Emerson 98 Data Sheet

Bulletin 71.4:98

November 2009

98 Series Backpressure Regulators

and Relief Valves

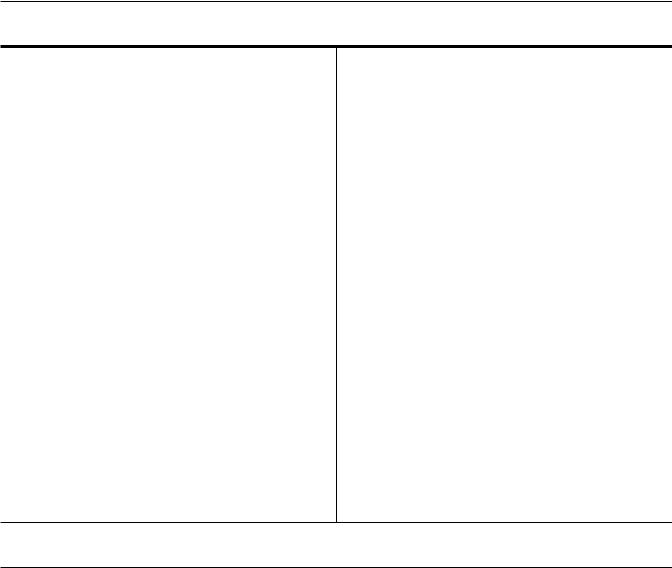

W6155

TYPE 98H

W6158

TYPE 98HD

Figure 1. Typical 98 Relief Valves

Introduction

The 98 Series (Figure 1) is used for backpressure or relief applications in liquid, gas, air, and steam service. The Types 98L, 98H, and 98HH are directoperated and spring-loaded. The Types 98LD and

98HD use additional pressure loading to maintain relief differential pressures, backpressures or for remote setpoint adjustment.

The Type 98HM is a direct-operated, spring to close regulator for backpressure or relief applications in liquid, gas, or steam service. The regulator requires no external power to operate and features a sensing line connection for sensing pressure externally from the regulator. A seal washer for the set screw can be included when applications require pressure loading of the spring case (not available on NPS 1-1/2 and 2 bodies (DN 40 and 50)).

Using a Type 98HM as a relief valve does not exclude the installation of an ASME certified full flow valve as specified by local codes and regulations or system design.

Hastelloy® C is a mark owned by Haynes International, Inc.

Monel® is a mark owned by Special Metals Corporation.

W6157

TYPE 98LD

W6156

TYPE 98L

Features

• Versatility—Typical applications include

backpressure on pumps, maintaining differential

pressure across lubricated seals, steam header

pressure, fuel and oil lines, air supply systems, pump bypass applications for API general and special purpose lube and seal oil systems, relief applications for flash tanks and accumulators, and other process and industrial uses.

• Excellent Fluid Compatibility—Diaphragms come

in stainless steel, Monel®, Hastelloy® C, or elastomers, and body is available in cast iron and steel as well as

stainless steel, Hastelloy® C, and Monel®. Corrosion-

resistant trims are available.

• Close, Stable Regulation—Diaphragm is isolated

from the main flow stream. Slotted valve plug and

pusher post assembly provides positive guiding for

improved shutoff.

• Compact Design—Small size allows easy

installation in limited spaces.

D100153X012

www.fisherregulators.com

Bulletin 71.4:98

Specifications

Available Constructions

Type 98L: Direct-operated low-pressure backpressure/relief valve with internal pressure registration and standard adjusting screw for

2 to 38 psig (0,14 to 2,6 bar) set pressure range

Type 98LD: Pressure-loaded low-pressure backpressure/relief valve with internal pressure registration and handwheel adjustment for 2 to 38 psi (0,14 to 2,6 bar) differential set pressure range

Type 98H: Direct-operated high-pressure backpressure/relief valve with internal pressure registration and standard adjusting screw for

5 to 200 psig (0,35 to 13,8 bar) set pressure range

Type 98HD: Pressure-loaded low-pressure

backpressure/relief valve with internal pressure registration and handwheel adjustment for

5 to 200 psi (0,35 to 13,8 bar) differential set pressure range

Type 98HH: Direct-operated high-pressure

backpressure/relief valve with internal pressure registration and standard adjusting screw for 150 to 375 psig (10,3 to 25,9 bar) set pressure range

Type 98HHD: Pressure-loaded high-pressure

backpressure/relief valve with internal pressure registration and handwheel adjustment for 150 to 375 psi (10,3 to 25,9 bar) differential set pressure range

Type 98HM: Direct-operated high-pressure backpressure/relief valve with external pressure registration and standard adjusting screw for 5 to 275 psig (0,35 to 19,0 bar) set pressure range

Body Sizes and End Connection Styles

|

BODY MATERIAL |

||

TYPES |

|

WCC Steel, |

|

Cast Iron |

CF8M Stainless steel, |

||

|

|||

|

|

Hastelloy® C, Monel® |

|

|

|

1/4 through 1 NPT, |

|

98L and 98LD |

1/4, 1/2, 3/4, 1 NPT |

NPS 1/2 through 1 SWE, |

|

CL150RF, CL300RF, |

|||

|

|

||

|

|

PN 16/25/40 RF |

|

|

|

1/4 through 2 NPT, |

|

98H and 98HD |

1/4, 1/2, 3/4, 1, |

NPS 1/2 through 2 SWE, |

|

1-1/2, 2 NPT |

CL150 RF, CL300 RF, |

||

|

|||

|

|

PN 16/25/40 RF |

|

98HM |

- - - - |

1/2, 3/4, 1, 1-1/2, 2 NPT |

|

98HH, 98HHD |

1/4, 1/2, |

3/4, 1 NPT |

|

Construction Materials

BODY |

SPRING CASE |

Cast iron, WCC Steel, CF8M |

Cast iron, WCC Steel, or |

Stainless steel, Monel®, or |

|

Hastelloy® C |

CF8M Stainless steel |

Trim Materials

See Table 1

Maximum Cold Working Pressures of Body Size

and Material(1)(3)

|

BODY |

BODY AND |

MAXIMUM INLET |

|

REGULATOR |

SPRING CASE |

PRESSURE(2)(4) |

||

|

SIZE |

MATERIALS |

PSIG (bar) |

|

|

|

|||

|

|

Cast Iron |

60 (4,1) |

|

Type 98L |

All Sizes |

Steel |

125 (8,6) |

|

|

|

Stainless Steel |

125 (8,6) |

|

|

|

|

|

|

|

|

Cast Iron |

60 (4,1) |

|

Type 98LD |

All Sizes |

Steel |

150 (10,3) |

|

|

|

Stainless Steel |

150 (10,3) |

|

|

|

Cast Iron |

300 (20,7) |

|

Type 98H |

All Sizes |

Steel |

300 (20,7) |

|

|

|

Stainless Steel |

300 (20,7) |

|

|

|

Cast Iron |

300 (20,7) |

|

Type 98HD |

All Sizes |

Steel |

400 (27,6) |

|

|

|

Stainless Steel |

400 (27,6) |

|

Type 98HH, |

|

Cast Iron |

400 (27,6) |

|

All Sizes |

Steel |

400 (27,6) |

||

98HHD |

||||

|

Stainless Steel |

400 (27,6) |

||

|

|

|||

|

|

|

|

|

Type 98HM |

All Sizes |

Steel |

300 (20,7) |

|

Stainless Steel |

300 (20,7) |

|||

|

|

|||

|

|

|

|

Relief Pressure Ranges

See Table 2

Temperature Capabilities for Elastomer Parts(1)(5)

MATERIAL |

TEMPERATURE RANGE |

Nitrile (NBR) |

-40° to 180°F (-40° to 82°C) |

|

|

Neoprene (CR) |

-40° to 180°F (-40° to 82°C) |

|

|

Fluorocarbon (FKM)(6) |

0° to 300°F (-18° to 149°C) |

|

Limited to 200°F (93°C) for hot water |

Ethylenepropylene (EPDM)(6) |

-40° to 275°F (-40° to 135°C) |

Perfluoroelastomer (FFKM)(6) |

0° to 425°F (-18° to 218°C) |

Polytetrafluoroethylene (PTFE) |

-40° to 400°F (-40° to 204°C) |

Diaphragm protector(6) |

1. The pressure/temperature limits in this Bulletin and any applicable standard limitation should not be exceeded.

2. Loading pressure plus spring setting should not exceed maximum inlet pressure.

3. Temperature and/or the body end connection may decrease these maximum pressures. 4. Maximum inlet pressure equals set pressure plus build-up.

5. Pressure and/or the body end connection may decrease these maximum temperatures.

6. Not for use on steam service.

7. Not available for Type 98HM.

2

Bulletin 71.4:98

Specifications (continued)

Temperature Capabilities for Metal Parts(1)(5)

MATERIAL |

TEMPERATURE RANGE |

Cast Iron(7) |

-40° to 406°F (-40° to 208°C) |

WCC Steel |

-20° to 450°F (-29° to 232°C) |

|

|

CF8M Stainless steel, Monel®, or |

-40° to 450°F (-40° to 232°C) |

Hastelloy® C |

Maximum Spring Case Loading Pressure for Types 98LD and 98HD (Spring Setting Plus Loading Pressure)(1)(2)

Type 98LD Spring Case

Cast Iron: 50 psig (3,4 bar)

Steel or Stainless steel: 125 psig (8,6 bar)

Type 98HD Spring Case

Cast Iron: 235 psig (16,2 bar)

Steel or Stainless steel: 300 psig (20,7 bar)

Type 98HHD Spring Case

Cast Iron: 250 psig (17,2 bar)

Steel or Stainless steel: 250 psig (17,2 bar)

Capacities

Types 98L and 98LD: See Tables 3 through 7 Types 98H and 98HD: See Tables 8 through 12 Type 98HH and 98HHD: See Tables 13 through 17 Type 98HM: See Tables 18 through 21

Shutoff Classification Per ANSI/FCI 70-3-2004

Metal Seats: Class IV

PTFE: Class IV

Elastomer Seats: Class VI

Flow Coefficient

C1: 35

Type 98HM Sensing Line Connection 1/2, 1-1/2, or 2 NPT body: 1/8 NPT 3/4 or 1 NPT body: 1/4 NPT

IEC Sizing Coefficients

BODY SIZES, |

XT |

FD |

FL |

Km |

|

NPS (DN) |

|||||

|

|

|

|

||

1/4 |

|

|

0.91 |

0.83 |

|

|

|

|

|

|

|

1/2 (15) |

|

|

0.83 |

0.69 |

|

|

|

|

|

|

|

3/4 and 1 |

0.78 |

0.50 |

0.88 |

0.77 |

|

(20 and 25) |

|

|

|||

|

|

|

|

||

1-1/2 and 2 |

|

|

0.92 |

0.85 |

|

(40 and 50) |

|

|

|||

|

|

|

|

||

|

|

|

|

|

Options

• Handwheel or tee handle for Types 98L, 98H, and 98HH

• Tapped spring case vent for Types 98L, 98H,

98HH, and 98HM

• Seal washer to permit spring case pressure loading for Types 98L, 98H, 95HH, and 98HM

1. The pressure/temperature limits in this Bulletin and any applicable standard limitation should not be exceeded.

2. Loading pressure plus spring setting should not exceed maximum inlet pressure.

5. Pressure and/or the body end connection may decrease these maximum temperatures. 7. Not available for Type 98HM.

• Differential Pressure Capability—Spring-loaded

PTFE packing and tapped connections permit pressure loading of Types 98LD and 98HD spring cases.

• Handwheels—Handwheels (standard on the

Types 98LD and 98HD and optional on some sizes of the Types 98L and 98H) allow easy pressure setting changes.

• Sour Gas Service Capability—Optional

materials are available for applications handling

sour gases. These constructions comply with

the recommendations of NACE International

Standards MR0175 and MR0103.

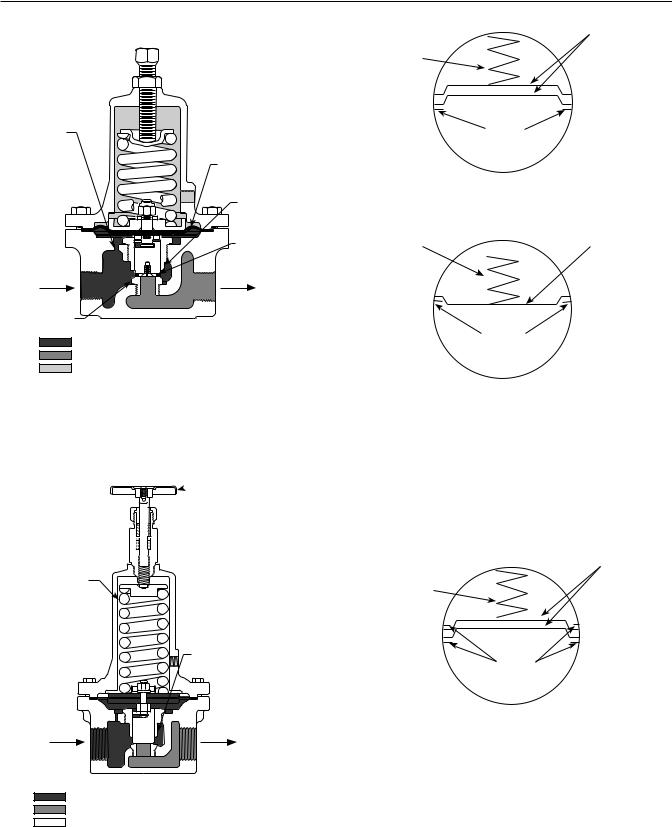

Principle of Operation

Relief or backpressure valves respond to changes in upstream pressure. Pressure changes register under the diaphragm (see Figure 2) through a registration

hole in the valve body (through upstream sensing line connection for Type 98HM). When the pressure increases beyond the spring setting, the diaphragm pressure overcomes the spring compression. This causes the valve plug to move away from the orifice. The flow line through the valve is open and excess pressure is vented. When upstream pressure drops back to normal, the valve resumes its closed position.

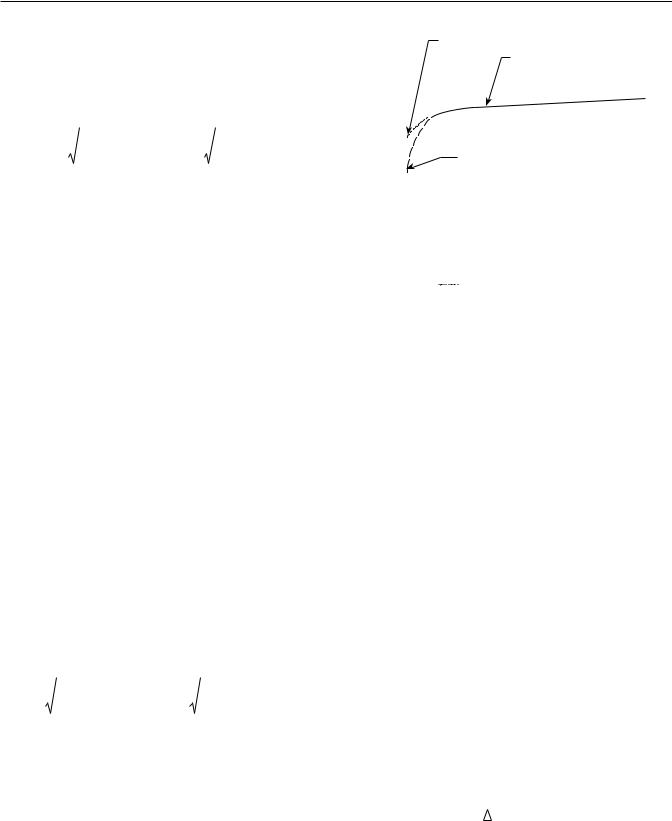

The chart in Figure 3 illustrates the operation of an NPS 1/2 (DN 15) body used in air service. As the inlet pressure increases, initial flow occurs at the bubble point of 10.5 psig (0,72 bar). Flow increases with further rises in the inlet pressure, reaching

500 SCFH (13,4 Nm3/h) at the relief pressure setting of 12 psig (0,83 bar). Greater capacities are obtained with higher build-ups over the relief pressure setting, as shown in the capacity tables.

When the inlet pressure decreases, flow decreases until the valve reseals to reseat point of 9 psig (0,62 bar).

3

Bulletin 71.4:98

REGISTRATION

HOLE

COMP |

METAL DIAPHRAGMS

SPRING

|

|

|

|

|

GASKET |

|

|

|

|

|

|

|

|

|

|

DIAPHRAGM |

|

|

|

|

|

|

FOR TYPE 98H WITH TWO METAL DIAPHRAGMS |

|

|

|

|

VALVE PLUG |

(ALSO TYPICAL OF 98HH AND 98L EXCEPT FOR |

|

|

|

|

||

|

|

|

|

TYPE 98L, 1/4 NPT, 2 TO 7 PSI (0,14 TO 0,48 bar) RANGE) |

|

|

|

|

|

|

|

|

|

|

|

|

|

O-RING SEAT |

SPRING |

METAL DIAPHRAGMS |

|

||

|

|

ORIFICE

GASKET

INLET PRESSURE

OUTLET PRESSURE

ATMOSPHERIC PRESSURE

A6925

TYPE 98L (1/4 NPT, 2 TO 7 PSI (0,14 TO 0,48 bar) RANGE)

WITH ONE METAL DIAPHRAGM

TYPE 98H (ALSO TYPICAL OF 98L AND 98HH)

HANDWHEEL

HANDWHEEL

METAL DIAPHRAGMS

CONTROL SPRING

SPRING

VALVE PLUG GUIDE

GASKET

FOR TYPE 98HD/LD/HHD WITH TWO METAL DIAPHRAGMS,

ASSEMBLE DIAPHRAGM GASKETS UNDER AND ABOVE

THE METAL DIAPHRAGMS AS SHOWN ABOVE

INLET PRESSURE

OUTLET PRESSURE

LOADING PRESSURE

M1005

TYPE 98HD (ALSO TYPICAL OF 98LD AND 98HHD)

Figure 2. 98 Series Operational Schematic

4

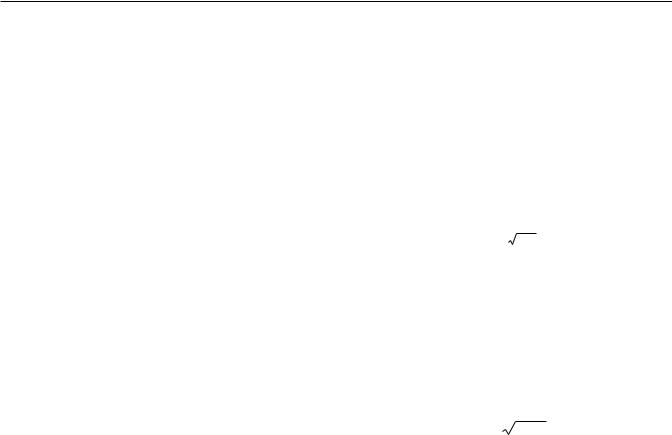

Bulletin 71.4:98

METAL DIAPHRAGMS

SPRING

GASKET

TO UPSTREAM

TO UPSTREAM

SENSING LINE

FOR TYPE 98HM WITH TWO METAL DIAPHRAGMS,

ASSEMBLE DIAPHRAGM GASKETS UNDER AND ABOVE

THE METAL DIAPHRAGMS AS SHOWN ABOVE

INLET PRESSURE

OUTLET PRESSURE

ATMOSPHERIC PRESSURE

M1155

TYPE 98HM

Figure 2. 98 Series Operational Schematic (continued)

Once the valve has resealed, leakage will not occur again until the bubble point pressure of 10.5 psig (0,72 bar) is reached.

Table 22 shows typical pressure differences between the relief pressure setting and the bubble point, and between the relief pressure setting and the reseat point. These differences are to be used in conjunction with the capacity tables to determine the total inlet pressure increase required to develop the tabulated flows and to determine the actual inlet pressure reductions required for reseat point.

Capacity Information

Relieving capacities at selected pressures and outlet pressure flows are given in SCFH (60°F and 14.7 psia) of air in Tables 6, 7, 11, 12, 16, 17, 18, and 19. To determine the equivalent capacities for other gases, multiply the table capacities by the following appropriate conversion factors: 1.29 for 0.6 specific gravity natural gas, 0.808 for propane, 0.707 for butane, or 1.018 for nitrogen. For gases of other specific gravities, divide by the square root of the appropriate specific gravity.

Then, if capacity is desired in normal cubic meters per hour at 0°C and 1,01325 bar, multiply SFCH by 0.0168.

Typical relieving capacities in pounds per hour and kilogram per hour of saturated steam are shown in Tables 5, 10, and 15.

Tables 3, 4, 8, 9, 13, 14, 20, and 21 gives relieving capacities in U.S. gallons per minute and in liters per minute of water.

Sizing

Determine Flow Rates for units used as differential relief valves as follows:

Air and Steam Service

When the Capacity Information section do not cover the actual service conditions, it will be necessary to calculate the flow rate available from the relief valve.

Step 1.

From the Capacity Information section determine a flow rate using the closest available data for setpoint

5

Bulletin 71.4:98

and build-up. With this information, calculate a flow coefficient using the following:

Equation 1:

Q

Cg = |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

3417 |

|

|

|

|

|

|

|

|

|

520 |

P SIN |

|

|

∆P |

|

DEG |

||||

|

|

|

GT |

) |

C1 |

|

P1a ) |

|||||

|

|

|

1a |

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

Cg |

= Calculated Flow coefficient |

Q |

= Flow rate from tables (SCFH) |

P1a |

= Inlet pressure from table (set pressure and |

|

build-up) converted to absolute pressure |

G = Specific gravity

T = Absolute temperature of gas at inlet degrees Rankine = °F + 460

P1 |

= Absolute inlet pressure, psia = psig + 14.7 |

C1 |

= 35 |

∆P |

= P1 - P2, psid |

Calculate the Cg coefficient for the setting and build-up nearest to the desired service conditions within the selected spring range. Then use this Cg to calculate the approximate flow available for the actual setpoint and build-up desired. Available Cg will vary based upon setpoint, differential pressure, build-up, and spring range.

Step 2.

Calculate the actual flow rate available using the coefficient from Step 1 and the actual inlet pressure

(setpoint plus build-up) and actual outlet pressure (if not atmospheric).

Equation 2: |

CgP1aSIN ) |

|

|

|

|

|

||

|

|

|

3417 |

|

|

|

|

|

QSCFH = |

520 |

|

∆P |

)DEG |

||||

|

GT |

C1 |

|

P1a |

||||

Example 1. Service Conditions:

Setpoint, 115 psi (7,9 bar) Build-up allowed, 10 psi (0,69 bar) Outlet discharges to atmosphere Require 13 200 SCFH (354 Nm3/h) air flow rate

|

16 (1,1) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

BUBBLE |

|

|

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

POINT |

|

|

|

|

|

|

|

|

|

|

|||||||||

|

14 |

(0,97) |

|

|

|

|

|

|

|

12 PSIG (0,83 bar) RELIEF |

|

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

SETTING 500 SCFH (13,4 Nm3/h) |

|

|

||||||

(bar) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

FLOW AT RELIEF SETTING |

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

NPS 1/2 (DN 15) TYPE 98L |

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

PSIG |

12 |

(0,83) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

PRESSURE, |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

10.5 |

(0,72) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

10 |

(0,69) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

TIGHT |

|

|

|

|

|

|

|

|

|

|||||||

INLET |

9 |

(0,62) |

|

|

|

|

|

SHUTOFF |

|

|

|

|

|

|

|

|

||||||||

8 (0,55) |

|

|

|

|

|

POINT |

|

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

6 |

(0,41) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

500 (13,4) |

1000 (26,8) |

|

1500 (40,2) |

|||||||||||||||||||

|

|

0 |

|

|||||||||||||||||||||

|

|

|

|

AIR FLOW, STANDARD CUBIC FEET PER HOUR (Nm3/h) |

||||||||||||||||||||

|

|

|

|

|

|

|

|

and |

|

|

|

|

|

|

|

INCREASING INLET PRESSURE |

|

|

|

|||||

A1309-1 |

|

|

|

|

|

|

and |

|

|

|

|

|

|

DECREASING INLET PRESSURE |

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

Figure 3. Typical Bubble Point and Reseat Point Performance

From Table 11, select NPS 3/4 or 1 (DN 20 or 25) body, red spring for 100 psi (6,9 bar) setpoint, and

10 psi (0,69 bar) build-up. The Type 98H will flow

13 000 SCFH (348 Nm3/h) air.

Calculate Cg for these table conditions using Equation 1:

P1 |

= 100 psig (6,9 bar) + 10 psig (0,69 bar) |

|

build-up = 110 psig or 124.7 psia |

|

(7,6 bar g or 8,6 bar a) |

∆P |

= P1 - P2 = 110 psid (7,6 bar d) |

Q |

= 13 000 SCFH (348 Nm3/h) |

C1 |

= 35 |

Answer from Equation 1, Cg = 104*

*Since build-up relates to travel, this coefficient is valid for all pressure settings on the spring used in the calculation whenever the build-up is 10 psi (0,69 bar).

Now, solve for actual flow, Q, from the original service conditions using Equation 2:

P1 |

= 115 psig (7,9 bar) + 10 psig (0,69 bar) |

|

build-up = 125 psig or 139.7 psia |

|

(8,6 bar or 9,6 bar a) |

P2 |

= 0, therefore P = P1 - P2 = |

|

125 psig (8,6 bar) - 0 = 125 psid (8,6 bar d) |

Cg |

= 104 (from above) |

C1 |

= 35 |

6

Bulletin 71.4:98

Answer from Equation 2, Q = 14 500 SCFH

(389 Nm3/h) rated capacity. Since this capacity is greater than the 13 200 SCFH (354 Nm3/h) required, the relief valve may be used or the calculation could be repeated to try for a smaller body size.

Example 2. Service Conditions:

Setpoint, 165 psi (11,4 bar) Build-up allowed, 10 psi (0,69 bar)

Outlet discharges into pressured system of 50 psi (3,4 bar)

Require 3000 SCFH (80,4 Nm3/h) air flow rate

From Table 11, select NPS 3/4 or 1 (DN 20 or 25) body, blue spring. For 150 psi (10,3 bar) setpoint and

10 psi (0,69 bar) build-up, the Type 98H will flow

9000 SCFH (241 Nm3/h) air.

Calculate Cg for these table conditions using Equation 1:

P1 (inlet) |

= 150 psig (10,3 bar) + 10 psig |

|

(0,69 bar) build-up = 160 psig or |

|

174.7 psia (11,0 bar g or 12,0 bar a) |

∆P |

= P1 - P2 = 160 psig (11,0 bar) - 0 = |

160 psid (11,0 bar d) |

|

Q |

= 9000 SCFH (241 Nm3/h) |

C1 |

= 35 |

Answer from Equation 1, Cg = 51.5*

*Since build-up relates to travel, this coefficient is valid for all pressure settings on the spring used in the calculation whenever the build-up is 10 psi (0,69 bar).

Now, solve for actual flow, Q, from the original service conditions using Equation 2:

P1 |

= 165 psig (11,4 bar) + 10 psig (0,69 bar) |

|

build-up = 175 psig or 189.7 psia |

|

(12,1 bar g or 13,1 bar a) |

∆P |

= P1 - P2 = 170 psig (11,7 bar) - 50 psig |

|

(3,4 bar) = 120 psid (8,3 bar d) |

Cg |

= 51.5 (from above) |

C1 |

= 35 |

Answer from Equation 2, Q = 9500 SCFH (255 Nm3/h) rated capacity. Since this capacity is greater than the 3000 SCFH (80,4 Nm3/h) required, the relief valve may be used or the calculation could be repeated to try for a smaller body size.

Liquid Sizing for Liquids Other than Water

Step 1.

Determine Cv at build-up conditions of application.

|

|

Cv = |

Q |

|

|

|

∆P |

||

|

|

|

||

Q |

= Flow in GPM from capacity tables |

|||

|

∆P |

= Pressure drop in psi (setpoint and build-up) |

||

|

Cv |

= Valve sizing coefficient |

||

Step 2.

To determine flow rate for liquids other than water or flow rate for differential relief service:

Q = Cv ∆P/G

G = Specific gravity of fluid

Maximum Allowable Pressure Drop for Liquid Service

Pressure drops in excess of allowable will result in choked flow and possible cavitation damage.

To determine maximum allowable pressure drop for water:

∆P(allow) |

= Km (P1) |

∆P |

= Valve differential - PSI |

Km |

= Valve recovery coefficient from table |

P1 |

= Valve inlet pressure psig |

To determine maximum allowable pressure drop for fluids other than water, see Fisher® Catalog 10.

7

Bulletin 71.4:98

Table 1. Trim Materials

ELASTOMER SEAT |

STANDARD |

OPTIONAL |

Orifiice |

416 Stainless steel |

316 Stainless steel |

O-ring retainer |

416 Stainless steel |

316 Stainless steel |

Valve plug |

416 Stainless steel |

316 Stainless steel |

Valve plug guide |

416 Stainless steel |

316 Stainless steel |

Pusher post |

416 Stainless steel |

316 Stainless steel |

Diaphragm retaining washer |

316 Stainless steel |

302 Stainless steel |

Diaphragm |

Neoprene (CR) |

Fluorocarbon (FKM)(3) or Ethyleneproplylene (EPDM); |

|

|

PTFE protector available; 302 Stainless steel(2) |

O-ring seat |

Nitrile (NBR) |

Fluorocarbon (FKM), Ethyleneproplylene EPDM, Perfluoroelastomer (FFKM)(1) |

METAL SEAT |

STANDARD |

OPTIONAL |

Orifiice |

416 Stainless steel, hardened |

316 Stainless steel, Hastelloy® C, Monel® |

Valve plug |

416 Stainless steel, hardened |

316 Stainless steel, Hastelloy® C, Monel® |

Valve plug guide |

416 Stainless steel |

316 Stainless steel, Hastelloy® C, Monel® |

Pusher post |

416 Stainless steel |

316 Stainless steel, Hastelloy® C, Monel® |

Diaphragm |

302 Stainless steel(2) |

Neoprene (CR), Fluorocarbon (FKM)(3), PTFE protector available , Hastelloy® C, Monel® |

Diaphragm retaining washer |

Not used |

302 Stainless steel |

1. Available for Type 98HM only.

2. Two metal diaphragms will be used except only for Type 98L, 1/4 NPT, 2 to 7 psi (0,14 to 0,48 bar) range which uses only one metal diaphragm (see Figure 2 for assembly reference). 3. Two diaphragms will be used if elastomer diaphragm is Fluorocarbon (FKM)

Table 2. Spring Ranges for Relief or Differential Relief Pressures

BODY SIZES, |

RELIEF SET PRESSURE RANGE(1), PSIG OR PSI (bar) |

|

SPRING PART NUMBER |

SPRING COLOR |

||||

NPS (DN) |

Type 98L or 98LD |

Type 98H, 98HD, or 98HM |

Type 98HH or 98HHD |

|||||

|

|

|||||||

|

2 to 7 (0,14 to 0,48 bar) |

15 to 35 (1,0 to 2,4 bar) |

- - - - |

1E392527022 |

Yellow |

|||

|

|

|

|

|

|

|||

|

6 to 14 (0,41 to 0,97 bar) |

25 to 75 (1,7 to 5,2 bar) |

- - - - |

1E392627012 |

Green |

|||

|

|

|

|

|

|

|

||

1/4(2) |

12 to 25 (0,83 to 1,7 bar) |

70 to 140 |

(4,8 to 9,7 bar) |

- - - - |

1E392727142 |

Red |

||

|

20 to 38 (1,4 to 2,6 bar) |

130 to 200 |

(9,0 to 13,8 bar) |

- - - - |

1L346127142 |

Blue |

||

|

|

|

|

|

|

|

|

|

|

- - - - |

|

- - - - |

150 to 375 |

(10,3 to 25,9) |

1N942227142 |

Light Gray |

|

|

|

|

|

|

|

|

||

|

2 to 7 (0,14 to 0,48 bar) |

15 to 35 (1,0 to 2,4 bar) |

- |

- - - |

1E395627022 |

Yellow |

||

|

|

|

|

|

|

|

||

|

6 to 14 (0,41 to 0,97 bar) |

25 to 75 (1,7 to 5,2 bar) |

- |

- - - |

1D7455T0012 |

Green |

||

|

|

|

|

|

|

|

|

|

|

12 to 25 (0,83 to 1,7 bar) |

70 to 140 |

(4,8 to 9,7 bar) |

- |

- - - |

1E395727192 |

Red |

|

|

|

|

|

|

|

|

|

|

1/2 (15) |

20 to 38 (1,4 to 2,6 bar) |

130 to 200 |

(9,0 to 13,8 bar) |

- |

- - - |

1L380027142 |

Blue |

|

|

|

|

|

|

|

|

||

|

- - - - |

15 to 100(3) (1,0 to 6,9 bar) |

- |

- - - |

14B9943X012 |

Unpainted |

||

|

- - - - |

100 to 275(3) (6,9 to 19,0 bar) |

- |

- - - |

14B9942X022 |

Unpainted |

||

|

- - - - |

|

- - - - |

150 to 375 |

(10,3 to 25,9) |

1N943427142 |

Light Gray |

|

|

|

|

|

|

|

|

||

|

2 to 7 (0,14 to 0,48 bar) |

15 to 35 (1,0 to 2,4 bar) |

- |

- - - |

1E398927022 |

Yellow |

||

|

|

|

|

|

|

|

||

|

6 to 14 (0,41 to 0,97 bar) |

25 to 75 (1,7 to 5,2 bar) |

- |

- - - |

1E399027142 |

Green |

||

|

|

|

|

|

|

|

||

3/4, 1 |

12 to 25 (0,83 to 1,7 bar) |

70 to 140 |

(4,8 to 9,7 bar) |

- - - - |

1E399127162 |

Red |

||

|

|

|

|

|

|

|

||

20 to 38 (1,4 to 2,6 bar) |

130 to 200 |

(9,0 to 13,8 bar) |

- - - - |

1L380127082 |

Blue |

|||

(20, 25) |

||||||||

|

|

|

|

|

|

|

||

|

- - - - |

15 to 100(3) (1,0 to 6,9 bar) |

- - - - |

14B9944X022 |

Unpainted |

|||

|

- - - - |

100 to 275(3) (6,9 to 19,0 bar) |

- - - - |

14B9945X022 |

Unpainted |

|||

|

- - - - |

|

- - - - |

150 to 375 |

(10,3 to 25,9) |

1N944127182 |

Black Stripe |

|

|

|

|

|

|

|

|

||

|

- - - - |

5 to 35 (0,34 to 2,4 bar) |

- |

- - - |

1E792327092 |

Dark Gray |

||

|

|

|

|

|

|

|||

1-1/2, 2 |

- - - - |

20 to 65 (1,4 to 4,5 bar) |

- - - - |

1E795327082 |

Light Blue |

|||

(40, 50) |

- - - - |

50 to 100 |

(3,4 to 6,9 bar) |

- - - - |

1E795427082 |

Light Gray |

||

|

||||||||

|

|

|

|

|

|

|||

|

- - - - |

80 to 170 (5,5 to 11,7 bar) |

- - - - |

1P788827082 |

Black |

|||

|

|

|

|

|

|

|

|

|

1. All springs may be backed off to 0 psig (0 bar). However, highest capacities and best performances are obtained by using these springs in their recommended ranges. Psi rather than psig are used for differential relief constructions.

2. Not available for Type 98HM.

3. Only available for Type 98HM. Stainless steel construction.

8

Bulletin 71.4:98

Table 3. Water Relief Capacities in Gallons per Minute (l/min), Types 98L and 98LD with Elastomer Diaphragm

NOMINAL |

SPRING |

|

RELIEF |

FLOW AT |

|

PRESSURE BUILD-UP OVER RELIEF SETTING, PSIG (bar) |

|

|||||||

|

|

|

RELIEF |

|

|

|

|

|

|

|

|

|

||

BODY |

|

|

|

PRESSURE |

|

|

|

|

|

|

|

|

|

|

SIZES, |

Part Number |

|

Color |

SETTING, |

SETTING, |

2 |

4 |

6 |

8 |

10 |

15 |

20 |

25 |

30 |

NPS (DN) |

|

Code |

PSIG (bar) |

GPM |

(0,14) |

(0,28) |

(0,41) |

(0,55) |

(0,69) |

(1,0) |

(1,4) |

(1,7) |

(2,1) |

|

|

|

|

|

|

(l/min) |

|

|

|

|

|

|

|

|

|

|

|

|

|

2 |

0.7 |

2.1 |

2.6 |

3 |

3.4 |

3.8 |

4.5 |

5.2 |

5.7 |

6.2 |

|

1E392527022 |

|

Yellow |

(0,14) |

(2,7) |

(8,0) |

(9,8) |

(11,4) |

(12,9) |

(14,4) |

(17,0) |

(19,7) |

(21,6) |

(23,5) |

|

|

5 |

0.7 |

2.9 |

3.3 |

3.7 |

4.1 |

4.5 |

5.2 |

5.8 |

6.4 |

6.9 |

||

|

|

|

|

|||||||||||

|

|

|

|

(0,34) |

(2,7) |

(11,0) |

(12,5) |

(14,0) |

(15,5) |

(17,0) |

(19,7) |

(22,0) |

(24,2) |

(26,1) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1E392627012 |

|

Green |

10 |

2.2 |

3.5 |

4.5 |

5 |

5.3 |

5.5 |

5.9 |

6.5 |

7.0 |

7.5 |

|

|

(0,69) |

(8,3) |

(13,2) |

(17,0) |

(18,9) |

(20,1) |

(20,8) |

(22,3) |

(24,6) |

(26,5) |

(28,4) |

||

|

|

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

15 |

1.8 |

3.1 |

4.3 |

5 |

5.5 |

6 |

6.4 |

6.9 |

7.4 |

7.8 |

|

|

|

|

(1,0) |

(6,8) |

(11,7) |

(16,3) |

(18,9) |

(20,8) |

(22,7) |

(24,2) |

(26,1) |

(28,0) |

(29,5) |

1/4 |

1E392727142 |

|

Red |

20 |

1.8 |

3.3 |

4.8 |

5.7 |

6.1 |

6.3 |

6.7 |

7 |

7.4 |

7.8 |

|

|

(1,4) |

(6,8) |

(12,5) |

(18,2) |

(21,6) |

(23,1) |

(23,8) |

(25,4) |

(26,5) |

(28,0) |

(29,5) |

||

|

|

|

|

|||||||||||

|

|

|

|

25 |

1.8 |

3.5 |

5.3 |

6.1 |

6.5 |

6.7 |

7.1 |

7.5 |

7.9 |

8.3 |

|

|

|

|

(1,7) |

(6,8) |

(13,2) |

(20,1) |

(23,1) |

(24,6) |

(25,4) |

(26,9) |

(28,4) |

(29,9) |

(31,4) |

|

|

|

|

25 |

1.8 |

3.4 |

4.7 |

5.5 |

6.1 |

6.6 |

7.2 |

7.6 |

8 |

8.4 |

|

|

|

|

(1,7) |

(6,8) |

(12,9) |

(17,8) |

(20,8) |

(23,1) |

(25,0) |

(27,3) |

(28,8) |

(30,3) |

(31,8) |

|

1L346127142 |

|

Blue |

30 |

1.8 |

3.8 |

5.2 |

6 |

6.7 |

7.2 |

7.6 |

8 |

8.4 |

8.5 |

|

|

(2,1) |

(6,8) |

(14,4) |

(19,7) |

(22,7) |

(25,4) |

(27,3) |

(28,8) |

(30,3) |

(31,8) |

(32,2) |

||

|

|

|

|

|||||||||||

|

|

|

|

35 |

1.8 |

4.2 |

5.6 |

6.5 |

7 |

7.4 |

8 |

8.4 |

8.7 |

9.2 |

|

|

|

|

(2,4) |

(6,8) |

(15,9) |

(21,2) |

(24,6) |

(26,5) |

(28,0) |

(30,3) |

(31,8) |

(32,9) |

(34,8) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2 |

2.2 |

5.2 |

7.5 |

8.5 |

9.5 |

10.2 |

12.1 |

13.8 |

15.3 |

16.6 |

|

1E395627022 |

|

Yellow |

(0,14) |

(8,3) |

(19,7) |

(28,4) |

(32,2) |

(36,0) |

(38,6) |

(45,8) |

(52,2) |

(57,9) |

(62,8) |

|

|

5 |

2.2 |

6 |

8.2 |

9.2 |

10.2 |

11.2 |

12.9 |

14.5 |

15.8 |

17.1 |

||

|

|

|

|

|||||||||||

|

|

|

|

(0,34) |

(8,3) |

(22,7) |

(31,0) |

(34,8) |

(38,6) |

(42,4) |

(48,8) |

(54,9) |

(59,8) |

(64,7) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1D7455T0012 |

|

Green |

10 |

2.2 |

6.7 |

8.5 |

10 |

11.5 |

12.5 |

14.2 |

15.6 |

16.8 |

18.0 |

|

|

(0,69) |

(8.3) |

(25,4) |

(32,2) |

(37,9) |

(43,5) |

(47,3) |

(53,7) |

(59,0) |

(63,6) |

(68,1) |

||

|

|

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

15 |

1.8 |

4.5 |

6.7 |

9.2 |

11.2 |

12.6 |

15 |

16.2 |

17.3 |

18.4 |

|

|

|

|

(1,0) |

(6,8) |

(17,0) |

(25,4) |

(34,8) |

(42,4) |

(47,7) |

(56,8) |

(61,3) |

(65,5) |

(69,6) |

1/2 (15) |

1E395727192 |

|

Red |

20 |

1.8 |

5 |

7.7 |

10.5 |

12.5 |

13.7 |

16.2 |

17.7 |

18.8 |

19.9 |

|

|

(1,4) |

(6,8) |

(18,9) |

(29,1) |

(39,7) |

(47,3) |

(51,9) |

(61,3) |

(67,0) |

(71,2) |

(75,3) |

||

|

|

|

|

|||||||||||

|

|

|

|

25 |

1.8 |

5.5 |

8.2 |

11.5 |

13.2 |

14.5 |

16.5 |

18.2 |

19.5 |

20.4 |

|

|

|

|

(1,7) |

(6,8) |

(20,8) |

(31,0) |

(43,5) |

(50,0) |

(54,9) |

(62,5) |

(68,9) |

(73,8) |

(77,2) |

|

|

|

|

25 |

1.8 |

4.2 |

7 |

9.7 |

12 |

13.5 |

16.2 |

18.2 |

19.5 |

20.5 |

|

|

|

|

(1,7) |

(6,8) |

(15,9) |

(26,5) |

(36,7) |

(45,4) |

(51,1) |

(61,3) |

(68,9) |

(73,8) |

(77,6) |

|

1L380027142 |

|

Blue |

30 |

1.8 |

4.5 |

7.5 |

10.2 |

12.5 |

14 |

16.7 |

18.7 |

20 |

21 |

|

|

(2,1) |

(6,8) |

(17,0) |

(28,4) |

(38,6) |

(47,3) |

(53,0) |

(63,2) |

(70,8) |

(75,7) |

(79,5) |

||

|

|

|

|

|||||||||||

|

|

|

|

35 |

1.8 |

4.7 |

8 |

10.7 |

13 |

14.7 |

17.5 |

19.5 |

21.5 |

21.2 |

|

|

|

|

(2,4) |

(6,8) |

(17,8) |

(30,3) |

(40,5) |

(49,2) |

(55,6) |

(66,2) |

(73,8) |

(81,4) |

(80,2) |

|

|

|

|

2 |

2.2 |

15 |

18.5 |

20 |

22.5 |

24 |

28.6 |

32.5 |

36.0 |

39.2 |

|

1E398927022 |

|

Yellow |

(0,14) |

(8,3) |

(56,8) |

(70,0) |

(75,7) |

(85,2) |

(90,8) |

(108) |

(123) |

(136) |

(148) |

|

|

5 |

2.2 |

15.5 |

19 |

21 |

23 |

24.5 |

28.9 |

33.5 |

36.7 |

39.6 |

||

|

|

|

|

|||||||||||

|

|

|

|

(0,34) |

(8,3) |

(58,7) |

(71,9) |

(79,5) |

(87,1) |

(92,7) |

(109) |

(127) |

(139) |

(150) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1E399027142 |

|

Green |

10 |

2.2 |

16.5 |

21.5 |

24.5 |

26.5 |

27.5 |

29.5 |

32.3 |

34.9 |

37.3 |

|

|

(0,69) |

(8.3) |

(62,5) |

(81,4) |

(92,7) |

(100) |

(104) |

(112) |

(122) |

(132) |

(141) |

||

|

|

|

|

|||||||||||

|

|

|

|

15 |

1.8 |

14 |

21 |

25.5 |

28 |

30 |

32 |

34.6 |

36.9 |

39.2 |

3/4, 1 |

|

|

|

(1,0) |

(6,8) |

(53,0) |

(79,5) |

(96,5) |

(106) |

(114) |

(121) |

(131) |

(140) |

(148) |

1E399127162 |

|

Red |

20 |

1.8 |

16.5 |

24 |

28.5 |

30.5 |

32 |

34 |

36 |

38.2 |

40.2 |

|

(20, 25) |

|

|||||||||||||

|

(1,4) |

(6,8) |

(62,5) |

(90,8) |

(108) |

(115) |

(121) |

(129) |

(136) |

(145) |

(152) |

|||

|

|

|

|

25 |

1.8 |

17.5 |

25.5 |

30.5 |

33 |

34 |

36 |

38 |

40 |

42.0 |

|

|

|

|

(1,7) |

(6,8) |

(66,2) |

(96,5) |

(115) |

(125) |

(129) |

(136) |

(144) |

(151) |

(159) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

25 |

1.8 |

10 |

20 |

25 |

29 |

32 |

36 |

38 |

40 |

42.0 |

|

|

|

|

(1,7) |

(6,8) |

(37,9) |

(75,7) |

(94,6) |

(110) |

(121) |

(136) |

(144) |

(151) |

(159) |

|

1L380127082 |

|

Blue |

30 |

1.8 |

11 |

24 |

30 |

33.5 |

35.5 |

38 |

40 |

42 |

44 |

|

|

(2,1) |

(6,8) |

(41,6) |

(90,8) |

(114) |

(127) |

(134) |

(144) |

(151) |

(159) |

(167) |

||

|

|

|

|

|||||||||||

|

|

|

|

35 |

1.8 |

19.5 |

30 |

34.5 |

36.5 |

38 |

40 |

42 |

44 |

51 |

|

|

|

|

(2,4) |

(6,8) |

(73,8) |

(114) |

(131) |

(138) |

(144) |

(151) |

(159) |

(167) |

(193) |

9

Bulletin 71.4:98

Table 4. Water Relief Capacities in Gallons per Minute (l/min), Types 98L and 98LD with Metal Diaphragm

NOMINAL |

SPRING |

|

RELIEF |

FLOW AT |

|

PRESSURE BUILD-UP OVER RELIEF SETTING, PSIG (bar) |

|

|||||||

|

|

|

RELIEF |

|

|

|

|

|

|

|

|

|

||

BODY |

|

|

|

PRESSURE |

|

|

|

|

|

|

|

|

|

|

SIZES, |

Part Number |

|

Color |

SETTING, |

SETTING, |

2 |

4 |

6 |

8 |

10 |

15 |

20 |

25 |

30 |

NPS (DN) |

|

Code |

PSIG (bar) |

GPM |

(0,14) |

(0,28) |

(0,41) |

(0,55) |

(0,69) |

(1,0) |

(1,4) |

(1,7) |

(2,1) |

|

|

|

|

|

|

(l/min) |

|

|

|

|

|

|

|

|

|

|

|

|

|

2 |

0.7 |

1.2 |

1.8 |

2.5 |

3.0 |

3.3 |

3.9 |

4.5 |

4.9 |

5.4 |

|

1E392527022 |

|

Yellow |

(0,14) |

(2,7) |

(4,5) |

(6,8) |

(9,5) |

(11,4) |

(12,5) |

(14,8) |

(17,0) |

(18,5) |

(20,4) |

|

|

5 |

0.7 |

1.3 |

2.1 |

3.0 |

3.5 |

3.8 |

4.4 |

4.9 |

5.4 |

5.8 |

||

|

|

|

|

|||||||||||

|

|

|

|

(0,34) |

(2,7) |

(4,9) |

(8,0) |

(11,4) |

(13,2) |

(14,4) |

(16,7) |

(18,5) |

(20,4) |

(22,0) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1E392627012 |

|

Green |

10 |

2.2 |

3.4 |

4 |

4.5 |

4.8 |

5.1 |

5.5 |

6.0 |

6.5 |

7.0 |

|

|

(0,69) |

(8,3) |

(12,9) |

(15,1) |

(17,0) |

(18,2) |

(19,3) |

(20,8) |

(22,7) |

(24,6) |

(26,5) |

||

|

|

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

15 |

1.8 |

3 |

3.9 |

4.5 |

5 |

5.4 |

5.8 |

6.3 |

6.7 |

7.1 |

|

|

|

|

(1,0) |

(6,8) |

(11,4) |

(14,8) |

(17,0) |

(18,9) |

(20,4) |

(22,0) |

(23,8) |

(25,4) |

(26,9) |

1/4 |

1E392727142 |

|

Red |

20 |

1.8 |

3.1 |

4 |

4.6 |

5.2 |

5.5 |

6.3 |

6.7 |

7.1 |

7.5 |

|

|

(1,4) |

(6,8) |

(11,7) |

(15,1) |

(17,4) |

(19,7) |

(20,8) |

(23,8) |

(25,4) |

(26,9) |

(28,4) |

||

|

|

|

|

|||||||||||

|

|

|

|

25 |

1.8 |

3.3 |

4.3 |

5.1 |

5.7 |

6.1 |

6.7 |

7.1 |

7.5 |

7.9 |

|

|

|

|

(1,7) |

(6,8) |

(12,5) |

(16,3) |

(19,3) |

(21,6) |

(23,1) |

(25,4) |

(26,9) |

(28,4) |

(29,9) |

|

|

|

|

25 |

1.8 |

2.6 |

3.7 |

4.5 |

5 |

5.5 |

6.5 |

7.1 |

7.5 |

7.9 |

|

|

|

|

(1,7) |

(6,8) |

(9,8) |

(14,0) |

(17,0) |

(18,9) |

(20,8) |

(24,6) |

(26,9) |

(28,4) |

(29,9) |

|

1L346127142 |

|

Blue |

30 |

1.8 |

3.1 |

4.1 |

4.9 |

5.5 |

6 |

7 |

7.5 |

7.9 |

8.3 |

|

|

(2,1) |

(6,8) |

(11,7) |

(15,5) |

(18,5) |

(20,8) |

(22,7) |

(26,5) |

(28,4) |

(29,9) |

(31,4) |

||

|

|

|

|

|||||||||||

|

|

|

|

35 |

1.8 |

3.2 |

4.4 |

5.3 |

6 |

6.5 |

7.5 |

7.9 |

8.3 |

8.7 |

|

|

|

|

(2,4) |

(6,8) |

(12,1) |

(16,7) |

(20,1) |

(22,7) |

(24,6) |

(28,4) |

(29,9) |

(31,4) |

(32,9) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2 |

2.2 |

3.7 |

6 |

7.2 |

8.2 |

9.2 |

11.0 |

12.5 |

13.8 |

15.0 |

|

1E395627022 |

|

Yellow |

(0,14) |

(8,3) |

(14,0) |

(22,7) |

(27,3) |

(31,0) |

(34,8) |

(41,6) |

(47,3) |

(52,2) |

(56,8) |

|

|

5 |

2.2 |

4.7 |

6.2 |

8 |

9.2 |

10.2 |

11.8 |

13.2 |

14.4 |

15.6 |

||

|

|

|

|

|||||||||||

|

|

|

|

(0,34) |

(8,3) |

(17,8) |

(23,5) |

(30,3) |

(34,8) |

(38,6) |

(44,7) |

(50,0) |

(54,5) |

(59,0) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1D7455T0012 |

|

Green |

10 |

2.2 |

3.8 |

5.5 |

7.5 |

9 |

10.5 |

13 |

14.2 |

15.4 |

16.4 |

|

|

(0,69) |

(8.3) |

(14,4) |

(20,8) |

(28,4) |

(34,1) |

(39,7) |

(49,2) |

(53,7) |

(58,3) |

(62,1) |

||

|

|

|

|

|||||||||||

|

|

|

|

15 |

1.8 |

4.2 |

6.2 |

7.5 |

8.7 |

9.7 |

11.5 |

12.4 |

13.3 |

14.1 |

|

|

|

|

(1,0) |

(6,8) |

(15,9) |

(23,5) |

(28,4) |

(32,9) |

(36,7) |

(43,5) |

(46,9) |

(50,3) |

(53,4) |

1/2 (15) |

1E395727192 |

|

Red |

20 |

1.8 |

4.7 |

7 |

8.5 |

9.7 |

10.7 |

12.7 |

14 |

14.8 |

15.6 |

|

|

(1,4) |

(6,8) |

(17,8) |

(26,5) |

(32,2) |

(36,7) |

(40,5) |

(48,1) |

(53,0) |

(56,0) |

(59,0) |

||

|

|

|

|

|||||||||||

|

|

|

|

25 |

1.8 |

5 |

7.5 |

9.2 |

10.7 |

12 |

14 |

15 |

16.2 |

17.0 |

|

|

|

|

(1,7) |

(6,8) |

(18,9) |

(28,4) |

(34,8) |

(40,5) |

(45,4) |

(53,0) |

(56,8) |

(61,3) |

(64,3) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

25 |

1.8 |

3.5 |

5.7 |

7.5 |

9.2 |

10.2 |

12.7 |

14.7 |

16.2 |

17.0 |

|

|

|

|

(1,7) |

(6,8) |

(13,2) |

(21,6) |

(28,4) |

(34,8) |

(38,6) |

(48,1) |

(55,6) |

(61,3) |

(64,3) |

|

1L380027142 |

|

Blue |

30 |

1.8 |

4 |

6.5 |

8.5 |

10.1 |

11.2 |

14 |

16 |

17.2 |

18.2 |

|

|

(2,1) |

(6,8) |

(15,1) |

(24,6) |

(32,2) |

(38,2) |

(42,4) |

(53,0) |

(60,6) |

(65,1) |

(68,9) |

||

|

|

|

|

|||||||||||

|

|

|

|

35 |

1.8 |

4.5 |

7.2 |

9.5 |

11 |

12.2 |

15.5 |

17.2 |

18.2 |

19.2 |

|

|

|

|

(2,4) |

(6,8) |

(17,0) |

(27,3) |

(36,0) |

(41,6) |

(46,2) |

(58,7) |

(65,1) |

(68,9) |

(72,7) |

|

|

|

|

2 |

2.2 |

13 |

16.5 |

18.5 |

19.5 |

20.5 |

24.4 |

27.8 |

30.8 |

33.5 |

|

1E398927022 |

|

Yellow |

(0,14) |

(8,3) |

(49,2) |

(62,5) |

(70,0) |

(73,8) |

(77,6) |

(93,4) |

(105) |

(117) |

(127) |

|

|

5 |

2.2 |

14.7 |

18.2 |

20 |

21 |

22 |

25.4 |

28.4 |

31.1 |

33.6 |

||

|

|

|

|

|||||||||||

|

|

|

|

(0,34) |

(8,3) |

(55,6) |

(68,9) |

(75,7) |

(79,5) |

(83,3) |

(96,1) |

(107) |

(118) |

(127) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1E399027142 |

|

Green |

10 |

2.2 |

11.5 |

17.5 |

20.2 |

20.5 |

24 |

26.5 |

29.0 |

31.4 |

33.5 |

|

|

(0,69) |

(8.3) |

(43,5) |

(66,2) |

(76,5) |

(77,6) |

(90,8) |

(100) |

(110) |

(119) |

(127) |

||

|

|

|

|

|||||||||||

|

|

|

|

15 |

1.8 |

5 |

14 |

18.5 |

21 |

23.5 |

27.5 |

29.7 |

31.7 |

33.7 |

3/4, 1 |

|

|

|

(1,0) |

(6,8) |

(18,9) |

(53,0) |

(70,0) |

(79,5) |

(88,9) |

(104) |

(112) |

(120) |

(128) |

1E399127162 |

|

Red |

20 |

1.8 |

5.2 |

15 |

20 |

23.5 |

26 |

30 |

31.5 |

33.4 |

35.2 |

|

(20, 25) |

|

|||||||||||||

|

(1,4) |

(6,8) |

(19,7) |

(56,8) |

(75,7) |

(88,9) |

(98,4) |

(114) |

(119) |

(126) |

(133) |

|||

|

|

|

|

25 |

1.8 |

5.5 |

18 |

23.5 |

26.5 |

29 |

32 |

33.5 |

35.5 |

37.2 |

|

|

|

|

(1,7) |

(6,8) |

(20,8) |

(68,1) |

(88,9) |

(100) |

(110) |

(121) |

(127) |

(134) |

(141) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

25 |

1.8 |

2.5 |

7.5 |

12.5 |

17 |

20 |

26 |

30.5 |

34.5 |

37.2 |

|

|

|

|

(1,7) |

(6,8) |

(9,5) |

(28,4) |

(47,3) |

(64,3) |

(75,7) |

(98,4) |

(115) |

(131) |

(141) |

|

1L380127082 |

|

Blue |

30 |

1.8 |

3 |

9 |

14 |

18 |

22 |

27.5 |

32 |

37.5 |

39.5 |

|

|

(2,1) |

(6,8) |

(11,4) |

(34,1) |

(53,0) |

(68,1) |

(83,3) |

(104) |

(121) |

(142) |

(150) |

||

|

|

|

|

|||||||||||

|

|

|

|

35 |

1.8 |

5.2 |

11.5 |

16.5 |

21.5 |

25 |

31.5 |

36 |

39.5 |

42 |

|

|

|

|

(2,4) |

(6,8) |

(19,7) |

(43,5) |

(62,5) |

(81,4) |

(94,6) |

(119) |

(136) |

(150) |

(159) |

10

Bulletin 71.4:98

Table 5. Steam Relief Capacities in Pounds per Hour (kg/h), Types 98L and 98LD with Metal Diaphragm Only

|

SPRING |

|

|

FLOW AT |

|

PRESSURE BUILD-UP OVER RELIEF SETTING, PSIG (bar) |

|

|||||||

NOMINAL |

|

|

|

RELIEF |

RELIEF |

|

|

|

|

|

|

|

|

|

BODY |

|

|

Color |

PRESSURE |

SETTING, |

2 |

4 |

6 |

8 |

10 |

15 |

20 |

25 |

30 |

SIZES, |

Part Number |

|

SETTING, |

POUNDS/ |

||||||||||

NPS (DN) |

|

Code |

PSIG (bar) |

HOUR |

(0,14) |

(0,28) |

(0,41) |

(0,55) |

(0,69) |

(1,0) |

(1,4) |

(1,7) |

(2,1) |

|

|

|

|

|

|

(kg/h) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2 |

7.5 |

18 |

30 |

41 |

48 |

54 |

64 |

74.1 |

84.2 |

94.3 |

|

1E392527022 |

|

Yellow |

(0,14) |

(3,4) |

(8,2) |

(13,6) |

(18,6) |

(21,8) |

(24,5) |

(29,0) |

(33,6) |

(33,2) |

(42,8) |

|

|

5 |

7.5 |

18 |

33 |

46 |

54 |

60 |

70.1 |

80.2 |

90.3 |

100 |

||

|

|

|

|

|||||||||||

|

|

|

|

(0,34) |

(3,4) |

(8,2) |

(15,0) |

(20,9) |

(24,5) |

(27,2) |

(31,8) |

(36,4) |

(41,0) |

(45,4) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1E392627012 |

|

Green |

10 |

25 |

39 |

50 |

54 |

59 |

68 |

86 |

96.8 |

108 |

119 |

|

|

(0,69) |

(11,3) |

(17,7) |

(22,7) |

(24,5) |

(26,8) |

(30,8) |

(39,0) |

(43,9) |

(49,0) |

(54,0) |

||

|

|

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

15 |

25 |

36 |

50 |

54 |

64 |

73 |

91 |

101 |

112 |

122 |

|

|

|

|

(1,0) |

(11,3) |

(16,3) |

(22,7) |

(24,5) |

(29,0) |

(33,1) |

(41,3) |

(45,8) |

(50,8) |

(55,3) |

1/4 |

1E392727142 |

|

Red |

20 |

25 |

39 |

52 |

59 |

68 |

77 |

95 |

105 |

115 |

124 |

|

|

(1,4) |

(11,3) |

(17,7) |

(23,6) |

(26,8) |

(30,8) |

(34,9) |

(43,1) |

(47,6) |

(52,2) |

(56,2) |

||

|

|

|

|

|||||||||||

|

|

|

|

25 |

25 |

41 |

54 |

64 |

73 |

82 |

105 |

123 |

132 |

142 |

|

|

|

|

(1,7) |

(11,3) |

(18,6) |

(24,5) |

(29,0) |

(33,1) |

(37,2) |

(47,6) |

(55,8) |

(59,9) |

(64,4) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

25 |

25 |

36 |

54 |

64 |

73 |

86 |

109 |

123 |

136 |

147 |

|

|

|

|

(1,7) |

(11,3) |

(16,3) |

(24,5) |

(29,0) |

(33,1) |

(39,0) |

(49,4) |

(55,8) |

(61,7) |

(66,7) |

|

1L346127142 |

|

Blue |

30 |

25 |

39 |

59 |

66 |

77 |

91 |

113 |

127 |

140 |

155 |

|

|

(2,1) |

(11,3) |

(17,7) |

(26,8) |

(29,9) |

(34,9) |

(41,3) |

(51,3) |

(57,6) |

(63,5) |

(70,3) |

||

|

|

|

|

|||||||||||

|

|

|

|

35 |

25 |

41 |

61 |

68 |

82 |

95 |

123 |

140 |

150 |

159 |

|

|

|

|

(2,4) |

(11,3) |

(18,6) |

(27,7) |

(30,8) |

(37,2) |

(43,1) |

(55,8) |

(63,5) |

(68,0) |

(72,1) |

|

|

|

|

2 |

25 |

59 |

86 |

100 |

114 |

127 |

151 |

175 |

198 |

222 |

|

1E395627022 |

|

Yellow |

(0,14) |

(11,3) |

(26,8) |

(39,0) |

(45,4) |

(51,7) |

(57,6) |

(68,5) |

(79,4) |

(89,8) |

(101) |

|

|

5 |

25 |

73 |

95 |

114 |

127 |

136 |

159 |

182 |

205 |

228 |

||

|

|

|

|

|||||||||||

|

|

|

|

(0,34) |

(11,3) |

(33,1) |

(43,1) |

(51,7) |

(57,6) |

(61,7) |

(72,1) |

(82,6) |

(93,0) |

(103) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1D7455T0012 |

|

Green |

10 |

25 |

77 |

105 |

122 |

136 |

145 |

173 |

195 |

216 |

238 |

|

|

(0,69) |

(11,3) |

(34,9) |

(47,6) |

(55,3) |

(61,7) |

(65,8) |

(78,5) |

(88,5) |

(98,0) |

(108) |

||

|

|

|

|

|||||||||||

|

|

|

|

15 |

25 |

59 |

95 |

122 |

141 |

155 |

187 |

208 |

229 |

250 |

|

|

|

|

(1,0) |

(11,3) |

(26,8) |

(43,1) |

(55,3) |

(64,0) |

(70,3) |

(84,8) |

(94,3) |

(104) |

(113) |

1/2 (15) |

1E395727192 |

|

Red |

20 |

25 |

64 |

100 |

127 |

145 |

168 |

204 |

227 |

248 |

269 |

|

|

(1,4) |

(11,3) |

(29,0) |

(45,4) |

(57,6) |

(65,8) |

(76,2) |

(92,5) |

(103) |

(112) |

(122) |

||

|

|

|

|

|||||||||||

|

|

|

|

25 |

25 |

68 |

109 |

136 |

164 |

182 |

228 |

260 |

286 |

308 |

|

|

|

|

(1,7) |

(11,3) |

(30,8) |

(49,4) |

(61,7) |

(74,4) |

(82,6) |

(103) |

(118) |

(130) |

(140) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

25 |

25 |

50 |

77 |

100 |

123 |

141 |

190 |

232 |

264 |

284 |

|

|

|

|

(1,7) |

(11,3) |

(22,7) |

(34,9) |

(45,4) |

(55,8) |

(64,0) |

(86,2) |

(105) |

(120) |

(129) |

|

1L380027142 |

|

Blue |

30 |

25 |

52 |

82 |

109 |

136 |

159 |

210 |

250 |

282 |

310 |

|

|

(2,1) |

(11,3) |

(23,6) |

(37,2) |

(49,4) |

(61,7) |

(72,1) |

(95,3) |

(113) |

(128) |

(141) |

||

|

|

|

|

|||||||||||

|

|

|

|

35 |

25 |

55 |

86 |

114 |

145 |

168 |

220 |

264 |

295 |

317 |

|

|

|

|

(2,4) |

(11,3) |

(24,9) |

(39,0) |

(51,7) |

(65,8) |

(76,2) |

(99,8) |

(120) |

(134) |

(144) |

|

|

|

|

2 |

25 |

122 |

177 |

210 |

236 |

264 |

313 |

363 |

412 |

462 |

|

1E398927022 |

|

Yellow |

(0,14) |

(11,3) |

(55,3) |

(80,3) |

(95,3) |

(107) |

(120) |

(142) |

(165) |

(187) |

(210) |

|

|

5 |

25 |

127 |

182 |

218 |

246 |

272 |

318 |

364 |

415 |

465 |

||

|

|

|

|

|||||||||||

|

|

|

|

(0,34) |

(11,3) |

(57,6) |

(82,6) |

(98,9) |

(112) |

(123) |

(144) |

(165) |

(188) |

(211) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1E399027142 |

|

Green |

10 |

25 |

136 |

200 |

240 |

280 |

310 |

370 |

417 |

463 |

509 |

|

|

(0,69) |

(11,3) |

(61,7) |

(90,7) |

(109) |

(127) |

(141) |

(168) |

(189) |

(210) |

(231) |

||

|

|

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

15 |

25 |

100 |

173 |

228 |

272 |

300 |

380 |

423 |

464 |

510 |

3/4, 1 |

|

|

|

(1,0) |

(11,3) |

(45,4) |

(78,5) |

(103) |

(123) |

(136) |

(172) |

(192) |

(210) |

(231) |

1E399127162 |

|

Red |

20 |

25 |

127 |

210 |

264 |

310 |

246 |

420 |

455 |

497 |

538 |

|

(20, 25) |

|

|||||||||||||

|

(1,4) |

(11,3) |

(57,6) |

(95,3) |

(120) |

(141) |

(112) |

(191) |

(206) |

(225) |

(244) |

|||

|

|

|

|

25 |

25 |

136 |

236 |

280 |

328 |

364 |

455 |

500 |

545 |

587 |

|

|

|

|

(1,7) |

(11,3) |

(61,7) |

(107) |

(127) |

(149) |

(165) |

(206) |

(227) |

(247) |

(266) |

|

|

|

|

25 |

25 |

91 |

164 |

228 |

272 |

320 |

420 |

500 |

545 |

587 |

|

|

|

|

(1,7) |

(11,3) |

(41,3) |

(74,4) |

(103) |

(123) |

(145) |

(191) |

(227) |

(247) |

(266) |

|

1L380127082 |

|

Blue |

30 |

25 |

118 |

190 |

254 |

318 |

354 |

455 |

545 |

590 |

680 |

|

|

(2,1) |

(11,3) |

(53,5) |

(86,2) |

(115) |

(144) |

(161) |

(206) |

(247) |

(268) |

(308) |

||

|

|

|

|

|||||||||||

|

|

|

|

35 |

25 |

127 |

220 |

280 |

346 |

390 |

500 |

590 |

640 |

730 |

|

|

|

|

(2,4) |

(11,3) |

(57,6) |

(99,8) |

(127) |

(157) |

(177) |

(227) |

(268) |

(290) |

(331) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

11

Loading...

Loading...