Emerson ACM1600M-XXX, ACM1000M-XXX, ACM1400M-XXX, ACM2000M-XXX User Manual

Media Air Cleaner

With Media Filter

Model Number

ACM1000M-XXX

ACM1400M-XXX

ACM1600M-XXX

ACM2000M-XXX

OWNERS MANUAL

•Installation

•Operation

•Maintenance

Please read and familiarize yourself with the contents of this manual before installing, operating or performing maintenance on the unit.

White-Rodgers is a division |

PART NO. 37-7001A |

of Emerson Electric Co. |

|

www.white-rodgers.com |

0922 |

INTRODUCTION

The Emerson Media Air Cleaner comes complete with a 4” media furnace air fi lter. This fi lter must be changed every three to six months to maintain effi ciency of the fi lter and furnace system.

Please read instructions before installing and using the Air Filter Compartment.

! CAUTION

The fiber filter used in this cabinet for air cleaning must be replaced every 90 to 180 days. Your heating and cooling efficiency will decrease due to insufficient air flow when filter becomes dirty.

!WARNING

Do not attempt installation of this unit unless you are familiar with the necessary tools, equipment, and potential hazards.

Installation should be performed only by a qualified service provider.

Failure to do so could result in reduced performance of the unit, serious personal injury or death.

GUARANTEE

Emerson will not assume any responsibility for component failures due to incorrect installation procedures.

RULES FOR SAFE INSTALLATION

AND OPERATION

1.Read the Owners Manual and the Rules for Safe Operation carefully. Failure to follow these rules and instructions could cause a malfunction of fi lter or unsatisfactory service.

!WARNING

Installation of this unit must comply with local electric codes or other applicable codes.

Review and understand local codes prior to installation.

!WARNING

Before installing or servicing, always shut off electricity. This will prevent any electrical shocks.

2.Follow a regular service and maintenance schedule for effi cient operation.

TABLE OF CONTENTS |

|

Rules for Safe Installation and Operation ...................... |

2 |

How the Air Filter Works ................................................ |

3 |

Construction of the Air Filter Compartment ................... |

3 |

Preinstallation................................................................ |

4 |

Installation ..................................................................... |

6 |

Maintenance.................................................................. |

6 |

BASIC TOOLS REQUIRED

•Tin Snip

•Screwdriver

•Ruler or Tape Measure

•Drill

DID YOU GET THE RIGHT SIZE

AIR FILTER COMPARTMENT

Model ACM1000M are designed for heating or cooling blowers delivering 600 to 1200 cubic feet of air per minute (cfm.)

Model ACM1400M are designed for heating or cooling blowers delivering 1000 to 1600 cfm.

Model ACM1600M are designed for heating or cooling blowers delivering 1200 to 1800 cfm.

Model ACM2000M are designed for heating or cooling blowers delivering 1600 to 2200 cfm.

Before installing the fi lter, make sure you have selected the proper size unit for your heating and cooling system requirements. See specifi cations on page 4.

2

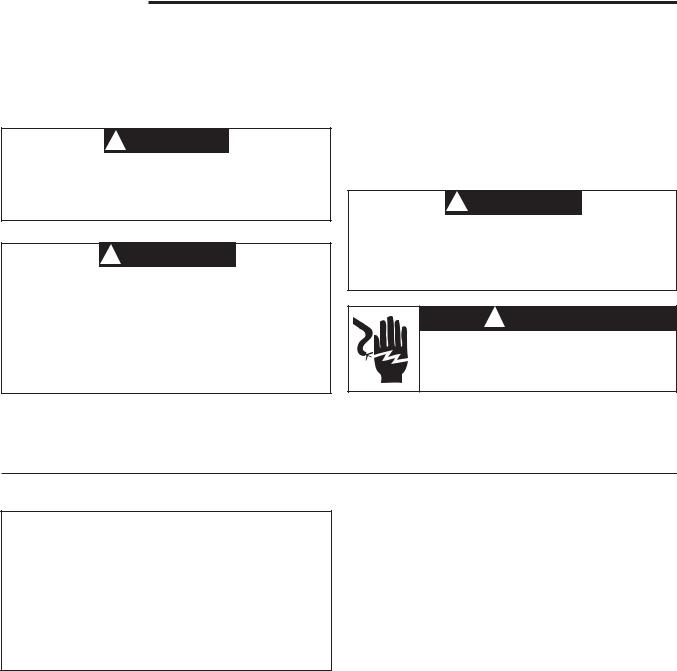

HOW THE AIR FILTER WORKS |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

Dirty air fl ows through your return air ducts and enters the |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

compartment where particles (hair, lint, etc.) are removed by |

|

|

|

4" FILTER |

|||||||||||||||||

the fi lter. See fi gure 1. |

|

|

|

||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

Filtered air re-enters to the supply duct system of your |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

building. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

DIRTY AIR IN |

|

|

|

|

|

|

|

FILTERED AIR OUT |

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Figure 1

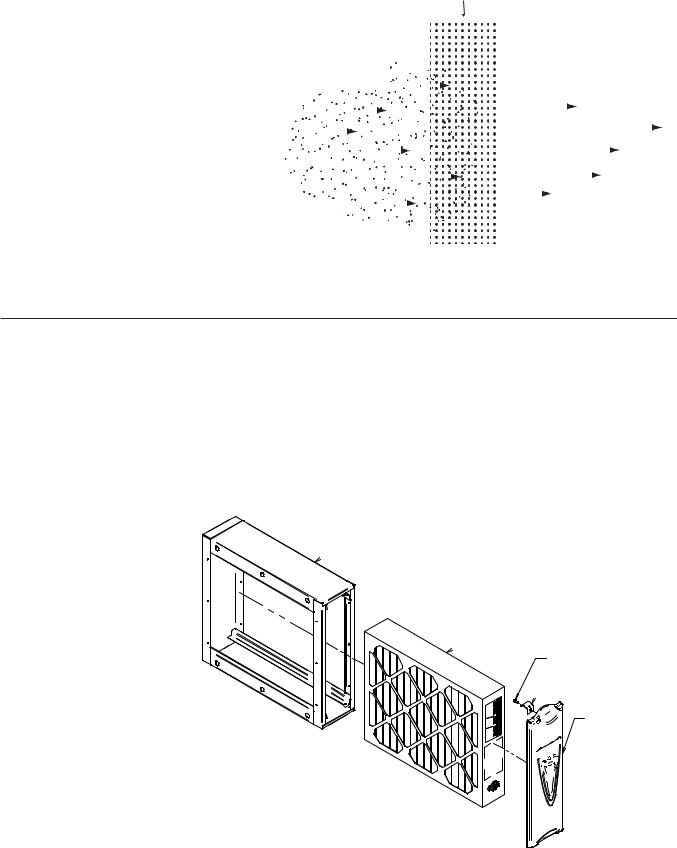

CONSTRUCTION OF THE AIR FILTER

COMPARTMENT

Not only is your air fi lter compartment easy to install, it is also easy to maintain. Its basic components, and their functions, are as follows: (See Figure 2)

Air Filter Cabinet – mounts to existing duct work and houses the fi lters

4” Filter – collects dust, dirt and other particles.

AIR FILTER CABINET

AIR FILTER CABINET

FILTER

FILTER

SCREW

LATCH

LATCH

DOOR

Figure 2

3

Loading...

Loading...