Page 1

MASSIF

RANGE BODYBUILDER INSTRUCTIONS

LIGHT RANGE

ISSUE 2008

Page 2

Publication Edited by:

Technical Application

Strada delle Cascinette, 424/34

10156 Turin - Italy

Publication Nr. 603.93.811 - 1

Printed in Italy - 04.08

st

Edition

Produced by:

B.U. TECHNICAL PUBLISHING

Iveco Technical Publications

Lungo Stura Lazio, 15/19

10156 Turin - Italy

Page 3

MASSIF

Bodybuilders instructions

Print 603.93.811 - 1

st

edition

Base - April 2008

UPDATE DATA

Section Description Page Revision date

Update data

Print 603.93.811 Base - April 2008

Page 4

Update data

Base - April 2008 Print 603.93.811

Page 5

Foreword

This publication provides the data, features and instructions for vehicle fitting and modifications.

It is intended for qualified, skill personnel. The body builder is responsible for designing the fitting, its modification and execution,

and will have to ensure compliance with the provisions both of this publication and the law regulations in force.

Prior to carrying out any work, make sure you have the publication of the vehicle model on which you are about to work. Also make

sure that all the accident-prevention equipment such as, for instance, goggles, helmet, gloves, boots, etc. as well as the working, lifting

and handling equipment are available and in good working order. Finally, make sure that you operate on the vehicle in such conditions

as to ensure maximum safety.

The execution of the work by strictly complying with the above provisions, as well as the use of the components shown, ensure that

the work is carried out correctly and safely.

Any change, modification or fitting not covered by this manual and not expressly authorized in written by IVECO will relieve the

latter of any responsibility and make, in particular, the vehicle guarantee null and void.

IVECO is available to provide all and every explanation required to carry out the work and also help you handle the cases not dealt

with in this publication.

After every single intervention, the functioning, efficiency and safety conditions established by IVECO shall be restored. Contact the

IVECO service network for vehicle set-up, if necessary.

IVECO shall not be responsible for any change, modification or fitting concerning the vehicle.

The data and information contained in this publication may not be updated due to the changes made by IVECO, at any time, for

technical or commercial reasons, or to make the vehicles comply with the law regulations in force in the different countries.

In case of disagreement between the provisions included herein and the actual vehicle make-up, contact IVECO prior to carrying

out any work.

Symbols - Warnings

Danger for p ersons

Missing or incomplete observance of these prescriptions can cause serious danger for persons’ safety.

Danger of serious damage for the vehicle

Partial or complete non observance of these prescriptions can cause serious damages to the vehicle and sometimes

guarantee lapse too.

General danger

!

It includes the dangers of above described signals.

Environment protection

It indicates correct behaviour in order that vehicle use is environmentally friendly as much as possible.

It indicates an additional explanation for a piece of information.NOTE

Foreword

Print 603.93.811 Base - April 2008

Page 6

Page header and footer interpretation

Vehicle type

Section title

Section number -

page number

Print

number

Foreword

Base - April 2008 Print 603.93.811

Chapter title

Basic edition -

month year

Page 7

INDEX OF SECTION

Section

General specifications

Operations on the vehicle 2

Fitting superstructures 3

Power Take-offs 4

Specific information and instructions 5

1

Index of section

Print 603.93.811 Base - April 2008

Page 8

Index of section

Base - April 2008 Print 603.93.811

Page 9

MASSIF

Index

GENERAL SPECIFICATIONS

SECTION 1

General specifications

Page

1.1 Aim of bodybuilders instructions 1-3

1.2 IVECO approval for changes and fit tings 1-3

1.3 Liabilities 1-4

1.4 Guarantees 1-4

1.5 Request for approval 1-4

1.6 IVECO technical documents available by means of computer 1-5

1.7 Trademarks and Logos 1-5

1.8 Legal Provisions 1-5

1-1

1.9 Prevention of accidents 1-6

1.10 Choice of material to use: Ecology - Recycling 1-6

1.11 Vehicle delivery 1-7

1.12 Vehicles identification 1-8

1.13 Dimensions and masses 1-9

1.13.1 General Specifications 1-9

1.13.2 Determining the Centre of Gravity of the Body and Payload 1-10

1.13.3 Observing the Permitted Weights 1-13

1.14 Instructions for the Correct Functioning of the Parts of the Vehicle and Accessibility for Maintenanc e 1-14

1.15 Quality System management 1-15

1.16 Vehicle maintenance 1-15

1.17 Conventions 1-16

Index

Print 603.93.811 Base - April 2008

Page 10

1-2

GENERAL SPECIFICATIONS

M

ASSIF

Index

Base - April 2008 Print 603.93.811

Page 11

MASSIF

Aim ofbodyb uilder si nstructi ons

GENERAL SPECIFICATIONS

1-3

1.1 Aim of bodybuilders instructions

The purpose of this publication is to provide data, specifications and instructions for the bodybuildingand conversion of an original

IVECO vehicle to ensure the functionality, safety and reliability of the vehicle and its components.

1.2 IVECO approval for changes and fittings

Changes must be carried out in accordance with the requirements set out in the following guidelines.

The following may be carried out only with IVECO’s approval after submitting a copy of the documentation required for technical

evaluation of the proposed change (drawings, calculations, technical report etc.):

- wheelbase modifications, whereby the value of the newly obtained wheelbase does not fall within the minimum and maximum

values available within the IVECO range for the same vehicle;

- work carried out on the braking system;

- work carried out on the suspension system;

- steering wheel modifications;

- changes to the stabiliser bars and suspensions;

- changes to the cab, cab supports, locking and tipping devices;

- changes to the engine intake and exhaust systems;

- engine cooling system modifications;

- power unit and driving component modifications;

- work carried out on front and rear axles;

- fitting decelerator brakes;

- fitting power take-offs;

- changing the tyre dimensions;

- coupling device (hooks, fifth wheels) modifications;

- electric/electronic unit modifications.

The other modifications of fittings covered by the following standards and made in c o mpliance with the same do not require specific

approval from IVECO. Any modification or fitting not covered by t hese standards shall, on the contrary, be authorized by IVECO

in advance.

Aim of bodybuilders instructions

Print 603.93.811 Base - April 2008

Page 12

1-4

GENERAL SPECIFICATIONS

Liabilities

M

ASSIF

1.3 Liabilities

The authorizations issued by IVECO conc ern solely the technical/con c eptual feasibility of the modification and/or fitting to be

made on a genuine IVECO vehicle.

The bodybuilder is responsible for the:

- project of the modification or fitting;

- choice and features of the products used;

- workmanship of the modification or fitting;

- compliance of the project an d its implementation with all the instructions provided by IVECO;

- compliance of the project and its implementation with all the current regulations in the country where the vehicle is registered;

- the functionality, safety and reliability and in general the effective performance of the vehicle and also the effects that th e changes

and th e conversion may have on vehicle performance and specifications.

1.4 Guarantees

The bodybuilder/chassis converter who has built the body or who has modified the chassis must guarantee that the work was

undertaken in a professional manner in full compliance with the specifications contained in this manual. IVECO reserves the right

to declare void its own warranties for the vehicles where:

- these specifications have not been adhered to or where unauthorised equipment was installed, or unauthorised modifications

were carried out;

- an unsuitable frame has been used for the required conversion or application;

- the specifications, standards or instructions issued by the Manufacturer for the flawless execution of the operations have not

been heeded;

- original spare parts or components which the Manufacturer has made available for specific interventions were not used;

- read and respect the safety standards and symbols applied before any operation;

- do not use the vehicle for applications other than those for which it is designed.

Maintaining the functionality of vehicle components.

The effective operation of vehicle components, all component safety and running conditions, com-

pliance with national and international regulations (e.g. EC Directives) and also accident prevention

standards must naturally be guaranteed in all permitted conversions and applications.

All our vehicles are covered by a warranty as laid down in the specific documents.

The bodybuilder must arrange to carry out operations at least in an equivalent manner.

1.5 Request for approval

The requests for approval or support to carry ou t work or make modifications or fittin gs shall be forwarded to t he IVECO marketing offices in charge.

To obtain the approval, the body builder shall provide adequate documents that illustrate the anticipated implementation, utilization

and conditions of use on the vehicle. The drawings shall highlight any item differing from the instructions contained in this manual.

The body builder shall submit the modification and/or fitting to the competent authorities for approval.

Liabilities

Base - April 2008 Print 603.93.811

Page 13

MASSIF

IVECO techni cal documents availabl eby means of computer

GENERAL SPECIFICATIONS

1-5

1.6 IVECO technical documents available by means of computer

The following technical documents are available on the Internet at www.thbiveco.com:

- directives for transformation and equipping of vehicles;

- technical cards;

- chassis cab diagrams;

- chassis diagrams;

- other specifications conc erning the vehicle range.

The body builder shall submit the modification and/or fitting to the competent authorities for approval.

1.7 Trademarks and Logos

Trademarks, nameplates and denominations must n ot be modified or displaced in relation to the original design. The appearance

of the vehicle must not be changed or modified.

The application of trademarks tied to the transformation or trim levels must be au th orised by IVECO. They must no t be applied

near to the IVECO tradenames or logos.

IVECO reserves the right to withdraw the tradenames and logos if the fitting or conversion fails to conform with requirements. The

bodybuilder accepts all responsibility for the entire vehicle.

Instruction for added assemblies

Where assembliesare added,the bodybuilder must provide the necessary service and maintenance instructions when the vehicle

is delivered.

1.8 Legal Provisions

On completing the vehicle, the bodybuilder/chassis converter must check the work (modifications, body + equipment etc.) to

ensure that the legal provisions required in the country of registration are observed (e.g. weights, dimensions, braking, noise,

emissions etc.). Information regarding these matters may be obtained from the competent Authorities or the IVECO Area Network.

The vehicles manufactured at our plant (except some versions for Extra-European countries) comply with the EC directives. Converted vehicles must also comply with these directives. The only permissible exception is granted where local type approval differs from

EC homologation.

IVECO technical documents available by means of computer

Print 603.93.811 Base - April 2008

Page 14

1-6

GENERAL SPECIFICATIONS

Preventi onof accide nts

1.9 Prevention of accidents

Do not allow unauthorised personnel to work on or operate the vehicle.

It is forbidden to use the vehicle if its safety devices have been tampered with or damaged.

The structures and devices fitted to the vehicles must comply with the current regulations concerning

the prevention of accidents and safety regulations in force in the countries where the vehicle is to be

used.

All the precautions dictated by technical awareness must be adopted to prevent malfunction and functional defects.

Compliance with these regulations will be the responsibility of the manufacturers of the structures and devices.

Components such as seats, coverings, linings, protective panels etc. may represent a potential fire hazard if they are exposed to an intense heat source.

!

Arrange for their removal before working with welding equipment and flames.

M

ASSIF

1.10 Choice of material to use: Ecology - Recycling

Increasingly greater attention should be paid, at the study and design st age, t o the ch oice of materials to be u sed.

This is especially the case as regards the aspects conn ected with ecology and recycling in the ligh t of domestic and international

regulations that are constan tly being developed in the sector.

In this connection:

- everyonemust be aware of the prohibitions on using harmful or potentially hazardous materials, such as ones containing asbestos,

lead, halogen additives, fluorocarbons, cadmium, mercury, hexavalent chrome, etc.

- Use materials whose processing produces limited waste and that permit easy recycling after their first use.

- With composite synthetic materials, use components that are c ompatible with each other, envisaging also their possible utilization with the addition of other salvaged components. Affix the markings required in compliance with the current regulations.

- Batteries contain substances that are very hazardous to the environment. When replacing batteries, we advise c ontacting the

service network, which is suitably equipped for battery disposal in compliance with environmental policies and laws.

In order to comply with EC directive 2000/53 (ELVs), IVECO S.p.A. prohibits fitting parts containing

lead, mercury, cadmium and hexavalent chrome to vehicles (except for the departures referred to in

Attachment II of the above directive).

Prevention of accidents

Base - April 2008 Print 603.93.811

Page 15

MASSIF

Vehicledelivery

GENERAL SPECIFICATIONS

1-7

1.11 Vehicle delivery

Prior to delivering the veh ic le, the body builder shall:

- verify that the work has been made correctly;

- perform vehicle and/or equipment set-up;

- check the operation and safety of the vehicle and/or equipment;

- prepare and deliver the necessary instru ctions for service and maintenance of the fitting and any additional units to the end customer;

- write the new data down on the special tags;

- confirm that the work c arried out complies with the indications provided by the vehicle manufacturer and with the law regulations;

- carry out the checks included in the ”IVECO Pre-Delivery inspection” list (available from the IVECO network) with regard to

the items affected by the work done;

- provide a guarantee for the modifications made;

- in the event that the connections originally provided with screws have been mounted and restored, the same screws shall not

be used. In such an instance, and in the event tha t nails have been replaced with screws, you must check again the closing o f

the connection after travelling approximately 500-1000 km.

- measure the battery voltage. Ensure there is a minimum charge of 12.5 V. If the voltage reading is between 12.1 and 12.49 V,

recharge the battery (slow charge). If the voltage is less than 12.1 V, the battery must be scrapped and replaced with a new one;

- the batteries must be serviced at regular intervals until the vehicle is handed over to th e customer to prevent problems of low

charge, short-circuits or corrosion. IVECO reserves the right to terminate the battery warranty if the maintenance proc edures

required by the IVECO network are not observed.

Vehicle delivery

Print 603.93.811 Base - April 2008

Page 16

1-8

GENERAL SPECIFICATIONS

Vehicl es identi ficati on

1.12 Vehicles identification

The commercial designation of IVECO vehicles is not the same as the type approval (homologation) designation. The tradename

is MASSIF. IVECO

M

ASSIF

Vehicles identification

Base - April 2008 Print 603.93.811

Page 17

MASSIF

Dimensionsandmasses

GENERAL SPECIFICATIONS

1-9

1.13 Dimensions and masses

1.13.1 General Specifications

The dimensions and maximum permissible weight on the axles are indicated on the bodybuilder layout drawings, on technical

specification sheets and, in greater details, on the official documentation issued by the Company. The kerb weights refer to vehicles

with standard equipment. Special equipment may involve considerable modification to the weight and its distribution on the axles.

On our vehicles, lights and rear-view mirrors are designed for widths of up to 2350 mm.

Weighing of the frame

As a result of production factors there could be at a ±5% variation in the published weights.

It is therefore, advisable to weigh the vehicle in the chassis cab condition before fitting the body and equipment and establish the

weight distribution on the axles.

Body conversions

The body building limits for each model are mainly defined by th e following:

- weight distribution on the axles;

- width of t he mirrors used;

- rearbumperposition

Greatervalues in compliance with the weights permittedon the axles may be authorized by IVECO aftermodifying such components

as the chassis, bumper, mirrors, etc .

Dimensions and masses

Print 603.93.811 Base - April 2008

Page 18

1-10

GENERAL SPECIFICATIONS

M

ASSIF

1.13.2 Determining the Centre of Gravity of the Body and Payload

Positioning on the longitudinal plane

To establish the location of the centre of gravity of the body and payload t h e following examples below may be used as guidelines.

The technical documentation specific to each model (chassis cab drawing) give t he positions permitted with the vehicle in its standard

form.

Figure 1.1

125490

W

⋅ L

1

=

L

1

W = Body + payload (kg)

W1 = Body and payload acting on front axle (kg)

W2 = Body and payload acting on rear axle (kg)

L1 = Distance of the centre of gravity from the rear axle centre line (mm)

L = Wheelbase (mm)

respectively L1 = L −

W

W2 ⋅ L

W

Example of calculation of the load barycentre position

Consider a Massif chassis cab vehicle with a wheelbase of 2768 mm with:

1. GWW= 3050 kg (permitted maximum: 1175 kg on the front and 2150 kg on the rear)

2. KERB WEIGHT = 1,955 kg (1,340 kg on the front axle, 615 kg on the rear)

The permitted maximum load (body + payload) will be W = 3050 - 1860 = 1190 kg. Let us calculate the position of the center

of gravity in which the maximum permitted on the front axle is achieved. Let us assume an uniform distributed load .

In this case, o ut of 1190 kg. W

= 1175 - 1020 = 155 kg will affect the front axle, while the remaining W2= 1190 - 155 = 1035

1

kg will affect the rear axle.

Thus, th e following will be obtained:

1

= 155 kg

1. W

2. L = 2768 mm

3. W = 1190 kg

=W1x L / W = 360 mm

L

1

The center of gravit y of the load (Body + payload) must not be more than 360 mm far from the rear axle; o therwise, the front

axle would be overloaded.

Dimensions and masses

Base - April 2008 Print 603.93.811

Page 19

MASSIF

GENERAL SPECIFICATIONS

1-11

In order to determine the payload on the axles, it must be uniformly distributed except when the shape of the loading surface itself

entails a different distribution of the load.

Regarding any equipment, the actual position of the centre of gravity must be u sed.

When building bodies or con tainers, loading and unloading systems must be devised whic h preclude excessive variations in the

distribution of the load and/or excessive loads on the axles. Relevant instructions should also be given to the operator.

Figure 1.2

Uniform load distribution Uneven load distribution

Figure 1.3

Uniform load distribution Uneven load distribution

(beware of axle loads and minimum axle ratio)

121792

Dimensions and masses

Print 603.93.811 Base - April 2008

Page 20

1-12

GENERAL SPECIFICATIONS

M

ASSIF

Height of centre of gravity

For testing the vehicle complete with superstructure, the bodybuilder must check that the height of the centre of gravity of the

equipment including the payload, or of the entire vehicle when fully loaded, falls within the maximum permitted values.

These limits are definedin compliance with the national or international regulations (e.g. EC Directive regarding braking) or requested

by the Manufactu rer to ensure good handling of th e vehicle (e.g. tran sverse stability of the moving vehic le).

Figure 1.4

Verification with full load:

Wt

Wb

Wc

121858

Wc x Hc + WbxHb

Ht =

Wc = Chassis cab vehicle kerb weight

Hc = Height of centre of gravity of chassis cab vehicle (laden condition)

Wb = Body and payload

Hb = Height of centre of gravity of body and payload in relation to ground

Wt = Vehicle weight when fully loaded

Ht = Height of centre of gravity of vehicle with full load

Wc + Wb

To check the vehicle with its body but no payload, use the above formula but for Wb use only the vehicle unladen weight (The

position for Hc will depend on the load and deflection of the suspension).

The height of the centre of gravity indicated in Table 2.6 represents values which are not to be exceeded for each given equipment

level. These values have been calculated only in terms of the transverse stability of the vehicle and are applicable to a mid wheelbase.

Any other possible restrictive specification , e.g. braking regulation, sh o uld be taken into consideration.

The values given in Table 2.6 refer to the body with fixed payload. In versions where the payload tends to move sideways (e.g.

suspended loads, fluid loads etc.) especially when turnin g, higher dynamic tran s verse forces is generated which makes the vehicle

less stable. This must be taken into consideration when providing vehicle operating instructions or for possible reduction in the height

of the centre of gravity.

(Wc + Wb) x Ht − Wc x Hc

Hb =

Wb

Dimensions and masses

Base - April 2008 Print 603.93.811

Page 21

MASSIF

GENERAL SPECIFICATIONS

1-13

Using Stabiliser Bars

Supplementary stabilising or anti-roll bars, where available, spring reinforcements or the application of ru bber components (in

compliance with point 2.11) may increase the height of the centre of gravity of the payload which must be defined as each occasion

arises. The modification must be carried out after careful consideration has been given to the specifications of the body type, to

the wheelbase and to the distribution of the transverse forces acting on the suspension both at the front and at the rear of the vehicle.

Modification to the fron t axle may be made where the load is positioned behind the cab (e.g. crane) or where the body is very rigid

(e.g. van conversio n).

1.13.3 Observing the Permitted Weights

All the limits specified on th e IVECO documents must be complied with. It is essential that the maximum weight on the front

axle is not exceeded, under any load condition, so as to ensure the correct steering and braking characteristics regardless of the

road surfac e conditions.

Particular attention must be taken with vehicles where the load is concentrated on the rear overhang (e.g. cranes, tail lifts, trailers)

and to vehicles with short wheelbases and a very high centre of gravity.

Ensure transverse loads are properly distributed when positioning auxiliary components and superstructu res. A +4% variation on

the rated load (50% of load on the axle) is permissible for each wheel (for example: permissible load on axle 2150 kg; 1032 to 1118

kg allowed for each wheel side); in compliance with load allowed by ty res, without affec t ing braking properties and vehicle driving

stability.

Apart from different specifications for s pecific vehicles, the following may be taken to be the minimum weights for the front axle:

30% of the total vehicle weight (with uniformly distributed loads and with loads concentrated on t he rear overhang).

The rear overhang of the body must be built in strict observance of the permitted axle loads, the minimum load required on the

front axle, the limitations in length, the positioning of any tow h ook and of the rear under-run guard stipulated by the relevant

National an d EC regulations.

Variations in the Permissible Weight

Special exceptions to the maximum permissible weights may be granted for particular applications for which, however, precise

limitations regarding the use will be imposed in addition to possible vehicle reinforcements.

Such exemptions, if they exceed the limits imposed by law, must be authorised by the Government Administrative Authority.

The request for authorisation must include:

- vehicle type, wheelbase, identification number, designated use;

- unladen weight on the axles (e.g. vehicles equipped with crane) including positions for the centre of gravity of the payload;

- proposals concerning the reinforcement of the vehicle components where necessary.

The reduction in the permissible weight on the vehicle (derating) may involve changing various components such as suspension,

brakes etc) and may require recalibration of the load sensing valve where one is fitted. In these circumstances necessary instructions

may be provided.

Dimensions and masses

Print 603.93.811 Base - April 2008

Page 22

1-14

GENERAL SPECIFICATIONS

Instructionsforthe CorrectFunctioningofthe Partsofthe Vehicleand AccessibilityforMaintenance

M

ASSIF

1.14 Instructions for the Correct Functioning of the Parts of the Vehicle

and Accessibility for Maintenance

As a ru le, when modifying or installing any type of equipment, nothing must be altered which prevents the correct functioning

of assemblies and parts of the vehicle under all operational conditions.

For example:

- Ready access to all parts requiring inspection or maintenance and periodic servicing must be provided. In the case of closed body

types suitable opening doors must be provided.

- Service access to chassis/driveline components must be retained. For instance repairing the gearbox or clutch must be possible

without necessitating the removal of major components of the added structure.

- The cooling system (radiator cowling, radiator, air passages, cooling circuit etc.), fuel supply (pump position, filters, pipe diameter,

etc.) and the engine air intake must not be altered.

- The anti-noise panels must not be altered or moved in order to prevent changes in the approved noise levels of the vehicle.

Should it be necessary to make openings (e.g. for the longitudinal runner of the body to pass through) these must be properly

closed off using material with inflammability and soundproofing charact eristics equivalent to those used originally.

- Adequate ventilation of the brakes and battery case (especially in the case of vans) must be guaranteed.

- When positioning the mudguards and wheel arches, the rear wheels must be free to rebound even when used with chains.

- When the vehicle has been set up, for safety reasons, headlight attitude must be checked and adjusted as necessary. Perform

the adjustment according to the instructions provided in the use and maintenance manual.

- In t h e case of parts whic h are supplied loose (e.g. spare wheel, ch o cks) it will be the responsibility of the bodybuilder to position

and secure them in an accessible and safe manner in compliance with possible national laws.

Instructions for the Correct Functioning of the Parts of the Vehicle and Accessibility for Maintenance

Base - April 2008 Print 603.93.811

Page 23

MASSIF

Quali tySy stem management

GENERAL SPECIFICATIONS

1-15

1.15 Quality System management

For some time IVECO has been promoting Quality System development and training for bodybuilders.

This is a requirement due not only to c ompliance with domestic an d in ternational regulations on product liability, but also the growing

demand for increasingly higher quality levels. The creation of new forms of organization in the various sectors and the quest for

increasingly more advanced levels of efficiency.

IVECO believes it essential for bodybuilders to be equipped with an organization where the following are defined and available:

- Organization charts for functions and responsibilities.

- Quality system.

- Quality goals.

- Technical design documentation.

- Process and control phases with relevant resources.

- Product improvement plan, obtained also with correct ive action s.

- After sales service.

- Staff training.

- Manufacturer liability documentation.

1.16 Vehicle maintenance

In addition to making the necessary checks on the outfit in keeping with customary working procedures, the bodybuilder shall

perform the checks specified in the “IVECO pre-delivery inspection” list, which c an be obtained from the IVE CO network, for the

aspects affected by the modifications performed.

Quality System management

Print 603.93.811 Base - April 2008

Page 24

1-16

GENERAL SPECIFICATIONS

Convention s

M

ASSIF

1.17 Conventions

In these bodybuilders instructions, the wheelbase is taken as the distance between the centreline of the first steering axle and

the centreline of the first rear axle (driven or non-driven). This definition differs from the definition of wheelbase in the CE Directives.

The rear overhang is taken as the distance between centreline of the last axle and the rear end of the chassis runner. For dimensions

H, L and s of the frame and counterframe section please refer to the figure below.

Figure 1.5

wheelbase area side member section rear overhang area side member section

121794

121795

Conventions

Base - April 2008 Print 603.93.811

Page 25

MASSIF

Index

OPERATIONS ON THE VEHICLE

SECTION 2

Operations on the vehicle

2.1 General instructions for chassis modifications 2-5

2.1.1 Specific Precautions 2-5

2.2 Protection against Rust and Painting 2-7

2.2.1 Original components 2-7

2.2.2 Added or modified painted parts 2-10

2.2.3 Precautions 2-10

2.2.4 Exceeding the Limits 2-11

2.3 Drilling the Chassis 2-12

2.3.1 Screws and nuts 2-12

2-1

Page

2.3.2 Characteristics of the material to be used when modifying the chassis 2-12

2.3.3 Stresses on the chassis 2-13

2.3.4 Welding the Chassis 2-13

2.3.5 Closing of existing holes 2-14

2.4 Modifying the Wheelbase 2-15

2.4.1 General Specifications 2-15

2.4.2 Authorisation 2-15

2.4.3 Consequences for steering 2-15

2.4.4 Effect on Braking 2-15

2.5 Modifying the Rear Overhang 2-15

2.5.1 Authorisation 2-15

2.6 Installing a Towing Device 2-16

2.6.1 General Specifications 2-16

2.6.2 Traditional towing hooks 2-17

2.6.3 Kinds of hook 2-18

2.6.4 Lowered Rear Cross Member 2-19

2.7 Installing a Supplementary Axle 2-20

2.8 Modifying the Drive Line 2-20

2.9 Modifications of the E n gin e Air Intake and Exhaust Systems 2-21

Index

Print 603.93.811 Base - April 2008

Page 26

2-2

OPERATIONS ON THE VEHICLE

M

ASSIF

Page

2.9.1 Intake 2-21

2.9.2 Engine exhaust 2-21

2.10 Modification of the Engine Cooling System 2-22

2.11 Work on the Suspension 2-23

2.11.1 General Specifications 2-23

2.12 Heating/Air conditioning sy stem modifications 2-24

2.12.1 Installation of a Supplementary Heating System 2-24

2.12.2 Installing an Air-Conditioning Sy stem 2-25

2.13 Cab Modifications 2-26

2.13.1 General Specifications 2-26

2.13.2 Roof Panel Modifications 2-26

2.13.3 Van and combi bodywork modifications 2-27

2.13.4 Crew Cabs 2-28

2.13.5 Occupant protection 2-28

2.14 Changing the Size of the Tyres 2-29

2.15 Modifications to the Braking System 2-30

2.15.1 General remarks 2-30

2.15.2 Brake pipes 2-30

2.15.3 Fitting pipes on the vehicle 2-31

2.15.4 Instruction s for adjusting the braking load proportioning valve 2-34

2.16 Electrical System: Modifications and Drawing-Off Power 2-37

2.16.1 Earth points 2-39

2.16.2 Electromagnetic compatibility 2-46

2.16.3 Additional equipment 2-53

2.16.4 Current drawing 2-56

2.16.5 Additional Circuits 2-64

2.16.6 Operations to adjust overh ang 2-65

2.16.7 Provision for trailer 2-65

2.16.8 Side Marker Lights 2-66

2.17 Repositioning Parts and Mounting Auxiliary Assemblies and Equipment 2-67

Index

Base - April 2008 Print 603.93.811

Page 27

MASSIF

OPERATIONS ON THE VEHICLE

2-3

Page

2.18 Retarder Installation 2-68

2.19 Modifications to the Rear Underrun 2-68

2.20 Rear mudguards and wheel boxes 2-68

2.21 Mudflaps 2-68

2.22 Side Guards 2-69

2.23 Chocks 2-69

Index

Print 603.93.811 Base - April 2008

Page 28

2-4

OPERATIONS ON THE VEHICLE

M

ASSIF

Index

Base - April 2008 Print 603.93.811

Page 29

MASSIF

2222.2

General i nstruction sfor chas sis modifi cations

OPERATIONS ON THE VEHICLE

2-5

2.1 General instructions for chassis modifications

Particular attention must be given to the following points:

- Welding to the bearing structures of the chassis is explicitly prohibited (with the exception of the items described at points

2.3.4 e 2.5);

- Holes in the flanges of the side members are not permitted (except for the items described at point 2.3.4);

- If the original bolted connections have been fitted and renewed, it is forbidden to reuse the same bolts. In this case, the tightness

of the connection must be rechecked after about 500-1000 km.

2.1.1 Specific Precautions

During the welding, drilling, grinding and cutting operations when working in the proximity

of brake lines and particularly if these are of plastic material or electric wiring, care must be

!

taken to ensure their protection. Where necessary they should be removed (comply with the

provisions given at points 2.15 and 2.16).

Figure 2.1

91444

General instructions for chassis modifications

Print 603.93.811 Base - April 2008

Page 30

2-6

OPERATIONS ON THE VEHICLE

M

ASSIF

Regarding the electrical equipment remember to:

a) Take precautions concerning the alternator and t he electric al/electronic components. In order to avoid damaging the diode

rectifier, never disconnect the batteries (or open the isolator) when the engine is running.

If the vehicle has to be tow started make certain that the batteries are connected. Should it be necessary to quick charge

the batteries, disconnect them from the vehicle circuit.

In order to run the engine wi th external means and in order to avoid current peaks which might damage the electric/electronic components, do not use the ”start” function in conjunction with external charge devices if such devices are equipped

with this function. Starting will have to be carried out only with the external battery trolley ensuring correct polarity.

b) Checking the earth connections.

As a general rule the original earth connections of the vehicle must not be changed. If it is necessary to move these connections or to implement further earth points use the existing holes on the chassis as far as possible and:

- Remove, mechanically, and/or with an appropriate chemical product, the paint on the chassis side and on the terminal side

creating a resting plane free from indentations or ridges.

- Apply appropriate h igh conductivity paint between the cable terminal and the metal surface (e.g. galvanizing paint IVECO

Part number 459622 by PPG).

- Connect the earth cables with in 5 minutes from the application of the paint.

For signal level earth connections (e.g. s ensors or devices with low power uptake), avoid using IVECO m3, m4, m5 (battery earth

connection), and is m6 standard points under all circumstances (see point 2.16.1).

With regard to the electronic devices, avoid linking earth connections between the devices; only use single wire earths with optimised

lengths (as short as possible).

c) Electric wiring

For further informatio n regarding the braking and electronic system, refer to point 2.15 and 2.16.

General instructions for chassis modifications

Base - April 2008 Print 603.93.811

Page 31

MASSIF

mainlystructuralcharacteristicsindirectview

.

Protectio nagai nst Rust and Paintin g

2.2 Protection against Rust and Painting

OPERATIONS ON THE VEHICLE

2-7

NOTE

All parts fitted to the frame must be painted in accordance with Iveco St. Iveco 18-1600 Colour IC444

RAL 7021 70/80 gloss.

2.2.1 Original components

In Table 2.1 details the operations for protecting and painting the components of the origin al vehicle (Table 2.3 for painted parts,

Table 2.2 for non-painted or aluminium parts).

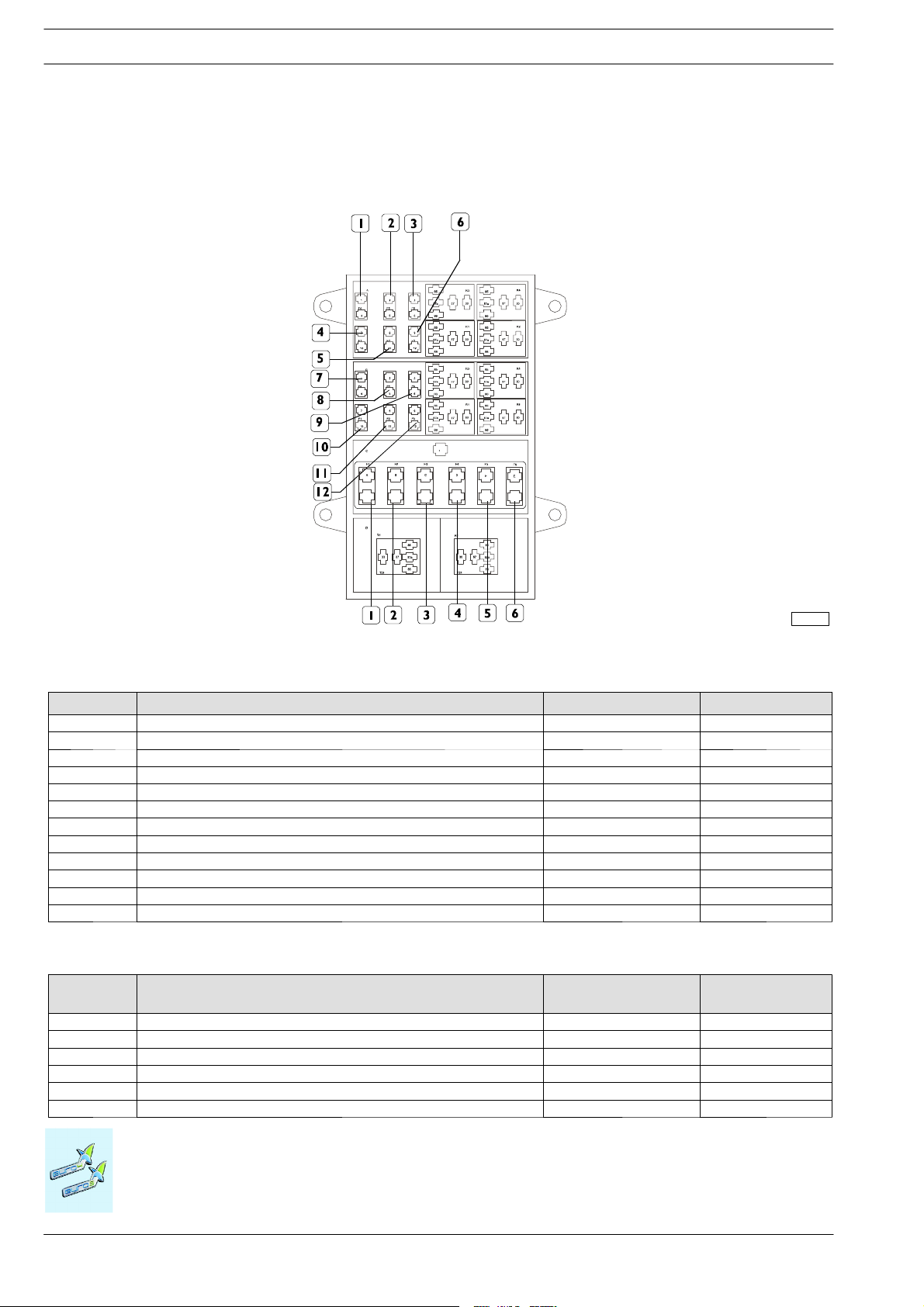

Table 2.1 - Protection category - STD 18 - 1600 (Schedule I)

Class Parts requirements Specific examples affected

Body - Door mirrors - Windscreen wipers - Aerodynamic

A Parts in direct contact with atmospheric agents.

B

B2

Parts in direct contact with atmospheric agents.with

mainly stru ctural c haracteristicsin direct view.

B1

C

Parts in direct contact with atmospheric agents.not in

direct view.

D Parts not in direct contact with atmospheric agents.

kit metal structure - sun blind metal struc ture - Metal

bumpers - Cab attachment lock- Door stopdevice - Body

fasteners (screws,bolts, n uts, washers), etc.

Frame and parts, includingfasteners.

Parts beneath grille (category B).

Exterior cab steps.

Only for rear axles and axles

Engine and parts

Pedals - Seat reinforcements - Fasteners - etc., fitted inside

cab.

NOTE

Parts must be supplied only with cataphoretic coating or rustproofing (Schedule III). The enamel will

be appliedduring the frame finishing stage.

Protection against Rust and Painting

Print 603.93.811 Base - April 2008

Page 32

2-8

Typeof

p

IVECO

y

acr

ome

t

Dacrome

t

y

(

)

y

Zinccoating

A

lumini

yesyesy

OPERATIONS ON THE VEHICLE

Table 2.2 - Various unpainted and aluminium parts and components - STD 18 - 1600 (Schedule IV)

M

ASSIF

rotection

IVECO

standard

A B-B1-B2 C D

Class

Stainless steel ¡ 18-0506 yes - - -

DAC 320-8

DAC 500-8

D

(H)

DAC 320-5

DAC 500-5

18-1101

es

-

-

- - -

- -

- -

es

- -

yes

DAC 500-5 PL -

Category B1

wheel studs

GEO

321-8-PM

yes -

GEO 321-5

Geomet

(HHH)

GEO

321-5-PM

GEO

321-5-PL

Fe/Zn 12 III

(yellow)

Fe/Zn 12 V

(olive green)

Zinc coating

(H)

Fe/Zn 25 V

(olive green)

Fe/Zn 12 III S

(yellow)

Fe/Zn 12 V S

(olive green)

Zinc coating

(HH)

FE/ZN 12 II - - yes yes

FE/ZN 12 IV S - yes - -

Anodic

oxidation

um

Painting

(H) Hexavalent chromium coatings.

(

HH) Hexavalent chromium-free coatings.

(

HHH) Chromium-free coatings.

18-1101

18-1102

18-1148 yes

See

Schedule III

-

-

- - yes yes

- - -

-

-

- - -

yes

yes

yes

Category B1

wheel studs

es

- -

- -

- -

¡ Matching with other metals must not generate battery effects.

es

Protection against Rust and Painting

Base - April 2008 Print 603.93.811

Page 33

MASSIF

D

i

pti

p

h

SUPERFICIAL

¡

yesL

PRETREATMEN

T

yesLyesLyesLyes

L

y

yes

L¥y

¥-¨

RUSTPROOFIN

G

yes

L¨yesL

yes

L

y

¦

¦

Table 2.3 - Painted parts - STD 18 - 1600 (Schedule III)

OPERATIONS ON THE VEHICLE

2-9

escr

on ofthecycle

ase

A B § B1 ¤ B2 C D

Sanding/sandblasting -

Classes

MECHANICALCLEANING

Brushing

yes L - yes L yes L yes L

Sandpapering

PRETREATMENT

Iron phosphatation (only for

non-precoated ferrous materials)

-

yes L - yes L yes L yes L

Zinc phosphatation l yes

High t hickness (30-40 µm) yes ©

CATAPHORESIS Medium thickness (20-30 µm) yes ¢

es L

yes L

-

es L

Acrylic top coat (>35 µm) -

CHIP-RESISTANT PRIMER

ENAMEL Powder (40-110 µm) yes £

Dual component (30-40 µm) yes - yes

Single component (30-40 µm)

Single (130 °C)

or dual component (30-40 µm)

Single (130 °C)

or dual component (30-40 µm)

Single component, low temperature

(30-40 µm)

-

- yes yes

yes ¢ - - - - -

yes

yes L -

- - yes

yes L

- yes L

¡ = Carry out operation in presence of shearing burrs, oxidation, welding swarf, laser-cut surfaces.

© = Two-coat body cycle.

¢ = Three-coat body cycle.

£ = As an alternative to single or dual component enamel only for body parts (windscreen wipers. Rear view mirrors etc.).

¤ = Only for rear axles and axles.

¥ = Excluding parts that cannot be submerged in pretreatment or paint baths because this would affect their operation (e.g.: mechanical parts).

¦ = Colour is specified on the drawing by means of an IC

§ = For fuel tanks in ferrous sheet metal or precoated.

¨ = Only parts to be fitted on engine.

= Parts that cannot be treated with cataphoresis (see ¥).

l = For galvanised or aluminium panels, use special phosphating treatments.

L = Alternative products and cycles for the same class, as long as they are compatible with the part being treated.

yes L

es L

Protection against Rust and Painting

Print 603.93.811 Base - April 2008

Page 34

2-10

D

i

pti

p

h

Mechanicalsur

f

g(includ

ingther

f

bur

rs/

rust

g

r

ts)Brushing/sanding/sandblastin

g

Typeof

p

y

OPERATIONS ON THE VEHICLE

M

ASSIF

2.2.2 Added or modified painted parts

All parts of the vehicle (cab, chassis, bodywork, etc.) which are added or subjected to modification must be protected from rust

and corrosion.

There must be no unprotected areas on ferrous materials.

Table 2.4 (p ai nted) and Tabl e 2.5 (unpainted) show the minimum treatments required for modified or added components when

it is not possible to provide the same protection as that used on IVECO original components. Different treatments are allowed

on condition that the same level of protection against rust and corrosion is guaranteed.

Never use powder enamels directly after degreasing.

Parts in light alloy, brass and copper must not be protected.

Table 2.4 - Added or modified painted parts

escr

ace cleanin

and cleaningof modifiedpa

on ofthecycle

ase

emovalo

A-B-D(1)

Brushing/sanding/sand blastin

Pre-treatment Degreasing

Anti-rust Bicomponent (30-40µm) (2)

Paint Bicomponent (30-40µm) (3)

Class

(1) = Modifications to rear axles, front axles and engine (Classes B1 and C) are not allowed.

(2) = Preferably epoxy.

(3) = Preferably polyurethane.

Table 2.5 - Added or modified unpainted and/or aluminium parts

Class

rotection

Stainless steel

Dacromet

A—B(1) D

es

-

-

Zinc treatment - yes

2.2.3 Precautions

Suitable precautions must be taken to protect those parts whose preservation and operation could be damaged by paints such

as:

- rubber or plastic pipes for the air and hydraulic installations;

- gaskets, parts in rubber or plastic;

- flanges of the transmission shafts or power take-offs;

-radiators;

- shock absorber and hydraulic or air cylinder rods;

- drainage and bleeder valves (mechanical components, air tanks, cold starting heater plug pre-heating tanks etc.);

- fuel sediment filter;

- nameplates and logos.

Protection against Rust and Painting

Base - April 2008 Print 603.93.811

Page 35

MASSIF

OPERATIONS ON THE VEHICLE

2-11

With particular regard to the engine and its electric and electronic components, adequate precautions shall be taken to protect:

- on the whole engine and vehicle wiring, including earth contacts;

- on all connectors on sensor/ac tu ator side and wiring side;

- on all sensors/actuators, on flywheel, on flywheel rev sensor bracket;

- on t he whole diesel fuel system pipes (plastic and metallic);

- on c omplete diesel fuel filter base;

- on control unit and control unit base;

- on t he whole soundproofing cover inner side (injectors, rail, pipes);

- on common rail pump including regulator;

- on vehicle electric pump;

- on tank;

- on front belt circuit and relevant pulleys;

- on power steering pump and relevant piping.

If the wheels are removed, protect the contact surfaces on the hubs, avoid increasing the thickness and especially avoid the build-up

of paint on the connecting flanges of the wheel disks and resting points of the fixing nuts.

Ensure that the disc brakes are adequately protected.

The electronic components and modules must be removed.

When the painting operation is to be completed by oven drying (max. temp. 80ºC), all parts which may

be damaged by exposure to heat, must be removed.

!

2.2.4 Exceeding the Limits

In case of special transport with considerable high centre of gravity (e.g. special body versions, advertising vehicles, etc.), from

a technical point the values shown in the table may be exceeded, provided the vehicle is driven carefully (e.g. low speed, gradual

running direction changes, etc.).

Table 2.6 - Maximum heights in relation to the centre of gravity of the payload and cornering stability

Max. height (approx.) of centre of gravity of payload

Models

- 955

(include. body and equipment) in relation to the

ground (mm)

Protection against Rust and Painting

Print 603.93.811 Base - April 2008

Page 36

2-12

OPERATIONS ON THE VEHICLE

DrillingtheChassis

M

ASSIF

2.3 Drilling the Chassis

The frame must not be drilled.

When auxiliary units or components are to be applied to the frame, existing factory-made holes must be used and the following

instructions must be applied.

Positioning and sizes

If it is necessary to make holes in the frame, it is compulsory to ask IVECO for authorisation.

2.3.1 Screws and nuts

In general, use connectors of the same type and class as those for similar fixings on the original vehicle (Table 2.7).

As a general rule, materials of class 8.8 are recommended. Class 8.8 and 10.9 screws must have been hardened and tempered. For

applications of diameter

in Table 2.2. A Dacromet finish is not recommended if the screws are to be subjected to welding. If space allows, use screws and

nuts with flange d heads. Use self-locki ng nuts. Nuts must be tightened using a torque wrench set to the correct torque setting for

the fixing.

± 6mm, stainless steel parts are recommended. Approved finishes are Dacromet and zinc coating, as detailed

Table 2.7 - Classes of resistance for screws

Class of resistance Usage

Tensile strength

(N/mm

2

)

Yield point

(N/mm

2

)

4 Non-load bearing screws 400 320

5.8 Low resistance screws 500 400

Medium resistance screws

8.8

(cross members, cleat plates,

800 640

brackets)

High resistance screws

10.9

(spring supports, stabilizer

1000 900

bars and shock absorbers)

2.3.2 Characteristics of the material to be used when modifying the chassis

When modifying the chassis of the vehicle, and in applicatio ns which reinforce the side members directly, the materia l used must

correspond in quality (Table 2.8) and thickness (Table 2.9) to that of the original chassis.

Should it not be possible to source materials of the thickness indicated, the next superior standard thickness may be used.

Table 2.8 - Materiale da utilizzare nelle modifiche del telaio Standard IVECO 15-2110 e 15-2812

Steel name

IVECO FEE490

Europe S355J0W

Germany

QSTE500TM -

S355J0W

UK S355J0W

Tensile strength

(N/mm

2

)

610 490 23%

Yield point

(N/mm

2

)

A5 elongation

Drilling the Chassis

Base - April 2008 Print 603.93.811

Page 37

MASSIF

Table 2.9 - Truck chassis dimensions, section and thickness

OPERATIONS ON THE VEHICLE

2-13

Model Type Wheelba se [mm]

Chassis rear

overhang [mm]

AxBxt

wheelbase area

side member

section [mm]

AxBxt

rear overhang area

side member

section [mm]

Chassis cab truck 2768 1000 170 x 75 x 3 156 x 75 x 2,5

2.3.3 Stresses on the chassis

Under no circumstances is it permitted to exceed the stress levels under static conditions, calculated taking into consideration

that:

• within the wheelbase, the safety coefficient relating to yield under conditions of maximum load on the axles is equal to 3.5

• On the rear overhang, the safety coefficient relating to yield under con ditions of maximum load on the axles, is equal to 3

When prescribed by national regulations, the bodybuilder must check that the stress limits are not exceeded.

Welding activity will cause a deterioration in the characteristics of the material. Therefore , when checking the stresse s in thermicallymodifie d zones, consider a reduction of app rox . 15% of the resistance characteristics.

2.3.4 Welding the Chassis

NOTE

All frame welding must be carried out after authorisation from IVECO.They must then be carried

out scrupulously following the instructions given below.

Welding operations must only be carried out by specialist, trained personnel, using suitable equipment

and in a perfectly workmanlike manner (see norms EN 287). Any intervention on the system not car-

!

ried out as per instructions provided by IVECO or carried out by unskilled staff, might severely damage

the on-board systems, thus adversely affecting vehicle operation safety and efficiency and causing damages not covered by guarantee contract.

Drilling the Chassis

Print 603.93.811 Base - April 2008

Page 38

2-14

OPERATIONS ON THE VEHICLE

In case of arc welding, strictly follow instructions below in order to protect electric units and ECUs:

- before disconnec ting power cables, check for no loads engaged;

- in case an electric switch is installed (main contactor) wait for cycle end;

- disconnect negative power pole;

- disconnect positive power pole without connecting it to ground and DO NOT short c ircuit it with negative pole;

- disconnect ECUs connectors, operate carefully and do not touch ECU connector pins;

- In case of welding next ECU, disconnect it from vehicle;

- connect welding machine ground directly on part to be welded;

- protect plastic material pipes against heat sources and disassemble, if required:

- in case of welding near leaf springs or air springs against welding spatters, carefully protect surfaces;

- avoid electrode or gun contac t w ith spring leaves;

Operations for welding preparation

M

ASSIF

As part of the procedure it will be necessary to remove the paint and deoxidise the parts of the chassis that are affected by the

welding operation as well as those parts wh ich may have to be covered by possible reinforcements. When work has been completed

the modified part must be protected with adequate rustproofing (see point 2.2.2).

a) Carry out arc welding in several passages using properly dried basic electrodes Recommended electrodes:

For S 500 MC (FeE490: QStE 500TM)

Diameter of the electrode is 2.5 mm, current intensity approx. 90A (max. 40A for each millimetre of diameter of the electrode).

Using MIG-MAG welding use a welding rod with the same characteristics as the material to be welded (diameter 1 to 1.2 mm).

Recommended welding rod: DIN 8559 - SG3 M2 5243

gas DI N 32526-M21 or DIN EN 439

If FeE490 is used at very low temperatures, we recommend:

PrEN 440 G7 AWS A 5.28 - ER 80S - Ni 1 gas DIN EN439-M21

Avoid current overloading. Welding must be free from marginal cuts and waste material.

b) Repeat the operation on the reverse side by welding as detailed in point a).

c) Allow the side members to cool slowly and uniformly. Cooling by air, water or other means is not permitted.

d) Remove excess material resulting from the welding operations by grinding.

2.3.5 Closing of existing holes

If, when making new holes, the existing holes are found to be too close these may be closed up by welding. To ensure the success

of this operation the outer edge of the hole should be chamfered and copper plate used for the inner part.

For holes with a diameter of over 20 mm, chamfered plugs may be used, welded on both sides.

Drilling the Chassis

Base - April 2008 Print 603.93.811

Page 39

MASSIF

ModifyingtheWheelbase

OPERATIONS ON THE VEHICLE

2-15

2.4 Modifying the Wheelbase

2.4.1 General Specifications

It is only possible to alter the wheelbase after obtaining specific approval from IVECO.

2.4.2 Authorisation

Provided the chassis converter gives sufficient guarantees from the technological and control point of view (qualified personnel,

adequate operating processes, etc.).

Conversion must be carried out performed in compliance with these instructions by making the necessary changes and adjustments

and taking the appropriate precautions (e.g., determining whether ECU parameters need updating, rearranging the exhaust pipes,

ensuring compliance with specific load limits on the rear axle, etc.), by taking into due account the requirements specified for the

original wh eelbase lengths.

2.4.3 Consequences for steering

In general,changes to the wheelbase affect steering specifications.Each operation is directly linked to the authorisation requested

from IVECO.

2.4.4 Effect on Braking

In general, changes t o the wheelbase affect braking specifications. Each operation is directly linked to the authorisation requested

from IVECO.

2.5 Modifying the Rear Overhang

2.5.1 Authorisation

Rear lengthenin g of the frame must be specifically authorised by IVECO.

Modifying the Wheelbase

Print 603.93.811 Base - April 2008

Page 40

2-16

OPERATIONS ON THE VEHICLE

InstallingaTowingDevice

M

ASSIF

2.6 Installing a Towing Device

2.6.1 General Specifications

Without prior authorisation, the installation of a tow-hook is permissible only on those cross members which are intended for

that use and on those vehicles which IVECO has intended for towing a trailer.

The subsequent installation of a tow hook in vehicles for which the installation of a tow hook was not originally contemplated, must

be authorised by IVECO.

In addition to the permissible towing weight, the authorisation will specify all other possible specifications that are to be adhered

to such as th e use of the vehic le, th e transmission ratio, th e type of braking system as well as possible specifications con cerning

reinforcements to be applied to the rear cross member or the necessity for employing specially in tended cross members.

In trailers with one or more axles close together (mid-axled trailers), bear in mind th e instruc tions given in point 2.6.3.

The tow hook must be appropriate for the permitted loads and of the type approved by national laws.

!

Since tow hooks are important to vehicle driving safety (in some countries they must be specifically

certified) they must not be modified in any way.

When mounting the tow hook to the cross member, the specifications of the hook manufacturer as well as the limitations imposed

by current standards - such as minimum space required for the brake and electrical connections the maximum distance between

the swivel h ook axis and the rear edge of the body - must be respected.

The size of the hook attachment flange does not coincide with the holes on the vehicle rear beam, modification of the drilling on

the beam may be authorised in specific cases after applying appropriate reinforcements.

The bodybuilder is obliged to construct and fit the superstructure to make the necessary manoeuvres and control of the attachment

possible without impediment or hazards.

The trailer drawbar must be free to move.

Installing a Towing Device

Base - April 2008 Print 603.93.811

Page 41

MASSIF

OPERATIONS ON THE VEHICLE

2-17

2.6.2 Traditional towing hooks

A towing hook may be fitted, without obtaining prior approval only on crossmembers provided for this purpose and to vehicles

on wh ich IVE CO provides for a towing hook to be installed.

The installation of a towing h ook on vehicles which IVECO does not provide a towing hook installation then authorisation from

IVECO must be obtained before any installation is carried out.

Detail of rail reinforcement for installation of the tow hook.

The values of the trailer loads and of the permissible vertical loads are contained in the technical documentation of the manufacturer

of t he tow hook o r on t he production data plate (e.g. DIN 74051 and DIN 74052).

There are also tow hooks with special type approval, who se values are greater than the ones mentioned in the above standards.

These hooks may in any case be subjected to restrictions depending on the trailers used (e.g. drawbar length). In addition this can

imply that the rear cross member should be further reinforced and a subframe runner of larger size be fitted.

For mechanical attachment devices designed for mid-axled trailers, the Dc, S and V values are defined by the following equations:

Dc = g ⋅

(T ⋅ C)

(T + C)

V = a ⋅

D = representative value of the class of jaw (kN). This is defined as the technical reference force for the horizontal force between the towing vehicle and

the trailer;

g = acceleration due to gravity (m/s

T = maximum weight (in tonnes) of the towing vehicle;

T+S = maximum weight (in tonnes) of the towing vehicle + the vertical load of a trailer with a centre axle;

R = maximum weight (in tonnes) of the trailer;

S = value of the static vertical load (in tonnes) which, in static conditions, is transmitted to the point of attachment.

Smustbe≤ 0,1 ⋅ R ≤ 1000kg;

C = sum of the maximum axle loads (in tonnes) of the trailer with a centre axle at maximumload. It is equal to the maximumweight of the trailer with a centre

axle less the static vertical load (C = R - S);

V = value V of the intensity of the theoretical dynamic vertical force;

a = for the equivalent acceleration at the point of attachment, as a function of the rear suspension of the towing unit, use the following values:

-a=1.8m/s

-a=2.4m/s

X = length of the load surfaces (m);

l = theoretical length of the drawbar (distance between the centre of the drawbar towing eye and the centre line of the trailer axle (m));

2/l2

X

≥ 1 if the result is less than 1, use the value 1.

2

for air susp ension;

2

for other su sp en sion types;

2

);

2

X

2

l

= (kN)

⋅ C(kN)

Example for calculating the class of towing gear for trailers with a centre axle

Let us c onsider a Massif chassis cab vehicle with maximum weight 2800 kg that is to be used to tow a mid-axled

trailer weighing 3000kg w ith S = 250 kg, load surface length of 5m and theoretical drawbar length of 4m.

Therefore, from the data

1. S = 0.25 t

2. C = R — S = 3.0 - 0.25 = 2.75 t

3. (T + S) = 2.8 + 0.25 = 3.05 t

2/l2

4. X

=25/16=1.5

we obtain:

= 9.81 x (2.8 x 2.75) / (2.8 + 2.75) = 13.61 kN, and V = 2.4 x 1.5 x 2.75 = 10.3 kN

D

c

Installing a Towing Device

Print 603.93.811 Base - April 2008

Page 42

2-18

A50-X

OPERATIONS ON THE VEHICLE

M

ASSIF

The use of trailers with centre axles (rigid tow bar trailers with single or tandem axles), with respect to articulated tow bar trailers,

entails an increase in bending st ress on the rear chassis overhang as well as an increased torsional stress of the rear towing cross

member resulting from the vertical static and dynamic loads which the tow bar exerts on the hook (for example when braking or

on bumpy roads).

Two tow hooks are available as options: one fixed and one mobile, with specification s as shown in the following table (see Table 2.10)

Table 2.10 - Approved towing hooks available

Maker Type Class D(kN) DC(kN) EC approval no.

LAFUENTE EE0146

LAFUENTE EE0180

-

22.5 15,42 e 9*94/20*94/20*2909* ???

22.5 15,42 e9*94/20*94/20*2918* ???

The following table shows S maximum admitted value for original t owing cross member when towing a central axle trailer.

Model Maximum S (kN)

Chassis cab 125

2.6.3 Kinds of hook

S) Ball hooks

In fitting the ball hook, in accordance with the manufacturer’s instructions, it is necessary to observe th e guidelines laid down

by the national and international regulations (e.g., EC Directives).

If required, the installer will need to present the necessary documentation to comply with the requirements of the law.

The automatic hook for the truck version can also be fitted to the same crossmembers provided for the ball hook.

S) Removable hook

When fitting the removable hook, carried out in accordance with the hook manufacturer’s instructions, the gu idelines laid down

in national and international regulations must be respected (e.g. EC directives).

If required, the installer will need to present the necessary documentation to comply with the requirements of the law.

The automatic the hook for the truck version may also be fitted to the crossmembers provided for the removable hook.

Installing a Towing Device

Base - April 2008 Print 603.93.811

Page 43

MASSIF

OPERATIONS ON THE VEHICLE

2-19

2.6.4 Lowered Rear Cross Member

If the type of trailer used requires that the tow hook be positionedlower than originally intended, IVECO may issue authorisation

for the original cross member to be lowered or for an additional cross member (of the original type) to be fitted in a lower position.

Figure 2.2 shows an example.

The installation of the new cross member in its new position must be carried out in the same manner as before, using the same

type (diameter and class) of bolt.

Figure 2.2

Figure 2.3

WELD THE LOWER PART OF

BOTH PLATES ALONG THIS LENGTH

2 POSITIONS

Figure 2.4

2 POSITIONS

SECTION A-A

121797

Fixed hook

121872

Removable hook

121873

A device to prevent th e bolts from loosening must be adopted for the joints.

Installing a Towing Device

Print 603.93.811 Base - April 2008

Page 44

2-20

OPERATIONS ON THE VEHICLE

M

ASSIF

Remarks about the Payload

It sh ould be ascertained that th e static drawbar load does not cause the allowable load on the rear axle or axles to be exceeded

and that the required minimum load acting on the front axle is adhered to see point 1.13.3.

Increasing the Towable Mass

For those vehicles which IVECO regards as suitable for towing a trailer, a request may be submitted to evaluate the possibility

of authorising a towable mass exceeding that which is normally permitted.

Such authorisation will include the conditions that must be complied with an d, where necessary, specifications concerning modifications and work to be carried out on the vehicle.

These include possible reinforcements to the standard cross member (see Figure 2.2), the instructions for installing a reinforced cross

member when available, and those on the brake system to be made.

The tow hook must be suitable for the new use. Its connecting flange must match that of the cross member.

To fasten the cross member to the chassis frame, preferably use flanged head nuts and bolts o r hex head screws of minimum class

8.8. Use self-locking nuts.

Rating plates

Some c o u n t ries require a plate t o be fitted, near the towing device, giving the maximum permitted towable weight and vertical

load. If not already fitted, this must be done by the bodybuilder.

2.7 Installing a Supplementary Axle

Supplementary axles are not approved for use on the vehicle.

2.8 Modifying the Drive Line

Modifications to the vehicle transmission are not allowed.

Installing a Towing Device

Base - April 2008 Print 603.93.811

Page 45

MASSIF

Modifi cations of the Engine Air I ntake andE xhaust System s

OPERATIONS ON THE VEHICLE

2.9 Modifications of the Engine Air Intake and Exhaust Systems

2.9.1 Intake

The specifications of the engine air intake and exhaust systems must not be altered without authorisation by Iveco. Operations

carried out should not alter the vacuum levels (for the intake) and the original counterpressure levels (for the exhaust).

Table 2.11 - Maximum back-pressure permitted at the intake and exhaust, at the rated engine speed and full load

2-21

Engine Engine Code

Back-pressure at the

exhaust (kPa)

back-pressure at the intake (kPa)

Minimum/maximum

.15 F1CE0481F*A 38 1.6 - 8.5

Any work done on the exhaust system of the vehicle requires that the vehicle be ho mologated again with regard to noise and smoke

wherever government regulat ions require it. The air intake must be positioned to avoid the intake of hot air from the engine and/or

of dusty air or snow and rain. The apertures for the intake of air which may have to be made in the bodies of vans, must have a

working surface of not less than two and a half times that of the master hose located upstream of the filter. These apertures (e.g.

openings in the grill) must be of such a dimension that they do not become obstructed. It is prohibited to alter the air filer or replace

the origin al filter with a lower air capacity unit. Modifications to the equipment (fuel injection pump, regulator, injectors etc.) are

not permissible as this may alter the correct functioning of the engine and adversely affect the exhaust emissions.

2.9.2 Engine exhaust

Pipes must be laid as straight as possible, bend angles must not exceed 90° and radiuses must be at least 2.5 times the outer

diameter. Leave a big enough gap between the exhaust piping and the electric system, plastic piping, spare wheel (minimum 150

mm), steel fuel tank (minimum 100 mm), etc. Lower values (e.g. 80 mm) may be approved if steel guard panels are used. Further

reductions require the use of heat insulation or the replacement of plastic pipes with steel pipes. Modifications to the silencer body

are not permitted and neither is it permitted to make changes to equipment (injection pump, regulator, injectors, etc.) that could

impair efficient engine operation and affect exhaust gas emissions.

Modifications of the Engine Air Intake and Exhaust Systems

Print 603.93.811 Base - April 2008

Page 46

2-22

OPERATIONS ON THE VEHICLE

Modificati onof the Engin eCool ing System

M

ASSIF

2.10 Modification of the Engine Cooling System

The proper functioning of the original system, especially in c o n nection with the radiator, the free surface of the radiator and hoses

(dimensions and layout) must not be tampered with. In any case, whenever modifications must be made that entail work on the

engine coolin g system (e.g., modifications to the cab), the following points must be considered:

- the useful area for the passage of air for the c ooling of the radiator must not be less than that which is available on vehicles with

the standard cab. Maximum venting of air from the engine compartment must be ensured and care must be taken - possibly

using shields or baffles - to avoid stagnant air pockets or back flow of air. The performance of the fan must not be altered;

- if it is necessary to re-position the hoses this must be done without affec t ing the complete filling of the system (which must occ ur

at a continuous flow. without forming blockages at the mouth) or the normal flow of water. The maximum stabilising t emperature

of the water must not be altered even under the most severe operating conditions;

- hoses must be located so that air pockets are not formed (i.e avoiding air traps and providing appropriate bleeding points) that

could hinder the circulation of water. So, it is necessary to check that the water pump primes immediately on starting the engine

and later operates with the engine idling (accelerate a few times, if necessary) even when the circuit is not pressurized.In addition

to this check that the delivery pressure of the water pump, when the engine is running under no load and at maximum RPM,

is n ot lower than 1 bar;

- always reinstall the radiator anti-clogging protection after making alterations to the engine cooling system.

Modification of the Engine Cooling System

Base - April 2008 Print 603.93.811

Page 47

MASSIF

Workonthe Suspension

OPERATIONS ON THE VEHICLE

2-23

2.11 Work on the Suspension

2.11.1 General Specifications

Company authorisation must be obtained to re-work the suspension systems and springs (e.g.

additional spring leaves, different cambering etc.) since these are important components for the

!

operation of the vehicle.

As a general rule no modification of the parabolic springs is permitted. On vehicles equipped with these springs, installation of

elastic rubber components may be authorised for special versions or operations in order to increase the stiffness of the suspension.

In very specific cases, an d for specific uses, the possibility of adding an extra leaf to the parabolic spring may be evaluated. This

operation should be carried out only by specialised firms after approval from IVECO.

It is forbidden to fit a parabolic spring on one side and a semi-elliptic spring on the other side on the same axle.

On vehicles equipped with a load apportioning valve (LAV) for the braking syst em, modification of the rear suspension requires

adjustment of this LAV valve (see point 2.15).

Modifications to the rear suspension

Changing the features of the rear spring (e.g., no. of leaves, spring rate etc.) requires adjusting the brake load apportioning valve

so as not to alter the vehicle’s braking performance. When work on the suspensions follows rather large changes in the permitted

loads on the axle(s) or the total weight of the vehicle, it may be necessary to adapt the braking forces to permit compliance with

the requirements for the brake regulations in force. The necessary instructions will be given on the documentation issued by IVECO.

If the vehicle is equipped with the ABS system, no adjustment need be made.

If the modification of the specifications of the rear spring does not require c hanging loads on both axles and total weight, the brake

load apportioning valve must be adjusted by an IVECO dealer. So as not to alter the vehicle’s braking capacity, it is necessary to

observe the ground load / brake pressure ratio (under various load conditions) given on the rating plate of the brake load

apportioning valve.

In these cases, to adjust the brake load apportioning valve, follow the instructions given in point 2.15.4, applying a load on hole 9

corresponding to the stiffness of the new spring.

It will be necessary to check the ground load / brake pressure ratio is observed for all load conditions.

Should this not be, contact IVECO for a further check on compliance with the brake regulations.

Changing the data on the rating plate of the load apportioning valve requires it to be replaced with a new on e giving the new data.

Work on the Suspension

Print 603.93.811 Base - April 2008

Page 48

2-24

OPERATIONS ON THE VEHICLE

Heating/Ai rcon ditioni ngsys temmodi fications

M

ASSIF

2.12 Heating/Air conditioning system modifications

2.12.1 Installation of a Supplementary Heating System

When the installation of a supplementary heating system is deemed necessary, it is advisable to use the types recommended

by IVECO.

For vehicles on which IVECO has not anticipated the use of supplementary heaters, the installation should be carried out in compliance with the supp lier’ s instructions (i.e . heater arrangement, piping, electrical system etc.) and following the directions given

below.

All national rules and regulations relevant to the matter should be adhered to (i.e. inspections, particula r installation for dangerous

cargo transpor ta tio n etc.). The supplem e nta ry heating system must not make use of the equipment that is specific to the vehicle

which is subject to approval if the use is liable to impair or alter the performance of the equipme nt.

Furthermore:

- ensure correct operation of the vehicle components and equipment (i.e. cooling system);

- check the electrical system to ensure that the battery capacity and alternator output is sufficient for the higher current requirements (see point 2.16). Provide the new circuitry with a protection fuse;

- connect the intake of the newly added fuel system to the reservoir connected to the engine fuel return line. Direct feed from

the vehicle fuel tank is permitted only if this is independent from the engine fuel system and the new circuit is perfectly leakproof;

- trace pipe and cable paths, the location of brackets and hoses bearing in mind that the overall dimensions and heat affect the

various units on the chassis. Avoid runs and arrangements that could lead to hazards when the vehicle is running. Use shields

or armouring if necessary;

a) When in stallin g a water heater, original vehicle heating and engine cooling circuits are involved (see point 2.10), it is advisable