HHFC SERIES

DELI DISPLAY CASES

MODEL

HHFC4 ML-114911 High Profile (573⁄8" High)

ML-114917 Low Profile (481⁄2" High)

ML-126809 Two Tier

ML-126810 Pedestal

ML-126821 Designer

HHFC4C ML-114914 Counter

HHFC5 ML-126815 High Profile (573⁄8" High)

ML-126816 Low Profile (481⁄2" High)

HHFC5C ML-126831 Counter

HHFC6 ML-114912 High Profile (573⁄8" High)

ML-114918 Low Profile (481⁄2" High)

ML-126811 Two Tier

ML-126812 Pedestal

ML-126822 Designer

HHFC6C ML-114915 Counter

HHFC8 ML-114913 High Profile (573⁄8" High)

ML-114919 Low Profile (481⁄2" High)

ML-126813 Two Tier

ML-126814 Pedestal

ML-126823 Designer

HHFC8C ML-114916 Counter

HHFC SERIES

DELI DISPLAY CASE

HIC4 ML-126817 Island Case

701 S. RIDGE AVENUE

TROY, OHIO 45374-0001

937 332-3000

www.hobartcorp.com

FORM 33798 Rev. A (Sept. 2001)

Euro Base

High or Low Profile

4, 5, 6 or 8 Foot

Full Service or Self-Service

Pedestal Base

4, 6 or 8 Foot

Full Service or Self-Service

Countertop Model

4, 5, 6 or 8 Foot

Full Service or Self-Service

© HOBART CORPORATION, 1997, 2001

– 2 –

Two Tier

4, 6 or 8 Foot

Self-Service

Designer Base

4, 6 or 8 Foot

Full Service or Self-Service

Island Case

4 Foot

Self-Service

– 3 –

Installation, Operation and Care of

HHFC SERIES DELI DISPLAY CASES

SAVE THESE INSTRUCTIONS

GENERAL

The HHFC Series Deli Display Cases hold food products at regulated temperatures, maintaining both

freshness and quality. The deli cases feature uniform heating. Clear-view glass surrounds the food

holding area. Full Service units provide the customer a full view of the displayed food products. SelfService or Partial Self-Service units provide an opening to permit the customer to get-it-and-go.

Overhead radiant heater and halogen lighting is standard. Overhead radiant heat lamp bulbs are

optional.

The deli cases have an easily accessible control panel and hold a variety of pan configurations.

INSTALLATION

Prior to installation, check the electrical service to make sure that it agrees with the specifications on

the data plate located on the electrical inspection plate beside the controls.

UNPACKING

Immediately after unpacking the deli case, check for possible shipping damage. If the deli case is found

to be damaged, save the packaging material and contact the carrier within 15 days of delivery.

The deli case is shipped on a full skid and is wood crated. All deli case components, such as side glass,

divider bars and bulbs, are separately boxed and shipped in the well area of the deli case.

1. Remove the top part of the crate first.

2. Remove the side parts of the crate.

3. Remove the PVC shrink-wrap material from around the unit. Care should be taken when removing

the protective shrink-wrap material.

4. Remove the end parts of the crate.

5. The glass side panels are packed in a separate carton and must be installed. The carton containing

the glass panels is secured in the well of the deli case. Take care when opening the carton to avoid

possible damage or breakage to the glass.

6. To remove the deli case from the shipping skid:

On a Countertop Model, cut and remove the retaining bands that secure the unit to the skid.

On display cases intended to be set on the floor, remove the retaining bolts located in each corner

of the base of the deli case.

Depending on the model of the deli case, it may be necessary to remove the sandwich preparation

board first. To remove the sandwich preparation board, place the board in its down position. The

board can then be lifted in an upward direction and removed from the hinging mechanism. It is not

necessary to remove any screws or the hinging mechanism.

LOCATION

The installation location must allow adequate clearances for servicing and proper operation.

– 4 –

INSTALLATION CODES AND STANDARDS

In the United States, Hobart HHFC Series Deli Display Cases must be installed in accordance with

state and local codes and the National Electrical Code, ANSI/NFPA-70 (latest edition).

In Canada, Hobart HHFC Series Deli Display Cases must be installed in accordance with local codes

and the Canadian Electrical Code Part 1, CSA Standard C22.1 (latest edition).

ASSEMBLY

Installation of Glass Side Panels

CAUTION: Handle glass panels with care during installation to avoid breakage. The glass side

panels and front viewing glass are tempered safety glass. If the edges of the glass come in contact

with concrete, stainless steel or other hard surfaces, breakage may occur.

1. Prior to installing the side glass, it is necessary to remove the front (customer's side) stainless steel

.

front well cover (all models except Two Tier and Designer)

This is the front cover located even with

the well. To remove the front well panel, lift the front glass into the upright position. Then carefully

pull the front well panel from the case. The front well panel snaps into place. You must pull hard

to remove.

2. When installing the side glass panels, it may be necessary to lift the lighting canopy to make sure

that the side glass panel follows the track where it is intended to fit. The canopy is designed for

this in order to properly fit the glass.

3. Install one side glass panel at a time, taking care to avoid fracturing the glass. Do not slide the glass

on the stainless steel surfaces. Push the glass panels all the way back. Notice where the front glass

rests when in the down position. The front edge of the side glass panels should stop just beyond

where the front glass rests in the down position.

4. After installing the side glass panels, replace the stainless steel front well panel by snapping it in

place. Lower the front glass panel slowly so it does not hit the side glass panel edges. Once the

front glass is in the down position, move the side glass panels forward so they come as close as

possible to the front glass panel without touching it. The deli case has been specifically designed

so the side panels and front glass do not touch each other in order to avoid possible fracture.

Installation of Divider Bars

Well divider bars are supplied with each case, with the exception of Two Tier models. The long divider

bars are placed onto the divider stationary brackets located in the case well. The long divider bars run

from the front of the case (customer side) to the back of the case (operator side). The short divider bars

are placed between the long divider bars to allow the operator to use varying pan sizes in the case.

Well Divider Bars

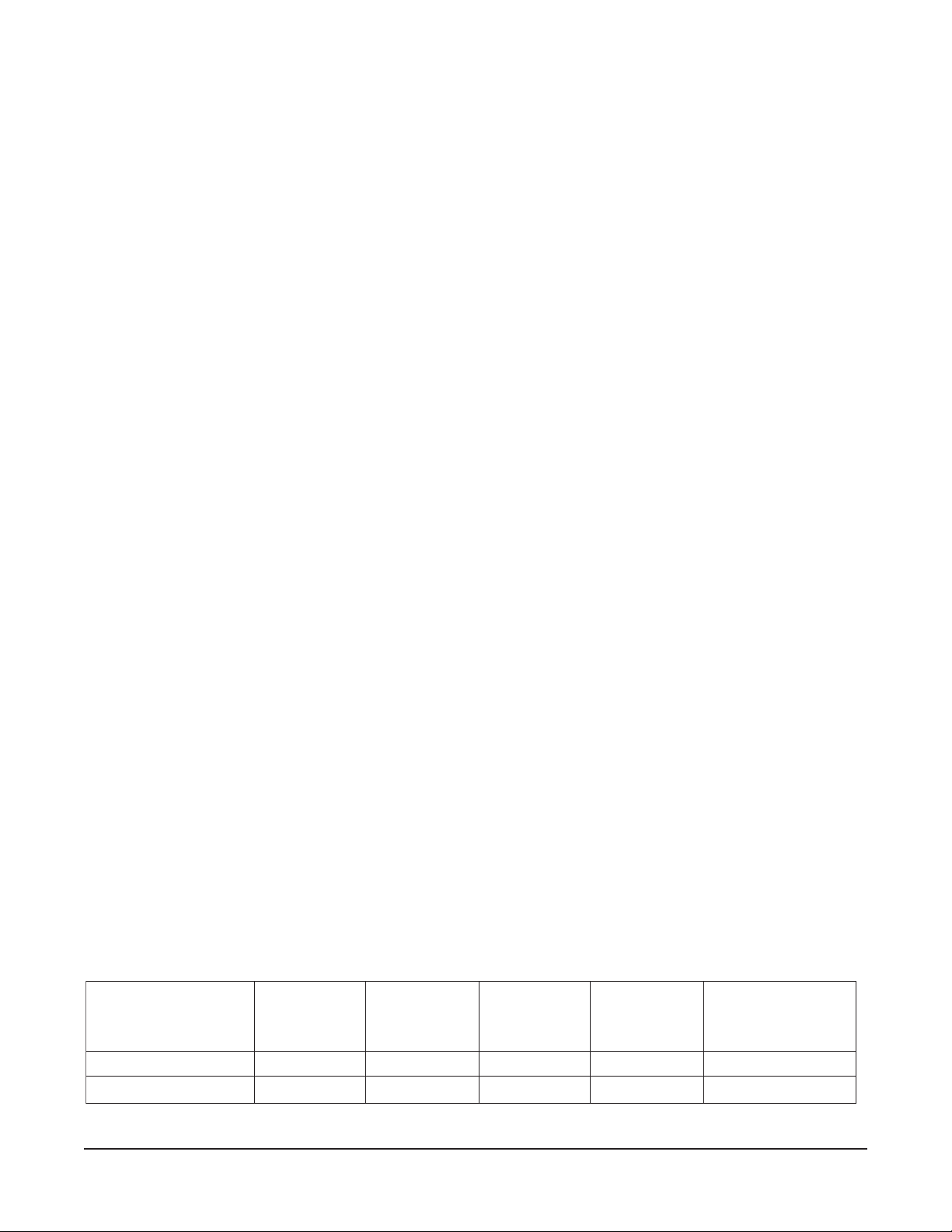

Depending upon the model, well divider bars are provided in the quantities shown in the table.

latsedeP,oruE

rengiseDro

4CFHH:sledoM

C4CFHHro

sraBrediviDtrohS6801410

sraBrediviDgnoL23460

latsedeP,oruE

rengiseDro

5CFHH:sledoM

C5CFHHro

latsedeP,oruE

rengiseDro

6CFHH:sledoM

C6CFHHro

latsedeP,oruE

rengiseDro

8CFHH:sledoM

C8CFHHro

:sledoMreiTowT

,5CFHH,4CFHH

8CFHHro6CFHH

– 5 –

Installation of Light Bulbs or Heat Lamps

Unpack light bulb(s) or heat lamp(s) and install in socket(s). If your model has halogen light bulbs, use

a soft cloth to handle them. Human contact with halogen bulbs can reduce bulb life.

Installation of Two-Foot Self-Service Section (Optional)

The Two-Foot Self-Service Section (Fig. 1,

right side) permits previously packaged hot

foods to be displayed and allows the

customer to grab-it-and-go. The Two-Foot

Self-Service Section consists of the following

components: A fabricated stainless steel

well adapter insert, an 18 x 26" insert tray, a

raised wire grid insert for the insert tray and

a mid-divider glass panel.

The mid-divider glass panel is certified

tempered safety glass.

For those cases where the Two-Foot SelfService Section and the Two-Foot Tile Insert

option are both furnished, the following

components are used: A fabricated stainless

steel well adapter insert, an insert tile tray

and a mid-divider glass panel.

Fig. 1

1. Lift the front glass into the upright position.

2. Remove the operator side service doors.

3. Place the stainless steel well adapter insert into the deli case well on the side (left or right) that is

provided with the two-foot wide short piece of front glass.

4. Align the mid-divider glass bracket located on the stainless steel insert with the glass bracket

located under the overhead heater assembly.

5. Install the mid-divider glass taking care to avoid fracturing the glass. Do not slide the glass on the

stainless steel surfaces.

6. After installing the mid-divider glass, lower the front glass slowly and make sure it does not hit the

side edge of the mid-divider glass. Notice where the front glass rests when in the down position.

The front edge of the mid-divider glass should stop just beyond where the front glass rests in the

down position. The mid-divider glass should come as close as possible to the front glass panel

without touching it. The deli case has been specifically designed so the mid-divider glass and front

glass do not touch each other in order to avoid possible fracture.

7. Place the 18 x 26" tray insert into the Two-Foot Self-Service adapter.

8. Place the raised wire grid insert into the 18 x 26" tray insert. The raised wire grid keeps the

packaged hot food products off the surface of the insert and level with the well surface.

– 6 –

ELECTRICAL CONNECTIONS

WARNING: ELECTRICAL AND GROUNDING CONNECTIONS MUST COMPLY WITH THE

APPLICABLE PORTIONS OF THE NATIONAL ELECTRICAL CODE AND/OR OTHER LOCAL

ELECTRICAL CODES.

WARNING: DISCONNECT ELECTRICAL SUPPLY AND PLACE A TAG AT THE DISCONNECT

SWITCH TO INDICATE THAT YOU ARE WORKING ON THE CIRCUIT.

Make electrical connections per the wiring diagram shipped with the deli case. Refer to the electrical

specifications on the data plate.

OPERATION

WARNING: THE DELI CASE AND ITS PARTS ARE HOT. USE CARE WHEN OPERATING,

CLEANING OR SERVICING THE DELI CASE.

CAUTION: The deli case is designed to operate without moisture. Do not place any water in the

well of the heated deli cabinet.

Your display case is equipped with either overhead radiant heat lamp bulbs and well heating elements

(page 8) or with overhead radiant heating elements with overhead halogen lamps and well heating

elements (pages 9 – 14). The combination of overhead heat and well heat generates the required heat

for food holding requirements. Each of these components operates independent of the other. Due to

the differences in food product densities, some food products will require higher or lower heat settings

than others.

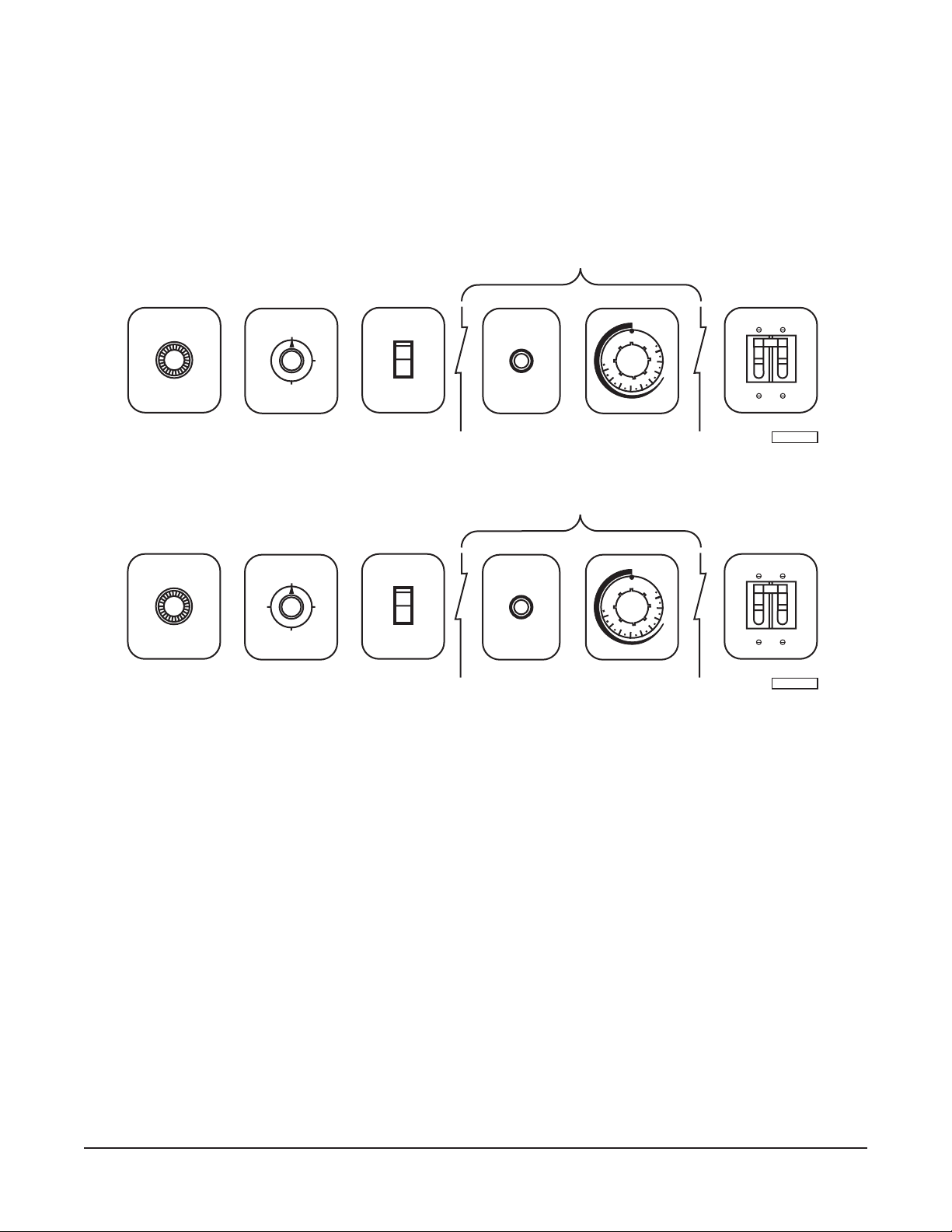

Depending on the case type, model and size, the control panel operating decal will vary. The following

summarizes the configuration of the controls.

– 7 –

CONTROLS — All Models with Overhead Radiant Heat Lamp Bulbs, Euro, Counter, Designer,

Two Tier or Pedestal Models, Full Service or Self-Service, Model HHFC4 (Case Length: 4 Foot),

Model HHFC5 (Case Length: 5 Foot), Model HHFC6 (Case Length: 6 Foot) or Model HHFC8 (Case

Length: 8 Foot)

The size of the deli case and the model number determine the number of heating zones required to

maintain temperature in the display case. Each zone has a separate heating element and overhead

heat lamp. Each zone has its own thermostat, heating indicator light and light rheostat. Monitor case

temperatures throughout the day as required.

HEATING INDICATOR LIGHT

FUSE HOLDER

THERMOSTAT

LIGHT RHEOSTAT

Thermostat — Regulates the well heating elements to maintain the set temperature.

Settings range from 1 to 10 (Low to High).

Heating Indicator Light — When lit, the heating element is providing heat to that zone.

Light Rheostat — Adjusts the amount of overhead radiant heat from heat lamp bulbs.

Fuse Holder — Replace fuse with same size and type.

CONTROLS — Island Case, Self-Service, Model HIC4 (Case Length: 4 Foot)

One thermostat control adjusts the well heaters for the entire case. One switch controls all overhead

radiant heat lamp bulbs. Monitor case temperatures throughout the day as required.

Well Thermostat — Regulates the well heating

elements to maintain the set

temperature.

Overhead Heater Switch — Turns the overhead radiant

heat lamp bulbs On or Off.

Well Heater Switch — Turns the bottom (well) heaters

On or Off.

– 8 –

CONTROLS — Countertop, Euro Style or Pedestal, Model HHFC4 or HHFC4C (Case Length:

4 Foot), with Overhead Heater and Halogen Lighting

Each zone has its own separate heating element with thermostat control and heating indicator light.

One control adjusts the overhead heater for the entire case. One switch controls all overhead lights.

Monitor case temperatures throughout the day as required.

Full Service

HIGH

MED

LOW

OFF

OVERHEAD

HEATER

Self-Service

OFF

OVERHEAD

HEATER

ZONE CONTROL

WELL

OFF

10

9

1

THERMOSTAT

8

7

2

6

3

5

4

ZONE CONTROL

WELL

OFF

10

9

1

THERMOSTAT

8

7

2

6

3

5

4

WELL

INDICATOR

LIGHT

WELL

INDICATOR

LIGHT

OVERHEAD

LIGHTS

ON/OFF

OVERHEAD

LIGHTS

ON/OFF

FUSE HOLDER

FUSE HOLDER

MAIN (ON/OFF)

PL-53651

MAIN (ON/OFF)

PL-53656

Overhead Heater — Regulates the heating elements to Low, Medium or High settings.

Well Thermostat — Regulates the well heating elements to maintain the set temperature.

Settings range from 1 to 10 (Low to High). Zone Controls are repeated

for each zone on longer cases.

Well Indicator Light — When lit, the well heating element is providing heat to that zone.

Overhead Lights — Turns the overhead halogen lights On or Off.

Fuse Holder — Replace fuse with same size and type.

Main Circuit Breaker — Turns power to the display case On or Off.

– 9 –

CONTROLS — Countertop, Euro Style or Pedestal, Model HHFC5 or HHFC5C (Case Length:

5 Foot), Model HHFC6 or HHFC6C (Case Length: 6 Foot), with Overhead Heater and Halogen

Lighting

Each zone has its own separate heating element with thermostat control and heating indicator light.

One control adjusts the overhead heater for the entire case. One switch controls all overhead lights.

Monitor case temperatures throughout the day as required.

ZONE CONTROL

Full Service

FUSE HOLDER

Self-Service

FUSE HOLDER

OFF

HIGH

OVERHEAD

HEATER

OFF

OVERHEAD

HEATER

LOW

OVERHEAD

LIGHTS

ON/OFF

OVERHEAD

LIGHTS

ON/OFF

WELL

INDICATOR

LIGHT

ZONE CONTROL

WELL

INDICATOR

LIGHT

WELL

OFF

10

1

7

2

6

3

5

4

THERMOSTAT

WELL

OFF

10

1

7

2

6

3

5

4

THERMOSTAT

MAIN (ON/OFF)

9

8

PL-53657

MAIN (ON/OFF)

9

8

PL-53653

Fuse Holder — Replace fuse with same size and type.

Overhead Heater — Regulates the heating elements to Low, Medium or High settings.

Overhead Lights — Turns the overhead halogen lights On or Off.

Well Indicator Light — When lit, the well heating element is providing heat to that zone.

Well Thermostat — Regulates the well heating elements to maintain the set temperature.

Settings range from 1 to 10 (Low to High). Zone Controls are repeated

for each zone on longer cases.

Main Circuit Breaker — Turns power to the display case On or Off.

– 10 –

CONTROLS — Countertop, Euro Style or Pedestal, Model HHFC8 or HHFC8C (Case Length:

8 Foot), with Overhead Heater and Halogen Lighting

Each zone has its own separate heating element with thermostat control and heating indicator light.

One control adjusts the overhead heater for the entire case. One switch controls all overhead lights.

Monitor case temperatures throughout the day as required.

Full Service

ZONE CONTROL ZONE CONTROL

WELL

INDICATOR

LIGHT

WELL

OFF

1

2

6

3

5

4

THERMOSTAT

OVERHEAD

10

9

8

7

OFF

HIGH

OVERHEAD

HEATER

LOW

LIGHTS

ON/OFF

WELL

INDICATOR

LIGHT

WELL

OFF

1

2

6

3

5

4

THERMOSTAT

10

9

8

7

MAIN (ON/OFF)

FUSE HOLDER

PL-53654

Self-Service

ZONE CONTROL ZONE CONTROL

WELL

INDICATOR

LIGHT

WELL

OFF

1

2

6

3

5

4

THERMOSTAT

OVERHEAD

10

9

8

7

OFF

OVERHEAD

HEATER

LIGHTS

ON/OFF

WELL

INDICATOR

LIGHT

WELL

OFF

1

2

6

3

5

4

THERMOSTAT

10

9

8

7

MAIN (ON/OFF)

FUSE HOLDER

PL-53659

Well Indicator Light — When lit, the well heating element is providing heat to that zone.

Well Thermostat — Regulates the well heating elements to maintain the set temperature.

Settings range from 1 to 10 (Low to High).

Overhead Heater — Regulates the heating elements to Low or High settings.

Overhead Lights — Turns the overhead halogen lights On or Off.

Fuse Holder — Replace fuse with same size and type.

Main Circuit Breaker — Turns power to the display case On or Off.

– 11 –

CONTROLS — Designer or Two Tier, Model HHFC4 (Case Length: 4 Foot), with Overhead Heater

and Halogen Lighting

One thermostat control adjusts the well heaters for the entire case; one heating indicator light indicates

when the heat is on. One control adjusts the overhead heater for the entire case. One switch controls

all overhead lights. Monitor case temperatures throughout the day as required.

Full Service

MED

LOW

OFF

OVERHEAD

HEATER

HIGH

WELLS

OFF

10

1

7

2

6

3

5

4

THERMOSTAT

WELLS

9

8

INDICATOR

LIGHT

OVERHEAD

LIGHTS

ON/OFF

FUSE HOLDER

MAIN (ON/OFF)

PL-53650

Self-Service

OFF

OVERHEAD

HEATER

WELLS

OFF

10

1

7

2

6

3

5

4

THERMOSTAT

WELLS

9

8

INDICATOR

LIGHT

OVERHEAD

LIGHTS

ON/OFF

FUSE HOLDER

MAIN (ON/OFF)

PL-53658

Overhead Heater — Regulates the heating elements to Low, Medium or High settings.

Wells Thermostat — Regulates the well heating elements to maintain the set temperature

for all wells. Settings range from 1 to 10 (Low to High).

Wells Indicator Light — When lit, the well heating element is providing heat.

Overhead Lights — Turns the overhead halogen lights On or Off.

Fuse Holder — Replace fuse with same size and type.

Main Circuit Breaker — Turns power to the display case On or Off.

– 12 –

CONTROLS — Designer or Two Tier, Model HHFC5 (Case Length: 5 Foot) or Model HHFC6 (Case

Length: 6 Foot), with Overhead Heater and Halogen Lighting

One thermostat control (with heating indicator light) adjusts the heaters for the extreme left and right

end wells while another thermostat control (and heating indicator light) adjusts the heaters for the

center wells. One control adjusts the overhead heater for the entire case. One switch controls all

overhead lights. Monitor case temperatures throughout the day as required.

Full Service

OFF

HIGH

OVERHEAD

HEATER

LOW

END WELLS

OFF

1

2

6

3

5

4

THERMOSTAT

WELLS

10

9

8

7

INDICATOR

LIGHT

CENTER WELLS

OFF

10

1

7

2

6

3

5

4

THERMOSTAT

9

8

WELLS

INDICATOR

LIGHT

OVERHEAD

LIGHTS

ON/OFF

FUSE HOLDER

MAIN (ON/OFF)

PL-53655

Self-Service

OFF

OVERHEAD

HEATER

END WELLS

OFF

1

2

6

3

5

4

THERMOSTAT

WELLS

10

9

8

7

INDICATOR

LIGHT

CENTER WELLS

OFF

10

9

8

1

7

2

6

3

5

4

THERMOSTAT

WELLS

INDICATOR

LIGHT

OVERHEAD

LIGHTS

ON/OFF

FUSE HOLDER

MAIN (ON/OFF)

PL-53660

Overhead Heater — Regulates the heating elements to Low, Medium or High settings.

End Wells Thermostat — Regulates the well heating elements for both the extreme left and right

wells to maintain the set temperature. Settings range from 1 to 10

(Low to High).

Wells Indicator Light — When lit, the well heating element is providing heat to that zone.

Center Wells Thermostat — Regulates the well heating elements for the center two wells on model

HHFC5 or the center three wells on model HHFC6 to maintain the set

temperature. Settings range from 1 to 10 (Low to High).

Wells Indicator Light — When lit, the heating element is providing heat to that zone.

Overhead Lights — Turns the overhead halogen lights On or Off.

Fuse Holder — Replace fuse with same size and type.

Main Circuit Breaker — Turns power to the display case On or Off.

– 13 –

CONTROLS — Designer or Two Tier, Model HHFC8 (Case Length: 8 Foot), with Overhead Heater

and Halogen Lighting

One thermostat control (with heating indicator light) adjusts the heaters for the two extreme left and

two extreme right end wells while another thermostat control (and heating indicator light) adjusts the

heaters for the three center wells. One control adjusts the overhead heater for the entire case. One

switch controls all overhead lights. Monitor case temperatures throughout the day as required.

Full Service

OFF

HIGH

OVERHEAD

HEATER

LOW

END WELLS

OFF

10

1

7

2

6

3

5

4

THERMOSTAT

WELLS

9

8

INDICATOR

LIGHT

CENTER WELLS

OFF

10

1

7

2

6

3

5

4

THERMOSTAT

9

8

WELLS

INDICATOR

LIGHT

OVERHEAD

LIGHTS

ON/OFF

FUSE HOLDER

MAIN (ON/OFF)

PL-53655

Self-Service

OFF

OVERHEAD

HEATER

END WELLS

OFF

1

2

6

3

5

4

THERMOSTAT

WELLS

10

9

8

7

INDICATOR

LIGHT

CENTER WELLS

OFF

10

1

7

2

6

3

5

4

THERMOSTAT

9

8

WELLS

INDICATOR

LIGHT

OVERHEAD

LIGHTS

ON/OFF

FUSE HOLDER

MAIN (ON/OFF)

PL-53660

Overhead Heater — Regulates the heating elements to Low, Medium or High settings.

End Wells Thermostat — Regulates the well heating elements for both the two extreme left and

two extreme right wells to maintain the set temperature. Settings

range from 1 to 10 (Low to High).

Wells Indicator Light — When lit, the well heating element is providing heat to that zone.

Center Wells Thermostat — Regulates the well heating elements for the center three wells to

maintain the set temperature. Settings range from 1 to 10 (Low to

High).

Wells Indicator Light — When lit, the heating element is providing heat to that zone.

Overhead Lights — Turns the overhead halogen lights On or Off.

Fuse Holder — Replace fuse with same size and type.

Main Circuit Breaker — Turns power to the display case On or Off.

– 14 –

BEFORE FIRST USE

Before using the deli case for the first time, thoroughly clean the deli case with warm soapy water.

Rinse thoroughly and wipe dry with a soft clean cloth. Clean all glass surfaces with a quality glass

cleaner.

USING THE DELI CASE

Preheating

Before placing products in the deli case, preheat for approximately 30 to 45 minutes by setting the well

thermostat control(s) to the highest setting and by turning the overhead heater control(s) to the

maximum setting. While preheating, empty pans should be placed in all open pan slots and removed

after the preheating. After loading the case, adjust the overhead heater control(s) and the well

thermostat(s) down to the desired holding temperature.

USING THE LASER TEMPERATURE SENSOR (Optional)

WARNING: LASER RADIATION — FOLLOW THE

INSTRUCTIONS ON THE TEMPERATURE SENSOR

(Fig. 2).

Your deli display case may have a laser temperature sensor.

To use the laser temperature sensor, open the door, point

the temperature sensor at the product and pull the switch.

The temperature sensor will display the surface temperature

AVOID EXPOSURE — LASER RADIATION

IS EMITTED FROM THIS APERTURE

CAUTION

LASER RADIATION – DO NOT STARE INTO BEAM

✴

✴

OUTPUT < 1 mW WAVELENGTH 630 – 670 nm

CLASS II LASER PRODUCT

COMPLIES WITH CFR 1040.10

Fig. 2

of the product. When finished, put the temperature sensor

back in the holder provided.

If your display case is equipped with a laser temperature sensor that is operated by a battery, replace

the battery as necessary. Battery size is 9 volt.

CLEANING

WARNING: DISCONNECT ELECTRICAL POWER SUPPLY BEFORE CLEANING.

Daily

Clean the glass in the deli case with a quality glass cleaner. Never use any type of abrasive cleaner

on the glass panels.

Wash all stainless steel surfaces at least once daily. Use a cloth with warm water and a mild soap or

detergent. Always rub in the direction of the polish lines on the stainless steel to preserve the original

finish. Do not use abrasive cleansers that could scratch the stainless steel. Do not use standard steel

wool on stainless steel finishes. Pieces of the steel wool will adhere to the stainless steel and cause

rusting. After cleaning, rinse thoroughly and wipe dry with a soft clean cloth.

Clean the well while still warm to make it easier to remove food spills. Use a mild detergent and water

solution to clean the well and the rims of the well. Do not use abrasive cleansers that could scratch

the stainless steel. Rinse thoroughly and wipe dry with a soft clean cloth.

– 15 –

MAINTENANCE

WARNING: THE DELI CASE AND ITS PARTS ARE HOT. USE CARE WHEN OPERATING,

CLEANING OR SERVICING THE DELI CASE.

WARNING: DISCONNECT ELECTRICAL SUPPLY AND PLACE A TAG AT THE DISCONNECT

SWITCH TO INDICATE THAT YOU ARE WORKING ON THE CIRCUIT BEFORE PERFORMING ANY

MAINTENANCE.

REPLACING THE OVERHEAD HEAT LAMPS

WARNING: THE HEAT LAMPS ARE HOT. THE LAMPS MUST BE ALLOWED TO COOL BEFORE

REPLACING.

Full Service

Unscrew old heat lamp bulb(s) and replace with Cov-R-Guard Opaque Coated bulb(s) rated 130 watt,

120 volt, either:

General Electric part number 150R/FL130WM/CVG; or

General Electric part number 120R40FL/STGPQ6.

Self-Service Cases, Self-Service Portion of Case or Two Tier Cases

Unscrew old heat lamp bulb(s) and replace with same type infrared bulb rated 250 watt, 120 volt, either:

Prism part number BR40-CL/250 (Clear Non-Cover Guard Coated)*; or

General Electric part number 250R40/1/CVG (Clear Cover Guard Coated)**.

* Factory Standard.

** Optional.

REPLACING THE HALOGEN LAMPS

WARNING: THE HALOGEN LAMPS ARE HOT. THE LAMPS MUST BE ALLOWED TO COOL

BEFORE REPLACING.

Unscrew old halogen lamp(s). Use a soft cloth to handle the bulbs. Human contact will reduce life of

bulbs. Replace with clear, standard base bulb rated 75 watt, 120 volt:

Abco part number 04812 (Westinghouse type JDD).

SERVICE

Contact your local Hobart Service Office for any repairs or adjustments needed on this equipment.

FORM 33798 Rev. A (Sept. 2001) PRINTED IN U.S.A.

– 16 –

Loading...

Loading...