Hobart HCG40D Manual

DGC1, HGC40, HGC60,

GAS CONVECTION OVENS

HGC40D & HGC60D

GAS CONVECTION OVENS

MODELS

DGC1 ML-43853

HGC40 ML-43856

HGC40D ML-43859

HGC60 ML-114731

HGC60D ML-114732

701 S. RIDGE AVENUE

TROY, OHIO 45374-0001

FORM 19240 Rev. D (3-98)

IMPORTANT FOR YOUR SAFETY

THIS MANUAL HAS BEEN PREPARED FOR PERSONNEL QUALIFIED TO INSTALL GAS

EQUIPMENT, WHO SHOULD PERFORM THE INITIAL FIELD START-UP AND

ADJUSTMENTS OF THE EQUIPMENT COVERED BY THIS MANUAL.

POST IN A PROMINENT LOCATION THE INSTRUCTIONS TO BE FOLLOWED IN THE

EVENT THE SMELL OF GAS IS DETECTED. THIS INFORMATION CAN BE OBTAINED

FROM THE LOCAL GAS SUPPLIER.

IMPORTANT

IN THE EVENT A GAS ODOR IS DETECTED, SHUT

DOWN UNITS AT MAIN SHUTOFF VALVE AND

CONTACT THE LOCAL GAS COMPANY OR GAS

SUPPLIER FOR SERVICE.

FOR YOUR SAFETY

DO NOT STORE OR USE GASOLINE OR OTHER

FLAMMABLE VAPORS OR LIQUIDS IN THE

VICINITY OF THIS OR ANY OTHER APPLIANCE.

WARNING

IMPROPER INSTALLATION, ADJUSTMENT,

ALTERATION OR MODIFICATION, SERVICE OR

MAINTENANCE CAN CAUSE PROPERTY

DAMAGE, INJURY OR DEATH. READ THE

INSTALLATION, OPERATING AND MAINTENANCE

INSTRUCTIONS THOROUGHLY BEFORE

INSTALLING OR SERVICING THIS EQUIPMENT.

IN THE EVENT OF A POWER FAILURE, DO NOT

ATTEMPT TO OPERATE THIS DEVICE.

© HOBART CORPORATION, 1993

– 2 –

TABLE OF CONTENTS

GENERAL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Unpacking. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Leveling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Installation Codes and Standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Installing Basic Oven . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Assembling the Legs to the Oven . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Assembling the Chimney and Flue Extension . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Assembling Stacked Ovens. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Assembling the Oven to the Stand . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Electrical Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Gas Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Testing the Gas Supply System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Burner Air Shutter Adjustments. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Flue Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Before First Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Controls — Models DGC1 and HGC40/HGC60 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Lighting the DGC1 and HGC40/HGC60 Ovens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Using the DGC1 and HGC40/HGC60 Ovens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Controls — Model HGC40D/HGC60D . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Lighting the HGC40D/HGC60D Oven. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Using the HGC40D/HGC60D Oven . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Error Messages — HGC40D/HGC60D Oven . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Cook and Hold Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Proper Utensils. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Conserving Energy. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Operating Hints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Cooking Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Replacing Lamps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

TROUBLESHOOTING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

– 3 –

Installation, Operation and Care of

DGC1, HGC40 & HGC40D GAS CONVECTION OVENS

SAVE THESE INSTRUCTIONS FOR FUTURE USE

GENERAL

The Model DGC1 Oven is equipped with a mechanical thermostat and 1-hour dial timer; the Model

HGC40 and HGC60 Ovens are equipped with a solid state thermostat with probe and 1-hour dial

timer; and the Model HGC40D and HGC60D Ovens feature an electronic thermostat, electronic timer,

a cook-and-hold function and a pulse control. Each oven is equipped with five racks, a two-speed

1

⁄2 H.P. blower motor and a 40,000 BTU/hr. burner as standard equipment, and requires a 120 volt

single phase electrical service. The doors open independently.

Models HGC60 and HGC60D have a deeper oven cavity.

A single oven is furnished with a set of four 25

Stacked ovens are furnished with a set of four 8" (203mm) adjustable painted or stainless steel legs,

and a stacking kit for mounting one oven on top of the other.

A single oven installed on a storage stand is furnished with four 6" (152mm) adjustable painted or

stainless steel legs.

Additional racks are available as accessories. The porcelain interior is standard. A stainless steel

interior is available as an option.

3

/4" (654mm) adjustable painted or stainless steel legs.

INSTALLATION

UNPACKING

Immediately after unpacking the oven, check for possible shipping damage. If this oven is found to be

damaged, save the packaging material and contact the carrier within 15 days of delivery.

Prior to installation, verify that the electrical service and type of gas (natural or propane) agree with the

specifications on the oven data plate, located on the inside of the bottom front cover.

Do not use the doors or their handle to lift the oven.

LOCATION

The equipment area must be kept free and clear of combustibles. Maintain clearances from

combustible or non-combustible construction for at least 6" (152mm) from the side and 6" (152mm)

from the back of the oven. The installation location must allow adequate clearances for servicing and

proper operation.

The oven must be installed so that the flow of combustion and ventilation air will not be obstructed.

Adequate clearance for air openings into the combustion chamber must be provided. Make sure there

is an adequate supply of air in the room to allow for that required for combustion of gas at the oven

burners.

– 4 –

LEVELING

Ensure that the oven racks are level in the final installed position.

INSTALLATION CODES AND STANDARDS

Hobart ovens must be installed in accordance with:

In the United States

1. State and local codes.

2. National Fuel Gas Code ANSI-Z223.1 (latest edition), available from American Gas Association,

1515 Wilson Boulevard, Arlington, VA 22209.

3. ANSI/NFPA 96, "Vapor Removal from Cooking Equipment" (latest edition), available from National

Fire Protection Association, Batterymarch Park, Quincy, MA 02269.

4. National Electrical Code, ANSI/NFPA-70 (latest edition).

In Canada

1. Local codes.

2. CAN/CGA-B149.1, "Natural Gas Installation Code" (latest edition).

3. CAN/CGA-B149.2, "Propane Installation Code" (latest edition) available from the Canadian Gas

Association, 178 Rexdale Blvd., Etobicoke, Ontario, Canada M9W 1R3.

4. Canadian Electrical Code, CSA Standard C22.2 No. 3 (latest edition).

INSTALLING BASIC OVEN

The basic oven must be installed on legs or be mounted on a modular stand. Installations on concrete

bases or other supports restricting air circulation underneath the oven is not advisable and may void

the warranty.

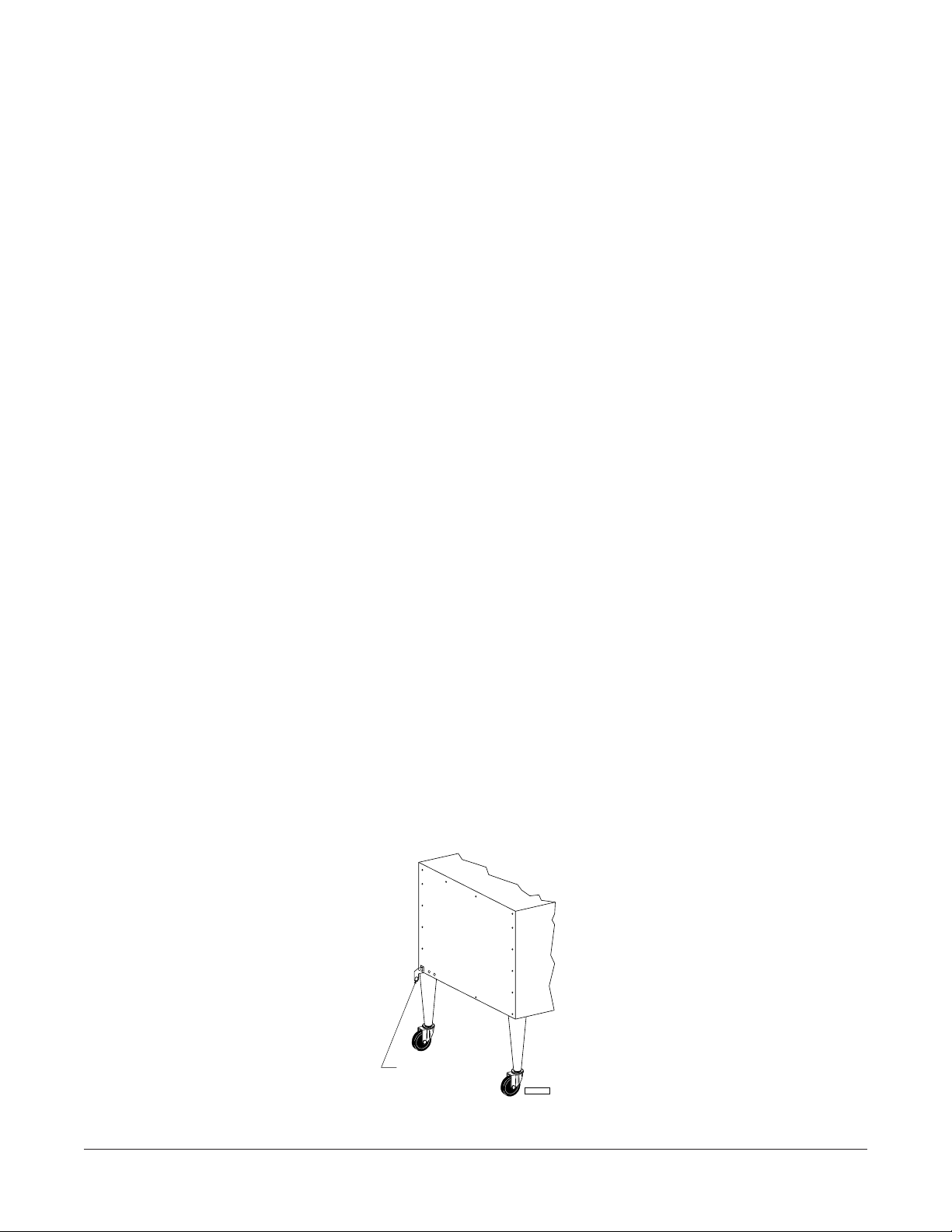

NOTICE: When the oven is mounted on casters, it must be installed with the casters supplied, a

connector (not supplied by Vulcan-Hart) complying with either ANSI Z21.69 (latest edition) or

CAN/CGA-6.16 (latest edition), and a quick-disconnect device complying with either ANSI Z21.41

(latest edition) or CAN1-6.9 (latest edition). It must also be installed with restraining means to guard

against transmission of strain to the connector, as specified in the appliance manufacturer’s instructions.

Attach the restraining device at the rear of the oven (Fig. 1).

CONNECT GAS

LINE STRAIN

RELIEF HERE

Fig. 1

– 5 –

PL-51216

ASSEMBLING THE LEGS TO THE OVEN

Unpack the oven and leg set.

Position oven on its back, taking care not to scratch or damage it. The gas pipe connection protrudes

beyond the back; provide for this when oven is tipped back by resting it on suitable spacers (2 x 4's etc.).

Attach each of the four leg assemblies to the bottom of the oven with the 24 bolts and lockwashers

(6 per leg).

Carefully raise the oven to its normal position. Turn the adjustable feet in or out to level the oven front-

to-back and side-to-side.

ASSEMBLING THE CHIMNEY AND FLUE EXTENSION

Remove the oven chimney and flue extension from the rear of the oven (motor compartment) and use

the screws provided to fasten the chimney to the top rear of the oven. The flanges on the chimney are

to be positioned under the top cover. Also attach the flue extension.

ASSEMBLING STACKED OVENS

Unpack the ovens and stack kit. Position one oven on its back for access to the oven bottom, taking

care not to scratch or damage it. The gas pipe protrudes beyond the back; provide for this when the

oven is tipped back by resting it on suitable spacers (2 x 4's, etc.). Attach the four leg assemblies with

the 24 bolts and lockwashers (6 per leg).

Place the lower oven (with legs) on the floor and remove the two

7

/16" (11.1mm) diameter knockouts on

each side of the top cover.

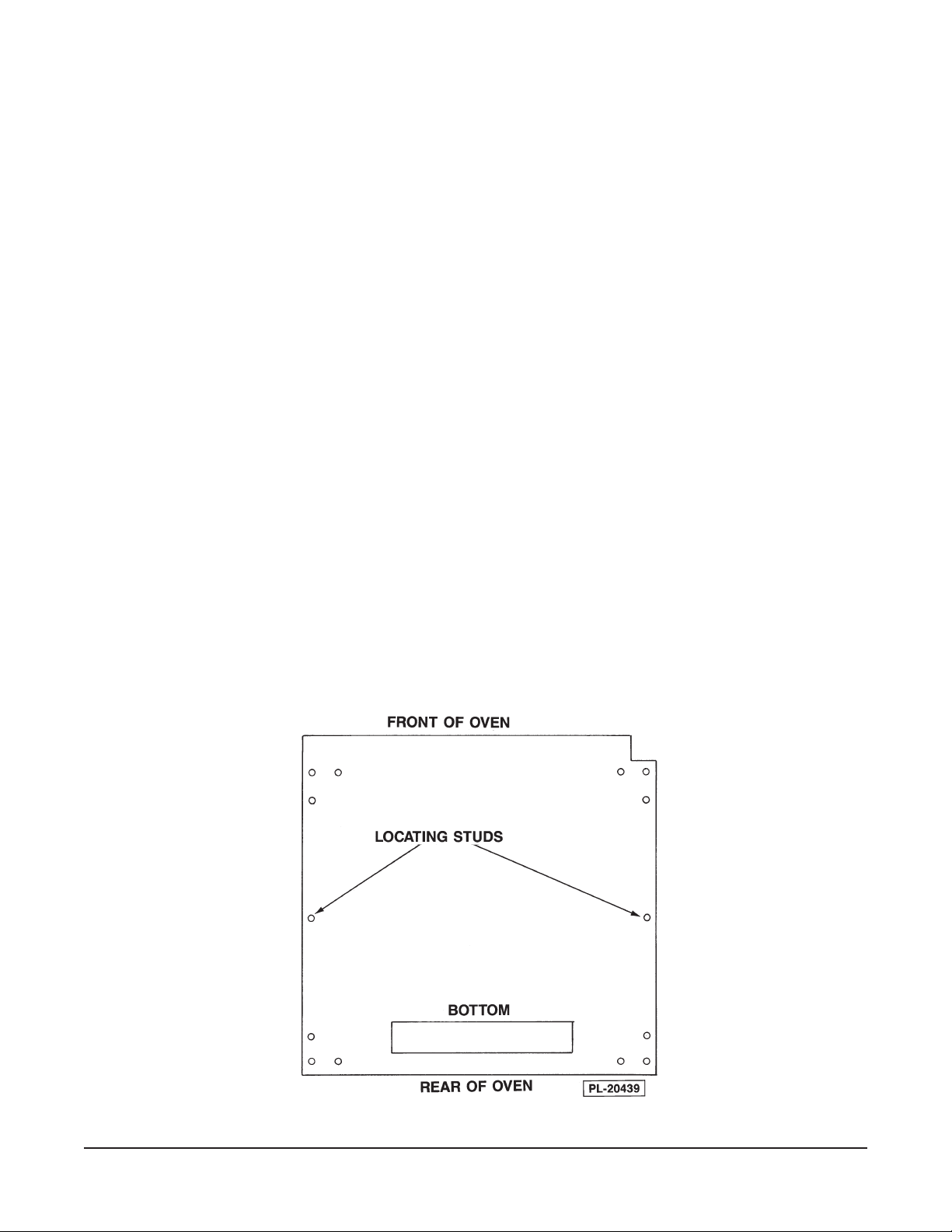

Install the two locating studs (included in the leg stack set) into the screw plates on the underside of

the upper oven (Fig. 2).

Fig. 2

– 6 –

Move the oven with legs to the installed position and place the upper oven on top of the lower oven using

the locating studs.

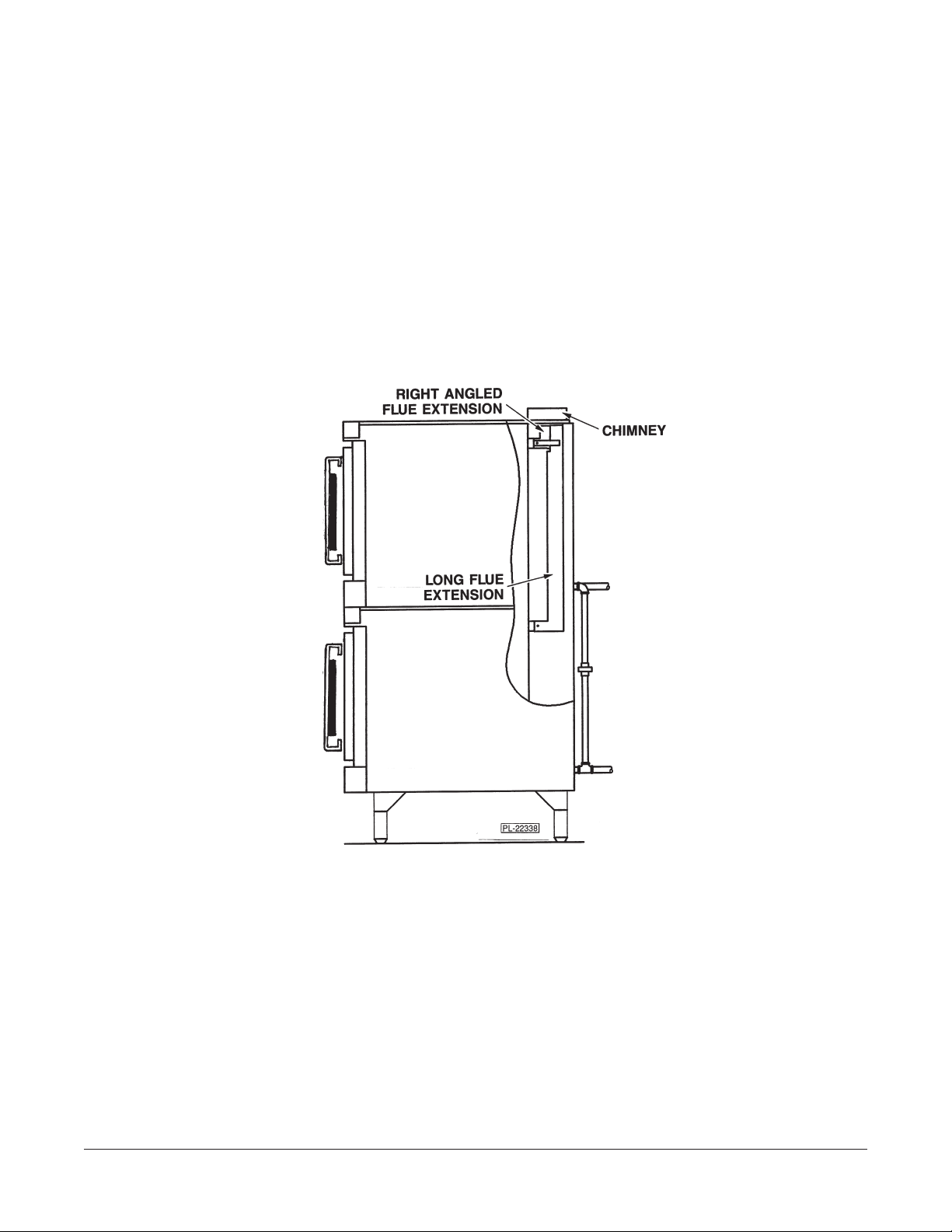

Remove the rear panels from both ovens. Remove the right angle flue extension (Fig. 3) from the top

oven.

Insert the right angle short flue extension into the top oven. Install the long flue extension (Fig. 3) from

the stack kit over the right angle flue extension on the top oven. Insert the right angle of the long flue

extension into the bottom oven. Secure the flue extensions with the screws provided.

Install rear panels on both ovens. Install chimney (Fig. 3) on upper oven. Connect the piping between

the top oven and bottom oven. Pipe compound must be suitable for the type of gas being used (natural

or propane).

The manual gas valve at the bottom of the control panel should remain off until all electrical connections

are made and the ovens are checked or used.

Fig. 3

ASSEMBLING THE OVEN TO THE STAND

Unpack the oven and stand. Position oven on its back, taking care not to scratch or damage it. The

gas pipe connection protrudes beyond the back; provide for this when the oven is tipped back by resting

it on suitable spacers (2 x 4's, etc.).

Install the two locating studs (included in the stand carton) into the screw plates on the underside of

the oven (see Fig. 2).

Attach each of the four leg assemblies to the bottom of the stand with the 24 bolts and lockwashers

(6 per leg).

Mount the oven on top of the stand.

– 7 –

ELECTRICAL CONNECTIONS

WARNING: THE POWER CORD IS PROVIDED WITH A GROUNDING PLUG. THE OUTLET TO

WHICH THIS PLUG IS CONNECTED MUST BE PROPERLY GROUNDED. IF THE RECEPTACLE IS

NOT THE PROPER GROUNDING TYPE, CONTACT AN ELECTRICIAN. DO NOT REMOVE THE

GROUNDING PRONG FROM THIS PLUG.

Your gas convection oven is equipped with a 120 volt / 60 Hz. / 1 phase cord and plug and requires

only that it be plugged into a properly grounded 120 volt receptacle.

A wiring diagram is located on the inside of the right side panel.

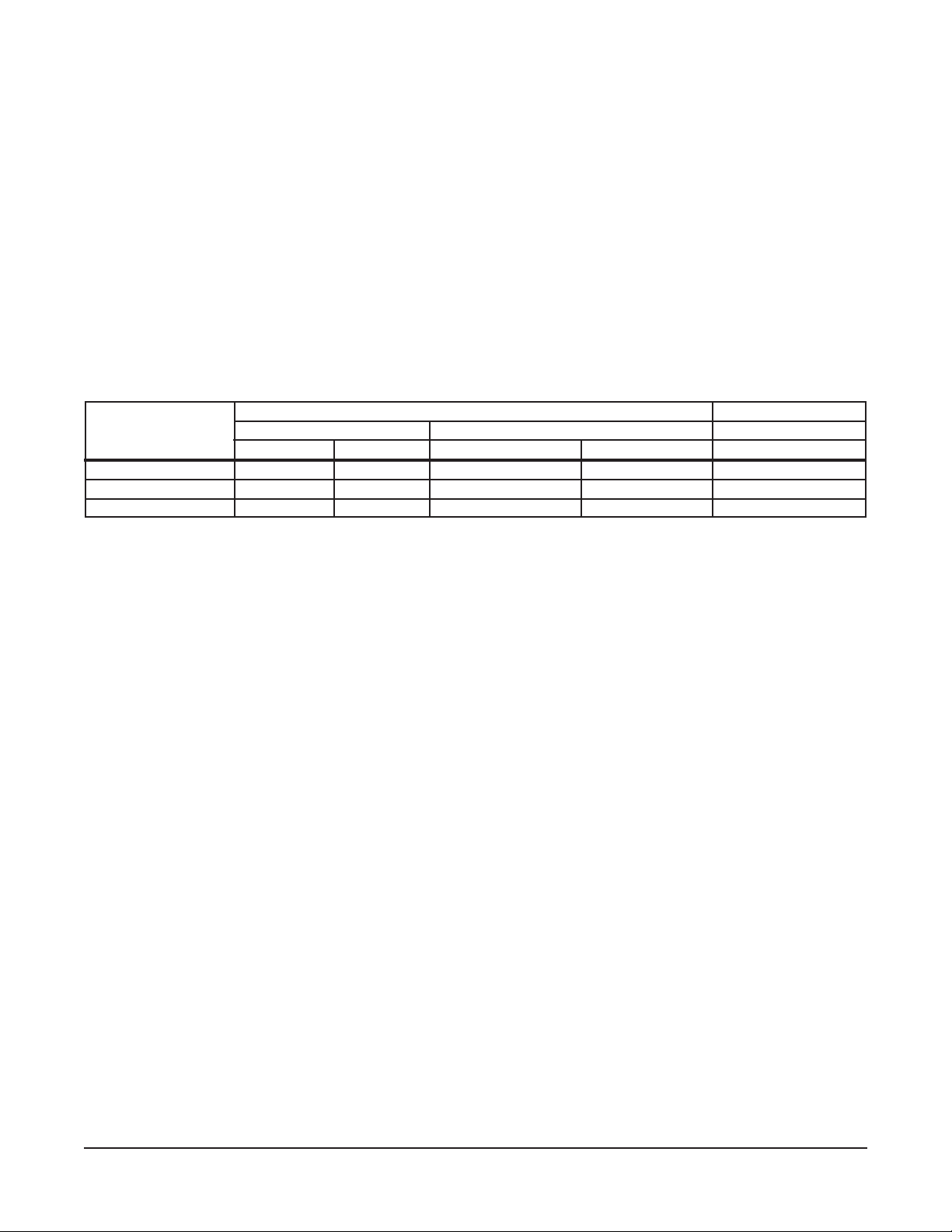

GAS AND ELECTRICAL DATA

GAS DATA ELECTRICAL DATA

MODEL INPUT BTU/HR MANIFOLD PRESSURE AMP/LINE

Natural Propane Natural Propane 120 Volts

DGC1 40,000 40,000 3.5" W.C. (0.8 kPa) 10" W.C. (2.5 kPa) 10 Amps

HGC40/HGC60 40,000 40,000 3.5" W.C. (0.8 kPa) 10" W.C. (2.5 kPa) 10 Amps

HGC40D/HGC60D 40,000 40,000 3.5" W.C. (0.8 kPa) 10" W.C. (2.5 kPa) 10 Amps

Stacked ovens require double BTU/Hr and double amperage.

GAS CONNECTIONS

Gas supply connections and pipe joint compound must be suitable for sealing piping for propane or

natural gases.

The oven is provided with a regulator integral to the gas solenoid valve and requires no external

regulator.

The manual gas shutoff valve is located at the bottom of the front control panel.

The oven should be connected to the gas line after leveling. The gas supply line must be at least the

equivalent of

3

/4" (19mm) iron pipe. Make sure piping is clean and free of obstructions, dirt or pipe joint

compound.

WARNING: PRIOR TO LIGHTING, CHECK ALL JOINTS IN THE GAS SUPPLY LINE FOR LEAKS.

USE SOAP AND WATER SOLUTION. DO NOT USE AN OPEN FLAME.

TESTING THE GAS SUPPLY SYSTEM

The oven and its individual shutoff valve must be disconnected from the gas supply piping system

during any pressure testing of that system at test pressures greater than

1

/2 psig (3.45 kPa).

The oven must be isolated from the gas supply piping system by closing the manual shutoff valve during

pressure testing of the gas supply piping system at test pressures equal to or less than 1/2 psig (3.45 kPa).

– 8 –

Loading...

Loading...