Emerson 670 Instruction Manual

Instruction Manual

Form 965

February 2015

670 Series

670 Series Panel-Mounted Loading

Regulator Assemblies

!WARNING

Fisher® regulators should be installed, operated and maintained in accordance with federal, state and local codes, rules and regulations and Emerson Process Management Regulator Technologies, Inc. instructions.

If a leak develops in the system, it indicates that service is required. Failure to take the regulator out of service immediately may create a hazardous condition.

Call a gas service person in case of trouble.

Only a qualified person must install or service the regulator.

Introduction

The 670 Series panel-mounted loading regulator assemblies are used primarily for manually controlling pressure to diaphragm control valves or as remote pressure loaders for pressure-balance gas regulators. They are also widely used for remote control of gas pressure to burners in refinery tube stills, power plants and similar process furnaces.

Principle of Operation

The 670 Series regulators are set manually to control supply pressure to diaphragm control valves or gas regulators. Instrument and manual loading pressures are read from the pressure gauges of the regulator. If pressure to the valve needs to be adjusted, the regulator handwheel is turned clockwise to increase the supply pressure or counterclockwise to decrease the supply pressure.

Installation

Inspect the panel after it is removed from its packing. Connect a 1/4 in. / 6.4 mm pipe line from the operating supply pressure to the connection marked “IN” on the pressure regulator.

One and two-gauge panels: Connect a line to the diaphragm casing of the main valve or regulator and run it to the connection marked “OUT” on the panel regulator. When installing a two-gauge panel, connect a line from the control pressure line to the upper diaphragm casing and to the

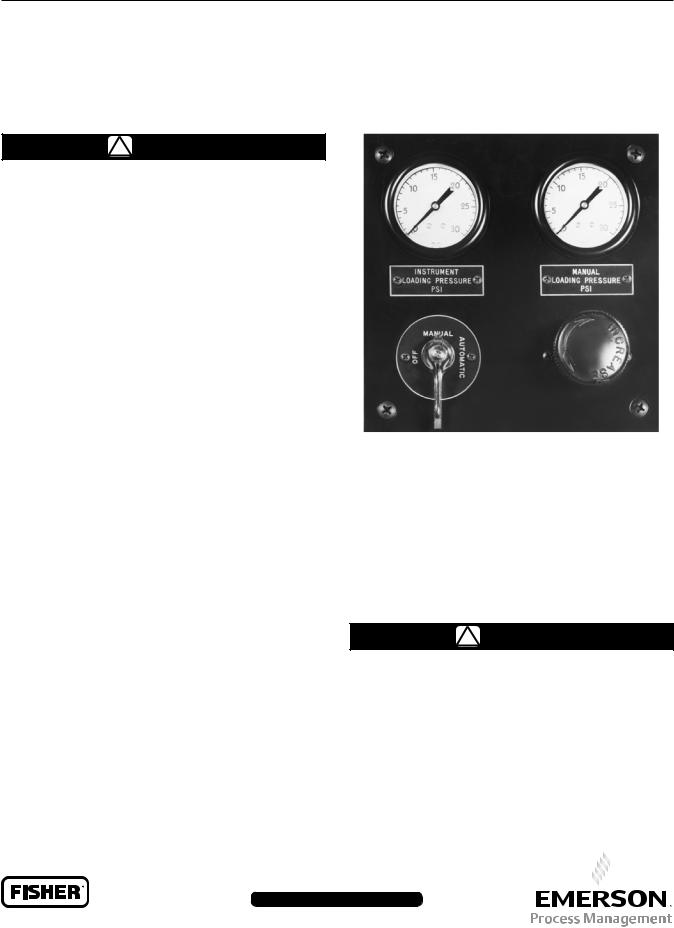

W0554

Figure 1. Typical 670 Series Regulators: Two-Gauge Panel with Three-Way Changeover Valve

control pressure gauge (instrument loading pressure) in the back of the panel (see Figure 2).

Two-gauge panel with a three-way changeover valve: Connect the air supply, diaphragm connection and instrument loading pressure line to the panel regulator as shown in Figure 4.

Overpressure Protection

!WARNING

Overpressuring any portion of this equipment may cause damage to regulator parts, leaks in the regulators or personal injury due to bursting of pressure-containing parts or explosion of accumulated gas.

To avoid overpressure, provide appropriate overpressure protection to ensure that none of the pressure limits will be exceeded.

The regulator assembly should be inspected for damage after any overpressure condition.

D200109X012

www.fisherregulators.com

670 Series

Table 1. Type Number Description

|

NUMBER |

|

REGULATOR |

MAXIMUM INLET |

MAXIMUM OUTLET |

MAXIMUM EMERGENCY |

||||

TYPE |

DESCRIPTION |

PRESSURE |

PRESSURE |

OUTLET PRESSURE |

||||||

OF GAUGE |

TYPE NUMBER |

|||||||||

|

|

psig |

bar |

psig |

bar |

psig |

bar |

|||

|

|

|

|

|||||||

670 |

1 |

Basic 1-gauge panel |

67CR |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

670F |

1 |

1-gauge panel; regulator has filter |

67CFR |

250 |

17.2 |

100 |

6.9 |

110 |

7.6 |

|

|

|

|

|

|

|

|

|

|

|

|

670FG |

2 |

2-gauge panel; regulator has filter |

67CFR |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

670FGV |

2 |

2-gauge panel with 3-way changeover valve; |

67CFR |

50 |

3.5 |

50 |

3.5 |

55 |

3.8 |

|

regulator has filter |

||||||||||

|

|

|

|

|

|

|

|

|

||

670G |

2 |

Basic 2-gauge panel |

67CR |

250 |

17.2 |

100 |

6.9 |

110 |

7.6 |

|

|

|

|

|

|

|

|

|

|

|

|

670GV |

2 |

2-gauge panel with 3-way or 4-way changeover valve |

67CR |

50 |

3.5 |

50 |

3.5 |

55 |

3.8 |

|

|

|

|

|

|

|

|

|

|

|

|

671 |

1 |

Basic 1-gauge panel |

912N |

250 |

17.2 |

5 |

0.35 |

10 |

0.69 |

|

|

|

|

|

|

|

|

|

|

|

|

675 |

2 |

Basic 2-gauge panel |

67CR |

250 |

17.2 |

100 |

6.9 |

110 |

7.6 |

|

|

|

|

|

|

|

|

|

|

|

|

As is the case with most regulators, regulators in the

670 Series have outlet pressure ratings which are lower than the inlet pressure ratings. Overpressure protection is needed if the actual inlet pressure can exceed the outlet pressure rating. A common method of overpressure protection is a relief valve.

Maximum emergency outlet pressure ratings are shown in Table 1 for each loading regulator.

Startup

Open the air supply line. Check all connections for leaks. The manual loading pressure gauge indicates the loading pressure on the diaphragm of the main valve. To increase the loading pressure, turn the handwheel clockwise. To decrease the loading pressure, turn the handwheel counterclockwise.

Units with a three-way changeover valve may be placed under manual operation. When changing from manual to automatic or from automatic to manual control, set the manual control pressure gauge to read the same as the instrument pressure in order to prevent bumping.

Maintenance

The regulator can be removed from the panel to be nut disassembled. Take out the set screws or loosen the hex to remove the regulators from the panel. Refer to the appropriate instruction manual for further maintenance on the regulator.

Parts Ordering

When corresponding with your local Sales Office about this equipment, be sure to include the serial number that is stamped on the nameplate on the back of the panel. Include

the complete eleven-character part numbers from the following Parts List when ordering new parts.

Parts List

Key Description Part Number

1 Regulator—Part numbers for the regulators

used in the 670 Series are shown in the

regulator instruction manuals

Key |

Description |

Part Number |

2 |

Gauge |

|

|

0 to 5 psig / 0 to 0.35 bar |

23A8325X012 |

|

0 to 15 psig / 0 to 1.0 bar |

2C2332000B2 |

|

0 to 30 psig / 0 to 2.1 bar |

2C2332000C2 |

|

0 to 60 psig / 0 to 4.1 bar |

2C2332000D2 |

|

0 to 100 psig / 0 to 6.9 bar |

2C2332000E2 |

|

0 to 160 psig / 0 to 11.0 bar |

2C2332X0022 |

|

0 to 200 psig / 0 to 13.8 bar |

2C2332000F2 |

|

0 to 300 psig / 0 to 20.7 bar |

2C2332X00A2 |

|

0 to 400 psig / 0 to 27.6 bar |

2C2332X0032 |

|

0 to 600 psig / 0 to 41.3 bar |

2C2332X0042 |

|

0 to 60 psig / 0 to 4.1 bar and 0 to 4 kg/cm2 |

1R766299012 |

|

0 to 60 to 200 psig / 0 to 4.1 to 13.8 bar |

|

|

and 0 to 4 to 14 kg/cm2 |

1R766399012 |

3 |

Panel |

|

|

Types 670 and 670F, Zinc |

1C233344012 |

|

Type 670FG, Steel |

3E660725132 |

|

Type 670G, Steel |

3J846025132 |

|

Types 670GV and 670FGV (3-way valve), |

|

|

Steel |

3E660825132 |

|

Type 671, Zinc |

1C233744012 |

|

Type 675G, Steel |

3H184325132 |

4 |

Clamp bar, Cadmium Plate steel (4 required) |

1C233824162 |

5 Hex Nut, Cadmium Plate Steel

Types 670, 670F, 670FG, 670FGV, 671

|

and 675G (4 required) |

1E985324142 |

|

Types 670G and 670GV |

|

|

(6 required) |

1E985324142 |

6 |

Machine Screw, Steel (4 required) |

1C233928992 |

7 |

Tubing, Copper |

|

|

Type 670 |

19A1553X012 |

|

Type 670F |

19A1562X012 |

|

Type 670FG |

19A1564X012 |

|

Type 670FGV |

19A1565X012 |

|

Type 670G |

19A1569X012 |

|

Type 670GV |

19A1556X012 |

|

Type 671 |

19A1511X012 |

|

Type 675G |

19A1573X012 |

8 |

Fitting, Brass |

|

|

Types 670, 670F and 671 |

15A6002X272 |

|

All other types |

15A6002X262 |

9 |

Fitting, Brass |

|

|

Types 670 and 670F |

1C619718992 |

|

Type 670FG |

15A6002X172 |

|

Types 670FGV and 670GV (3 required) |

15A6002X172 |

|

Type 670G |

15A6002X212 |

|

Type 671 |

15A6002XA92 |

|

Type 675G (2 required) |

1C619718992 |

2

Loading...

Loading...