Item # ________________________________

Quantity _______________________________

C.S.I. Section 11400

FD3-50 FD3-75 FD3-125

701 S Ridge Avenue, Troy, OH 45374

1-888-4HOBART • www.hobartcorp.com

COMPACT SIZE BIG VERSATILITY

Hobart Disposers are well recognized for quality

and capacity. They’re designed with your needs in

mind - built with a large capacity for food wastes.

The following pages illustrate the variations of

controls and accessories available to make these

food waste disposers the most versatile equipment for small to medium sized clean-up systems.

SPECIFICATIONS

Listed by Underwriters Laboratories Inc. and meets requirements of

A.S.S.E. Standard No. 1009 (50 Hz. Electrical Specifications not U L

Listed.)

MOTORS: Continuous duty rating, equipped with

manual reset thermal overload inherent protector.

Permanently lubricated ball bearings for upper

and lower shelf support. Upper bearing is sealed

on both sides.

FOODWASTE DISPOSERS

MOTOR SHAFT SEAL: Face-type seal consists

of sintered bronze mating ring and spring loaded

carbon ring insert in chemical resistant neoprene

bellows. Mating surfaces are protected from grit or

fibers by being recessed into flywheel. Should any

moisture pass this seal, a flinger and drain tube

are provided to insure immediate removal. In

addition, a lip-type oil seal (located beneath the

bearings) is an “added protection” water seal.

DRAIN CONNECTOR: A chrome plated brass tailpiece is provided for connection to a 11⁄2" standard

drain trap.

DUAL DIRECTIONAL GRINDING: All Disposers

operate in either direction of flywheel rotation.

Direction of rotation can be controlled by the

operator (to increase life and efficiency of grinding

elements — back flywheel free of a “jam”) when

installed with Control Groups 2, 3 or 4.

WEIGHT: Shipping – Approx. 60 lbs. (does not

include accessory group or controls).

FD3-50 FD3-75 FD3-125 FOODWASTE DISPOSERS

HOUSINGS: Heavy aluminum grind and discharge

housings. Four bolts fasten the motor unit to the

grind chamber, permit easy removal.

MOUNTING: All Hobart Disposers (except when

using accessory group E), fasten to 7" I.D. (throat

opening) cones. A vinyl isolating ring eliminates

metal-to-metal contact at the cone mounting,

reduces vibration and noise transmission.

STATIONARY SHREDDER RING: 13⁄4" high,

4 machine ground primary action breaker bars,

42 secondary action grinding teeth.

FLYWHEEL: Breaker blade, mounted at center,

speeds grinding, prevents objects from “riding” at

center. Two hardened stainless steel cutter blocks

(fastened to flywheel with nylock screws) are

replaceable, can be indexed for new cutting

edges. Ni-Resist flywheel is 63⁄16" diameter,

slots undercut the shredder ring to assure that

particles are cut to proper size before passing

to the drain line.

R

Long Housing Model

F-8567 – FD3-50 FD3-75 FD3-125 Foodwaste Disposers Page 1 of 4

FD3-50 FD3-75 FD3-125

FOODWASTE DISPOSERS

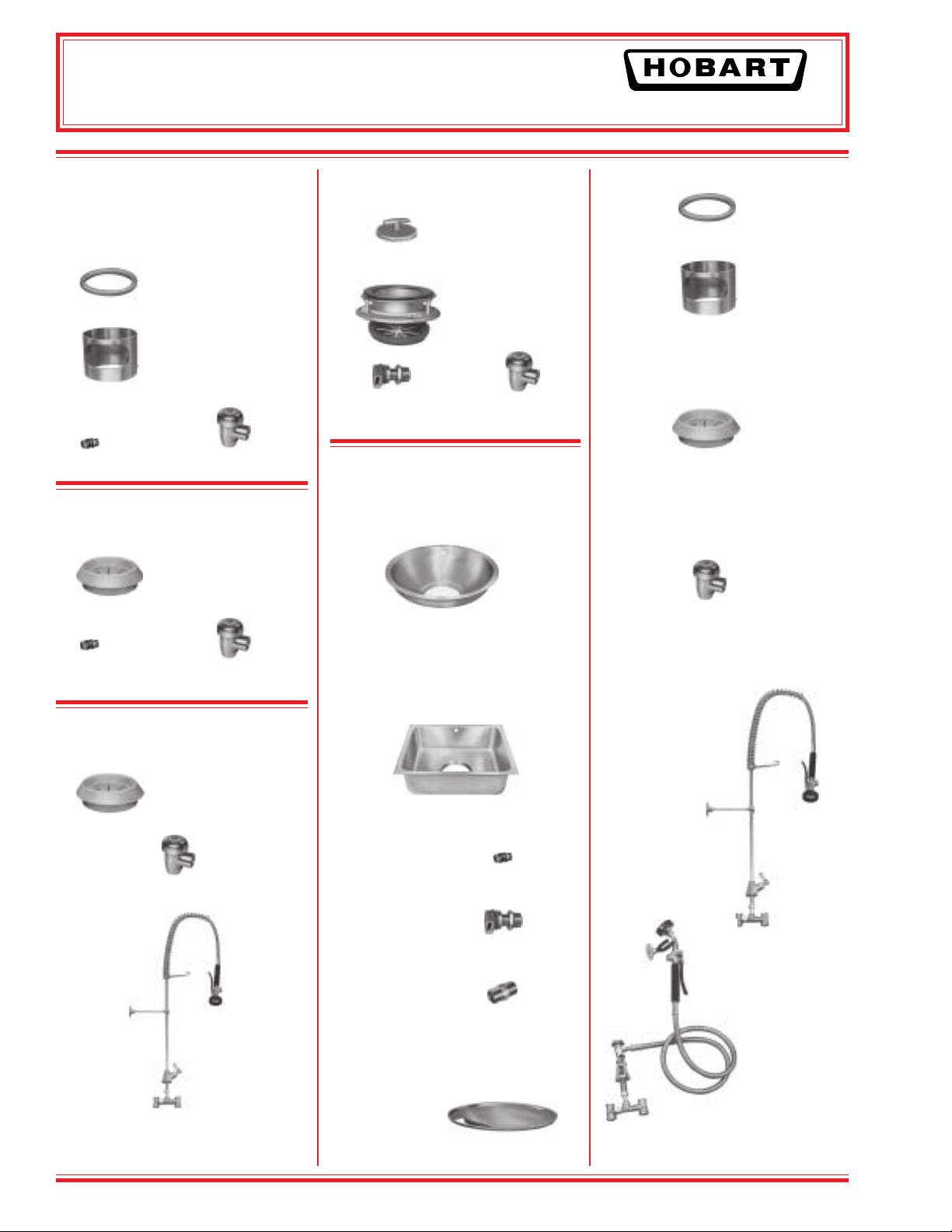

ACCESSORY GROUPS

GROUP A (For use with long upper

housing only.)

Vinyl Scrapping

Ring

Stainless Steel

Silver-Saver Sleeve

with Side Feed

Hole

Water Swirl Vacuum Breaker

GROUP B (For use with long upper

housing only.)

Vinyl Silver-Saver

Splash Guard Ring

Water Swirl Vacuum Breaker

GROUP C (For use with long upper

housing only.)

Vinyl Silver-Saver

Splash Guard Ring

GROUP E (For use with short upper

housing only.)

Fixed Direction Vacuum Breaker

Water Inlet for Sink

ACCESSORY

COMPONENTS

CONES-SINK – Stainless Steel

Cone 15" I.D. w/hole for water swirl

inlet ........................................... 204007

Cone 18" I.D. w/hole for water swirl

inlet ........................................... 204004

Cone 15" I.D. w/out swirl hole ... 204006

Cone 18" I.D. w/out swirl hole ... 204003

Sink 16" x 20" x 7" (7" opening)

w/hole for water inlet ............ 204015-2

NOTE: For use with

short Upper Housing

Foodwaste Disposer

only.

Cover Stopper and

Sink Adapter

Assembly for 31⁄2"

to 4" Sink Opening

Part No.

701 S Ridge Avenue, Troy, OH 45374

1-888-4HOBART • www.hobartcorp.com

CONE FEEDING ACCESSORIES

Part No.

Vinyl Scrapping Ring .................. 202113

Stainless Steel Silver-Saver Sleeve

with side feed hole .................. 203870

SILVER-SAVER SPLASH

GUARD RING

Vinyl Silver-Saver and Splash Guard

Ring (for 7" opening cones, sinks

and adapter) ............................ 202120

VACUUM BREAKERS –

Chrome Plated

3

⁄4" ................................................. 277112

PRE-RINSE SPRAYS

PR-3 Heavy-duty

Flexible Pre-Rinse

Spray (38" high

with wall

bracket)

ML-32333

WATER INLETS

Vacuum Breaker

Cone Water Swirl Inlet 1⁄2" N.P.T.

............................................. 204380

Fixed Direction Water Inlet (for sinks or

troughs) 1⁄2" N.P.T............... 204346

FLOW CONTROL

5 Gallons per minute for Models

FD3-50 through FD3-125 3⁄4" N.P.T.

............................................. 201721

PR-4 Utility Spray

(with wall bracket)

ML-32334

CONE COVER –

STAINLESS STEEL

Pre-Rinse Spray

with Wall Bracket

15" Cone Cover w/feed hole ...... 204024

18" Cone Cover w/feed hole ...... 204023

Adapters are available to install Hobart Disposers

on existing competitive cones. See Form F-7543.

Page 2 of 4 F-8567 – FD3-50 FD3-75 FD3-125 Foodwaste Disposers

FD3-50 FD3-75 FD3-125

701 S Ridge Avenue, Troy, OH 45374

1-888-4HOBART • www.hobartcorp.com

FOODWASTE DISPOSERS

ELECTRICAL CONTROL GROUPS Listed by Underwriters Laboratories Inc., for use with FD Disposers

(50 Hz. Electrical Specifications not submitted for UL Listing.)

Group 2 - For all Models

Includes:

Magnetic Contactors

Pushbutton Start and Stop

Automatic Reversing

Made from a NEMA 12 Enclosure

Solenoid Valve

Approximate

Shipping Wt. 31 lbs.

Group 3 - For all Models

Includes:

Magnetic Contactors

Pushbutton Start and Stop

Automatic Reversing

Low Water Pressure Cut-off

Time Delay for water after shut-off

Line Disconnect

Solenoid Valve

Made from a NEMA 12 Enclosure

Model H.P. Ph. Hz. Volts Rated Amps

160120/208-240 9.2/4.2-4.6

FD3-50

FD3-75

FD3-125

FD3-50

FD3-75

FD3-125

The dash (-) between voltages represents the range (low-high) of voltage operation. The slant (/) line

indicates the dual voltage operation accomplished by motor lead connection: follow connecting diagram on

motor. (50 Hz. models not submitted for U L Listing.)

1

⁄

2

360208-240/480 1.8-2.0/1.0

160120/208-240 10.8/5.3-5.4

3

⁄

4

360208-240/480 2.6-3.0/1.5

160120/208-240 14.8/7.7-7.4

11⁄

4

360208-240/480 4.2-4.0/2.0

150110-120/220-240

1

⁄

2

350220-240/380-415

150110-120/220-240

3

⁄

4

350220-240/380-415

150110-120/220-240

11⁄

4

350220-240/380-415

Contact

Customer

Service

For

Amperage

Data

Approximate

Shipping Wt. 38 lbs.

Group 4 - For Models thru

FD3-200

Includes:

Manual Reversing Switch

NEMA 1 Enclosure Standard

NEMA 4 Enclosure Optional

Not available above 250 volts

Optional Solenoid Valve

Approximate

Shipping Wt. 11 lbs.

SAMPLE SPECIFICATION

FD3-75 — B — 2 (230/60/3)

Electrical Specifications

Electrical Control Group

Accessory Group

Model Number

Cut hole 19" for 18" cone. Hole to be 16" for 15" cone.

Solenoid must be installed in upright position.

Disposer may be easily rotated for better drain line connection.

Center line at wall outlet of trap should not be higher than center

line of disposer discharge opening.

If water pressure is in excess of 60 P.S.I. install a pressure

reducing valve.

F-8567 – FD3-50 FD3-75 FD3-125 Foodwaste Disposers Page 3 of 4

FD3-50 FD3-75 FD3-125

FOODWASTE DISPOSERS

DETAILS AND DIMENSIONS

15" or 18"

5"

61⁄2"

83⁄8"

10"

WASTE

OUTLET

WASTE

EXIT

20" FD3-125 1 PH.

193⁄8" FD3-50, 75 1 PH.

183⁄4" FD3-50, 75, 125 3 PH.

1

21

⁄8" FD3-125 1 PH.

1

20

⁄2" FD3-50, 75 1 PH.

197⁄8" FD3-50, 75, 125 3 PH.

701 S Ridge Avenue, Troy, OH 45374

1-888-4HOBART • www.hobartcorp.com

71⁄4"

7"

9"

ROUGH IN

WASTE OUTLET

WASTE EXIT

47⁄32"

67⁄16"

813⁄32"

LONG UPPER HOUSING

NOTE: Specify 15" or 18" Cone When Desired.

TYPICAL INSTALLATION - Unit with Long Upper Housing.

SWIRL & FLOW CONTROL

11⁄2" WASTE LINE

161/2"

PLUMBING

ROUGH-IN

SHORT UPPER HOUSING

VACUUM BREAKER

SOLENOID VALVE

FURNISHED WITH CONTROL

GROUPS 2 & 3

PRESSURE SWITCH, TEE & NIPPLE

FURNISHED WITH

CONTROL GROUP 3 ONLY

PRESSURE REDUCING

VALVE - BY OTHERS

SHUT — OFF

VALVE BY OTHERS

As continued product improvement is a policy of Hobart, specifications are subject to change without notice.

Page 4 of 4 F-8567 – FD3-50 FD3-75 FD3-125 Foodwaste Disposers

F-8567 (REV. 8/03) LITHO IN U.S.A. (H-01)

Printed On Recycled Paper

Loading...

Loading...