Page 1

Technical Manual

TNC 122

April 97

Page 2

This Technical Manual for the HEIDENHAIN TNC 122 straight cut control applies for the

NC software version 246 117 08 and is subject to change without notice.

Page 3

Foreword

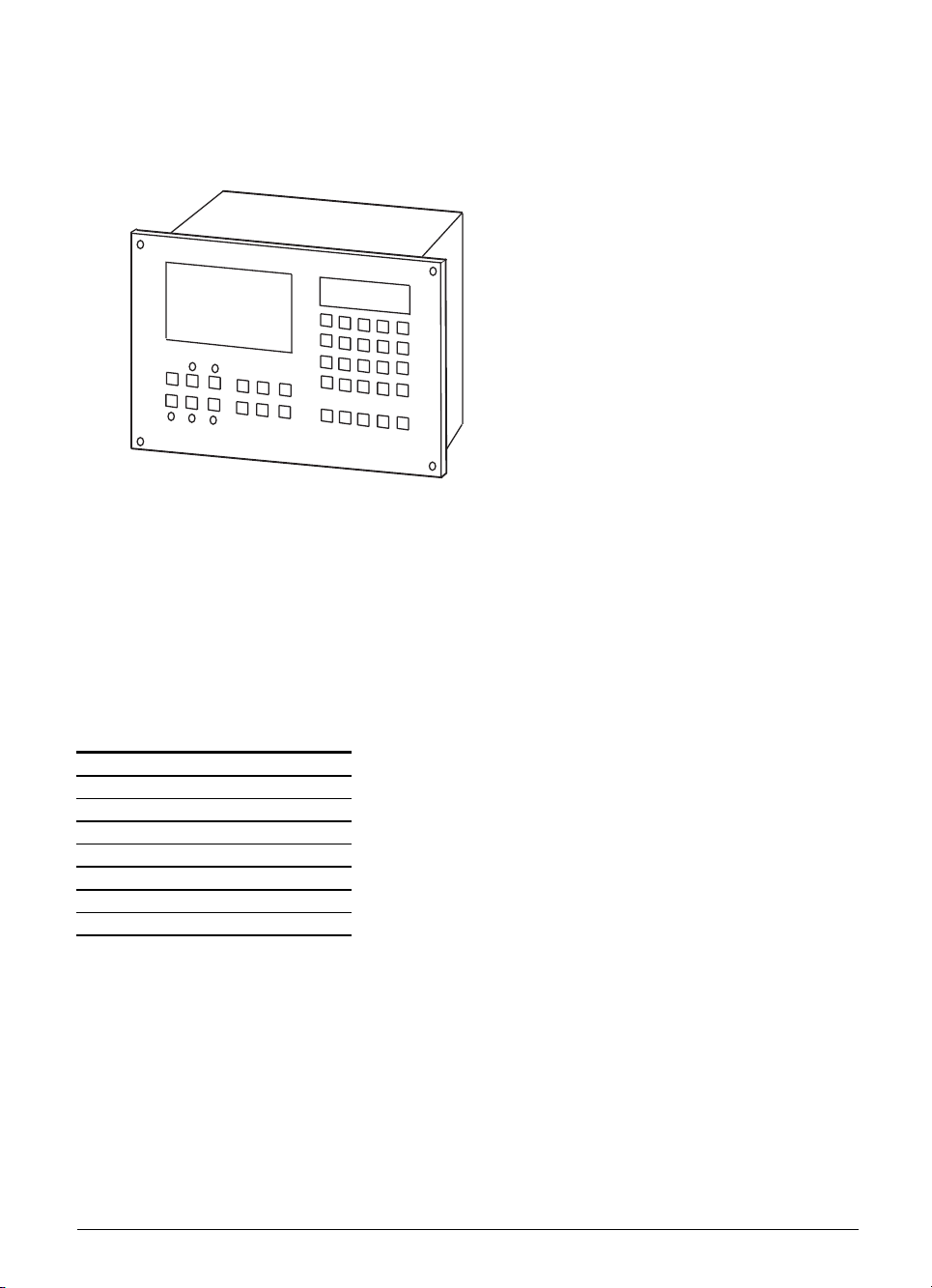

The HEIDENHAIN TNC 122 is a compact, three-axis straight cut control for machine tools with

central drive. It has been developed as the successor model for the TNC 121, to which it is

compatible for installation. The TNC 122 has an expanded range of functions.

This Technical Manual is intended for all machine tool builders and machine tool distributors, and for

retrofitting companies who wish to replaced an installed TNC 121 with a TNC 122. It provides the

information required for mounting, electrical connection and commissioning the control.

For information on the new and improved operating features, please refer to the User's Manual.

Page 4

Contents

1 Specifications 4

2 Hardware 6

3 Software 6

4 EPROM Sockets 7

5 Power Supply 8

6 Grounding Diagram 9

7 Connections 10

8 Pin Layout 11

8.1 Data interface 15

9 Machine Integration 16

9.1 Encoders 16

9.2 Traverse ranges 17

9.3 Reference marks 18

9.4 Position feedback control of the NC axes 24

9.5 Monitoring functions 29

9.6 Display and operation 31

9.7 EMERGENCY STOP circuit 33

10 Exchanging the control 36

11 Machine Parameters 37

11.1 Entering and changing machine parameters 37

11.2 Machine parameter list 38

12 PLC Description 45

12.1 PLC-EPROM 45

12.2 PLC Commands 46

12.2.1 Load and store commands 46

12.2.2 Set commands 49

12.2.3 Logical connective operations 50

12.2.4 Arithmetic commands 52

12.2.5 Comparisons 54

12.2.6 Parenthetical expressions 55

12.2.7 Shift commands 56

12.2.8 Bit commands 57

12.2.9 Stack operations 57

12.2.10 Jump commands 59

12.3 Classes of markers and bytes 60

12.4 Marker list 61

13 Error Messages 65

14 Dimensions 66

15 Subject Index 69

4/97 TNC 122 Contents 3

Page 5

1 Specifications

Type of control

Program memory

Design

Tool memory

Modes of operation

Program input

Display step

Programmable function

Languages

Max. traverse

Max. traversing speed

Position encoders

PLC cycle time

Control inputs

Control outputs

Data interface

Straight cut control for 3 axes

and paraxial positioning

Memory for up to 500 NC blocks,

20 NC programs

Compact control for panel mounting

7-segment LED for actual position display

LED dot matrix 5 x 7 for preset display

One tool for length and radius compensation

Manual operation

Positioning with manual data input

Program run single block

Program run automatic

Programming and editing

Manually through TNC keyboard

Through RS-232-C/ V.24

1 µm or 5 µm (0.000 05 in., 0.000 2 in.)

Nominal position in absolute or incremental dimensions

Subprograms, program section repeats

Tool radius compensation R+/RBolt-hole circle, hole circle segment, linear hole pattern

Feed rate / rapid traverse

M functions

Dutch, English, French, German, Spanish

± 9999.999 mm

30 000 mm/min

Incremental HEIDENHAIN position encoders, optionally

with distance-coded reference marks

16 µA

Grating Periods: 4, 10, 20, 40, 100, 200 µm

24 ms

3 position encoder inputs (sinusoidal inputs)

15 PLC inputs +1 PLC input for a control-is-ready

acknowledgment

One analog output (for central drive)

15 PLC outputs + 1 PLC input for control-is-ready signal

RS-232-C/ V.24, up to 38 400 baud

/40 µAPP selectable

PP

4 TNC 122 1 Specifications 4/97

Page 6

Power supply

Power consumption

Ambient requirements

Weight

Primary-clocked power supply 100 V to 240 V

19 W

Operation : 0° to +45° C

Storage : –30° to +70° C

Relative humidity, mean annual: < 75%, for max. 30 days

per annum, naturally distributed: < 95%

Approx. 3 kg

4/97 TNC 122 1 Specifications 5

Page 7

2 Hardware

Id. Nr. 284 083 xx

3 Software

Software versions

The NC software 246 117 07, together with the PLC software 277 938 13 of the TNC 122 replaces

the following software versions of the TNC 121:

Software Version of TNC 121

205 438

205 443

205 444

205 446

205 455

205 456 unipolar standard

205 457 bipolar standard

205 430

6 TNC 122 2 Hardware 4/97

Page 8

4 EPROM Sockets

IC-P1 NC

IC-P2 PLC

The PLC EPROM is a 2 MB or 4 MB chip.

Danger of electrical shock!

Unplug the power cord before opening the housing.

Danger to internal components!

When handling components that can be damaged by electrostatic discharge (ESD),

observe the safety recommendations in DIN EN 100 015. Use only antistatic packaging

material. Be sure that the work station and the technician are properly grounded during

installation.

4/97 TNC 122 4 EPROM Sockets 7

Page 9

5 Power Supply

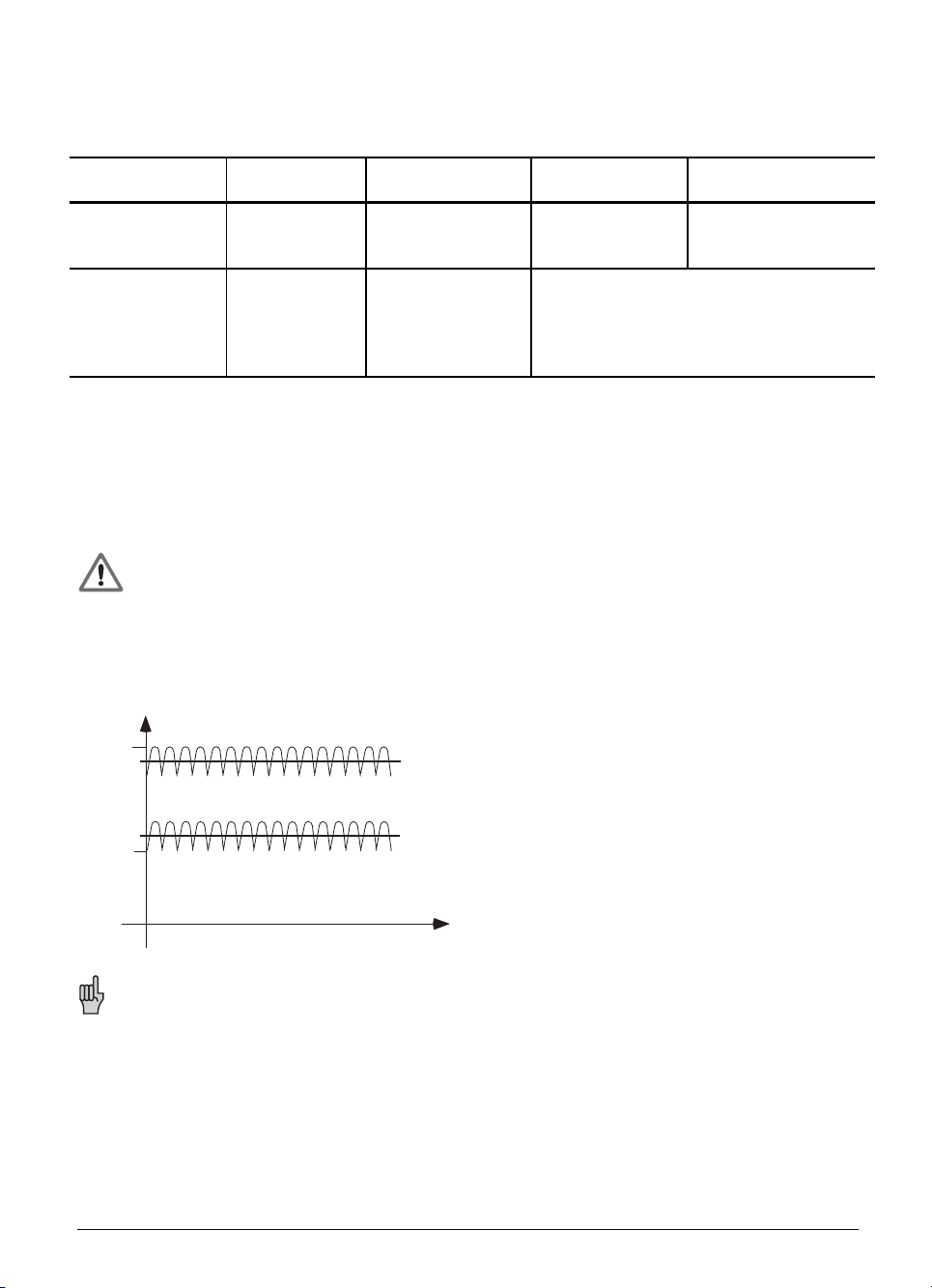

The voltage must comply with specifications:

Component Power supply Voltage range Max. power

Power consumption

consumption

NC Primary clocked

power supply

100 – 240 V

(–15% to +10%)

— Approx. 19 W

48 – 62 Hz

PLC 24 V

(with basis

insulation

according to

Lower limit

20.4 V__....

Upper limit

31 V __....

1)

Max. 10 mA per input

Max. 100 mA per output

EN 50 178)

1)

Voltage surges up to 36 V __.... for t < 100 ms are permissible.

All small contactors and relays must have a quenching diode.

PLC power supply

The PLC (PLC inputs and outputs) of the TNC 122 is powered from the 24 V machine control voltage

supply.

Danger to internal components!

Connect inductive loads only with a quenching diode parallel to the inductance.

Superposed AC components as they arise from a three-phase bridge rectifier without smoothing

(see DIN 40110/1075, Section 1.2) must not exceed 5%. This results at the upper limit in the

absolute value 33.4 V and at the lower limit the absolute value of 18.5 V.

U

32.6 V

31 V

20.4 V

18.5 V

t

To increase the noise immunity, connect the ground terminal on the rear panel to the

central ground point of the machine.

(Minimum cross-section: 6 mm

The 0 V line of the PLC power supply must be grounded with an earth lead (∅ ≥ 6 mm

2

)

2

) to the main

frame ground of the machine.

8 TNC 122 5 Power Supply 4/97

Page 10

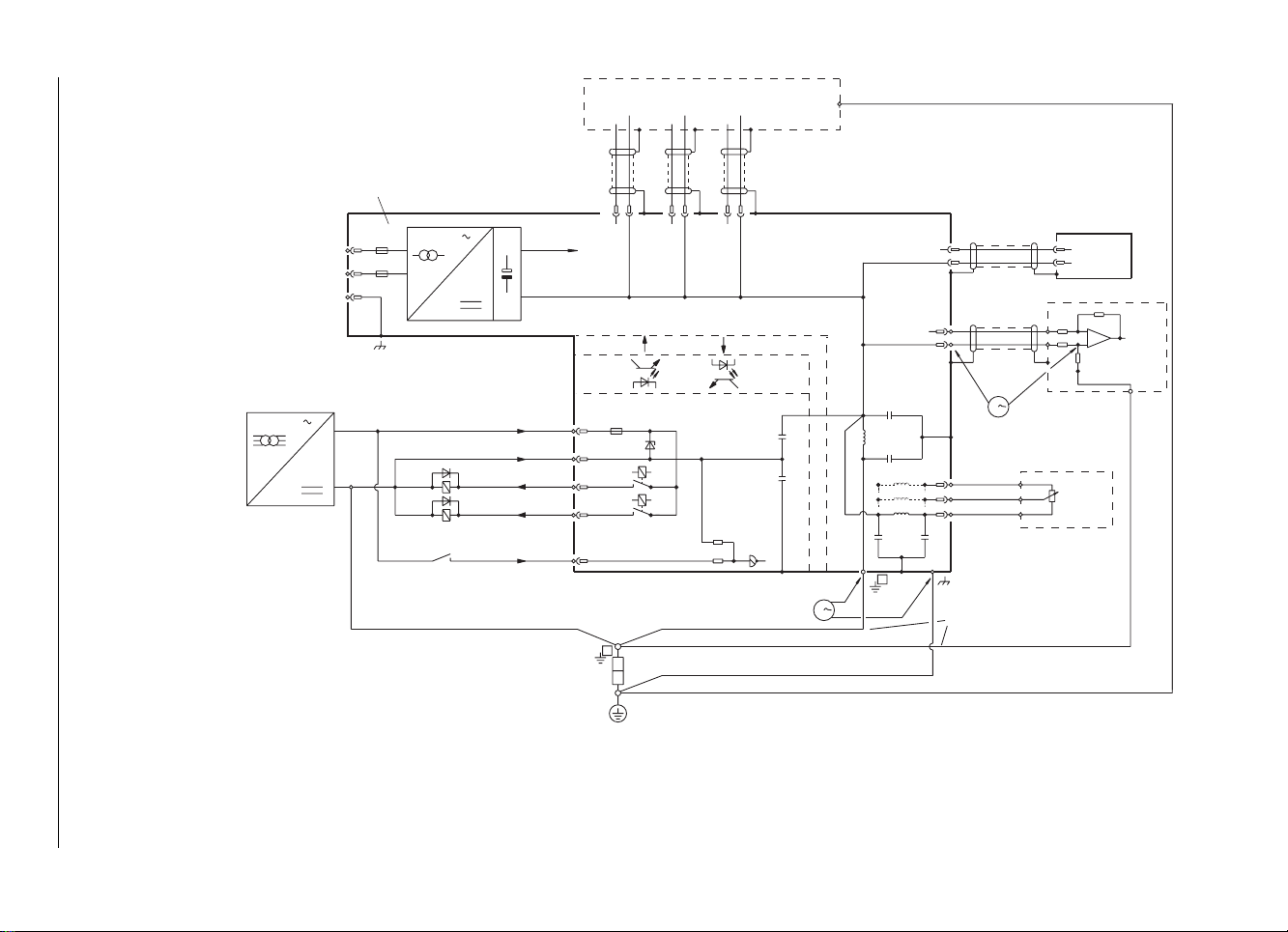

4/97 TNC 122 6 Grounding Diagram 9

Machine-Encoders

321

6 Grounding Diagram

Line voltage

100 - 240V

Line frequency

50 - 60 Hz

PLC supply voltage

with basic insulation

3

X51

TNC 122

L1

N

PE

+24V-

0V

X1 X2 X3

SI

SI

1

stab. power

supply

0V

X21

Adapter

V.24

X41/23

Motor controller

with nominal value

0V

difference input

Pot. for

feed rate

X41/9

X41/33

0V +24V-

15 outputs

0,1A

EMERGENCY STOP

0,1A

16 inputs

X41

X41/10

X41

6mm

Optoc.

SI

2

B

1

0

6mm

6mm

6mm

6mm

2

2

2

2

C

C

Test point 1

(Fault voltg. 0V/

housing)

V

C

L

C

L

B

X41/22

V

Test point 2

(Fault voltg. with

grounded nominal

value input)

X41/48

X41/24

X41/47

CC

If nominal value input is grounded,

a ground loop will result. Therefore

be sure that 0 V and ground wire

are short and configured for low noise.

Page 11

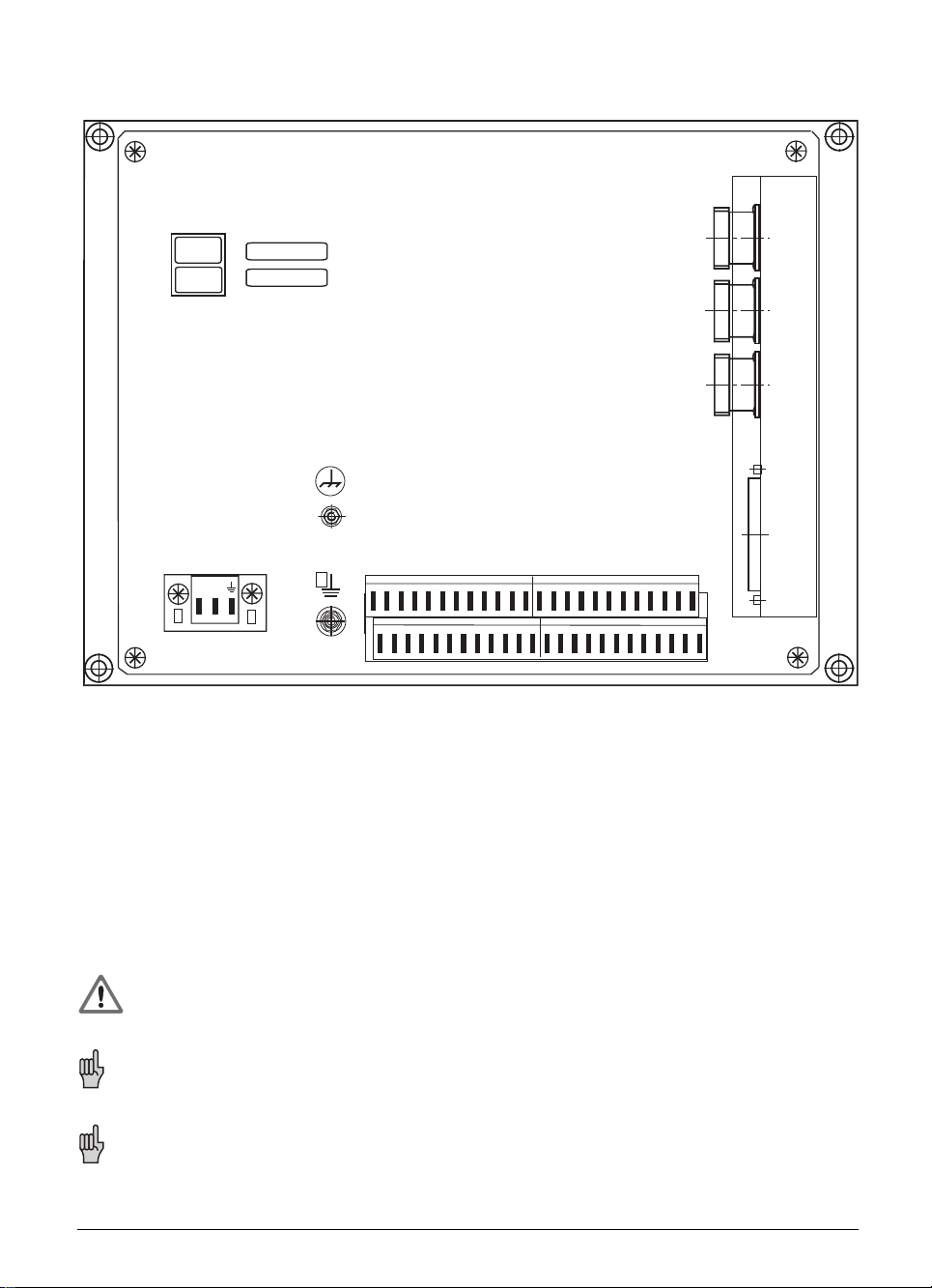

7 Connections

X1 = Encoder 1

X2 = Encoder 2

X3 = Encoder 3

L1

X51

N

NC xxx xxx xx

PLC xxx xxx xx

X1

X2

X3

X21

12

B

3 4 5 6 7 8 9 101112 1314 151617 18192021222324

25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 434445 46 47 48

X41(EXT)

X21 = RS-232-C/V.24 data interface

X41 = PLC inputs/PLC outputs/analog output/feed rate override/24 V PLC

X51 = Power supply

B = Signal ground

Danger to internal components!

Do not engage or disengage any connections while the unit is under power.

Interfaces X1, X2, X3, X21 comply with the recommendations in EN 50 178 for separation

from line power.

The outputs at connection X41 are metallically isolated from the device electronics by

means of optocouplers.

10 TNC 122 7 Connections 4/97

Page 12

8 Pin Layout

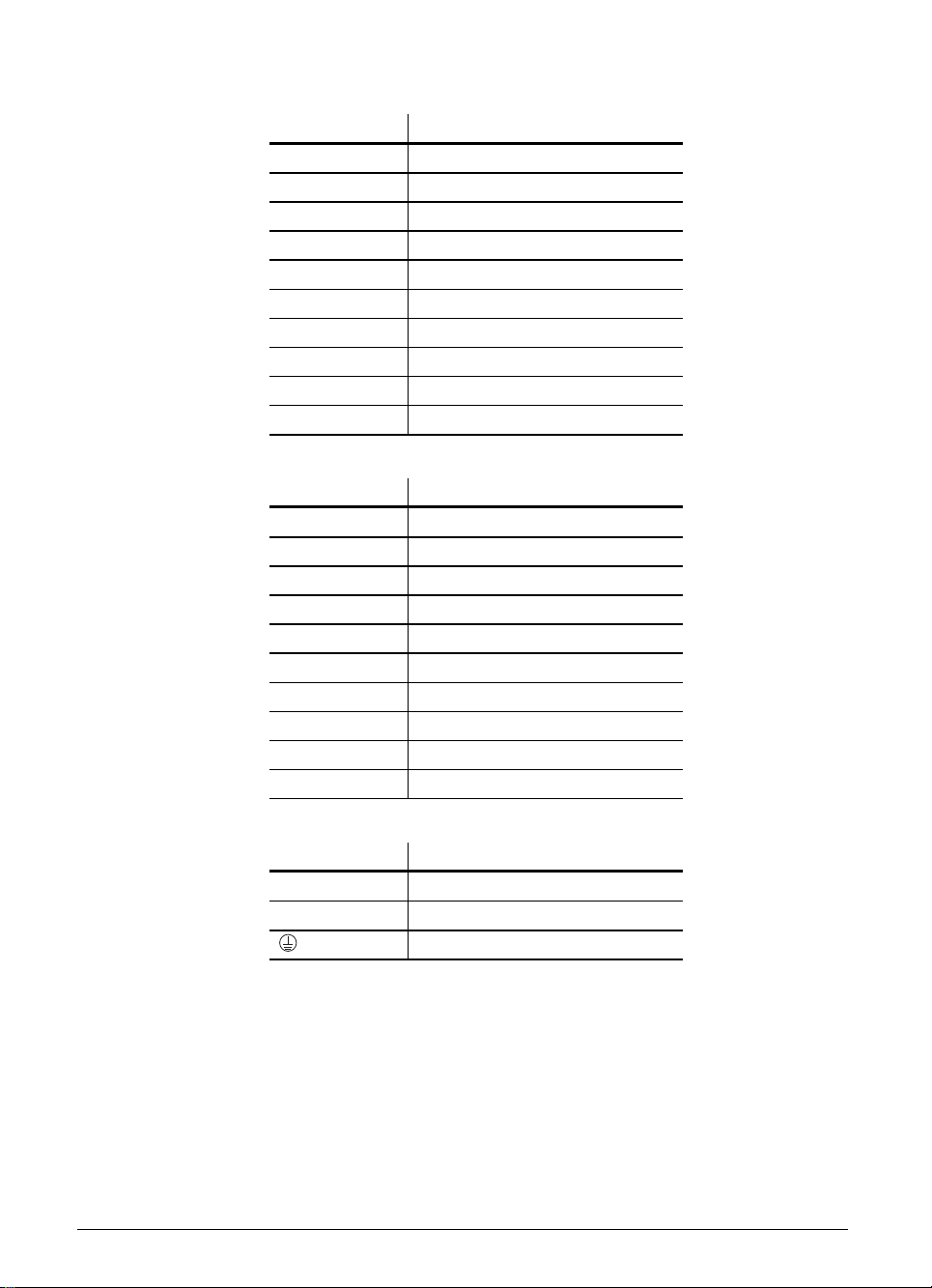

X1, X2, X3 Pin number Assignment

Encoder input

Flange socket with 5 I2+

9-pin female insert 6 I2–

X21 Data interface Pin number Assignment

RS-232-C/V.24

D-sub connector with 3 TXD

25-pin female insert 4 CTS

1I

2I

7I

8I

+

1

–

1

+

0

–

0

3+ 5 V

40 V

9 Internal shield

Housing External shield

1 Housing

2RXD

5RTS

6DTR

7 GND signal ground

8 – 19 Do not use

20 DSR

21 – 25 Do not use

X51 Power connector Pin number Assignment

L1 Live (230 V, F2.5 A fuse)

Terminal board, 3-pole N Neutral

Protective ground

Power consumption: typically 10 W

4/97 TNC 122 8 Pin Layout 11

Page 13

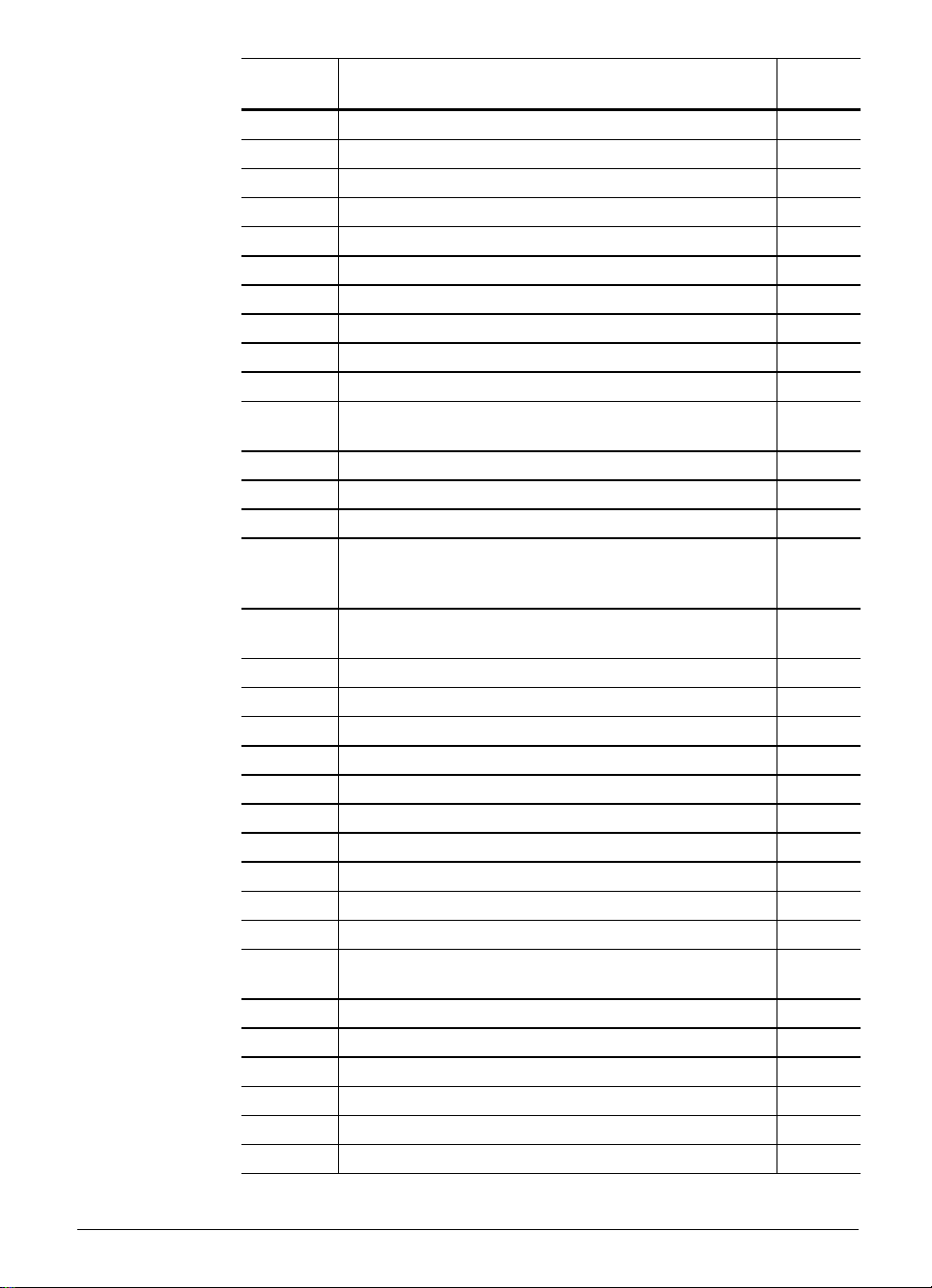

X41 TNC 122 Connection-assignment TNC 121

Contact Contact

PLC inputs

PLC outputs

Feed rate override

PLC power supply

1 I8 High=M26/ Low=M27

2 I9 High=M24/ Low=M25

3 I10 High=M22/ Low=M23 or M09

4 I11 High=M20/ Low=M21 or M05

5 I12 M08 coolant ON/ M09 OFF

Terminal board, 6 I13 M04 left spindle ON/ M05 OFF

48 contacts 7 I14 M03 right spindle ON/ M05 OFF

8 I15 acknowledgment M function

9 +24 V PLC

10 Control-is-ready output

11 O13 M04 left spindle ON/ M05 OFF or High=M18/

Low M19

12 O11 High=M20/ Low=M21 or M05

13 O9 High=M24/ Low=M25

14 O7 High=M28/ Low=M29

15 O5 Output for negative traverse direction (for one-

13

quadrant drives)

Erosion (205430) M02,M30 switches the output = 0

16 O4 Output for rapid traverse

11

(erosion 205430 M02,M30 Stop-erosion output=0)

17 O3 Output for Z axis enable 18

18 O2 Output for Y axis enable 20

19 O1 Output for X axis enable 22

20 O0 Output for Manual operating mode 16

21 not assigned

22

0 V

Analog voltage 8

23 +/– 10 V Analog voltage (depending on MP 70) 9

24 Feed rate override (wiper

)

4

25 I0 Input NC start 1

26 I1 Input NC stop 2

27 I2 Input rapid traverse key (Erosion 205430 erosion

7

ended, acknowledge with M36)

28 I3 Input for control-is-ready acknowledgment

29 I4 not assigned

30 I5 not assigned

31 I6 High=M23/ Low=M33

32 I7 High=M28/ Low=M29

33 0 V PLC 6

12 TNC 122 8 Pin Layout 4/97

Page 14

X41 TNC 122 Connection-assignment TNC 121

continued

The assignments are in accordance with the PLC Standard Program Id. Nr. 277 938 13!

Contact Contact

34 O14 M04 right spindle ON/ M05 OFF or High=M16/

Low=M17

35 O12 M08 coolant ON/ M09 OFF

36 O10 High=M22/ Low=M23 or M09

37 O8 High= M26/ Low=M27

38 O6 High=M32/ Low= M33

39 24 V for neg. traverse direction output 12

40 24 V for rapid traverse output 10

41 24 V for Z axis enable output 17

42 24 V for Y axis enable output 19

43 24 V for X axis enable output 21

44 24 V for “manual“ / “not manual“ output 15

45 “Not manual” output (inverted O0) 14

46 not assigned

47 Feed rate override 0 V 3

48 Feed rate override 15 V 5

The 24 Vdc power supply is monitored for reverse polarity and overvoltage. Reverse

polarity blows a fuse (F 2.0 A). Overvoltage above 47 V destroys the damping diode and

blows the fuse. Maximum current load is 300 mA.

PLC outputs: Inductive loads are permitted only with anti-surge diode!

Change of the I/O assignment only if Program 205 430 is active:

With the M functions M02 an M30 the output is switched to zero. Through the M function M36 the

output O5 is switched to 1 and is used to start the erosion process. Through input I2 the function

M36 is acknowledged and indicates that erosion has ended. In this case the feed-rate potentiometer

is without function.

4/97 TNC 122 8 Pin Layout 13

Page 15

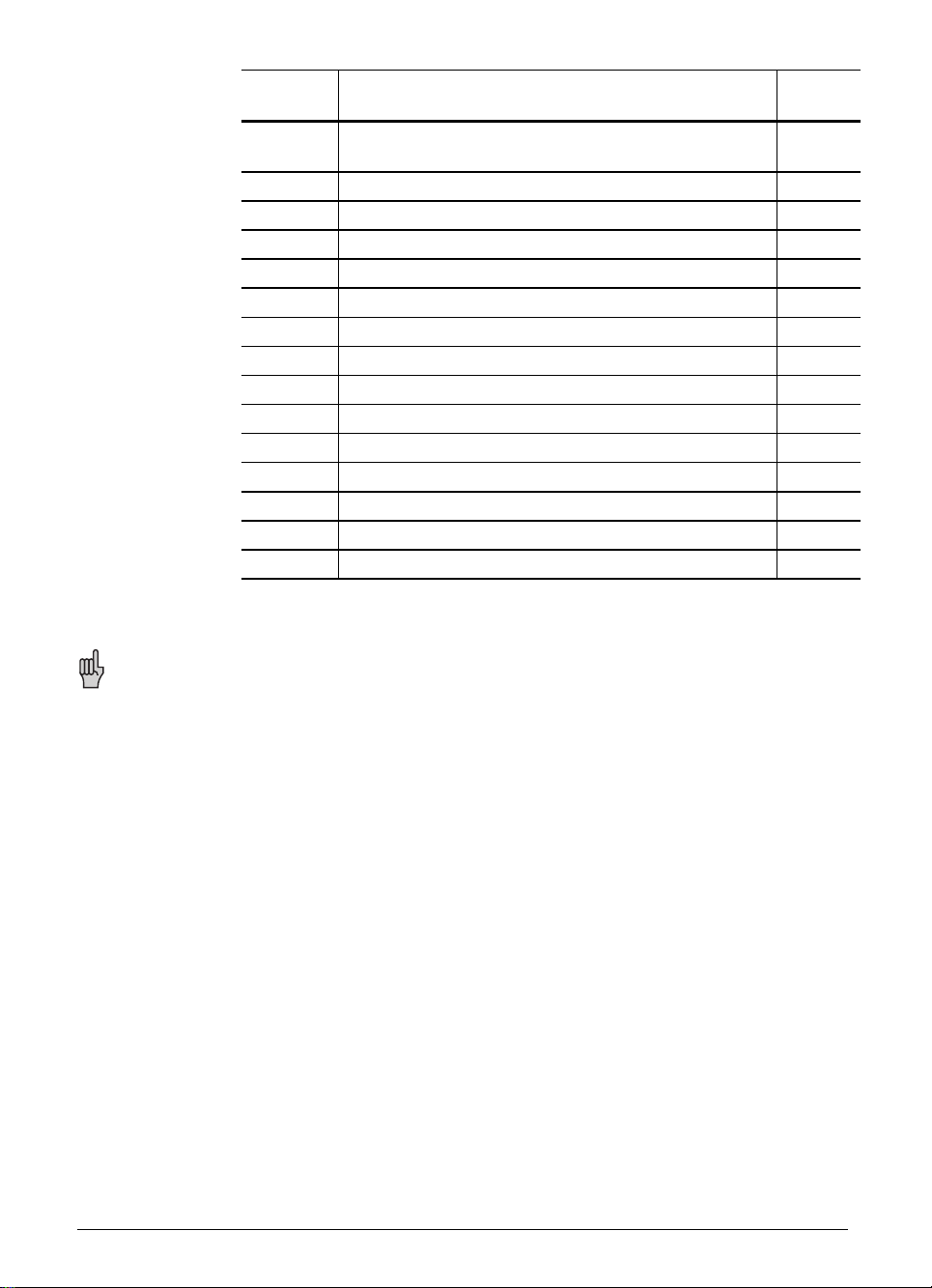

Installation of the Potentiometer:

6OLGHU

6OLGHU

Internal-source voltage for pot

External-source voltage for pot

14

TNC 122 8 Pin Layout 4/97

Page 16

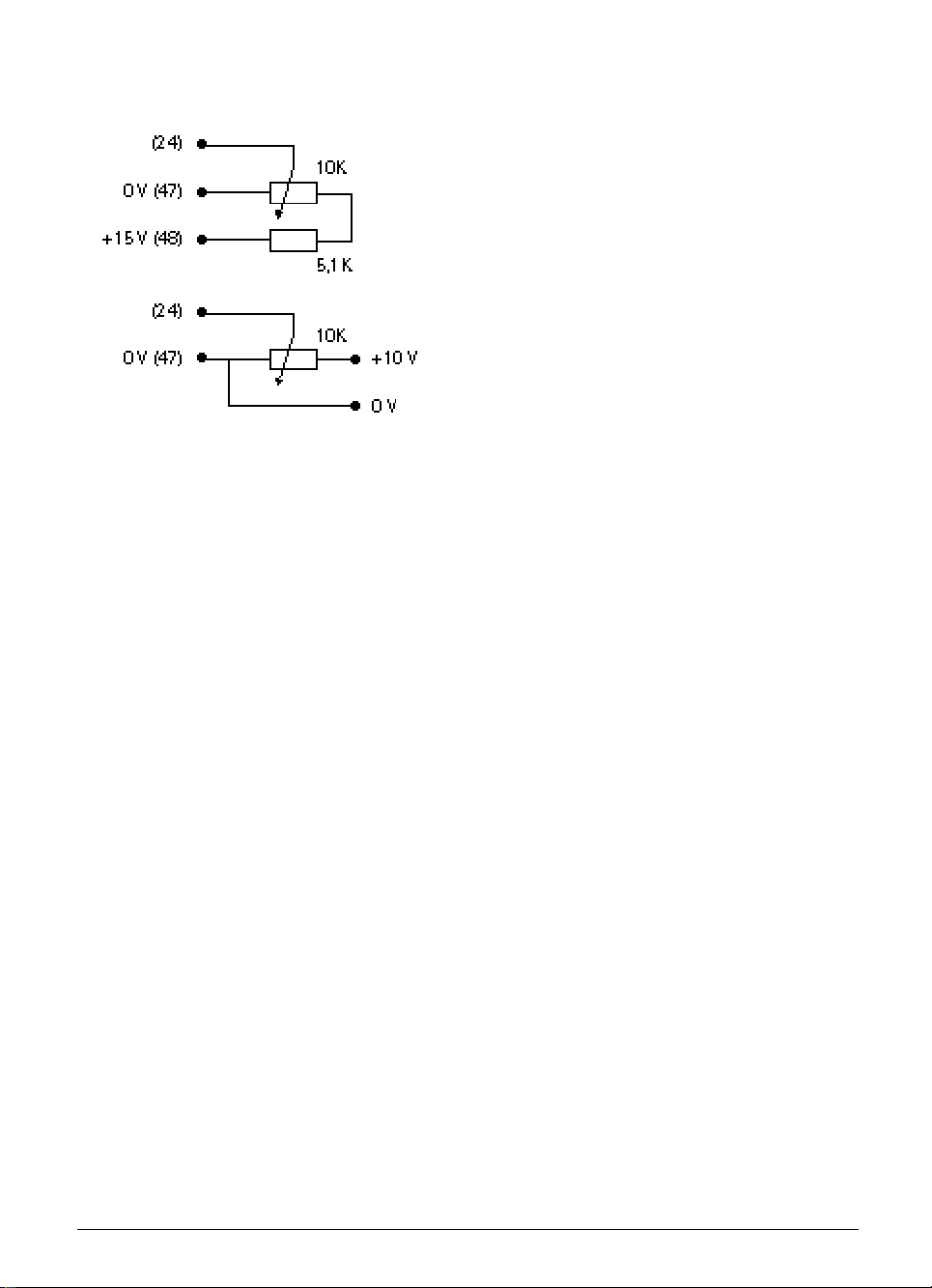

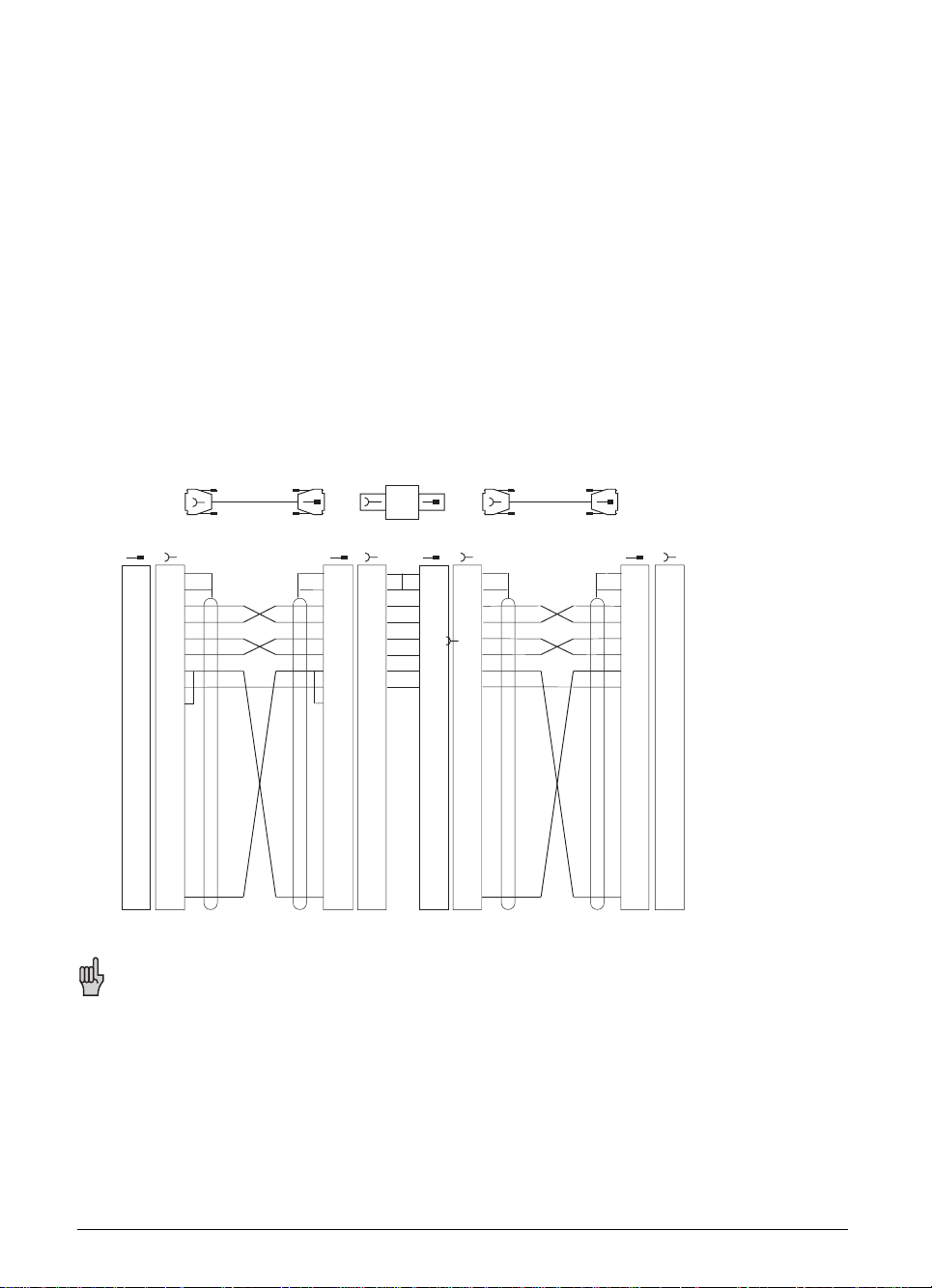

X21 Data Interface

The TNC 122 is equipped with an RS-232-C/V.24 data interface for operation in FE or EXT mode (see

the User's Manual). Programs and a list of the machine parameters can be output though this

interface. An RS-232-C adapter must be provided for a peripheral unit, such as a PC, FE 401, or

printer, to be connected to the control panel. The following drawing illustrates how to connect the

adapter block to X21.

HEIDENHAIN guarantees that, if properly connected, the RS-232-C/V.24 serial interface will reliably

transmit data between the TNC and a peripheral unit up to a distance of 20 meters.

HEIDENHAIN provides a standard cable 3 meters in length (Id.-Nr. 274 545 01) for connecting

peripheral units.

The data format in FE and EXT mode is fixed at 7 data bits, 2 stop bits and even parity. The FE mode

operates with ACK/NAK handshake, the EXT mode with DC1/DC3 handshake and RTS/CTS. The

data transfer rates are 9600 baud in FE mode and 2400 baud in EXT.

Peripheral

unit

GND

TXD

RXD

RTS

CTS

DSR

GND

DTR

3 m

Id.-Nr. 274 545 01

WH/BN WH/BN WH/BN

•

1

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

2

3

4

5

6

•

7

8

9

10

11

12

13

14

15

16

17

18

19

20

•

WH/BN

GN

YL

GY

PK

BL

RD

BN

V.24-Adapter Block

Id.-Nr. 239 758 01

•

•

•

•

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

9

9

10

10

11

11

12

12

13

13

14

14

15

15

16

16

17

17

18

18

19

19

20

20

•

1

••

2

3

4

5

6

7

8

9

10

10

11

11

12

12

13

13

14

14

15

15

16

16

17

17

18

18

19

19

20

20

Id.-Nr. 239 760..

•

1

2

3

4

5

6

7

8

9

max. 17 m

YL

GN

PK

GY

BN

RD

BL

•

1

•

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

9

9

10

10

11

11

12

12

13

13

14

14

15

15

16

16

17

17

18

18

19

19

20

20

X21 RS-232-C/V.24

GND Chassis

RXD Receive data

TXD Transmit data

CTS Clear to send

RTS Request to send

DTR Data terminal ready

GND Signal ground

DSR Data set ready

The interface complies with the recommendations in EN 50 178 for separation from line

power.

4/97 TNC 122 8 Pin Layout 15

Page 17

9 Machine Integration

9.1 Encoders

You can continue to use the same incremental position feedback encoders on the TNC 122, as you

used on the TNC 121.

Signal period

The signal period of the linear encoder is entered in machine parameter MP330.x (in µm). On linear

encoders with sinusoidal output signals, the signal period is the same as the grating period:

Signal period (~) = Grating period

The standard linear encoders from HEIDENHAIN have a grating period of 20 µm. Older encoders

have a grating period of 40 µm.

If linear position feedback is carried out with a rotary encoder on the ballscrew, then to calculate the

signal period you must consider not only the line count of the encoder (see the technical data for the

encoder) but also the pitch of the ballscrew:

Signal period (~) =

MP330

MP330.0 Axis 1

MP330.1 Axis 2

MP330.2 Axis 3

Machine parameter MP7320 can set the encoder amplitude so that older encoder models (on

machines with TNC 121) can be adapted to the TNC 122.

MP7320

Signal period

Input values: 4, 10, 20, 40, 100, 200 [µm]

Switchover of encoder input amplitude

Input values: 0 to 7

Bit 0 Axis X +0 = 16 µA

Bit 1 Axis Y +0 = 16 µA

Bit 2 Axis Z +0 = 16 µA

Screw pitch [mm] · 1000 [µm/mm]

Line count

+1 = 40 µA

+2 = 40 µA

+4 = 40 µA

16 TNC 122 9 Machine Integration 4/97

Page 18

Traverse direction

Machine parameters MP210 and MP1040 define the axis traverse direction. The traverse directions

for the axes on numerically controlled machine tools are specified in DIN.

MP210 defines the counting direction of the encoder signals. The counting direction depends on the

mounting configuration of the encoders.

MP210

MP1040 defines the polarity of the nominal voltage for positive direction of traverse.

MP1040

Assignment of encoder inputs

The individual axes can be assigned to the encoder inputs X1 to X3 with machine parameter MP110.

MP110

Counting direction of encoder signals

Input values: 0 to 7

Bit 0 Axis X +0 = positive

+1 = negative

Bit 1 Axis Y +0 = positive

+2 = negative

Bit 2 Axis Z +0 = positive

+4 = negative

Polarity of the nominal voltage with positive direction of traverse

Input values: 0 to 7 (must be "0" if MP70 is on "1" or "2")

Bit 0 Axis X +0 = positive

+1 = negative

Bit 1 Axis Y +0 = positive

+2 = negative

Bit 2 Axis Z +0 = positive

+4 = negative

Assignment of axes to encoder inputs

Input values: 0 to 2

0 = encoder input X1

1 = encoder input X2

2 = encoder input X3

MP110.0 Axis 1

MP110.1 Axis 2

MP110.2 Axis 3

9.2 Traverse Ranges

The traverse ranges are set with machine parameters. The traverse ranges are defined by software

limit switches. The input values for the software limit switches are based on the scale datum.

If the machine moves to a software limit switch, the following error message appears:

LIMIT SWITCH <axis>...

and the corresponding marker is set (M2624 to M2629).

4/97 TNC 122 9 Machine Integration 17

Page 19

MP 910

Entry range: –9999.999 to +9999.999 [mm]

MP910.0 Software limit switch axis X+

MP910.1 Software limit switch axis Y+

MP910.2 Software limit switch axis Z+

Positive traverse direction

MP 920

MP920.0 Software limit switch axis X–

MP920.1 Software limit switch axis Y–

MP920.2 Software limit switch axis Z–

M2624

M2625

M2626

M2627

M2628

M2629

Negative traverse direction

Entry range: –9999.999 to +9999.999 [mm]

Set Reset

Limit switch axis X+ NC NC

Limit switch axis X– NC NC

Limit switch axis Y+ NC NC

Limit switch axis Y– NC NC

Limit switch axis Z+ NC NC

Limit switch axis Z– NC NC

9.3 Reference Marks

For workpiece machining, the datum setting procedure assigns a unique position value (coordinate)

to each axis position. Since the actual position values are generated incrementally by the encoder,

this relationship between axis positions and position values must be restored each time the power is

interrupted.

HEIDENHAIN linear encoders are provided with one or more reference marks. When a reference

mark is traversed, a signal is generated that identifies that position as a reference point. After a

power interruption, crossing over the reference marks will restore the relationship between axis

slide positions and position values that was last established through the datum setting procedure.

Crossing over the reference marks also restores all machine-based references.

Since it is inconvenient to move the axes over large traverses to restore the reference point,

HEIDENHAIN recommends position encoders with distance-coded reference marks. On these

encoders the absolute position value is available after crossing two reference marks.

18 TNC 122 9 Machine Integration 4/97

Page 20

9.3.1 Traversing the Reference Marks

The reference marks of the axes should be traversed after the control is switched on. Machines

with the TNC 121 are usually equipped with scales that have a reference mark at each end. To

prevent the software limit switch ranges from being shifted, always traverse the reference mark

upon which the software limit switches are based.

If referencing is not desired, it can be deactivated with machine parameter MP1340.x or by pressing

the NO ENT key.

To traverse the reference marks, press the machine axis direction buttons. The sequence of axes is

determined by the user.

When the reference marks are crossed over,

the software limit switches are activated

•

the datum point last set is restored

•

If the position encoders have distance-coded reference marks, the machine datum is based on the

scale reference point (on linear encoders the scale reference point is the first reference mark after

the start of the measuring length; on angle encoders the scale reference point is marked).

Manual execution (standard process)

The reference mark is traversed with the axis-direction keys.

Automatic execution (not in TNC 122)

The direction of traverse and the speed when crossing over the reference marks is defined with

machine parameters (MP1320.x, MP1330.x). The sequence of functions when crossing over the

reference marks can be defined separately for each axis with MP1350.x.

A trip dog for the reference end position is necessary to prevent the traverse range from being

exceeded when the reference marks are crossed over. Install the trip dog at the end of the traverse

range. The trigger signal line from the trip dog is connected to a vacant PLC input. In the PLC

program, this PLC input is combined with the markers for “Reference end position” (M2556 to

M2558)

Encoders with distance-coded reference marks

Machine parameter MP1350.x=0

Reference marks

Trip dog

Closed

Open

Traverse direction MP1320.x

4/97 TNC 122 9 Machine Integration 19

"Reference end position"

Page 21

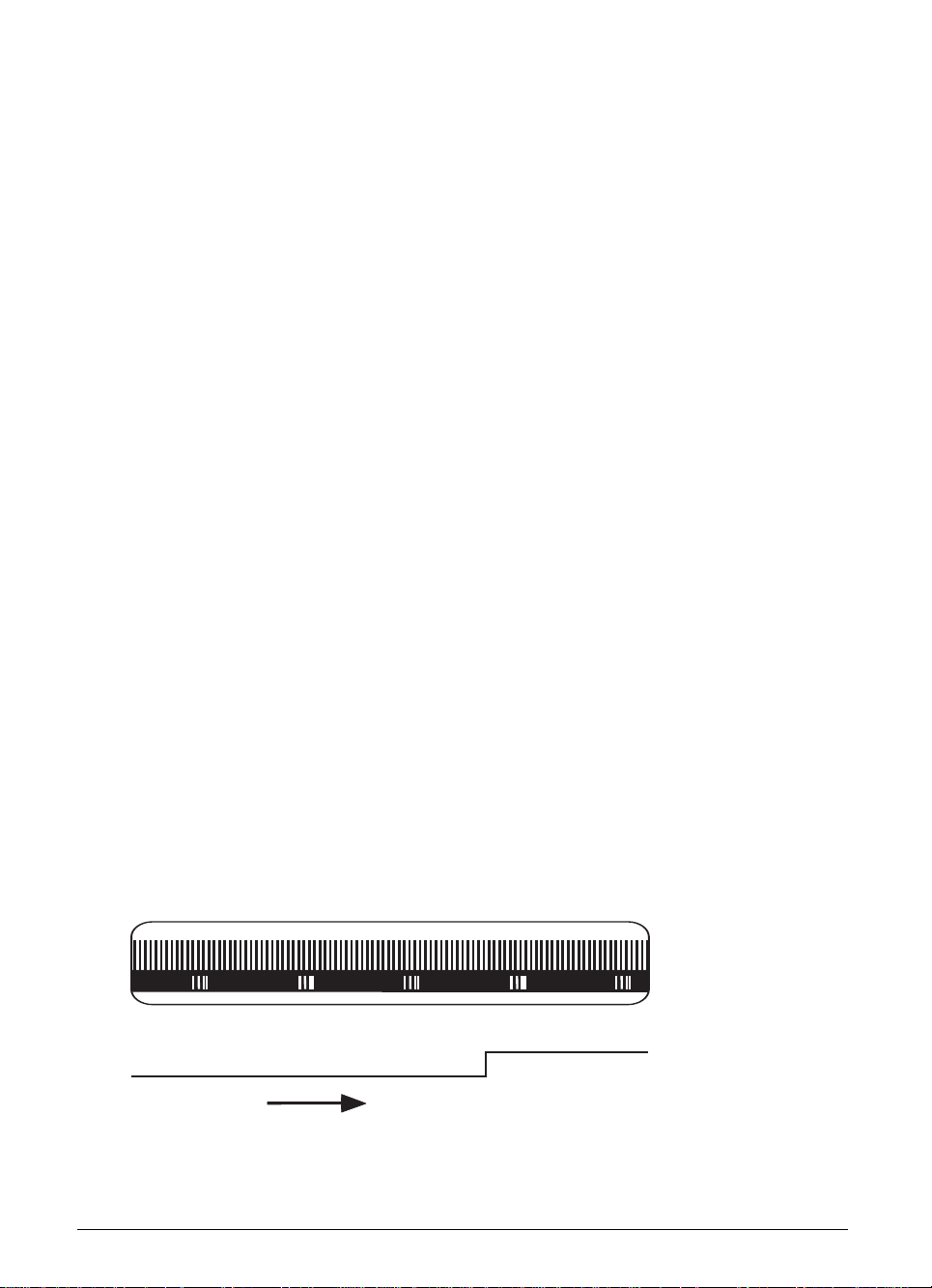

Sequence for “Automatic reference mark traverse” (pressing the machine START key).

MP1350.x = 0

Press the external START key

No Yes

"Reference end position"

Machine moves

in direction from

MP1320.x

Trip dog

"Reference end position" is

closed before two successive

reference marks are

traversed

No

Two successive reference marks traversed

Trig dog

closed?

Ye s

Machine moves in inverted

traverse direction from

MP1320.x

Is the machine

outside the software

limit switch range?

No

Machine stops

software limit switch

Ye s

Machine moves to

20 TNC 122 9 Machine Integration 4/97

Page 22

Encoders with one reference mark

Machine parameter MP1350.x = 1

Reference marks

Closed

Open

Trip dog

"Reference end position"

Traverse direction MP1320.x

4/97 TNC 122 9 Machine Integration 21

Page 23

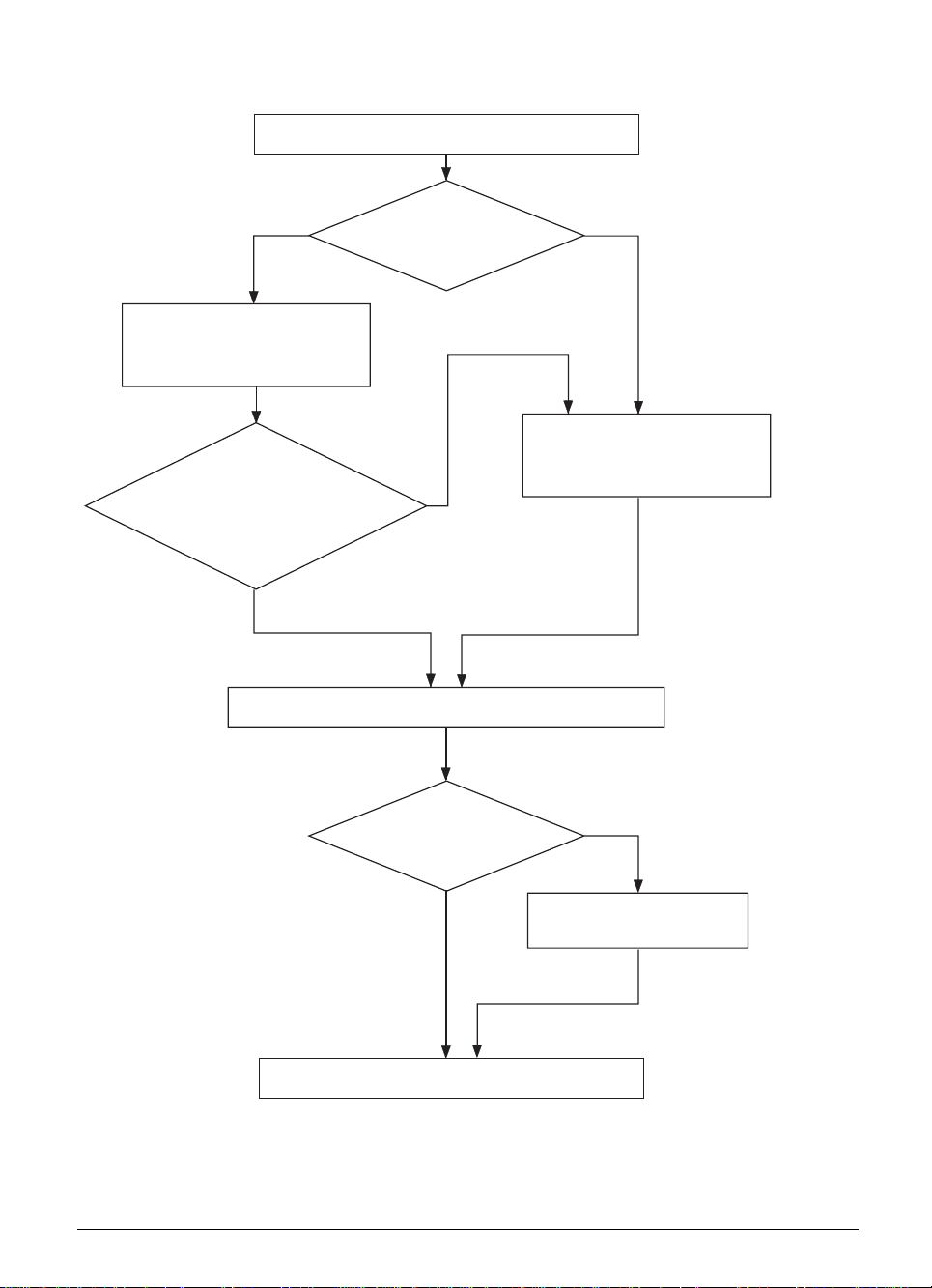

Sequence for “Automatic reference mark traverse” (pressing the machine START key).

MP1350.x = 1

Press the machine START key

No Yes

Machine moves

in direction from

MP1320.x

Trip dog

"Reference end position"

is closed before reference

mark is passed over

No

Reference mark is passed over

Trip dog

"Reference end position"

closed?

Ye s

Machine moves in

inverted direction from

MP1320.x

Is the machine

outside the software

limit switch range?

No

Machine stops

software limit switch

Ye s

Machine moves to

22 TNC 122 9 Machine Integration 4/97

Page 24

MP1320 Traverse direction for crossing over the reference marks with EXT start

Input values: 0 to 7

Bit 0 Axis X +0 = positive

+1 = negative

Bit 1 Axis Y +0 = positive

+2 = negative

Bit 2 Axis Z +0 = positive

+4 = negative

MP1330 Feed rate for crossing over the reference marks

Entry range: 80 to 30 000[mm/min]

MP1330.0 Axis X

MP1330.1 Axis Y

MP1330.2 Axis Z

MP1340 Sequence when crossing over the reference marks

Input values: 0 = no reference mark evaluation

1 = 1st axis

2 = 2nd axis

3 = 3rd axis

MP1340.0 Axis X

MP1340.1 Axis Y

MP1340.2 Axis Z

MP1350 Sequence for crossing over reference marks

Input values: 0 = encoder with distance-coded reference marks

1 = encoder with one reference mark

MP1350.0 Axis X

MP1550.1 Axis Y

MP1350.2 Axis Z

Set Reset

M2556 Reference end position for axis X PLC PLC

M2557 Reference end position for axis Y PLC PLC

M2558 Reference end position for axis Z PLC PLC

4/97 TNC 122 9 Machine Integration 23

Page 25

9.4 Position Feedback Control of the NC Axes

The TNC 122 operates according to the principle of closed-loop control with servo lag. Servo lag

means that there is always a difference (trailing error) between the nominal position commanded by

the NC and the actual position of the axes. Closed-loop control would not be possible without this

difference.

The k

factor (position loop gain) must be matched to the machine (see also “Characteristic kink”). If

v

a very high k

machine axis. If the k

The maximum feed rate (not the rapid traverse) is defined in machine parameter MP1010.0–2. It

represents the feed rate at an analog voltage of 11 V at the servo input.

The acceleration can be entered in machine parameter MP1060.x. It determines the ramp gradient

of the rising edge (MP1060.0–2) and the approach to the position (MP1060.3–5).

To improve the positioning behavior, machine parameter MP1051.x can be used to define a bottom

voltage below which the control will not go.

When the axis is in position (the positioning window has been reached) the “axis in position” marker

is set. The PLC program must then disable the position controller for the axes to come to a stop.

factor is chosen the servo lag will be very small, but this may cause oscillations in the

v

factor is too small, the new position will be reached too slowly.

v

The optimum k

behavior at different k

factor must be determined empirically. The following diagram illustrates traversing

v

factors:

v

U [V]

kv correct

kv too large

kv too small

MP1810

MP1060.0-2

MP1060.3-5

t [s]

The kv factor (MP1810) is generally determined by the maximum feed rate of the machine (MP1010)

and the servo lag according to the following formula:

Ve

=

k

k

v

s

a

= position loop gain [

v

ve = maximum feed rate [

= servo lag [mm]

s

a

m/min

mm

m

min

]

]

or

Ve

s

=

a

k

v

24 TNC 122 9 Machine Integration 4/97

Page 26

Rapid traverse control

For operation at rapid traverse, both programmed and manually actuated, MP80 determines the

analog supply voltage for the motor controllers. The machine's circuit diagram will indicate whether

the controller input should be supplied by external analog voltage or the analog voltage of the

control, and whether amplified tachometer signals are used.

Programming of rapid traverse: Select the axis, enter the value, press and hold the machine rapid

traverse button, confirm by pressing the "ENT" key.

External analog voltage for rapid traverse at the controller input (MP80 =1):

If MP80 = 1, the controller will be switched to external analog voltage supply when the machine

axes are moving at rapid traverse. The control loop remains closed although the control is not

monitoring it. The control does not begin monitoring the loop until the axis comes within a certain

distance to the target position. This distance is defined in MP4210 and is transmitted to the PLC. To

resume feedback control, the PLC resets the "rapid traverse" output (X41, pin 16).

In order to ensure that servo lag monitoring does not respond during rapid traverse, the control

operates internally with a rapid traverse from MP1010.3-5 and a “servo lag” is internally adjusted

such that it remains within the permissible range of servo lag monitoring (floating nominal value).

The servo lag internal adjustment is defined with machine parameter MP1850 such that no

oscillations result. The rapid traverse in MP1010.3-5 must correspond with the actual rapid traverse.

The correct setting for the internal adjustment can be checked in a special display (activated with

MP7322) showing the actual feed rate, the analog voltage of the control and the internal nominal

servo lag as a percentage of the actual servo lag.

If the display sways between 80% and 120% this results in oscillations within the control. These

oscillations can be prevented by properly setting MP1850. The setting in MP1010.x is correct if the

display remains stable at approx. 100%. The behavior of the floating nominal value can also be

measured at the analog output with an oscilloscope.

Analog voltage of the control for rapid traverse at the servo input of (MP80 = 2):

If the feedback input is supplied from the control during rapid traverse and the tachometer voltage

must be switched, then enter the value 2 in MP80. In MP1010.3-5 enter the same rapid traverse

rate as the machine had with the TNC 121.

MP1010 Feed rate at 10 V analog voltage

Input: 80 to 30 000 [mm/min]

MP1010.0 Axis X

MP1010.1 Axis Y

MP1010.2 Axis Z

Rapid traverse for amplified tachometer signals or external rapid traverse voltage

Input range: 80 to 30 000 [mm/min]

MP1010.3 Axis X

MP1010.4 Axis Y

MP1010.5 Axis Z

4/97 TNC 122 9 Machine Integration 25

Page 27

MP1050 Analog voltage for rapid traverse

Input range: 4.5 to 11.0 [V]

MP1050.0 Axis X

MP1050.1 Axis Y

MP1050.2 Axis Z

MP1051 Lower limit of analog voltage

Input range: 0 to 35 [transformer increment]

(1 transformer increment = 2.93 mV)

MP1051.0 Axis X

MP1052.1 Axis Y

MP1053.2 Axis Z

MP70 Bipolar or unipolar analog voltage

Input: 0 or 2

0 = bipolar

1 = unipolar, traversing the position outputs 0 volt

2 = unipolar, traversing the position inverts the voltage

MP80 Supply voltage for position controller during rapid traverse

Input range: 0 to 2

0 = Reserved

1 = Controller input supplied with external voltage (MP1850)

2 = Controller input supplied with analog voltage from the control

MP1060 Acceleration during position approach

Input range: 0.001 to 3.0 [m/s

2

]

MP1060.0 Axis X

MP1060.1 Axis Y

MP1060.2 Axis Z

Deceleration during position approach

Input range: 0.001 to 3.0 [m/s

2

]

MP1060.3 Axis X

MP1060.4 Axis Y

MP1060.5 Axis Z

MP1810 k

factor

v

Input range: 0.10 to 10.00 [

m/min

mm

]

MP1810.0 Axis 1

MP1810.1 Axis 2

MP1810.2 Axis 3

26 TNC 122 9 Machine Integration 4/97

Page 28

MP1850 Proportion for internal adjustment of servo lag (if MP80 = 1)

Input range: 0 to 65535

Characteristic kink

To enable correct processing of the internal nominal value on machines that have a high rapid

traverse speed, the k

In such cases a characteristic kink can be entered, providing the following advantages:

factor must be adjusted to this speed range.

v

• a normal k

• a separate k

The position of this characteristic kink is defined in machine parameter MP1830. In the upper range

the k

v

U [V]

MP1830

The kink point must lie above the range of machining feed rates. Under these conditions the lag can

be calculated as follows:

Ve

s

=

a

k

100 [%] MP1820 · 100 [%]

factor for the machining feed rate

v

factor for rapid traverse

v

factor is multiplied by the factor in MP1820.

9

MP1810 · MP1820

MP1810 (= kv)

MP1830 [%] + 100 [%] – MP1830 [%]

·

[

v

sa

]

MP1820 Multiplication factor for the kv factor

Input range: 0.001 to 9.000

MP1820.0 Axis X

MP1820.1 Axis Y

MP1820.2 Axis Z

MP1830 Characteristic kink

Input range: 0.000 to 100.000 [%]

MP1830.0 Axis X

MP1830.1 Axis Y

MP1830.2 Axis Z

4/97 TNC 122 9 Machine Integration 27

Page 29

Offset compensation

An offset error can be compensated. An offset error exists if the axis drifts when the controller input

is supplied with 0V analog voltage. If the axis does drift, an offset voltage must be output to prevent

the drifting. To define the analog offset voltage, press MOD and enter the code number 75 368 to

call the “AV OFFSET” dialog prompt. The optimum input value (a multiple of 2.93 mV = 1

transformer step) must be determined empirically. Before this, the bottom voltage must be set to

zero with MP1051. For bipolar drives, enter the proper algebraic sign for the voltage.

Feed rate enable

It is only possible to move the axes if the feed rate enable is present in marker M2451 and

complementary marker M2467. If the feed rate enable is removed, the analog voltage output is 0 V

and the axes stop moving immediately.

Set Reset

M2451 Feed rate enable PLC PLC

M2467 Complementary feed rate enable PLC PLC

Axes in position

When the axes have reached the defined positioning window (MP1030.x), the “Axis in position”

markers are set by the NC. This is also done when the control voltage is switched on.

The markers will only be reset by the NC if the axes leave the positioning window when being

traversed. This also applies when the reference marks are crossed over.

Set Reset

M2008 Axis X in position NC NC

M2009 Axis Y in position NC NC

M2010 Axis Z in position NC NC

Open the control loop

In order to lock or disengage an axis, the control loop must be opened by the PLC. As soon as the

“Axis in position” markers (M2008 to M2010) are reset, the control loop must be closed again so

that the axis can be moved. Before the control loop is closed, an actual and nominal value transfer

must be performed.

Set Reset

M2544 Open control loop axis X PLC PLC

M2545 Open control loop axis Y PLC PLC

M2546 Open control loop axis Z PLC PLC

Actual/nominal value transfer

If markers M2552 to M2554 are set, the momentary actual position value is taken as the nominal

position value.

Set Reset

M2552 Actual/nominal value transfer axis X PLC PLC

M2553 Actual/nominal value transfer axis Y PLC PLC

M2554 Actual/nominal value transfer axis Z PLC PLC

28 TNC 122 9 Machine Integration 4/97

Page 30

9.5 Monitoring Functions

The NC monitors the axis positions and the dynamic behavior of the machine. If the fixed values in

the machine parameters are exceeded, an error message is displayed and the machine is stopped.

Position, standstill and movement are monitored.

Position monitoring

Machine parameters MP1720.x determine the range for the continuous position monitoring of the

machine (servo lag monitoring). Monitoring goes into effect as soon as the axes are under control of

the position control loop. If the limits in MP1720 are exceeded, the following blinking error message

appears:

POS. ERROR A <axis>

The control must be switched off to correct this error. Realistic input values are approximately 1 to

1.4 times the servo lag at rapid traverse.

MP1720

Movement monitoring

At short intervals (several control cycles) the path actually traversed is compared with the nominal

path as calculated by the NC. If the path traversed during this interval deviates from the calculated

path, the following blinking error message will appear:

Movement monitoring is not active below the voltage entered in machine parameter MP1140.

If 12 [V] is entered in this machine parameter, no movement monitoring will be in effect.

It is not possible to safely operate the machine without movement monitoring.

MP1140

Standstill monitoring

This monitoring goes into effect when the axes have reached the positioning window. The range

within which the axes may move is defined in MP1110. As soon as the position deviation is larger

than the value in MP1110, the following blinking error message is displayed:

The message will also appear during approach to a target position if an overshoot is larger than the

value entered in MP1110, or if the axis moves in the opposite direction at the beginning of a

positioning move.

Position monitoring

Input range: 0.001 to 200.000 [mm]

POS. ERROR C <axis>

Movement monitoring

Input range: 0.03 to 12.00 [V]

POS.ERROR D <axis>

MP1110

Positioning window

The positioning window defines the range within which the control considers a position to have

been reached. When the position has been reached, the control starts the execution of the next

block. The size of the positioning window is defined in MP1030.x.

4/97 TNC 122 9 Machine Integration 29

Standstill monitoring

Entry range: 0.001 to 30.000 [mm]

Page 31

When the axes reach the positioning window, markers M2008 to M2010 are set.

MP1030

Positioning window

Entry range: 0.001 to 2.000 [mm]

MP1030.0 Axis X

MP1030.1 Axis Y

MP1030.2 Axis Z

Encoder monitoring

Monitoring of the encoder signals must be activated with MP31.

If the signal amplitude is faulty the following error messages can appear:

ENCODER <axis> DEFECT If the signal amplitude is no longer being evaluated

AMPL <axis> TOO SMALL If the signal amplitude is too small

OVERLOAD <axis> If the signal amplitude is too large

MP31

Monitoring of the amplitude of the encoder signals

Input values: 0 to 7

Bit 0 Axis X +0 = no monitoring

+1 = monitoring active

Bit 1 Axis Y +0 = no monitoring

+2 = monitoring active

Bit 2 Axis Z +0 = no monitoring

+4 = monitoring active

30 TNC 122 9 Machine Integration 4/97

Page 32

9.6 Display and Operation

The position display can be set with MP7322 to show:

the actual position referenced to the currently set datum

•

the actual position referenced to the scale reference point

•

the current trailing error

•

the actual feed rates and the nominal voltage and % value for servo lag

•

MP7322

The display step for the axis positions can be selected with MP7290.

MP7290

Machine parameter MP7285 can be used to define whether the position of the tool tip or the face of

the spindle (zero tool) is displayed as the actual value.

MP7285

The TNC 122 can switched to different dialog languages with machine parameter MP7230.

Position display

Input values: 0 to 3

0 = Actual position referenced to the currently set datum

1 = Current servo lag

2 = Position referenced to scale reference point

3 = Actual feed rates, nominal voltage, % value for trailing error

Display step

Input values: 0 or 1

0 = 1 µm

1 = 5 µm

Take tool length into account in position display

Input values: 0 or 1

0 = position of tool tip is displayed

1 = position of zero tool is displayed

MP7230

4/97 TNC 122 9 Machine Integration 31

Dialog language

Input values: 0 to 7

0 = German

1 = English

2 = French

3 = Dutch

4 = Spanish

5 to 7 =

reserved

Page 33

Machine parameters can select whether the RAM and the EPROM are to be tested when the

control is switched on. When commissioning it is recommended that the memory test be

deactivated. The message “Memory test” is displayed during the memory test.

MP7690

The TNC 122 can also be used when no machine is connected to it. MP7210 sets the modes it can

then be used in.

MP7210

Memory test at switch-on

Input values: 0 to 3

0 = EPROM and RAM test at switch-on

1 = EPROM test at switch-on

2 = RAM test at switch-on

3 = No memory test at switch-on

Programming station

Input values: 0 to 2

0 = Control

1 = Programming station, PLC active

2 = Programming station, PLC not active

32 TNC 122 9 Machine Integration 4/97

Page 34

9.7 EMERGENCY STOP Circuit

The control has one PLC input (X41/28) and one PLC output (X41/10) with the designation “Control is

ready” for the EMERGENCY STOP routine.

If a malfunction is recognized in the control, the TNC switches the control-is-ready output off, a

blinking error message appears on the screen, the PLC program is halted and the outputs are reset.

This error message cannot be cleared. When the error has been corrected it is necessary to run

through the switch-on routine again.

If the control-is-ready input is switched off by an event outside the control, the following error

message will appear:

EMERGENCY STOP

The NC then sets markers M2190 and M2191. This error message cannot be cleared until the

control voltage is switched on again.

When an EMERGENCY STOP occurs all outputs are reset.

The control evaluates an external EMERGENCY STOP like an external and internal stop. If the

EMERGENCY STOP button is pressed while an axis is moving, the axis is brought to a stop. I

If the EMERGENCY STOP causes the servo amplifier to block, the output nominal values can

exceed the position monitoring defined by machine parameters. In such a case the following error

message will be displayed:

POS. ERROR <axis>

M2190

M2191

Set Reset

Non-blinking error message displayed NC NC

EMERGENCY STOP displayed NC NC

4/97 TNC 122 9 Machine Integration 33

Page 35

9.7.1 EMERGENCY STOP Connection Diagram

In case of a malfunction, the control-is-ready output should switch the 24 V supply voltage off.

Because this function is so critical, the TNC 122 checks this output each time the power supply is

switched on.

HEIDENHAIN recommends the following wiring:

TNC 122

Switch opens briefly when the control voltage

of each microprocessor is switched on

X41/10 X41/9 X41/28

"Control is

ready"

EMERGENCY

STOP

buttons

Control

voltage

on

If the control is not to be part of the EMERGENCY STOP circuit, output X41/10 must be shortcircuited with input X41/28.

k1

K1

24V not

interruptible

+ -

24 V

PLC

"Control ready"

feedback

k1

34 TNC 122 9 Machine Integration 4/97

Page 36

9.7.2 EMERGENCY STOP Flowchart

The external electronics must fulfill the prescribed basic requirements. In particular, the

acknowledgment for “control is ready” must be received within 200 ms.

X41/10

X41/28

1 2 3 4 5 6 7 8 9

Display

1 Waiting for control voltage. NO CONTROL VOLTG

2 Recognition of the control voltage at X41/28 and reset control-

is-ready output at X41/10.

3 Maximum time until control-is-ready signal at X41/28 must go

to 0 (t < 200 ms). If time limit is exceeded, error message:

4 Recognition of acknowledgment, output X41/10 set.

5 Waiting for control voltage. NO CONTROL VOLTG

6 Normal control operation. Output and control-is-ready

acknowledgment are set.

7 Control voltage switched off by external event. EMERGENCY STOP

8 When the control voltage is switched on again the error

message can be cleared; then return to normal operation.

9 If an error is detected, the control switches off the control-is-

ready output (X41/10).

EMERG STOP DEFEC

Blinking error message

4/97 TNC 122 9 Machine Integration 35

Page 37

10 Exchanging the Control

The control should be exchanged only on machines that are recommended by HEIDENHAIN. If you

wish to retrofit other machines, contact your HEIDENHAIN service representative.

The PLC EPROM contains the appropriate machine parameters and the PLC program for the

following software types of the TNC 121. These are activated with a code number (see below).

Software of the

TNC 121

205 438 1

205 443 2

205 329 2

205 444 3

205 446

205 455

205 456

205 457

205 430

The TNC 122 with standard PLC program can also replace a TNC 121 with SE 121

(see machine parameters MP4xxx for more information on this.)

Proceed as follows to replace the TNC 121 by the TNC 122:

Before removing the TNC 121

• Check the software number to see whether the PLC and NC software number of the TNC122

can perform the functions of the TNC 121 (see the above table). If there is any doubt, contact

your HEIDENHAIN service representative.

PLC software no.

TNC 122

277 939 14 246 117 08 4

NC software no.

TNC 122

Code no.

5

6

7

8

• Determine the following parameters and functions of the machine with the TNC 121 still

installed:

What is the maximum feed rate? What is the analog voltage at the maximum feed rate?

Is the analog voltage for the rapid traverse supplied by the control or by an external source

(shown on wiring diagram)?

Are the drives bipolar or unipolar?

Axis lock yes/no?

Reference mark traverse desired yes/no?

• Determine the pin layout of the terminal board using the circuit diagram and mark the wires for

the connection to X41 of the TNC 122.

Removing the TNC 121

• Disconnect the power supply, disconnect the cable from the terminal board, remove the

encoder connector.

• Remove the mounting screws, remove the housing.

36 TNC 122 10 Exchanging the Control 4/97

Page 38

Installing the TNC 122

• Insert sponge rubber gasket, slide unit into position, tighten screws.

Insert encoder connectors, wire connector X41 according to the documented layout of the

TNC 121 (see connector layout X41).

Connect power supply.

• Differences compared to TNC 121:

Connect signal ground to the central ground point of the machine.

Include control-is-ready output (X41/10) and control-is-ready input (X41/28) in the emergency

stop circuit (see Section 9.7).

Commissioning the TNC 122:

• Switch on the control.

• Activate the appropriate PLC program and machine parameters with the code number as

follows:

– Press the MOD key

– Enter code number 77 80 83

– Press the ENT key

– Press the MOD key

– Enter the appropriate code number from the above list

– Press the ENT key

Depending on the model of machine and its mechanical condition it may be necessary

to re-optimize the machine parameters that affect the control loop. especially

parameters MP1010, MP1030, MP1050, MP1051, MP1060, MP1810 and MP1850.

This requires checking the analog output and the tachometer voltage with an

oscilloscope.

• If desired, set the software limit switch ranges to conform to maximum permissible traverse.

Note:

The software limit switches are always referenced to a fixed reference mark!

Ensure that the same reference mark is always used for referencing.

Test all functions.

11 Machine Parameters

11.1 Entering and Changing Machine Parameters

A list of machine parameters is accessible through the MOD function

operation mode. To call the complete list of machine parameters, enter the code number 95148. A

subset of MOD functions is more readily available through the MOD function

machine parameters included in the user parameters are indicated in the following list with *). It is

possible to change these parameters.

The values of the machine parameters can be changed as follows:

• Select the list of machine parameters.

• Use the arrow key to select the desired machine parameter.

• Enter the new value.

• Confirm your entry by pressing ENT.

To leave the list of machine parameters, press DEL.

4/97 TNC 122 11 Machine Parameters 37

Code number

User parameters.

in the manual

The

Page 39

11.2 Machine Parameter List

Machine

Parameter

MP 31 Monitoring of encoder signal amplitude

MP 40 Displayed axes

MP70 Analog output bipolar or unipolar

MP80 Analog voltage source for rapid traverse from

MP110.0-2 Assignment of encoder inputs to the machine

MP210 Counting direction of encoder signals

MP330.0-2 Grating period

Function and input Input value

Input values: 0 to 7

Bit 0 Axis X +0 inactive

+1 active

Bit 1 Axis Y +0 inactive

+2 active

Bit 2 Axis Z +0 inactive

+4 active

Input values: 0 to 7

Bit 0 Axis X +0 not displayed

+1 displayed

Bit 1 Axis Y +0 not displayed

+2 displayed

Bit 2 Axis Z +0 not displayed

+4 displayed

Input values: 0 or 2

0 = bipolar

1 = unipolar (ensure that MP1040 = 0!)

traversing the end position outputs 0 V

2 = unipolar, traversing the end position inverts

the nominal-value voltage

the control or from external source

Input values: 0 to 2

0 =

reserved

1 = analog voltage from external source

2 = analog voltage from control

(Position control loop closed)

axes

Input values: 0 to 2

0 = encoder input X1

1 = encoder input X2

2 = encoder input X3

Input values: 0 to 7

Bit 0 Axis X +0 = positive

+1 = negative

Bit 1 Axis Y +0 = positive

+2 = negative

Bit 2 Axis Z +0 = positive

+4 = negative

Input values: 4, 10, 20, 40, 100, 200 [µm]

38 TNC 122 11 Machine Parameters 4/97

Page 40

Machine

Function and input Input value

Parameter

MP910.0-2 Software limit switch max. value

Input range:

–9 999.99 to +9 999.99 [mm]

MP920.0-2 Software limit switch min. value

Input range:

–9 999.99 to +9 999.99 [mm]

MP1010.0-5 Rapid traverse for normal and amplified

tachometer signals

Input range: 80 to 30 000 [mm/min]

MP1010.0-2 normal rapid traverse for X, Y, Z

MP1010.3-5 increased rapid trav. for X, Y, Z

MP1030.0-2 Positioning window

Input values: 0.005 to 2.000 [mm]

MP1040 Polarity of nominal value voltage for positive

traversing direction

Input values: 0 to 7

Bit 0 Axis X +0 = positive

+1 = negative

Bit 1 Axis Y +0 = positive

+2 = negative

Bit 2 Axis Z +0 = positive

+4 = negative

MP1050.0-2 Analog voltage for rapid traverse

Input values: 4.5 to 11 [V]

MP1051.0-2 Lower limit of analog voltage

Input values: 0 to 35 [ factor 2.93 mV]

MP1060.0-5 Acceleration

Input values: 0.001 to 3.000 [m/s

2

]

1060.0 to 1060.2: accelerate

1060.3 to 1060.5: decelerate

MP1110 Standstill monitoring

Input values: 0.001 to 30.000 [mm]

MP1140 Motion monitoring

Input values: 0.03 to 10 [V]

MP1320 Traverse direction when crossing over the

reference marks

Input values: 0 to 7

Bit 0 Axis X: + 0 = positive

+ 1 = negative

Bit 1 Axis Y: + 0 = positive

+ 2 = negative

Bit 2 Axis Z: + 0 = positive

+ 4 = negative

If MP70 = 1, then MP1040 must

equal 0.

10 V

4/97 TNC 122 11 Machine Parameters 39

Page 41

Machine

Function and input Input value

Parameter

MP1330.0-2 Feed rate for crossing over the reference marks

Input values: 80 to 30 000 [mm/min]

MP1340.0-2 Sequence of axes for crossing over the

reference marks

Input values: 0 to 3

0 = no reference mark evaluation

1 = Axis X

2 = Axis Y

3 = Axis Z

MP1350.0-2 Type of referencing

Input values: 0 or 1

0 = encoder with distance-coded reference

marks

1 = encoder with one reference mark

MP1720 Position monitoring with servo lag

(EMERGENCY OFF)

Input values: 0 to 200 [mm]

MP1810.0-2 kv factor for operation with servo lag

Input values: 0.1 to 10 [1/min]

MP1820 Multiplication factor for the kv factor

Input values: 0.001 to 9

MP1830 Characteristic kink for the kv factor

Input values: 0 to 100 [%]

MP1850 Factor for internal servo-lag adjustment with

external rapid traverse voltage

Input values: 0 to 65535

Only if MP80 = 1

40 TNC 122 11 Machine Parameters 4/97

Page 42

Machine

Parameter

MP4110 Time for timers T0 to T15

MP4110.0 Waiting time controller enable X

MP4110.1 Waiting time unclamp X start

MP4110.2 Waiting time clamp X stop

MP4110.3 Waiting time controller enable Y

MP4110.4 Waiting time unclamp Y start

MP4110.5 Waiting time clamp Y stop

MP4110.6 Waiting time controller enable Z

MP4110.7 Waiting time unclamp Z start

MP4110.8 Waiting time clamp Z stop

MP4110.9 SE pulse formation / duration

MP4110.10 Waiting time O5 traverse

MP4110.11 Delay time for rapid traverse

MP4110.12

MP4110.13

MP4110.14

MP4110.15

MP4120.0

to

MP4120.7

MP4210 Setting a number in the PLC word range

MP4210.0 X switch-off point for rapid trav.

MP4210.1 Y switch-off point for rapid trav.

MP4210.2 Z switch-off point for rapid trav.

MP4210.3 Position control loop to XYZ potentiometer=0,

MP4210.4 Number of D/A converter steps per PLC cycle

MP4210.5 Multiplication factor for the feed rate

MP4210.6

MP4210.7 Selection of code no. for software level for

MP4210.8

MP4210.9

Function and input Input value

Input values: 0 to 65 535 [24 ms]

direction, delay erosion start M36

output O4 (night erosion switchoff)

Preset value for counters C0 to C7

Input values: 0 to 65 535

D768 to D804

Input values: –9 999.999 to +9 999.999 [mm]

Only with MP 4310.4 and .5 =1

NC stop, lag<0.5

Input approx. 0.4

with control by PLC

Input approx. 0.1 to 1.2

potentiometer

Potentiometer value * MP4210.5= NC % block

position control loop via PLC

External pot. 100%: factor 0.66

External pot. 150%: factor 1.0

Input 1 to 8 (for software level of

TNC 121, see Chapter 10)

4/97 TNC 122 11 Machine Parameters 41

Page 43

Machine

Parameter

MP4220 Setting a number in the PLC word range

MP4220.0 1 = bipolar without SE functions

MP4220.1 0 = Static M output

MP4220.2 0 = M acknowledgment to

MP4220.3 If potentiometer closed, NC stop feed rate

MP4220.4 If potentiometer closed, NC stop feed rate

Function and input Input value

W960 to W968

Input values: 0 to 65535

2 = unipolar without SE functions

5 = bipolar with SE functions

6 = unipolar with SE functions

12 = erosion with SE functions

+1 = M03/M05 impulse or

M16/M17 impulse

+2 = M04/M05 impulse or

M18/M19 impulse

+4 = M08/M09 impulse

+8 = M20/M21 impulse

+16 = M22/M23 impulse

+32 = M24/M25 impulse

+64 = M26/M27 impulse

+128 = M28/M29 impulse

+256 = M32/M33 impulse

I15

+1 = M03 automatic

+2 = M04 automatic

+4 = M8/M9 automatic

+8 = M16/M17 automatic

+16 = M18/M19 automatic

+32 = M20/M21 automatic

+64 = M22/M23 automatic

+128 = M24/M25 automatic

+256 = M26/M27 automatic

+512 = M28/M29 automatic

+1024 = M32/M33 automatic

+2048 = M00/M02/M05/M30

automatic

Minimum potentiometer feed

potentiometer minimum

potentiometer maximum

rate 0%

Active minimum potentiometer

feed rate 0%

A change to the machine parameters MP4220.x only becomes active after a power

interruption.

42 TNC 122 11 Machine Parameters 4/97

Page 44

Machine

Parameter

MP4310 Setting a number in the PLC marker range

MP4310.0 X trav. direction 0=neg., 1=pos.

MP4310.1 Y trav. direction 0=neg., 1=pos.

MP4310.2 Z trav. direction 0=neg., 1=pos.

MP4310.3 Actual and nominal value transfer

MP4310.4 1 = open position control loop

MP4310.5 Only effective if MP 4310.4 is active 1 = no controller enable when

MP4310.6 1 = rapid traverse output O4 set

MP4310.7 1 = M05 output via O11

MP4310.8 0 = EMERGENCY STOP cancels

MP4310.9 Position control loop

MP4310.10 0 = M functions active in MDI

MP4310.11 1= switch off PLC position

MP4310.12 1= rapid traverse information (MP

MP4310.13

MP4310.14

MP4310.15

MP4310.16

MP4310.17

MP4310.18

MP4310.19

Function and input Input value

M2192 to M2211

Input values: 0 or 1

in automated operational mode

0 = no, 1=yes

when override closed or NC stop

override closed or NC stop

in automated operating mode

(M20/M21) and reset via M03,

M04, M13, M14;

M09 output via O10 (M22/M23)

and reset via M08, M13, M14

the SE outputs

1 = EMERGENCY STOP does not

cancel the SE outputs

0 = NC control

1 = PLC control

1 = M functions not active in MDI

control loop monitoring

block) is not switched when the

advance switch point is reached

A change to the machine parameters MP4310.x only becomes active after a power

interruption.

4/97 TNC 122 11 Machine Parameters 43

Page 45

Machine

Parameter

MP7210 *) Programming station or machine control

MP7230 *) Dialog language

MP7285 *) Tool length is included in the position display

MP7290 *) Display step 1 µm or 5 µm

MP7320 Encoder signal amplitude

MP7322 *) Position display mode

MP7680 *) Memory function for axis direction buttons

MP7690 Memory test during switch-on or after reset

Function and input Input value

Input values: 0 to 2

0 = control

1 = programming station, PLC active

2 = programming station, PLC not active

Input: 0 to 7

0 = German

1 = English

2 = French

3 = Dutch

4 = Spanish

5 = reserved

6 = reserved

7 = reserved

value for the tool axis

Input values: 0 or 1

0 = tool length is included

1 = tool length is not included

Input values: 0 or 1

0 = 1µm

1 = 5 µm

Input values: 0 to 7

0 = 16µA encoders

+1 = 40µA encoders on X-axis

+2 = 40µA encoders on Y-axis

+4 = 40µA encoders on Z-axis

Input values: 0 to 3

0 = display actual position

1 = display servo lag

2 = display reference position

3 = display actual feed rate and nominal value

voltage

Input values: 0 or 1

0 = not stored

1 = stored

Input values: 0 to 3

+0 = memory test during switch-on

+1 = no RAM test during switch-on

+2 = no EPROM test during switch-on

44 TNC 122 11 Machine Parameters 4/97

Page 46

12 PLC Description

The TNC 122 features an integrated PLC for 15 inputs and 15 outputs. PLC programs for specific

machine models (see Chapter 10) have been prepared and stored by HEIDENHAIN in the EPROM.

If in rare cases the PLC program must be altered or rewritten, we recommend using the

programming software

, version 2.2 from HEIDENHAIN. This program can also generate the binary

PLC.EXE

code for the PLC EPROM (see the User's Manual for PLC.EXE).

The PLC program assigns fixed functions to the inputs and outputs at the X41 terminal block (see

Chapter 8 "Pin Layout."

In the TNC 122 the PLC program is run directly from the EPROM; there is no RAM memory for this

task.

For servicing purposes the logical status of the markers, inputs, outputs, timers and counters can be

transmitted through the RS-232-C/V.24 port to a computer. Transmission is activated by entering the

code number 807 667 in the TNC 122.

Under menu item "File/TNC 12x Monitor" the program PLC.EXE provides a function (PLCMONI.EXE)

for immediately displaying the logical status of operands, provided that the code number was

entered.

• Use the rightward cursor key on the TNC to scroll through the markers.

• Use the "R+/-" key on the TNC to scroll back through the markers.

• Press the NO ENT key to leave the display.

12.1 PLC EPROM

The PLC EPROM is a 2-MB or 4 MB chip with 16-bit data organization. It is programmed in Motorola

format, which means that the most significant byte of a word is located at the first (lowest) address.

Addresses:

$00000

...

$00400

$00402

$00403

$0000

...

PLC Program start address

Chip identifier (1 word)

PLC program length

$00405 $0000

$00406

...

$0041C

$0041E

10th MP list

...

nd

2

MP list

st

1

MP list

$00420 $0000

$007E0 PLC Program in binary format

and

up to 10 machine parameter tables

$1C000 20 PLC error messages in 7 languages

20 dialogs in 7 languages (30 characters each)

$1FF00 PLC software number

$1FFFC Checksum

$1FFFE One's complement checksum

4/97 TNC 122 12 PLC Description 45

Page 47

The error messages and dialogs are filed in the individual languages in the sequence and syntax

('...',0). Each dialog can have up to 16 characters (see also the User's Manual for PLC.EXE).

German '..............................',0

English '..............................',0

French '..............................',0

12.2 PLC Commands

12.2.1 Load and store commands

LOAD (L)

Logic execution with the LOAD command

Operands: M, I, O, T, C

The addressed operand is copied into the Logic Accumulator. An L command is always used at the

start of a logic chain to enable subsequent gating commands.

Word execution with the LOAD command

Operands: B, W, D, K

The addressed operand (B, W, D) or a Constant (K) is copied or loaded into the Word Accumulator.

The sign is added if necessary. In contrast to logic execution, an L command must always be used

at the start of a word gating chain. It is not possible to use a gating command.

LOAD NOT (LN)

Logic execution with the LOAD NOT command

Operands: M, I, O, T, C

The complement of the addressed operand is loaded into the Logic Accumulator. A load command is

always used at the start of a logic chain to enable subsequent gating commands.

Word execution with the LOAD NOT command

Operands: B, W, D, K

The content of the addressed operands (B, W, D) or a Constant (K) is loaded into the Word

Accumulator as a complement. The sign is added if necessary. In contrast to logic execution, a load

command must always be used at the start of a word gating chain. It is not possible to use a gating

command.

LOAD TWO'S COMPLEMENT (L–)

Operands: B, W, D, K

The contents of the addressed operand (B, W, D) or a Constant (K) is loaded into the Word

Accumulator as a two's complement. The sign is added if necessary. The two's complement allows

negative numbers to be stored, i.e. if a number is loaded with L–, it appears in the Accumulator with

the opposite sign. This command can only be used with Word execution.

46 TNC 122 12 PLC Description 4/97

Page 48

LOAD BYTE (LB)

Operands: M, I, O, T, C

The LB command copies 8 Markers, Inputs, Outputs, Timers or Counters with ascending numbering

into the Word Accumulator. Each operand occupies 1 bit in the Accumulator. The designated

operand address occupies the LSB in the Accumulator, the designated address + 1 the LSB + 1 and

so on. In this way, the last affected operand occupies the MSB. The sign is added if necessary.

LOAD WORD (LW)

Operands: M, I, O, T, C

The LW command copies 16 Markers, Inputs, Outputs, Timers or Counters with ascending

numbering into the Word Accumulator. Each operand occupies 1 bit in the Accumulator. The

designated operand address occupies the LSB in the Accumulator, the designated address + 1 the

LSB + 1 and so on. In this way, the last affected operand occupies the MSB The sign is added if

necessary.

LOAD DOUBLEWORD (LD)

Operands: M, I, O, T, C

The LD command copies 32 Markers, Inputs, Outputs, Timers or Counters with ascending

numbering into the Word Accumulator. Each operand occupies 1 bit in the Accumulator. The

designated operand address occupies the LSB in the Accumulator, the designated address + 1 the

LSB + 1 and so on. In this way, the last affected operand occupies the MSB.

ASSIGN (=)

Logic execution with the ASSIGN command

Operands: M, I, O, T, C

In conjunction with a Logic Operand (M, I, O, T, C), ASSIGN copies the contents of the Logic

Accumulator into the addressed operand. ASSIGN is only used at the end of a logic chain to ensure

that a gating result is available. The command can be used several times in succession.

Word execution with the ASSIGN command

Operands: B, W, D

ASSIGN in conjunction with a Word Operand (B, W, D) copies the contents of the Word

Accumulator into the addressed operand. In contrast to bit execution, ASSIGN can also be used

within a word logic chain. The command can be used several times in succession.

4/97 TNC 122 12 PLC Description 47

Page 49

ASSIGN BYTE (B=)

Operands: M, I, O, T, C

ASSIGN BYTE copies 8 bits from the Word Accumulator to Markers, Inputs, Outputs, Timers or

Counters with ascending numbering. Each bit corresponds to one operand. The LSB in the

Accumulator is copied to the designated operand address, the LSB + 1 to the designated address

+ 1 and so on. The last affected operand is occupied by the MSB.

ASSIGN WORD (W=)

Operands: M, I, O, T, C

ASSIGN WORD copies 16 bits from the Word Accumulator to Markers, Inputs, Outputs, Timers or

Counters with ascending numbering. Each bit corresponds to one operand. The LSB in the

Accumulator is copied to the designated operand address, the LSB + 1 to the designated address

+ 1 and so on. The last affected operand is occupied by the MSB.

ASSIGN DOUBLEWORD (D=)

Operands: M, I, O, T, C

ASSIGN DOUBLEWORD copies 32 bits from the Word Accumulator to Markers, Inputs, Outputs,

Timers or Counters with ascending numbering. Each bit corresponds to one operand. The LSB in

the Accumulator is copied to the designated operand address, the LSB + 1 to the designated

address + 1 and so on. The last affected operand is occupied by the MSB.

ASSIGN NOT (=N)

Logic execution

Operands: M, I, O, T, C

In conjunction with a logic operand (M, I, O, T, C), ASSIGN NOT copies the complement of the

contents of the Logic Accumulator into the addressed operand. See ASSIGN (=) for the sequence of

operations.

Word execution

Operands: B, W, D

In conjunction with a word operand (B, W, D), ASSIGN NOT copies the complement of the contents

of the Word Accumulator into the addressed operand.

ASSIGN TWO'S COMPLEMENT (=-)

Operands: B, W, D

ASSIGN TWO'S COMPLEMENT copies the TWO'S COMPLEMENT of the contents of the Word

Accumulator into the addressed operand.

48 TNC 122 12 PLC Description 4/97

Page 50

12.2.2 Set commands

SET (S)

Operands: M, I, O, T, C

The function of this command depends on the contents of the Logic Accumulator. If the Logic

Accumulator = 1, the addressed operand is set to 1; otherwise the operand remains unchanged. An

S command is used at the end of a logic chain so that the gating result influences the operand. The

command can be used several times in succession.

RESET (R)

Operands: M, I, O, T, C

The function of this command depends on the contents of the Logic Accumulator. If the Logic

Accumulator = 1, the addressed operand is set to 0; otherwise the operand remains unchanged. An

R command is used at the end of a logic chain so that the gating result influences the operand. The

command can be used several times in succession.

SET NOT (SN)

Operands: M, I, O, T, C

The function of this command depends on the contents of the Logic Accumulator. If the Logic

Accumulator = 0, then the addressed operand is set to 1; otherwise the operand remains

unchanged. An SN command is used at the end of a logic chain so that the gating result influences

the operand. The command can be used several times in succession.

RESET NOT (RN)

Operands: M, I, O, T, C

The function of this command depends on the contents of the Logic Accumulator. If the Logic

Accumulator = 0, then the addressed operand is set to 0; otherwise the operand remains

unchanged. An RN command is used at the end of a logic chain so that the gating result influences

the operand. The command can be used several times in succession

4/97 TNC 122 12 PLC Description 49

Page 51

12.2.3 Logical Connective Operations

AND (A)

Logic execution with the AND command

Operands: M, I, O, T, C

This command functions in different ways depending on its position in the program:

a) At the start of a logic chain the command functions as an L command. That is, the logic state of

the operand is loaded into the Logic Accumulator.

b) Within a logic chain the contents of the Logic Accumulator and the logic state of the operand

(M, I, O, T, C) are gated with AND. The result of the operation is stored in the Logic Accumulator.

Word execution with the AND Command

Operands: B, W, D, K

The contents of the Word Accumulator and the contents of the operand (B, W, D, K) are gated with

AND. In accordance with the different sizes of operand (B = 8 bits; W = 16 bits; D = K = 32 bits),

8, 16 or 32 bits will be influenced in the Accumulator.

Thus: Bit 0 of the Accumulator is gated with bit 0 of the operand

Bit 1 of the Accumulator is gated with bit 1 of the operand, and so on.

AND NOT (AN)

Logic execution with the AND NOT command

Operands: M, I, O, T, C

This command functions in different ways depending on its position in the program:

a) At the start of a logic chain the command functions as an LN command. That is, the complement

of the operand is loaded into the Logic Accumulator.

b) Within a logic chain, the contents of the Logic Accumulator and the logic state of the operand

(M, I, O, T, C) are gated with AND NOT. The result of the operation is stored in the Logic

Accumulator.

Word execution with the AND NOT command

Operands: B, W, D, K

The contents of the Word Accumulator and the contents of the operand (B, W, D, K) are gated with

AND NOT. In accordance with the different sizes of operand (B = 8 bits; W = 16 bits;

D = K = 32 bits), 8, 16 or 32 bits will be influenced in the Accumulator.

Thus: Bit 0 of the Accumulator is gated with bit 0 of the operand

Bit 1 of the Accumulator is gated with bit 1 of the operand, and so on.

The result of the operation is stored in the Word Accumulator.

50 TNC 122 12 PLC Description 4/97

Page 52

OR (O)

Logic execution with the OR command

Operands: M, I, O, T, C

This command functions in different ways depending on its position in the program:

a) At the start of a logic chain the command functions as an L command. That is. the logic state of

the operand is loaded into the Logic Accumulator.

b) Within a logic chain, the contents of the Logic Accumulator and the logic state of the operand

(M, I, O, T, C) are gated with OR. The result of the operation is stored in the Logic Accumulator.

Word execution with the OR command

Operands: B, W, D, K

The contents of the Word Accumulator and the contents of the operand (B, W, D, K) are gated with

OR. In accordance with the different sizes of operand (B = 8 bits; W = 16 bits; D = K = 32 bits),

8, 16 or 32 bits will be influenced in the Accumulator.

Thus: Bit 0 of the Accumulator is gated with bit 0 of the operand

Bit 1 of the Accumulator is gated with bit 1 of the operand, and so on.

The result of the operation is stored in the Word Accumulator.

OR NOT (ON)

Logic execution with the OR NOT command

Operands: M, I, O, T, C

This command functions in different ways depending on its position in the program:

a) At the start of a logic chain this command functions as an LN command. That is, the

complement of the operand is loaded into the Logic Accumulator.

b) Within a logic chain, the contents of the Logic Accumulator and the logic state of the operand

(M, I, O, T, C) are gated with OR NOT. The result of the operation is stored in the Logic

Accumulator.

Word execution with the OR NOT command

Operands: B, W, D, K

The contents of the Word Accumulator and the contents of the operand (B, W, D, K) are gated with

OR NOT. In accordance with the different sizes of operand (B = 8 bits; W = 16 bits; D = K = 32 bits),

8, 16 or 32 bits will be influenced in the Accumulator.

Thus: Bit 0 of the Accumulator is gated with bit 0 of the operand

Bit 1 of the Accumulator is gated with bit 1 of the operand, and so on.

The result of the operation is stored in the Word Accumulator.

EXCLUSIVE OR (XO)

Logic execution with the EXCLUSIVE OR command

Operands: M, I, O, T, C

This command functions in different ways depending on its position in the program:

a) At the start of a logic chain the command functions as an L command. That is, the logic state of

the operand is loaded into the Logic Accumulator.

b) Within a logic chain the contents of the Logic Accumulator and the logic state of the operand (M,

I, O, T, C) are gated with EXCLUSIVE OR. The result of the operation is stored in the Logic

Accumulator.

4/97 TNC 122 12 PLC Description 51

Page 53

Word execution with the EXCLUSIVE OR command

Operands: B, W, D, K

The contents of the Word Accumulator and the contents of the operand (B, W, D, K) are gated with

EXCLUSIVE OR. In accordance with the different sizes of operand (B = 8 bits; W = 16 bits;

D = K = 32 bits), 8, 16 or 32 bits will be influenced in the Accumulator.