Emerson 630, 630R Instruction Manual

Instruction Manual

Form 1243

November 2008

630 Series Regulators and Relief Valves

Introduction

Scope of Manual

This Instruction Manual provides operating,

installation, maintenance, and parts information for the

630 Series regulators and relief valves.

Description

The 630 Series consists of self-operated, spring

loaded Type 630 Big Joe® pressure regulators and

Type 630R relief valves, which are designed for

maximum inlet pressures to 1500 psig (103 bar) and

outlet pressures from 3 to 500 psig (0,21 to 34,5 bar).

630 Series

Specications

Specications section lists the specications for the

630 Series constructions.

Installation

WARNING

!

Personal injury, property damage,

equipment damage, or leakage due to

escaping gas or bursting of pressurecontaining parts may result if this

regulator is overpressured or is installed

where service conditions could exceed

the limits given in Specications section,

Tables 1 through 3 or where conditions

exceed any ratings of the adjacent piping

or piping connections.

To avoid such injury or damage,

provide pressure-relieving or

pressure-limiting devices (as required

by the appropriate code, regulation, or

W1934

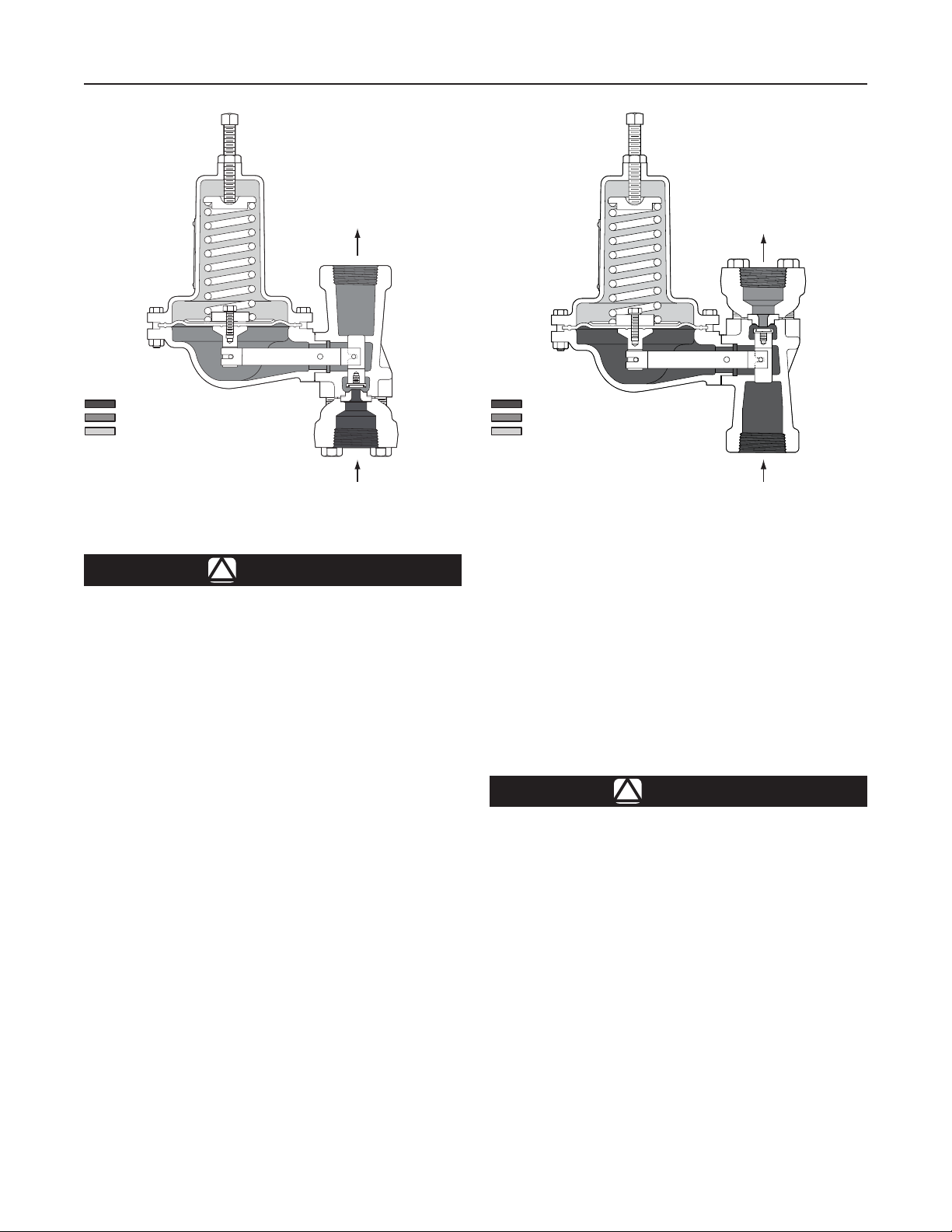

Figure 1. Spring-Loaded Type 630 Regulator

standard) to prevent service conditions

from exceeding those limits.

Additionally, physical damage to the

regulator could cause personal injury or

property damage due to escaping gas.

To avoid such injury or damage, install

the regulator in a safe location.

Before installing, inspect the unit for any damage and

any foreign material. The regulator or relief valve may

be mounted in any position, however, ensure that the

ow direction corresponds with the direction of the

arrow on the nameplate. Apply a good grade of pipe

compound to the male threads of the pipeline.

www.emersonprocess.com/regulators

D100300X012

630 Series

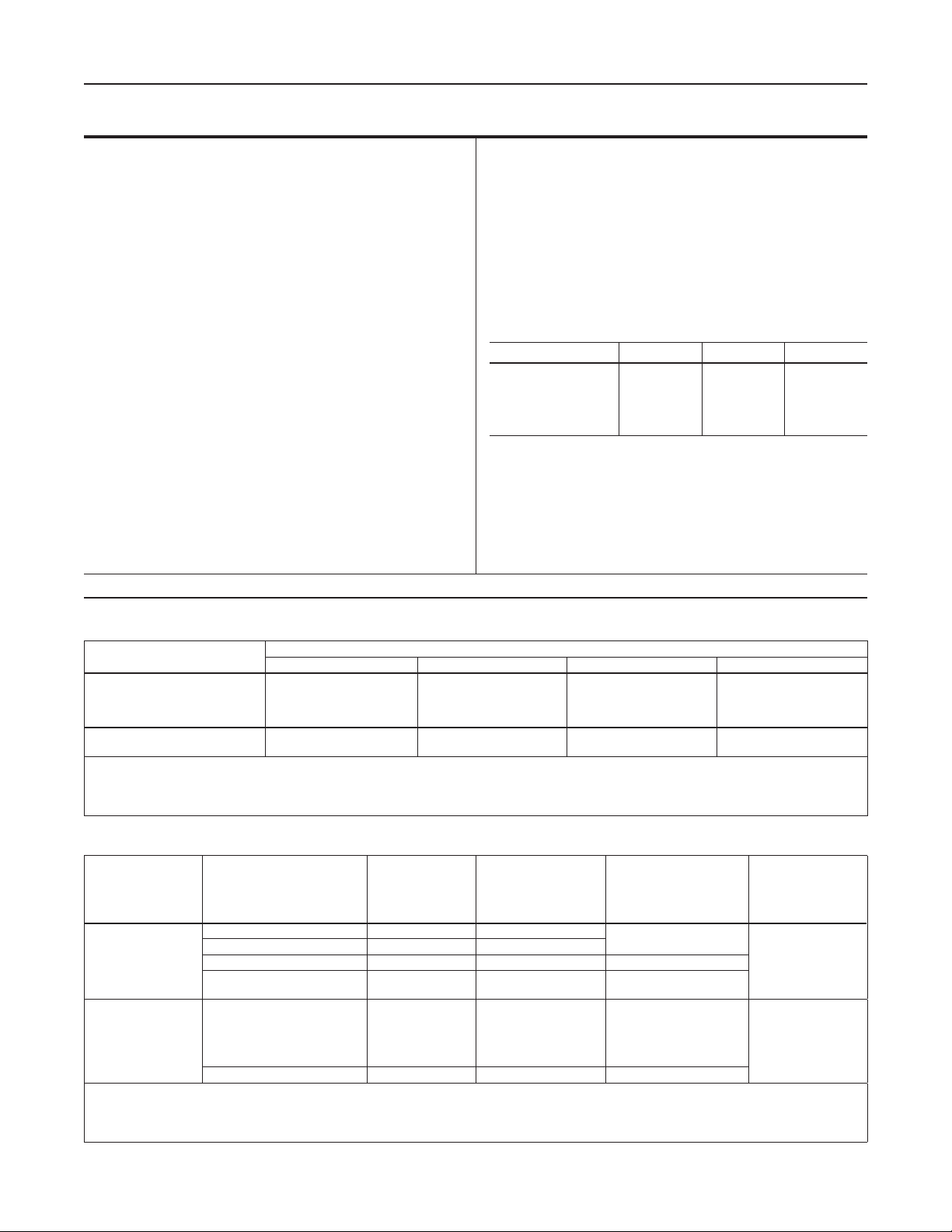

Specications

Available Congurations

Type 630: Spring-loaded reducing regulators

Type 630R: Spring-loaded relief valves

End Connection Sizes and Styles

1 or 2-inch NPT, CL150 RF, CL300 RF, or CL600 RF

Maximum Allowable Inlet Pressures

(1)

Type 630 Regulators: See Table 1

Type 630R Relief Valves: See Table 3

Type 630 Outlet Pressure Ranges

(1)

3 to 500 psig (0,21 to 34,5 bar) with intermediate

values shown in Table 2

Type 630R Relief Pressure Ranges

(1)

3 to 250 psig (0,21 to 17,2 bar)

See Table 3

Maximum Allowable Outlet Pressures

(1)

See Table 2

Maximum Allowable Pressure Drops

(1)

See Table 1

Pressure Registration

Spring Case Vent

1/4-inch NPT

Material Temperature Capabilities

Standard: -20° to 180°F (-29° to 82°C)

Optional: -20° to 300°F (-29° to 149°C)

Orice Sizes

1/8, 3/16, 1/4, 3/8,or 1/2-inch

(3,18; 4,76; 6,35; 9,53; or 12,7 mm)

Coefcients for Relief Valve Sizing

ORIFICE SIZE C

1/8-inch

1/4-inch

3/8-inch

1/2-inch

(3,18 mm)

(4,76 mm)

(6,35 mm)

(9,53 mm)

(12,7 mm)

3/16-inch

Approximate Weights

1-inch End Connection:

25 pounds (11,3 kg)

2-inch End Connection:

30 pounds (13,6 kg)

Internal

1. The pressure/temperature limits in this Instruction Manual or any applicable standard limitation should not be exceeded.

13.9

31.3

55.1

122.5

216.0

(1)

g

C

0.49

1.11

2.03

4.61

8.18

V

C

28.4

28.2

27.2

26.6

26.4

1

Table 1. Maximum Allowable Inlet Pressures and Pressure Drops. Maximum inlet pressure not to exceed 1500 psig (103 bar).

DISK MATERIAL

Nylon (PA) and

Polytetrauoroethylene (PTFE)

Nitrile (NBR)

Fluorocarbon (FKM)

MAXIMUM ALLOWABLE INLET

PRESSURE, PSIG (bar)

1. Inlet pressure must not exceed the sum of the actual outlet pressure setting and the maximum allowable pressure drop. For example, with an outlet pressure setting of 200 psig

(13,8 bar) and a 3/8-inch (9,53 mm) orice with a maximum allowable pressure drop of 500 psid (34,5 bar, differential), the maximum allowable inlet pressure is 700 psig (48,3 bar).

2. Nitrile (NBR) valve disks are normally furnished for pressure drops to 200 psi (13,8 bar, differential). For better erosion resistance, nylon valve disks are normally furnished for higher

pressure drops. Some erosion of valve disks occurs at all pressure drops due to solid particles in the ow stream. The rate of erosion is higher with large amounts of impurities in

the ow stream and with high pressure drops. Valve disks and other regulator parts must be inspected periodically for erosion and damage and must be replaced as necessary.

1/8 and 3/16 (3,17 and 4,76) 1/4 (6,35) 3/8 (9,52) 1/2 (12,7)

1500

(103)

600

(41,4)

200

(13,8)

1500 (103)

(1)

ORIFICE SIZE, INCHES (mm)

1000

(68,9)

600

(41,4)

200

(13,8)

1500 (103)

(1)

500

(34,5)

500

(34,5)

200

(13,8)

1000 (68,9)

250

(17,2)

250

(17,2)

200

(13,8)

(1)

750 (51,7)

(1)

Table 2. Type 630 Regulator Outlet Pressure Ranges and Maximum Outlet Pressures

REGULATOR

CONSTRUCTION

Low-Pressure

High-Pressure

1. Damage to internal parts of the regulator may occur if outlet pressure exceeds the actual pressure setting by amounts greater than those shown in this column.

2. For outlet pressure settings to 25 psig (1,72 bar) only. For pressure settings over 25 psig (1,72 bar), outlet pressure is limited by maximum emergency outlet pressure of 45 psig (3,10 bar).

3. For outlet pressure settings to 350 psig (24,1 bar) only. For pressure settings over 350 psig (24,1 bar), outlet pressure is limited by maximum emergency outlet pressure of

550 psig (37,9 bar).

4. Leakage or bursting of pressure-containing parts may occur if outlet pressure exceeds these values.

OUTLET PRESSURE

RANGE, PSIG (bar)

3 to 10 (0,21 to 0,69) 0W019227022 10 (0,69)

8 to 20 (0,55 to 1,38) 0W019127022 20 (1,38)

17 to 30 (1,17 to 2,07) 0W019027022 30 (2,07) 20

27 to 40 (1,86 to 2,76) 0Y066427022 40 (2,76)

27 to 50

(1,86 to 3,45)

46 to 95

90 to 150

150 to 200

200 to 275

275 to 500 (19,0 to 34,5) 1K370927082 500 (34,5) 200

(3,17 to 6,55)

(6,21 to 10,3)

(10,3 to 13,8)

(13,8 to 19,0)

SPRING

PART NUMBER

0W019227022

0W019127022

0W019027022

0Y066427022

1J146927142

MAXIMUM OPERATING

OUTLET PRESSURE,

PSIG (bar)

50

(3,45)

95

(6,55)

150

(10,3)

200

(13,8)

275

(19,0)

MAXIMUM OUTLET

PRESSURE OVER

SETPOINT

PSIG (bar)

20 (1,38)

Limited by Maximum

Emergency Outlet Pressure

200 (13,8)

(2)

(3)

(1,38)

(13,8)

(1)

,

MAXIMUM

EMERGENCY

OUTLET (CASING)

PRESSURE

PSIG (bar)

66 (4,55)

550 (37,9)

(4)

,

2

630 Series

INLET PRESSURE

OUTLET PRESSURE

ATMOSPHERIC PRESSURE

46A2976-A

A2525-1

Figure 2. Type 630 Regulator Operational Schematic

Vents

WARNING

!

When the unit is installed in an enclosed

area or indoors, escaping gas may

accumulate and be an explosion hazard.

Under these conditions the vent should

be piped away from the unit to a freely

ventilated outdoor location away from air

intakes, windows, etc. Protect all vent

openings against weather or the entrance

of any foreign material that may plug the

vent or affect operation of the regulator

or relief valve. Inspect all vent openings

periodically to be sure they are not

plugged. If the vent is in an environment

where freezing rain, ice, or snow could

clog the vent, it is recommended that a

weatherproof vent be used.

Spring-loaded constructions have a screened vent

assembly (key 27, Figures 4, 5, and 6) installed in the

1/4-inch NPT spring case vent opening. If a remote

vent is required, remove the vent assembly and install

a remote vent line.

Overpressure Protection

As is the case with most regulators, the Type 630

spring-loaded regulators have outlet pressure

ratings that are lower than the inlet pressure ratings.

Overpressure protection must be provided if the

INLET PRESSURE

OUTLET PRESSURE

ATMOSPHERIC PRESSURE

46A2977

A2526-1

Figure 3. Type 630R Relief Valve Operational Schematic

actual inlet pressure can exceed the outlet pressure

rating. Overpressure protection is also required for the

loading regulator and main regulator spring case of

relief valves.

Refer to the following tables to determine pressure ratings:

1. Spring-loaded Type 630 regulators.

a. Inlet pressure and pressure drop—Table 1.

b. Outlet pressure—Table 2.

2. Spring-loaded Type 630R relief valve pressure Table 3.

WARNING

!

Overpressuring any portion of this

equipment may cause damage to

regulator parts, leaks in the regulator,

or personal injury due to bursting of

pressure-containing parts or explosion

of accumulated gas.

To avoid overpressure, provide an

appropriate overpressure protection

device to ensure that none of the limits

listed in Specications section, Tables 1

through 3 will be exceeded.

Regulator or relief valve operation below the limits

specied in Specications section, Tables 1 through 3

does not preclude the possibility of damage from external

sources or from debris in the gas line. Inspect the

regulator for damage after any overpressure condition.

3

630 Series

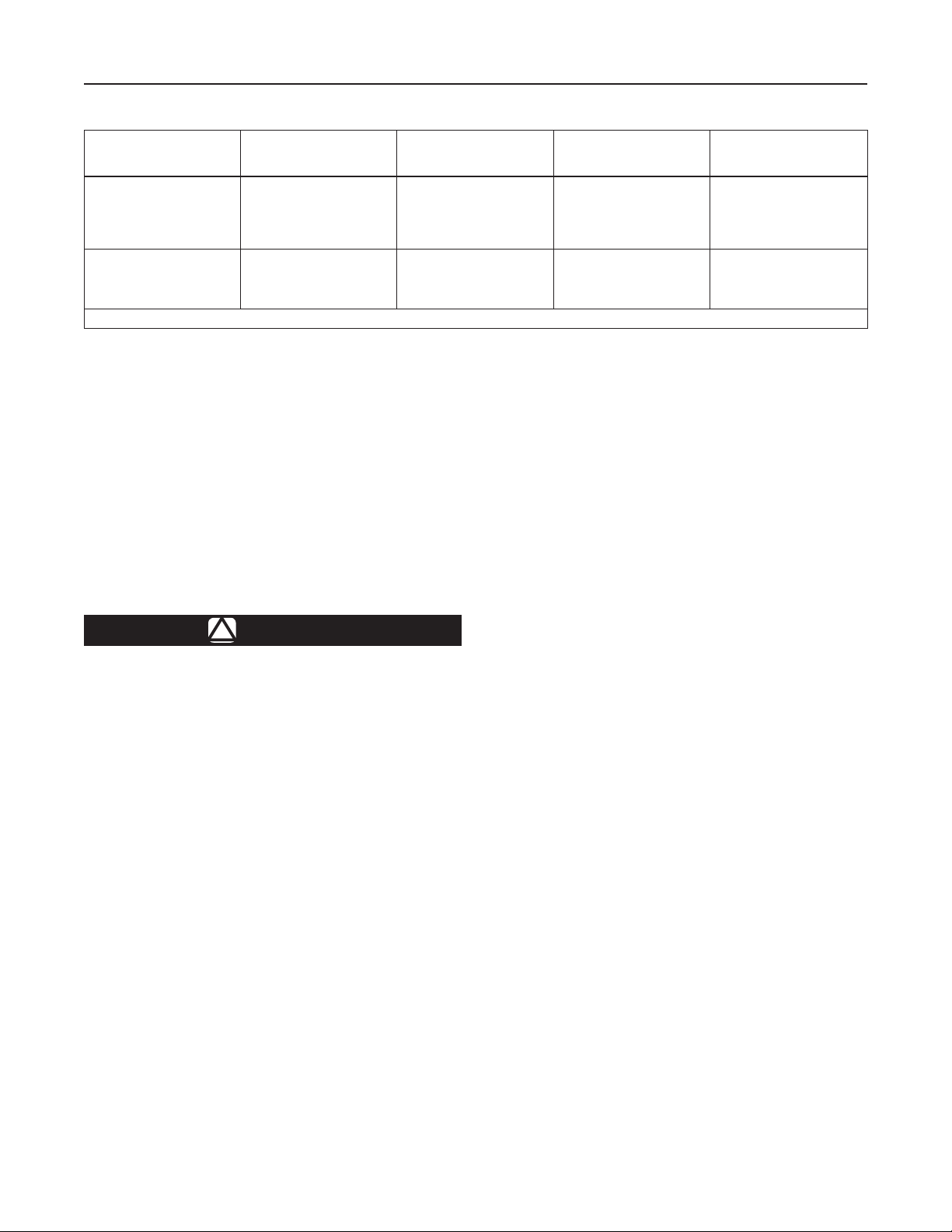

Table 3. Type 630R Relief Pressure Ranges

RELIEF VALVE

CONSTRUCTION

Low-Pressure

High-Pressure

1. Leakage or bursting of pressure-containing parts may occur if inlet pressure exceeds these values.

RELIEF (INLET)

PRESSURE RANGES,

PSIG (bar)

3 to 8

(0,21 to 0,55)

6 to 17

(0,41 to 1,17)

15 to 22

(1,03 to 1,52)

20 to 35

(1,38 to 2,41)

35 to 50

(2,41 to 3,45)

30 to 70

(2,07 to 4,83)

50 to 95

75 to 175

150 to 250

(3,45 to 6,55)

(5,17 to 12,1)

(10,3 to 17,2)

PART NUMBER

0W019227022

0W019127022

0W019027022

0Y066427022

1J146927142

0W019127022

0W019027022

0Y066427022

1J146927142

MAXIMUM ALLOWABLE

RELIEF (INLET)

PRESSURE, PSIG (bar)

Relief Pressure Setting Plus

Maximum Allowable Buildup

of 25 psig (1,72 bar)

Relief Pressure Setting Plus

Maximum Allowable Buildup

of 250 psig (17,2 bar)

MAXIMUM EMERGENCY

INLET (CASING)

PRESSURE

(1)

, PSIG (bar)

75 (5,17)

550 (37,9)

Startup

Starting up the unit consists of opening the upstream

block valve, introducing gas pressure. Use gauges to

monitor pressures during startup.

The range of allowable pressure settings is marked

on the nameplate. If a pressure setting beyond the

nameplate range is required, substitute an appropriate

spring selected from Table 5. Be sure to change the

nameplate to indicate the new pressure range.

WARNING

!

To avoid the consequences of

over-tightening the spring in

spring-loaded regulators or relief

valves, consult Table 4 and replace the

adjusting screw with one of the correct

length when replacing the spring.

Some pressure ratings are dependent upon the actual

outlet pressure settings being used. For example,

with a Type 630 regulator, outlet pressure must not

exceed the setting by more than 20 psig (1,38 bar)

for low pressure constructions or 200 psig (13,8 bar)

for high pressure constructions, or damage to internal

regulator parts may occur. However, with some higher

pressure ranges, the setting plus 20 psig (1,38 bar) or

200 psig (13,8 bar) exceeds the maximum emergency

outlet (casing) pressure. Before increasing the setting,

refer to Tables 2 and 3 (as appropriate). Review the

pressure limits for the spring range being used, and

be certain that the new pressure setting will not result

in an overpressure condition. Always use a pressure

gauge to monitor pressure when making adjustments.

Adjusting Spring-Loaded Regulators and

Relief Valves

Loosen the hex nut (key 2, Figures 4, 5, and 6) atop the

spring case. While monitoring the pressure, rotate the

adjusting screw (key 1, Figures 4, 5, and 6) clockwise to

increase set pressure or counterclockwise to decrease

it. When the unit is regulating or relieving pressure at

the desired value, tighten the hex nut.

Shutdown

Slowly close the upstream block valve.

Principle of Operation

This section describes the operation of the Type 630

regulator and the Type 630R relief valve with spring

loading. Set pressure is changed with the adjusting

screw on the regulator or relief valve. The Type 630R

relief valve uses a light spring for added stability.

Type 630 Regulators

Refer to Figure 2. In the regulator construction, outlet

pressure registers beneath the diaphragm. As long as

the outlet pressure is less than the set pressure, spring

force on the diaphragm causes the lever to hold the

valve open. When the outlet pressure exceeds the set

pressure, the diaphragm moves to compress the spring

and the lever closes the valve until the outlet pressure

returns to set pressure.

4

Loading...

Loading...