INFICON SKY CDG025D User Manual

Capacitance Diaphragm Gauge

CDG025D

CDG025D-S

Operating Manual

Incl. Declaration of Conformity

tina49e1-c (2009-06) |

1 |

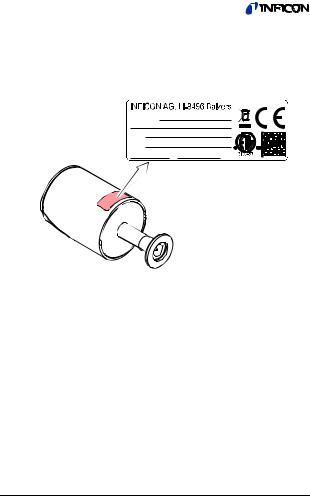

Product Identification

In all communications with INFICON, please specify the information given on the product nameplate. For convenient reference copy that information into the space provided below.

Model:

PN:

SN:

V W

2 |

tina49e1-c (2009-06) |

Validity

This document applies to products of the CDG025D and CDG025D-S series.

Part numbers of standard products are indicated below. OEM products have other part numbers and different parameter settings (e.g. factory setting of setpoint) as defined in the corresponding ordering information.

Flange

3xx-x0x

Switching function

Unit

Measurement range (F.S.)

0 1/2" tube

1DN 16 ISO-KF

2DN 16 CF-R

38 VCR female

74 VCR male

Without switching function

0 Torr (x 133 Pa; x 1.3 mbar)

2 mbar (x 100 Pa)

With switching function

3 Torr (x 133 Pa; x 1.3 mbar)

5 mbar (x 100 Pa)

75 1000 (Torr only)

75 1100 (mbar only)

76 100

77 10

78 1

76 0.1

82 200

83 20

84 2

85 0.25

87 500

The part number (PN) can be taken from the product nameplate.

tina49e1-c (2009-06) |

3 |

If not indicated otherwise in the legends, the illustrations in this document correspond to CDG025D-S gauges with the

DN 16 ISO-KF vacuum connection. They apply to other vacuum connections by analogy.

We reserve the right to make technical changes without prior notice.

All dimensions in mm.

Intended Use

The Capacitance Diaphragm Gauges of the CDG025 series are intended for absolute pressure measurement of gases in their respective pressure ranges (→ 3).

The gauges belong to the SKY® Smart Sensors family and can be operated in connection with an INFICON Vacuum Gauge Controller (VGC series) or another appropriate measuring unit.

Function

The Capacitance Diaphragm Gauge consists of a capacitive sensor element made of aluminum oxide ceramics and electronics which convert the capacitance into a DC voltage output signal.

The output signal is linear to the measured pressure and independent of the gas type.

Trademarks

SKY® |

INFICON GmbH |

VCR® |

Swagelok Marketing Co. |

Patents

EP 1070239, 1040333

US Patents 6528008, 6591687, 7107855, 7140085

4 |

tina49e1-c (2009-06) |

Scope of Delivery

1× gauge 1× pin

1× Calibration Test Report 1× Operating Manual

1× Gebrauchsanleitung

tina49e1-c (2009-06) |

5 |

Contents

Product Identification |

2 |

|

Validity |

3 |

|

Intended Use |

4 |

|

Function, Trademarks, Patents |

4 |

|

Scope of Delivery |

5 |

|

1 |

Safety |

7 |

1.1 |

Symbols Used |

7 |

1.2 |

Personnel Qualifications |

7 |

1.3 |

General Safety Instructions |

8 |

1.4 |

Liability and Warranty |

8 |

2 |

Technical Data |

9 |

3 |

Installation |

14 |

3.1 |

Vacuum Connection |

14 |

3.2 |

Electrical Connection |

17 |

4 |

Operation |

19 |

4.1 |

Displays |

19 |

4.2 |

Zeroing the Gauge |

20 |

4.2.1 <ZERO> Adjustment |

21 |

|

4.3 |

Switching Functions (CDG025D-S only) |

24 |

4.4 |

Activating the Factory Setting (Factory Reset) |

27 |

5 |

Deinstallation |

28 |

6 |

Maintenance, Repair |

30 |

7 |

Returning the Product |

30 |

8 |

Disposal |

31 |

Further Information |

32 |

|

Declaration of Contamination |

33 |

|

ETL Certification |

34 |

|

EC Declaration of Conformity |

35 |

|

For cross-references within this document, the symbol (→ XY) is used, for cross-references to further documents, listed under

"Further Information", the symbol (→ |

[Z]). |

|

|

6 |

tina49e1-c (2009-06) |

1 Safety

1.1Symbols Used

DANGER

Information on preventing any kind of physical injury.

WARNING

Information on preventing extensive equipment and environmental damage.

Caution

Information on correct handling or use. Disregard can lead to malfunctions or minor equipment damage.

Notice

1.2Personnel Qualifications

Skilled personnel

All work described in this document may only be carried out by persons who have suitable technical training and the necessary experience or who have been instructed by the end-user of the product.

tina49e1-c (2009-06) |

7 |

1.3General Safety Instructions

•Adhere to the applicable regulations and take the necessary precautions for the process media used.

Consider possible reactions with the product materials.

•Adhere to the applicable regulations and take the necessary precautions for all work you are going to do and consider the safety instructions in this document.

•Before beginning to work, find out whether any vacuum components are contaminated. Adhere to the relevant regulations and take the necessary precautions when handling contaminated parts.

Communicate the safety instructions to all other users.

1.4Liability and Warranty

INFICON assumes no liability and the warranty becomes null and void if the end-user or third parties

•disregard the information in this document

•use the product in a non-conforming manner

•make any kind of interventions (modifications, alterations etc.) on the product

•use the product with accessories not listed in the product documentation.

The end-user assumes the responsibility in conjunction with the process media used.

Gauge failures due to contamination are not covered by the warranty.

8 |

tina49e1-c (2009-06) |

2 |

Technical Data |

|

|

|

Measurement range |

→ "Validity" |

|

|

Accuracy 1) |

0.20% of reading |

|

|

≥1 Torr/mbar (F.S.) |

|

|

|

0.25 Torr/mbar (F.S.) |

0.25% of reading |

|

|

0.1 Torr/mbar (F.S.) |

0.50% of reading |

|

|

Temperature effect on zero |

0.0050% F.S./ °C |

|

|

≥10 Torr/mbar (F.S.) |

|

|

|

1 / 2 Torr/mbar (F.S.) |

0.015% F.S./ °C |

|

|

0.1 / 0.25 Torr/mbar (F.S.) |

0.020% F.S./ °C |

|

|

Temperature effect on span |

|

|

|

≥1 Torr/mbar (F.S.) |

0.01% of reading / °C |

|

|

0.1 / 0.25 Torr/mbar (F.S.) |

0.03% of reading / °C |

|

|

Resolution |

0.003% F.S. |

|

|

Gas type dependence |

none |

|

|

Output signal analog |

|

|

|

(measuring signal) |

|

|

|

Voltage range |

–5 … +10.24 V |

|

|

Measuring range |

0 … +10 V |

|

|

Relationship voltage-pressure |

linear |

|

|

Output impedance |

0 Ω (short-circuit proof) |

|

|

Loaded impedance |

>10 kΩ |

|

|

Response time |

30 ms |

|

|

≥0.25 Torr/mbar (F.S.) |

|

|

|

0.1 Torr/mbar (F.S.) |

130 ms |

|

|

Gauge identification |

Resistance 13.2 kΩ refer- |

|

|

|

enced to supply common |

|

|

|

(Voltage at pin 10 ≤5 V) |

|

1)Non-linearity, hysteresis, repeatability in the calibrated range at 25 °C ambient operating temperature without temperature effects after operation of 2 h.

tina49e1-c (2009-06) |

9 |

Switching functions |

SP1, SP2 |

Setting range |

0 … +10 V |

Hysteresis |

1% F.S. |

Relay contact |

30 VDC / ≤0.5 ADC |

|

floating (n.o.) |

closed |

at low pressure |

|

(LED is lit) |

open |

at high pressure |

|

(LED is dark) |

Switching time |

≤50 ms |

RS232C interface |

9600 baud |

Transmission rate |

|

Data format |

binary |

|

8 data bits |

|

one stop bit |

|

no parity bit |

Connection |

no handshake |

→ "Electrical Connection" |

Further information about the RS232C interface → [3].

Supply

DANGER

The gauge may only be connected to power supplies, instruments or control devices that conform to the requirements of a grounded protective extralow voltage (SELV) and limited power source

(LPS), Class 2. The connection to the gauge has to be fused 2).

|

Supply voltage |

|

|

|

at the gauge |

+14 … +30 VDC |

|

|

|

Class 2 / LPS |

|

|

ripple |

≤1 Vpp |

|

|

|

|

|

|

2) INFICON controllers fulfill this requirement. |

||

|

|

|

|

10 |

|

tina49e1-c (2009-06) |

|

Current consumption |

<500 mA |

|

(max. starting current) |

Power consumption |

|

(depending on supply voltage) |

≤1 W |

Fuse required 2) |

1 AT (slow), automatic reset |

|

(Polyfuse) |

The gauge is protected against reverse polarity of the supply voltage.

Electrical connection |

15 poles D-Sub, male |

Sensor cable |

5 poles plus shielding |

without switching functions |

|

with switching functions |

9 poles plus shielding |

Cable length |

≤100 m (0.14 mm² conductor) |

For longer cables, larger conductor cross-sections are required (Rcable ≤1.0 Ω).

Grounding concept |

|

Vacuum flange - signal common |

→ "Electrical Connection" |

Supply common - signal common |

conducted separately; for dif- |

|

ferential measurement (10 Ω) |

Materials exposed to vacuum |

|

Flange, tube |

stainless steel AISI 316L |

Sensor and diaphragm |

ceramics (Al2O3 ≥99.5%) |

Sensor–diaphragm connection |

glass ceramics solder |

Ceramics–metal connection |

AgTiCu hard solder, Vacon 70 |

|

(28% Ni, 23% Co, 49% Fe) |

Internal volume |

≤3.6 cm3 |

Admissible pressure (absolute) |

|

≥200 Torr/mbar (F.S.) |

3 bar |

1 … 100 Torr/mbar (F.S.) |

2 bar |

0.1 / 0.25 Torr/mbar (F.S.) |

1.3 bar |

Bursting pressure (absolute) |

5 bar |

tina49e1-c (2009-06) |

11 |

Loading...

Loading...