5 MAINTENANCE

This sub-section contains general safety precautions which

must be observed during maintenance of this machine. Additional precautions to be observed during machine maintenance are inserted at the appropriate points in this manual

and in the Service and Maintenance Manual. It is of utmost

importance that maintenance personnel pay strict attention

to these precautions to avoid possible injury to personnel or

damage to the machine or property. A maintenance program

must be established by a qualified person and must be followed to ensure that the machine is safe.

Maintenance Hazards

• Shut off power to all controls and ensure that all moving

parts are secured from inadvertent motion prior to performing any adjustments or repairs.

• Never work under an elevated platform until it has been

fully lowered to the full down position, if possible, or otherwise supported and restrained from movement with appropriate safety props, blocking, or overhead supports.

• DO NOT attempt to repair or tighten any hydraulic hoses or

fittings while the machine is powered on or when the

hydraulic system is under pressure.

3121744 – JLG Lift – 1-11

Page 22

SECTION 1 - SAFETY PRECAUTIONS

• Always relieve hydraulic pressure

from all hydraulic circuits before

loosening or removing hydraulic

components.

• DO NOT use your hand to check for

leaks. Use a piece of cardboard or

paper to search for leaks. Wear

gloves to help protect hands from

spraying fluid.

• Ensure replacement parts or components are identical or

equivalent to original parts or components.

• Never attempt to move heavy parts without the aid of a

mechanical device. Do not allow heavy objects to rest in an

unstable position. Ensure adequate support is provided

when raising components of the machine.

• Use only approved non-flammable cleaning solvents.

• Do not replace items critical to stability, such as batteries or

solid tires, with items of different weight or specification.

Do not modify unit in any way to affect stability.

• Reference the Service and Maintenance Manual for the

weights of critical stability items.

MODIFICATION OR ALTERATION OF AN AERIAL WORK PLATFORM SHALL BE

MADE ONLY WITH PRIOR WRITTEN PERMISSION FROM THE MANUFACTURER.

Battery Hazards

• Always disconnect batteries when servicing electrical components or when performing welding on the machine.

• Do not allow smoking, open flame, or sparks near battery

during charging or servicing.

• Do not contact tools or other metal objects across the battery terminals.

• Always wear hand, eye, and face protection when servicing

batteries. Ensure that battery acid does not come in contact

with skin or clothing.

BATTERY FLUID IS HIGHLY CORROSIVE. AVOID CONTACT WITH SKIN AND

CLOTHING AT ALL TIMES. IMMEDIATELY RINSE ANY CONTACTED AREA WITH

CLEAN WATER AND SEEK MEDICAL ATTENTION.

• Charge batteries only in a well ventilated area.

• Avoid overfilling the battery fluid level. Add distilled water

to batteries only after the batteries are fully charged.

1-12 – JLG Lift – 3121744

Page 23

SECTION 2 - USER RESPONSIBILITIES, MACHINE PREPARATION AND INSPECTION

SECTION 2. USER RESPONSIBILITIES, MACHINE PREPARATION AND INSPECTION

2.1 PERSONNEL TRAINING

The aerial platform is a personnel handling device; so it is necessary that it be operated and maintained only by trained personnel.

Operator Training

Operator training must cover:

• Use and limitations of the controls in the platform and at the

ground, emergency controls and safety features.

• Control labels, instructions, and warnings on the machine.

• Rules of the employer and government regulations.

• Use of approved fall protection equipment.

• Enough knowledge of the mechanical operation of the machine to

recognize a malfunction or potential malfunction.

• The safest means to operate the machine where overhead obstructions, other moving equipment, and obstacles, depressions, holes,

and drop-offs exist.

• Means to avoid the hazards of unprotected electrical conductors.

• Specific job requirements or machine application.

• Reading and understanding the Operation and Safety Manual.

3121744 – JLG Lift – 2-1

Page 24

SECTION 2 - USER RESPONSIBILITIES, MACHINE PREPARATION AND INSPECTION

Training Supervision

Training must be done under the supervision of a qualified person in an open area free of obstructions until the trainee has

developed the ability to safely control and operate the machine.

Operator Responsibility

The operator must be instructed that he/she has the responsibility and authority to shut down the machine in case of a malfunction or other unsafe condition of either the machine or the

job site.

NOTE: The Manufacturer or Distributor will provide qualified

people for training assistance with the first unit(s) delivered and from that time forward as requested by the user

or his/her personnel.

2.2 PREPARATION, INSPECTION, AND MAINTENANCE

Table 2-1 explains the periodic machine inspections and maintenance recommended by JLG Industries, Inc. Consult local regulations for further requirements for aerial work platforms. The

frequency of inspections and maintenance must be increased

as necessary when the machine is used in a harsh or hostile

environment, if the machine is used with increased frequency,

or if the machine is used in a severe manner.

2-2 – JLG Lift – 3121744

Page 25

SECTION 2 - USER RESPONSIBILITIES, MACHINE PREPARATION AND INSPECTION

NOTICE

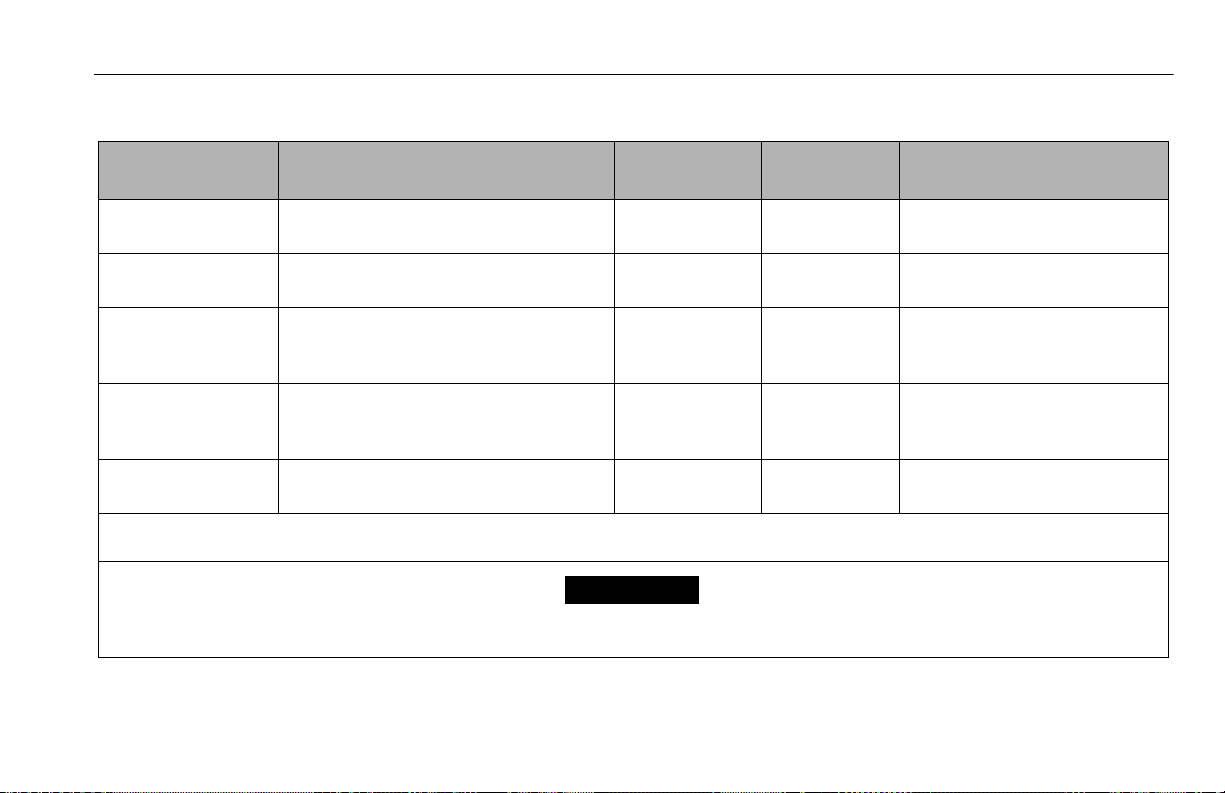

Table 2-1. Inspection and Maintenance Table

TYPE FREQUENCY

Pre-Start Inspec tion Before using each day; or

whenever there’s an Operator change.

Pre-Delivery Inspection

(see note below)

Frequent Inspection In service for 3 months or 150 hours, whichever comes

Annual Machine

Inspection

(see note below)

Preventative Maintenance At intervals as specified in the Ser vice and Mainte-

NOTE: Inspection forms are available from JLG. Use the Service and Maintenance Manual to perform inspections.

JLG INDUSTRIES, INC. RECOGNIZES A FACTORY-TRAINED SERVICE TECHNICIAN AS A PERSON WHO HAS SUCCESSFULLY COMPLETED THE JLG SERVICE TRAINING SCHOOL FOR

THE SPECIFIC JLG PRODUCT MODEL.

Before each sale, lease, or rental delivery. Owner, Dealer, or User Qualified JLG

first; or Out of service for a period of more than 3

months; or Purchased used.

Annually, no later than 13 months from the date of

prior inspection.

nance Manual.

PRIMARY

RESPONSIBILITY

User or Operator User or Operator Operation and Safety Manual

Owner, Dealer, or User Qualified JLG

Owner, Dealer, or Us er Fa ctory Trained Ser-

Owner, Dealer, or User Qualified JLG

SERVICE

QUALIFICATION

Mechanic

Mechanic

vice Technician

(Recommended)

Mechanic

REFERENCE

Service and Maintenance Manual and

applicable JLG inspection form

Service and Maintenance Manual and

applicable JLG inspection form

Service and Maintenance Manual and

applicable JLG inspection form

Service and Maintenance Manual

3121744 – JLG Lift – 2-3

Page 26

SECTION 2 - USER RESPONSIBILITIES, MACHINE PREPARATION AND INSPECTION

2.3 PRE-START INSPECTION

The Pre-Start Inspection should include each of the following:

1. Cleanliness – Check all surfaces for leakage (oil or battery fluid) or foreign objects. Report this to the proper

maintenance personnel.

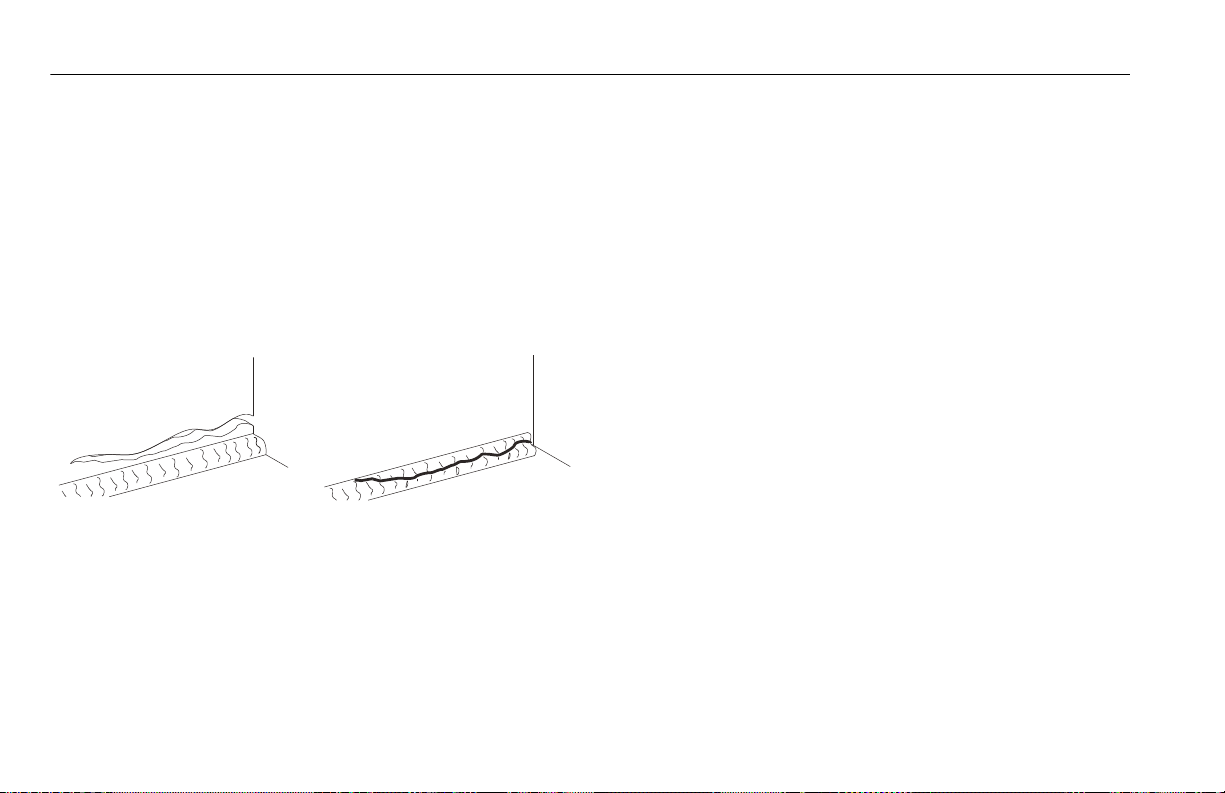

2. Structure - Inspect the machine structure for dents,

damage, weld or parent metal cracks or other discrepancies. Report this to the proper maintenance personnel.

.

Parent Metal Crack Weld Crack

3. Decals and Placards – Check all for cleanliness and

legibility. Ensure none of the decals and placards are

missing. Ensure all illegible decals and placards are

cleaned or replaced. (See Section 5.7, DECAL INSTALLATION)

4. Operation and Safety Manuals - Ensure that a copy

of the Operation and Safety Manual, AEM Safety Manual (ANSI markets only), and ANSI Manual of Responsibilities (ANSI markets only) is enclosed in the weather

resistant storage container.

5. “Walk-Around” Inspection – Refer to Figure 2-1. on

page 2-8.

6. Battery – Charge as required.

7. Hydraulic Oil Level - Check the hydraulic oil level in

the pump reservoir, add as required. (See Section 5.5)

8. Accessories/Attachments - Reference the Operation

and Safety Manual of each attachment or accessory

installed upon the machine for specific inspection,

operation, and maintenance instructions.

9. Function Check – Once the “Walk-Around” Inspection

is complete, perform a functional check of all systems

in an area free of overhead and ground level obstructions. Refer to Section 3 for more specific instructions

on the operation of each function.

2-4 – JLG Lift – 3121744

Page 27

SECTION 2 - USER RESPONSIBILITIES, MACHINE PREPARATION AND INSPECTION

10. Platform Gate - Keep gate and surrounding area clean and unobstructed. Check that gate closes properly and is not bent

or damaged. During operation keep gate closed.

Chain Gate

3121744 – JLG Lift – 2-5

Self-Closing Swing Gate

Page 28

SECTION 2 - USER RESPONSIBILITIES, MACHINE PREPARATION AND INSPECTION

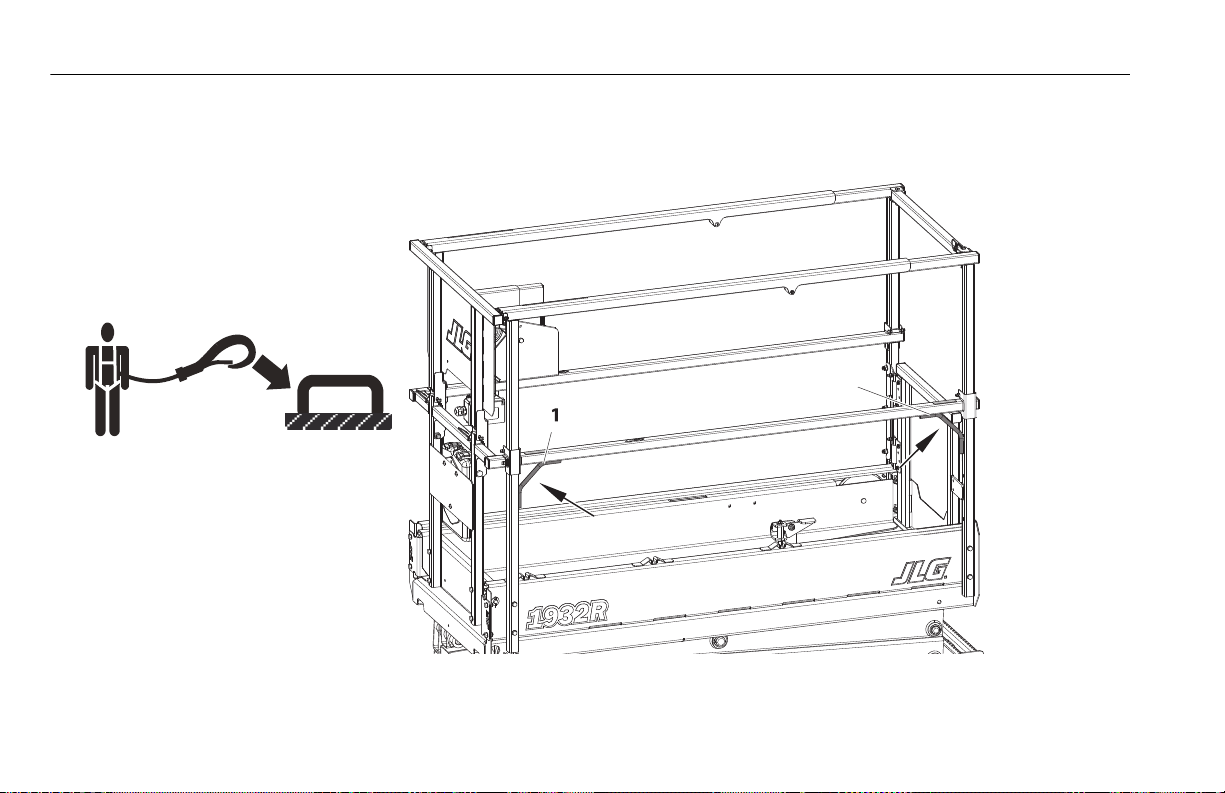

1

11. Lanyard Anchorage Points - JLG Industries, Inc. recommends personnel in the platform wear a full body harness with a

lanyard attached to an authorized lanyard anchorage point (1).

Lanyard Attach Points

2-6 – JLG Lift – 3121744

Page 29

SECTION 2 - USER RESPONSIBILITIES, MACHINE PREPARATION AND INSPECTION

NOTICE

2.4 DAILY WALK-AROUND INSPECTION

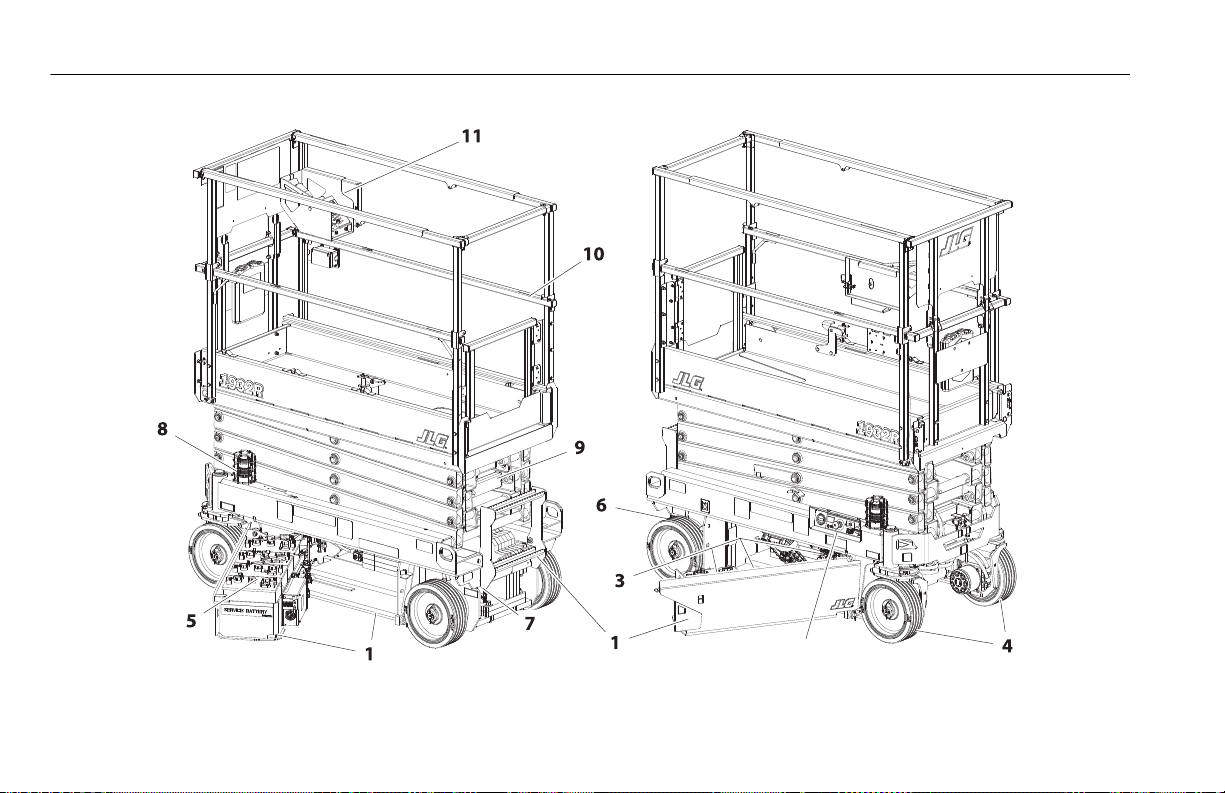

Begin the “Walk-Around Inspection” at item 1, see Figure 2-1.

Continue checking each item in sequence for the conditions

listed in the following checklist.

TO AVOID POSSIBLE INJURY, BE SURE MACHINE POWER IS “OFF”. DO NOT

OPERATE UNTIL ALL MALFUNCTIONS HAVE BEEN CORRECTED.

DO NOT OVERLOOK VISUAL INSPECTION OF CHASSIS UNDERSIDE. CHECKING

THIS AREA MAY RESULT IN DISCOVERY OF CONDITIONS WHICH COULD CAUSE

EXTENSIVE MACHINE DAMAGE.

INSPECTION NOTE: On all components, make sure there are no

loose or missing parts, that they are securely fastened, and that

no visible damage, leaks or excessive wear exists in addition to

any other criteria mentioned.

1. Frame/Chassis/Ladder - See Inspection Note. Ensure

that pothole protection (PHP) components on frame

are in place, undamaged, not bent or worn. Side compartment doors open and close properly.

2. Ground Controls - Placard secure and legible, control

switches return to neutral position, emergency stop

switch functions properly. Control markings legible.

3. Hydraulic Pump/Motor, Control Valve Installation - No

unsupported wires or hoses; no damaged or broken

wires - See Inspection Note.

4. Front Wheels, Tires and Drive Motors - Steer linkage,

and Steer Cylinder - See Inspection Note.

5. Battery Compartment - See Inspection Note.

6. Rear Wheels, Tires and Hydraulic Brake - Wheel nut

properly secured. Refer to “Tire Wear and Damage” on

page 5-15. Inspect wheels for damage and corrosion,

check hydraulic brake hoses for damage or leakage -

See Inspection Note.

7. Manual Descent Control - See Inspection Note.

8. Beacon(s) (if equipped) - See Inspection Note.

9. Scissor Arms, Pivot Pins and Sliding Wear Pads, Lift Cyl-

inder - See Inspection Note.

10. Platform/Handrail/Gate/Chain Installation - Deck

extension slides in and out and locks in place properly.

Gate closes properly. All fold-down rail pins (if

equipped) in place and secure - See Inspection Note.

11. Platform Control Console - Ensure that the control

console is firmly secured in the proper location. Placards secure and legible, control lever and switches

return to neutral, and emergency stop switch function

properly, required manuals in storage box.

3121744 – JLG Lift – 2-7

Page 30

SECTION 2 - USER RESPONSIBILITIES, MACHINE PREPARATION AND INSPECTION

2

Figure 2-1. Daily Walk-Around Inspection (Side Compartment Doors Open)

2-8 – JLG Lift – 3121744

Page 31

SECTION 2 - USER RESPONSIBILITIES, MACHINE PREPARATION AND INSPECTION

2.5 FUNCTION CHECK

Perform the Function Check as follows:

1. From the Ground Control Panel with no load in the

platform: (See Figure 3-2. on page 3-5)

a. Ensure that the key selector switch and the plat-

form lift switch operates properly.

b. Ensure that all machine functions are disabled

when the Emergency Stop Button is depressed.

c. With platform raised a few feet (1m), ensure that

the manual descent control (T-handle located at

the left rear of the machine, next to the battery charger), lowers the platform properly.

d. Check that pot-hole-protection system bars are

fully lowered when the platform is raised.

.

Platform Elevated - Pot-Hole Bars Fully Lowered

Platform Fully Lowered - Pot-Hole Bars Raised

Pot-Hole-Protection System - Operation

2. From the Platform Control Console:

a. Ensure that the control console is firmly secured

in the proper location.

b. Ensure that all guards protecting switches are in

place.

c. Operate all switch functions, drive/lift mode

select switch, and horn button.

d. Operate all platform joystick functions to ensure

proper operation of drive, lift, steer, and enable

trigger switch operation.

3121744 – JLG Lift – 2-9

Page 32

SECTION 2 - USER RESPONSIBILITIES, MACHINE PREPARATION AND INSPECTION

e. Ensure that all machine functions are disabled

when the platform Emergency Stop Button is

depressed.

f. With the platform elevated on a smooth, firm,

level surface with no overhead obstructions, drive

the machine to check if the high drive cutback

speed-limit is engaged at the height indicated in

Table 2-2. Ensure drive speed is reduced from a

top speed to a slower speed.

Table 2-2. High Drive Cutback Height

MODEL

1532R 58 in. (1.5 m) 2.0 mph (3.2 kph)

1932R 67 in. (1.7 m)

3. With the platform in the transport (stowed) position.

a. Drive the machine on a grade, not to exceed the

rated gradeability, and stop to ensure the drive

motor brakes hold.

b. Check the tilt indicator light to ensure proper

operation. The light should be illuminated if tilted

beyond allowed settings in Table 2-3.

HIGH DRIVE SPEED

CUTOUT HEIGHT

DRIVE SPEED REDUCTION

to

0.5 mph (0.8 kph)

NOTE: When the tilt indicator warning is activated the following

MODEL

1532R

(ANSI/JPN/

CSA)

1532R

(CE/CHN/

AUS)

1932R

(ANSI/JPN/

CSA)

1932R

(CE/CHN/

AUS)

functions are affected; drive and lift u

abled, platform must be fully lowered (stowed) to drive.

Table 2-3. Tilt Activation Setting

TILT SETTING

(front to back)

4°

3.75°

3.25°

3.75°

TILT SETTING

(side to side)

2.25° 4 - 4.6 m (Full) 13 - 15 ft.

2.75° 3.4 -4 m 11 - 13 ft.

3.25° 0 - 3.4 m 0 - 11 ft.

1.50° - outdoor

1.75° - indoor

2.00 ° - outdoor

2.25° - indoor

3.00° - outdoor

3.00° - indoor

1.50° 5.2 - 5.8 m (Full) 17 - 19 ft.

2.00° 4.6 - 5.2 m 15 - 17 ft.

2.75° 0 - 4.6 m 0 - 15 ft.

1.50° - outdoor

1.75° - indoor

2.00 ° - outdoor

2.25° - indoor

3.00° - outdoor

3.00° - indoor

p functions are dis-

Maximum Deck Elevation

4 - 4.6 m (Full) 13 - 15 ft.

3.4 -4 m 11 - 13 ft.

0 - 3.4 m 0 - 11 ft.

5.2 - 5.8 m (Full) 17 - 19 ft.

4.6 - 5.2 m 15 - 17 ft.

0 - 4.6 m 0 - 15 ft.

2-10 – JLG Lift – 3121744

Page 33

SECTION 3 - MACHINE CONTROLS, INDICATORS AND OPERATION

NOTICE

SECTION 3. MACHINE CONTROLS, INDICATORS AND OPERATION

3.1 GENERAL

THE MANUFACTURER HAS NO DIRECT CONTROL OVER MACHINE APPLICATION AND OPERATION, THE USER AND OPERATOR ARE RESPONSIBLE FOR

CONFORMING WITH GOOD SAFETY PRACTICES.

This section provides the necessary information needed to

understand controls and their functions.

DO NOT RAISE PLATFORM EXCEPT ON A SMOOTH, FIRM AND LEVEL SURFACE

FREE OF OBSTRUCTIONS AND HOLES.

TO AVOID SERIOUS INJURY, DO NOT OPERATE MACHINE IF ANY CONTROL

LEVERS OR TOGGLE SWITCHES CONTROLLING PLATFORM MOVEMENT DO NOT

RETURN TO THE OFF OR NEUTRAL POSITION WHEN RELEASED.

IF THE PLATFORM DOES NOT STOP WHEN A CONTROL SWITCH OR LEVER IS

RELEASED, USE THE EMERGENCY STOP SWITCH TO STOP THE MACHINE.

3121744 JLG Lift – 3-1

3.2 DESCRIPTION

This machine is a self-propelled aerial work platform on top of

an elevating scissor arm mechanism. The Lift’s intended purpose is to position personnel with their tools and supplies at

positions above ground level. The machine can be used to reach

work areas located above machinery or equipment positioned

at ground level.

This JLG Lift has a primary operator control station in the platform. From this control station, the operator can drive and steer

the machine in both forward and reverse directions, raise and

lower the platform.

The machine can be driven on a smooth, firm, and level surface

from an elevated platform position - Reference “Steering And

Traveling” on page 3-13. of this manual for specific requirements.

The machine also has a ground control station which can override the platform control station. Ground controls operate lift up

and down. Ground controls are to be used only in an emergency

to lower the platform to the ground should the operator in the

platform be unable to do so.

Page 34

SECTION 3 - MACHINE CONTROLS, INDICATORS AND OPERATION

3.3 OPERATING CHARACTERISTICS AND LIMITATIONS

General

A thorough knowledge of the operating characteristics and limitations of the machine is always the first requirement for any

user, regardless of user’s experience with similar types of equipment.

Placards

Important points to remember during operation are provided at

the control stations by DANGER, WARNING, CAUTION, NOTICE,

and INSTRUCTION placards. This information is placed at various

locations for the express purpose of alerting personnel of

potential hazards constituted by the operating characteristics

and limitations of the machine. See foreword for definitions of

placard safety signal words.

3.4 PLATFORM LOADING

The platform maximum rated load capacity is shown on a placard located on the platform billboard and ground control station and is based upon the machine positioned on a smooth,

firm, and level surface. Refer to Section 5, Table 5-2 on page 5-4,

for the maximum platform capacity.

The platform is entered through an entry gate at the rear of the

platform. Keep entry gate closed during machine operation.

NOTE: It is important to remember that the load should be

evenly distributed on the platform. The load should be

placed near the center of the platform when possible.

3-2 – JLG Lift – 3121744

Page 35

3.5 MACHINE CONTROL LOCATIONS

1

SECTION 3 - MACHINE CONTROLS, INDICATORS AND OPERATION

1. Ground Control Station

2. Platform Control Station

3. Platform Manual Descent Control (T-Handle)

4. AC Plug - At Front of Machine - For Platform AC

Receptacle Outlet Box

5. AC Plug - Battery Charger Input

6. Side Compartment Doors (Both Sides)

7. Side Compartment Door Latch Location (Both Sides)

Figure 3-1. Location of Machine Controls.

3121744 JLG Lift – 3-3

Page 36

SECTION 3 - MACHINE CONTROLS, INDICATORS AND OPERATION

3.6 BATTERY CHARGING

NOTE: Be sure that machine is parked in a well ventilated area

before charging begins.

ONLY PLUG THE CHARGER INTO A PROPERLY INSTALLED AND GROUNDED

OUTLET. DO NOT USE GROUND ADAPTORS OR MODIFY PLUG. DO NOT TOUCH

NON-INSULATED PORTION OF OUTPUT CONNECTOR OR NON-INSULATED

BATTERY TERMINAL.

DO NOT OPERATE CHARGER IF THE AC SUPPLY CORD IS DAMAGED OR IF THE

CHARGER HAS RECEIVED A SHARP BLOW, BEEN DROPPED, OR OTHERWISE

DAMAGED IN ANY WAY.

ALWAYS DISCONNECT THE CHARGER AC SUPPLY BEFORE MAKING OR BREAKING THE (POS/NEG) CONNECTIONS TO THE BATTERY.

DO NOT OPEN OR DISASSEMBLE CHARGER.

1. The battery charger AC input plug is located inside the

frame at the left rear of the machine next to the battery charger.

See charger specific information in Section 5 starting on

page 5-12.

2. Connect the charger AC input plug to a grounded out-

let using a 3 wire heavy duty extension cord.

(See Table 5-6, “Battery Charger Specifications,” on

page 5-6, for battery charger AC input specifications.).

3. After connecting the charger to an AC outlet at the

start of the charging cycle, check the LED indicators on

the charger for normal operation or if a fault has

occurred.

See LED indicator status of each charger in Section 5,

starting on page 5-12.

4. Current battery charge state can also be seen on the

platform control station panel LEDs, or the MDI indicator (if equipped) on the ground control station, when

machine is powered up.

5. The batteries are fully charged when all three GREEN

LED indicators on the platform control station or MDI

battery charger status panel are illuminated.

(See “MDI-Indicator - (If Equipped)” on page 3-7 for MDI

indicator information.

NOTE: If the charger is left plugged in, the charger will automati-

cally restart a complete charge cycle if the batteries voltage drops below a minimum voltage or 30 days has

elapsed.

3-4 – JLG Lift – 3121744

Page 37

3.7 GROUND CONTROL STATION

ON

1. Ground/Platform/OFF Key Selector Switch

2. Platform Lift/Lower Switch

3. Inverter ON/OFF Switch (If Equipped)

4. Ground Emergency Stop Button

SECTION 3 - MACHINE CONTROLS, INDICATORS AND OPERATION

Figure 3-2. Ground Control Station

5. Hourmeter

6. Overload Indicator (If LSS Equipped)

7. MDI - Indicator (If Equipped)

3121744 JLG Lift – 3-5

Page 38

SECTION 3 - MACHINE CONTROLS, INDICATORS AND OPERATION

1

2

3

Platform Lift/Lower Switch

DO NOT OPERATE FROM GROUND CONTROL STATION WITH PERSONNEL IN

THE PLATFORM EXCEPT IN AN EMERGENCY.

PERFORM AS MANY PRE-OPERATIONAL CHECKS AND INSPECTIONS FROM

THE GROUND CONTROL STATION AS POSSIBLE.

Ground/Platform/OFF Key Selector Switch

(Item 1 - Figure 3-2.)

The key selector switch on the

Ground Control Station functions to direct electrical power

to the desired control station.

With the switch turned to the

ground position (1), power is

supplied to the controls at the

ground control station. When

the switch is turned to the

platform position (2), power

is supplied to the controls at

the platform control station. The switch should be set to the

OFF position (3) when not using machine or parking the

machine overnight.

(Item 2 - Figure 3-2.)

A three position, momentary contact lift

control switch provides raising and lowering

of the platform from the Ground Control

Station.

When operating platform from the

ground controls -

Toggle the lift/lower switch to up position and hold to raise platform, or down position and hold to lower an elevated platform.

Release to center position to stop all movement.

Inverter ON/OFF Switch (If Equipped)

(Item 3 - Figure 3-2.)

When switched on the inverter converts the DC voltage stored

in the on-board batteries to AC voltage for use at the AC receptacle outlet mounted on the platform rail.

Ground Emergency Stop Switch

(Item 4 - Figure 3-2.)

Power is turned on by pulling the switch out,

and is turned off by depressing switch. A twoposition, red, mushroom-shaped emergency

stop switch, when positioned to ON with the key

selector switch positioned to ground, furnishes

operating power to the ground control station

3-6 – JLG Lift – 3121744

Page 39

SECTION 3 - MACHINE CONTROLS, INDICATORS AND OPERATION

key switch. In addition, the switch can be used to turn off power

to the function controls in the event of an emergency.

Hourmeter

(Item 5 - Figure 3-2.)

The machine is equipped with an hour meter to

indicate the number of hours the machine has

been operated.

Overload Indicator (If LSS Equipped)

(Item 6 - Figure 3-2.)

Overload Indicator - Indicates the platform has

been overloaded. An audible alarm will also signal when the platform is overloaded.

NOTE: If the Overload Indicator is illuminated;

CE: All functions will be prevented from the platform and

ground controls. Lower platform using the machine manual descent control.

ANSI Export/Australia/Japan: All platform functions

will be prevented. Fully lower the platform from the

ground controls or using the machine manual descent

control. Reduce the weight in the platform to not exceed

the rated workload indicated on the capacity decal.

MDI-Indicator - (If Equipped)

(Item 7 - Figure 3-2.)

The MDI indicator or Multifunction Digital Indicator displays a

Battery Discharge Indicator (BDI), an LCD display which shows

the current hour-meter reading or Diagnostic Trouble Code(s)

(DTC) when a functional problem occurs with the machine, and

a system distress LED.

When a problem occurs (DTC Code displayed):

• A wrench Icon (item 1) LED will illuminate. (See Figure 3-3.)

• A three to five digit DTC code will display on the Diagnostic

Trouble Code LCD display (item 2), below the wrench

icon.

3121744 JLG Lift – 3-7

Page 40

SECTION 3 - MACHINE CONTROLS, INDICATORS AND OPERATION

000000

.

Figure 3-3. MDI Indicator

1. System Fault LED Indicator (RED

LED)

2. Hour-meter/DTC Code Display

3. 100% Battery Charge Indicator

(GREEN AREA)

4. Battery Charge LOW Indicator

(YELLOW AREA)

5. Battery Re-Charge Indicator

(RED AREA)

NOTE: When more than one DTC exists, each DTC will be dis-

played on the LCD for 3 seconds before changing to the

next DTC. Once the last active DTC is displayed, the display

will recycle indefinitely until the DTC’s are corrected.

For DTC’s and descriptions, refer to Section 5.8.

Also located on the MDI are Battery Discharge Indicators

(BDI) (items 3, 4 and 5). The (3) GREEN LEDs indicate the level of

charge (voltage) remaining in the batteries.

NOTE: When the battery voltage is low and will need a charge

soon, the YELLOW LED (item 4) begin to flash.

Under normal operating conditions the BDI’s and hour-meter

will be displayed. When a DTC exists (other than 00x

BDI LEDs and hour-meter will not be displayed. Also when platform is elevated and the machine is being driven the creep

mode (turtle) is displayed.

DTC’s) the

3-8 – JLG Lift – 3121744

Page 41

SECTION 3 - MACHINE CONTROLS, INDICATORS AND OPERATION

3.8 PLATFORM MANUAL DESCENT CONTROL

The platform manual descent control is used in the event of

total power failure to lower the platform using gravity. The manual descent control T-handle is located on the left rear of the

machine, just below the platform ladder. Look for the instruction decal located beside the release handle.

The lowering procedure is as follows:

1. Locate the manual descent control T-handle.

(See Figure 3-4.)

KEEP HANDS AND ARMS OUT OF THE PATH OF THE SCISSOR ARMS AND PLATFORM WHILE LOWERING.

2. Grasp the T-handle and slowly pull out to lower the

scissor arms/platform, when the platform is lowered

to desired level, allow the T-handle to return to it’s

closed position.

Figure 3-4. Location of Manual Descent Control

(Left Rear of Machine)

3121744 JLG Lift – 3-9

Page 42

SECTION 3 - MACHINE CONTROLS, INDICATORS AND OPERATION

1

Figure 3-5. Platform Control Station

1. Emergency Stop Switch

2. Lift/Drive Select Switch

3. Black/White Directional Arrow

4. Steer Switch

5. Controller

6. Trigger Switch (on front of controller)

7. Overload Indicator (LSS - if equipped)

8. Tilt Indicator

9. Horn Button

10. Battery Discharge Indicator

11. System Fault Indicator

12. Alarm (not shown, located on bottom of box)

13. Indoor-Zone A (CE)/Outdoor-Zone B (CE) Indicators

14. Indoor-Zone A/Outdoor-Zone B - Select Switch (CE)

NOTE: 1932R machines are equipped with a platform control station

shown in either Figure 3-5. or Figure 3-6.

3.9 PLATFORM CONTROL STATION

3-10 – JLG Lift – 3121744

Page 43

SECTION 3 - MACHINE CONTROLS, INDICATORS AND OPERATION

1

1. Emergency Stop Switch

2. Lift/Drive Select Switch

3. Black/White Directional Arrow

4. Steer Control Switch and Direction Decal

5. Controller

6. Trigger (Enable) Switch

7. Overload Indicator (LSS - if equipped)

8. Tilt Indicator

9. Horn Button

10. Battery Discharge Indicator

11. System Fault Indicator

12. Alarm

13. Indoor/Outdoor Operation Indicator (CE/AUS

ONLY)

14. Indoor/Outdoor Operation Mode Switch (CE/AUS

ONLY)

3121744 JLG Lift – 3-11

Figure 3-6. Platform Control Station.

Page 44

SECTION 3 - MACHINE CONTROLS, INDICATORS AND OPERATION

NOTE: (Reference either Figure 3-5. or Figure 3-6.)

Platform Emergency Stop Switch

(Item 1)

NOTE: Both the ground and platform emergency stop buttons

must be set to ON in order to operate the machine.

When power is directed to the platform from the ground control

station, the platform emergency stop switch is turned on by

pulling the switch out (on), and is turned off by pushing the

switch in (off). The two-position, red, mushroom-shaped emergency stop switch functions to provide power to the platform

control station and also to turn off power to machine functions

in the event of an emergency.

Lift/Drive Select

(Item 2)

NOTE: When selecting between the Lift and Drive functions the

joystick control must be returned to the neutral position

for approximately 1/2 second before the function change

is operable.

This toggle switch is used to select operation of either the drive

or lift function. After selecting a function, the joystick controller

must be moved in the proper direction in order to activate that

function. Only change the function selected, with the joystick in

the neutral position. Otherwise, the function selected will not

change until the joystick is returned to the neutral position.

Forward/Reverse/Lift/Lower Direction

Decal

(Item 3)

This decal indicates the proper direction to

mount the platform control box, the black

arrow must point to the front of the machine.

The black/white arrow also indicates the

direction to move the joystick control per the lift/drive selector

switch decal for the lift and drive select functions.

3-12 – JLG Lift – 3121744

Page 45

SECTION 3 - MACHINE CONTROLS, INDICATORS AND OPERATION

Drive/Lift/Steer Joystick Control

(Items 4, 5, and 6)

Trigger (Enable) Switch - This switch is located on the front of

the joystick controller. The trigger switch acts as an enable and

must be depressed before operating the drive, steer and lift

functions. When released, the function being operated will stop.

NOTE: Once the trigger switch is pressed, the operator has (5)

seconds to begin operating a function, after 5 seconds you

must release the trigger switch and press it again to operate a joystick function.

The speed on all selected functions is proportionally controlled by the distance from the neutral (center) position

of the joystick controller.

NOTE: If the machine is also equipped with a foot-switch (Japa-

nese Specification Only), the foot-switch must be

depressed in conjunction with the trigger (enable) switch,

located on the controller. Power is removed from the platform controls when the footswitch is released.

Steer Switch - The steer switch is a thumb operated switch

located at the top of the control handle. Depressing the switch

to the right will steer the wheels to the right. Depressing the

switch to the left will steer the wheels to the left.

Joystick Controller - The control handle controls two functions:

drive and lift.

Steering And Traveling

DO NOT DRIVE WITH PLATFORM RAISED EXCEPT ON A SMOOTH, FIRM AND

LEVEL SURFACE FREE OF OBSTRUCTIONS AND HOLES.

TO AVOID LOSS OF TRAVEL CONTROL OR UPSET ON GRADES AND SIDESLOPES,

DO NOT DRIVE MACHINE ON GRADES OR SIDESLOPES EXCEEDING THOSE

SPECIFIED IN TABLE 5-1 ON PAGE 5-2.

BEFORE DRIVING, LOCATE THE DECALS WITH THE BLACK/WHITE ORIENTATION ARROWS ON THE CHASSIS AND THE PLATFORM CONTROLS. MOVE THE

JOYSTICK IN THE DIRECTION OF THE BLACK OR WHITE ARROW THAT

MATCHES THE COLOR OF THE ARROW ON THE CHASSIS FOR THE INTENDED

DIRECTION OF TRAVEL.

IF THE TILT INDICATOR WARNING LIGHT/ALARM IS ACTIVATED WHILE DRIVING WITH PLATFORM RAISED, LOWER PLATFORM COMPLETELY AND DRIVE

TO A FIRM LEVEL SURFACE.

1. Place key selector switch at the ground control station

to platform operation.

2. Position emergency stop switches, one at the platform

and one at the ground control station to the ON position.

3121744 JLG Lift – 3-13

Page 46

SECTION 3 - MACHINE CONTROLS, INDICATORS AND OPERATION

Steering

(Item 4)

On the platform control station, position the

lift/drive select switch to the drive position.

To steer the machine, engage trigger switch

and the thumb operated steer rocker-switch

on the joystick handle. Press to the right for

steering right, or to the left for steering left. When released, the

switch will return to the center-off position and the wheels will

remain in the previously selected position. To return the wheels

to the center position, the switch must be activated in the opposite direction until the wheels are centered.

Traveling Forward and Reverse

(Item 5 and 3)

Position the platform lift/drive

select switch to drive/steer position. Squeeze the trigger switch

on front of the joystick, and

move the joystick forward to

drive forward or backward to

drive in reverse. The drive system is proportional, for additional

drive speed push the joystick further from the neutral position

in the direction of travel. Releasing the trigger switch or returning the joystick to center will stop machine movement.

Raising And Lowering Platform

1. If the machine was shut down, place the key selector

switch to the platform position.

2. Position emergency stop switches, one at the platform

and one at the ground control station to the ON position.

3. Position the lift/drive

select switch to lift.

(Item 2)

4. Squeeze and hold the

trigger switch, and

move the joystick back

(platform up - white arrow direction) or move the joystick forward (platform down - black arrow direction)

and hold until desired elevation is reached. Releasing

the trigger switch or moving the joystick back to it’s

center position will stop the function being operated.

NOTE: To ensure proper operation of the desired platform func-

tion, move the joystick in the direction of the black or

white arrow that matches the color of the arrow on the

chassis for the intended direction of travel.

3-14 – JLG Lift – 3121744

Page 47

SECTION 3 - MACHINE CONTROLS, INDICATORS AND OPERATION

LEVEL

Figure 3-7. Grade and Sideslope Definition

3121744 JLG Lift – 3-15

Page 48

SECTION 3 - MACHINE CONTROLS, INDICATORS AND OPERATION

Arm Guards (If Equipped)

If the machine is equipped with electronic arm guards, the platform will stop lowering at a predetermined height and the

machine’s beacons will flash at a different rate to warn ground

personnel, machine lowering can continue after a three (3) second delay. Once the lowering function is re-engaged an audible

alarm will sound. After a one and a half (1.5) second delay the

platform will continue lowering.

Overload Indicator (LSS) (If Equipped)

(Item 7)

Indicates the platform has been overloaded.

An audible alarm will also signal when the

platform is overloaded.

NOTE: If the Overload Indicator is illuminated;

CE: All functions will be prevented from the platform and

ground controls. Lower platform using the machine manual descent control.

ANSI Export/Australia/Japan: All platform functions

will be prevented. Fully lower the platform from the

ground controls or using the machine manual descent

control. Reduce the weight in the platform to not exceed

the rated workload indicated on the capacity decal.

Tilt Indicator Warning Light and Alarm

(Item 8)

A red warning light on the control panel illuminates and an audible alarm sounds when

the chassis is at or beyond the tilt cutout settings.

IF THE TILT INDICATOR WARNING LIGHT/ALARM IS ACTIVATED WHEN PLATFORM IS RAISED LOWER PLATFORM AND DRIVE TO A SMOOTH FIRM LEVEL

SURFACE.

Horn

(Item 9)

This push-button switch, when pressed, permits the operator to warn job site personnel

when the machine is operating in the area.

3-16 – JLG Lift – 3121744

Page 49

SECTION 3 - MACHINE CONTROLS, INDICATORS AND OPERATION

Battery Charge Indicator

(Item 10 )

The battery charge indicator displays the

current charge status of the onboard batteries. RED LED flashing = batteries depleted,

RED LED ON solid = batteries low, RED LED

ON and GREEN LEDs ON = batteries FULL

charge.

System Fault Indicator

(Item 11)

When this indicator light is flashing a system fault has occurred, possibly stopping

machine operation. Check the MDI indicator

(if equipped) on the Ground Control Station

to see if a (DTC) Diagnostic Trouble Code(s) is

displayed. An explanation of DTC codes is

shown in Section 5.8.

If the code cannot be cleared by the operator, the machine will

require service by a qualified JLG mechanic.

Alarm

(Item 12)

This alarm mounted on the front of the platform control station

will sound for various machine conditions or warnings such as,

system ready chirp or if the machine tilt warning is activated.

Indoor-Zone A/Outdoor-Zone B Operation Indicator

CE/AUS ONLY (Item 13 - Figure 3-5.)

The Indoor/Zone A (GREEN) indicator and

the Outdoor/Zone B (YELLOW) indicator,

displays which mode the machine is currently set to operate in.

Indoor-Zone A/Outdoor-Zone B

Operation Mode Switch

CE/AUS ONLY (Item 14 - Figure 3-5.)

This button will toggle between the outdoor/indoor operation modes. Outdoor

mode (Zone B) will restrict platform operations if operating machine outside rated

wind speed specifications.

3121744 JLG Lift – 3-17

Page 50

SECTION 3 - MACHINE CONTROLS, INDICATORS AND OPERATION

Outdoor/Indoor Operation Indicator

CE/AUS ONLY (Item 13 - Figure 3-6.)

The Outdoor (YELLOW) indicator and the

Indoor (GREEN) indicator, displays which

mode the machine is currently set to operate in.

Outdoor/Indoor Operation Mode Switch

CE/AUS ONLY (Item 14 - Figure 3-6.)

This button will toggle between the outdoor/indoor operation modes. Outdoor

mode will restrict platform operations if

operating machine outside rated wind

speed specifications.

3-18 – JLG Lift – 3121744

Page 51

SECTION 3 - MACHINE CONTROLS, INDICATORS AND OPERATION

1

3.10 PLATFORM EXTENSION

(See Figure 3-8.)

This machine is equipped with an extension deck, giving the

operator better access to certain work areas. The deck extension

adds length to the front of the platform.

FOR MAXIMUM CAPACITY OF THE DECK EXTENSION SEE SECTION 5, TABLE 52 OR REFER TO THE CAPACITY PLACARD ON THE PLATFORM BILLBOARD.

DO NOT “LOWER” WITHOUT COMPLETELY RETRACTING THE PLATFORM

EXTENSION.

To extend t h e deck:

1. Push down on the locking mechanism lever (1) using

your foot, while holding down on the lever, slide the

top handrails (2) until the locking mechanism pin

clears the rear platform extension lock (3).

2. Grasp the top handrails (2) of the extendible deck and

push the extension out until it hits the stops and the

locking mechanism pin is locked into one of the forward platform extension locks (4) or (5).

To retract the deck:

1. Push down on the locking mechanism lever (1) using

your foot, hold down on the lever and slide the top

handrails (2) rearward until the locking mechanism

pin clears the forward platform extension locks (4)

and (5).

2. Grasp the top handrails (2) of the extendible deck and

pull the extension back until it hits the stops and the

locking mechanism pin is locked into the rear platform

extension lock (3).

3121744 JLG Lift – 3-19

Figure 3-8. Platform Deck Extension