Item # _____________________________________

Quantity ___________________________________

C.S.I. Section 11400

HBA2G DOUBLE RACK

701 S Ridge Avenue, Troy, OH 45374

1-888-4HOBART • www.hobartcorp.com

STANDARD FEATURES

■ Advanced digital programmable control panel

includes:

- Bake/steam timers

- Cool-down mode

- Four stage baking

- Auto on/off control

- Auto vent

- 99 menus

- Energy saving idle mode

■ 300,000 BTU in-shot burner system

■ Heat exchanger with weldless construction for

longer life

■ Heavy duty rack lift with rack jam warning

system utilizing slip clutch feature

■ Soft start rotation system

■ Stainless steel construction

■ Oven body shipped in two main sections for

ease of installation

■ Flush oor with patented adjustable oor

construction provides easy access - no ramp

required

■ Field reversible bake chamber door

■ Hood with plenum for Type II installation

■ Space saving 72" wide x 62" deep footprint

(less canopy)

■ Wide viewing glass (21" W x 57.5" H) with triple

pane glass for reduced heat loss and cooler

working area in front of oven

■ Patented self-contained cast spherical steam

system

■ Pre-plumbed water regulator

■ Built-in rollers and levelers for ease of

installation

■ Single point 10" vent connection

■ Stainless steel “B” style rack lift

■ Capacity - two single racks or one double rack

■ One year parts/labor warranty

OVEN – GAS

MODEL

❑ HBA2G – Double Rack Oven, Gas

OPTIONS AND ACCESSORIES

❑ Back-up control

❑ Propane gas

❑ Floor extender kit

❑ Shipped assembled (less canopy/steam

system)

❑ Aluminum or stainless steel oven racks

❑ High output 350,000 BTU burner system

❑ Hood with grease lters – Type 1 (UL listed to

Standard UL 710 and meets all requirements of

NFPA-96)

❑ “C” style rack lift

❑ Kosher package

❑ 50 Hz available, consult factory for details

Specications, Details and Dimensions on Back.

HBA2G DOUBLE RACK OVEN – GAS

ANSI/NSF Standard #4

City of LA (M-910049) and State of MA (C3-0606-363)

F-40014 – HBA2G Double Rack Oven – Gas Page 1 of 2

HBA2G DOUBLE RACK

OVEN – GAS

SPECIFICATIONS

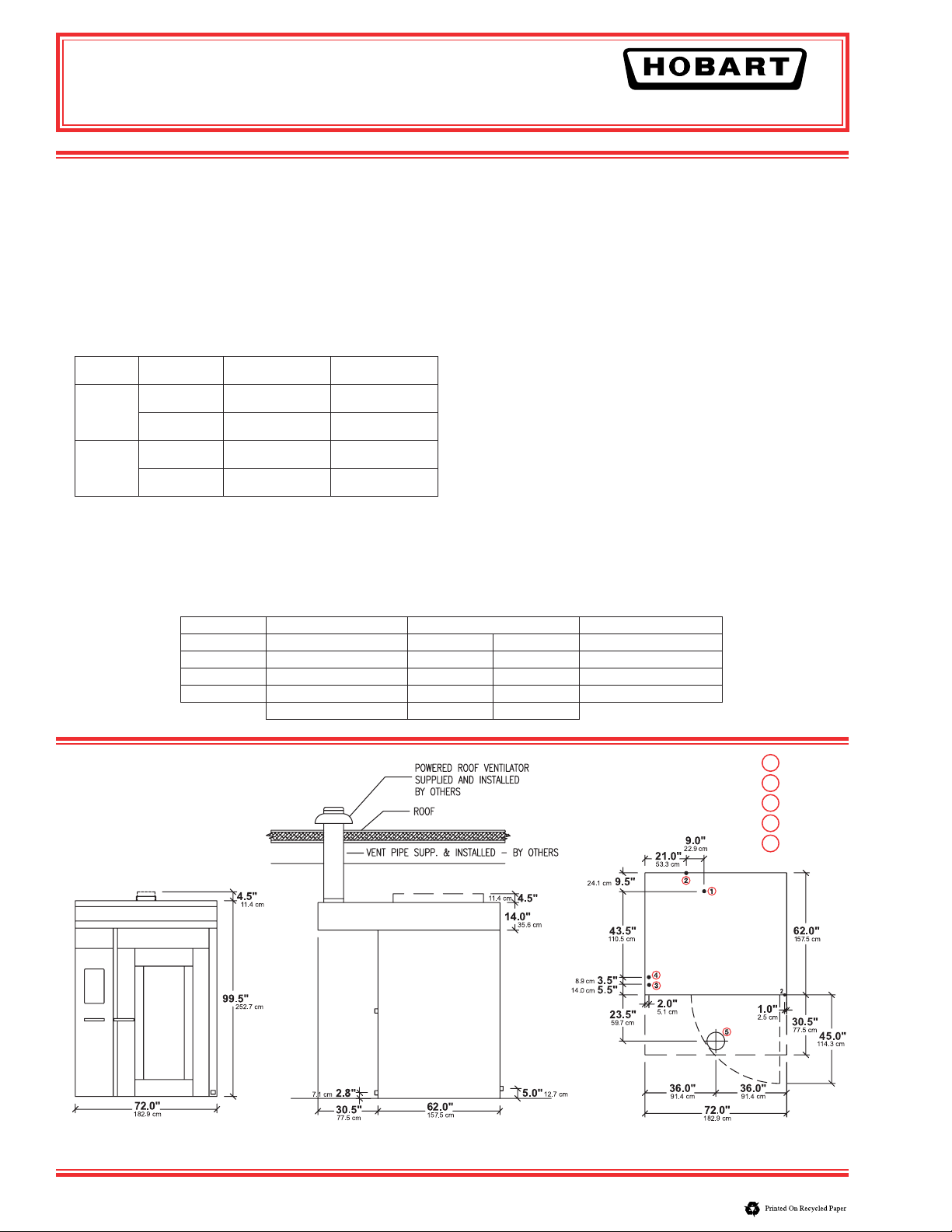

1. Water—1⁄2" NPT. Cold water @ 30 psi. minimum @ 3.0 GPM ow rate.

Water supply must have the proper hardness, pH and chloride concentration. Consult your local Hobart service ofce, water company and/or

water conditioner dealer before installation.

Recommended water hardness range: 2-4 grains per gallon

Recommended pH range: 7.0 to 8.0

Acceptable range for chloride concentration: 0-30 ppm

2. Drain—Choose either rear or front drain and plug the drain connection

that is not in use. Route to air-gap drain.

Rear drain: 3⁄4" FNPT; Kit is provided to extend drain to left or right side of

oven. Front drain: 3⁄8" FNPT.

3. Gas—11⁄4" NPT. Connect Point

Gas Input Rate

Standard

Natural Gas

Propane Gas

Natural Gas

Optional

Propane Gas

4. Electrical—2 supplies required.

1) 120/60/1. 15 amps – dedicated circuit required max. 20A

2) 208-230/60/3 4.4-4.2 amps

220/60/1 8.6 amps

460/60/3 2.2 amps

5. Hood Vent—10" diameter connection collar. Minimum 900 cfm

(25.5 m3/min) required with 0.6" w.c. (150 Pa) static pressure drop through

300,000 BTU/hr.

(88 kJ/s)

300,000 BTU/hr.

(88 kJ/s)

350,000 BTU/hr.

(102 kJ/s)

350,000 BTU/hr.

(102 kJ/s)

Supply Pressure

(owing)

5-14" w.c.

(1.25-3.5 kPa)

10-14" w.c.

(2.5-3.5 kPa)

6-14" w.c.

(1.5-3.5 kPa)

12-14" w.c.

(3.0-3.5 kPa)

701 S Ridge Avenue, Troy, OH 45374

1-888-4HOBART • www.hobartcorp.com

hood. Customer to supply duct and ventilator fan per local code. Air

proving switch factory installed and integrated with burner system

operation. Oven provided relay with max. 10.0 amp 1⁄2 H.P. @ 120V output

for fan operation.

NOTES

1. The purchaser is responsible for all installation costs and for providing:

Disposal of packing materials; labor to unload oven upon arrival;

installation mechanics; and all local service connections including

electricity, vents, gas, water and drain per local code. A factory technician

or factory authorized installation technician must supervise and approve

any installation. In order to validate the warranty, the start-up must be

performed by an Authorized Servicer.

2. All services must comply with federal, state and local codes. Input rates

will be reduced when oven installed at elevations over 3,000' (915 m).

Consult factory for elevation correction.

3. CAUTION – To reduce the risk of re, the appliance is to be mounted on

oors of non-combustible construction with non-combustible ooring and

surface nish and with no combustible material against the underside

thereof, or on non-combustible slabs or arches having no combustible

material against the underside. IMPORTANT: Do not route utilities (wiring,

plumbing, etc.) in or under the non-combustible oor beneath the oven.

4. For proper installation, oor should be level within 1⁄8" per foot not to

exceed 3⁄4". Floor anchors require minimum of 1" thick solid oor substrate.

5. Minimum clearances to combustible construction: 0 inches from sides

and back; 18" from top (99.5"). 10 feet minimum ceiling height for service

access and tilt up for installation.

6. Ventilator fan is required. Consult local authorities to determine whether

TYPE 1 (grease) or TYPE 2 (vapor) duct will be required. Hood connection

suitable for connection to Type B vent, except when products of baking are

grease laden.

7. Actual weight: 3,520 lbs.;

Shipping weight: 4,185 lbs. (freight class 70)

SECTION W x L x H (CRATED) PALLET WT. (lbs.) / CU. FT. W x D x H (ACTUAL)

Heating 71" x 111" x 47" 1,965 214.4 36" x 62" x 104"

Bake 71" x 111" x 47" 1,670 214.4 36" x 62" x 100"

Hood 23" x 98" x 40" 270 52.2 18" x 72" x 31"

Door 11" x 78" x 50" 280 24.9 44.5" x 5" x 74"

DETAILS AND DIMENSIONS

Highest Point on Oven—104.0" (264.2 cm)

Shipping Total 4,185 505.9

1 Water

2 Drain

3 Gas

4 Electrical

5 Hood Vent

Front View Side View Top View

As continued product improvement is a policy of Hobart, specications are subject to change without notice.

Page 2 of 2 F-40014 – HBA2G Double Rack Oven – Gas

F-40014 (REV. 10/09) LITHO IN U.S.A. (H-01)

Loading...

Loading...