HP LaserJet Pro M402, LaserJet Pro M403, MFP M426, MFP M427 Troubleshooting Manual and Repair Manual

Troubleshooting Manual

www.hp.com/support/ljM402

www.hp.com/support/ljM403

www.hp.com/support/ljM426MFP

www.hp.com/support/ljM427MFP

For printer theory and troubleshooting

information, see the Repair Manual.

HEWLETT-PAC

KARD

2

1

M402d

M402n

M402dn

M402dw

M403n

M403d

M403dn

M403dw

2

1

M426dw

M426fdn

M426fdw

M427dw

M427fdn

M427fdw

LaserJet Pro MFP M426, M427

LaserJet Pro M402, M403

HP LaserJet Pro M402, M403 and

HP LaserJet Pro MFP M426, M427

Troubleshooting Manual

Copyright and License

Trademark Credits

© Copyright 2015 HP Development Company,

L.P.

Reproduction, adaptation, or translation

without prior written permission is prohibited,

except as allowed under the copyright laws.

The information contained herein is subject to

change without notice.

The only warranties for HP products and

services are set forth in the express warranty

statements accompanying such products and

services. Nothing herein should be construed

as constituting an additional warranty. HP shall

not be liable for technical or editorial errors or

omissions contained herein.

Edition 1, 9/2015

Microsoft®, Windows®, Windows® XP, and

Windows Vista® are U.S. registered trademarks

of Microsoft Corporation.

Conventions used in this guide

TIP: Helpful hints or shortcuts.

Reinstallation tip: Reinstallation helpful hints, shortcuts, or considerations.

NOTE: Information that explains a concept or how to complete a task.

IMPORTANT: Information that help the user to avoid potential printer error conditions.

CAUTION: Procedures that the user must follow to avoid losing data or damaging the printer.

WARNING! Procedures that the user must follow to avoid personal injury, catastrophic loss of data, or

extensive damage to the printer.

ENWW iii

iv Conventions used in this guide ENWW

For additional service and support information

HP service personnel, go to the Service Access Work Bench (SAW) at http://h41302.www4.hp.com/km/saw/

home.do.

Channel partners, go to HP Channel Services Network (CNS) at https://h30125.www3.hp.com/hpcsn.

At these locations, nd information on the following topics:

●

Install and congure

●

Printer specications

●

Up-to-date control panel message (CPMD) troubleshooting

●

Solutions for printer issues and emerging issues

●

Remove and replace part instructions and videos

●

Service advisories

●

Warranty and regulatory information

To access HP PartSurfer information from any mobile device, go to http://partsurfermobile.hp.com/ or scan

the Quick Response (QR) code below.

ENWW v

vi For additional service and support information ENWW

Table of contents

1 Theory of operation ....................................................................................................................................... 1

Related documentation and software ................................................................................................................... 2

Basic operation ...................................................................................................................................................... 3

Sequence of operation ........................................................................................................................ 4

Engine-control system .......................................................................................................................................... 5

DC controller ........................................................................................................................................ 6

Motor control ..................................................................................................................... 8

Fan control ........................................................................................................................ 8

Low-voltage power supply .................................................................................................................. 9

Over-current/over-voltage protection ........................................................................... 10

Safety ............................................................................................................ 10

Low-voltage power supply functions ........................................................... 10

High-voltage power supply ............................................................................................................... 11

High-voltage power supply circuits ................................................................................ 12

Fuser bias ........................................................................................................................ 12

Fuser control ..................................................................................................................................... 12

Fuser circuits ................................................................................................................... 13

Fuser control functions ................................................................................................... 14

Fuser heater protection .................................................................................................. 15

Engine laser/scanner system .............................................................................................................................. 16

Laser/scanner failure detection ........................................................................................................ 17

Safety ................................................................................................................................................ 17

Image-formation process ................................................................................................................. 18

Step 1: Primary charging ................................................................................................ 21

Step 2: Laser-beam exposure ......................................................................................... 22

Step 3: Development ...................................................................................................... 22

Step 4: Transfer ............................................................................................................... 23

Step 5: Separation ........................................................................................................... 24

Step 6: Fusing .................................................................................................................. 24

Step 7: Drum cleaning ..................................................................................................... 24

Toner cartridges ................................................................................................................................ 25

Design ............................................................................................................................. 25

ENWW vii

Memory chip .................................................................................................................... 27

Toner level and cartridge life detection .......................................................................... 27

Pickup, feed, and delivery system ....................................................................................................................... 27

Sensors and switches ........................................................................................................................ 29

Motors, clutches, and solenoids ........................................................................................................ 31

Jam detection/prevention ................................................................................................................. 31

Paper feeder (optional Tray 3) ............................................................................................................................. 35

Basic operation .................................................................................................................................. 35

Paper path ....................................................................................................................... 35

Paper feeder controller ................................................................................................... 35

Motor control .................................................................................................................. 36

Pickup and feed operation ................................................................................................................ 36

Electrical components, pickup and feed ......................................................................... 36

Other functions ............................................................................................................... 37

Jam detection .................................................................................................................. 38

2 Solve problems ............................................................................................................................................ 39

For additional service and support ..................................................................................................................... 40

Solve problems checklist ..................................................................................................................................... 41

Solve problems checklist ................................................................................................................... 41

Print the menu map ........................................................................................................ 42

Print a conguration page .............................................................................................. 42

Print the service page (includes the event log) .............................................................. 43

Print the demo page ....................................................................................................... 43

Troubleshooting process ..................................................................................................................................... 44

Determine the problem source ......................................................................................................... 44

Pre-troubleshooting checklist ........................................................................................ 44

Determine the problem source ....................................................................................... 46

Power subsystem .............................................................................................................................. 47

Power-on checks ............................................................................................................. 47

Control panel checks ......................................................................................................................... 47

Tools for troubleshooting .................................................................................................................................... 49

Component diagnostics .................................................................................................................... 49

LED diagnostics ............................................................................................................... 49

Network LEDs (network models only) ......................................................... 49

Control panel LEDs ....................................................................................... 49

Engine diagnostics .......................................................................................................... 50

Engine test .................................................................................................... 50

Diagrams ........................................................................................................................................... 51

Diagrams: Block diagrams .............................................................................................. 51

Cross-sectional view of printer .................................................................... 51

viii ENWW

Cross-sectional view of 550–sheet paper feeder ........................................ 52

Diagrams: Printed circuit assembly (PCA) connector locations ..................................... 53

Diagrams: DC controller connections ........................................................... 53

Paper feeder controller PCA ......................................................................... 54

Diagrams: External plug and port locations ................................................................... 54

Diagrams: Locations of major components ................................................................... 56

Major components (printer base) ................................................................. 56

Motor and fan ............................................................................................... 57

Rollers and pads (printer base) .................................................................... 58

PCAs (printer base) ....................................................................................... 59

Diagrams: Timing chart .................................................................................................. 60

Diagrams: Circuit diagrams ............................................................................................. 61

Advanced conguration with HP Embedded Web Server (EWS) and HP Device Toolbox

(Windows 7) ....................................................................................................................................... 62

Internal print-quality test pages ....................................................................................................... 64

Clean the paper path ....................................................................................................... 64

Clean the paper path (LCD control panel) .................................................... 64

Clean the paper path (touchscreen control panel) ...................................... 65

Print the conguration page ........................................................................................... 65

Print the conguration page from an LCD control panel ............................. 65

Print the conguration page from a touchscreen control panel ................. 65

Print-quality troubleshooting tools .................................................................................................. 66

Repetitive image defect ruler ......................................................................................... 66

Use a ruler to measure between repetitive defects ..................................... 66

Control panel menus ......................................................................................................................... 70

HP Web Services menu ................................................................................................... 70

Reports menu ................................................................................................................. 70

Quick Forms menu .......................................................................................................... 71

USB Flash Drive menu ..................................................................................................... 71

System Setup menu ........................................................................................................ 72

Service menu ................................................................................................................... 74

Network Setup menu ...................................................................................................... 77

Control panel message document (CPMD) ....................................................................................... 79

Control-panel message types ........................................................................................ 79

Control-panel messages and event log entries ............................................................. 79

30.XX Error Messages ................................................................................... 79

49.XX.YY Error Messages ............................................................................. 80

50.XX fuser errors ........................................................................................ 80

51.XX and 52 Laser/Scanner Errors ............................................................. 81

55.XXXX Error Messages .............................................................................. 82

57.XX Error Messages ................................................................................... 83

ENWW ix

58.XX Error Messages ................................................................................... 83

59.XX Error Messages ................................................................................... 84

79 Errors ....................................................................................................... 85

Alpha Error Messages ................................................................................... 85

Event-log messages .......................................................................................................................... 96

Print the event log .......................................................................................................... 96

Print the event log (LCD control panel) ........................................................ 96

Print the event log (touchscreen control panel) .......................................... 97

Show an event log ........................................................................................................... 97

Event-log messages ....................................................................................................... 97

Clear paper jams ................................................................................................................................................ 101

Clear paper jams (M402, M403) ...................................................................................................... 101

Introduction .................................................................................................................. 101

Experiencing frequent or recurring paper jams? ......................................................... 101

Jam locations ................................................................................................................ 102

Clear paper jams in Tray 1 ............................................................................................ 103

Clear paper jams in Tray 2 ............................................................................................ 104

Clear paper jams in optional Tray 3 .............................................................................. 108

Clear paper jams in the fuser ........................................................................................ 111

Clear paper jams in the output bin ............................................................................... 115

Clear paper jams in the duplexer .................................................................................. 117

Clear paper jams (M426, M427) ...................................................................................................... 119

Introduction .................................................................................................................. 119

Experiencing frequent or recurring paper jams? ......................................................... 119

Jam locations ................................................................................................................ 120

Clear paper jams in the document feeder .................................................................... 122

Clear paper jams in Tray 1 ............................................................................................ 125

Clear paper jams in Tray 2 ............................................................................................ 126

Clear paper jams in optional Tray 3 .............................................................................. 130

Clear paper jams in the fuser ........................................................................................ 134

Clear paper jams in the output bin ............................................................................... 137

Clear paper jams in the duplexer .................................................................................. 140

Solve paper-handling problems ........................................................................................................................ 142

The printer picks up multiple sheets of paper ................................................................................ 142

The printer does not pick up paper ................................................................................................. 142

Solve image quality problems ........................................................................................................................... 143

Print quality examples .................................................................................................................... 143

Clean the printer ................................................................................................................................................ 150

Clean the pickup and separation rollers ......................................................................................... 150

Clean the paper path ....................................................................................................................... 150

Clean the paper path (LCD control panel) ..................................................................... 150

x ENWW

Clean the paper path (touchscreen control panel) ....................................................... 150

Clean the touchscreen ..................................................................................................................... 150

Solve performance problems ............................................................................................................................ 152

Factors aecting print performance ............................................................................................... 152

Print speeds .................................................................................................................. 152

The product does not print or it prints slowly ................................................................................ 153

The product does not print ........................................................................................... 153

The product prints slowly ............................................................................................. 154

Solve connectivity problems ............................................................................................................................. 155

Solve direct-connect problems ....................................................................................................... 155

Solve network problems ................................................................................................................. 155

Poor physical connection .............................................................................................. 155

The computer is using the incorrect IP address for the product .................................. 155

The computer is unable to communicate with the product ......................................... 156

The product is using incorrect link and duplex settings for the network .................... 156

New software programs might be causing compatibility problems ........................... 156

The computer or workstation might be set up incorrectly .......................................... 156

The product is disabled, or other network settings are incorrect ............................... 156

Solve wireless network problems ................................................................................................... 157

Wireless connectivity checklist ..................................................................................... 157

The control panel displays the message: The wireless feature on this product has

been turned o ............................................................................................................. 157

The product does not print after the wireless conguration completes ..................... 158

The product does not print, and the computer has a third-party rewall installed ... 158

The wireless connection does not work after moving the wireless router or

product .......................................................................................................................... 158

Cannot connect more computers to the wireless product ........................................... 158

The wireless product loses communication when connected to a VPN ...................... 159

The network does not appear in the wireless networks list ........................................ 159

The wireless network is not functioning ...................................................................... 159

Service mode functions ..................................................................................................................................... 160

Service menu ................................................................................................................................... 160

Service menu settings .................................................................................................. 160

Restore the factory-set defaults .................................................................................. 160

Restore the factory-set defaults (LCD control panel) ................................ 160

Restore the factory-set defaults (touchscreen control panel) .................. 161

Secondary service menu ................................................................................................................. 161

Open the secondary service menu ............................................................................... 161

Open the secondary service menu (LCD control panel) ............................. 161

Open the secondary service menu (touchscreen control panel) ............... 161

Secondary service menu structure ............................................................................... 162

ENWW xi

Developer's menu ............................................................................................................................ 162

Open the Developer's menu (LCD control panel) ......................................................... 162

Open the Developer's menu (touchscreen control panel) ........................................... 163

Product resets ................................................................................................................................. 164

NVRAM initialization ..................................................................................................... 164

Solve fax problems (fax models only) ............................................................................................................... 165

Introduction ..................................................................................................................................... 165

Fax troubleshooting checklist ......................................................................................................... 165

Solve general fax problems ............................................................................................................ 166

Faxes are sending slowly .............................................................................................. 166

Fax quality is poor ......................................................................................................... 167

Fax cuts o or prints on two pages .............................................................................. 168

Solve email problems (M426, M427 printes) .................................................................................................... 169

Cannot connect to the email server ................................................................................................ 169

Validate the SMTP gateway (Windows) .......................................................................................... 169

Validate the LDAP gateway (Windows) ........................................................................................... 169

Manually update the rmware .......................................................................................................................... 170

Manually update the rmware (LCD control panel) ........................................................................ 170

Manually update the rmware (touchscreen control panel) .......................................................... 170

Appendix A Printer specications .................................................................................................................. 171

Printer dimensions M426 and M427 ................................................................................................................. 172

Printer dimensions M402 and M403 ................................................................................................................. 174

Printer space requirements ............................................................................................................................... 176

Power consumption, electrical specications, and acoustic emissions ........................................................... 176

Operating-environment range .......................................................................................................................... 176

Certicate of Volatility ....................................................................................................................................... 177

Index ........................................................................................................................................................... 181

xii ENWW

List of tables

Table 1-1 Sequence of operation .......................................................................................................................................... 4

Table 1-2 Motors ................................................................................................................................................................... 8

Table 1-3 Fans ....................................................................................................................................................................... 8

Table 1-4 List of DC voltages ................................................................................................................................................ 9

Table 1-5 Low-voltage power supply functions ................................................................................................................. 10

Table 1-6 High-voltage power supply circuits .................................................................................................................... 12

Table 1-7 Fuser components .............................................................................................................................................. 13

Table 1-8 Fuser control functions ...................................................................................................................................... 14

Table 1-9 Sensors ............................................................................................................................................................... 20

Table 1-10 Image formation process ................................................................................................................................. 21

Table 1-11 Toner cartridge functions ................................................................................................................................. 26

Table 1-12 Pickup, feed, and delivery system functions ................................................................................................... 28

Table 1-13 Photo sensors and switches ............................................................................................................................. 30

Table 1-14 Motors, solenoids, and clutches ....................................................................................................................... 31

Table 1-15 Jams that the printer detects ........................................................................................................................... 32

Table 1-16 Electrical component list, paper feeder ........................................................................................................... 36

Table 1-17 Motors, paper feeder ........................................................................................................................................ 36

Table 1-18 Electrical components, pickup and feed .......................................................................................................... 37

Table 1-19 Other functions, paper feeder .......................................................................................................................... 37

Table 2-1 DC controller connectors .................................................................................................................................... 53

Table 2-2 Paper feeder controller PCA connectors ............................................................................................................ 54

Table 2-3 M402, M403 external plugs and ports ............................................................................................................... 54

Table 2-4 M426, M427 external plugs and ports ............................................................................................................... 55

Table 2-5 Major components (printer base) ....................................................................................................................... 56

Table 2-6 Motor and fan (printer base) .............................................................................................................................. 57

Table 2-7 Rollers and pads (printer base) .......................................................................................................................... 58

Table 2-8 Main PCAs (printer base) ..................................................................................................................................... 59

Table 2-9 Repetitive defects ............................................................................................................................................... 66

Table 2-10 Event-log messages (X=0: black cartridge) ..................................................................................................... 97

Table 2-11 Fax event log codes ........................................................................................................................................ 100

Table 2-12 Print quality examples ................................................................................................................................... 143

Table 2-13 Secondary Service menu ................................................................................................................................ 162

ENWW xiii

Table A-1 Operating-environment specications ............................................................................................................ 176

xiv ENWW

List of gures

Figure 1-1 Relationship between the main printer systems ............................................................................................... 3

Figure 1-2 Engine-control system ........................................................................................................................................ 5

Figure 1-3 DC controller block diagram ................................................................................................................................ 6

Figure 1-4 Low-voltage power-supply circuit ...................................................................................................................... 9

Figure 1-5 High-voltage power supply circuits .................................................................................................................. 12

Figure 1-6 Fuser components ............................................................................................................................................ 13

Figure 1-7 Fuser control ..................................................................................................................................................... 14

Figure 1-8 Laser/scanner system ....................................................................................................................................... 16

Figure 1-9 Image-formation system .................................................................................................................................. 18

Figure 1-10 Fuser motor (M1) and image formation components .................................................................................... 19

Figure 1-11 Toner-level sensor .......................................................................................................................................... 20

Figure 1-12 Image-formation process ............................................................................................................................... 20

Figure 1-13 Primary charging ............................................................................................................................................. 21

Figure 1-14 Laser-beam exposure ..................................................................................................................................... 22

Figure 1-15 Development ................................................................................................................................................... 22

Figure 1-16 Primary transfer .............................................................................................................................................. 23

Figure 1-17 Separation ....................................................................................................................................................... 24

Figure 1-18 Fusing .............................................................................................................................................................. 24

Figure 1-19 Drum cleaning ................................................................................................................................................. 25

Figure 1-20 Toner cartridge system ................................................................................................................................... 26

Figure 1-21 Pickup, feed, and delivery system .................................................................................................................. 28

Figure 1-22 Sensors and switches for the pickup, feed, and delivery system .................................................................. 29

Figure 1-23 Motors, solenoids, and clutches ..................................................................................................................... 31

Figure 1-24 Jam detection sensors .................................................................................................................................... 32

Figure 1-25 Optional Tray 3 paper path ............................................................................................................................. 35

Figure 1-26 Paper feeder controller ................................................................................................................................... 36

Figure 1-27 Electrical components, pickup and feed ......................................................................................................... 37

Figure 2-1 Cross-sectional view of printer ......................................................................................................................... 51

Figure 2-2 Cross-sectional view of 500–sheet paper feeder ............................................................................................ 52

Figure 2-3 DC controller PCA connectors ........................................................................................................................... 53

Figure 2-4 Paper feeder controller PCA connectors ........................................................................................................... 54

Figure 2-5 M402, M403 external plugs and ports locations .............................................................................................. 54

ENWW xv

Figure 2-6 M426, M427 external plug and port locations ................................................................................................. 55

Figure 2-7 Major components (printer base) ..................................................................................................................... 56

Figure 2-8 Motor and fan .................................................................................................................................................... 57

Figure 2-9 Rollers and pads (printer base) ......................................................................................................................... 58

Figure 2-10 Main PCAs (printer base) ................................................................................................................................. 59

Figure 2-11 General timing chart ....................................................................................................................................... 60

Figure 2-12 General circuit diagram (printer base) ............................................................................................................ 61

Figure 2-13 Examples of repetitive defects ....................................................................................................................... 67

Figure 2-14 Place the ruler on the page ............................................................................................................................. 68

Figure 2-15 Locate the next repetitive defect ................................................................................................................... 68

Figure 2-16 Determine the defective assembly ................................................................................................................. 69

Figure A-1 Dimensions for the M426 and M427 models ................................................................................................. 172

Figure A-2 Dimensions for the optional 550-sheet tray .................................................................................................. 172

Figure A-3 Dimensions for the printer with the optional 550-sheet tray ....................................................................... 173

Figure A-4 Dimensions for the M402 and M403 models ................................................................................................. 174

Figure A-5 Dimensions for the optional 550-sheet tray .................................................................................................. 174

Figure A-6 Dimensions for the printer with the optional 550-sheet tray ....................................................................... 175

Figure A-7 Certicate of Volatility M402/M403 (1 of 2) ................................................................................................... 177

Figure A-8 Certicate of Volatility M402/M403 (2 of 2) ................................................................................................... 178

Figure A-9 Certicate of Volatility M426/M427 (1 of 2) ................................................................................................... 179

Figure A-10 Certicate of Volatility M426/M427 (2 of 2) ................................................................................................ 180

xvi ENWW

1 Theory of operation

●

Related documentation and software

●

Basic operation

●

Engine-control system

●

Engine laser/scanner system

●

Pickup, feed, and delivery system

●

Paper feeder (optional Tray 3)

ENWW 1

Related documentation and software

HP service personnel, go to the Service Access Work Bench (SAW) at http://h41302.www4.hp.com/km/saw/

home.do.

Channel partners, go to HP Channel Services Network (CSN) at https://h30125.www3.hp.com/hpcsn.

2 Chapter 1 Theory of operation ENWW

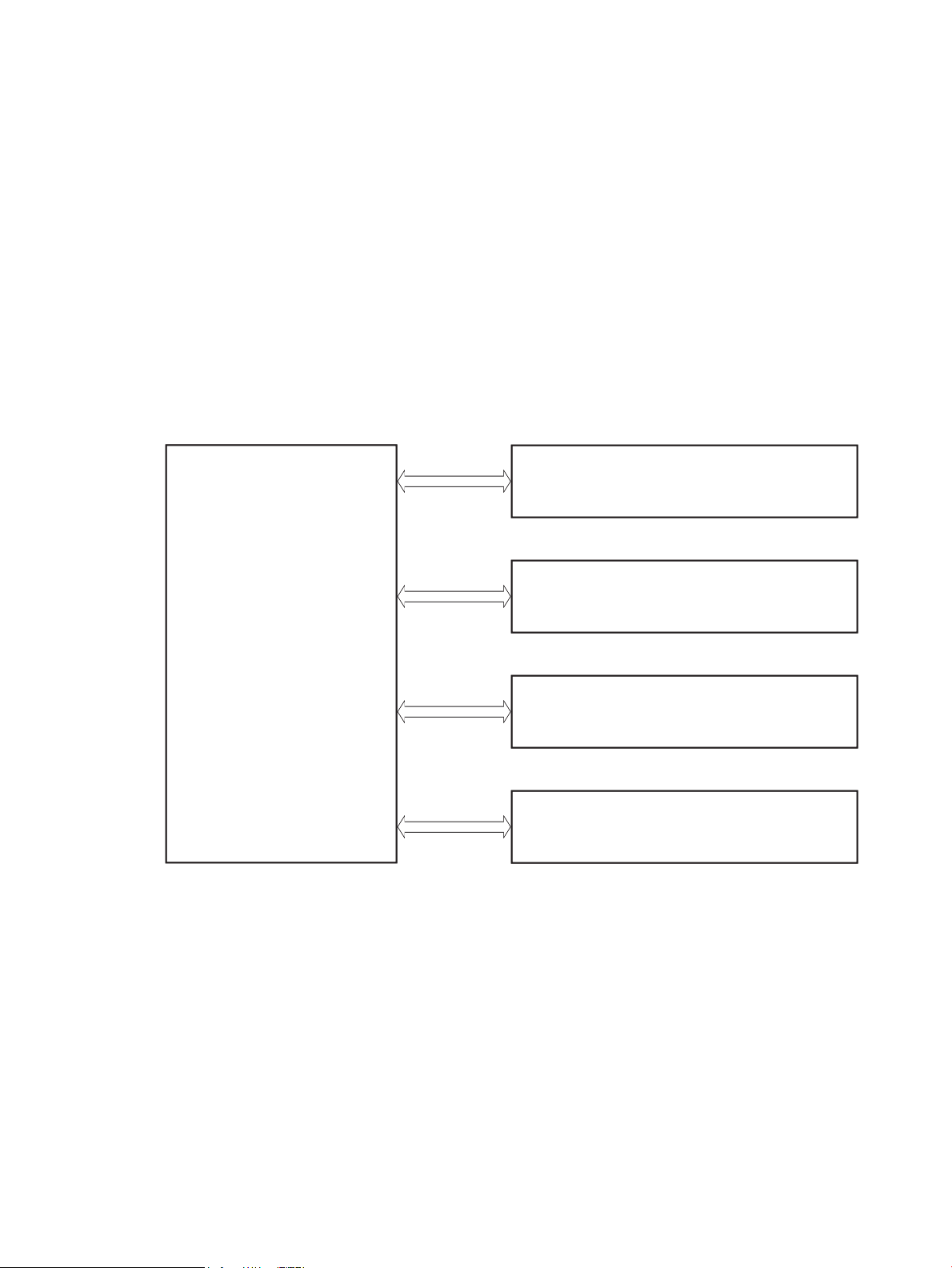

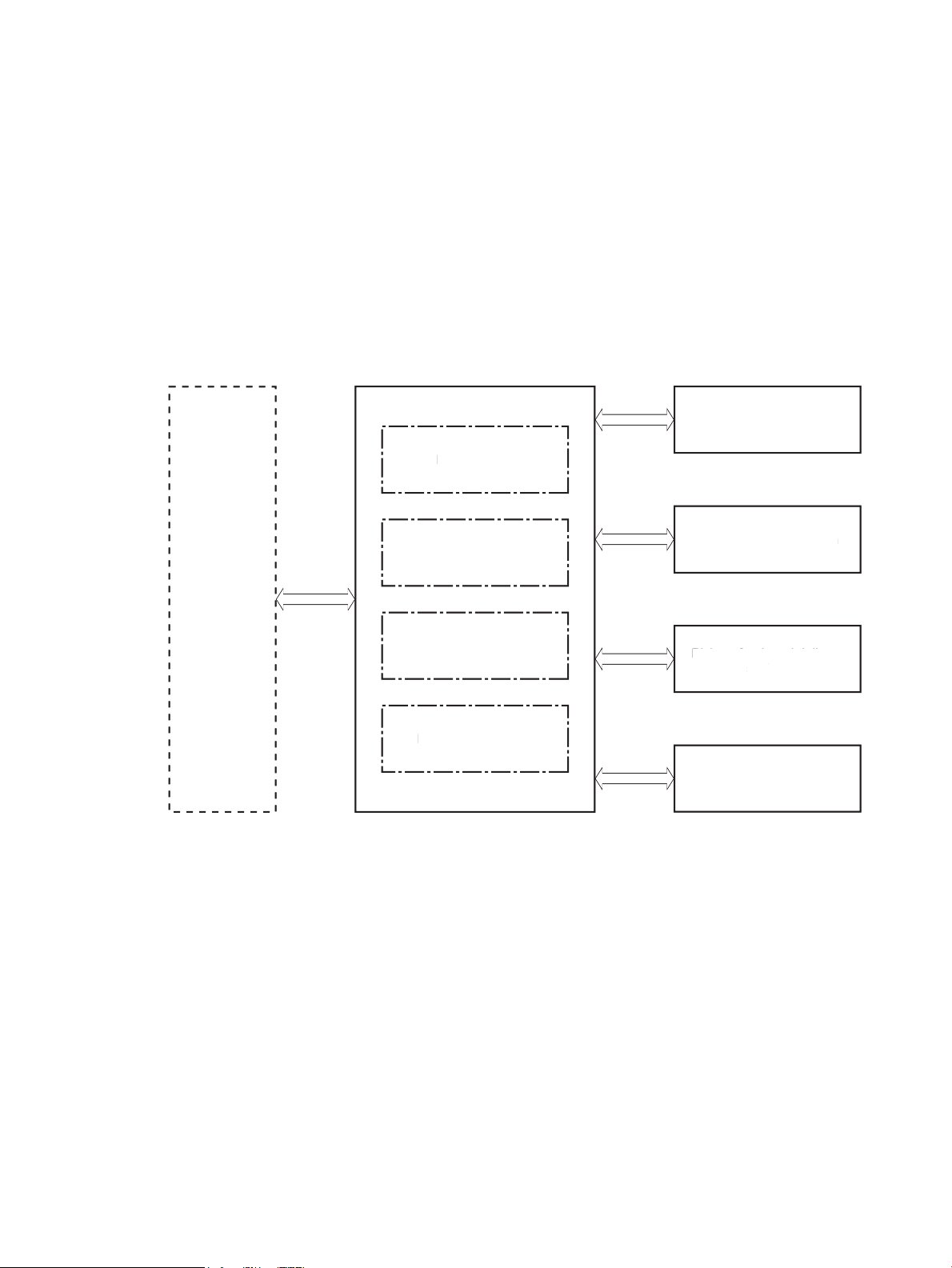

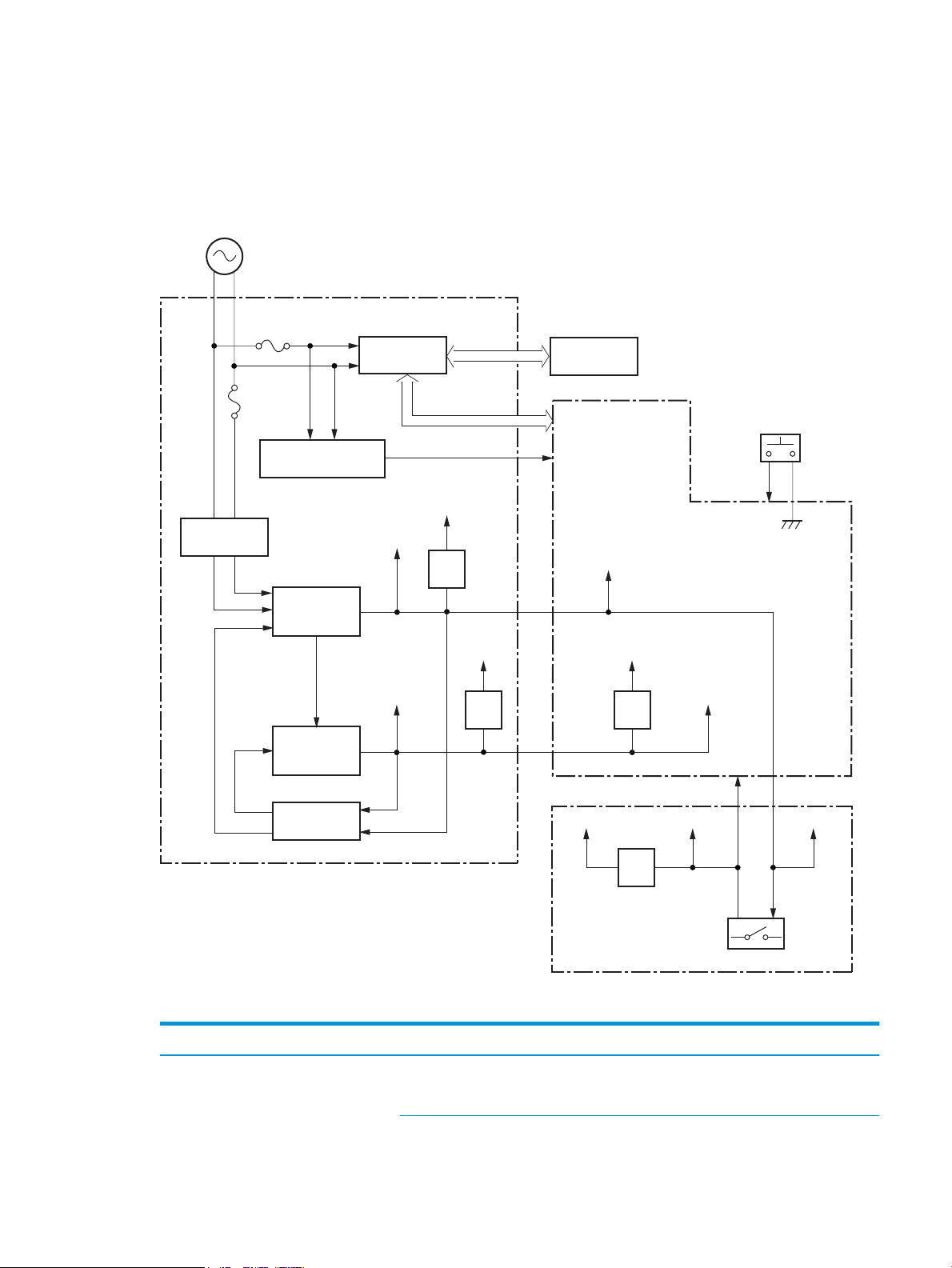

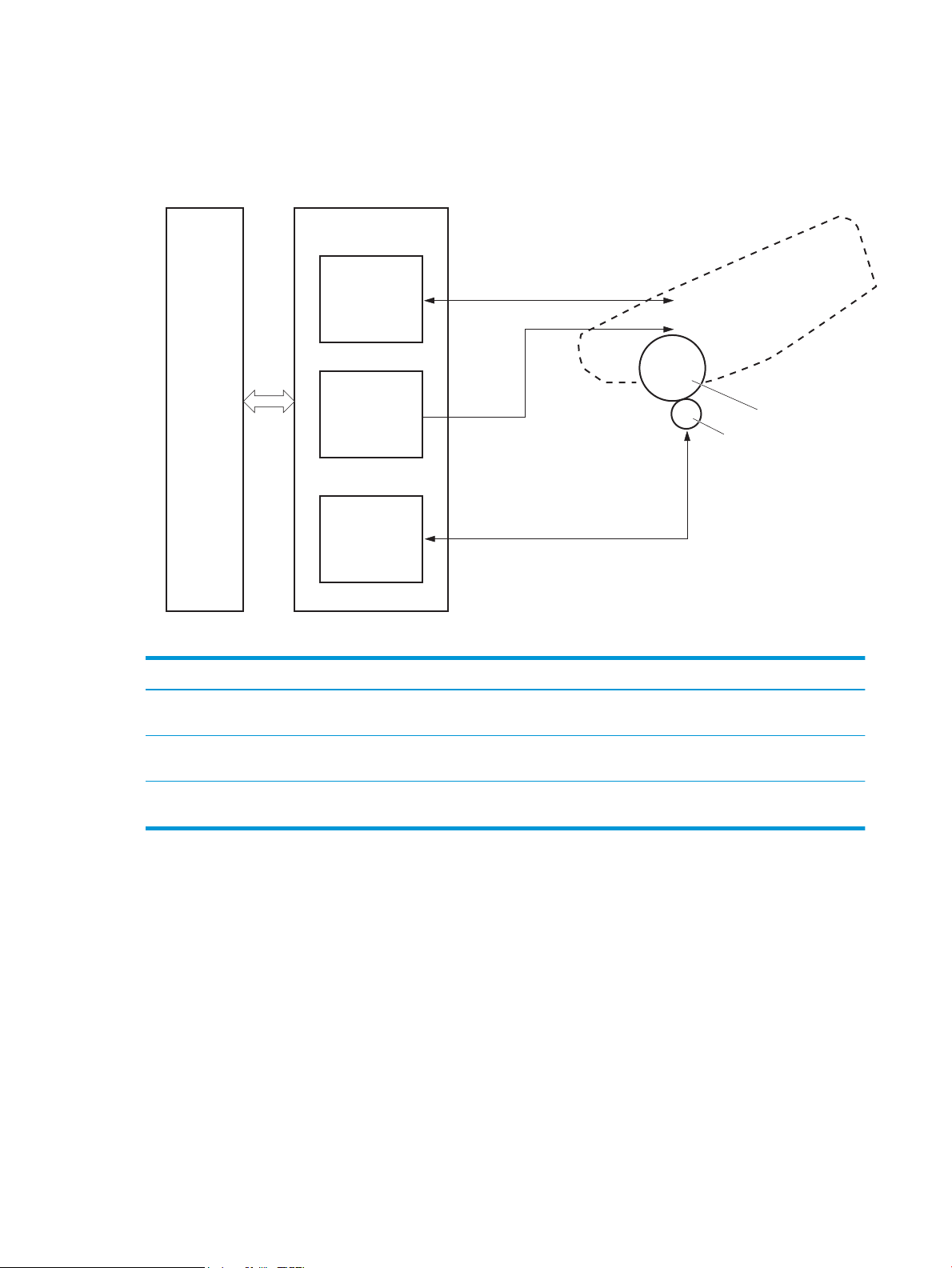

Basic operation

Engine-control system

Laser scanner system

Image-formation system

Pickup, feed, and delivery system

Accessory

Engine-control system

Laser scanner system

Image-formation system

Pickup, feed, and delivery system

Accessor

y

The printer routes all high-level processes through the formatter, which stores font information, processes

the print image, and communicates with the host computer.

The basic printer operation comprises the following systems:

●

Engine-control system

●

Laser/scanner system

●

Image-formation system

●

Pickup, feed, and delivery system

●

Accessory (optional paper feeder)

Figure 1-1 Relationship between the main printer systems

ENWW Basic operation 3

Sequence of operation

The DC controller PCA controls the operating sequence, as described in the following table.

Table 1-1 Sequence of operation

Period Duration Description

Waiting From the time the power is turned on, the door is

closed, or when the printer exits Sleep mode until the

printer is ready for printing.

Standby From the end of the waiting sequence or the last

rotation until the formatter receives a print command,

or until the printer is turned o.

Initial rotation From the time the formatter receives a print command

until the paper enters the paper path.

Printing From the time the rst sheet of paper enters the paper

path until the last sheet passes through the fuser.

●

Heats the fuser lm in the fuser

●

Detects the toner cartridge

●

Rotates and stops each motor

●

Rotates and stops each fan

●

Cleans the transfer roller

●

Is in the Ready state

●

Enters Sleep mode if the formatter sends the

sleep command

●

Rotates and stops each fan

●

Rotates each motor

●

Rotates each fan

●

Activates the high-voltage power supply (highvoltage bias)

●

Prepares the laser/scanner unit

●

Warms the fuser to the correct temperature

●

Forms the image on the photosensitive drums

●

Transfers the toner to the paper

Last rotation From the time the last sheet of paper exits the fuser

until the motors stop rotating.

●

Fuses the toner image onto the paper

●

Stops each motor

●

Stops each fan

●

Stops the high-voltage power supply (highvoltage bias)

●

Stops the laser/scanner unit

●

Turns the fuser heater o

●

If another print command is received, the printer

enters the initial rotation period when the last

rotation is complete.

4 Chapter 1 Theory of operation ENWW

Engine-control system

Formatter

Engine-control system

DC controller

Low-voltage power supply

Laser scanner system

Image-formation system

Pickup, feed, and delivery

system

Accessory

High-voltage power supplies

Fuser power supply

Formatter

Engine-control system

DC controller

Low-voltage power suppl

y

Laser scanner system

Image-formation system

Pickup, feed, and delivery

sy

stem

Accessor

y

igh-voltage power supplies

Fuser power suppl

y

The engine-control system receives commands from the formatter and interacts with the other main systems

to coordinate all printer functions. The engine-control system consists of the following components:

●

DC controller

●

Low-voltage power supply

●

High-voltage power supplies

●

Fuser power supply

Figure 1-2 Engine-control system

ENWW Engine-control system 5

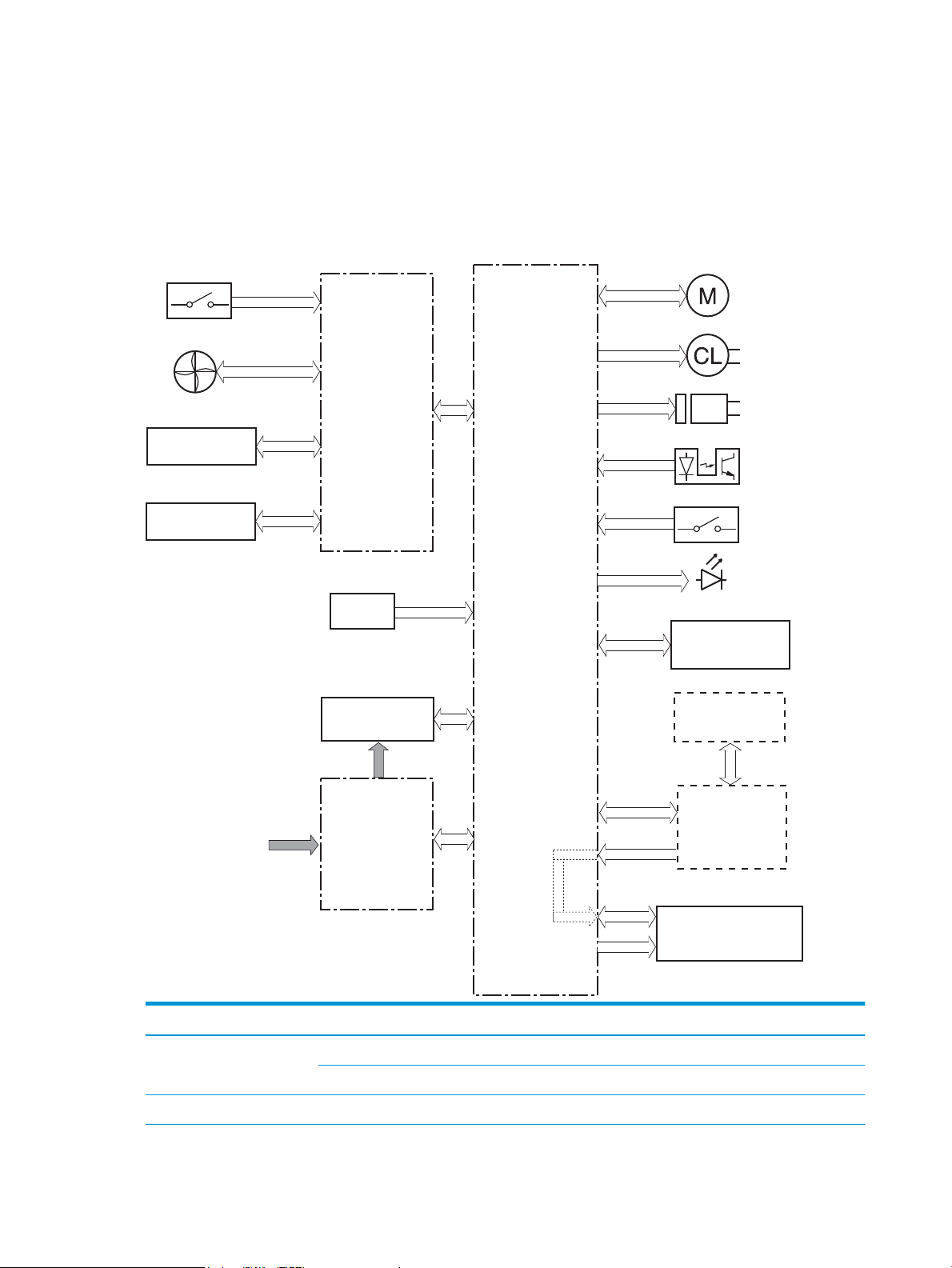

DC controller

Transfer roller

High-voltage

power supply

Fan

Cartridge

LED

Motor

Clutch

Solenoid

Switch

Photointerrupter

Formatter

Control panel

Accessory

Laser scanner ass’y

Fuser

AC input

Low-voltage

power supply

DC controller

Switch

Sensor

The DC controller controls the operation of the printer and its components. The DC controller starts the

printer operation when the printer power is turned on and the power supply sends DC voltage to the DC

controller. After the printer enters the standby period, the DC controller sends out various signals to operate

motors, solenoids, and other printer components based on the print command and image data that the host

computer sends.

Figure 1-3 DC controller block diagram

Component type Abbreviation Description

Motor M1 Fuse motor

M3 Scanner motor

Fan Fm1 Main fan

6 Chapter 1 Theory of operation ENWW

Component type Abbreviation Description

Solenoid SL1 Cassette pickup solenoid

SL2 MP tray pickup solenoid

SL3 Duplex switchback solenoid

Clutch CL1 Duplex re-pickup clutch

Switch SW1 Power switch

SW101 Cartridge door switch

Photointerrupter PS1a Media width sensor

PS2b Duplex feed sensor

PS1 Cassette media out sensor

PS2 Top sensor

PS3 MP tray media out sensor

PS4 Output bin media-full sensor

PS13 Fuser output sensor

Sensor TH1 Environment sensor

LED LED1 Power supply LED

1

Duplex models only.

ENWW Engine-control system 7

Motor control

The printer has two motors. The motors drive the components in the paper-feed and image-formation

systems.

The DC controller monitors the fuser motor and the scanner motor to determine if a motor has failed. It

noties the formatter when it encounters the following conditions:

●

●

Table 1-2 Motors

Abbreviation Name Purpose Failure detection

Startup failure: the motor does not reach a specied speed within a specied time from when the motor

starts.

Rotational failure: the rotational speed of the motor is not in the specied range for a specied time

after the motor reaches a specied speed.

Fan control

The printer has one fan for preventing the temperature from rising in the printer and for cooling the printed

pages.

The DC controller determines if there is a fan failure and noties the formatter if the fan locks for a specied

time from when the fan starts.

Table

M1 Fuser motor Drives the pressure roller and delivery roller;

the pressurization and release of the pressure

roller; and the engagement and

disengagement of the primary and secondary

transfer rollers

M3 Scanner motor Drives the scanner mirror Yes

1-3 Fans

Abbreviation Name Cooling area Type Speed

FM1 Main fan Inside of printer Intake Full

Yes

8 Chapter 1 Theory of operation ENWW

Low-voltage power supply

AC input

+24VA

FET

FET

+24VB

+24VC

+24VD

+24VBSNS

+24VA

FET

PWRSW

+3.3VA

FET

+3.3VC

+3.3VB

+3.3VA

+24VA

Low-voltage power supply

Rectifying

circuit

Protection

circuit

+24V

generation

circuit

Fuse

FU101

Fuse

FU102

+3.3V

generation

circuit

Fuser

Power switch

SW1

DC controller

High-voltage power supply

Interlock switch

SW101

Fuser control

circuit

FREQSNS_LVT

Frequency

detection circuit

The low-voltage power-supply (LVPS) circuit converts the AC power from the wall receptacle into the DC

voltage that the printer components use.

Figure 1-4 Low-voltage power-supply circuit

Table 1-4 List of DC voltages

DC power supply Description

+24V +24VA Constantly supplied

Becomes 4.5V during active OFF or inactive OFF

ENWW Engine-control system 9

Table 1-4 List of DC voltages (continued)

DC power supply Description

+3.3V +3.3VA Constantly supplied

Over-current/over-voltage protection

The low-voltage power supply has a protective function against overcurrent and overvoltage conditions to

prevent failures in the power supply circuit. If an overcurrent or overvoltage event occurs, the system

automatically cuts o the output voltage.

+24VB Stopped when cartridge door is opened. (SW101)

Stopped during active OFF or inactive OFF

+24VC Stopped when cartridge door is opened. (SW101)

Stopped during active OFF or inactive OFF

+24VD Constantly supplied

Stopped during active OFF or inactive OFF

+3.3VB Constantly supplied

Stopped during active OFF or inactive OFF

+3.3VC Constantly supplied

Stopped during inactive OFF

If the DC power is not being supplied from the low-voltage power supply, the protective function might have

activated. In this case, turn o the power switch, and then unplug the power cord. Do not plug in the power

cord or turn the power switch on again until the root cause is found.

In addition, two fuses in the low-voltage power supply protect against an overcurrent event. If an overcurrent

event occurs in the AC line, the fuse blows and cuts o the power distribution.

Safety

For personal safety, the printer interrupts +24VB and +24VC power when the cartridge door detection switch

is turned o. This stops DC power supply to the high-voltage power supply (HVPS).

The remote switch control circuit turns on or o the printer power so that the AC power ows even the power

switch is turned o. Unplug the printer power cord before disassembling the printer.

Low-voltage power supply functions

The printer has the following low-voltage power supply functions.

1-5 Low-voltage power supply functions

Table

Failure detective function Applied

Sleep mode NA

Power supply voltage detection NA

Automatic power OFF NA

Automatic power ON/OFF NA

10 Chapter 1 Theory of operation ENWW

Table 1-5 Low-voltage power supply functions (continued)

Failure detective function Applied

Active OFF Yes

Inactive OFF Yes

Network mode NA

Power switch illumination Yes

Low-voltage power supply failure detection Yes

Power save mode NA

High-voltage power supply

The DC controller controls the high-voltage power supply (HVPS) to generate biases. The high-voltage power

supply delivers the high-voltage biases to the following components used to transfer toner during the imageformation process:

●

Primary charging roller (in the toner cartridge)

●

Developing roller (in the toner cartridge)

●

Transfer roller

●

Pressure roller

ENWW Engine-control system 11

High-voltage power supply circuits

PRI

DEV

TR

DC controller

High-voltage power supply

To primary charge roller

To developing roller

Cartridge

Photosensitive drum

Transfer roller

Primary

charging bias

circuit

Developing

bias circuit

Transfer bias

circuit

The high-voltage power supply contains the following separate circuits.

Figure 1-5 High-voltage power supply circuits

Fuser bias

Fuser control

Table 1-6 High-voltage power supply circuits

Circuit Description

Primary-charging-bias generation The primary charging bias negatively charges the surface of the photosensitive drum to

prepare for image formation.

Developing-bias generation The developing bias adheres toner to an electrostatic latent image formed on the

photosensitive drums.

Transfer-bias generation The primary transfer bias transfers the toner from each photosensitive drum onto the

page.

The printer uses on-demand fusing. The fuser bias is DC positive for improved print quality. The fuser bias

circuit is located in the high-voltage power supply, HVPS (T).

The DC controller and components in the fuser perform the following functions related to fuser operation:

●

Control fuser temperature

●

Detect fuser failures

●

Prevent excessive temperature rise

12 Chapter 1 Theory of operation ENWW

Loading...

Loading...