FANUC Series 0i-MODEL C, Series 0i Mate-MODEL C MAINTENANCE MANUAL

*

*

FANUC Series 0 -MODEL C

FANUC Series 0 Mate-MODEL C

MAINTENANCE MANUAL

B-64115EN/02

• No part of this manual may be reproduced in any form.

• All specifications and designs are subject to change without notice.

The products in this manual are controlled based on Japan’s “Foreign Exchange and

Foreign Trade Law”. The export from Japan may be subject to an export license by the

government of Japan.

Further, re-export to another country may be subject to the license of the government of

the country from where the product is re-exported. Furthermore, the product may also be

controlled by re-export regulations of the United States government.

Should you wish to export or re-export these products, please contact FANUC for advice.

In this manual we have tried as much as possible to describe all the various matters.

However, we cannot describe all the matters which must not be done, or which cannot be

done, because there are so many possibilities.

Therefore, matters which are not especially described as possible in this manual should be

regarded as ”impossible”.

SAFETY PRECAUTIONS

This section describes the safety precautions related to the use of CNC units. It is essential that these precautions

be observed by users to ensure the safe operation of machines equipped with a CNC unit (all descriptions in this

section assume this configuration).

CNC maintenance involves various dangers. CNC maintenance must be undertaken only by a qualified

technician.

Users must also observe the safety precautions related to the machine, as described in the relevant manual supplied

by the machine tool builder.

Before checking the operation of the machine, take time to become familiar with the manuals provided by the

machine tool builder and FANUC.

Contents

1. DEFINITION OF WARNING, CAUTION, AND NOTE s–2. . . . . . . . . . . . . . . . . . . . . . .

2. WARNINGS RELATED TO CHECK OPERATION s–3. . . . . . . . . . . . . . . . . . . . . . . . .

3. WARNINGS RELATED TO REPLACEMENT s–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4. WARNINGS RELATED TO PARAMETERS s–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5. WARNINGS AND NOTES RELATED TO DAILY MAINTENANCE s–7. . . . . . . . . . . .

s–1

1

SAFETY PRECAUTIONS

B–64115EN/02

DEFINITION OF WARNING, CAUTION, AND NOTE

This manual includes safety precautions for protecting the maintenance personnel (herein referred

to as the user) and preventing damage to the machine. Precautions are classified into W arnings and

Cautions according to their bearing on safety. Also, supplementary information is described as a

Note. Read the Warning, Caution, and Note thoroughly before attempting to use the machine.

WARNING

Applied when there is a danger of the user being injured or when there is a danger of both the user

being injured and the equipment being damaged if the approved procedure is not observed.

CAUTION

Applied when there is a danger of the equipment being damaged, if the approved procedure is not

observed.

NOTE

The Note is used to indicate supplementary information other than Warning and Caution.

` Read this manual carefully, and store it in a safe place.

s–2

B–64115EN/02

2

SAFETY PRECAUTIONS

W ARNINGS RELA TED TO CHECK OPERATION

WARNING

1. When checking the operation of the machine with the cover removed

(1) The user’s clothing could become caught in the spindle or other components, thus

presenting a danger of injury . When checking the operation, stand away from the machine

to ensure that your clothing does not become tangled in the spindle or other components.

(2) When checking the operation, perform idle operation without workpiece. When a

workpiece is mounted in the machine, a malfunction could cause the workpiece to be

dropped or destroy the tool tip, possibly scattering fragments throughout the area. This

presents a serious danger of injury . Therefore, stand in a safe location when checking the

operation.

2. When checking the machine operation with the power magnetics cabinet door opened

(1) The power magnetics cabinet has a high–voltage section (carrying a

touch the high–voltage section. The high–voltage section presents a severe risk of electric

shock. Before starting any check of the operation, confirm that the cover is mounted on

the high–voltage section. When the high–voltage section itself must be checked, note that

touching a terminal presents a severe danger of electric shock.

(2) Within the power magnetics cabinet, internal units present potentially injurious corners and

projections. Be careful when working inside the power magnetics cabinet.

3. Never attempt to machine a workpiece without first checking the operation of the machine.

Before starting a production run, ensure that the machine is operating correctly by performing

a trial run using, for example, the single block, feedrate override, or machine lock function or

by operating the machine with neither a tool nor workpiece mounted. Failure to confirm the

correct operation of the machine may result in the machine behaving unexpectedly, possibly

causing damage to the workpiece and/or machine itself, or injury to the user.

4. Before operating the machine, thoroughly check the entered data.

Operating the machine with incorrectly specified data may result in the machine behaving

unexpectedly , possibly causing damage to the workpiece and/or machine itself, or injury to the

user.

mark). Never

s–3

SAFETY PRECAUTIONS

B–64115EN/02

WARNING

5. Ensure that the specified feedrate is appropriate for the intended operation. Generally , for each

machine, there is a maximum allowable feedrate. The appropriate feedrate varies with the

intended operation. Refer to the manual provided with the machine to determine the maximum

allowable feedrate. If a machine is run at other than the correct speed, it may behave

unexpectedly , possibly causing damage to the workpiece and/or machine itself, or injury to the

user.

6. When using a tool compensation function, thoroughly check the direction and amount of

compensation.

Operating the machine with incorrectly specified data may result in the machine behaving

unexpectedly , possibly causing damage to the workpiece and/or machine itself, or injury to the

user.

s–4

B–64115EN/02

3

SAFETY PRECAUTIONS

W ARNINGS RELATED TO REPLACEMENT

WARNING

1. Always turn off the power to the CNC and the main power to the power magnetics cabinet. If

only the power to the CNC is turned off, power may continue to be supplied to the serve section.

In such a case, replacing a unit may damage the unit, while also presenting a danger of electric

shock.

2. When a heavy unit is to be replaced, the task must be undertaken by two persons or more. If

the replacement is attempted by only one person, the replacement unit could slip and fall,

possibly causing injury.

3. After the power is turned off, the servo amplifier and spindle amplifier may retain voltages for

a while, such that there is a danger of electric shock even while the amplifier is turned off. Allow

at least twenty minutes after turning off the power for these residual voltages to dissipate.

4. When replacing a unit, ensure that the new unit has the same parameter and other settings as the

old unit. (For details, refer to the manual provided with the machine.) Otherwise, unpredictable

machine movement could damage the workpiece or the machine itself, and present a danger of

injury.

s–5

4

SAFETY PRECAUTIONS

B–64115EN/02

W ARNINGS RELATED TO PARAMETERS

WARNING

1. When machining a workpiece for the first time after modifying a parameter, close the machine

cover. Never use the automatic operation function immediately after such a modification.

Instead, confirm normal machine operation by using functions such as the single block function,

feedrate override function, and machine lock function, or by operating the machine without

mounting a tool and workpiece. If the machine is used before confirming that it operates

normally, the machine may move unpredictably, possibly damaging the machine or workpiece,

and presenting a risk of injury.

2. The CNC and PMC parameters are set to their optimal values, so that those parameters usually

need not be modified. When a parameter must be modified for some reason, ensure that you

fully understand the function of that parameter before attempting to modify it. If a parameter

is set incorrectly, the machine may move unpredictably, possibly damaging the machine or

workpiece, and presenting a risk of injury.

s–6

B–64115EN/02

5

1. Memory backup battery replacement

SAFETY PRECAUTIONS

W ARNINGS AND NOTES RELATED TO DAILY MAINTENANCE

WARNING

When replacing the memory backup batteries, keep the power to the machine (CNC) turned on,

and apply an emergency stop to the machine. Because this work is performed with the power

on and the cabinet open, only those personnel who have received approved safety and

maintenance training may perform this work.

When replacing the batteries, be careful not to touch the high–voltage circuits (marked

fitted with an insulating cover).

Touching the uncovered high–voltage circuits presents an extremely dangerous electric shock

hazard.

and

NOTE

The CNC uses batteries to preserve the contents of its memory, because it must retain data such as

programs, offsets, and parameters even while external power is not applied.

If the battery voltage drops, a low battery voltage alarm is displayed on the machine operator’s panel

or CRT screen.

When a low battery voltage alarm is displayed, replace the batteries within a week. Otherwise, the

contents of the CNC’s memory will be lost.

To replace the battery, see the procedure described in Section 2.10 of this manual.

s–7

SAFETY PRECAUTIONS

B–64115EN/02

WARNING

2. Absolute pulse coder battery replacement

When replacing the memory backup batteries, keep the power to the machine (CNC) turned on,

and apply an emergency stop to the machine. Because this work is performed with the power

on and the cabinet open, only those personnel who have received approved safety and

maintenance training may perform this work.

When replacing the batteries, be careful not to touch the high–voltage circuits (marked

fitted with an insulating cover).

Touching the uncovered high–voltage circuits presents an extremely dangerous electric shock

hazard.

NOTE

The absolute pulse coder uses batteries to preserve its absolute position.

If the battery voltage drops, a low battery voltage alarm is displayed on the machine operator’s panel

or CRT screen.

When a low battery voltage alarm is displayed, replace the batteries within a week. Otherwise, the

absolute position data held by the pulse coder will be lost.

To replace the battery, see the procedure described in Servo Amplifier Maintenance Manual.

and

s–8

B–64115EN/02

3. Fuse replacement

SAFETY PRECAUTIONS

WARNING

Before replacing a blown fuse, however, it is necessary to locate and remove the cause of the

blown fuse.

For this reason, only those personnel who have received approved safety and maintenance

training may perform this work.

When replacing a fuse with the cabinet open, be careful not to touch the high–voltage circuits

(marked

Touching an uncovered high–voltage circuit presents an extremely dangerous electric shock

hazard.

and fitted with an insulating cover).

s–9

B–64115EN/02

PREFACE

PREFACE

Description of

this manual

1.Display and operation

This chapter covers those items, displayed on the screen, that are related

to maintenance. A list of all supported operations is also provided at the

end of this chapter.

2.Hardware

This chapter describes the configuration of the hardware, lists the

hardware units, and explains how to replace printed–circuit boards.

3.Data input/output

This chapter describes the input/output of data, including programs,

parameters, and tool compensation data, aswell as the input/output

procedures for conversational data.

4.Interface between the CNC and PMC

This chapter describes the PMC specifications, the system configuration,

and the signals used by the PMC.

5.Digital servo

This chapter describes the servo tuning screen and how to adjust the

reference position return position.

6.AC spindles

These chapters describe the spindle amplifier checkpoints, as well as the

spindle tuning screen.

7.Trouble shooting

This chapter describes the procedures to be followed in the event of

certain problems occurring.

Appendix

A. Alarm list

B. List of maintenance parts

C. Boot system

D. FSSB start–up procedure/materials

E. Notation of MDI keys

This manual does not provide a parameter list. If necessary, refer to the

separate PARAMETER MANUAL.

p–1

PREFACE

Series 0i

Series 0i Mate

B–64115EN/02

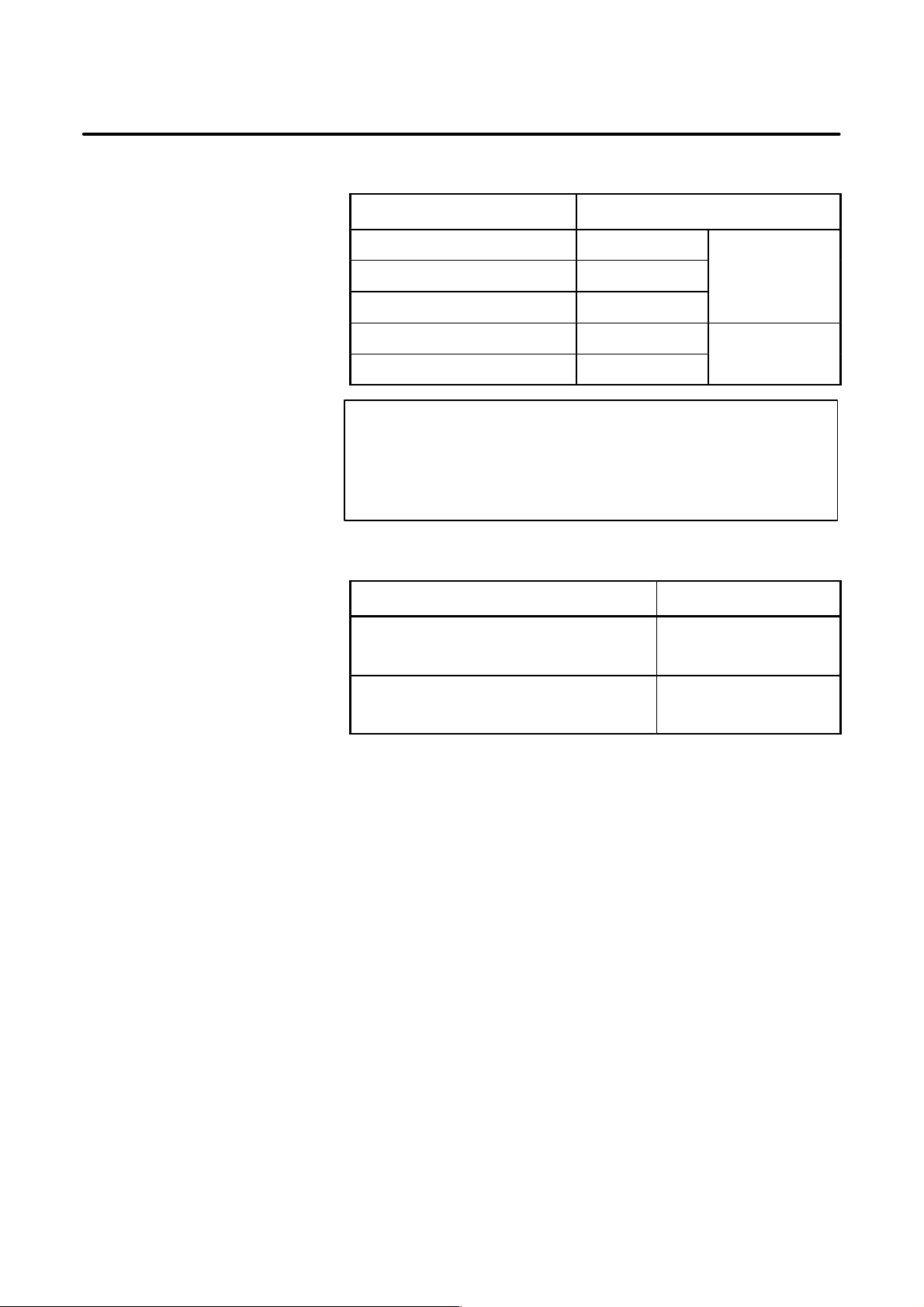

Applicable models

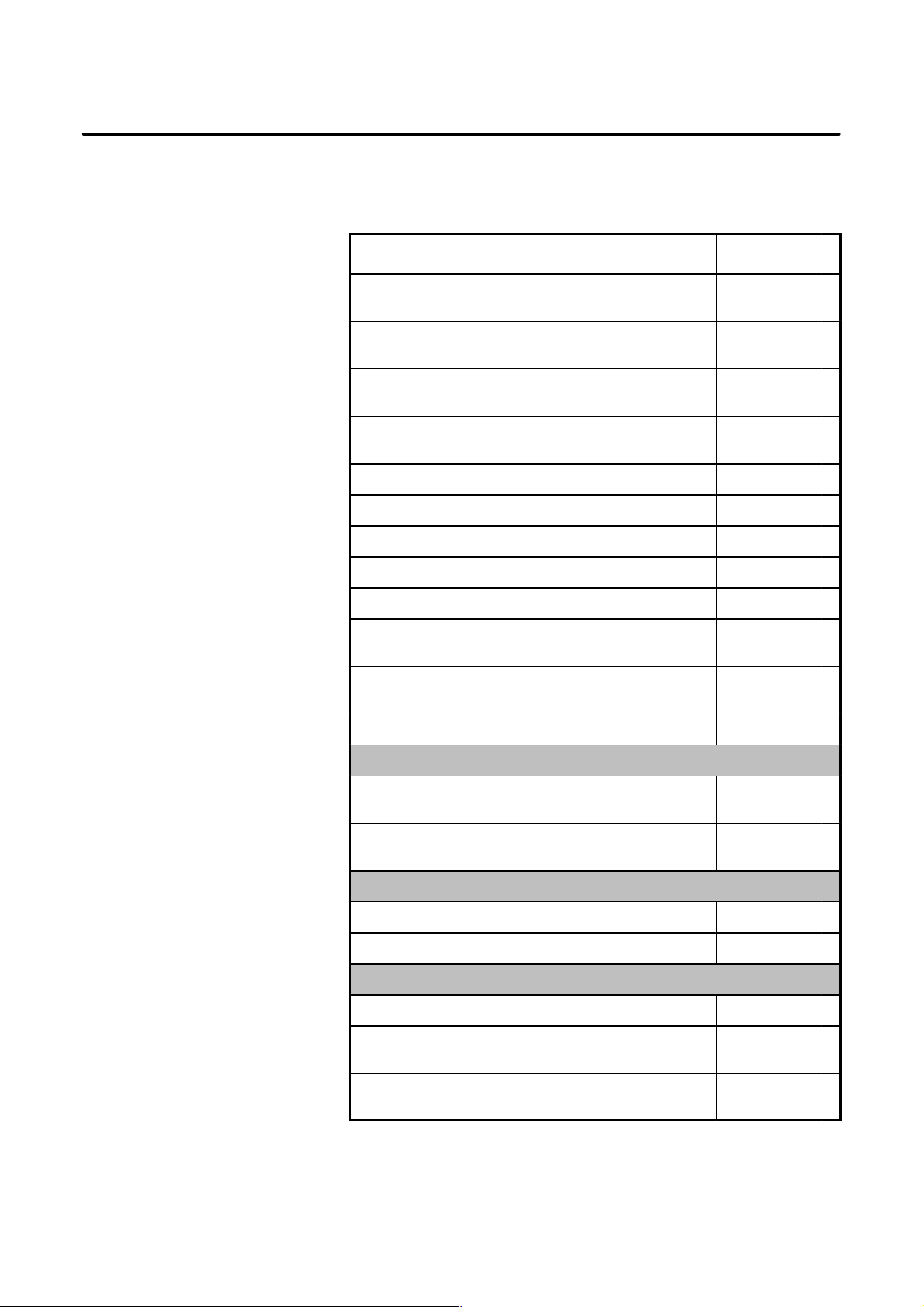

The models covered by this manual, and their abbreviations are:

Product name Abbreviation

FANUC Series 0i–TC 0i–TC

FANUC Series 0i–MC 0i–MC

FANUC Series 0i–PC 0i–PC

FANUC Series 0i Mate–TC 0i–Mate TC

FANUC Series 0i Mate–MC 0i–Mate TC

NOTE

Some function described in this manual may not be applied

to some products.

For details, refer to the DESCRIPTIONS manual

(B–64112EN)

There are two types of basic units for Series 0i–C and Series 0i Mate–C:

Basic unit drawing No. Model

A02B–0309–B50n (n=0,1,...,9)

A02B–031 1–B50n (n=0,1,...,9)

A02B–031 1–B51n (n=0,1,...,9)

A02B–0309–B52n (n=0,1,...,9)

A02B–031 1–B52n (n=0,1,...,9)

A02B–031 1–B53n (n=0,1,...,9)

Series 0i –C

Series 0i Mate–C

Series 0i Mate–C

Series 0i –C

Series 0i Mate–C

Series 0i Mate–C

p–2

B–64115EN/02

PREFACE

Related manuals of

Series 0i–C/0i Mate–C

The following table lists the manuals related to Series 0i–C, Series 0i

Mate–C.

This manual is indicated by an asterisk(*).

Manual name

FANUC Series 0i–MODEL C/0i Mate–MODEL C

DESCRIPTIONS

FANUC Series 0i–MODEL C/0i Mate–MODEL C

CONNECTION MANUAL (HARDWARE)

FANUC Series 0i–MODEL C/0i Mate–MODEL C

CONNECTION MANUAL (FUNCTION)

FANUC Series 0i–PC

CONNECTION MANUAL (FUNCTION)

FANUC Series 0i–TC OPERATOR’S MANUAL B–64114EN

FANUC Series 0i–MC OPERATOR’S MANUAL B–64124EN

FANUC Series 0i Mate–TC OPERATOR’S MANUAL B–64134EN

FANUC Series 0i Mate–MC OPERATOR’S MANUAL B–64144EN

FANUC Series 0i–PC OPERATOR’S MANUAL B–64154EN

Specification

number

B–64112EN

B–64113EN

B–64113EN–1

B–64153EN

FANUC Series 0i–MODEL C/0i Mate–MODEL C

MAINTENANCE MANUAL

FANUC Series 0i–MODEL C/0i Mate–MODEL C

P ARAMETER MANUAL

FANUC Series 0i–PC PARAMETER MANUAL B–64160EN

PROGRAMMING MANUAL

Macro Compiler/Macro Executor

PROGRAMMING MANUAL

FANUC MACRO COMPILER (For Personal Computer)

PROGRAMMING MANUAL

PMC

PMC Ladder Language PROGRAMMING MANUAL B–61863E

PMC C Language PROGRAMMING MANUA B–61863E–1

Network

PROFIBUS–DP Board OPERA T OR’S MANUAL B–62924EN

Ethernet Board/DA T A SERVER Board

OPERA T OR’S MANUAL

B–64115EN *

B–64120EN

B–61803E–1

B–66102E

B–63354EN

AST Ethernet Board/FAST DATA SERVER

OPERA T OR’S MANUAL

p–3

B–63644EN

PREFACE

B–64115EN/02

Related manuals of

SERVO MOTOR

αiS/αiF/βiS series

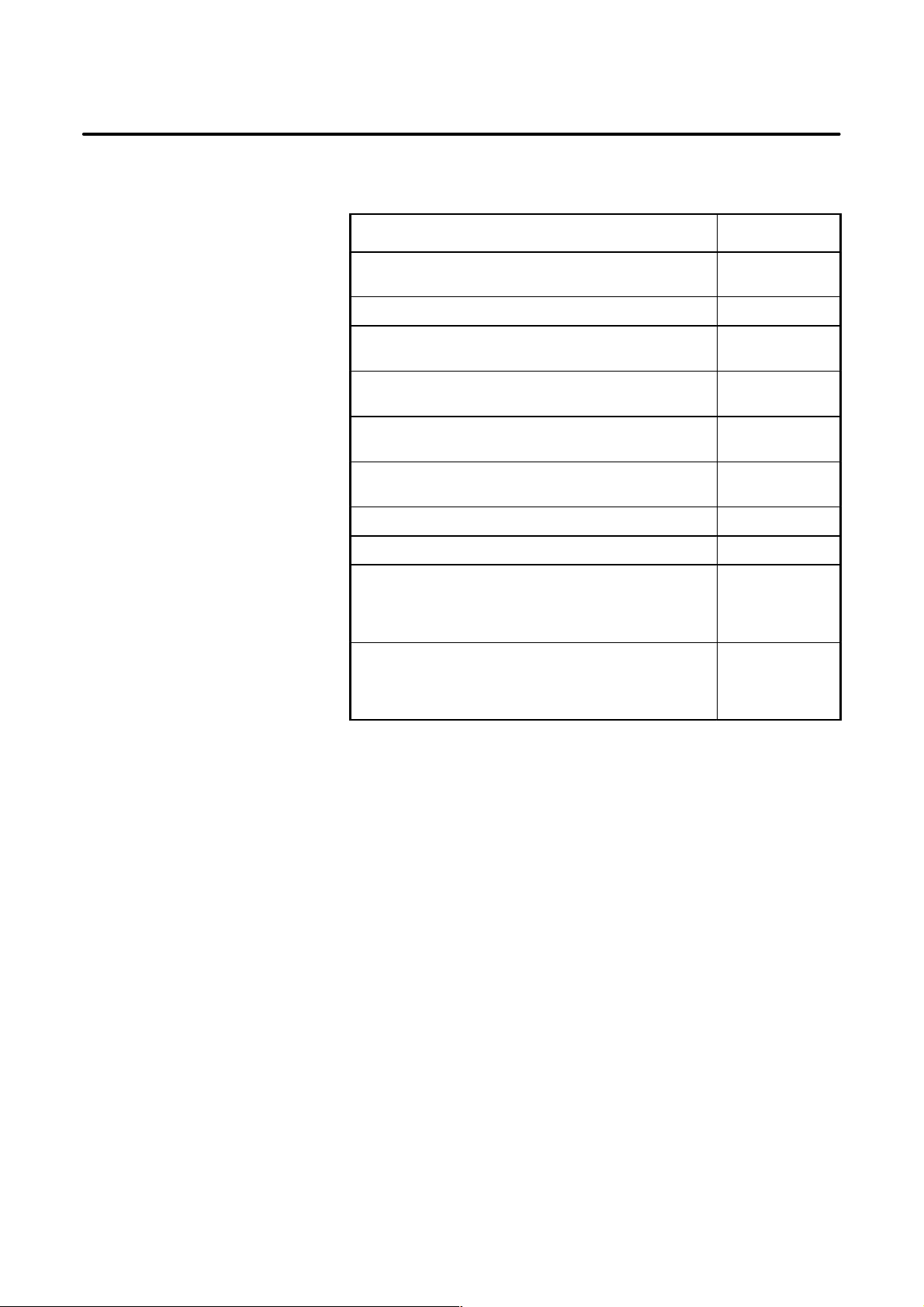

The following table lists the manuals related to SERVO MOTOR

αiS/αiF/βiS series

Manual name

FANUC AC SER VO MOTOR αiS/αiF series

DESCRIPTIONS

FANUC AC SER VO MOTOR βiS series DESCRIPTIONS B–65302EN

FANUC AC SER VO MOTOR αiS/αiF/βiS series

P ARAMETER MANUAL

FANUC AC SPINDLE MOT OR αi series

DESCRIPTIONS

FANUC AC SPINDLE MOT OR βi series

DESCRIPTIONS

FANUC AC SPINDLE MOT OR αiS/βiS series

P ARAMETER MANUAL

FANUC SER VO AMPLIFIER αi series DESCRIPTIONS B–65282EN

FANUC SER VO AMPLIFIER βi series DESCRIPTIONS B–65322EN

FANUC AC SER VO MOTOR αiS/αiF series,

FANUC AC SPINDLE MOT OR αi series,

FANUC SER VO AMPLIFIER αi series

MAINTENANCE MANUAL

Specification

number

B–65262EN

B–65270EN

B–65272EN

B–65312EN

B–65280EN

B–65285EN

FANUC AC SER VO MOTOR βiS series,

FANUC AC SPINDLE MOT OR βi series,

FANUC SER VO AMPLIFIER βi series

MAINTENANCE MANUAL

B–65325EN

p–4

B–64115EN/02

Table of Contents

SAFETY PRECAUTIONS s–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PREFACE p–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1. DISPLAY AND OPERATION 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1 FUNCTION KEYS AND SOFT KEYS 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1.1 Soft Keys 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 SCREEN DISPLAYED IMMEDIATELY AFTER POWER IS TURNED ON 26. . . . . . . . . . . . . . . . .

1.2.1 Slot Status Display 26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2.2 Setting Module Screen 27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2.3 Configuration Display of Software 27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3 SYSTEM CONFIGURATION SCREEN 28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3.1 Display Method 28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3.2 Configuration of PCBs 28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3.3 Software Configuration Screen 29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3.4 Module Configuration Screen 30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3.5 ID Information Screen (αi Servo Information Screen/αi Spindle Information Screen) 30. . . . . . . . . . . . .

1.4 ALARM HISTORY SCREEN 31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4.1 Alarm History Screen 31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4.1.1 General 31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4.1.2 Screen display 31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4.1.3 Clearing alarm history 31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4.1.4 Alarm display 31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4.2 System Alarm History 32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4.2.1 General 32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4.2.2 System alarm history screen (history list screen) 32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4.2.3 System alarm history screen (detail screen) 34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4.2.4 Parameter 37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.5 EXTERNAL OPERATOR MESSAGES RECORD 38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.5.1 Screen Display 38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.5.2 Deletion of External Operator Messages Record 38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.5.3 Parameter 39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.5.4 Notes 39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.6 OPERATION HISTORY 40. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.6.1 Parameter Setting 40. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.6.2 Screen Display 45. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.6.3 Setting the Input Signal or Output Signal to be Recorded in the Operation History 49. . . . . . . . . . . . . . .

1.6.4 Inputting and Outputting the Operation History Data 53. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.6.5 Notes 58. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.7 HELP FUNCTION 59. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.7.1 General 59. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.7.2 Display Method 59. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.8 DISPLAYING DIAGNOSTIC PAGE 62. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.8.1 Displaying Diagnostic Page 62. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.8.2 Contents Displayed 62. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.9 CNC STATE DISPLAY 90. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.10 WAVEFORM DIAGNOSTIC FUNCTION 92. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.10.1 Setting Parameters 92. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.10.2 W aveform Diagnostic Parameter Screen 93. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.10.3 Graphic of W ave Diagnosis Data 96. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.10.4 Data Sampling for Storage T ype W aveform Diagnosis 98. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

c–1

Table of Contents

1.10.5 Outputting Waveform Diagnosis Data (Storage T ype) 100. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.10.6 Notes 103. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B–64115EN/02

1.11 OPERATING MONITOR 104. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.11.1 Display Method 104. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.11.2 Parameters 105. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.12 LIST OF OPERATIONS 106. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.13 WARNING SCREEN DISPLAYED WHEN AN OPTION IS CHANGED 116. . . . . . . . . . . . . . . . . . .

1.14 WARNING SCREEN DISPLAYED WHEN SYSTEM SOFTWARE IS REPLACED

(SYSTEM LABEL CHECK ERROR) 118. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.15 MAINTENANCE INFORMATION SCREEN 119. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.15.1 Screen Display and Operation 119. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.15.2 Maintenance Information Input/Output 122. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.16 COLOR SETTING SCREEN (8.4″ COLOR LCD) 123. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.16.1 Screen Display 125. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.16.2 Color Setting 125. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.16.3 Parameters 127. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.16.4 Notes 128. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.17 CONTRAST ADJUSTMENT 129. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.18 POWER MATE CNC MANAGER 130. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.18.1 Parameter 130. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.18.2 Screen Display 131. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.18.3 Parameter Input/Output 137. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.18.4 Notes 139. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.19 PERIODIC MAINTENANCE SCREENS 140. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.19.1 Overview 140. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.19.2 Screen Display and Setting 140. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.19.3 Status Screen Display and Setting 141. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.19.4 Setting Screen Display and Setting 146. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.19.5 Registered Data Input/Output 148. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.19.6 F ANUC T wo–Byte Character Code T able 150. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2. HARDWARE 156. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1 HARDWARE CONFIGURATION 157. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2 HARDWARE OVERVIEW 158. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3 TOTAL CONNECTION DIAGRAMS 160. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4 CONNECTOR AND CARD CONFIGURATIONS OF PRINTED CIRCUIT BOARDS 163. . . . . . . . .

2.4.1 Main Board 163. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4.2 Inverter PCBs 178. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4.3 Fast Ethernet Board 180. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4.4 Fast Data Server Board 187. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4.5 PROFIBUS–DP Board 193. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4.6 I/O Board for 0i 199. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.5 UNITS AND PRINTED CIRCUIT BOARDS 200. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.5.1 Basic Units 200. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.5.2 LCD/MDI Units 200. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.5.3 Printed Circuit Boards 201. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.5.4 I/O 203. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.5.5 Other Units 203. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.6 REPLACING THE MAIN BOARD 204. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.7 MOUNTING AND DEMOUNTING CARD PCBS 208. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.7.1 Demounting a Card PCB 209. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.7.2 Mounting a Card PCB 210. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

c–2

B–64115EN/02

2.8 MOUNTING AND DEMOUNTING DIMM MODULES 211. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.9 REPLACING FUSE ON CONTROL UNIT 213. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.10 REPLACING BATTERY 215. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.11 REPLACING FAN MOTORS 222. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.12 REPLACING LCD BACKLIGHT 225. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.13 DISTRIBUTED I/O SETTING 234. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.14 REPLACING FUSES ON VARIOUS UNITS 236. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.15 ENVIRONMENTAL REQUIREMENTS OUTSIDE THE CONTROL UNIT 239. . . . . . . . . . . . . . . . .

2.16 ACTION AGAINST NOISE 240. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table of Contents

2.8.1 Demounting a DIMM Module 212. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.8.2 Mounting a DIMM Module 212. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.10.1 Battery for Separate Absolute Pulse Coders (6VDC) 220. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.10.2 Battery for Absolute Pulse Coder Built into the Motor (6VDC) 221. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.16.1 Separating Signal Lines 240. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.16.2 Ground 242. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.16.3 Connecting the Ground Terminal of the Control Unit 243. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.16.4 Noise Suppressor 244. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.16.5 Cable Clamp and Shield Processing 245. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3. INPUT AND OUTPUT OF DATA 248. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1 SETTING PARAMETERS FOR INPUT/OUTPUT 249. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2 INPUTTING/OUTPUTTING DATA 251. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.1 Confirming the Parameters Required for Data Output 251. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.2 Outputting CNC Parameters 252. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.3 Outputting PMC Parameters 253. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.4 Outputting Pitch Error Compensation Amount 253. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.5 Outputting Custom Macro V ariable Values 254. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.6 Outputting Tool Compensation Amount 254. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.7 Outputting Part Program 254. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.8 Inputting CNC Parameters 255. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.9 Inputting PMC Parameters 256. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.10 Inputting Pitch Error Compensation Amount 257. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.11 Inputting Custom Macro V ariable Values 257. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.12 Inputting Tool Compensation Amount 258. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.13 Inputting Part Programs 258. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3 DATA INPUT/OUTPUT ON THE ALL IO SCREEN 260. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3.1 Setting Input/Output–Related Parameters 261. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3.2 Inputting and Outputting Programs 263. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3.3 Inputting and Outputting Parameters 267. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3.4 Inputting and Outputting Offset Data 268. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3.5 Outputting Custom Macro Common Variables 269. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3.6 Inputting and Outputting Floppy Files 270. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4 DATA INPUT/OUTPUT USING A MEMORY CARD 275. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4. INTERFACE BETWEEN CNC AND PMC 286. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1 GENERAL OF INTERFACE 287. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2 SPECIFICATION OF PMC 288. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2.1 Specification 288. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2.2 Address 289. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2.3 System Reserve Area of Internal Relay 290. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2.4 Execution Period of PMC 293. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2.5 I/O Module Assignment Name List 295. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

c–3

Table of Contents

B–64115EN/02

4.3 PMC SCREEN (PMC–SA1) 298. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.1 PMC Menu Selection Procedure Using Soft Keys 298. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.2 Dynamic Display of Sequence Program 299. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.3 Display of PMC Diagnosis Screen 304. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.3.1 T itle screen (TITLE) 304. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.3.2 Status screen (STATUS) 305. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.3.3 Alarm screen (ALARM) 306. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.3.4 T race screen (TRACE) 306. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.4 PMC Parameter 308. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.4.1 Input of PMC parameter from MDI 308. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.4.2 T imer screen (TIMER) 308. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.4.3 Counter screen (COUNTER) 309. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.4.4 Keep relay screen (KEEPRL) 309. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.4.5 Data table screen (C. DATA) 312. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.4.6 Setting screen 314. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.5 Input/Output of PMC Data 315. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.5.1 Start of the built-in type PMC programmer 315. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.5.2 Input/output method 315. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.5.3 Copy function (COPY) 316. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.6 System Parameters 317. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.7 Online Monitor Setting Screen 318. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4 PMC SCREEN (PMC–SB7) 321. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4.1 PMC Menu Selection Procedure Using Soft Keys 321. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4.2 Dynamic Display of Sequence Programs 322. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4.2.1 Ladder diagram display screen 323. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4.2.2 Selection monitor screen 325. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4.2.3 Ladder diagram editing screen 326. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4.2.4 Net editing screen 328. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4.3 Display of the PMC Diagnosis Screen 331. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4.3.1 T itle screen 331. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4.3.2 Status screen 332. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4.3.3 Alarm screen 332. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4.3.4 T race function 333. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4.3.5 I/O Link connection check screen 337. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4.4 PMC Parameters 337. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4.4.1 Parameter input/output method 337. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4.4.2 TIMER screen 338. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4.4.3 COUNTER screen 339. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4.4.4 KEEP RELAY screen 340. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4.4.5 Data table screen 343. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4.4.6 Setting screens 345. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4.5 PMC Data Input/Output 348. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4.5.1 Starting the built–in programmer 348. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4.5.2 Input/output method 349. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4.6 System Parameters 350. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4.7 Online Monitor Setting Screen 352. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.5 LIST OF SIGNALS BY EACH MODE 354. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.6 LIST OF INPUT/OUTPUT SIGNALS 356. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.7 LIST OF ADDRESSES 371. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

c–4

B–64115EN/02

Table of Contents

5. FOCAS1/ETHERNET PARAMETER SETTING 398. . . . . . . . . . . . . . . . . . . . . . . . . . . .

6. DIGITAL SERVO 401. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1 INITIAL SETTING SERVO PARAMETERS 402. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2 SERVO TUNING SCREEN 412. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2.1 Parameter Setting 412. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2.2 Displaying Servo Tuning Screen 412. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3 ADJUSTING REFERENCE POSITION (DOG METHOD) 415. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3.1 General 415. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.4 DOGLESS REFERENCE POSITION SETTING 418. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.4.1 General 418. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.4.2 Operation 418. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.4.3 Associated Parameters 419. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.5 αi SERVO WARNING INTERFACE 420. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.6 αi SERVO INFORMATION SCREEN 422. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7. AC SPINDLE (SERIAL INTERFACE) 426. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1 AC SPINDLE (SERIAL INTERFACE) 427. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1.1 Outline of Spindle Control 427. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1.1.1 Method A of gear change for machining center (PRM 3705#2=0) 429. . . . . . . . . . . . . . . . . . . . . .

7.1.1.2 Method B of gear change for machining center (PRM 3705#2=1) 429. . . . . . . . . . . . . . . . . . . . . .

7.1.1.3 T series 429. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1.2 Spindle Setting and Tuning Screen 430. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1.2.1 Display method 430. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1.2.2 Spindle setting screen 430. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1.2.3 Spindle tuning screen 431. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1.2.4 Spindle monitor screen 433. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1.2.5 Correspondence between operation mode and parameters on spindle tuning screen 435. . . . . . . . .

7.1.3 Automatic Setting of Standard Parameters 438. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1.4 W arning Interface for the αi Spindle 440. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1.5 αi Spindle Error State Messages 442. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1.6 αi Spindle Information Screen 443. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2 AC SPINDLE (ANALOG INTERFACE) 447. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2.1 Outline of Spindle Control 447. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2.1.1 Block diagram 448. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2.1.2 Calculation of S analog voltage and related parameters 449. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2.1.3 Tuning S analog voltage (D/A converter) 451. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8. TROUBLESHOOTING 453. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.1 CORRECTIVE ACTION FOR FAILURES 455. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.1.1 Investigating the Conditions Under which Failure Occurred 455. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2 NO MANUAL OPERATION NOR AUTOMATIC OPERATION CAN BE EXECUTED 457. . . . . . . .

8.3 JOG OPERATION CANNOT BE DONE 461. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.4 MANUAL HANDLE OPERATION CANNOT BE DONE 465. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.5 AUTOMATIC OPERATION CANNOT BE DONE 470. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.6 CYCLE START LED SIGNAL HAS TURNED OFF 478. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.7 NOTHING IS DISPLAYED ON THE LCD WHEN THE POWER IS TURNED ON 480. . . . . . . . . . .

c–5

Table of Contents

8.8 INPUT FROM AND OUTPUT TO I/O DEVICES CANNOT BE PERFORMED

INPUT/OUTPUT CANNOT BE PERFORMED PROPERLY 482. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.9 IN A CONNECTOR PANEL I/O UNIT, DATA IS INPUT TO AN UNEXPECTED ADDRESS 484. .

8.10 IN A CONNECTOR PANEL I/O UNIT, NO DATA IS OUTPUT TO AN EXPANSION UNIT 485. . .

8.11 ALARM 85 TO 87 (READER/PUNCHER INTERFACE ALARM) 486. . . . . . . . . . . . . . . . . . . . . . . .

8.12 ALARM 90 (REFERENCE POSITION RETURN IS ABNORMAL) 490. . . . . . . . . . . . . . . . . . . . . . .

8.13 ALARM 300 (REQUEST FOR REFERENCE POSITION RETURN) 492. . . . . . . . . . . . . . . . . . . . . . .

8.14 ALARM 401 (V READY OFF) 493. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.15 ALARM 404 (V READY ON) 495. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.16 ALARM 462 (SEND CNC DATA FAILED)

ALARM 463 (SEND SLAVE DATA FAILED) 496. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.17 ALARM 417 (DIGITAL SERVO SYSTEM IS ABNORMAL) 497. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.18 ALARM 700 (OVERHEAT: CONTROL UNIT) 498. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.19 ALARM 701 (OVERHEAT: FAN MOTOR) 499. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.20 ALARM 704 (SPINDLE SPEED FLUCTUATION DETECTION ALARM) 500. . . . . . . . . . . . . . . . . .

8.21 ALARM 749 (SERIAL SPINDLE COMMUNICATION ERROR) 501. . . . . . . . . . . . . . . . . . . . . . . . . .

8.22 ALARM 750 (SPINDLE SERIAL LINK STARTUP FAILURE) 502. . . . . . . . . . . . . . . . . . . . . . . . . . .

8.23 ALARM 5134 (FSSB: OPEN READY TIME OUT)

ALARM 5135 (FSSB: ERROR MODE)

ALARM 5137 (FSSB: CONFIGURATION ERROR)

ALARM 5197 (FSSB: OPEN TIME OUT)

ALARM 5198 (FSSB: ID DATA NOT READ) 504. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.24 ALARM 5136 (FSSB: NUMBER OF AMPS IS SMALL) 506. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.25 ALARM 900 (ROM PARITY) 507. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.26 ALARMS 912 TO 919 (DRAM PARITY) 508. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.27 ALARM 920 (SERVO ALARMS) 509. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.28 ALARM 926 (FSSB ALARM) 510. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.29 ALARM 930 (CPU INTERRUPT) 513. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.30 ALARM 935 (SRAM ECC ERROR) 514. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.31 ALARM 950 (PMC SYSTEM ALARM) 515. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.32 ALARM 951 (PMC WATCHDOG ALARM) 518. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.33 ALARM 972 (NMI ALARM ON AN OPTION BOARD) (SERIES 0i–C ONLY) 519. . . . . . . . . . . . . .

8.34 ALARM 973 (NMI ALARM WITH AN UNKNOWN CAUSE) 520. . . . . . . . . . . . . . . . . . . . . . . . . . .

8.35 ALARM 974 (F–BUS ERROR) 521. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.36 ALARM 975 (BUS ERROR) 522. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.37 ALARM 976 (LOCAL BUS ERROR) 523. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.38 SERVO ALARMS 524. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.39 SPC ALARMS 527. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.40 SPINDLE ALARMS 528. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B–64115EN/02

APPENDIX

A. ALARM LIST 531. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.1 LIST OF ALARM CODES (CNC) 532. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.2 LIST OF ALARMS (PMC) 569. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.3 ALARM LIST (SERIAL SPINDLE) 594. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

c–6

B–64115EN/02

Table of Contents

A.4 ERROR CODES (SERIAL SPINDLE) 606. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B. LIST OF MAINTENANCE PARTS 608. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C. BOOT SYSTEM 609. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C.1 OVERVIEW 610. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C.1.1 Starting the Boot System 610. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C.1.2 System Files and User Files 611. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C.2 SCREEN CONFIGURATION AND OPERATING PROCEDURE 612. . . . . . . . . . . . . . . . . . . . . . . . . .

C.2.1 System Data Loading Screen 613. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C.2.2 System Data Check Screen 615. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C.2.3 System Data Delete Screen 617. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C.2.4 System Data Save Screen 618. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C.2.5 SRAM Data Backup Screen 620. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C.2.6 Memory Card File Delete Screen 623. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C.2.7 Memory Card Format Function 624. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C.2.8 Load Basic System Function 625. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C.3 ERROR MESSAGES AND REQUIRED ACTIONS 627. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

D. FSSB START–UP PROCEDURE/MATERIALS 630. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

D.1 OVERVIEW 631. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

D.2 SLAVE 632. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

D.3 AUTOMATIC SETTING 633. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

D.3.1 (Sample Setting 1] General Configuration (Semi–Closed Loop) 635. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

D.3.2 [Sample Setting 2] General Configuration (Closed Loop) 636. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

D.3.3 [Sample Setting 3] When the C–Axis is a Cs Axis 638. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

D.4 MANUAL SETTING 2 640. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

D.5 MANUAL SETTING 1 646. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

D.6 ALARMS 647. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

D.7 ACTIONS FOR TROUBLE ENCOUNTERED AT START–UP TIME 652. . . . . . . . . . . . . . . . . . . . . .

D.8 FSSB DATA DISPLAY 654. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

D.8.1 Amplifier Setting Screen 654. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

D.8.2 Axis Setting Screen 655. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

D.8.3 Amplifier Maintenance Screen 656. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

E. NOTATION OF MDI KEYS 658. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

c–7

B–64115EN/02

1

1. DISPLAY AND OPERATION

DISPLAY AND OPERATION

This chapter describes how to display various screens by the function

keys. The screens used for maintenance are respectively displayed.

1.1 FUNCTION KEYS AND SOFT KEYS 2. . . . . . . . . . . .

1.2 SCREEN DISPLAYED IMMEDIATELY AFTER

POWER IS TURNED ON 26. . . . . . . . . . . . . . . . . . . . . .

1.3 SYSTEM CONFIGURATION SCREEN 28. . . . . . . . . .

1.4 ALARM HISTORY SCREEN 31. . . . . . . . . . . . . . . . . . .

1.5 EXTERNAL OPERATOR MESSAGES

RECORD 38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.6 OPERATION HISTORY 40. . . . . . . . . . . . . . . . . . . . . . .

1.7 HELP FUNCTION 59. . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.8 DISPLAYING DIAGNOSTIC PAGE 62. . . . . . . . . . . . .

1.9 CNC STATE DISPLAY 90. . . . . . . . . . . . . . . . . . . . . . . .

1.10 WAVEFORM DIAGNOSTIC FUNCTION 92. . . . . . . . .

1.11 OPERATING MONITOR 104. . . . . . . . . . . . . . . . . . . . .

1.12 LIST OF OPERATIONS 106. . . . . . . . . . . . . . . . . . . . . .

1.13 WARNING SCREEN DISPLAYED WHEN

AN OPTION IS CHANGED 116. . . . . . . . . . . . . . . . . . . .

1.14 WARNING SCREEN DISPLAYED

WHEN SYSTEM SOFTWARE IS REPLACED

(SYSTEM LABEL CHECK ERROR) 118. . . . . . . . . . . . .

1.15 MAINTENANCE INFORMATION SCREEN 119. . . . . .

1.16 COLOR SETTING SCREEN

(8.4″ COLOR LCD) 123. . . . . . . . . . . . . . . . . . . . . . . . . .

1.17 CONTRAST ADJUSTMENT 129. . . . . . . . . . . . . . . . . .

1.18 POWER MATE CNC MANAGER 130. . . . . . . . . . . . . .

1.19 PERIODIC MAINTENANCE SCREENS 140. . . . . . . . .

1

1. DISPLAY AND OPERATION

B–64115EN/02

1.1

FUNCTION KEYS AND SOFT KEYS

1.1.1

Soft Keys

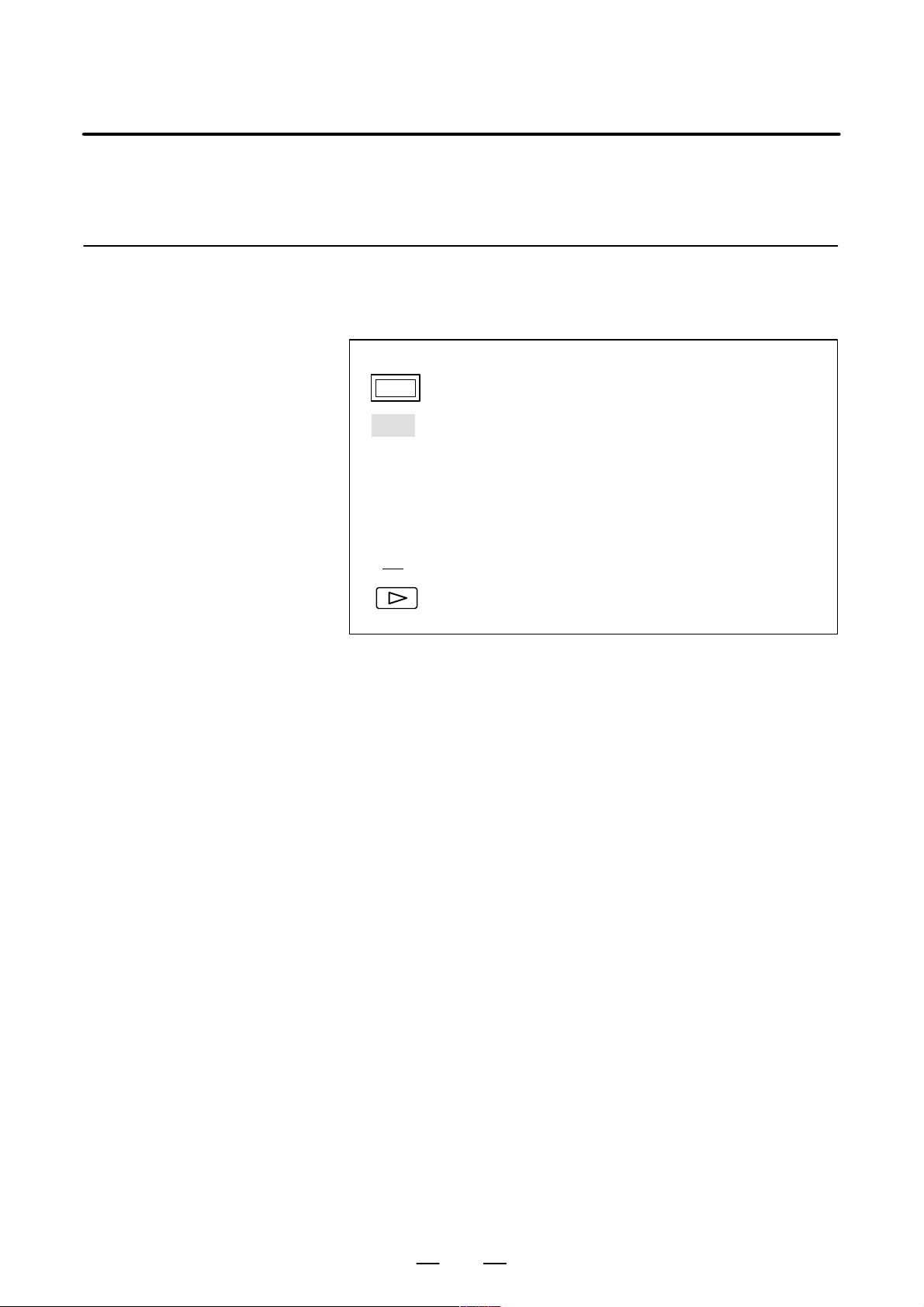

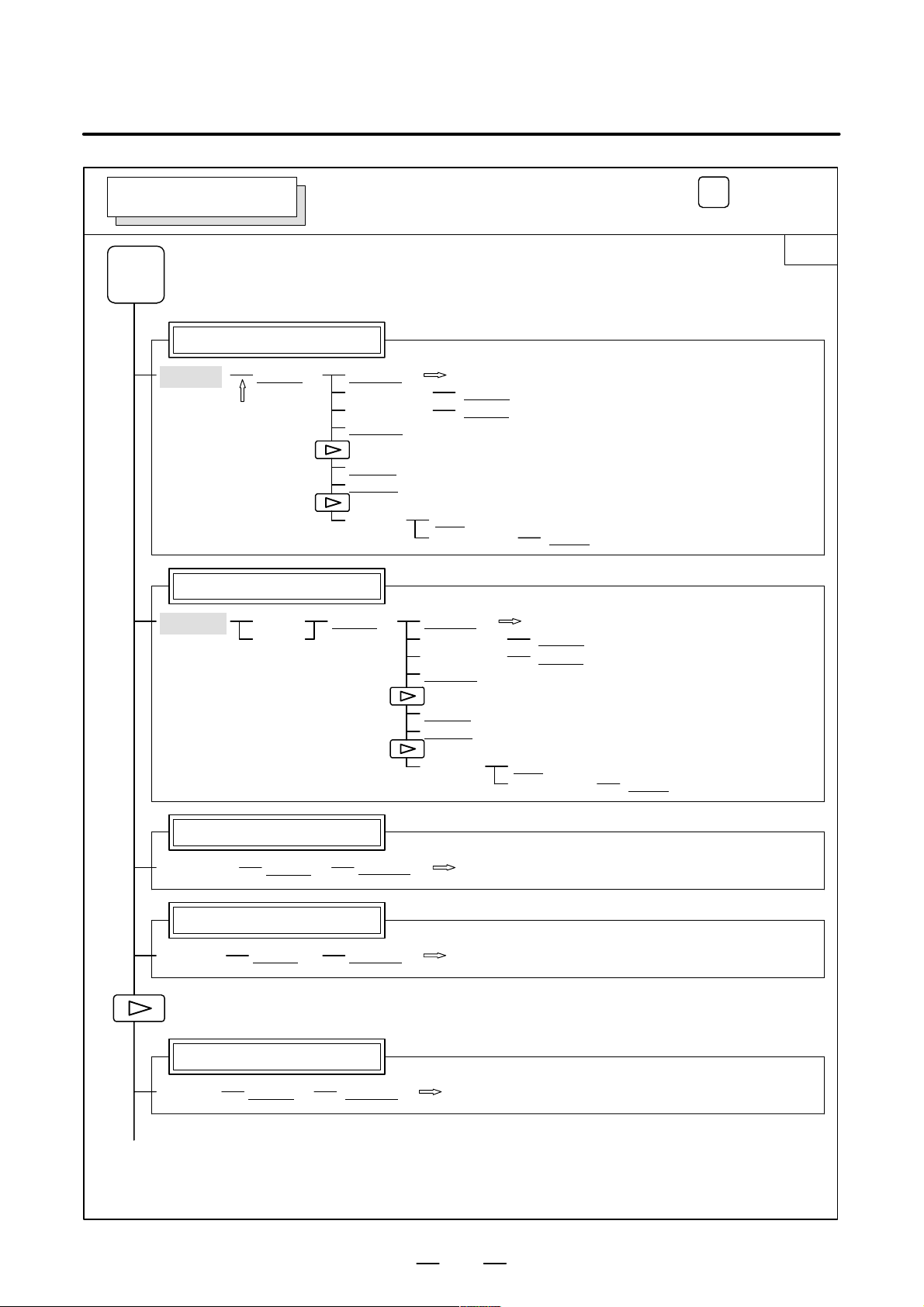

Operations and soft key display staturs for each function key are described

below:

T o display a more detailed screen, press a function key followed by a soft

key. Soft keys are also used for actual operations.

The following illustrates how soft key displays are changed by pressing

each function key.

The symbols in the following figures mean as shown below :

: Indicates screens

[]

()

[ ]

: Indicates a screen that can be displayed by pressing a

: Indicates a soft key(*2)

: Indicates input from the MDI panel.

: Indicates a soft key displayed in green (or highlighted).

: Indicates the continuous menu key (rightmost soft key)(*3).

function key(*1)

*1 Press function keys to switch between screens that are used frequently.

*2 Some soft keys are not displayed depending on the option configuration.

*3 In some cases, the continuous menu key is omitted when the 12 soft keys

type is used.

2

B–64115EN/02

1. DISPLAY AND OPERATION

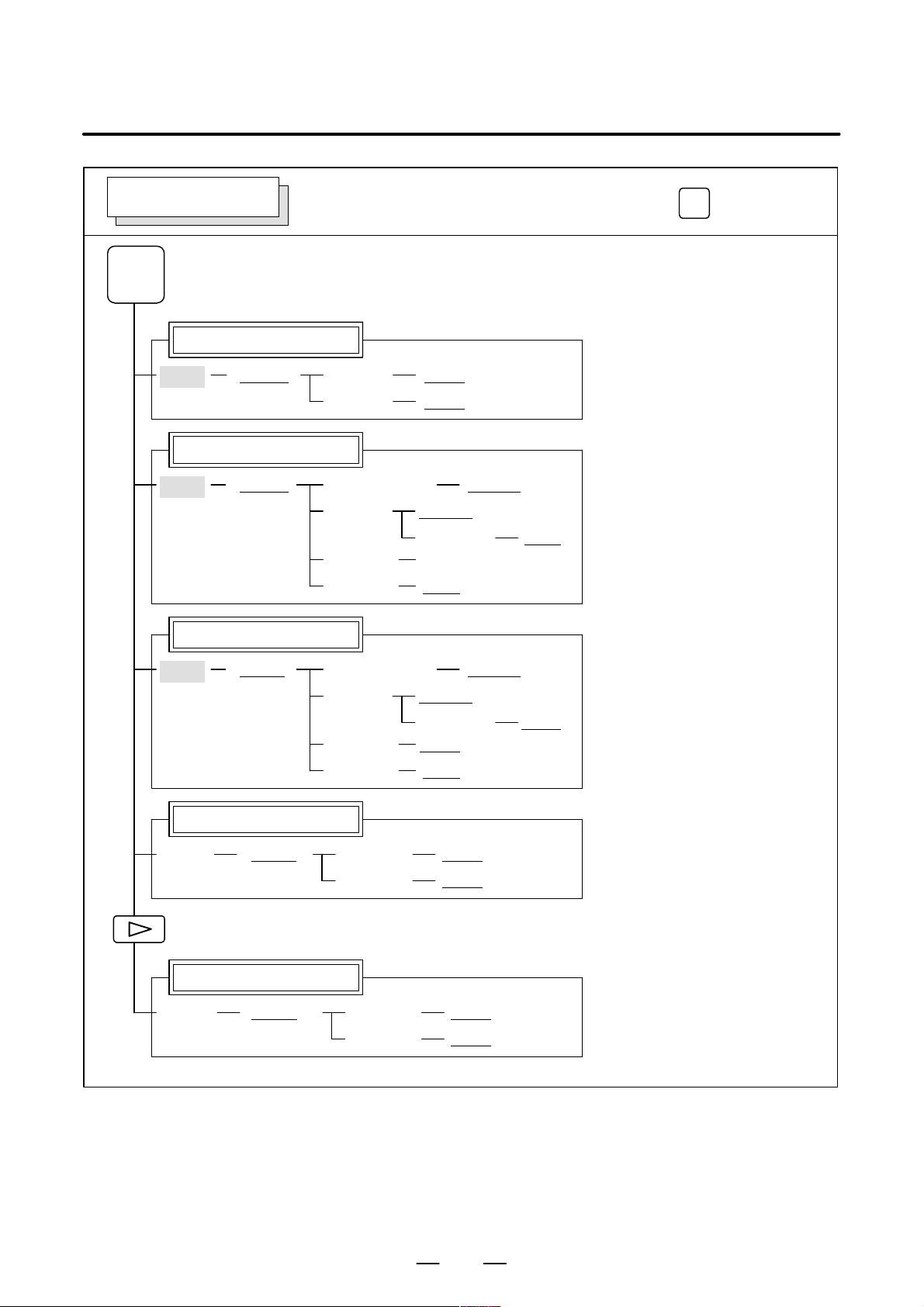

POSITION SCREEN

POS

Absolute coordinate display

[ABS]

Relative coordinate display

Current position display

[(OPRT)] [PTSPRE] [EXEC]

[(OPRT)][REL]

Soft key transition triggered by the function key

[RUNPRE] [EXEC]

(Axis or numeral)

[ORIGIN]

[PTSPRE] [EXEC]

[RUNPRE] [EXEC]

[ALLEXE]

(Axis name) [EXEC]

[PRESET]

POS

[ALL]

[(OPRT)]

Handle interruption

[HNDL]

Monitor screen

[MONI]

[(OPRT)] [PTSPRE] [EXEC]

[(OPRT)] [PTSPRE] [EXEC]

(Axis or numeral)

[ORIGIN]

[PTSPRE] [EXEC]

[RUNPRE] [EXEC]

[RUNPRE] [EXEC]

[RUNPRE] [EXEC]

[ALLEXE]

(Axis name) [EXEC]

[PRESET]

3

1. DISPLAY AND OPERATION

B–64115EN/02

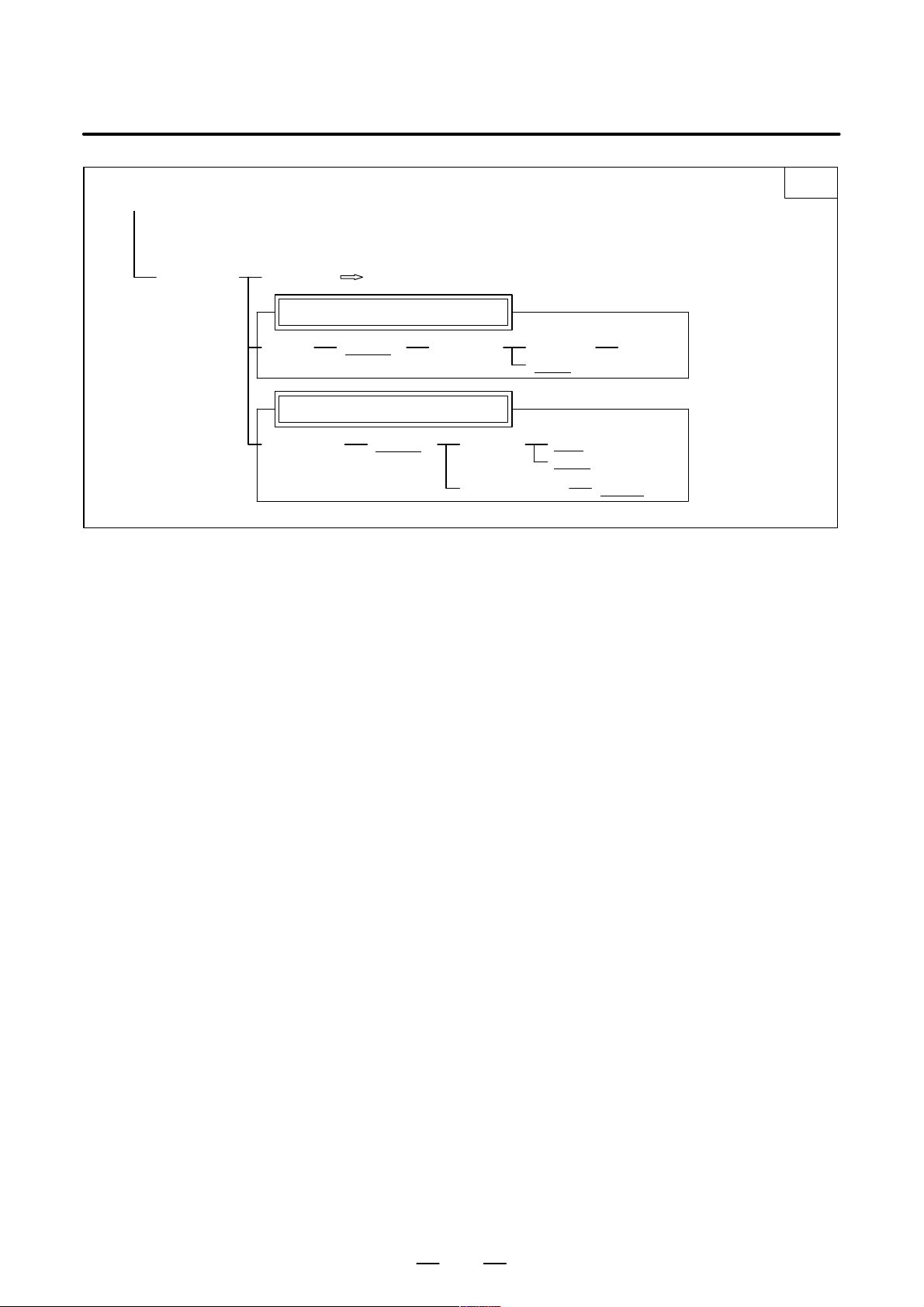

PROGRAM SCREEN

PROG

Program display screen

[PRGRM]

(1)

Program check display screen

Soft key transition triggered by the function key

in the MEM mode

[(OPRT)] [BG–EDT]

(O number)

(N number)

[REWIND]

[P TYPE]

[Q TYPE]

[F SRH]

[ABS]

[REL]

[(OPRT)][CHECK]

See “When the soft key [BG–EDT] is pressed”

[O SRH]

[N SRH]

[CAN]

(N number)

[BG–EDT]

(O number)

(N number)

[REWIND]

[EXEC]

See “When the soft key [BG–EDT] is pressed”

[O SRH]

[N SRH]

PROG

1/2

Current block display screen

[(OPRT)]

Next block display screen

[(OPRT)] [BG–EDT][NEXT]

Program restart display screen

[(OPRT)] [BG–EDT][RSTR]

(2)(Continued on the next page)

[P TYPE]

[Q TYPE]

[F SRH]

[BG–EDT][CURRNT]

See “When the soft key [BG–EDT] is pressed”

[CAN]

(N number)

[EXEC]

See “When the soft key [BG–EDT] is pressed”

See “When the soft key [BG–EDT] is pressed”

4

B–64115EN/02

1. DISPLAY AND OPERATION

(2)

[FL.SDL] [PRGRM]

Return to (1) (Program display)

File directory display screen

[(OPRT)][DIR] [SELECT]

Schedule operation display screen

[SCHDUL] [CLEAR]

[(OPRT)]

(Schedule data)

2/2

(File No. ) [F SET]

[EXEC]

[CAN]

[EXEC]

[INPUT]

5

1. DISPLAY AND OPERATION

B–64115EN/02

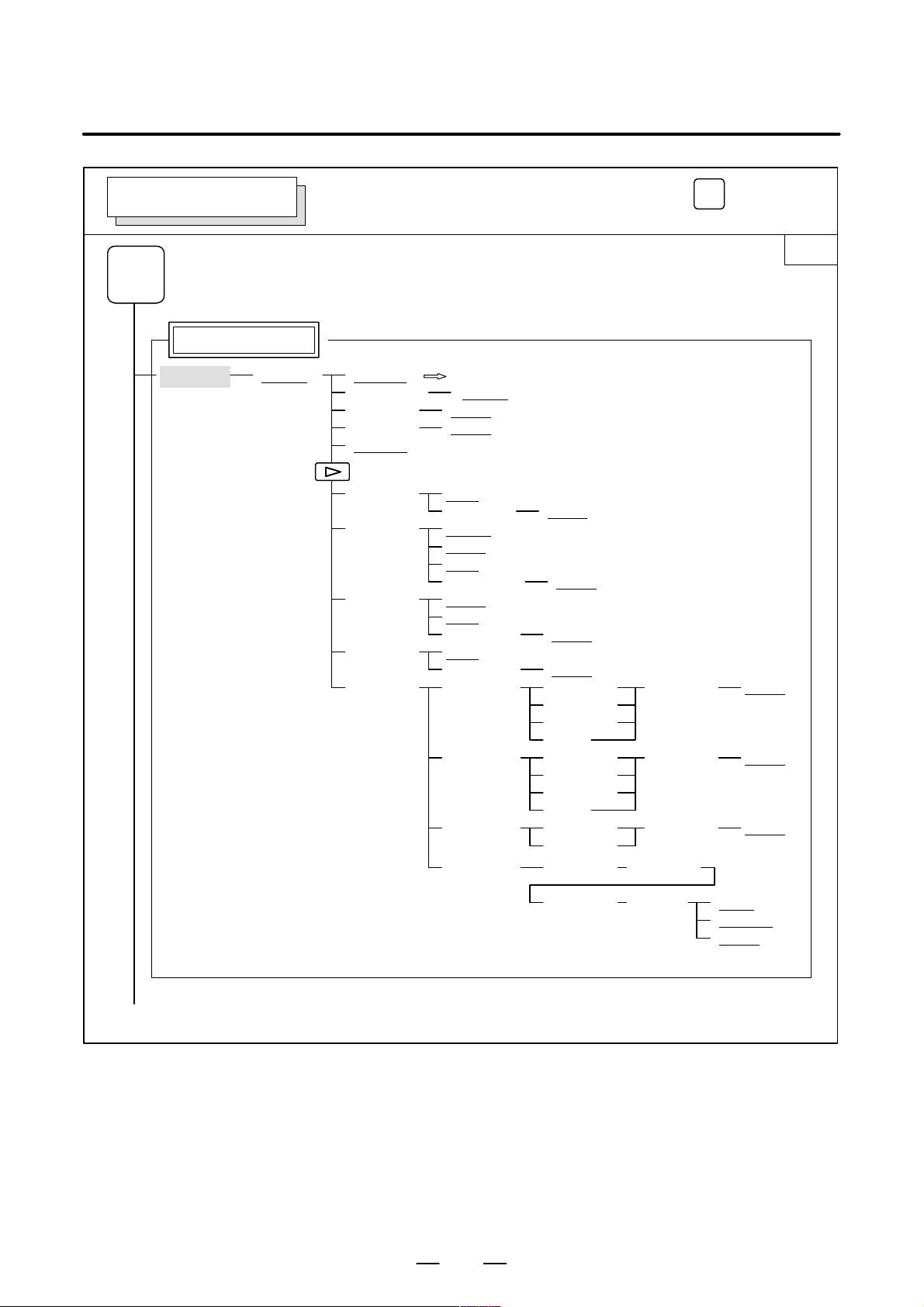

PROGRAM SCREEN

PROG

Program display

[PRGRM]

Soft key transition triggered by the function key

in the EDIT mode

[(OPRT)] [BG–EDT]

(O number) [O SRH]

(Address) [SRH↓]

(Address) [SRH↑]

[REWIND]

[F SRH] [CAN]

[READ] [CHAIN]

[PUNCH] [STOP]

[DELETE] [CAN]

[EX–EDT] [COPY] [CRSR∼]

PROG

See “When the soft key [BG–EDT] is pressed”

(N number) [EXEC]

(The cursor moves to the end of a program.)

[STOP]

[CAN]

(O number)

[CAN]

(O number)

(N number)

[MOVE] [CRSR∼]

[MERGE] [∼CRSR]

[CHANGE] (Address) [BEFORE]

[EXEC]

[EXEC]

[EXEC]

(O number) [EXEC]

[∼CRSR]

[∼BTTM]

[ALL]

(O number) [EXEC]

[∼CRSR]

[∼BTTM]

[ALL]

(O number) [EXEC]

[∼BTTM]

1/2

(1)(Continued on the next page)

(Address) [AFTER] [SKIP]

[1–EXEC]

[EXEC]

6

Loading...

Loading...