INFICON XTM-2 User Manual

O P E R A T I N G M A N U A L

XTM/2

Deposition Monitor

IPN 074-186

O P E R A T I N G M A N U A L

XTM/2

Deposition Monitor

IPN 074-186S

T W O T E C H N O L O G Y P L A C E |

A LT E L A N D S T R A S S E 6 |

B O N N E R S T R A S S E 4 9 8 |

E A S T S Y R A C U S E , N Y 1 3 0 5 7 - 9 7 1 4 U S A |

L I - 9 4 9 6 B A L Z E R S , L I E C H T E N S T E I N |

D - 5 0 9 6 8 C O L O G N E , G E R M A N Y |

P h o n e : + 3 1 5 . 4 3 4 . 11 0 0 |

P h o n e : + 4 2 3 . 3 8 8 . 3 111 |

P h o n e : + 4 9 . 2 2 1 . 3 4 7 . 4 0 |

F a x : + 3 1 5 . 4 3 7 . 3 8 0 3 |

F a x : + 4 2 3 . 3 8 8 . 3 7 0 0 |

F a x : + 4 9 . 2 2 1 . 3 4 7 . 4 1 4 2 9 |

E m a i l : r e a c h u s @ i n f i c o n . c o m |

E m a i l : r e a c h . l i e c h t e n s t e i n @ i n f i c o n . c o m |

E m a i l : r e a c h . g e r m a n y @ i n f i c o n . c o m |

V I S I T U S O N T H E W E B AT w w w. i n f i c o n . c o m

© 2 0 0 1 I N F I C O N 0 9 2 3 0 4

Trademarks

The trademarks of the products mentioned in this manual are held by the companies that produce them.

INFICON®, CrystalSix® are trademarks of INFICON Inc.

All other brand and product names are trademarks or registered trademarks of their respective companies.

The information contained in this manual is believed to be accurate and reliable. However, INFICON assumes no responsibility for its use and shall not be liable for any special, incidental, or consequential damages related to the use of this product.

©2001 All rights reserved.

Reproduction or adaptation of any part of this document without permission is unlawful.

DECLARATION

OF

CONFORMITY

This is to certify that this equipment, designed and manufactured by:

INFICON Inc.

2 Technology Place

East Syracuse, NY 13057

USA

meets the essential safety requirements of the European Union and is placed on the market accordingly. It has been constructed in accordance with good engineering practice in safety matters in force in the Community and does not endanger the safety of persons, domestic animals or property when properly installed and maintained and used in applications for which it was made.

Equipment Description: |

XTM/2 Deposition Monitor, including the Oscillator |

|

|

|||

|

|

Package and Crystal Sensor as properly installed. |

|

|

||

Applicable Directives: |

73/23/EEC as amended by 93/68/EEC |

|

|

|

||

|

|

89/336/EEC as amended by 93/68/EEC |

|

|

||

Applicable Standards: |

EN 61010-1 : 1993, Fixed Equipment |

|

|

|||

|

|

EN 55011, Group 1, Class A : 1991 |

|

|

|

|

|

|

EN 50082-2 : 1995 |

|

|

||

CE Implementation Date: |

January 3, 1995 |

|

|

|||

|

|

Revised to include EMC Directive: January 2, 1997 |

|

|

||

Authorized Representative: |

Gary W. Lewis |

|

|

|||

|

|

Vice President - Quality Assurance |

|

|

||

|

|

INFICON Inc. |

|

|

||

ANY QUESTIONS RELATIVE TO THIS DECLARATION OR TO THE SAFETY OF INFICON'S PRODUCTS SHOULD BE DIRECTED, IN WRITING, TO THE QUALITY ASSURANCE DEPARTMENT AT THE ABOVE ADDRESS.

11/14/01

Registration Card

Thank you for selecting INFICON® instrumentation.

Please fill out and return this postage paid card as soon as possible.

Model |

|

|

|

|

|

Serial # |

|

|

|

|

|

|

|||

Name |

|

|

|

|

|

|

|

|

|

|

|

|

|

||

Title |

|

|

|

|

|

|

|

|

|

|

|

|

|

||

Company |

|

|

|

|

|

|

Bldg./MS |

|

|||||||

Address |

|

|

|

|

|

|

|

Phone # |

|

||||||

City |

|

|

|

|

State |

|

|

Zip |

|

|

|

||||

Country |

|

|

Fax# |

|

|

|

|||||||||

Your help is very important in our continuing efforts to improve our manuals. Using the table below, please circle the appropriate rank for each aspect.

In the Importance column, please indicate the importance of each aspect.

Manual Title

Part # (see Title Page) 074-

|

|

|

|

|

|

Importance |

|

|

Very |

|

No |

|

Very |

(ranked from |

|

Aspect |

Dissatisfied |

Satisfied |

1 to 5, where |

||||

Dissatisfied |

Opinion |

Satisfied |

|||||

|

|

|

|

|

|

1 is low and |

|

|

|

|

|

|

|

5 is high) |

|

|

|

|

|

|

|

|

|

Found everything |

VD |

D |

NO |

S |

VS |

|

|

I needed |

|

||||||

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

Easy to read |

VD |

D |

NO |

S |

VS |

|

|

|

|

|

|

|

|

|

|

Easy to use |

VD |

D |

NO |

S |

VS |

|

|

|

|

|

|

|

|

|

|

Relevant to |

VD |

D |

NO |

S |

VS |

|

|

my work |

|

||||||

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

Accurate |

VD |

D |

NO |

S |

VS |

|

|

information |

|

||||||

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

Well-written |

VD |

D |

NO |

S |

VS |

|

|

|

|

|

|

|

|

|

|

Well-organized |

VD |

D |

NO |

S |

VS |

|

|

|

|

|

|

|

|

|

|

Technical Enough |

VD |

D |

NO |

S |

VS |

|

|

|

|

|

|

|

|

|

|

Helped me |

VD |

D |

NO |

S |

VS |

|

|

solve problems |

|

||||||

|

|

|

|

|

|

||

|

|

|

|

|

|

|

If you have additional comments, please contact INFICON®.

T W O T E C H N O L O G Y P L A C E |

A LT E L A N D S T R A S S E 6 |

B O N N E R S T R A S S E 4 9 8 |

E A S T S Y R A C U S E , N Y 1 3 0 5 7 - 9 7 1 4 U S A |

L I - 9 4 9 6 B A L Z E R S , L I E C H T E N S T E I N |

D - 5 0 9 6 8 C O L O G N E , G E R M A N Y |

P h o n e : + 3 1 5 . 4 3 4 . 11 0 0 |

P h o n e : + 4 2 3 . 3 8 8 . 3 111 |

P h o n e : + 4 9 . 2 2 1 . 3 4 7 . 4 0 |

F a x : + 3 1 5 . 4 3 7 . 3 8 0 3 |

F a x : + 4 2 3 . 3 8 8 . 3 7 0 0 |

F a x : + 4 9 . 2 2 1 . 3 4 7 . 4 1 4 2 9 |

E m a i l : r e a c h u s @ i n f i c o n . c o m |

E m a i l : r e a c h . l i e c h t e n s t e i n @ i n f i c o n . c o m |

E m a i l : r e a c h . g e r m a n y @ i n f i c o n . c o m |

V I S I T U S O N T H E W E B AT w w w. i n f i c o n . c o m

BUSINESS REPLY MAIL

FIRST CLASS PERMIT NO. 49 EAST SYRACUSE, NEW YORK

POSTAGE WILL BE PAID BY ADDRESSEE

INFICON INC.

Two Technology Place

East Syracuse, New York 13057-9714

Warranty

WARRANTY AND LIABILITY - LIMITATION: Seller warrants the products manufactured by it, or by an affiliated company and sold by it, and described on the reverse hereof, to be, for the period of warranty coverage specified below, free from defects of materials or workmanship under normal proper use and service. The period of warranty coverage is specified for the respective products in the respective Seller instruction manuals for those products but shall in no event exceed one (1) year from the date of shipment thereof by Seller. Seller's liability under this warranty is limited to such of the above products or parts thereof as are returned, transportation prepaid, to Seller's plant, not later than thirty (30) days after the expiration of the period of warranty coverage in respect thereof and are found by Seller's examination to have failed to function properly because of defective workmanship or materials and not because of improper installation or misuse and is limited to, at Seller's election, either (a) repairing and returning the product or part thereof, or (b) furnishing a replacement product or part thereof, transportation prepaid by Seller in either case. In the event Buyer discovers or learns that a product does not conform to warranty, Buyer shall immediately notify Seller in writing of such non-conformity, specifying in reasonable detail the nature of such non-conformity. If Seller is not provided with such written notification, Seller shall not be liable for any further damages which could have been avoided if Seller had been provided with immediate written notification.

THIS WARRANTY IS MADE AND ACCEPTED IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, WHETHER OF MERCHANTABILITY OR OF FITNESS FOR A PARTICULAR PURPOSE OR OTHERWISE, AS BUYER'S EXCLUSIVE REMEDY FOR ANY DEFECTS IN THE PRODUCTS TO BE SOLD HEREUNDER. All other obligations and liabilities of Seller, whether in contract or tort (including negligence) or otherwise, are expressly EXCLUDED. In no event shall Seller be liable for any costs, expenses or damages, whether direct or indirect, special, incidental, consequential, or other, on any claim of any defective product, in excess of the price paid by Buyer for the product plus return transportation charges prepaid.

No warranty is made by Seller of any Seller product which has been installed, used or operated contrary to Seller's written instruction manual or which has been subjected to misuse, negligence or accident or has been repaired or altered by anyone other than Seller or which has been used in a manner or for a purpose for which the Seller product was not designed nor against any defects due to plans or instructions supplied to Seller by or for Buyer.

This manual is intended for private use by INFICON® Inc. and its customers.

Contact INFICON before reproducing its contents.

NOTE: These instructions do not provide for every contingency that may arise in connection with the installation, operation or maintenance of this equipment. Should you require further assistance, please contact INFICON.

T W O T E C H N O L O G Y P L A C E |

A LT E L A N D S T R A S S E 6 |

B O N N E R S T R A S S E 4 9 8 |

E A S T S Y R A C U S E , N Y 1 3 0 5 7 - 9 7 1 4 U S A |

L I - 9 4 9 6 B A L Z E R S , L I E C H T E N S T E I N |

D - 5 0 9 6 8 C O L O G N E , G E R M A N Y |

P h o n e : + 3 1 5 . 4 3 4 . 11 0 0 |

P h o n e : + 4 2 3 . 3 8 8 . 3 111 |

P h o n e : + 4 9 . 2 2 1 . 3 4 7 . 4 0 |

F a x : + 3 1 5 . 4 3 7 . 3 8 0 3 |

F a x : + 4 2 3 . 3 8 8 . 3 7 0 0 |

F a x : + 4 9 . 2 2 1 . 3 4 7 . 4 1 4 2 9 |

E m a i l : r e a c h u s @ i n f i c o n . c o m |

E m a i l : r e a c h . l i e c h t e n s t e i n @ i n f i c o n . c o m |

E m a i l : r e a c h . g e r m a n y @ i n f i c o n . c o m |

V I S I T U S O N T H E W E B AT w w w. i n f i c o n . c o m

IPN 074-186S

XTM/2 Operating Manual

Table Of Contents

Chapter 1

Introduction and Specifications

1.1 Instrument Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.1.1 Notes, Cautions, Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.1.2 General Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.1.3 Earth Ground. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1.1.4 Main Power Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

1.2 Introduction to the Instrument . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

1.3 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

1.3.1 Specifications XTM/2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

1.3.1.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

1.3.1.2 Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

1.3.1.3 Recorder Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

1.3.1.4 Input/Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

1.3.1.5 Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

1.3.1.6 Process Variable Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

1.3.1.7 Hardware Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

1.3.1.8 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

1.3.1.9 Mechanical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

1.3.2 Transducer Specifications (optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

1.3.3 XIU (Crystal Interface Unit) Specifications . . . . . . . . . . . . . . . . . . . . . . . 1-9

1.4 Guide to the Use of the Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

1.5 How To Contact Customer Support . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

1.5.1 Application Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

1.5.2 Field Service and Repair Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

1.5.3 Returning Your Instrument . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

Chapter 2

Quick Use Guide

2.1 Unpacking, Initial Inspection and Inventory . . . . . . . . . . . . . . . . . . . . . . 2-1

2.1.1 Unpacking and Inspection Procedures . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.1.2 Inventory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.1.2.1 XTM/2 System Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2.1.2.2 Ship Kit - XTM/2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2.2 Voltage Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2.3 Installation Guide and Schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

TOC - 1

XTM/2 Operating Manual

2.4 XTM/2 Front Panel Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

2.4.1 XTM/2 Front Control Panel Description . . . . . . . . . . . . . . . . . . . . . . . . 2-9

2.4.2 XTM/2 Display Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

2.5 XTM/2 Rear Panel Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

2.5.1 Power Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

2.5.2 Configuration Switches 1 & 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-15

2.5.3 Grounding Stud . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

2.5.4 System I/O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

2.5.5 RS232 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-19

2.5.6 Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-20

2.5.7International Warning Symbol for

|

Users and Technicians . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2-20 |

2.5.8 |

Recorder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2-20 |

2.5.9 |

Comm. Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2-21 |

2.5.10 |

Manufacturer’s Identification and |

|

|

Serial Number Plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2-21 |

2.6 |

Operation as a Deposition Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2-22 |

2.6.1 |

Monitoring - Systems Without a Source Shutter . . . . . . . . . . . . . . . . . |

2-22 |

2.6.2 |

Monitoring - Systems with a Source Shutter . . . . . . . . . . . . . . . . . . . . |

2-23 |

2.6.3 |

Rate Sampling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2-23 |

2.7 |

Nontraditional Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2-24 |

2.7.1 |

Etching . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2-24 |

2.7.2 |

Immersion in Liquids . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2-24 |

2.7.3 |

Biological . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2-25 |

2.7.4 |

Measurement of Liquids . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2-25 |

2.7.5 |

Use as a Frequency Counter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2-25 |

2.7.6 |

Contamination Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2-26 |

Chapter 3

Installation

3.1 |

Installing the Instrument - Details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-1 |

3.1.1 |

Control Unit Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-1 |

3.2 |

Electrical Grounding and Shielding Requirements . . . . . . . . . . . . . . . . |

3-1 |

3.2.1 |

Verifying / Establishing Earth Ground . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-2 |

3.2.2 |

Connections to Earth Ground . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-2 |

3.2.3 |

Minimizing Noise Pickup from External Cabling . . . . . . . . . . . . . . . . . . |

3-3 |

3.3 |

Connection to Rear Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-4 |

3.3.1 |

The BNC Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-4 |

3.3.2 |

The "D" Shell Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-4 |

3.4 |

Sensor Selection Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-6 |

3.5 |

Guidelines for Transducer Installation . . . . . . . . . . . . . . . . . . . . . . . . . |

3-7 |

TOC - 2

IPN 074-186S

IPN 074-186S

XTM/2 Operating Manual

3.5.1 Sensor Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7 3.5.2 CrystalSix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10 3.5.3 Check List for Transducer Installation . . . . . . . . . . . . . . . . . . . . . . . . . 3-11 3.6 Use of the Test Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11 3.6.1 Operational Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12 3.7 Input and Output Details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14 3.7.1 Relays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14 3.7.2 Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15 3.7.3 Chart Recorder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15 3.8 Computer Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16 3.8.1 Communications Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16 3.8.1.1 IEEE Settings for a National Instruments IEEE-GPIB Board . . . . . . . . 3-17 3.8.2 Basic Command Structure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-18 3.8.3 Service Requests and Message Available . . . . . . . . . . . . . . . . . . . . . . 3-20 3.8.4 Datalogging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-21 3.8.5 Computer Command Details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-22 3.8.5.1 Echo Command. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-22 3.8.5.2 Hello Command. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-22 3.8.5.3 Query Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-22 3.8.5.4 Update Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-23 3.8.5.5 Status Command. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-23 3.8.5.6 Remote Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-26 3.8.6 Examples of RS232 Programs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-27 3.8.6.1 Example of SEMI II Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-29 3.8.7 Example of IEEE488 Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-31

Chapter 4

Programming System Operation Details

4.1 State and Measurement System Sequencing . . . . . . . . . . . . . . . . . . . . 4-1

4.2 State Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

4.3 Parameter Limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

4.4 Crystal Fail . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

4.5 Crystal Fail Inhibit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

4.6 Crystal Life and Starting Frequency. . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Chapter 5

Calibration and Measurement

5.1 Importance of Density, Tooling and Z-ratio . . . . . . . . . . . . . . . . . . . . . . 5-1

5.2 Determining Density . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5.3 Determining Tooling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

TOC - 3

XTM/2 Operating Manual

5.4 Laboratory Determination of Z-ratio . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

5.5 Measurement Theory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

5.5.1 Basics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

5.5.2 Monitor Crystals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

5.5.3 Period Measurement Technique . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

5.5.4 Z-Match Technique . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

5.5.5 Active Oscillator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

5.5.6 ModeLock Oscillator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-12

Chapter 6

Adjustments and Problems

6.1 LCD Contrast Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

6.2 Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

6.2.1 Powerup Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

6.2.2 Parameter Update Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

6.2.3 Other Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

6.3 Troubleshooting Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

6.3.1 Major Instrument Components, Assemblies and Mating Connectors. . . 6-3

6.3.2 Troubleshooting the Instrument . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

6.3.3 Troubleshooting Transducers/Sensors . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

6.3.4 Troubleshooting Computer Communications . . . . . . . . . . . . . . . . . . . 6-11

6.3.5 Leaf Spring Concerns. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-14

6.4 Replacing the Crystal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-15

6.4.1 Standard and Compact. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-16

6.4.2 Shuttered and Dual Sensors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-17

6.4.3 Bakeable Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-17

6.4.4 Sputtering Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-18

6.4.5 Crystal Snatcher. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-19

6.5Crystal Sensor Emulator

|

IPN 760-601-G1 or 760-601-G2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

6-20 |

6.5.1 |

Diagnostic Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

6-21 |

6.5.1.1 |

Measurement System Diagnostic Procedure . . . . . . . . . . . . . . . . . . . |

6-21 |

6.5.1.2 |

Feed-Through Or In-Vacuum Cable |

|

|

Diagnostic Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

6-22 |

6.5.1.3 |

Sensor Head Or Monitor Crystal |

|

|

Diagnostic Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

6-23 |

6.5.1.4 |

System Diagnostics Pass But |

|

|

Crystal Fail Message Remains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

6-24 |

6.5.2 |

% XTAL Life . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

6-24 |

6.5.3 |

Sensor Cover Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

6-25 |

6.5.3.1 |

Compatible Sensor Heads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

6-25 |

TOC - 4

IPN 074-186S

XTM/2 Operating Manual

6.5.3.2 Incompatible Sensor Heads. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-25

6.5.4 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-26

Appendix A

Table of Densities and Z-ratios

Index

IPN 074-186S

TOC - 5

XTM/2 Operating Manual

IPN 074-186S

TOC - 6

IPN 074-186S

XTM/2 Operating Manual

Chapter 1

Introduction and Specifications

1.1 Instrument Safety

1.1.1 Notes, Cautions, Warnings

When using this manual, please pay attention to the NOTES, CAUTIONS and WARNINGS found throughout. For the purposes of this manual they are defined as follows:

NOTE: Pertinent information that is useful in achieving maximum instrument efficiency when followed.

CAUTION

CAUTION

Failure to heed these messages could result in damage to the instrument or the loss of data.

WARNING

Failure to heed these messages could result in personal injury.

WARNING

WARNING

Dangerous voltages are present. Failure to heed these messages could result in personal injury.

1 - 1

XTM/2 Operating Manual

1.1.2 General Safety Information

WARNING

WARNING

There are no user serviceable components within the instrument case.

Potentially lethal voltages are present when the line cord or system I/O are connected.

Refer all maintenance to qualified personnel.

CAUTION

CAUTION

This instrument contains delicate circuitry which is susceptible to transient power line voltages. Disconnect the line cord whenever making any interface connections. Refer all maintenance to qualified personnel.

IPN 074-186S

1 - 2

XTM/2 Operating Manual

1.1.3 Earth Ground

This instrument is connected to earth via a sealed three-core (three-conductor) power cable, which must be plugged into a socket outlet with a protective earth terminal. Extension cables must always have three conductors, including a protective earth conductor.

WARNING

WARNING

Never interrupt the protective earth circuit.

Any interruption of the protective earth connection inside or outside the instrument, or disconnection of the protective earth terminal is likely to make the instrument dangerous.

This symbol indicates where the protective earth ground is connected inside the instrument. Never unscrew or loosen this connection.

IPN 074-186S

1 - 3

XTM/2 Operating Manual

1.1.4 Main Power Connection

WARNING

WARNING

This instrument has a line voltage present on the primary circuits whenever it is plugged into a main power source.

Never remove the covers from the instrument during normal operation.

There is no operator serviceable items within this instrument.

Removal of the top or bottom covers must be done only by a technically qualified person.

In order to comply with accepted safety standards, this instrument must be installed into a rack system which contains a mains switch. This switch must break both sides of the line when it is open and it must not disconnect the safety ground.

IPN 074-186S

1 - 4

XTM/2 Operating Manual

1.2 Introduction to the Instrument

The XTM/2 is an economical quartz crystal transducer type deposition/etch process monitor that incorporates the patented (US#5,117,192 — May 27,1992) ModeLock measurement system. This innovative system provides process security, measurement speed and precision at a level that no active oscillator based instrument can provide.The Liquid Crystal Display of the XTM/2 is easily read and keeps the operator continuously informed with pertinent deposition data including rate, thickness and elapsed time. Special messages such as Crystal Fail, achievement of setpoints, measurement units or etch mode are clearly presented to reduce operator uncertainty and eliminate the possibility of costly mistakes. Basic instrument operation is easily verified with a built-in test mode and preprogrammed parameters.The set up and storage of nine different process variable sets is provided.The RATE and THICKNESS displays as well as the limit parameters may be read and programmed in the traditional kÅ units or directly in mass (mg, µgm,ngm).

All units come with RS232 (and support Data Rates to 9,600 Baud).The SECSII protocol is supported.The optional computer interface is IEEE-488. Four relays are used to manipulate various external devices such as source and sensor shutters, heaters or valves.There are five input lines to provide the ability to sense and react to discrete external signals.These instruments are fully compatible with the complete family of INFICON transducers, excluding Dual and CrystalSix®.

IPN 074-186S

1 - 5

XTM/2 Operating Manual

1.3 Specifications

At the time of this manual’s writing, the specifications for performance are as published below. INFICON continuously improves its products, affecting the instrument’s performance.

1.3.1 Specifications XTM/2

1.3.1.1 General

Usage . . . . . . . . . . . . . . . . . . . . . . Indoor use only. Altitude Range . . . . . . . . . . . . . . . . Up to 2000 m (6,561 ft) Pollution Degree . . . . . . . . . . . . . . 1—No pollution occurs

Overvoltage Category . . . . . . . . . . 2—Local level, appliances, etc.

Cleaning . . . . . . . . . . . . . . . . . . . . The unit enclosure can be safely cleaned with a mild detergent or spray cleaner designed for that purpose. Care should be taken to prevent any cleaner from entering the unit.

1.3.1.2 Measurement

Crystal Range & Precision . . . . . . . 6.0 to 5.0 MHz +/- 0.1 Hz (per 250 msec sample)

Thickness & Rate Resolution* . . . . 0.123Å (per 250 msec sample)

* Material density = 1.0; Z-ratio = 1.0; crystal frequency = 6 MHz.

Å/S/M = Angstroms/second/measurement. Thickness accuracy . . . . . . . . . . . . 0.5%

Measurements/second . . . . . . . . . . 4 max., user selectable multiple measurement averaging to 16 seconds in four ranges.

1.3.1.3 Recorder Output

Voltage . . . . . . . . . . . . . . . . . . . . . 0 to ±10 v

Resolution . . . . . . . . . . . . . . . . . . . 13 bits over full range (one reserved for sign)

Update Rate . . . . . . . . . . . . . . . . . 4 Hz

Function. . . . . . . . . . . . . . . . . . . . . Rate / Thickness / Mass

Maximum Load . . . . . . . . . . . . . . . 2.0 KOhm (100 Ohm internal impedance)

IPN 074-186S

1 - 6

IPN 074-186S

XTM/2 Operating Manual

1.3.1.4 Input/Output

Inputs . . . . . . . . . . . . . . . . . . . . . . 5 TTL inputs

Outputs . . . . . . . . . . . . . . . . . . . . . 4 SPST 2.5 amp relays rated

@ 30 V(dc) / 30 V(ac) / 42 V(peak) max. Scan/Change Rate . . . . . . . . . . . . 4 Hz

1.3.1.5 Display

Type . . . . . . . . . . . . . . . . . . . . . . . 2x multiplexed custom LCD

Thickness Resolution* . . . . . . . . . 1 Å

Rate Resolution* . . . . . . . . . . . . |

. .1 Å for 1 to 99.9 Å/sec |

|

1 Å for 100 to 999 Å/sec |

|

* Other units appropriately scaled. |

|

Enhanced resolution is achieved when |

|

multiple measurement averaging is |

|

employed. |

Update Rate . . . . . . . . . . . . . . . . . 1 Hz

1.3.1.6 Process Variable Storage

Quantity . . . . . . . . . . . . . . . . . . . . 9 sets Variables per set . . . . . . . . . . . . . . 6

1.3.1.7 Hardware Interface

Sensors . . . . . . . . . . . . . . . . . . . . 1, 15 pin D-Sub type

I/O

Standard (inputs/outputs) . . . . 5/4

Optional . . . . . . . . . . . . . . . . . None

Communications

Standard . . . . . . . . . . . . . . . . . RS232C, 9 Pin D-Sub type

Optional . . . . . . . . . . . . . . . . . IEEE-488

Chart Recorder . . . . . . . . . . . . . . . BNC

1 - 7

XTM/2 Operating Manual

1.3.1.8 Operation

Power Requirements

"115 V" input range. . . . . . . . . . 90 to 132 V(ac), 49 to 61 Hz, 45 VA max. fused at 3/8 Amp Type T fuse

"230 V" input range . . . . . . . . . 180 to 264 V(ac), 49 to 61 Hz, 45 VA max. fused at 3/16 Amp Type T fuse

Operating Temperature . . . . . . . . . 0 to 50 °C (32 to 122 °F)

1.3.1.9 Mechanical

Size . . . . . . . . . . . . . . . . . . . . . . . . 3.5" H x 8" W x 12" D

(89 mm H x 203 mm W x 305 D mm) Weight . . . . . . . . . . . . . . . . . . . . . . 6 lb. (2.7 kg)

1.3.2 Transducer Specifications (optional)

|

Max. Bakeout |

Size (Max. Envelope) |

Water Tube & |

Body & Holder |

IPN |

|

|

|

Temperature* |

|

Coax Length |

|

|

|

|

|

|

|

|

|

|

|

|

Standard Sensor |

130 °C |

1.063" x 1.33" x .69" high |

30" (762 mm) |

304 SS |

750-211-G1 |

|

|

|

|

(27 mm dia. x 34 mm x 17.5 mm high) |

|

|

|

|

|

|

|

|

|

|

|

|

|

Standard Sensor |

130 °C |

1.06" x 2.24" x .69" high |

30" (762 mm) |

304 SS |

750-211-G2 |

|

|

with Shutter |

|

(27 mm dia. x 57 mm x 17.5 mm high) |

|

|

|

|

|

|

|

|

|

|

|

|

|

Sputtering Sensor |

105 °C |

1.36" dia. x .47" high |

30" (762 mm) |

Au-plated BeCu |

007-031 |

|

|

|

|

(34.5 mm dia. x 11.8 mm high) |

|

|

|

|

|

|

|

|

|

|

|

|

|

Compact Sensor |

130 °C |

1.11" x 1.06" x 1.06" high |

30" (762 mm) |

304 SS |

750-213-G1 |

|

|

|

|

(28 mm x 27 mm x 27 mm high) |

|

|

|

|

|

|

|

|

|

|

|

|

|

Compact Sensor |

130 °C |

2.08" x 1.62" x 1.83" high |

30" (762 mm) |

304 SS |

750-213-G2 |

|

|

with Shutter |

|

(53 mm x 41 mm x 46 mm high) |

|

|

|

|

|

|

|

|

|

|

|

|

|

UHV Bakeable |

450 °C |

1.35" x 1.38" x .94" high |

12" (305 mm) |

304 SS |

007-219 |

|

|

Sensor |

|

(34 mm x 35 mm x 24 mm high) |

20" (508 mm) |

|

007-220 |

|

|

|

|

|

30" (762 mm) |

|

007-221 |

|

|

|

|

|

|

|

|

|

|

UHV Bakeable |

400 °C |

1.46" x 1.37" x 1.21" high |

12" (305 mm) |

304 SS |

750-012-G1 |

186S |

|

Sensor with Shutter |

|

(37 mm x 35 mm x 3.1 mm high) |

20" (508 mm) |

|

750-012-G2 |

||

|

|

074- |

|||||

|

|

|

30" (762 mm) |

|

750-012-G3 |

||

|

|

|

|

|

|

IPN |

|

Shutter Assembly |

400 °C |

two models available |

N/A |

300-series SS |

750-210-G1 |

||

|

|||||||

|

|

|

|

|

750-005-G1 |

|

|

|

|

|

|

|

(Sputtering) |

|

|

|

|

|

|

|

|

|

|

*For Bake only; waterflow is required for actual deposition monitoring. These temperatures are conservative maximum |

|

||||||

device temperatures, limited by the properties of Teflon (PTFE) at higher temperatures. In usage, the water cooling allows |

|

||||||

operation in environments that are significantly elevated, without deleterious affects. |

|

|

|

||||

|

|

|

|

|

|

|

|

1 - 8

IPN 074-186S

XTM/2 Operating Manual

1.3.3 XIU (Crystal Interface Unit) Specifications

The XTM/2 Series instruments use a new type of "passive intelligent" oscillator. It is available with cable lengths of 15’ (4.572 m), 30’ (9.144 m), 50’ (15.24 m), and 100’ (30.28 m) as IPN 757-305-G15, G30, G50, or G100, respectively.

Conventional, active style oscillators do not work with these instruments. In-vacuum cable lengths to a maximum of 2 m (6.6’) are supported with this new technology.

1.4 Guide to the Use of the Manual

This manual is configured to be used by both experienced and inexperienced deposition process engineers. For those with significant experience, especially on INFICON controllers, nearly all pertinent information is contained in Chapter 2, Quick Use Guide. Other sections contain the details that supplement the information in the quick use section.

Every user should read the complete manual. It is strongly suggested that the user or installer follow the following plan to gain the most information in the shortest period of time.

Register the instrument to receive updates and important information from the factory.

Read section 1.1.1, Notes, Cautions, Warnings, on page 1-1 to understand the safety related issues.

Read Chapter 2, Quick Use Guide, to become familiar with the instrument’s needs and capabilities. Use the other sections of the manual to supplement areas where you do not feel you have an adequate understanding of the material. Throughout Chapter 2 there will be frequent references to the manual sections that provide more detailed information. The final sections of the Chapter 2 build the understanding of the full use of the instrument in a logical progression, as suggested in section 2.3 on page 2-7.

WARNING

WARNING

There are no user serviceable components within the instrument case.

Potentially lethal voltages are present when the line cord or System I/O are connected.

Refer all maintenance to qualified personnel.

1 - 9

XTM/2 Operating Manual

1.5 How To Contact Customer Support

If you cannot find the answer to your question in this manual, please contact one of the following Customer Support groups after deciding whether:

your difficulty is with how you are using the instrument—in this case, contact Application Support.

or

your instrument needs repair—in this case, contact Field Service and Repair Support.

When you contact Customer Support, please have this manual at hand, along with the following information:

The serial number for your instrument.

A description of your problem.

An explanation of the corrective action that you may have already attempted.

The exact wording of any error messages that you have received from the instrument.

Within the USA, you may reach Customer Support at the following phone numbers. Please contact the location that is closest to you. If you are located outside of the USA, please contact your sales office. A complete listing of INFICON Worldwide Service Centers is available at www.inficon.com.

1.5.1 Application Support

Austin, TX . . . . . . ph. 512-448-0488. . . . . . . . . . fax 512-448-0398 San Jose, CA. . . . ph. 408-361-1200 ext. 125 . . . fax 408-362-1556 Syracuse, NY. . . . ph. 315-434-1128 . . . . . . . . . . fax 315-437-3803

If you are located outside the USA, please contact your sales office. A complete listing of INFICON Worldwide Service Centers is available at www.inficon.com.

1.5.2 Field Service and Repair Support

Austin, TX . . . . . . ph. 512-448-0488. . . . . . . . . . fax 512-448-0398 San Jose, CA. . . . ph. 408-361-1200 ext. 120 . . . fax 408-362-1556 Syracuse, NY. . . . ph. 315-434-1167 . . . . . . . . . . fax 315-434-2551

If you are located outside the USA, please contact your sales office. A complete listing of INFICON Worldwide Service Centers is available at www.inficon.com.

1.5.3 Returning Your Instrument

Do not send your instrument without first speaking with a Customer Support Representative.

You must obtain an RMA (Return Material Authorization) number from the Customer Support Representative. If the delivery of a package without an RMA number is attempted, INFICON will refuse the delivery and the package will be returned to you.

If your instrument has been exposed to process materials, you will be required to complete a Declaration Of Contamination form.

1 - 10

IPN 074-186S

XTM/2 Operating Manual

Chapter 2

Quick Use Guide

2.1 Unpacking, Initial Inspection and Inventory

2.1.1Unpacking and Inspection Procedures

1If you haven’t removed the instrument from its shipping containers, do so now.

2Carefully examine the unit for damage that may have occurred during shipping. This is especially important if you notice signs of obvious rough handling on the outside of the cartons. Report any damage to the carrier and to INFICON, immediately.

3DO NOT discard any packing materials until you have taken inventory and have verified proper instrument operation to your satisfaction. See section 2.2 on page 2-3 for voltage selection and section 3.6 on page 3-11 for test mode operation.

2.1.2Inventory

Make sure you have received all of the necessary equipment by checking the contents of the shipping containers with the parts list below. INFICON ships these products on a feature-option basis. Check your order for the part number before comparing to the lists below.

IPN 074-186S

2 - 1

XTM/2 Operating Manual

2.1.2.1 XTM/2 System Configuration

|

|

XTM/2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

BASIC CONFIGURATION |

IPN # |

CODE# |

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

||||||

115V 50/60 Hz |

758-500-G1 |

1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

230V 50/60 Hz |

758-500-G2 |

2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

Optional Computer Communications Module |

|

|

|

|

|

|

|

|

|

|

Sensor/feedthrough |

||||||

|

|

|

|

|

|

|

|

|

|

combinations. Some |

|||||||

None |

757-211-G1 |

1 |

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

instruments are sold as |

||||||||

|

|

|

|

|

|

|

|

|

|||||||||

IEEE-488 Parallel |

760-122-G1 |

2 |

|

|

|

|

|

|

|

|

|

complete packages. |

|||||

|

|

|

|

|

|

|

|

|

|||||||||

Rack Mounting |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

None |

|

0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

1 Unit Mounting Kit |

757-212-G1 |

1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

2 Unit Mounting Kit |

757-212-G2 |

2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2.1.2.2 Ship Kit - XTM/2

Both instruments are shipped with the following accessories. To find which accessories were shipped with your unit look for the "X" which represents the voltage of your particular instrument and follow that column.

|

Qty |

|

|

|

|

G2 G1 |

|

|

|

Item |

(230V)(115V) |

IPN Number |

Part # and/or Description |

|

01 |

- |

X |

758-203-G1 |

Ship Kit - XTM/2 115V |

02 |

X |

- |

758-203-G2 |

Ship Kit - XTM/2 230V |

03 |

- |

1 |

068-0385 |

North America Power Cord, shielded |

04 |

1 |

- |

068-0390 |

European Power Cord, shielded |

05 |

1 |

1 |

051-485 |

Conn 9 Pin Male D/Sub Sod. Cup |

06 |

1 |

1 |

051-620 |

Cable Clamp 11.3015 |

07 |

1 |

1 |

051-483 |

Conn 25 Pin Female D/Sub Sod. Cup |

08 |

1 |

1 |

051-619 |

Cable Clamp |

09 |

- |

1 |

062-011 |

3/8 Amp Fuse Type T |

10 |

1 |

- |

062-053 |

3/16 Amp Fuse Type T |

11 |

4 |

4 |

070-811 |

8014 Bumpon Feet |

|

|

|

|

|

In addition, you have already found a copy of this manual, IPN 074-186.

IPN 074-186S

2 - 2

XTM/2 Operating Manual

2.2 Voltage Selection

Voltage selection is required only between low (nominal 100-120 V) and high (nominal 200-240 V) ranges. There is no distinction between 50 and 60 Hz supplies. Refer to section 1.3.1 on page 1-6 for specific power requirements.

CAUTION

CAUTION

Verify that the correct fuse is in place by visually inspecting the fuse for the proper rating. Use of an improperly sized fuse may create a safety hazard.

For 100-120 V(ac) operation use a 3/8 Amp Type T fuse.

For 200-240 V(ac) operation use a 3/16 Amp Type T fuse.

NOTE: These instruments are designed to operate between 90 V(ac) and 132 V(ac) on Low Range and between 180 V(ac) and 264 V(ac) on High Range.

WARNING

WARNING

This instrument has line voltage present on the primary circuits whenever it is plugged into a main power source.

Potentially lethal voltages are present when the line cord, system I/O or aux I/O are connected.

This instrument must be disconnected from the main power source before inspecting or replacing the fuse.

IPN 074-186S

2 - 3

XTM/2 Operating Manual

To inspect the fuse, proceed as follows.

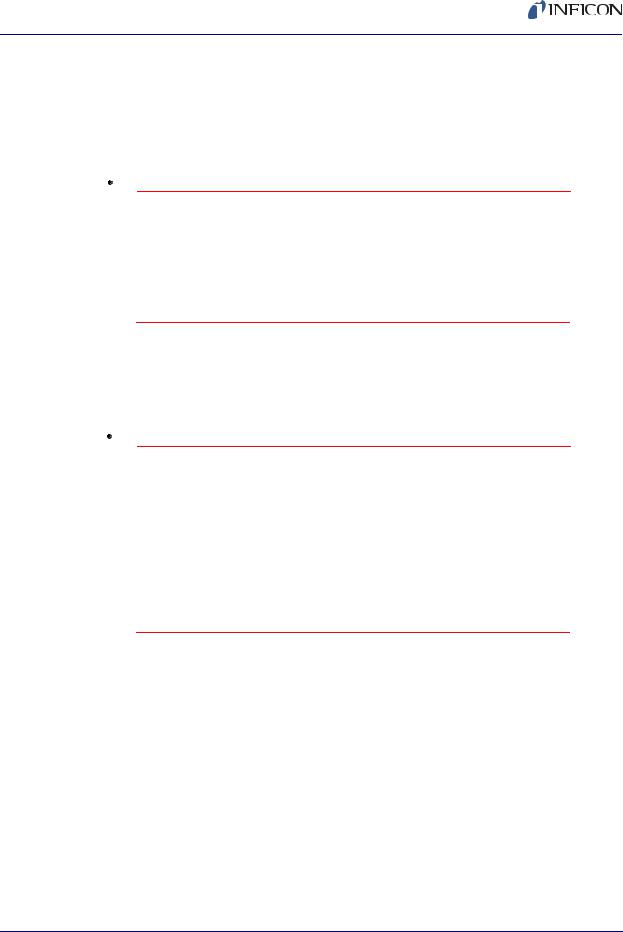

1 Pry open the power entry module cover. See Figure 2-1.

Figure 2-1 Opening the Power Entry Module Cover

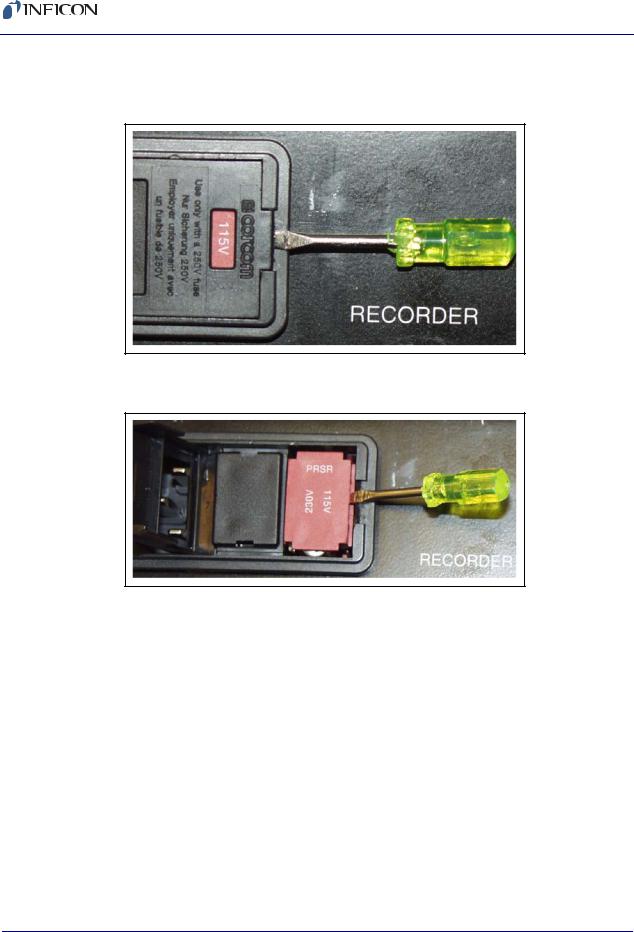

2 Pry the fuse holder out of the housing. See Figure 2-2.

Figure 2-2 Removing the Fuse Holder

IPN 074-186S

2 - 4

Loading...

Loading...