FOOD EQUIPMENT

Qty. Item No.

FT -800 SERIES

DISHW ASHER

FT-800 SERIES

DISHWASHER WITH

ELECTROMECHANICAL

CONTROLS

OUTSTANDING

STANDARD FEATURES

• Energy saving low water

consumption design—5.7 GPM

Hot Water (180°F); 3.9 GPM

Low Temp (140°F).

• Stainless steel construction

including frame, legs, feet, drain

piping, wash arms.

• Electro-mechanical controls in

top mounted stainless steel

control center.

• 36" Load/Unload height.

• Energy efficient convertible hot

water or low temp/chemical

sanitizing.

• Door actuated drain closers.

• Sealed dial type thermometers

for wash—power rinse—final

rinse—temperature indication.

• Water and energy saving

design through reduced water

and tank heat usage and

automatic pump shut down

control through conveyor.

• Common water, drain, electric

and steam connections.

• Exclusive load end flush

system.

• Built-in integral wiring channel.

• Automatic temperature control

and positive low-water heater

and pump seal protection.

• Built-in inherent motor overload

protection with manual reset.

• Built-in vent ducts—dampers

and drip control.

• Improved washability with high

pressure prewash—wash and

power rinse systems.

• Compct modular design.

• 115 volt pilot circuit.

• Lower prewash arm.

• Automatic initial fill.

• Wash arms easily installed and

removed without tools.

• All function components

(motors, drains, etc.) located

on operators side of dishmachine for accessibility and

ease of maintenance.

• Built-in integral prewash water

replenishment system.

• Final rinse actuator.

• Removable self-flushing stainless steel strainer pans and

large deep scrap buckets for

each tank.

• Door interlocks on all doors.

• Optional energy saving blowerdryer.

Electric 20 KW—63% energy

reduction.

Steam 75 lbs./hr.—56%

energy reduction.

• Choice of electric, steam

injection or steam coil heat.

Specifications, Details, Dimensions and

Connections inside.

FT -800 SERIES

DISHW ASHER

FOOD EQUIPMENT

STANDARD DESIGN FEATURES

TOP MOUNTED CONTROL PANEL –

Controls in top-mounted stainless steel control

center with master On/Off Power Switch.

STOP/START PUSH BUTTONS – Recessed, side located waterproof Start/Stop push

buttons and flip-up hinged dishware platform on both ends of dishwasher.

WASH ARMS – Computer-designed prewash,

wash and power rinse arms. Arms designed so

they can be installed only in correct position.

FLUSH DOWN –

Exclusive load end

flush down system.

DRAIN CLOSERS – Door operated drain

closers . . . front located drains, stainless steel

tank overflow tubing to prewash, and final

rinse water feed piping.

PUMP – Self-draining Hobart pump motors

with inherent motor protection and manual

overload reset push buttons on each motor.

FOOD EQUIPMENT

Qty. Item No.

FT -800 SERIES

DISHW ASHER

WIRING CHANNEL – Built-in integral wireway above tank water level.

SCRAP PANS – Large one-piece sloped

scrap screens and deep removable recessed

scrap buckets for prewash, wash and power

rinse tanks.

VENT DUCTS – Built-in vent ducts with

adjustable dampers and drip shield on each

end of dishwasher. 2" x 24" load end and

4" x 24" discharge end (inside dimensions).

POSITIVE LOW WATER PROTECTION –

Solid state positive low water protection for

tank heaters.

FT -800 SERIES

DISHW ASHER

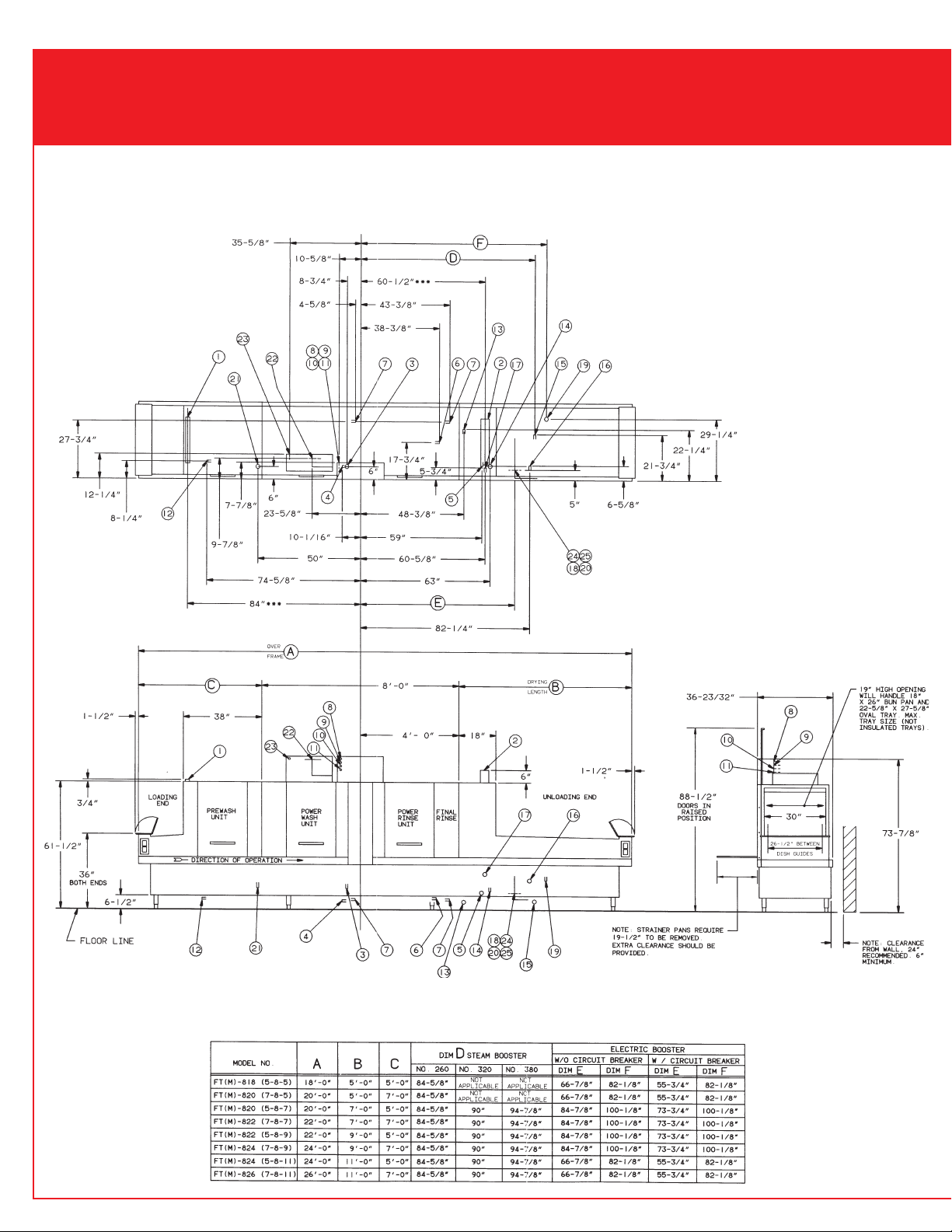

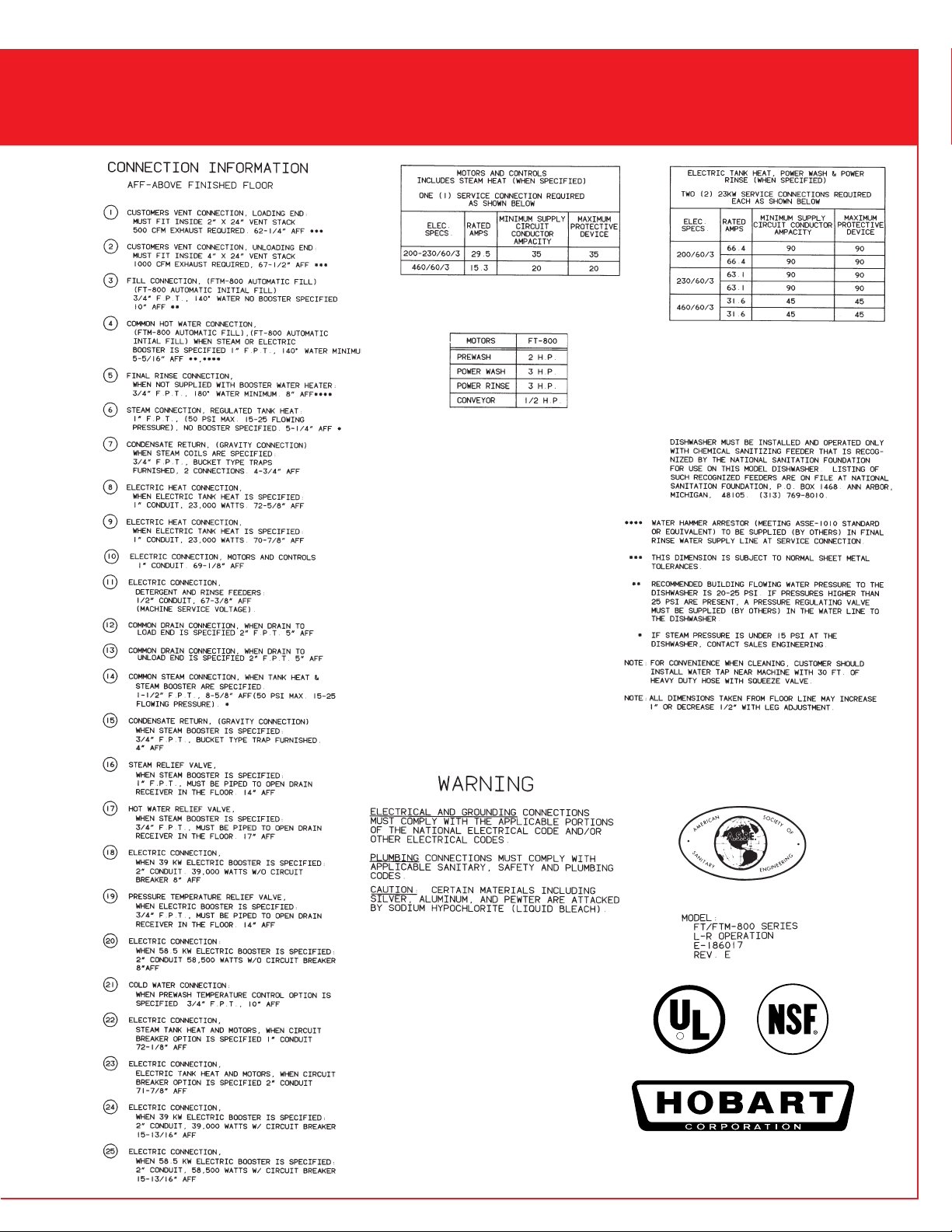

DETAILS, DIMENSIONS AND CONNECTIONS RIGHT TO LEFT OPERATION

FOOD EQUIPMENT

FOOD EQUIPMENT

Qty. Item No.

FT -800 SERIES

DISHW ASHER

R

701 RIDGE AVENUE

TROY, OHIO 45374-0001

FT -800 SERIES

DISHW ASHER

DETAILS, DIMENSIONS AND CONNECTIONS LEFT TO RIGHT OPERATION

FOOD EQUIPMENT

FOOD EQUIPMENT

Qty. Item No.

FT -800 SERIES

DISHW ASHER

R

701 RIDGE AVENUE

TROY, OHIO 45374-0001

FT -800 SERIES

DISHW ASHER

FOOD EQUIPMENT

SPECIFICATIONS Listed by Underwriters Laboratories Inc. and National Sanitation Foundation.

Meets Requirements of A.S.S.E. Standard No. 1004.

DESIGN: Fully automatic, flight-type dishwasher

machine, consisting of a 5' x 7' loading section

with power recirculating prewash, an 8' power

wash, power rinse and fresh water final rinse

section, and a 5', 7', 9' or 11' drying and

unloading section. Recirculating water prewash,

power wash, power rinse, and final rinse

compartments constructed with splash baffles

and flexible plastic strip curtains for effective

control and separation of spray systems. Specify

high or low temperature operation.

CONSTRUCTION: Tank and chambers are

heavy gauge stainless steel with No. 3 polish

on appearance surfaces. Stainless steel

frames, legs, and feet are standard. Three large

inspection doors with welded handles.

PUMPS: Recirculating pumps with Ni-Resist

impellers and face seal with stainless steel

metal parts and ceramic seat. Readily

removable motor-impeller assembly permits

quick inspection. All pumps are self-draining.

MOTORS: Hobart-built, grease-packed ball

bearings, splashproof design, ventilated with

inherent overload protection in each motor.

Recirculating prewash unit 2 H.P., power wash

and power rinse 3 H.P. each, conveyor 1⁄2 H.P.

Available in electrical specifications of

200-230/60/3 and 460/60/3 with manual reset.

CONTROLS: A stainless steel control center

with Power “On/Off” switch is mounted on top of

the center section. Controls use 115 volt pilot

circuit. Recessed “Start/Stop” controls at each

end of machine in stainless steel enclosure,

factory wired. Electrical components are

completely wired with 105°C, 600V thermoplastic insulated wire with stranded conductors

routed through covered wireway built into the

front of the machine above tank water level and

UL Listed electrical metallic tubing or liquid-tight

flexible metal conduit. Locking style electrical

connectors are used for connections between

machine sections. As an energy saving control

feature, operation of pumps, final rinse and

optional blower-dryer stop when conveyor stops.

FLIGHT TYPE CONVEYOR: Stainless steel

side links, and tie rods and conveyor tracks.

Injection molded, resilient Duraflex flight links to

accommodate flatware and trays in preferred

inclined position.

VAPOR CONTROL: Built in vent ducts with

dampers and drip shields located on both

ends of machine. Load end duct connection is

2" x 24" inside. Unload end duct connection is

4" x 24" inside.

RECIRCULATING PREWASH SECTION:

Removes soil by means of recirculated water

sprayed over dishes before they enter the power

wash zone. The unit receives its water from two

sources. The design provides for receiving all

detergent overflow water from the wash tank

and all the rinse tank overflow. Prewash

compartment is fitted with stainless steel upper

and lower wash arms having specially shaped

FORM F-7964 (REV. 1092) LITHO IN U.S.A. (H-01)

nozzles with large openings arranged to

effectively remove soil from all types of ware.

Prewash flushdown is supplied as standard.

Large removable one-piece perforated

stainless steel screen sloped downward to

deep perforated stainless steel basket. Baskets

and screens are removable from front of

machine.

DRAIN AND OVERFLOW: Prewash tank

equipped with bell type overflow and drain

valve. Closing the inspection door will

automatically close the drain valve.

POWER WASH AND POWER RINSE: Power

wash and power rinse tanks are equipped with

upper and lower stainless steel wash arms

with specially-shaped nozzles having large

openings and arranged to effectively direct

water jets to all ware surfaces. Wash arms are

easily removable without use of tools. Large

one-piece removable perforated stainless steel

screen sloped downward to deep perforated

stainless steel baskets. Baskets and screens

removable from front of machine.

DRAIN AND OVERFLOW: Power wash and

power rinse overflow system directs water

through internal connecting stainless steel

tubing to prewash section. Drain valve is

controlled from front of machine and is

automatically closed by closing inspection door.

TANK HEATING: Power Wash tank and Power

Rinse tank water temperatures are each

thermostatically controlled. The tank heat with

positive low water protection is automatically

activated when the Power switch is turned “On.”

If the tank is accidentally drained, the low water

protection device automatically turns the tank

heat off. Select one of the optional heats listed

under Optional Equipment—Tank Heating.

FINAL RINSE: Upper rinse arm has two rows of

nozzles above and lower arm has one row of

nozzles below dishware. Final rinse water line is

equipped with vacuum breaker on downstream

side of solenoid valve. Design provides for

collection and division of final rinse water after

use to power wash tank and power rinse tank.

Sanitizer and rinse agent dispenser injection

ports provided in final rinse piping above rinse

chamber. Final rinse water saver “Rinse Gate”

supplied as standard energy saving feature.

Machine (line) voltage, fuse protected terminal

provision for detergent and rinse agent

dispensers.

CONVEYOR DRIVE UNIT: Powered by a

Hobart-built, inherent overload protected

1

⁄2 H.P. grease packed ball bearing motor. Trip

mechanism provided on unloading end of

conveyor. Jam protection is provided by load

sensing switch at drive platform. These devices

interrupt operation of the conveyor motor which

stops the conveyor, pumps and final rinse

flow. Operation is restarted automatically by

removing item which has actuated the trip

mechanism, or by operator switch if shutdown

resulted from other cause.

STANDARD EQUIPMENT: Automatic initial

fill, prewash flushing. Final rinse saver. Sealed

dial-type thermometers indicate water

temperature in Power Wash, Power Rinse and

Final Rinse. Positive low water protection for

tank heat. Plastic strip curtains throughout

machine. Stainless steel control panel. 115 volt

pilot circuit. Inspection door interlocks which

prevent pump/conveyor operation when

inspection door on prewash, wash or rinse

chambers is open. Built-in wireway. Drains are

automatically closed when inspection doors

are closed. Stainless steel framing members,

legs and adjustable feet. Common drain to

load end. Common water connection. Common

steam connection for tank heat and optional

booster on steam heated machine. Common

electric connection for motors and controls.

OPTIONAL EQUIPMENT AT EXTRA COST—

MECHANICAL: Stainless steel hang-on/

drop-in-place front and rear panels. Energysaving Blower-Dryer: Electric or steam heated.

Common drain to unload end. Modified

conveyor for insulated trays.

OPTIONAL EQUIPMENT AT EXTRA COST—

TANK HEATING: Regulated stainless steel

3

⁄4" steam injectors in power wash and power

rinse tanks. Stainless steel steam coils.

Regulated electric immersion heaters.

OPTIONAL EQUIPMENT AT EXTRA COST—

BOOSTERS: Steam heat exchanger with

electric thermostatic control, basket type trap,

pressure relief valves for both water and steam,

pressure reducing valve and pressure gauge

for incoming water. Booster amply sized to raise

120°F inlet water to 180°F with minimum of 20

PSI flowing steam pressure (or 140°F inlet

water to 180°F with minimum of 10 PSI flowing

steam). Maximum steam pressure is 50 PSI.

Electric booster adequately sized to raise

140°F inlet water to 180°F. Pressure/temperature relief valve, pressure reducing valve and

pressure gauge for incoming water.

OPTIONAL EQUIPMENT AT EXTRA COST—

CHEMICAL SANITIZING: Chemical injection

pump for low temperature operation.

OPTIONAL EQUIPMENT AT EXTRA COST—

ELECTRICAL: Prewash thermometer.

As continued product improvement is a policy of Hobart,

specifications are subject to change without notice.

701 RIDGE AVENUE

TROY, OHIO 45374-0001

Printed On Recycled Paper

Loading...

Loading...