Page 1

®

ELECTRIC CHAINSAW FKS 2200 D2

ELECTRIC CHAINSAW

Translation of original operation manual

ELEKTROMOS LÁNCFŰRÉSZ

Az originál használati utasítás fordítása

ELEKTRICKÁ ŘETĚZOVÁ PILA

Překlad originálního provozního návodu

ELEKTRO-KETTENSÄGE

Originalbetriebsanleitung

ELEKTRYCZNA PIŁA ŁAŃCUCHOWA

Tłumaczenie oryginalnej instrukcji obsługi

ELEKTRIČNA VERIŽNA ŽAGA

Prevod originalnega navodila za uporabo

ELEKTRICKÁ REŤAZOVÁ PÍLA

Preklad originá lneho návodu na obsluhu

IAN 96817

Page 2

Before reading, unfold the page containing the illustrations and familiarise yourself with all functions

of the device.

Przed przeczytaniem proszę rozłożyć stronę z ilustracjami, a następnie proszę zapoznać się z

wszystkimi funkcjami urządzenia.

Olvasás előtt kattintson az ábrát tartalmazó oldalra és végezetül ismerje meg a készülék mindegyik

funkcióját.

Pred branjem odprite stran s slikami in se nato seznanite z vsemi funkcijami naprave.

Před čtením si otevřete stranu s obrázky a potom se seznamte se všemi funkcemi přístroje.

Pred čítaním si odklopte stranu s obrázkami a potom sa oboznámte so všetkými funkciami prístroja.

Klappen Sie vor dem Lesen die Seite mit den Abbildungen aus und machen Sie sich anschließend

mit allen Funktionen des Gerätes vertraut.

GB Translation of original operation manual Page

P L Tłumaczenie oryginalnej instrukcji obsługi Strona

HU Az originál használati utasítás fordítása Oldal

SI Prevod originalnega navodila za uporabo Stran

CZ Překlad originálního provozního návodu Strana

SK Preklad originálneho návodu na obsluhu Strana

DE / AT / CH Originalbetriebsanleitung Seite

4

26

49

71

93

114

136

Page 3

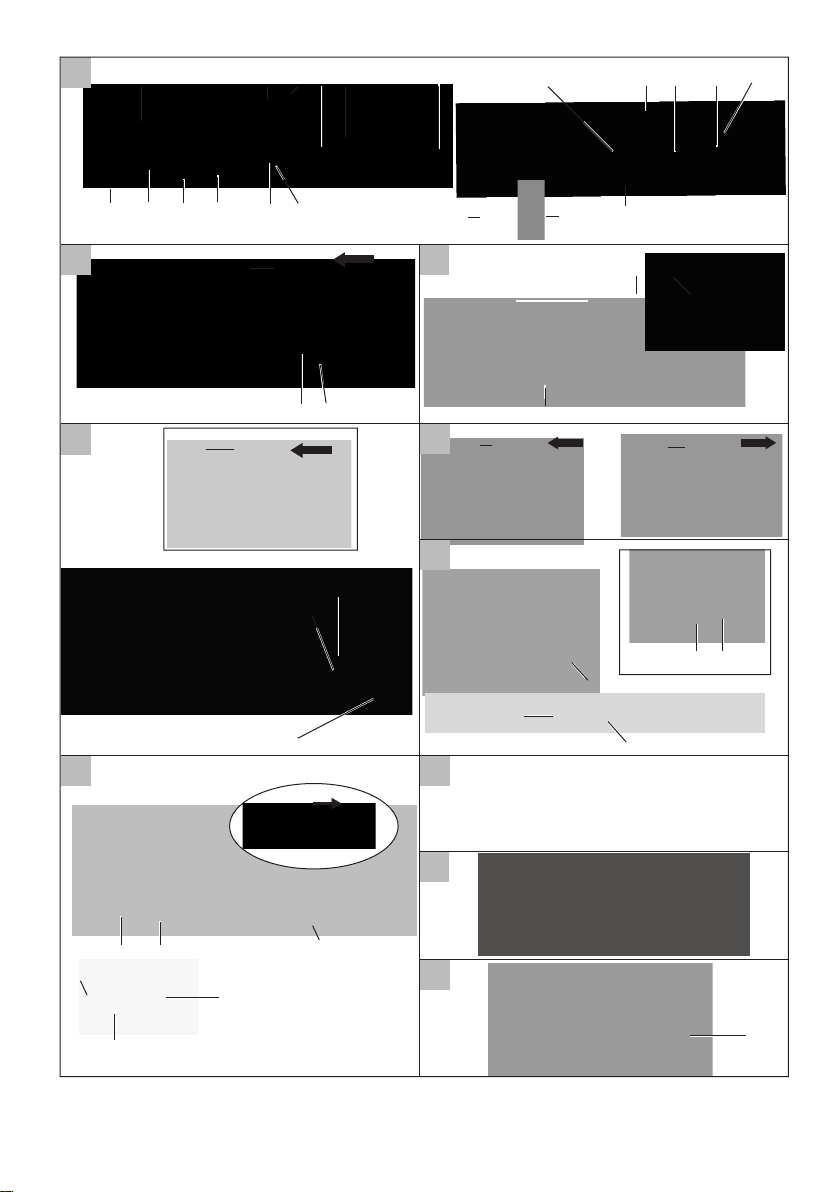

G

C

F

1 2 3 5 6 7

J

H

E

A

B

D

4

10 1198

18

17

16

15

8

1314

8

14

10

17

3

13

3

11

19

22

8

24

20

23

12

21

2

3

8

4

3

151414

26

15

25

24

I

5

27

Page 4

GB

Content

Introduction .................................4

Intended purpose .........................4

General description ......................5

Extent of the delivery ........................5

Overview ........................................5

Function description..........................5

Technical data ..............................6

Safety functions ..............................6

Notes on safety ..............................7

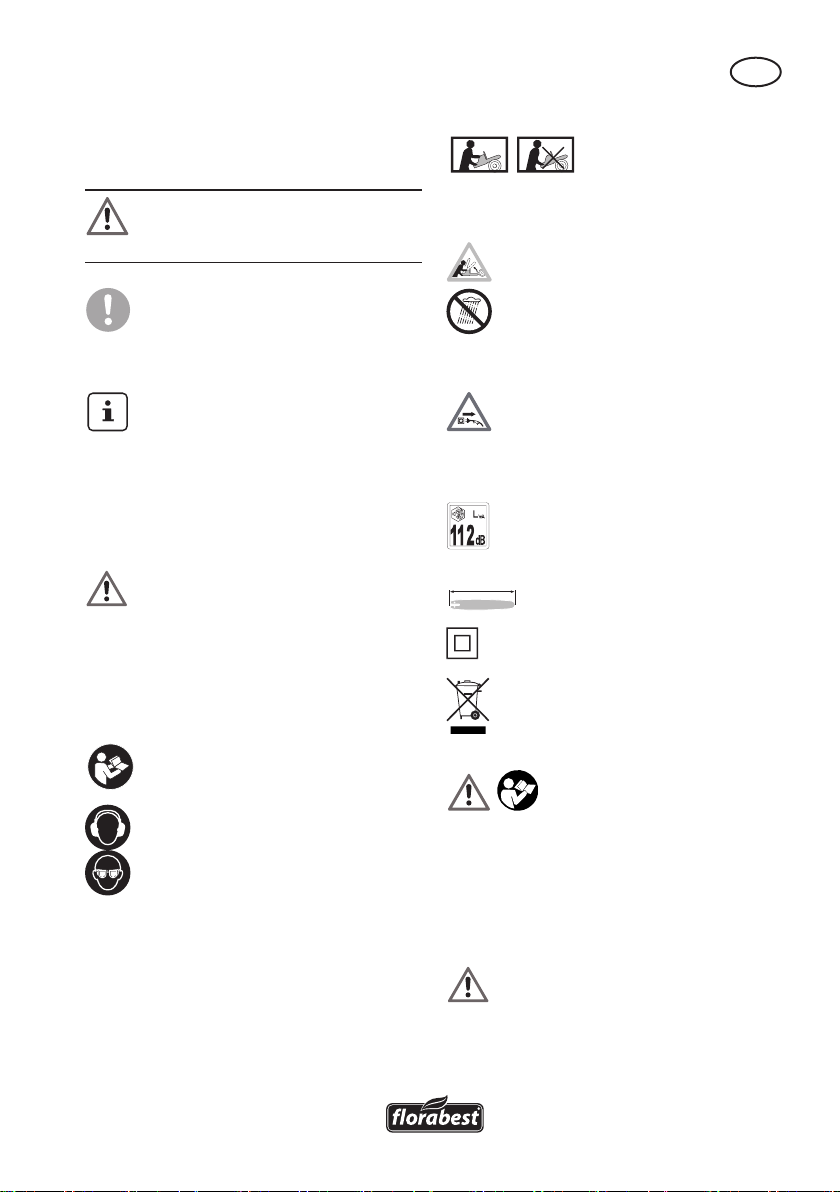

Symbols used on the instructions .......7

Symbols used on the saw ................7

General notes on safety...................8

General safety instructions for

power tools....................................8

Causes and operator prevention of

kickback

Further safety directions .................12

Operation startup ......................12

Tensioning the saw chain ...............13

Chain lubrication ..........................13

Operating the chainsaw .............14

Switching on ................................14

Checking the chain brake .............15

Checking the chain lubrication ........15

Fitting the saw chain .....................15

Changing the saw bar ..................16

......................................11

Sawing techniques .....................16

General.......................................16

Bucking .......................................16

Limbing ......................................17

Felling trees .................................17

Maintenance and cleaning .........19

Cleaning .....................................19

Maintenance Interval Table ............19

Maintenance intervals ...................20

Trouble shooting ...........................20

Oiling the saw chain .....................21

Sharpening the saw chain ..............21

Adjusting the chain tension ............22

Starting up a new saw chain .........22

Maintaining the chain bar .............22

Waste disposal and

environmental protection ...........23

Spare parts ................................23

Guarantee .................................24

Repair Service ............................25

Service-Center ............................25

Importer ....................................25

Translation of the original

EC declaration of conformity ....160

Exploded Drawing ...................169

Introduction

Congratulations on the purchase of your

new device. With it, you have chosen a

high quality product.

The operating instructions constitute part of

this product. They contain important information on safety, use and disposal.

Before using the product, familiarise yourself with all of the operating and safety

instructions. Use the product only as de-

scribed and for the applications specied.

Keep this manual safely and in the event

that the product is passed on, hand over

all documents to the third party.

4

Intended purpose

The electric chainsaw is constructed for

sawing wood only. The saw is not designed for any other types of application

(e.g. cutting of brickwork, plastic or food).

The chainsaw is designed for employment

in the do-it-yourselfer sector. It was not

designed for continuous employment in the

commercial sector.

The device is designed for use by adults.

Young people over 16 years old may use

the chainsaw under supervision only.

Page 5

GB

A

C

F

G

J

The manufacturer is not liable for damages, which were caused through use in

applications for which it was not designed,

or incorrect operation.

This electric chainsaw is to be used only

by one person and only for sawing wood.

The chainsaw must be held with the right

hand on the rear handle and the left hand

on the front handle. Before use, the user

must have read and understood all of the

information and directions in the operating

instructions. The user must wear appropriate personal protective equipment (PPE).

The chainsaw is to be used only for sawing

wood. Materials such as plastic, stone,

metal or wood containing foreign objects

(e.g. nails or screws) must not be cut with

the chain saw!

General description

Extent of the delivery

- Chainsaw

- Chain bar (mounted)

- Saw chain (mounted)

- Saw bar protection sheath

- 180ml Grizzly bio chain oil

- Instruction Manual

The diagrams can be found on

the front old-out pages.

Overview

1 Rear handle

2 Oil ller cap

3 Chain brake handle, front hand

guard

4 Chain bar

5 Saw chain

6 Nose sprocket

7 Bumper

8 Front handle

9 Electric motor

10 On/off switch

11 Safety lock

12 Chain catcher

13 Chain adjustment ring

14 Fastening bolt for sprocket chain

wheel covering

15 Sprocket chain wheel covering

16 Rear hand guard

17 Cable holder

18 Mains cable

19 Saw bar protection sheath

20 Oil bottle

21 upper Oil level control

22 lower Oil level control

23 Bar bolt

24 Tensioning plate

25 Sprocket

26 Tab

27 Oil passages

Function description

The chainsaw is driven by an electric motor. The circulating chain is led around a

saw bar (guide rail)

The tool is tted with a rapid-action chain-

tensioning system and a fast-acting chain

brake. An automatic oil dosing regulator

ensures continuous chain lubrication.

The chainsaw is equipped with various

protection ttings for the protection of the

user.

Refer to the following descriptions for the

function of control elements.

5

Page 6

GB

A

Technical Data

Electrical chainsaw ..... FKS 2200 D2

Rated input voltage ..........230 V~, 50 Hz

Input power ...............................2200 W

Safety class ...................................

Chain speed .............................13.6 m/s

Weight

(without guide rail and chain) .........4.7 kg

Weight (with guide rail and chain) ..5.9 kg

Oiltank .......................................270 ml

Chain ..........................Oregon 91P057X

Chrome cutting teeth, low-kickback

Chain bar Oregon 160SDEA041 (112364)

Chain link separation ...................10 mm

Chain width ...............................1.3 mm

Teeth of the sprocket chain wheel ........... 7

Length of the chain bar ...............460 mm

Sawing length ...........................395 mm

Acoustic pressure level

(L

pA) ...........96.0 dB (A); KpA=3.0 dB (A)

Sound power level (L

measured ..... 108 dB (A); K

WA)

WA=3.0 dB (A)

guaranteed ............................. 112 dB (A)

Vibration (a

n) ....... 6.97 m/s

2

; K=1.5 m/s

Noise and vibration values were determined according to the standards and

stipulations mentioned in the declaration of

conformity.

Technical and optical changes can be

carried out in the course of further development without notice. All dimensions, references and information of this instruction

manual are therefore without guarantee.

Legal claims, which are made on the basis

of the instruction manual, cannot thus be

considered as valid.

/ II

The stated vibration emission value may

also be used for a preliminary exposure

assessment.

Warning: The vibration

emission value may differ during

actual use of the power tool from

the stated value depending on the

manner in which the power tool is

used.

Safety precautions aimed at protect-

ing the user should be based on estimated exposure under actual usage

conditions (all parts of the operating

cycle are to be considered, including, for example, times during which

the power tool is turned off and

times when the tool is turned on but

is running idle).

Safety functions

1 Rear grip with hand guard

2

Protects the hand against branch-

3 Chain braking lever/hand

(16)

es and boughs in the case of

springing away by the chain.

guard

Control system, which stops the

saw chain immediately in case

of a spring-back; lever can also

be activated manually; protects

the left hand of the operator if it

slides from the front grip.

The motor cannot be turned on if

the chain brake has engaged.

The stated vibration emission value was

measured in accordance with a standard

testing procedure and may be used to compare one power tool to another.

6

5 Saw chain with small

spring-back

Helps you to catch spring-backs

with specially developed control

systems.

Page 7

GB

7 Metal stop claw

Reinforces the stability when

vertical cuts are carried out and

facilitates sawing.

9 Electric motor

Double insulated for safety rea-

sons.

10 On-off switch with safety

chain brake

On releasing the On/Off switch,

the device immediately switches

off.

11 Switch-on block

The switch-on block must be

released for switching on the device.

12 Chain catcher

Decreases the danger of injuries

if the chain breaks or if it comes

off.

Notes on safety

This section deals with the basic safety

regulations while working with the electric

chainsaw.

An electric chainsaw is a danger-

ous device, which can cause serious or even fatal injuries with incorrect or careless use. Thus, for your

own safety and the safety of others,

you should always take note of the

instructions on safety and, in case

of difculties, consult a specialist for

advice.

Precaution symbol (explanation of

precaution instead of exclamation

mark) with information on prevention of harm / damage.

Notice symbol with information on

how to handle the device properly.

Symbols used on the saw

Make yourself familiar with all

control elements before any work.

Practice handling the saw and have

explained the functions, operating

methods and sawing techniques by

a practiced user or specialist.

Read and take note of the operat-

ing manual belonging to the machine!

Wear personal protective equip-

ment. Basically, wear protective

goggles or, even better, face protection, ear protection, safety helmet,

cut-protection working clothes, cutprotection gloves, and cut-protection safety boots with anti-slip soles.

Only use the saw with

both hands on the

device

Caution! Spring-back - Be careful of

spring-back of the machine during

work.

Symbols used in the instructions

Hazard symbols with in-

formation on prevention of

personal injury and property

damage.

Do not expose the unit to rain. The

device must not be wet, nor should

it be operated in a moist environment.

7

Page 8

GB

Caution! Remove the plug immedi-

ately from the plug socket in case

of damage or cutting through of the

mains cable

Information of the acoustic power

level L

460 mm

in dB.

WA

Length of the chain bar

Safety class II

Machines do not belong with do-

mestic waste.

The motor cannot be turned

on if the chain brake has

engaged. Release the chain

brake by shifting the brake

arm over against the front

grip.

General notes on safety

Before you do any work with the

electric chainsaw, make yourself familiar with all operating parts. Practise using the saw (sawing logs on a

sawhorse) and get an experienced

user or a specialist to explain to you

the function of the saw, the way of

working, the techniques of sawing

and the personal protection equipment.

Observe noise control and local

regulations.

Caution! When using power tools,

observe the following basic safety

measures for the prevention of electric shocks and the risk of injury and

re. There is a risk of injury!

8

General safety instructions

for power tools

WARNING! Read all safety

directions and instructions.

Omissions in the compliance with

safety directions and instructions

can cause electrical shock, re

and/or severe injuries.

Retain all safety directions and instructions for future use.

The term “Power Tools” used in the safety

instructions refers to mains-operated power

tools (with power cord) and to battery-operated power tools (without power cord).

Work area safety

• Keep work area clean and well

lit. Cluttered or dark areas invite acci-

dents.

• Do not operate power tools in

explosive atmospheres, such as

in the presence of ammable

Iiquids, gases or dust. Power tools

create sparks which may ignite the dust

or fumes.

• Keep children and bystanders

away while operating a power

tool. Distractions can cause you to lose

control.

Electrical safety

• Power tool plugs must match

the outlet. Never modify the

plug in any way. Do not use

any adapter plugs with earthed

(grounded) power tools. Unmodi-

ed plugs and matching outlets will

reduce risk of electric shock

Page 9

GB

• Avoid body contact with

earthed or grounded surfaces,

such as pipes, radiators, ranges

and refrigerators. There is an in-

creased risk of electric shock if your

body is earthed or grounded.

• Do not expose power tools to

rain or wet conditions. Water

entering a power tool will increase the

risk of electric shock.

• If the supply cord of this power tool

is damaged, it must be replaced by

a specially prepared cord available

through the service organization.

• If it is necessary to replace the connection cable, we recommend that this be

performed by the manufacturer or an

authorised representative (e.g. authorised

workshop, customer service, etc.).

• Do not abuse the cord. Never use

the cord for carrying, pulling or

unplugging the power tool. Keep

cord away from heat, oil, sharp

edges or moving parts. Damaged

or entangled cords increase the risk of

electric shock.

• When operating a power tool

outdoors, use an extension cord

suitable for outdoor use. Use of a

cord suitable for outdoor use reduces

the risk of electric shock.

• If operating a power tool in a

damp location is unavoidable,

use a residual current device

(RCD) protected supply. Use of an

RCD reduces the risk of electric shock.

Personal safety

• Stay alert, watch what you are

doing and use common sense

when operating a power tool.

Do not use a power tool while

you are tired or under the inuence of drugs, alcohol or medication. A moment of inattention white

operating power tools may result in

serious personal injury.

• Wear personal protective equip-

ment and always wear safety

glasses. Wearing personal protective

equipment such as nonslip safety boots,

cut protection trousers, a hard hat or ear

protection reduces the risk of injuries.

• Prevent unintentional starting.

Ensure the switch is in the offposition before connecting to

power source and/or battery

pack, picking up or carrying

the tool. Carrying power tools with

your nger on the switch or energising

power tools that have the switch on

invites accidents.

• Remove any adjusting key or

wrench before turning the power tool on. A wrench or a key left at-

tached to a rotating part of the power

tool may result in personal injury.

• Do not overreach. Keep proper

footing and balance at all times.

This enables better control of the power tool in unexpected situations.

• Keep your hair, clothing and

gloves away from moving parts.

Jewellery or long hair can be caught in

moving parts.

• Warning! During operation, this elec-

tric tool generates an electromagnetic

eld which, under certain circumstances,

may impair the functionality of active

or passive medical implants. To reduce

the risk of serious or lethal injuries, we

recommend that persons with medical

implants consult their doctor and the

manufacturer of their medical implant

before operating the machine.

9

Page 10

GB

Power tool use and care

• Do not force the power tool. Use

the correct power tool for your

application. The correct power tool

will do the job better and safer at the

rate for which it was designed.

• Do not use the power tool if the

switch does not turn it on and

off. Any power tool that cannot be

controlled with the switch is dangerous

and must be repaired.

• Disconnect the plug from the

power source and/or the battery pack from the power tool

before making any adjustments, changing accessories, or

storing power tools. Such preven-

tive safety measures reduce the risk of

starting the power tool accidentaIly.

• Store idle power tools out of the

reach of children and do not allow persons unfamiliar with the

power tool or these instructions

to operate the power tool. Power

tools are dangerous in the hands of

untrained users.

• Maintain power tools. Check

for misalignment or binding

of moving parts, breakage of

parts and any other condition

that may affect the power tool’s

operation. If damaged, have

the power tool repaired before

use. Many accidents are caused by

poorly maintained power tools.

• Keep cutting tools sharp and

clean. Properly maintained cutting

tools with sharp cutting edges are less

Iikely to bind and are easier to control.

• Use the power tool, accessories

and tool bits etc. in accordance

with these instructions, taking

into account the working conditions and the work to be performed. Use of the power tool for op-

erations different from those intended

could result in a hazardous situation.

• For sawing work on a slope, always

stand above the tree trunk. To keep control at the moment of “sawing through”,

reduce the contact pressure at the end

of the cut without loosening the rm grip

on the chainsaw handles. Ensure that the

saw chain does not come into contact

with the ground. After completing the

cut, wait for the chainsaw to come to a

standstill before removing the chainsaw.

Always switch off the chainsaw motor

before moving from one tree to another.

• Dirt, stones, loose bark, nails, staples

and wire must be removed from the tree.

Service

• Have your power tool serviced

by a qualied repair person using only identical replacement

parts. This will ensure that the safety

of the power tool is maintained.

Chain saw safety warnings:

• Keep all parts of the body

away from the saw chain when

the chain saw is operating. Before you start the chain saw,

make sure the saw chain is not

contacting anything. A moment of

inattention white operating chain saws

may cause entanglement of your clothing or body with the saw chain.

• Always hold the chain saw with

your right hand on the rear

handle and your left hand on

the front handle. Holding the chain

saw with a reversed hand congura-

10

Page 11

GB

tion increases the risk of personal injury and should never be done.

• Wear safety glasses and ear

protection. Other protective

equipment for the head, hands,

legs and feet is compulsory. Ad-

equate protective clothing will reduce

personal injury by ying debris or accidentaI contact with the saw chain.

• Do not operate a chain saw in a

tree. Operation of a chain saw white

up in a tree may result in personal in

jury.

• Always keep proper footing

and operate the chain saw only

when standing on xed, secure

and level surface. Slippery or unstable surfaces such as ladders may

cause a loss of balance or control of

the chain saw.

• When cutting a branch that

is under tension be alert for

spring back. When the tension in

the wood bres is released the spring

loaded Iimb may strike the operator

and/or throw the chain saw out of

control.

• Use extreme caution when cut-

ting brush and saplings. The slen-

der material may catch the saw chain

and be whipped toward you or pull

you off balance.

• Carry the chain saw by the

front handle with the chain saw

switched off and away from

your body. When transporting

or storing the chain saw always

t the guide bar cover. Proper

handling of the chain saw will reduce

the Iikelihood of accidentaI contact

with the moving saw chain.

• Follow instructions for lubri-

cating, chain tensioning and

changing accessories.

Improperly tensioned or lubricated

chain may either break or increase the

chance for kickback.

• Keep handles dry, clean, and

free from oil and grease. Greasy,

oily handles are slippery causing loss

of control.

• Cut wood only. Do not use chain

saw for purposes not intended.

For example: do not use chain

saw for cutting plastic, masonry

or non-wood building materials.

Use of the chain saw for operations

different than intended could result in a

hazardous situation

• Hold the power tool only on the

insulated handle surfaces, as the

saw chain may come into contact

with concealed power cables.

Contact between the saw chain and a

live cable may render metallic components live and result in an electric shock

Causes and operator prevention of kickback

Beware of kickback! Be careful of

kickback of the machine during

work. There is danger of injury here.

You can avoid kickbacks by exercising caution and using a correct sawing technique.

Fig. 1

11

Page 12

GB

• Kickback may occur when the nose or

tip of the guide bar touches an object, or

when the wood closes in and pinches the

saw chain in the cut

(cf. image 1/g. B).

• Tip contact in some cases may cause

a sudden reverse reaction, kicking the

guide bar up and back towards the op-

erator (cf. image 1/g. A).

• Pinching the saw chain along the top of

the guide bar may push the guide bar

rapidly back towards the operator.

• Either of these reactions may cause

you to lose control of the saw which

could result in serious personal injury.

Do not rely exclusively upon the safety

devices built into your saw. As a chain

saw user, you should take several steps

to keep your cutting jobs free from accident or injury.

Kickback is the result of tool misuse and/

or incorrect operating procedures or conditions and can be avoided by taking proper

precautions as given below:

• Maintain a rm grip, with thumbs

and ngers encircling the chain

saw handles, with both hands on

the saw and position your body

and arm to allow you to resist

kickback forces. Kickback forces can

be controlled by the operator, if proper

precautions are taken. Do not let go of

the chain saw.

• Do not overreach and do not cut

above shoulder height. This helps

prevent unintended tip contact and enables better control of the chain saw in

unexpected situations.

• Only use replacement bars and

chains specied by the manufacturer. Incorrect replacement bars and

chains may cause chain breakage and/

or kickback.

• Follow the manufacturer´s sharp-

ening and maintenance instructions for the saw chain. Decreasing

the depth gauge height can lead to

increased kickback.

Further safety directions

• If the supply cord of this power tool is

damaged, it must be replaced by a specially prepared cord available through

the service organization.

• If it is necessary to replace the connection cable, we recommend that this be

performed by the manufacturer or an

authorised representative (e.g. authorised

workshop, customer service, etc.).

• Lay the extension cable in such a way

that it will not be caught by branches

or similar during sawing.

• Use a surge protector with a release current of 30 mA or less.

• Comply carefully with maintenance,

control and service instructions in

this manual. Damaged protective devices and parts have to be repared or

changed except as noted otherwise in

this manual.

Operation startup

Always wear protective

gloves when working with

the chainsaw and employ

only original parts. Pull out

the power plug before doing

any work on the chainsaw

itself -– injury hazard!

The tool is completely assembled on delivery.Before you start up the electric chain-

saw, adjust the chain, ll up with chain oil

12

Page 13

GB

B

and check the automatic lubrication and

chain brake function.

Note that the saw can re-oil.

Please note that the saw re-oils after use

and oil may leak out if it is stored on its

side or on the head. This is a normal

process due to the necessary ventilation

opening on the upper edge of the tank and

does not constitute a reason for complaint.

As each saw is checked during production

and tested with oil, a small residue may

be in the tank despite draining, which may

slightly dirty the housing with oil in transit.

Please clean the housing with a cloth.

Tensioning the saw chain

Regularly tightening the saw chain provides safety for the user and reduces and/

or prevents wear and chain damages.

Before the start of work and in approx. 10

minute intervals, we recommend the user to

examine the chain tension and correct it, if

necessary.

The chain warms up when working with

the saw and thus expands slightly. These

“expansions” can be expected especially

from newer chains.

rotated completely around with the gloved

hand.

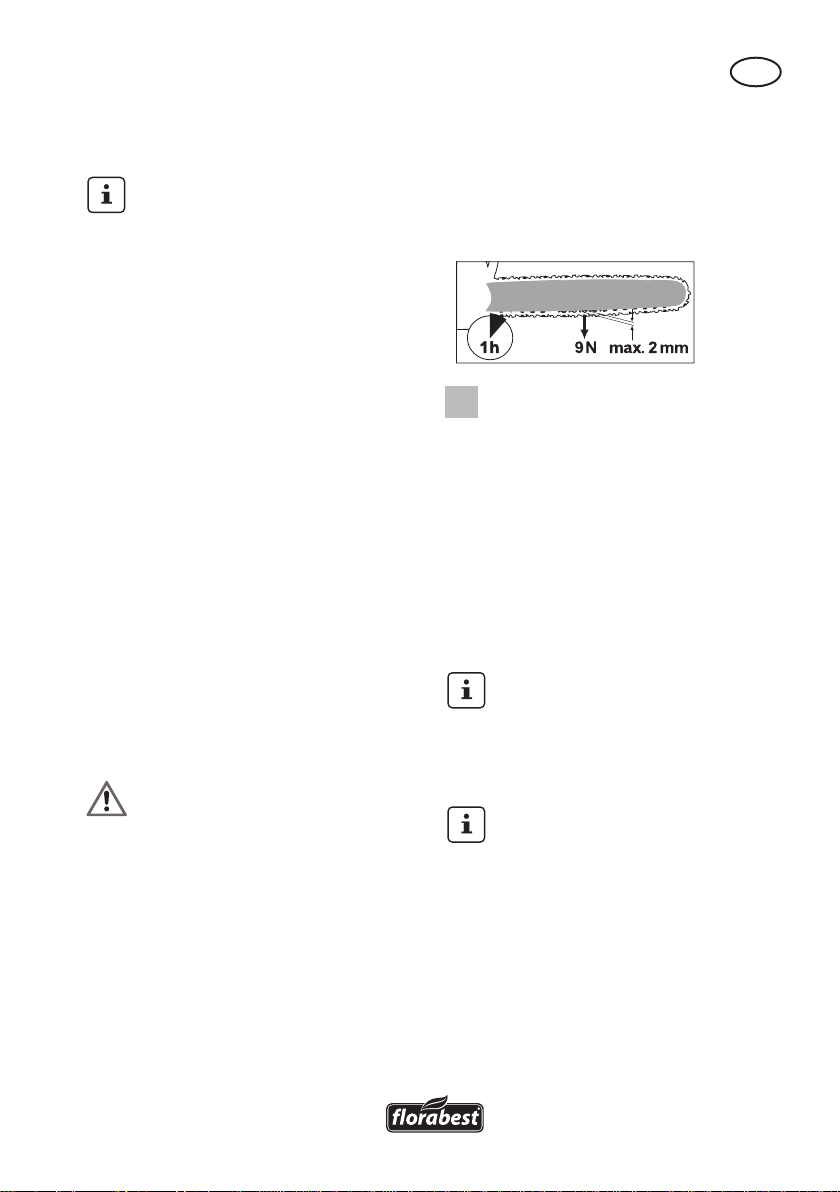

When the saw chain is tensioned with 9 N

(approx. 1 kg), the gap between the saw

chain and the guide rail may not be more

than 2 mm.

1. Ensure that the chain brake has

been released, that is, that the

chain brake lever (3) is pulled up

against the front grip (8).

2. Unscrew the fastening bolt (14).

3. To tighten the saw, turn the chain

adjustment ring (13) clockwise.

To loosen the tension, turn the

chain adjustment ring anti-clockwise.

4. Tighten up the fastening bolt (14)

again.

With a new saw chain, you must

readjust the chain tension after at

least 5 cutting operations.

Chain lubrication

Do not re-tighten or change the chain

when it is hot because it shrinks slightly

once it has cooled down. In case of nonobservance, this can lead to damages on

the guide rail or the engine because now

the chain is too taut on the blade.

Chain tension and chain lubrication have

a signicant impact on the service life of

the chain.

The chain is correctly tensioned if it does

not sag at the rail underside and can be

The rail and chain must never be

without oil. If you operate the electric chainsaw with too little oil, the

cutting performance and the lifetime

of the saw chain is reduced, since

the chain becomes blunt faster. You

can identify a case of too little oil

where smoke development or discoloration of the rail occurs.

As soon as the motor is speeded up, the oil

also ows faster to the chain bar (4).

13

Page 14

GB

C

C

D

Filling up with chain oil:

• Check the oil ll level (

regularly top up with oil. The oil tank

holds 270 ml oil.

• Use Parkside bio-oil; this product con-

tains additives that reduce wear and

tear and does not damage the pump

system. bio-oil is available from our

Service-Center.

• If you have no Grizzly bio-oil available,

use chain lubrication oil with low adhesive additive content.

• Empty the oil tank before longer periods

(several month) of non-use

1. Unscrew the oil ll cap (2) and ll

up with chain oil.

2. Wipe off any spilled oil and

close the cap again.

Always switch off the device

and allow the motor to cool

before lling with chain oil.

There is a risk of re if oil

overows.

21/22) and

Operating the chainsaw

Switch on the chainsaw only when

chain bar, saw chain and sprocket

chain wheel covering are correctly

assembled. Ensure the voltage of the

mains connection agrees with the

label on the device. Make sure you

have a secure stance

Note: The saw is a high-powered

device, where a 13 A fuse gener-

ally sufces, provided that further

current consumers with high service

are not connected. However, if

the premises installations are not

implemented optimally and “quick-

acting” protection fuses are built-in

(e.g. B 16), the protection fuse

will be activated due to the current

peaks during switch-on. You should

install time-delay fuses with the designation “L”, which can be bought

in every hardware store. Fuses with

the designation “G” are provided

with even longer time delay, however they are not usually employed

in households.

Caution! Saw can oil up, see notes

on Operation startup.

Switching on

1. Check before the start, whether

sufcient chain oil is in the tank

and, if necessary, rell with chain

oil (see Chapter Operation Start).

2. Form a loop from the end of the

extension cable and hang this

into the tension relief (17) on the

rear grip (1).

3. Connect the device to the mains

voltage.

4. Release the chain brake, where

you shift the brake arm (3) back

against the front grip (8).

5. Hold the electric chainsaw rmly

with both hands, with the right

hand on the rear grip (1) and

the left hand on the front handle

(8). Thumb and nger must close

securely over the handles.

6. For switching on, activate the

switch-on block (11) with the right

thumb and then press the On/Off

switch (10), the electric power

saw runs with highest speed.

Release the switch-on block

again.

14

Page 15

GB

E

A

J

G

7. The power saw switches off when

you release the On/Off switch

(10) again. Switching for continuous running is not possible.

Checking the chain brake

The motor cannot be turned on if

the chain brake has engaged. Do

not employ the chain brake in order

to start the chainsaw or to switch it

off.

1. Place the electric chainsaw onto

a solid, at surface. It must not

contact any objects.

2. Connect the device to the mains

voltage.

3. Release the chain brake by

shifting the brake arm (3) over

against the front grip (8).

4. Hold the electric chainsaw rmly

with both hands, with the right

hand on the rear handle (

and the left hand on the front

handle (8). Thumb and nger

must close securely over the handles.

5. Turn on the electric chainsaw.

6. Activate the chain braking lever

(3), with running motor, with

the left hand. To do so, push the

chain braking lever/front hand

protection (3) away from the front

handle (8). Chain should stop

abruptly.

7. Once the chain brake is working properly, release the on/off

switch (10) and the chain brake.

If the chain brake does not

function correctly, you must

not use the electric chainsaw.

A slack saw chain leads to

1)

danger of injury.

Return the electric chainsaw

to our Service-Center for repair.

Checking the chain

lubrication

Check the oil level and the chain lubrication system before commencement of work.

• Switch on the chainsaw and hold it

above a bright background. The saw

must not touch the ground.

If an oil trace can be seen, the chainsaw is

working trouble-free.

If no oil trace can be seen clean the

oil passages or turn the chainsaw

to our Service-Center for repair.

4. Clean the oil passages of the

chain bar (27), in order to guarantee a trouble-free, automatic

oiling of the saw chain during

operation.

Fitting the saw chain

1. Switch the saw off and unplug it

from the mains.

2. Spread the chain (5) out into a

loop with the cutting edges running clockwise .

3. Slide the saw chain (5) into the

bar guide groove. To mount the

guide bar (4), raise it to an angle

of approx. 45 degrees. This will

make it easier to replace the saw

chain (5) onto the sprocket (25).

It is normal that the saw chain (5)

is slack. Sagging in the chain is

normal.

15

Page 16

GB

F

A

A

K

4. Pre-tighten the chain (5) by turning the tensioning plate (24)

clockwise.

5. Position the sprocket chain wheel

covering (15). First place the tab

(26) on the cover into the corresponding notch on the plate (15).

Only lightly tighten the fastening

bolt (14), as you will still have to

tension the saw.

Refer to the start-up section on how

to tension the saw chain.

Prior to changing the chain, the nut of the

guide rail must be cleaned of dirt because

dirt deposits available can cause the chain

to break out of the rail. The deposits can

also absorb the chain oil. So the consequence would be that the chain oil would

not or only a small part of it would reach

the underside of the rail and the lubrication

would be reduced.

Changing the saw bar

1. Switch the saw off and unplug it

from the mains.

2. Lay the saw on a at surface.

3. Turn the fastening bolt (14) anticlockwise and loose the chain

adjustment ring (

the sprocket chain wheel covering (15).

4. Remove the saw bar (4) and saw

chain (

bar (4), raise it to an angle of approx. 45 degrees. This will make

it easier to take the saw chain (5)

off the sprocket

5. To t the new bar, place the bar

(4) onto the bar bolt (22) with

the tensioning plate pointing outwards (24).

5). To remove the guide

13) to remove

(G25).

Sawing techniques

General

• You have better control when you saw

with the bottom side of the chain bar

(with pulling saw chain) and not to with

the top side of the chain bar (with pushing saw chain).

• The saw chain must not contact either

the ground or another object during

sawing through or after sawing completion.

• Make sure that the saw chain does not

become jammed in the wood. Do not

let the tree trunk break or split off.

• Consider also the precautions against

spring-back (see notes on safety).

If the saw chain jams, you

do not attempt to pull out the

electric chainsaw using power. There is a danger of injury

here. Switch off the motor

and use a lever or wedge to

free the electric chainsaw.

Bucking

This refers to sawing up a felled tree trunk

into smaller sections.

• Ensure that the saw chain does not

come in contact with the ground during

sawing.

• Make sure you have a secure stance

and, in the case of sloping ground,

stand above the log.

1. Log is lying on the ground:

Saw through the log completely

from above and ensure at the

end of the cut not to contact the

ground.

16

Page 17

GB

L

M

N

O

If you can turn the tree trunk, saw

two-thirds of the way through it.

Then turn the trunk around and

saw the rest of the way through

from above.

2. Log is supported at one

end:

Start sawing from the bottom and

work your way up (with the upper edge of the bar) a third of the

way into the diameter of the trunk

to prevent splitting. Then saw from

the top downwards with the lower

edge of the bar towards the rst

cut to prevent the bar from becoming jammed in the wood.

3. Log is supported at both

ends:

Start from the top and work down

(with the lower edge of the bar)

to a third of the diameter of the

trunk. Then saw from underneath

with the upper edge of the bar

until the two cuts meet.

4. Sawing on a sawhorse:

Hold the electric chainsaw steady

with both hands, keeping the

saw in front of you while sawing. Once the saw is through the

wood, guide the machine passed

you on the right (1). Hold your left

arm as straight as you can (2).

Watch out for the falling trunk.

Position yourself to prevent any

danger from the separated trunk.

Watch your feet. The trunk may

cause injuries when falling. Keep

your balance (3).

Limbing

Limbing is the designation for the sawing off

of branches and boughs from a felled tree.

Many accidents occur dur-

ing the removal of branches.

Never cut tree limbs when

you are standing on the log.

Keep the spring-back area in

mind if branches are under

tension.

• Do not remove support branches until

after the sawing off.

• Branches under tension must be sawed

from below to above, in order to prevent jamming of the chainsaw.

When working on thicker branches, use

the same technique as when you are

sawing up a felled trunk.

• Work to the left of the log and as near

as possible to the electric chainsaw. As

far as possible, the weight of the saw

should rest on the log.

• Change position to saw off branches

on the other side of the trunk.

• Branches sticking out are cut off sepa-

rately.

Felling trees

A lot of experience is nec-

essary in felling trees. Cut

down trees only when you

can safely handle the electric

chainsaw. In no case should

you use the electric chainsaw

if you feel unsure about anything.

• Ensure that no people or animals are

in the eld of action. The safety distance between the tree to be felled and

the nearest-located workplace must be

2 ½ tree lengths.

• Note the felling direction:

The user must be able to move safely

near the felled tree, to saw off the tree

17

Page 18

GB

Q

P

Q

Q

R

S

easily and remove branches.It is to be

avoided that the felled tree snags itself

on another tree. Note the natural felling direction, which is dependent on

the slope and curvature characteristic

of the tree, wind direction and the

number of branches.

• In the case of sloping ground, stand

above the tree to be felled.

• Small trees, with a diameter of 15-18

cm, can usually be sawn off with one

cut.

• In case of trees with a larger diameter,

a notched cut and a back cut must be

implemented (see diagram

Do not fell any trees when

a strong or changing wind

is blowing, if the danger of

property damage exists or if

the tree could fall on electric

wires.

Immediately after termination of

the sawing procedure, remove the

ear protection so that you can hear

hooter and alarm signals.

1. Removal of branches:

Remove hanging branches by

positioning the cut from above the

branch. With removal of branches,

never work higher than shoulder

level.

2. Escape area:

Remove the undergrowth around

the tree to ensure an easy escape. The escape area (1) should

be around 45° either side behind

the planned felling direction (2).

).

3. Cutting notch (A):

Make a felling notch in the direc-

tion in which you wish the tree to

fall. Start with the bottom, hori-

zontal cut. The cut depth should

be around 1/3 of the trunk diameter. Now make a slanted saw

cut from above at an angle of

roughly 45° to meet exactly with

the bottom saw cut.

Never step in front of a tree

which is notched.

4. Felling back cut (B):

Make the back cut from the other

side of the log, where you stand

to the left of the log and saw with

the chainsaw pulling. The back

cut must run horizontally 5 cm

above the horizontal notched cut.

The back cut should be so deep

that the separation distance between the back cut and the notch

cutting line is at least 1/10 of the

trunk diameter. The part of the

log not sawed through is designated as a break dimension.

Insert a felling wedge or a crow-

bar into the back cut, as soon as

the depth of cut permits this, in

order to prevent a jamming of the

chain bar.

5. If the trunk diameter is larger than

the length of the chain bar, make

two cuts.

For safety reasons, we ad-

vise inexperienced users not

to fell any logs with a rail

length which is smaller than

the trunk diameter.

18

Page 19

GB

6. After carrying out of the back cut,

the tree falls by itself or with the

aid of the felling wedge or crowbar.

As soon as the tree begins to

fall, pull out the saw from the

section, stop the motor, place

the electric chainsaw down

and leave the workplace using the withdrawal path.

Maintenance and

cleaning

Basically, carry out mainte-

nance and cleaning works

with switched-off motor and

power plug removed. Danger

of injury!

Leave any maintenance and

servicing work not covered

by this manual to our Service-Center. Use only original

spare parts.

Allow the machine to cool

down before all maintenance

and cleaning works. Danger

of burn injuries!

Cleaning

• Clean the machine thoroughly after

every use. In this way, you extend the

life of the machine and avoid accidents.

• Keep the gripping handles free of pet-

rol, oil or grease. Clean the gripping

handles, where appropriate, with a

moist cloth soaked in soap. Use no solvents or petrol for cleaning!

• Clean the saw chain after every use.

Use a paint brush or wipe for that. Do

not use any liquids to clean the chain.

After cleaning, oil the chain lightly with

chain oil.

• When cleaning, also remove the chain

wheel cover (15) so that this area can

be cleaned as well.

• Clean the ventilation slots and the

surfaces of the machine with a paint

brush, whisk or dry cloth. Do not use

any liquids for cleaning.

Maintenance Interval Table

Machine part Action

Components of the chain

brake

Sprocket chain wheel Check, replace if required

Saw chain (5)

Guide bar (4)

Check, replace if required

Check oil, regrind or replace if required

Check, turn round, clean

and oil

Before

every

use

After 10 hours

of operation

19

Page 20

GB

Maintenance intervals

Regularly carry out the maintenance operations listed in the following table. The life

of the saw is extended by regular maintenance of your chainsaw. Furthermore,

you get optimum cutting performance and

avoid accidents.

Trouble shooting

Problem Possible cause Fault correction

Device does not start

Chain does not

rotate

Inferior cutting

performance

Saw runs with

difculty, chain

comes off

Mains voltage defective

House protection fuse

activated

Defective On/Off switch (10) Repair by customer service

Worn carbon brushes Repair by customer service

Defective motor Repair by customer service

Chain brake blocks saw

chain (5)

Incorrectly mounted saw

chain (5)

Saw chain (5) blunt

Chain tension insufcient Check chain tension

Chain tension insufcient Check chain tension

Check plug socket, cable, line

and plug, where appropriate,

repair by electrical specialist.

Check house protection fuse,

see note

Check chain brake.

Possibly release chain brake

Mount saw chain correctly

Sharpen cutting teeth or place

on new chain

Chain becomes hot,

smoke development

during sawing,

discoloration of the

rail

20

Too little chain oil

Check oil level and, where

appropriate, rell with chain oil,

check oil automatic system and,

where appropriate, clean oil

outow duct or have repaired by

customer service

Page 21

GB

H

I

Oiling the saw chain

Clean and oil the chain regularly.

In this way, you keep the chain

sharp and get optimum machine

performance. In case of damage

due to inadequate maintenance of

the saw chain, the guarantee claim

is invalid.

Remove the power plug and use

cut-protection gloves when you are

handling the chain or the chain bar.

• Oil the chain after cleaning, after 10

hours of use or at least once weekly,

depending on which comes rst.

• Before oiling, the chain bar must be

cleaned thoroughly, in particular the

teeth of the rail. Use a whisk and a dry

cloth for that.

• Oil the individual chain links with the

aid of an oil suction gun with pinpoint

tip (available in the specialist trade).

Place individual oil drops onto the articulated links and onto the tooth tips of

the individual chain links.

Sharpening the saw chain

An incorrectly sharpened

saw chain increases the danger of spring-back!

Use cut-protection gloves

when you are handling the

chain or the chain bar.

A sharp chain guarantees an op-

timal cutting performance. It eats

effortlessly through the wood and

leaves large, long wooden chips.

A saw chain is blunt if you have to

press the cutting equipment through

the wood and the wooden chips

are very small. In the case of a very

blunt saw chain, no chip cuttings

result at all, only sawdust.

• The sawing parts of the chain are the

cutting elements, which consist of a cutting tooth and a depth limiting projection. The vertical separation distance

between these two determines the

sharpness depth.

• The following values must be noted in

sharpening the cutting teeth:

- Sharp edge angle (30°)

- Breast angle (85°)

- Sharpness depth (0.65 mm)

- Round le diameter (4.0 mm)

Deviations from the meas-

urement data of the cutting

geometry can lead to an

increase of the spring-back

slope of the machine. Increased danger of accident!

Special tools are necessary for sharpening

the chain, which guarantee that the cutting

edges are sharpened at the correct angle

and to the correct depth. For the inexperienced user of chainsaws, we recommend

to have the saw chain sharpened by a

specialist or a specialist workshop. If you

think yourself capable of sharpening the

chain, you can acquire the special tools in

the specialist trade.

1. Switch the saw off and unplug it

from the mains.

2. Remove the saw chain (refer

to the section on operating the

saw). The chain should be welltensioned to ensure proper sharpening.

3. For the sharpening, a round le

with 4.0mm diameter is neces-

sary.

21

Page 22

GB

J

F

Other diameters damage the

chain and can lead to danger

during work!

4. Sharpen only from the inside to

the outside. Guide the le from

the inner side of the cutting teeth

to the outer side. Lift the le when

you are withdrawing it.

5. Sharpen rst the teeth on one

side. Turn the saw around and

sharpen the teeth of the other

side.

6. The chain is worn and must be

replaced by a new saw chain if

only approx. 4 mm of the cutting

teeth is remaining.

7. After the sharpening, all cutting

elements must now be equal in

length and width.

8. After every third sharpening, the

sharpness depth (depth limitation)

must be checked and the height

led with the aid of a at le. The

depth limitation should be set back

about 0.65 mm from the cutting

tooth. After the setting back of

depth limitation, round it off a little at the front.

Adjusting the chain tension

The adjustment of the chain tension is described in the chapter: Starting operation,

tensioning chainsaw.

• Switch off the saw and pull out the

power plug.

• Check the chain tension regularly and

re-adjust this as often as possible.When

the saw chain is tensioned with 9 N

(approx. 1 kg), the gap between the

saw chain and the guide rail may not

be more than 2 mm.

Starting up a new saw chain

In the case of a new chain, the tensioning

force decreases after some time. Therefore

you must re-tension the chain after the rst

5 cuts and at longer intervals after this.

Never attach a new chain

to a worn drive pinion or

place onto a damaged or

worn chain bar. The chain

could spring back or break,

potentially leading to serious

injury.

Maintaining the chain bar

Use cut-protection gloves

when handling the chain or

the chain bar.

The chain bar must be turned round every

10 working minutes, in order to guarantee

uniform wear.

1. Switch off the saw and pull out the

power plug (18).

2. Remove the sprocket chain wheel covering (15), the saw chain (5) and the

chain bar (4).

3. Check the chain bar (4) for wear. Remove burrs and straighten the guide

surfaces with a at le.

4. Clean the oil passages (

the chain bar, in order to guarantee

a trouble-free, automatic oiling of the

saw chain during operation.

5. Mount chain bar (4), chainsaw (5) and

sprocket chain wheel covering (15)

and tighten the chainsaw.

Turning over the bar (4) requires you to

move the tensioning screw (

other side of the bar. Unscrew the retaining bolt attaching the bar to the tensioning

27) of

24) to the

22

Page 23

GB

screw. Move the tensioning screw over to

the other side of the bar and screw the retaining bolt back in.

With the oil nozzles in good condi-

tion and the oil regulator set correctly, the saw chain will spray a

little oil off after starting.

Waste disposal

and environmental

protection

Do not dispose of used oil in the sewage

system or drains. Dispose of used oil in an

environmentally correct manner - bring it to

a waste disposal center.

Be environmentally friendly. Return the

tool, accessories and packaging to a recy-

cling centre when you have nished with

them.

Machines do not belong with do-

mestic waste.

Empty the oil tank carefully and hand in

your electric chainsaw at a disposal center.

The plastic and metal parts employed can

be separated out and thus recycled use

can be implemented. Ask our ServiceCenter for details.

Spare parts

The following spares are available from

Service-Center. Please indicate the machine

type and the number of the spare part with

your order.

Oil ller cap

Saw chain ............................3009 1570

Chain bar ............................3010 0420

Bio chain oil 1 liter ................3023 0001

Bio chain oil 5 liter ................3023 0002

If further spare parts should be necessary,

please nd the part number on the exploded drawings.

.........................9109 7802

The Oregon replacement saw

chain is to be used only in

conjunction with the associated Oregon blade and the

electric chainsaw approved

for this. There is a risk of injury.

Spare parts and accessories can be obtained at www.grizzly-service.eu

If you do not have internet access, please contact the Service Centre via

telephone (see “Sercice-Center” Page 25). Please have the order number

mentioned below ready.

23

Page 24

GB

Guarantee

Dear Customer,

This equipment is provided with a 3-year

guarantee from the date of purchase.

In case of defects, you have statutory rights

against the seller of the product. These

statutory rights are not restricted by our

guarantee presented below.

Terms of Guarantee

The term of the guarantee begins on the

date of purchase. Please retain the original

receipt. This document is required as proof

of purchase.

If a material or manufacturing defect

occurs within three years of the date of

purchase of this product, we will repair or

replace – at our choice – the product for

you free of charge. This guarantee requires

the defective equipment and proof of purchase to be presented within the three-year

period with a brief written description of

what constitutes the defect and when it occurred.

If the defect is covered by our guarantee,

you will receive either the repaired product

or a new product. No new guarantee period begins on repair or replacement of the

product.

Guarantee Period and Statutory

Claims for Defects

The guarantee period is not extended by

the guarantee service. This also applies for

replaced or repaired parts. Any damages

and defects already present at the time of

purchase must be reported immediately after unpacking. Repairs arising after expiry

of the guarantee period are chargeable.

Guarantee Cover

The equipment has been carefully produced in accordance with strict quality

guidelines and conscientiously checked

prior to delivery.

The guarantee applies for all material and

manufacturing defects. This guarantee

does not extend to cover product parts that

are subject to normal wear and may therefore be considered as wearing parts (e.g.

lters or attachments) or to cover damage

to breakable parts (e.g. switches, batteries,

or parts made of glass).

This guarantee shall be invalid if the product has been damaged, used incorrectly or

not maintained. Precise adherence to all of

the instructions specied in the operating

manual is required for proper use of the

product. Intended uses and actions against

which the operating manual advises or

warns must be categorically avoided.

The product is designed only for private

and not commercial use. The guarantee

will be invalidated in case of misuse or

improper handling, use of force, or interventions not undertaken by our authorised

service branch.

Processing in Case of Guarantee

To ensure quick handling of you issue,

please follow the following directions:

• Please have the receipt and item number (IAN 96817) ready as proof of

purchase for all enquiries.

• Please nd the item number on the rating plate.

• Should functional errors or other defects occur, please initially contact the

service department specied below

by telephone or by e-mail. You will

then receive further information on the

processing of your complaint.

24

Page 25

GB

• After consultation with our customer

service, a product recorded as defective can be sent postage paid to the

service address communicated to you,

with the proof of purchase (receipt)

and specication of what constitutes

the defect and when it occurred. In order to avoid acceptance problems and

additional costs, please be sure to use

only the address communicated to you.

Ensure that the consignment is not sent

carriage forward or by bulky goods,

express or other special freight. Please

send the equipment inc. all accessories

supplied at the time of purchase and

ensure adequate, safe transport packaging.

Repair Service

For a charge, repairs not covered by the

guarantee can be carried out by our ser-

vice branch, which will be happy to issue

a cost estimate for you.

We can handle only equipment that has

been sent with adequate packaging and

postage.

Attention: Please send your equipment to

our service branch in clean condition and

with an indication of the defect.

Equipment sent carriage forward or by

bulky goods, express or other special

freight will not be accepted.

We will dispose of your defective devices

free of charge when you send them to us.

Service-Center

Service Great Britain

Tel.: 0871 5000 720

(£ 0.10/Min.)

E-Mail: grizzly@lidl.co.uk

IAN 96817

Importer

Please note that the following address is

not a service address. Please initially con-

tact the service centre specied above.

Grizzly Gartengeräte

GmbH & CO KG

Am Gewerbepark 2

64823 Groß-Umstadt

Germany

www.grizzly-service.eu

25

Page 26

PL

Spis tresci

Wstęp ........................................ 26

Przeznaczenie ............................ 27

Opis ogólny ............................... 27

Zawartość opakowania ..................27

Przegląd ....................................... 27

Opis działania ..............................27

Dane techniczne ......................... 28

Zasady bezpieczeństwa .............28

Symbole zawarte w instrukcji ..........29

Zasady bezpieczeństwa, symbole

znajdujące się na pile ....................29

Ogólne zasady bezpieczeństwa ......29

Środki ostrożności

przeciwko odrzutom .......................34

Funkcje bezpieczeństwa .................34

Uruchamianie ............................35

Napinanie łańcucha tnącego ..........35

Smarowanie łańcucha ....................36

Obsługa piły łańcuchowej..........37

Włączanie ....................................37

Sprawdzanie hamulca łańcucha .........37

Sprawdzanie automatycznego układu

oliwienia ...........................................38

Montaż łańcucha tnącego ...............38

Wymiana miecza ..........................39

Techniki piłowania .....................39

Informacje ogólne ..........................39

Przycinanie ...................................39

Okrzesywanie ...............................40

Ścinanie drzew ..............................40

Konserwacja i oczyszczanie .......42

Oczyszczanie ............................... 42

Czasokresy konserwacyjne .............42

Oliwienie łańcucha tnącego ............ 42

Ostrzenie łańcucha tnącego ........... 43

Regulacja naciągu łańcucha ...........44

Docieranie nowego łańcucha piły .... 44

Konserwacja szyny napędowej ....... 44

Tabela czasokresów

konserwacyjnych .......................46

Utylizacja i ochrona środowiska

naturalnego ...............................45

Części zamienne ........................ 45

Gwarancja ................................. 46

Serwis naprawczy .....................47

Service-Center ............................47

Importer ....................................48

Poszukiwanie błędów ............... 48

Tłumaczenie oryginalnej deklaracji

zgodności WE ............................161

Rysunek samorozwijający ........169

Wstęp

Gratulujemy zakupu nowego urządzenia.

Zdecydowali się Państwo na zakup wartościowego produktu. Instrukcja obsługi jest

częścią składową produktu. Zawiera ona

ważne wskazówki dotyczące bezpieczeństwa, eksploatacji i utylizacji. Przed rozpoczęciem użytkowania produktu należy

się zapoznać ze wszystkimi wskazówkami

dotyczącymi obsługi i bezpieczeństwa.

Produkt należy użytkować tylko zgodnie z

opisem i podanym przeznaczeniem.

Instrukcję należy przechowywać starannie,

a w przypadku przekazania produktu osobom trzecim należy dostarczyć nabywcy

kompletną dokumentację.

Niniejsza elektryczna piła łańcuchowa przeznaczona jest tylko do cięcia drewna i może

ją obsługiwać tylko jedna osoba. Piłę należy

trzymać prawą ręką za uchwyt tylny i lewą

– za uchwyt przedni. Przed rozpoczęciem

korzystania z piły użytkownik musi przeczytać

i zrozumieć wszystkie wskazówki i instrukcje

zawarte w instrukcji eksploatacji. Użytkownik

musi nosić odpowiedni sprzęt ochrony osobistej. Piłą łańcuchową wolno ciąć tylko drewno.

Nie wolno ciąć materiałów takich jak tworzywa sztuczne, kamień, metal czy drewna

zawierającego przedmioty obce (gwoździe,

wkręty)!

26

Page 27

PL

A

C

F

G

J

Przeznaczenie

Elektryczna piła łańcuchowa jest przeznaczona

tylko do cięcia drewna. Piła nie jest przewidziana

do żadnych innych zastosowań (np. przecinania murów, tworzyw sztucznych czy środków spożywczych). Piła jest przeznaczona do

wykonywania prac domowych. Nie jest ona

przystosowana do ciągłego używania zarobkowego. Urządzenie jest przeznaczone do

używania przez osoby dorosłe. Nieletni

powyżej 16 roku życia mogą używać

piły tylko pod nadzorem osoby dorosłej.

Producent nie odpowiada za szkody wywołane niezgodnym z przeznaczeniem

stosowaniem i nieprawidłową obsługą

urządzenia.

Opis ogólny

Zawartość opakowania

- Piła łańcuchowa

- Szyna prowadząca (miecz)

- Łańcuch tnący

- Kołczan ochronny na miecz

- Śrubokręt

- 180 ml bio-olej Grizzly

- Instrukcja obsługi

Ilustracje sposobu obsługi i

konserwacji znajdziesz na

przedniej odchylanej stronie.

Przegląd

1 Tylny uchwyt

2 Pokrywa zbiornika oleju

3 Dźwignia hamulca łańcucha i

przednia osłona dłoni

4 Szyna prowadząca (miecz)

5 Łańcuch tnący

6 Gwiazda zwrotna

7 Ogranicznik pazurowy

8 Przedni uchwyt

9 Silnik elektryczny

10 Włącznik-wyłącznik

11 Blokada włącznika

12 Trzpień przechwytujący łańcuch

13 Pierścień napinacza łańcucha

14 Śruba mocująca osłony koła

łańcucha

15 Osłona koła łańcucha

16 Tylna osłona dłoni

17 Uchwyt kabla

18 Kabel sieciowy

19 Kołczan ochronny na miecz

20 Butelka oleju

21 górny poziom wskaźnika

22 niższy wskaźnik poziomu oleju

23 Śruby kolei

24 Śruba zaciskająca

25 Koło zębate

26 Nos

27 Przejście oleju

Opis działania

Pilarka łańcuchowa jest napędzana przez

silnik elektryczny. Obiegowy łańcuch tnący jest prowadzony przez miecz (prowadnicę szynową).

Urządzenie jest wyposażone system szybkiego napinania łańcucha i szybkodziałający hamulec łańcucha. Automatyczny

układ zasilania olejem zapewnia ciągłe

smarowanie łańcucha.

Do ochrony użytkownika służą różne zabezpieczenia pilarki.

Funkcje elementów urządzenia są podane

w poniższym opisie.

27

Page 28

PL

Dane techniczne

Elektryczna piła łańcuchowa ..........

.................................. FKS 2200 D2

Napięcie znamionowe wejścia

....................................... 230 V~, 50 Hz

Pobór mocy

Klasa zabezpieczenia ....................

Prędkość ruchu łańcucha ............13,6 m/s

Ciężar

(bez szyny prowadzącej i łańcucha) 4,7 kg

Ciężar

(z szyną prowadzącą i łańcuchem) .5,9 kg

Poj. zbiornika .............................. 270 ml

Łańcuch .......................Oregon 91P057X

... chromowany ząb tnący, niskoodrzutowy

Miecz .... Oregon 160SDEA041 (112364)

Odstęp łańcucha ........................ 10 mm

Grubość łańcucha ....................... 1,3 mm

Zęby łańcucha .....................................7

Długość miecza .........................460 mm

Długość cięcia .......................... 395 mm

Poziom ciśnienia

akustycznego

(L

) .............. 96 dB (A); KpA= 3,0 dB (A)

pA

poziom mocy

akustycznej

(L

) .............108 dB (A); KwA= 3,0 dB (A)

WA

gwarantowany poziom mocy

akustycznej ........................... 112 dB (A)

Wibracja (a

.......................... 6,97 m/s

Podana wartość emisji drgań została

zmierzona metodą znormalizowaną i

może być wykorzystywana do porównań

urządzenia elektrycznego z innymi urządzeniami.

Podana wartość emisji drgań może też

służyć do szacunkowej oceny stopnia ekspozycji użytkownika na drgania.

28

...............................2200 W

/ II

n)

2

; K=1,5 m/s

Ostrzeżenie:

Wartość emisji drgań może się

różnić w czasie korzystania z urządzenia od podanej wartości, jest

to zależne od sposobu używania

urządzenia.

Istnieje konieczność określenia i

zastosowania środków ochrony

użytkownika, opartych na ocenie

ekspozycji w rzeczywistych warunkach używania urządzenia (należy

przy tym uwzględnić wszystkie części

cyklu roboczego, na przykład okresy

czasu, w których urządzenie elektryczne jest wyłączone bądź jest włączone, ale pracuje bez obciążenia).

Zmiany techniczne i optyczne mogą być

dokonywane bez zapowiedzi w trakcie

udoskonalania produktu. W związku z tym

wszelkie podane w niniejszej instrukcji obsługi wymiary, wskazówki i dane nie posiadają

gwarancji bezwzględnej prawidłowości. W

związku z powyższym wyklucza się wszelkie

roszczenia prawne zgłaszana na podstawie

danych instrukcji obsługi.

Zasady

bezpieczeństwa

Ten rozdział zawiera podstawowe zasady

2

bezpieczeństwa dotyczące pracy z elektryczną piłą łańcuchową.

Elektryczna piła łańcuchowa

zalicza się do niebezpiecznych

urządzeniem, które w przypadku

nieprawidłowego lub lekkomyślnego użytkowania może powodować

poważne, a nawet śmiertelne obrażenia. W związku z tym w celu

zapewnienia bezpieczeństwa sobie

i innym zawsze przestrzegaj poniższych zasad, a w razie niepewności zasięgnij porady specjalisty.

Page 29

PL

Symbole zawarte w

instrukcji

Znakiniebezpieczeństwazin-

formacjamidot.zapobiegania

wypadkom.

Znaki nakazowe (wyjaśnienie

nakazu zamiast wykrzyknika) z

informacjami dot. zapobiegania

wypadkom.

Wskazówki zawierające informa-

cje dot. lepszego użytkowania

urządzenia.

Zasady bezpieczeństwa,

symbole znajdujące się na

pile

Przed rozpoczęciem pracy zapoznaj

się dokładnie z wszystkimi elementami piły. Przećwicz sposób postępowania z piłą i poproś doświadczonego użytkownika o wyjaśnienie

funkcji, sposobu działania piły oraz

technik piłowania drewna.

Przeczytaj instrukcję obsługi urzą-

dzenia i zastosuj się do niej.

Noś osobiste wyposażenie ochron-

ne. Zasadniczo noś okulary ochronne lub, lepiej, maskę ochronną na

twarz, nauszniki, kask ochronny,

zabezpieczoną przed przecięciem

odzież roboczą, zabezpieczone

przed przecięciem rękawice oraz

zabezpieczone przed przecięciem

obuwie ochronne z przeciwpoślizgową podeszwą.

Mocno trzymaj

maszynąobiema

dłońmi.Nigdyniepracuj

jednąręką.

Uwaga! Odbój - podczas pracy

uważaj na odboje urządzenia.

Nie wystawiaj maszyny na deszcz.

Urządzenie nie może być wilgotne

ani używane w wilgotnym otocze-

niu.

Uwaga! W razie uszkodzenia lub

przecięcia kabla sieciowego natychmiast wyjmij wtyczkę z gniazdka sieci elektrycznej.

gwarantowany poziommocy aku-

stycznej

460 mm

Długość miecza

Klasa zabezpieczenia II

Urządzeń elektrycznych nie należy

wyrzucać razem z odpadami do-

mowymi

Łańcuch piły nie obraca

się, gdy jest zablokowany

hamulec łańcucha. Przyłącz

piłę do źródła napięcia

elektrycznego.

Ogólne zasady

bezpieczeństwa

Przed rozpoczęciem pracy elektryczną

piłą łańcuchową zapoznaj się dokładnie z wszystkimi jej elementami. Proszę

przećwiczyć obchodzenie się z piłą

(przycinanie na długość drewna

okrągłego na koźle do piłowania)

29

Page 30

PL

i zlecić wyjaśnienie sobie przez

doświadczonego użytkownika lub

specjalistę działania, sposobu oddziaływania, technik piłowania i osobistego wyposażenia ochronnego.

Proszę przeczytać następujące

wskazówki w celu uniknięcia szkód

osobowych i rzeczowych:

OSTRZEŻENIE!Przeczytaj

wszystkiezasadyiinstrukcjebezpieczeństwa.

Niedokładne przestrzeganie zasad

i instrukcji bezpieczeństwa może

spowodować porażenie prądem,

pożar i/lub inne ciężkie zranienia.

Zachowaj wszystkie zasady

bezpieczeństwa i instrukcje na

przyszłość.

Użyte w zasadach bezpieczeństwa pojęcie „narzędzie elektryczne“ dotyczy

narzędzi elektrycznych zasilanych prądem

sieciowym (za kablem sieciowym) oraz narzędzi elektrycznych zasilanych z baterii

(bez kabla sieciowego).

Bezpieczeństwo miejsca pracy

• Zapewnij porządek i wystarcza-

jące oświetlenie w miejscu pracy.

Nieporządek lub nieoświetlone miejsce

pracy może spowodować wypadek.

• Nie pracuj pilarką elektryczną

w atmosferze potencjalnie wy-

buchowej, w której znajdują się

palne ciecze, gazy lub pyły. Na-

rzędzia elektryczne wytwarzają iskry,

które mogą zapalić pył lub pary.

• Trzymaj od dzieci i innych ludzi

w bezpiecznej odległości podczas

używania pilarki elektrycznej.

Odwrócenie uwagi może spowodować

utratę kontroli nad urządzeniem.

Bezpieczeństwo elektryczne:

Ostrożnie: W ten sposób unikniesz

wypadków i zranień wskutek porażenia prądem:

• Wtyczka pilarki elektrycznej musi

pasować do gniazdka. Wtyczki

nie można w żaden sposób modykować. Nie używaj adapterów

wtyczek razem z narzędziami

elektrycznymi posiadającymi

zestyk ochronny (uziemiający).

Nienaruszone wtyczki i dopasowane

gniazdka zmniejszają ryzyko porażenia

prądem.

• Unikaj dotykania uziemionych po-

wierzchni, takich jak rury, kalory-

fery, piecyki, kuchenki, lodówki.

Gdy Twoje ciało jest uziemione, ryzyko

porażenia prądem jest większe.

• Trzymaj pilarkę elektryczną z daleka od deszczu i wilgoci/wody.

Dostanie się wody do wnętrza urządzenia elektrycznego zwiększa ryzyko porażenia prądem.

• Jeżeli kabel zasilający tego urządzenia

jest uszkodzony, musi on zostać wymieniony przez producenta lub jego serwis

albo osobę posiadającą podobne

kwalikacje - tylko w ten sposób można

zapewnić bezpieczeństwo urządzenia.

• W przypadku konieczności wymiany

przewodu przyłączeniowego, zalecamy

zlecenie wymiany przewodu producentowi lub jego przedstawicielowi (np. autoryzowany warsztat serwisowy, dział

obsługi klienta itd.)

• Prowadź przewód sieciowy tak, by podczas piłowania nie został pochwycony

przez gałęzie i podobne przedmioty.

30

Page 31

PL

• Nie używaj kabla do przenoszenia pilarki elektrycznej, do jej

zawieszania ani do wyciągania

wtyczki z gniazdka. Chroń kabel

przed gorącem, olejem, ostrymi

krawędziami i ruchomymi częściami urządzenia. Uszkodzone i splątane

kable zwiększają ryzyko porażenia prądem.

• Pracując pilarką elektryczną na

dworze, używaj tylko przedłużaczy dopuszczonych do używania

na dworze. Używanie przedłużacza

przystosowanego do używania na dworze zmniejsza ryzyko porażenia prądem.

• Jeżeli nie da się uniknąć użycia

pilarki elektrycznej w mokrym

otoczeniu, zastosuj wyłącznik

ochronny (FI). Używanie wyłącznika

ochronnego zmniejsza ryzyko porażenia

prądem. Zastosuj wyłącznik ochronny o

prądzie zadziałania 30 mA lub mniejszym.

Bezpieczeństwo osób:

Ostrożnie: W ten sposób unikniesz

wypadków i zranień:

• Zachowuj uwagę, uważaj na to,

co robisz i pracuj pilarką elektryczną rozsądnie. Nie używaj

pilarki elektrycznej, jeżeli jesteś

zmęczony albo jeżeli pod wpływem narkotyków, alkoholu albo

leków. Chwila nieuwagi podczas uży-

wania pilarki elektrycznej może doprowadzić do poważnych zranień.

• Używać sprzętu ochrony osobistej

i zawsze – okularów ochronnych.

Używanie sprzętu ochrony osobi-

stej, takiego jak obuwie ochron-

ne, przeciwpoślizgowe obuwie

ochronne, kask ochronny czy

sprzęt do ochrony słuchu zmniejsza ryzyko odniesienia obrażeń.

• Unikaj przypadkowego urucho-

mienia narzędzia. Przed podłączeniem pilarki elektrycznej do źródła zasilania i/lub baterii, przed

jej podniesieniem i przeniesieniem

upewnij się, że jest ona wyłączona.

• Jeżeli podczas przenoszenia pilarki elektrycznej palec osoby niosącej znajdzie

się na włączniku, albo jeżeli włączone