Page 1

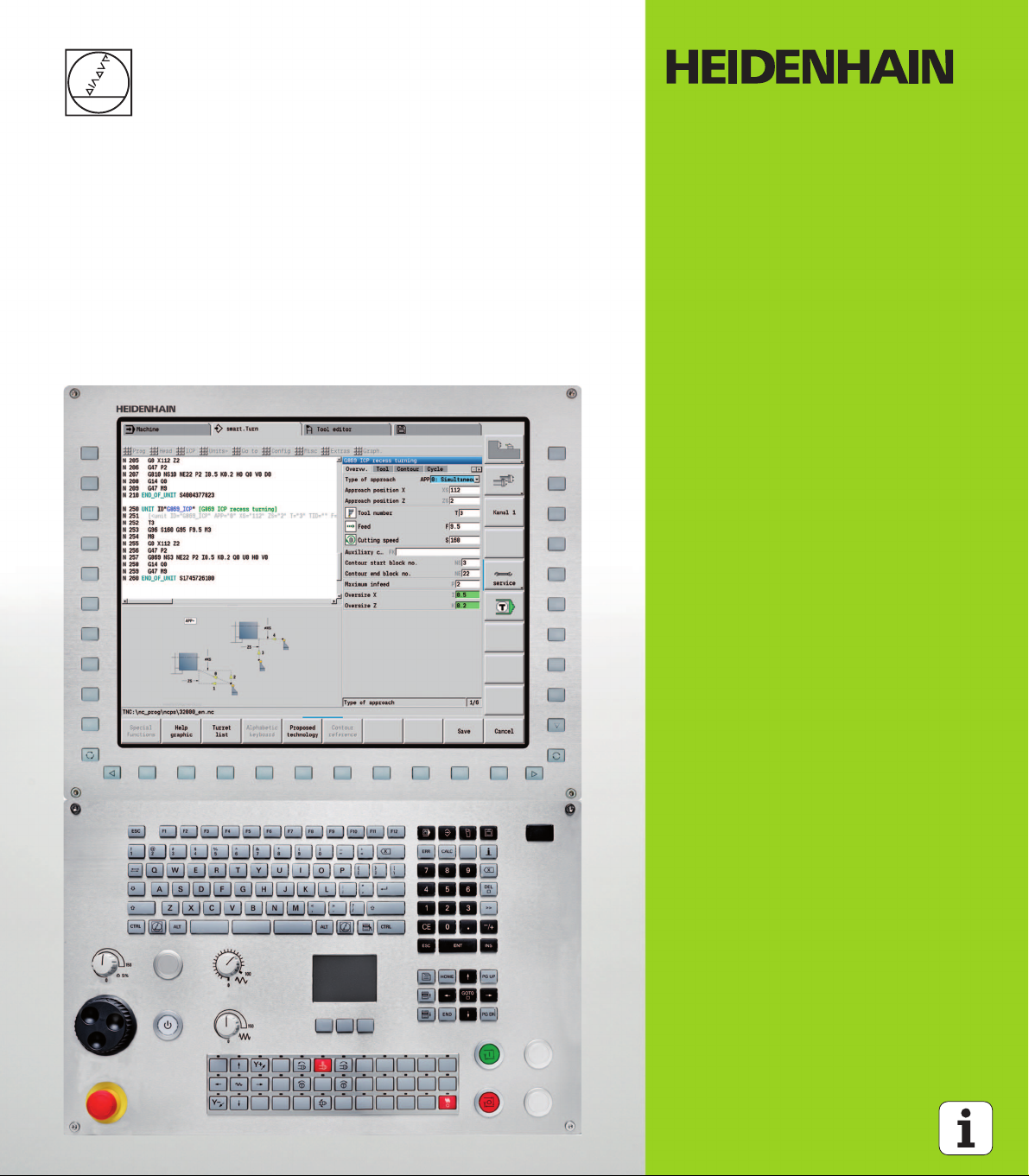

User’s Manual

CNC PILOT 640

NC Software

688946-03

688947-03

English (en)

1/2015

Page 2

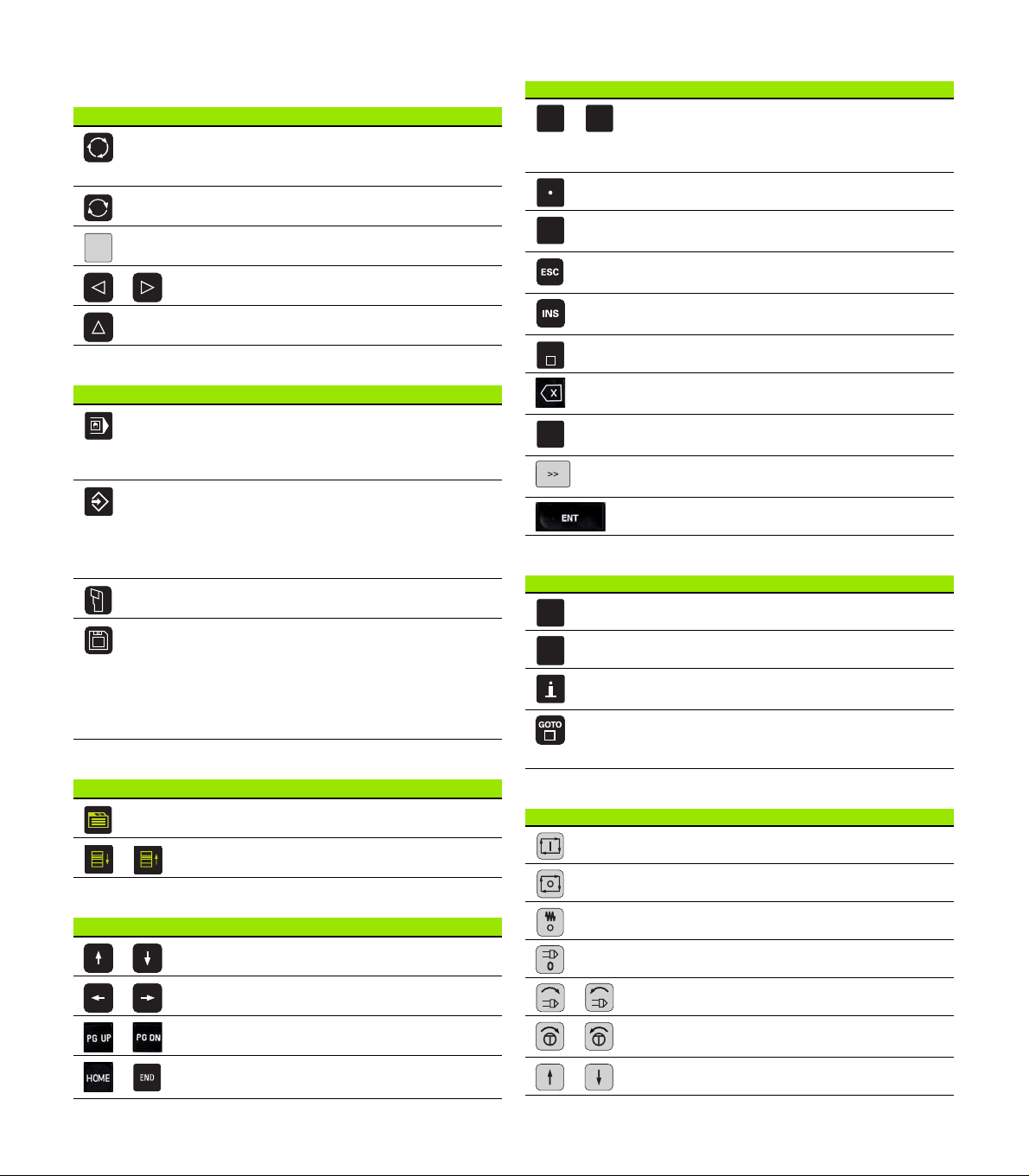

Controls and displays of the CNC PILOT

0

9

+

/

DEL

CE

ERR

CALC

Keys on visual display unit

Key Function

Switches the help graphics between outside

and inside machining (only in the cycle

programming)

No function

Soft keys for selecting functions on screen

Switches to the soft-key menu at left / right

Switches to the next menu in the PLC menu

Operating mode keys

Key Function

Machine operating modes:

Manual Operation

Program Run

Programming modes

smart.Turn

DINplus

DIN/ISO

Tables for tool data and technology data

Organization:

Parameters

File organization

Transfer

Diagnosis

smart.Turn keys

Key Function

Go to the next form

Next/previous group

Navigation keys

Key Function

Up/Down arrow keys

Numeric keypad

Key Function block

Number keys 0-9:

Numeric input keys

Menu operation

Decimal point

Switchover between positive and negative

values

Escape key: Cancelation of dialogs and next

higher menu level

Insert key: OK in dialogs and new NC blocks

in the editor

Delete block: Deletes the selected area

Backspace: Deletes the character to the left

of the cursor

CE key: Deletes the error messages in the

machine operating mode

Next: Enables input fields for additional

entries in dialog boxes

Enter: Confirms the input

Special keys

Key Function

Error key: Opens the error window

Starts the integrated calculator

Info key: Shows additional information in the

parameter editor

Activates special functions, such as input

options or input of characters as on an

alphabetic keyboard

Machine operating panel

Key Function

Cycle start

Cycle stop

Feed rate stop

Spindle stop

Left/Right arrow keys

Screen page or dialog page up/down

Go to beginning of program/list or to end of

program/list

Spindle on – M3/M4 direction

Spindle jog – M3/M4 direction. The spindle

rotates as long as you press the key.

Manual direction keys +X/–X

Page 3

Operating panel of the CNC PILOT

Page 4

Page 5

CNC PILOT 640, software and features

This manual describes functions that are available in the CNC PILOT

with NC software number 688946-03 and 688947-03.

The programming of smart.Turn and DIN PLUS is not included in this

manual. These functions are described in the User's Manual for

smart.Turn and DIN PLUS Programming (ID 685556-xx). Please

contact HEIDENHAIN if you require a copy of this manual.

The machine manufacturer adapts the features offered by the control

to the capabilities of the specific machine tool by setting machine

parameters. Therefore, some of the functions described in this manual

may not be among the features provided by the CNC PILOT on your

machine tool.

Some of the CNC PILOT functions that are not available on every

machine are:

Positioning of spindle (M19) and driven tool

Operations with the C or Y axis

Please contact your machine manufacturer for detailed information on

the features that are supported by your machine tool.

Many machine manufacturers and HEIDENHAIN offer programming

courses. We recommend these courses as an effective way of

improving your programming skill and sharing information and ideas

with other CNC PILOT users.

HEIDENHAIN also offers the DataPilot MP 620 or DataPilot CP 640

software for personal computers, which is designed to simulate the

functions of the MANUALplus 620 and CNC PILOT 640. The

DataPilot is suitable for both shop-floor programming as well as offlocation program creation and testing. It is also ideal for training

purposes. The DataPilot can be run on PCs with WINDOWS

operating systems.

Intended place of operation

The CNC PILOT complies with the limits for Class A devices in

accordance with the specifications in EN 55022, and is intended for

use primarily in industrially-zoned areas.

Legal information

This product uses open source software. Further information is

available on the control under

Organization mode of operation

LICENSE INFO SOFT KEY

HEIDENHAIN CNC PILOT 640 5

Page 6

New functions of software 688945-02

In the program simulation, the current contour description (of work-

piece blank and finished part) can be mirrored and saved. In

smart.Turn, these contours can be reinserted (siehe Seite 498)

On machines with opposing spindle, the workpiece spindle can now

be selected in the TSF menu (siehe Seite 98)

On machines with opposing spindle, its zero point can be shifted

(see Seite 98)

The user documentation is now also available in the context-sensi-

tive help system TURNguide (see Seite 66)

You can make your own project folder in the project management,

so that you can centrally manage associated files (see Seite 129)

With a manual tool change system it is possible to insert tools that

are not in the turret during a program run (see Seite 511)

Engraving cycles are now available in the Teach-In mode of opera-

tion (see Seite 345)

During tool data backup, you can now select in a dialog window the

data to be saved or restored (see Seite 596)

The G30 function is now available for converting G functions, M

functions or spindle numbers, as well as for mirroring traverse paths

and tool dimensions (see the smart.Turn and DIN Programming

User’s Manual)

The "traverse to a fixed stop" function (G916) is now available for

transferring the workpiece to the second traversable spindle or for

pressing the tailstock against the workpiece (see the smart.Turn and

DIN Programming User’s Manual)

The G925 function makes it possible to define and monitor the max-

imum contact force for an axis. This function can be applied to use

the opposing spindle as a mechatronic tailstock, for example (see

the smart.Turn and DIN Programming User’s Manual)

Controlled parting using servo-lag monitoring (G917) can now be

activated to prevent collisions caused by incomplete parting processes (see the smart.Turn and DIN Programming User’s Manual)

The spindle synchronization option G720 synchronizes the shaft

speeds of two or more spindles so that they rotate synchronously

with a gear ratio or a defined offset (see the smart.Turn and DIN Programming User’s Manual)

In combination with the synchronization (G720) of main spindle and

tool spindle, the new "Hobbing" cycle (G808) is available for milling

external teeth and profiles (see the smart.Turn and DIN Programming User’s Manual)

With G924, a "fluctuating speed" can now be programmed to pre-

vent resonance (see the smart.Turn and DIN Programming User’s

Manual)

6

Page 7

New functions of software 688945-03 and 68894x-01

In the Organization mode of operation, you can grant or restrict

access to the control by using the EXTERNAL ACCESS soft key

(siehe auch „Organization mode of operation” auf Seite 542)

The pocket calculator can now be activated in each application and

also remains active after a change in operating modes. The Get current value and Load current value soft keys enable you to fetch

numerical values from an active input field or to transfer them to an

active input field (siehe auch „Integrated calculator” auf Seite 58)

Tool touch probes can now be calibrated in the Machine Setup

menu (siehe auch „Calibrating the tool touch probe” auf Seite 100)

The workpiece zero point can now also be set in the direction of the

Z axis using a touch probe (siehe auch „Machine setup” auf Seite

92)

In Teach-in mode, the oversizes RI and RK for the workpiece blank

were introduced for finishing in the recess-turning cycles (siehe

auch „Recess turning, radial finishing—expanded” auf Seite 250)

The oversizes RI and RK for the workpiece blank were introduced for

finishing in the recess-turning units and in Cycle G869 (see

smart.Turn and DIN Programming User's Manual).

On machines with a B axis it is now also possible to drill, bore, and

mill in oblique planes. In addition to this, the B axis enables you to

use tools even more flexibly during turning (see smart.Turn and DIN

Programming User's Manual).

The control now provides numerous touch probe cycles for various

applications (see smart.Turn and DIN Programming User's Manual):

Calibrating a touch trigger probe

Measuring circles, circle segments, angle and position of the C

axis

Misalignment compensation

Single-point and double-point measurement

Finding a hole or stud

Zero point setting in the Z or C axis

Automatic tool measurement

HEIDENHAIN CNC PILOT 640 7

Page 8

The new TURN PLUS function automatically generates NC pro-

grams for turning and milling operations based on a fixed machining

sequence (see smart.Turn and DIN Programming User's Manual).

The G940 function now provides a way to calculate the tool lengths

in the basic (definition) position of the B axis (see smart.Turn and

DIN Programming User's Manual).

For machining operations that require rechucking, you can define a

separation point on the contour description with G44 (see

smart.Turn and DIN Programming User's Manual).

The G927 function enables you to convert tool lengths to the refer-

ence position of the tool (B axis = 0) (see smart.Turn and DIN Programming User's Manual).

Recesses that were defined with G22 can now be machined with

the new Cycle 870 ICP Recessing (see smart.Turn and DIN Programming User's Manual).

8

Page 9

New functions of software 68894x-02

The "Zero point shift" miscellaneous function was introduced in ICP

(siehe auch „Zero point shift” auf Seite 389)

In ICP contours, fit dimensions and inside threads can now be cal-

culated using an input form (siehe auch „Fits and inside threads” auf

Seite 384)

The miscellaneous functions "Copy in linear/circular series, and by

mirroring" were introduced in ICP (siehe auch „Copying a contour

section in linear series” auf Seite 389)

The system time can now be set using an input form (siehe auch

„Displaying operating times” auf Seite 101)

The parting cycle G859 was expanded by the parameters K, SD and

U (siehe auch „Parting” auf Seite 267)

The angle of approach and departure can now be defined for ICP

recess turning (siehe auch „ICP recess turning, radial finishing” auf

Seite 258)

With TURN PLUS you can now create programs for machining with

an opposing spindle and for multipoint tools (see the smart.Turn and

DIN Programming User’s Manual)

In the G797 Area Milling function, milling contours can now be

selected (see the smart.Turn and DIN Programming User’s Manual)

The G720 function was expanded by the Y parameter (see the

smart.Turn and DIN Programming User’s Manual)

The G860 function was expanded by the O and U parameters (see

the smart.Turn and DIN Programming User’s Manual)

HEIDENHAIN CNC PILOT 640 9

Page 10

New functions of software 68894x-03

In the Teach-In submode, the parameter RB was added to the cycles

"Figure, axial", "Figure, radial", "ICP contour, axial" and "ICP contour,

radial" (siehe „Milling cycles” auf Seite 317)

In the Teach-In submode, the parameters SP and SI were added to

all tapping cycles (siehe „Drilling cycles” auf Seite 299)

In the Simulation submode, the 3-D view provides additional fea-

tures (siehe „3-D view” auf Seite 491)

Tool control graphics were introduced in the Tool Editor mode of

operation (siehe „Tool control graphics” auf Seite 505)

An ID number can be entered directly in the turret list (siehe „Filling

the turret list” auf Seite 88)

The tool list provides additional filter options (siehe „Sorting and fil-

tering the tool list” auf Seite 502)

The Transfer submode provides enhanced tool backup functionality

(siehe „Transferring tool data” auf Seite 596)

The Transfer submode provides enhanced tool import functionality

(siehe „Importing tool data of the CNC PILOT 4290” auf Seite 604)

The Set Axis Values menu item now also enables you to define off-

set values for shifts using G53, G54 and G55 (siehe „Defining offsets” auf Seite 94)

Load monitoring was introduced in the Program Run submode

(siehe „Load monitoring (option)” auf Seite 119)

The definition of skip levels was introduced in the Program Run sub-

mode (siehe „Program execution” auf Seite 114)

A function was introduced to query information on the tool status

(siehe „Tool life monitoring”, Seite 90), (siehe „Editing tool-life

data” auf Seite 509)

A user parameter was introduced to enable you to activate and deac-

tivate the software limit switches for the Simulation submode (siehe

„List of user parameters” auf Seite 545)

A user parameter was introduced to enable you to suppress the

error message for the software limit switches (siehe „List of user

parameters” auf Seite 545)

A user parameter was introduced to enable you to use NC Start for

executing a tool change programmed in the T,S,F dialog (siehe „List

of user parameters” auf Seite 545)

A user parameter was introduced to divide the T,S,F dialog into sep-

arate dialogs (siehe „List of user parameters” auf Seite 545)

The parameter WE was added to G32 (see the smart.Turn and DIN

Programming User's Manual)

The parameters U, V and W were added to G51, G56 and G59 (see

the smart.Turn and DIN Programming User's Manual)

Parameters ensuring maximum compatibility with the ICP contour

description were added to G0, G1, G12/G13, G101, G102/G103,

G110, G111, G112/G113, G170, G171, G172/G173, G180, G181 and

G182/G183 (see the smart.Turn and DIN Programming User's Manual)

The parameter C was added to G808 (see the smart.Turn and DIN

Programming User's Manual)

10

Page 11

The parameter U was added to G810 and G820 (see the smart.Turn

and DIN Programming User's Manual)

The parameter D was added to G4 and G860 (see the smart.Turn

and DIN Programming User's Manual)

The parameter B was added to G890 (see the smart.Turn and DIN

Programming User's Manual)

The parameter RB was added to the units G840 "Contour milling, fig-

ures" and G84X "Pocket milling, figures" (see the smart.Turn and DIN

Programming User's Manual)

The parameters SP and SI were added to all tapping units (see the

smart.Turn and DIN Programming User's Manual)

G48 was introduced to allow limiting the rapid traverse rate for

rotary and linear axes (see the smart.Turn and DIN Programming

User's Manual)

G53, G54 and G55 were introduced for zero point shifts using offset

values (see the smart.Turn and DIN Programming User's Manual)

The functions for superimposing axis movements G725 "Eccentric

turning", G726 "Transition to eccentric" and G727 "Eccentric X" were

introduced (see the smart.Turn and DIN Programming User's Manual)

The load monitoring functions G995 "Monitoring zone definition" and

G996 "Type of load monitoring" were introduced (see the smart.Turn

and DIN Programming User's Manual)

The AWG submode now also supports tools with quick-change

holders (see the smart.Turn and DIN Programming User's Manual)

A tree view is available in the smart.Turn operating mode (see the

smart.Turn and DIN Programming User's Manual)

Skip levels can be defined in the smart.Turn operating mode (see

the smart.Turn and DIN Programming User's Manual)

A function was introduced to query information on the tool status

(see the smart.Turn and DIN Programming User's Manual)

HEIDENHAIN CNC PILOT 640 11

Page 12

12

Page 13

About this manual

The symbols used in this manual are described below.

This symbol indicates that important information about the

function described must be considered.

This symbol indicates that there is one or more of the

following risks when using the described function:

Danger to workpiece

Danger to fixtures

Danger to tool

Danger to machine

Danger to operator

This symbol indicates that the described function must be

adapted by the machine tool builder. The function

described may therefore vary depending on the machine.

This symbol indicates that you can find detailed

information about a function in another manual.

About this manual

Would you like any changes, or have you found any errors?

We are continuously striving to improve our documentation for you.

Please help us by sending your requests to the following e-mail

address: tnc-userdoc@heidenhain.de.

HEIDENHAIN CNC PILOT 640 13

Page 14

About this manual

14

Page 15

Contents

Introduction and fundamentals

1

Basics of operation

2

Machine mode of operation

3

Teach-in mode

4

ICP programming

5

Graphic simulation

6

Tool and technology database

7

Organization mode of operation

8

Tables and overviews

9

Overview of cycles

10

HEIDENHAIN CNC PILOT 640 15

Page 16

Page 17

1 Introduction and fundamentals ..... 35

1.1 The CNC PILOT ..... 36

1.2 Configuration ..... 37

Slide position ..... 37

Tool carrier systems ..... 37

The C axis ..... 37

The Y axis ..... 38

Full-surface machining ..... 39

1.3 Features ..... 40

Configuration ..... 40

Modes of operation ..... 40

1.4 Data backup ..... 42

1.5 Explanation of terms ..... 43

1.6 CNC PILOT design ..... 44

1.7 Fundamentals ..... 45

Position encoders and reference marks ..... 45

Axis designations ..... 45

Coordinate system ..... 46

Absolute coordinates ..... 46

Incremental coordinates ..... 47

Polar coordinates ..... 47

Machine zero point ..... 47

Workpiece zero point ..... 48

Units of measure ..... 48

1.8 Tool dimensions ..... 49

Tool length ..... 49

Tool compensation ..... 49

Tool-tip radius compensation (TRC) ..... 50

Milling cutter radius compensation (MCRC) ..... 50

HEIDENHAIN CNC PILOT 640 17

Page 18

2 Basics of operation ..... 51

2.1 General information on operation ..... 52

Operation ..... 52

Setup ..... 52

Programming – Teach-in mode ..... 52

Programming – smart.Turn ..... 52

2.2 The CNC PILOT screen ..... 53

2.3 Operation and data input ..... 54

Operating modes ..... 54

Menu selection ..... 55

Soft keys ..... 55

Data input ..... 56

smart.Turn dialogs ..... 56

List operations ..... 57

Alphanumeric keyboard ..... 57

2.4 Integrated calculator ..... 58

Calculator functions ..... 58

Adjusting the position of the calculator ..... 60

2.5 Types of programs ..... 61

2.6 The error messages ..... 62

Display of errors ..... 62

Opening the error window ..... 62

Closing the error window ..... 62

Detailed error messages ..... 63

"Details" soft key ..... 63

Clearing errors ..... 64

Error log file ..... 64

Keystroke log file ..... 65

Saving service files ..... 65

2.7 TURNguide context-sensitive help system ..... 66

Application ..... 66

Working with the TURNguide ..... 67

Downloading current help files ..... 71

18

Page 19

3 Machine mode of operation ..... 73

3.1 Machine mode of operation ..... 74

3.2 Switch-on / Switch-off ..... 75

Switch-on ..... 75

Monitoring EnDat encoders ..... 75

Traversing the reference marks ..... 76

Switch-off ..... 77

3.3 Machine data ..... 78

Input of machine data ..... 78

Machine data display ..... 80

Cycle statuses ..... 84

Axis feed rate ..... 84

Spindle ..... 84

3.4 Setting up a tool list ..... 85

Machine with turret ..... 85

Machine with multifix ..... 85

Tools in different quadrants ..... 86

Filling the turret list from the database ..... 87

Filling the turret list ..... 88

Tool call ..... 89

Driven tools ..... 89

Tool life monitoring ..... 90

3.5 Machine setup ..... 92

Defining the workpiece zero point ..... 93

Defining offsets ..... 94

Homing the axes ..... 95

Setting the protection zone ..... 96

Defining the tool change position ..... 97

Setting C-axis values ..... 98

Setting up machine dimensions ..... 99

Calibrating the tool touch probe ..... 100

Displaying operating times ..... 101

Setting the system time ..... 102

3.6 Tool measurement ..... 103

Touch off ..... 104

Touch probe (tool touch probe) ..... 105

Optical gauge ..... 106

Tool compensation ..... 107

3.7 Manual mode ..... 108

Tool change ..... 108

Spindle ..... 108

Handwheel operation ..... 108

Manual direction keys ..... 109

Teach-in cycles in Manual mode ..... 109

HEIDENHAIN CNC PILOT 640 19

Page 20

3.8 Teach-in mode ..... 110

Teach-in mode ..... 110

Programming Teach-in cycles ..... 110

3.9 Program Run mode ..... 111

Loading a program ..... 111

Comparing a tool list ..... 112

Before executing a program ..... 112

Finding a start block ..... 113

Program execution ..... 114

Entering compensation values during program run ..... 115

Program execution in "dry run" mode ..... 118

3.10 Load monitoring (option) ..... 119

Reference machining ..... 121

Checking the reference values ..... 122

Adapting the limit values ..... 124

Using load monitoring during production ..... 125

3.11 Graphic simulation ..... 126

3.12 Program management ..... 127

Program selection ..... 127

File manager ..... 128

Project management ..... 129

3.13 Conversion into DIN format ..... 130

Making a conversion ..... 130

3.14 Units of measure ..... 131

20

Page 21

4 Teach-in mode ..... 133

4.1 Working with cycles ..... 134

Cycle starting point ..... 134

Help graphics ..... 135

DIN macros ..... 135

Graphical test run (simulation) ..... 135

Contour follow-up in Teach-in mode ..... 136

Cycle keys ..... 136

Switching functions (M functions) ..... 137

Comments ..... 137

Cycle menu ..... 138

Addresses used in many cycles ..... 140

4.2 Workpiece blank cycles ..... 141

Bar/tube blank ..... 142

ICP workpiece blank contour ..... 143

4.3 Single cut cycles ..... 144

Rapid traverse positioning ..... 145

Move to the tool change position ..... 146

Linear machining, longitudinal ..... 147

Linear machining, transverse ..... 148

Linear machining at angle ..... 149

Circular machining ..... 151

Chamfer ..... 153

Rounding arc ..... 155

M functions ..... 157

HEIDENHAIN CNC PILOT 640 21

Page 22

4.4 Turning cycles ..... 158

Tool position ..... 159

Cut longitudinal ..... 161

Cut transverse ..... 163

Roughing, longitudinal—expanded ..... 165

Roughing, transverse—expanded ..... 167

Finishing cut, longitudinal ..... 169

Finishing cut, transverse ..... 170

Finishing cut, longitudinal—expanded ..... 171

Finishing cut, transverse—expanded ..... 173

Cut, longitudinal plunge ..... 175

Cut, transverse plunge ..... 177

Cut, longitudinal plunging—expanded ..... 179

Cut, transverse plunging—expanded ..... 181

Cut, longitudinal finishing plunge ..... 183

Cut, transverse finishing plunge ..... 185

Cut, longitudinal finishing plunge—expanded ..... 187

Cut, transverse finishing plunge—expanded ..... 189

Cut, ICP contour-parallel, longitudinal ..... 191

Cut, ICP contour-parallel, transverse ..... 194

Cut, ICP contour-parallel, longitudinal finishing ..... 196

Cut, ICP contour-parallel, transverse finishing ..... 198

ICP cutting, longitudinal ..... 200

ICP cut transverse ..... 202

ICP longitudinal finishing cut ..... 204

ICP transverse finishing cut ..... 206

Examples of turning cycles ..... 208

22

Page 23

4.5 Recessing cycles ..... 212

Cutting and infeed directions for recessing cycles ..... 212

Undercut position ..... 213

Contour forms ..... 213

Recessing, radial ..... 214

Recessing, axial ..... 216

Recessing, radial—expanded ..... 218

Recessing, axial—expanded ..... 220

Recessing radial, finishing ..... 222

Recessing axial, finishing ..... 224

Recessing radial, finishing—expanded ..... 226

Recessing axial, finishing—expanded ..... 228

ICP recessing radial ..... 230

ICP recessing cycles, axial ..... 232

ICP recessing, radial finishing ..... 234

ICP recessing, axial finishing ..... 236

Recess turning ..... 238

Recess turning, radial ..... 239

Recess turning, axial ..... 240

Recess turning, radial—expanded ..... 242

Recess turning, axial—expanded ..... 244

Recess turning, radial finishing ..... 246

Recess turning, axial finishing ..... 248

Recess turning, radial finishing—expanded ..... 250

Recess turning, axial finishing—expanded ..... 252

ICP recess turning, radial ..... 254

ICP recess turning, axial ..... 256

ICP recess turning, radial finishing ..... 258

ICP recess turning, axial finishing ..... 260

Undercutting type H ..... 262

Undercutting type K ..... 264

Undercutting type U ..... 265

Parting ..... 267

Examples of recessing cycles ..... 269

HEIDENHAIN CNC PILOT 640 23

Page 24

4.6 Thread and undercut cycles ..... 271

Thread position, undercut position ..... 271

Handwheel superimposition ..... 272

Feed angle, thread depth, proportioning of cuts ..... 273

Thread run-in / thread run-out ..... 273

Last cut ..... 274

Thread cycle (longitudinal) ..... 275

Thread cycle (longitudinal)—expanded ..... 277

Tapered thread ..... 279

API thread ..... 281

Recut (longitudinal) thread ..... 283

Recut (longitudinal) thread—expanded ..... 285

Recut tapered thread ..... 287

Recut API thread ..... 289

Undercut DIN 76 ..... 291

Undercut DIN 509 E ..... 293

Undercut DIN 509 F ..... 295

Examples of thread and undercut cycles ..... 297

4.7 Drilling cycles ..... 299

Drilling, axial ..... 300

Drilling, radial ..... 302

Deep-hole drilling, axial ..... 304

Deep-hole drilling, radial ..... 307

Tapping, axial ..... 309

Tapping, radial ..... 311

Thread milling, axial ..... 313

Examples of drilling cycles ..... 315

4.8 Milling cycles ..... 317

Rapid positioning milling ..... 318

Slot, axial ..... 319

Figure, axial ..... 321

ICP contour, axial ..... 325

Face milling ..... 328

Slot, radial ..... 331

Figure, radial ..... 333

ICP contour, radial ..... 337

Helical-slot milling, radial ..... 340

Milling direction for contour milling ..... 342

Milling direction for pocket milling ..... 343

Example of milling cycle ..... 344

Engraving, axial ..... 345

Engraving, radial ..... 347

Engraving, axial/radial ..... 349

24

Page 25

4.9 Drilling and milling patterns ..... 350

Drilling pattern linear, axial ..... 351

Milling pattern linear, axial ..... 353

Drilling pattern circular, axial ..... 355

Milling pattern circular, axial ..... 357

Drilling pattern linear, radial ..... 359

Milling pattern linear, radial ..... 361

Drilling pattern circular, radial ..... 363

Milling pattern circular, radial ..... 365

Examples of pattern machining ..... 367

4.10 DIN cycles ..... 370

DIN cycle ..... 370

HEIDENHAIN CNC PILOT 640 25

Page 26

5 ICP programming ..... 373

5.1 ICP contours ..... 374

Loading contours ..... 374

Form elements ..... 375

Machining attributes ..... 375

Calculation of contour geometry ..... 376

5.2 ICP editor in cycle mode ..... 377

Editing contours for cycles ..... 377

File organization with the ICP editor ..... 378

5.3 ICP editor in smart.Turn ..... 379

Editing a contour in smart.Turn ..... 380

5.4 Creating an ICP contour ..... 382

Entering an ICP contour ..... 382

Absolute or incremental dimensioning ..... 383

Transitions between contour elements ..... 383

Fits and inside threads ..... 384

Polar coordinates ..... 385

Angular input ..... 385

Contour graphics ..... 386

Selection of solutions ..... 387

Colors in contour graphics ..... 387

Selection functions ..... 388

Zero point shift ..... 389

Copying a contour section in linear series ..... 389

Copying a contour section in circular series ..... 390

Copying a contour section by mirroring ..... 390

Inverting ..... 390

Contour direction (cycle programming) ..... 391

5.5 Editing ICP contours ..... 392

Superimposing form elements ..... 392

Adding contour elements ..... 392

Editing or deleting the last contour element ..... 393

Deleting a contour element ..... 393

Editing contour elements ..... 394

5.6 The zoom function in the ICP editor ..... 399

Changing the view ..... 399

5.7 Defining the workpiece blank ..... 400

"Bar" blank ..... 400

"Tube" blank ..... 400

"Cast part" blank ..... 400

5.8 Contour elements of a turning contour ..... 401

Basic elements of a turning contour ..... 401

Contour form elements ..... 405

26

Page 27

5.9 Contour elements on face ..... 412

Starting point of face contour ..... 412

Vertical lines on face ..... 413

Horizontal lines on face ..... 414

Line at angle on face ..... 415

Circular arc on face ..... 416

Chamfer/rounding arc on face ..... 417

5.10 Contour elements on lateral surface ..... 418

Starting point of lateral surface contour ..... 418

Vertical lines on lateral surface ..... 420

Horizontal lines on lateral surface ..... 420

Line at angle on lateral surface ..... 421

Circular arc on lateral surface ..... 422

Chamfer/rounding arc on lateral surface ..... 423

5.11 C and Y axis machining in smart.Turn ..... 424

Reference data, nested contours ..... 425

Representation of the ICP elements in the smart.Turn program ..... 426

5.12 Face contours in smart.Turn ..... 427

Reference data for complex face contours ..... 427

TURN PLUS attributes ..... 428

Circle on face ..... 428

Rectangle on face ..... 429

Polygon on face ..... 430

Linear slot on face ..... 431

Circular slot on face ..... 431

Hole on face ..... 432

Linear pattern on face ..... 433

Circular pattern on face ..... 434

5.13 Lateral surface contours in smart.Turn ..... 435

Reference data of lateral surface ..... 435

TURN PLUS attributes ..... 436

Circle on lateral surface ..... 437

Rectangle on lateral surface ..... 438

Polygon on lateral surface ..... 439

Linear slot on lateral surface ..... 440

Circular slot on lateral surface ..... 441

Hole on lateral surface ..... 442

Linear pattern on lateral surface ..... 443

Circular pattern on lateral surface ..... 444

HEIDENHAIN CNC PILOT 640 27

Page 28

5.14 Contours in the XY plane ..... 446

Reference data in XY plane ..... 446

Starting point of contour in XY plane ..... 447

Vertical lines in XY plane ..... 447

Horizontal lines in XY plane ..... 448

Line at angle in XY plane ..... 449

Circular arc in XY plane ..... 450

Chamfer/rounding arc in XY plane ..... 451

Circle in XY plane ..... 452

Rectangle in XY plane ..... 453

Polygon in XY plane ..... 454

Linear slot in XY plane ..... 455

Circular slot in XY plane ..... 456

Hole in XY plane ..... 457

Linear pattern in XY plane ..... 458

Circular pattern in XY plane ..... 459

Single surface in XY plane ..... 460

Centric polygon in XY plane ..... 461

5.15 Contours in the YZ plane ..... 462

Reference data in YZ plane ..... 462

TURN PLUS attributes ..... 463

Starting point of contour in YZ plane ..... 464

Vertical lines in YZ plane ..... 464

Horizontal lines in YZ plane ..... 465

Line at angle in YZ plane ..... 466

Circular arc in YZ plane ..... 467

Chamfer/rounding arc in YZ plane ..... 468

Circle in YZ plane ..... 469

Rectangle in YZ plane ..... 470

Polygon in YZ plane ..... 471

Linear slot in YZ plane ..... 472

Circular slot in YZ plane ..... 473

Hole in YZ plane ..... 474

Linear pattern in YZ plane ..... 475

Circular pattern in YZ plane ..... 476

Single surface in YZ plane ..... 477

Centric polygons in YZ plane ..... 478

5.16 Loading existing contours ..... 479

Integrating cycle contours in smart.Turn ..... 479

DXF contours (option) ..... 480

28

Page 29

6 Graphic simulation ..... 483

6.1 Simulation mode of operation ..... 484

Using the graphic simulation ..... 485

The miscellaneous functions ..... 486

6.2 Simulation window ..... 487

Setting up the views ..... 487

Single-window view ..... 488

Multiple window view ..... 488

6.3 Views ..... 489

Traverse path display ..... 489

Tool depiction ..... 490

Material-removal graphic ..... 490

3-D view ..... 491

6.4 The zoom function ..... 493

Adjusting the visible section ..... 493

6.5 Simulation with mid-program startup ..... 495

Startup block with smart.Turn programs ..... 495

Mid-program startup in cycle programs ..... 496

6.6 Time calculation ..... 497

Showing the machining times ..... 497

6.7 Saving the contour ..... 498

Saving the generated contour in the simulation ..... 498

HEIDENHAIN CNC PILOT 640 29

Page 30

7 Tool and technology database ..... 499

7.1 Tool database ..... 500

Tool types ..... 500

Multipoint tools ..... 501

Tool life management ..... 501

7.2 Tool editor ..... 502

Sorting and filtering the tool list ..... 502

Editing the tool data ..... 504

Tool control graphics ..... 505

Tool texts ..... 506

Editing multipoint tools ..... 507

Editing tool-life data ..... 509

Manual change systems ..... 511

7.3 Tool data ..... 516

General tool parameters ..... 516

Standard turning tools ..... 519

Recessing tools ..... 520

Thread-cutting tools ..... 521

Twist drills and indexable-insert drills ..... 522

NC center drill ..... 523

Centering tool ..... 524

Counterbore ..... 525

Countersink ..... 526

Tap ..... 527

Standard milling tools ..... 528

Thread milling tools ..... 529

Angle cutters ..... 530

Milling pins ..... 531

Knurling tool ..... 532

Touch probes ..... 533

Stopper tool ..... 534

Gripper ..... 535

7.4 Technology database ..... 536

Technology editor ..... 537

Editing a workpiece material or cutting material list ..... 538

Displaying/editing cutting data ..... 539

30

Page 31

8 Organization mode of operation ..... 541

8.1 Organization mode of operation ..... 542

8.2 Parameters ..... 543

Parameter editor ..... 543

List of user parameters ..... 545

Descriptions of the most important machining parameters (processing) ..... 561

General settings ..... 561

Thread cutting ..... 576

8.3 Transfer ..... 581

Data backup ..... 581

Data exchange with TNCremo ..... 581

External access ..... 581

Connections ..... 582

Ethernet interface CNC PILOT 620 ..... 583

Ethernet interface CNC PILOT 640 ..... 584

USB connection ..... 591

Data transfer options ..... 592

Transferring programs (files) ..... 593

Transferring parameters ..... 595

Transferring tool data ..... 596

Service files ..... 598

Creating a data backup file ..... 599

Importing NC programs from predecessor controls ..... 600

Importing tool data of the CNC PILOT 4290 ..... 604

8.4 Service pack ..... 605

Installing a service pack ..... 605

HEIDENHAIN CNC PILOT 640 31

Page 32

9 Tables and overviews ..... 607

9.1 Thread pitch ..... 608

Thread parameters ..... 608

Thread pitch ..... 609

9.2 Undercut parameters ..... 615

DIN 76—undercut parameters ..... 615

DIN 509 E – undercut parameters ..... 617

DIN 509 F – undercut parameters ..... 617

9.3 Technical information ..... 618

9.4 Compatibility in DIN programs ..... 627

Syntax elements of the CNC PILOT 640 ..... 629

32

Page 33

10 Overview of cycles ..... 641

10.1 Workpiece blank cycles, single cut cycles ..... 642

10.2 Turning cycles ..... 643

10.3 Recessing and recess-turning cycles ..... 644

10.4 Thread cycles ..... 645

10.5 Drilling cycles ..... 646

10.6 Milling cycles ..... 647

HEIDENHAIN CNC PILOT 640 33

Page 34

34

Page 35

Introduction and fundamentals

HEIDENHAIN CNC PILOT 640 35

Page 36

1.1 The CNC PILOT

The CNC PILOT was conceived for CNC lathes. It is suitable for

horizontal and vertical lathes. The CNC PILOT supports lathes with

tool turrets. The tool carrier of horizontal lathes can be located in front

of or behind the workpiece.

The CNC PILOT supports lathes with spindle, one slide (X and Z axis),

C axis or positionable spindle, driven tool and machines with a Y axis.

Regardless of whether you are turning simple parts or complex

workpieces, the CNC PILOT provides you with the benefits of

graphical contour input and convenient programming with smart.Turn.

1.1 The CNC PILOT

Programming with variables, controlling special machine components,

or using externally created programs, etc. is no problem: Simply

switch to DINplus. This programming mode helps you solve all your

special tasks.

The CNC PILOT also offers the powerful Teach-in mode. It enables

you to perform simple machining, rework or repair operations without

writing NC programs.

The CNC PILOT supports operations with the C axis in cycle,

smart.Turn and DIN programming. In the Y axis, the CNC PILOT

supports operations with smart.Turn and DIN programming.

36 Introduction and fundamentals

Page 37

1.2 Configuration

In the standard version, the control is equipped with the axes X and Z

and a main spindle. Optionally, a C axis, a Y axis, and a driven tool can

be configured.

Slide position

The machine tool builder configures the CNC PILOT. These are the

available possibilities:

Z axis horizontal with tool slide behind the workpiece

Z axis horizontal with tool slide in front of the workpiece

Z axis vertical with tool slide to the right of the workpiece

The menu symbols, help graphics and graphic representations during

ICP and simulation consider the slide position.

The representations in this User’s Manual assume a lathe with tool

carrier behind the workpiece.

Tool carrier systems

The CNC PILOT supports turrets with a number n of tool mounts as

tool carriers.

The C axis

1.2 Configuration

With a C axis you can drill and mill a workpiece on its face and lateral

surfaces.

When the C axis is used, one axis interpolates linearly or circularly with

the spindle in the given working plane, while the third axis interpolates

linearly.

The CNC PILOT supports part program creation with the C axis in:

Teach-in mode

smart.Turn programming

DINplus programming

HEIDENHAIN CNC PILOT 640 37

Page 38

The Y axis

With a Y axis you can drill and mill a workpiece on its face and lateral

surfaces.

During use of the Y axis, two axes interpolate linearly or circularly in

the given working plane, while the third axis interpolates linearly. This

enables you to machine slots or pockets, for example, with plane

floors and perpendicular edges. By defining the spindle angle, you can

determine the position of the milling contour on the workpiece.

The CNC PILOT supports program creation with the Y axis in:

Teach-in mode

1.2 Configuration

smart.Turn programs

DINplus programs

38 Introduction and fundamentals

Page 39

Full-surface machining

Functions like angle-synchronous part transfer with rotating spindle,

traversing to a stop, controlled parting, and coordinate transformation

ensure efficient machining as well as simple programming of fullsurface machining.

The CNC PILOT supports full-surface machining for all common

machine designs.

Examples: Lathes with

Rotating gripper

Movable opposing spindle

Several spindles and tool carriers

1.2 Configuration

HEIDENHAIN CNC PILOT 640 39

Page 40

1.3 Features

Configuration

Basic version: X and Z axis, spindle

Positionable spindle and driven tool

C axis and driven tool

1.3 Features

Y axis and driven tool

B axis for machining a tilted plane

Digital current and speed control

Modes of operation

Manual operation

Manual slide movement through axis-direction keys or electronic

handwheels.

Graphic support for entering and running Teach-in cycles without

saving the machining steps in alternation with manual machine

operation.

Thread reworking (thread repair in a second workpiece setup).

Teach-in mode

Sequential linking of Teach-in cycles, where each cycle is run

immediately after input, or is graphically simulated and subsequently

saved.

Program run

All are possible in single-block and full-sequence modes

DINplus programs

smart.Turn programs

Teach-in programs

Setup functions

Setting the workpiece zero point

Defining the tool-change point

Defining the protection zone

Tool measurement through touch-off, touch probe or optical gauge

Programming

Teach-in programming

Interactive Contour Programming (ICP)

smart.Turn programming

Automatic program creation with TURN PLUS

DINplus programming

40 Introduction and fundamentals

Page 41

Graphic simulation

Graphic depiction of the sequence of smart.Turn or DINplus

programs and graphic depiction of a Teach-in cycle or Teach-in

program

Simulation of the tool paths as wire-frame or cutting-path graphics,

special identification of the rapid-traverse paths

Machining simulation (2-D material-removal graphic)

Side or face view, or 2-D view of cylindrical surface

Display of programmed contours

Shifting and magnifying functions

Tool system

Database for 250 tools, optionally 999 tools

Description can be entered for every tool

Optional support of multipoint tools (tools with multiple reference

points or multiple cutting edges)

Turret or multifix system

Technology database

Cutting data is entered in the cycle or in the UNIT as default values

9 workpiece-material/tool-material combinations (144 entries)

Optionally 62 workpiece-material/tool-material combinations (992

entries)

Interpolation

Linear: In 2 principal axes (max. ± 100 m)

Circular: in 2 axes (radius max. 999 m)

C axis: Interpolation in the linear axes X and Z with the C axis

Y axis: Linear or circular interpolation of two axes in the given plane.

The respective third axis can simultaneously perform linear

interpolation.

G17: XY plane

G18: XZ plane

G19: YZ plane

B axis: Drilling, boring and milling operations in oblique planes

1.3 Features

HEIDENHAIN CNC PILOT 640 41

Page 42

1.4 Data backup

HEIDENHAIN recommends saving new programs and files created on

a PC at regular intervals.

HEIDENHAIN provides a backup function for this purpose in the data

transfer software TNCremoNT. Your machine tool builder can provide

you with a copy.

You additionally need a data medium on which all machine-specific

data, such as the PLC program, machine parameters, etc., are stored.

1.4 Data backup

Please contact your machine tool builder.

42 Introduction and fundamentals

Page 43

1.5 Explanation of terms

Cursor: In lists, or during data input, a list item, an input field or a

character is highlighted. This "highlight" is called a cursor. Entries

and operations, like copying, deleting, inserting a new item, etc.,

refer to the current cursor position.

Arrow keys: The cursor is moved with the horizontal and vertical

arrow keys and with the PG UP / PG DN keys.

Page keys: The PG UP / PG DN keys are also called "Page keys."

Navigation: Within a list or an input box, you can move the cursor

to any position you would like to check, change, delete or add to. In

other words, you "navigate" through the list.

Active/ inactive windows, functions, menu items: Of all

windows that are displayed on the screen, only one is active. That

means, any data you type on the keyboard or keypad are entered in

the active window only. In the active window the title bar is shown

in color. In the inactive windows, the title bar appears dimmed.

Inactive function keys or menu keys also appear dimmed.

Menu, menu key: The CNC PILOT arranges the available functions

and function groups in a 9-field box. This box is called a menu. Each

symbol in the menu is a menu key.

Editing: Editing is changing, deleting and adding to parameters,

commands, etc. within programs, tool data or parameters.

Default value: If the parameters of cycles or DIN commands are

preassigned values, these values are referred to as default values.

These values are used if you do not enter the parameters.

Byte: The capacity of storage media is measured in bytes. Since the

CNC PILOT features an internal memory, the individual program

lengths are expressed in bytes.

Extension: File names consist of the actual name and the

extension. The name part and the extension part are separated by a

dot ("."). The extension indicates the type of file. Examples:

*.NC "DIN programs"

*.NCS "DIN subprograms (DIN macros)"

Soft key: Soft keys are the unmarked keys along the side of the

screen. The meaning of each key is shown on the screen.

Form: The individual pages of a dialog are shown as easy-to-fill

forms.

UNITS: A UNIT is a group of functions united into a dialog in

smart.Turn.

1.5 Explanation of terms

HEIDENHAIN CNC PILOT 640 43

Page 44

1.6 CNC PILOT design

The dialog between machinist and control takes place via:

Screen

Soft keys

Data input keypad

Machine operating panel

The entered data can be displayed and checked on the screen. With

the soft keys directly below the screen, you can select functions,

capture position values, confirm entries, and a lot more.

With the ERR key you can call error and PLC information.

The data input keyboard (operating panel) serves for the input of

1.6 CNC PILOT design

machine data, positioning data, etc. The CNC Pilot has an

alphanumeric keyboard for easy input of tool descriptions, program

descriptions or comments in an NC program. The machine operating

panel contains all necessary controls for manual operation of the lathe.

Cycle programs, ICP contours and NC programs are stored in memory

in the CNC PILOT.

For data exchange and data backup, you can use the Ethernet

interface and the USB interface.

44 Introduction and fundamentals

Page 45

1.7 Fundamentals

Zref

Xref

M

M

Z

Z+

Y+

X

X+

Position encoders and reference marks

The machine axes are equipped with position encoders that register

the positions of the slide or tool. When a machine axis moves, the

corresponding position encoder generates an electrical signal. The

control evaluates this signal and calculates the precise actual position

of the machine axis.

If there is a power interruption, the calculated position will no longer

correspond to the actual position of the machine slide. To recover this

association, incremental position encoders are provided with

reference marks. The scales of the position encoders contain one or

more reference marks that transmit a signal to the control when they

are crossed over. This enables the CNC PILOT to re-establish the

assignment of the displayed position to the current machine position.

For linear encoders with distance-coded reference marks, you only

need to move each axis a maximum of 20 mm (0.8 in.) for these, and

a maximum of 20° for angle encoders.

If incremental encoders are without reference marks, fixed reference

positions have to be traversed after switch-on. The control knows the

exact distance between these reference points and the machine

datum (see figure).

With absolute encoders, an absolute position value is transmitted to

the control immediately upon switch-on. In this way the assignment

of the actual position to the machine slide position is re-established

directly after switch-on.

X

MP

X (Z,Y)

1.7 Fundamentals

Axis designations

The cross slide is referred to as the X axis and the saddle as the Z

axis.

All X-axis values that are displayed or entered are regarded as

diameters.

Lathes with Y axis: The Y axis is perpendicular to the X axis and Z axis

(Cartesian system).

When programming paths of traverse, remember to:

Program a positive value to depart the workpiece.

Program a negative value to approach the workpiece.

HEIDENHAIN CNC PILOT 640 45

Page 46

Coordinate system

The meanings of the coordinates X, Y, Z, and C are specified in DIN

66 217.

The coordinates entered for the principal axes X, Y and Z are

referenced to the workpiece zero point. The angles entered for the

rotary axis (C axis) are referenced to the datum of the C axis.

The axis designations X and Z describe positions in a two-dimensional

coordinate system. As you can see from the figure to the center right,

the position of the tool tip is clearly defined by its X and Z coordinates.

The CNC PILOT can connect points by linear and circular paths of

1.7 Fundamentals

traverse (interpolations). Workpiece machining is programmed by

entering the coordinates for a succession of points and connecting the

points by linear or circular paths of traverse.

Like the paths of traverse, you can also describe the complete contour

of a workpiece by defining single points through their coordinates and

connecting them by linear or circular paths of traverse.

Positions can be programmed to an accuracy of 1 µm (0.001 mm). This

is also the accuracy with which they are displayed.

Absolute coordinates

If the coordinates of a position are referenced to the workpiece datum,

they are referred to as absolute coordinates. Each position on a

workpiece is clearly defined by its absolute coordinates (see figure).

46 Introduction and fundamentals

Page 47

Incremental coordinates

Incremental coordinates are always given with respect to the last

programmed position. They specify the distance from the last active

position to the subsequent position. Each position on a workpiece is

clearly defined by its incremental coordinates (see figure).

Polar coordinates

Positions located on the face or lateral surface can either be entered

in Cartesian coordinates or polar coordinates.

When programming with polar coordinates, a position on the

workpiece is clearly defined by the entries for diameter and angle (see

figure).

1.7 Fundamentals

Machine zero point

The point of intersection of the X and Z axes is called the machine

zero point. On a lathe, the machine zero point is usually the point of

intersection of the spindle axis and the spindle surface. It is designated

with the letter "M" (see figure).

HEIDENHAIN CNC PILOT 640 47

Page 48

Workpiece zero point

To machine a workpiece, it is easier to enter all input data with respect

to a zero point located on the workpiece. By programming the zero

point used in the workpiece drawing, you can take the dimensions

directly from the drawing, without further calculation. This point is the

workpiece zero point. It is designated with the letter "W" (see figure).

1.7 Fundamentals

Units of measure

You can program the CNC PILOT either in the metric or inch system.

The units of measurement listed in the table below apply to all inputs

and displays.

Dimensions Metric Inches

Coordinates mm inch

Lengths mm inch

Angle Degrees Degrees

Spindle speed rpm rpm

Cutting speed m/min ft/min

Feed per revolution mm/rev inch/rev

Feed per minute mm/min inch/min

Acceleration m/s

48 Introduction and fundamentals

2

ft/s

2

Page 49

1.8 Tool dimensions

The CNC PILOT requires information on the specific tools for a variety

of tasks, such as calculating the cutting radius compensation or the

proportioning of cuts.

Tool length

All programmed and displayed position values are given with respect

to the distance between the tool tip and workpiece zero point. Since

the control only knows the absolute position of the tool carrier (slide),

the CNC PILOT needs the dimensions XL and ZL (see figure) to

calculate and display the position of the tool tip.

Tool compensation

The tool tip is subjected to wear during machining processes. To

compensate for this wear, the CNC PILOT uses compensation values.

The compensation values are managed independent of the values for

length. The system automatically adds the compensation values to the

values for length.

1.8 Tool dimensions

HEIDENHAIN CNC PILOT 640 49

Page 50

Tool-tip radius compensation (TRC)

The tip of a lathe tool has a certain radius. When machining tapers,

chamfers and radii, this results in inaccuracies which the CNC PILOT

compensates with its cutting radius compensation function.

Programmed paths of traverse are referenced to the theoretical tool

tip S. With non-paraxial contours, this will lead to inaccuracies during

machining.

The TRC function compensates for this error by calculating a new path

of traverse, the equidistant line (see figure).

The CNC PILOT calculates the TRC for cycle programming. The

smart.Turn and DIN programming feature also takes the TRC for

clearance cycles into account. During DIN programming with single

1.8 Tool dimensions

paths, you can also enable/disable TRC.

Milling cutter radius compensation (MCRC)

In milling operations, the outside diameter of the milling cutter

determines the contour. When the MCRC function is not active, the

system defines the center of the cutter as reference point. The MCRC

function compensates for this error by calculating a new path of

traverse equidistant line.

50 Introduction and fundamentals

Page 51

Basics of operation

HEIDENHAIN CNC PILOT 640 51

Page 52

2.1 General information on

operation

Operation

Select the desired operating mode with the corresponding operating

mode key.

Within the operating mode, you can change the mode through the

soft keys.

With the numeric keypad you can select the function within the

menus.

Dialogs can consist of multiple pages.

Besides with the soft keys, dialogs can be concluded positively with

"INS" or negatively with "ESC."

Changes made in lists are effective immediately. They are also

saved if the list is closed with "ESC" or "Cancel."

Setup

You will find all setup functions in the machine mode in "Manual

mode."

All preparatory work can be performed through the "setup" menu

item and "Set S,F,T."

2.1 General information on operation

Programming – Teach-in mode

Select Teach-in in the "machine" mode and use the Program list

soft key to open a new cycle program.

Activate the cycle menu through the Add cycle soft key. Here you

select the operation and enter the details.

Then press the Input finished soft key. Now you can start the

simulation and check the machining process.

Start the operation in the machine with "Cycle on."

Save that cycle after the operation is completed.

Repeat the last steps for each new operation.

Programming – smart.Turn

Convenient programming with UNITS in a structured NC program.

Combinable with DIN functions.

Contour definition is graphically possible.

Contour follow-up when used with a workpiece blank.

Conversion of cycle programs to smart.Turn programs with the

same functions.

52 Basics of operation

Page 53

2.2 The CNC PILOT screen

The CNC PILOT shows the data to be displayed in windows. Some

windows only appear when they are needed, for example, for typing

in entries.

In addition, the control shows the type of operation, the soft-key

display and the PLC soft-key display on the screen. Each function

that appears in a field of the soft-key row is activated by pressing the

soft key directly below it.

Operating mode line

The operating mode tabs (at the top of the screen) show the four

operating modes as well as the submodes.

Machine display

The machine display field (beneath the operating mode tabs) is

configurable. It shows all important information on axis positions, feed

rates, rotational speeds, and tool.

Other windows used:

List and program window

Display of program lists, tool lists, parameter lists, etc. To select

specific elements from the list, simply move the highlight to the

desired element with the arrow keys.

Menu window

Display of menu symbols. This window only appears on the screen

in the Teach-in and Manual modes.

Input window/Dialog window

For entering the parameters of a cycle, ICP element, DIN command,

etc. Look over the existing data, then delete or edit them in the

dialog window.

Graphic support window

Input data (such as cycle parameters, tool data, etc.) are explained

with graphics. The switchover key (the key with three rotating

arrows at the left edge of the screen) allows you to switch between

the help graphics for internal and external machining (only for cycle

programming).

Simulation window

The simulation window shows a graphic representation of the

contour elements and a simulation of the tool movements. This

enables you to check cycles, entire cycle programs, and DIN

programs.

ICP contour graphics

Display of the contour during ICP programming.

DIN editing window

Display of the DIN program during DIN programming.

Error window

Display of occurred errors and warnings.

2.2 The CNC PILOT screen

HEIDENHAIN CNC PILOT 640 53

Page 54

2.3 Operation and data input

Operating modes

The active mode of operation is highlighted in the operating-mode tab.

The CNC PILOT differentiates between the following operating

modes:

Machine—with the submodes:

Manual (display: "Machine")

Teach-in (Teach-in mode)

Program Run

Programming—with the submodes:

smart.Turn

Simulation

ICP

TURN PLUS: Automatic working plan generation (AWG)

2.3 Operation and data input

Tool management—with the submodes:

Tool editor

Technology editor

Organization—with the submodes:

User parameters

Transfer

User login

You can use the operating mode keys to switch between the modes.

The selected submode and the current menu position remain during

the mode change.

If you press the operating mode key in a submode, the CNC PILOT

switches back to the main level of the mode.

At some places, a dialog has to be ended in order to switch

modes (e.g. in the tool editor).

54 Basics of operation

Page 55

Menu selection

The numerical keypad is used for activating a menu and for entering

data. They are displayed differently depending on the operating mode.

During setup, Teach-in mode etc., the functions are shown in a 9-

field box, the menu window. The meaning of the selected symbol

/ menu item is described in the footer.

In other operating modes, the keypad symbol is shown with the

position of the function marked (see figure).

Press the corresponding numerical key, or move the highlight with the

arrow keys to the symbol on the screen and press the ENT key.

Soft keys

With some system functions, the available functions are arranged

on several soft-key levels.

Some soft keys work like “toggle switches.” A function is active

when the associated field in the soft-key row is highlighted in color.

The setting remains in effect until the function is switched off again.

With functions like Take over position you do not have to enter

values manually. The data are automatically written into the

appropriate input fields.

Data entries are not concluded until the Save or Input finished soft

key has been pressed.

The Back soft key takes you back to the previous operating level.

2.3 Operation and data input

HEIDENHAIN CNC PILOT 640 55

Page 56

Data input

Input windows comprise several input fields. You can move the

cursor to the desired input field with the vertical arrow keys. The CNC

PILOT shows the function of the selected field in the footer of the

window.

Place the highlight on the desired input field and enter the data.

Existing data are overwritten. With the horizontal arrow keys, you can

move the cursor within the input field and place it on the position

where you want to delete, copy or add characters.

To confirm the data you entered in a field, press a vertical arrow key

or the ENTER key.

If there are more input fields than a window can show, a second input

window is used. You will recognize this through the symbol in the

bottom line of the input window. To switch back and forth between

the windows, press the PG UP/PG DN keys.

Data entry is concluded when you press the OK or Input

2.3 Operation and data input

finished or Save soft key. The Back or Cancel soft key

discards input or changes.

smart.Turn dialogs

The unit dialog is divided into fillable forms and the forms are divided

again into groups. The forms are identified by tabs and fine lines divide

each tab into groups. You can navigate between the forms and groups

with the smart keys.

smart keys

Go to the next form

Next/previous group

56 Basics of operation

Page 57

List operations

Cycle programs, DIN programs, tool lists, etc. are displayed as lists.

You can scroll through a list with the arrow keys to check data or to

highlight elements for operations like deleting, copying, editing, etc.

Alphanumeric keyboard

You enter letters and special characters with the screen keypad or (if

available) with a PC keyboard connected over the USB port.

Entering text with the screen keyboard

Press the "Alphabetic keyboard" soft key or the GOTO key to enter

a text, for example a program name.

The CNC PILOT opens the Text Input window.

Just as on a cell phone, you press the numerical keys a few times

to get the desired letters or special characters.

Wait until the selected character is transferred to the entry field

before you enter the next character.

Use the OK soft key to load the text into the open dialog field.

Use the abc/ABC soft key to select upper or lower case.

To delete individual characters, use the Backspace soft key.

2.3 Operation and data input

HEIDENHAIN CNC PILOT 640 57

Page 58

2.4 Integrated calculator

Calculator functions

The calculator can be selected only from open dialogs in cycle

programming or smart.Turn programming. You can use the calculator

in the following three views (see figures at right):

Scientific

Standard

Equation editor. Here you can type in multiple calculations in

immediate sequence (for example 17*3+5/9).

The calculator remains in effect even after a change in

operating modes. Press the END soft key to close the

2.4 Integrated calculator

Using the calculator

Use the arrow keys to select the input field.

calculator.

The GET CURRENT VALUE soft key enables you to

transfer a numerical value from the active input field to the

calculator. The CONFIRM VALUE soft key enables you to

load the current value from the calculator to the active

input field.

Use the CALC key to activate and deactivate the

calculator.

Shift the soft-key menu until the desired function

appears.

Perform the calculation.

Press the soft key. The CNC PILOT transfers the value

into the active input box and closes the calculator.

Switching the view of the calculator

Shift the soft-key menu until the VIEW soft key appears.

Press the View soft key until the desired view is set.

Mathematical function Shortcut (soft key)

Addition +

Subtraction -

Multiplication *

Division /

Calculations in parentheses ()

Arc cosine ARC

Sine SIN

58 Basics of operation

Page 59

Mathematical function Shortcut (soft key)

Cosine COS

Tangent TAN

Powers of values X^Y

Square root SQRT

Inversion 1/x

pi (3.14159265359) PI

Add value to buffer memory M+

Save the value to buffer memory MS

Recall from buffer memory MR

Delete buffer memory contents MC

Natural logarithm LN

Logarithm LOG

Exponent function e^x

Check the algebraic sign SGN

Form the absolute value ABS

Truncate decimal places INT

Truncate places before the decimal point FRAC

Modulus operator MOD

Select view View

Delete value DEL

Unit of measure MM or INCH

Display mode for angle values DEG (degree) or

RAD (radian

measure)

Display mode of the numerical value DEC (decimal) or

HEX (hexadecimal)

2.4 Integrated calculator

HEIDENHAIN CNC PILOT 640 59

Page 60

Adjusting the position of the calculator

You can move the calculator as follows:

Move the calculator with the arrow keys

Move the calculator to the center

2.4 Integrated calculator

60 Basics of operation

Page 61

2.5 Types of programs

The CNC PILOT supports the following programs/contours:

Teach-in programs (cycle programs) are used in the "Teach in"

mode of operation.

smart.Turn and DIN main programs are written in the smart.Turn

mode of operation.

DIN subprograms are written in the smart.Turn operating mode

and are used in cycle programs and smart.Turn main programs.

ICP contours are generated during Teach-in in the Teach-in or

Manual mode of operation. The extension depends on the contour

described.

In smart.Turn the contours are saved directly in the main program.

Program type Folder Extension

Teach-in programs

(cycle programs)

smart.Turn and DIN

main programs

DIN subprograms "nc_prog\ncps" "*.ncs"

ICP contours "nc_prog\gti"

Turning contours "*.gmi"

Contours of

workpiece blanks

Contours on face "*.gms"

Lateral surface

contours

"nc_prog\gtz" "*.gmz"

"nc_prog\ncps" "*.nc"

"*.gmr"

"*.gmm"

2.5 Types of programs

HEIDENHAIN CNC PILOT 640 61

Page 62

2.6 The error messages

Display of errors

The CNC PILOT generates error messages when it detects problems

such as:

Incorrect data input

Logical errors in the program

Contour elements that are impossible to machine

When an error occurs, it is displayed in red type in the header. Long

and multi-line error messages are displayed in abbreviated form. If an

error occurs in a background mode, the error symbol is shown in the

operating mode tab. Complete information on all pending errors is

shown in the error window.

2.6 The error messages

If a rare "processor check error" should occur, the CNC PILOT

automatically opens the error window. You cannot remove such an

error. Shut down the system and restart the CNC PILOT.

The error message is displayed in the header until it is cleared or

replaced by a higher-priority error.

An error message that contains the block number of an NC program

was caused by an error in the indicated block or in the preceding block.

Opening the error window

Press the ERR key. The CNC PILOT opens the error

window and displays all accumulated error

messages.

Closing the error window

Press the END soft key—or

Press the ERR key. The CNC PILOT closes the error

window.

62 Basics of operation

Page 63

Detailed error messages

The CNC PILOT displays possible causes of the error and suggestions

for solving the problem:

Information on error causes and remedies:

Open the error window.

Position the cursor on the error message and press

the soft key. The CNC PILOT opens the window with

information on the error cause and corrective action.

To exit the info, press the Info soft key again.

"Details" soft key

The DETAILS soft key supplies information on the error message.

This information is only required if servicing is needed.

Open the error window.

Position the cursor on the error message and press

the soft key. The CNC PILOT opens the window with

internal information about the error.

To exit the details, press the Details soft key again.

2.6 The error messages

HEIDENHAIN CNC PILOT 640 63

Page 64

Clearing errors

Clearing errors outside of the error window:

Open the error window.

To clear the error/message in the header: Press the

CE key.

In some operating modes (such as the Editing mode), the

CE key cannot be used to clear the error, since the key is

reserved for other functions.

Clearing more than one error:

Open the error window.

2.6 The error messages

To delete an individual error: Position the cursor on the

error message and press the soft key.

To delete all errors: Press the Delete All soft key.

If the cause of the error has not been removed, the error

message cannot be deleted. In this case, the error

message remains in the window.

Error log file

The CNC PILOT stores errors and important events (e.g. system

startup) in an error log file. The capacity of the error log file is limited.

If the log file is full, it switches to the next one, etc. If the last log file

is full, the first one is overwritten by a new one, etc. If necessary,

switch the log file to see the history. 5 log files are available.

Open the error window.

Press the Log file soft key.

Open the log file.

Select previous log file, if needed.

Select current log file, if needed.

The oldest entry is at the beginning of the log file, and the most recent

entry is at the end.

64 Basics of operation

Page 65

Keystroke log file

The CNC PILOT stores keystrokes and important events (e.g. system

startup) in the keystroke log file. The capacity of the keystroke log file

is limited. If the log file is full, it switches to the next one, etc. If the

last log file is full, the first one is overwritten by a new one, etc. If

necessary, switch the log file to see the history. 10 log files are

available.

Open the keystroke log file.

Press the Log file soft key.

Open the log file.

Select previous log file, if needed.

Select current log file, if needed.

The CNC PILOT saves each key pressed during operation in the

keystroke log file. The oldest entry is at the beginning of the log file,

and the most recent entry is at the end.

Saving service files

If necessary, you can save the "Current status of the CNC PILOT," and

make it available to a service technician for evaluation. A group of

service files is saved that contain information about the current status

of the machine and the machining. See “Service files” auf Seite 598.

The information is summarized in a service files data record as a zip

file.

TNC:\SERVICEx.zip

The "x" designates a consecutive serial number. The CNC PILOT

always generates the service file with the number 1, and all existing

files are renamed to the numbers 2 to 5. An existing file with the

number 5 is deleted.

Saving service files

Open the error window.

Press the Log file soft key.

2.6 The error messages

Press the Service files soft key.

HEIDENHAIN CNC PILOT 640 65

Page 66

2.7 TURNguide context-sensitive

help system

Application

Before you can use the TURNguide, you need to

download the help files from the HEIDENHAIN home

page (siehe „Downloading current help files” auf Seite

71).

The TURNguide context-sensitive help system includes the user

documentation in HTML format. The TURNguide is called with the Info

key, and the control often immediately displays the information

specific to the condition from which the help was called (contextsensitive call). Even if you are editing in a cycle and press the Info key,

you are usually brought to the exact place in the documentation that

describes the corresponding function.

The control always tries to start the TURNguide in the

language that you have selected as the conversational

language on your control. If the files with this language are

not yet available on your control, it automatically opens

the English version.

The following user documentation is available in the TURNguide:

User's Manual (BHBoperating.chm)

smart.Turn and DIN (ISO) programming (smartTurn.chm)

List of All Error Messages (errors.chm)

2.7 TURNguide context-sensitive help system

In addition, the main.chm "book" file is available, with the contents of

all existing .chm files.

As an option, your machine tool builder can embed

machine-specific documentation in the TURNguide.

These documents then appear as a separate book in the

main.chm file.

66 Basics of operation

Page 67

Working with the TURNguide

Calling the TURNguide

There are several ways to start the TURNguide:

Press the Info key if the control is not already showing an error

message

Click the help symbol at the lower right of the screen beforehand,

then click the appropriate soft keys

If one or more error messages are waiting for your

attention, the control shows the help directly associated

with the error messages. To start the TURNguide, you

first have to acknowledge all error messages.