Electrolux EWM10931 TC1, EWM10931 TC2, EWM10931 TC3 Schematic

SERVICE MANUAL

WASHING

Washing machines

guide to diagnostics of

electronic controls

EWM10931

THE INSPIRATION

RANGE

TC3 / TC2 / TC1

© ELECTROLUX HOME PRODUCTS

Customer Care - EMEA

Training and Operations Support

Technical Support

Publication

number

599 75 27-46

Edition: 04/2012 - Rev. 00

EN

Guide to diagnostics of electronic controls EWM10931

2012 TS/DT-mdm FCPD-dp 2/79 599 75 27-46 Rev.00

Guide to diagnostics of electronic controls EWM10931

2012 TS/DT-mdm FCPD-dp 3/79 599 75 27-46 Rev.00

Index

1

INTRODUCTION .................................................................................................................................. 5

1.1 Purpose of this manual .................................................................................................................. 5

1.2 Cautions ........................................................................................................................................ 5

1.3 How to proceed ............................................................................................................................. 6

2 WM APPLIANCE CONTROL PANELS ................................................................................................. 7

3 PROGRAMMING/UPDATING THE MAIN CIRCUIT BOARD ................................................................. 7

4 DIAGNOSTICS SYSTEM ..................................................................................................................... 8

4.1 Accessing diagnostics ................................................................................................................... 8

4.2 Quitting the diagnostics system ..................................................................................................... 8

4.3 Phases of the diagnostics test ....................................................................................................... 9

4.3.1 TC3-TC2 styling .................................................................................................................... 9

4.3.2 TC1 styling .......................................................................................................................... 11

5 ALARMS ............................................................................................................................................ 13

5.1 Displaying the alarms to the user ................................................................................................. 13

5.2 Reading the alarms ..................................................................................................................... 14

5.2.1 TC3-TC2 styling .................................................................................................................. 14

5.2.2 TC1 styling .......................................................................................................................... 14

5.3 Rapid reading of alarms ............................................................................................................... 14

5.4 Deleting the last alarm ................................................................................................................. 15

5.5 ALARM SUMMARY TABLE ......................................................................................................... 16

5.6 Notes on the behaviour of certain alarms ..................................................................................... 20

6 CANNOT ACCESS THE DIAGNOSTICS PROGRAMME .................................................................... 21

6.1 None of the LEDs on the circuit board light up ............................................................................. 21

7 TROUBLESHOOTING BASED ON ALARM CODES .......................................................................... 22

E11: Water fill difficulty during washing ............................................................................................ 22

E13: Water leaks ............................................................................................................................. 24

E21: Drain difficulty ......................................................................................................................... 26

E23: Problems with the component (triac) controlling the drain pump .............................................. 28

E24: Sensing circuit of the component (triac) controlling the drain pump faulty................................. 30

E31: The analogue pressure switch provides the main circuit board with a signal outside the limits. 30

E32: The analogue pressure switch causes an error during calibration ............................................ 31

E35: Water level too high ................................................................................................................ 32

E38: Internal pressure chamber is clogged ...................................................................................... 33

E41: Door open (device with 4 connections) .................................................................................... 34

E42: Problems opening door (device with 4 connections) ................................................................ 36

E43: Problems with the component (triac) controlling the door delay system (device with

4 connections) ........................................................................................................................ 38

E44: Door closed “sensing” circuit faulty .......................................................................................... 39

E45: Problems with the “sensing” circuit of the component (triac) controlling the door delay system . 39

E52: No signal from the motor tachimetric generator (1

st

part) ......................................................... 40

E52: No signal from the motor tachimetric generator (2

nd

part) ......................................................... 42

E57: Inverter is drawing more than 16A current ............................................................................... 44

E58: Inverter is drawing more than 4A current ................................................................................. 46

E59: No signal from the tachometric generator ................................................................................ 48

E5A: Overheating on Inverter board heat dissipator ......................................................................... 50

E5C: The Inverter board input voltage is too high (beyond 430 V) .................................................... 51

E5d: Data transfer error between Inverter board and main circuit board ........................................... 52

E5E: Communication error between Inverter board and main circuit board ...................................... 53

E5F: Inverter board fails to start the motor ....................................................................................... 53

E5H: The Inverter board input voltage is too low (less than 175 V) .................................................. 54

E62: Overheating during washing .................................................................................................... 55

E66: Heating element power supply relay faulty .............................................................................. 56

E68: Washing heating element leakage ........................................................................................... 57

E69: Washing heating element damaged ........................................................................................ 58

E6A: Heating relay sensing faulty .................................................................................................... 59

E6H: Heating element power relay faulty (incongruence between sensing and relay status) ............ 59

E71: Washing NTC probe faulty ...................................................................................................... 60

E74: NTC probe improperly positioned ............................................................................................ 61

E83: Error reading the programme selector code............................................................................. 62

E86: Programme selector configuration error................................................................................... 62

E87: Display board microprocessor faulty ........................................................................................ 62

E91: Communication error between the display board and the main circuit board (1

st

part) .............. 63

Guide to diagnostics of electronic controls EWM10931

2012 TS/DT-mdm FCPD-dp 4/79 599 75 27-46 Rev.00

E91: Communication error between the display board and the main circuit board (2

nd

part) ............. 64

E91: Communication error between the display board and the main circuit board (3

rd

part) .............. 65

E92: protocol incongruence ............................................................................................................. 66

E93: Appliance configuration error................................................................................................... 66

E94: Incorrect configuration of washing cycle .................................................................................. 66

E97: Inconsistency between control selector version and configuration data .................................... 66

E98: Communication error between main PCB and Inverter board .................................................. 66

E9C: Display board configuration error ............................................................................................ 67

E9E: Display board sensor/touch key faulty ..................................................................................... 67

EC1: Water fill solenoid valves blocked ........................................................................................... 68

EC2: Problem with weight sensor .................................................................................................... 69

EC3: Problem with weight sensor .................................................................................................... 70

EF1: Drain hose blocked/kinked/too high; drain filter clogged/dirty ................................................... 71

EF2: Excessive detergent dosing; drain hose kinked/blocked; drain filter dirty/clogged ................... 71

EF3: Aqua Control device triggered ................................................................................................. 71

EF4: Water fill pressure too low and solenoid valve open ................................................................ 71

EF5: Unbalanced load, spin phases skipped. .................................................................................. 71

EF6: Reset appliance. ..................................................................................................................... 72

EH1: Mains frequency incorrect ....................................................................................................... 72

EH2: Supply voltage too high .......................................................................................................... 72

EH3: Supply voltage too low ............................................................................................................ 73

EH4: “zero watt” relay not functioning .............................................................................................. 73

EHE: Inconsistency between safety relay (main circuit board) and safety sensing circuit ................. 73

EHF: Safety sensing circuit faulty .................................................................................................... 73

8 WM OPERATING CIRCUIT DIAGRAM ............................................................................................... 74

8.1 Key to circuit diagram WM ........................................................................................................... 75

8.2 Main circuit board connectors ...................................................................................................... 76

8.3 Burns on the main circuit board EWM10931 ................................................................................ 77

Guide to diagnostics of electronic controls EWM10931

2012 TS/DT-mdm FCPD-dp 5/79 599 75 27-46 Rev.00

1 INTRODUCTION

1.1 Purpose of this manual

The purpose of this manual is to explain, simply and schematically, the steps any Technician must take

when faced with the problems indicated by the various alarm codes on appliances with electronic control in

the EWM10931 TC1-TC2-TC3 THE INSPIRATION RANGE.

Depending on the appliance configuration, the alarms may be entirely or partially displayed to the user: the

latter solution is usually adopted.

The diagnostics system is used by Service Technicians to:

♦ Read alarms

♦ delete the alarm stored,

♦ Test the appliance operation.

1.2 Cautions

Any work on electrical appliances must only be carried out by qualified personnel.

Before servicing an appliance, check the efficiency of the electrical system in the

home using appropriate instruments. For example: refer to the indications

provided/illustrated in the <<metratester>> course at the address

(http://electrolux.edvantage.net

) on the Electrolux Learning Gateway portal.

When the work is finished check that the equipment's safety conditions have

been reinstated, as though it were straight off the assembly line.

If the circuit board has to be handled/replaced, use the ESD kit (Cod. 405 50 63-95/4)

to avoid static electricity from damaging the circuit board, see S.B. No. 599 72 08-09

or consult the course “Electrostatic charges” at the address

(http://electrolux.edvantage.net

) on the Electrolux Learning Gateway portal.

This platform is not fitted with an ON/OFF switch. Before you access internal

components, take the plug out of the socket to cut the power supply.

Make resistance measurements, rather than direct voltage and current

measurements.

Warning the sensors located on the display board could be at a potential of

220 Volts.

When replacing the heating element, replace it with one

that has the same characteristics (2 thermal fuses) in order

not to compromise the safety of the appliance. Do not

remove/switch the NTC sensors between heating elements.

Always empty the appliance of all the water before laying it

on its side.

Never place the appliance on its right side (electronic control system side):

some of the water in the detergent dispenser could leak onto the

electrical/electronic components and cause these to burn.

When replacing components, please refer to the code shown in the list of spare

parts relating to the appliance.

The resistance values of the components shown in this S.M. are purely

indicative (relating to a sample appliance with new components).

For the actual value of the component, please refer:

to S.B. 599706597 for motors, and for the other components, please consult

S.M. 599728903 “Component Characteristics”.

Guide to diagnostics of electronic controls EWM10931

2012 TS/DT-mdm FCPD-dp 6/79 599 75 27-46 Rev.00

1.3 How to proceed

1. Identify the type of control in question (page 7) and access the diagnostic cycle. (see page 8)

2. Read the alarm stored (page 14) and consult the instructions regarding the “alarm codes”, page 16÷19

3. Delete the alarms stored (page 15)

4. If you are unable to access the diagnostic mode, consult the chapter entitled “The diagnostics system

cannot be accessed” (page 21)

5. Should the main electronic circuit board need to be replaced, make sure there are no burns. (see page 77)

6. After all interventions, check the appliance is operating correctly using the diagnostic cycle. (page 9)

7. Delete any alarm that may have been stored during the diagnostics operations (page 15)

Guide to diagnostics of electronic controls EWM10931

2012 TS/DT-mdm FCPD-dp 7/79 599 75 27-46 Rev.00

2 WM APPLIANCE CONTROL PANELS

These are the stylings available at the time of printing of this Service Manual. Others may be developed

in future.

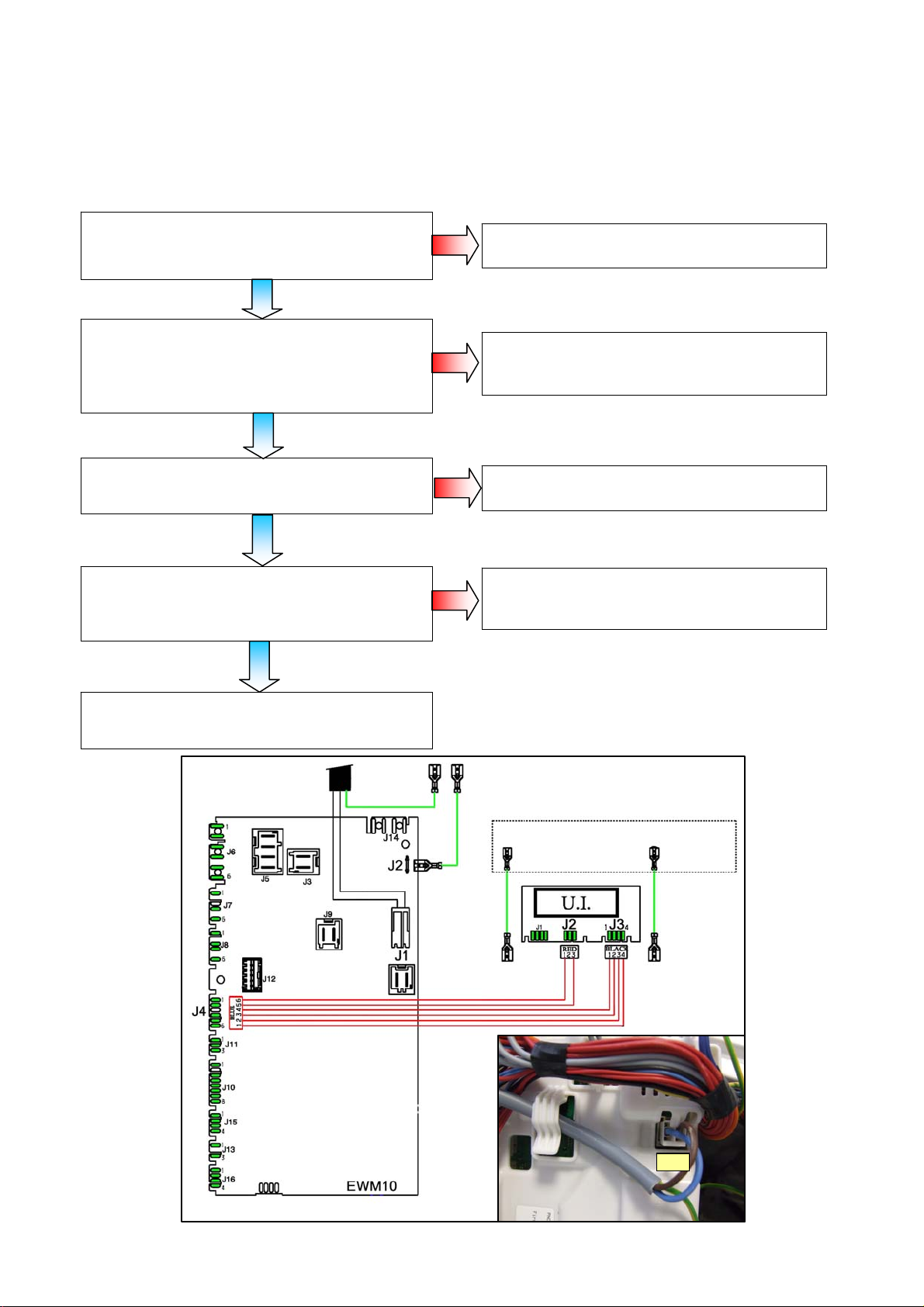

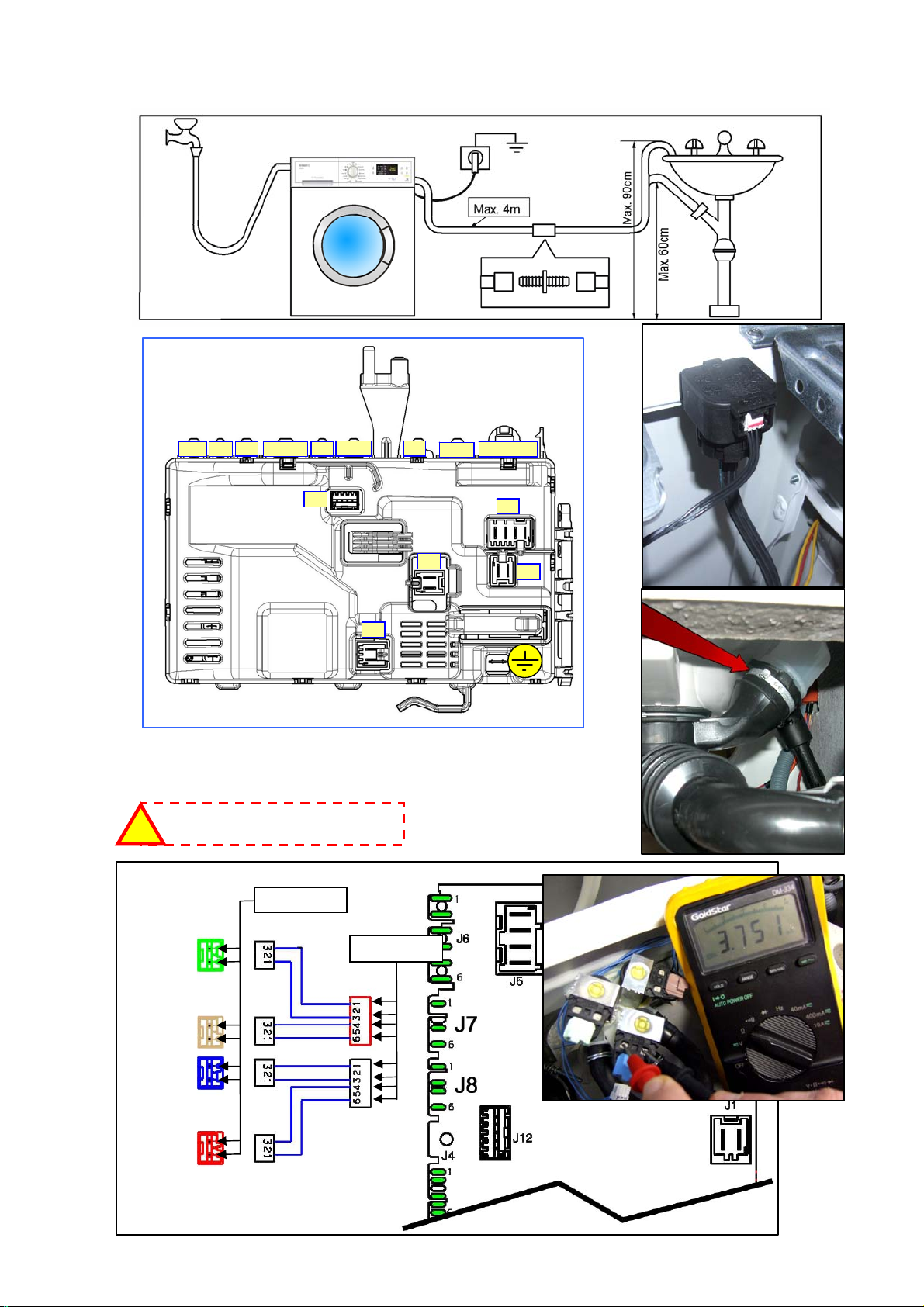

3 PROGRAMMING/UPDATING THE MAIN CIRCUIT BOARD

In the Service Notes the main circuit board (587) is identified with two spare parts

codes:

ª Code 973 914… identifies the pre-programmed board.

ª Code 132… identifies the unprogrammed board.

The circuit board can be programmed/updated using the Sidekick application.

For further information, please refer to the instructions provided/illustrated in the course entitled << Guide

to Sidekick >> at the address (http://electrolux.edvantage.net

) on the Electrolux Learning Gateway portal.

In order to update / programme the main board, insert the Sidekick

connector in the position indicated by the red arrow:

• For WASHING MACHINES, this is done directly from the

main board, see Fig.a.

THE INSPIRATION RANGE

TC 1

TC 2

TC 3

587

fig. a

Guide to diagnostics of electronic controls EWM10931

2012 TS/DT-mdm FCPD-dp 8/79 599 75 27-46 Rev.00

4 DIAGNOSTICS SYSTEM

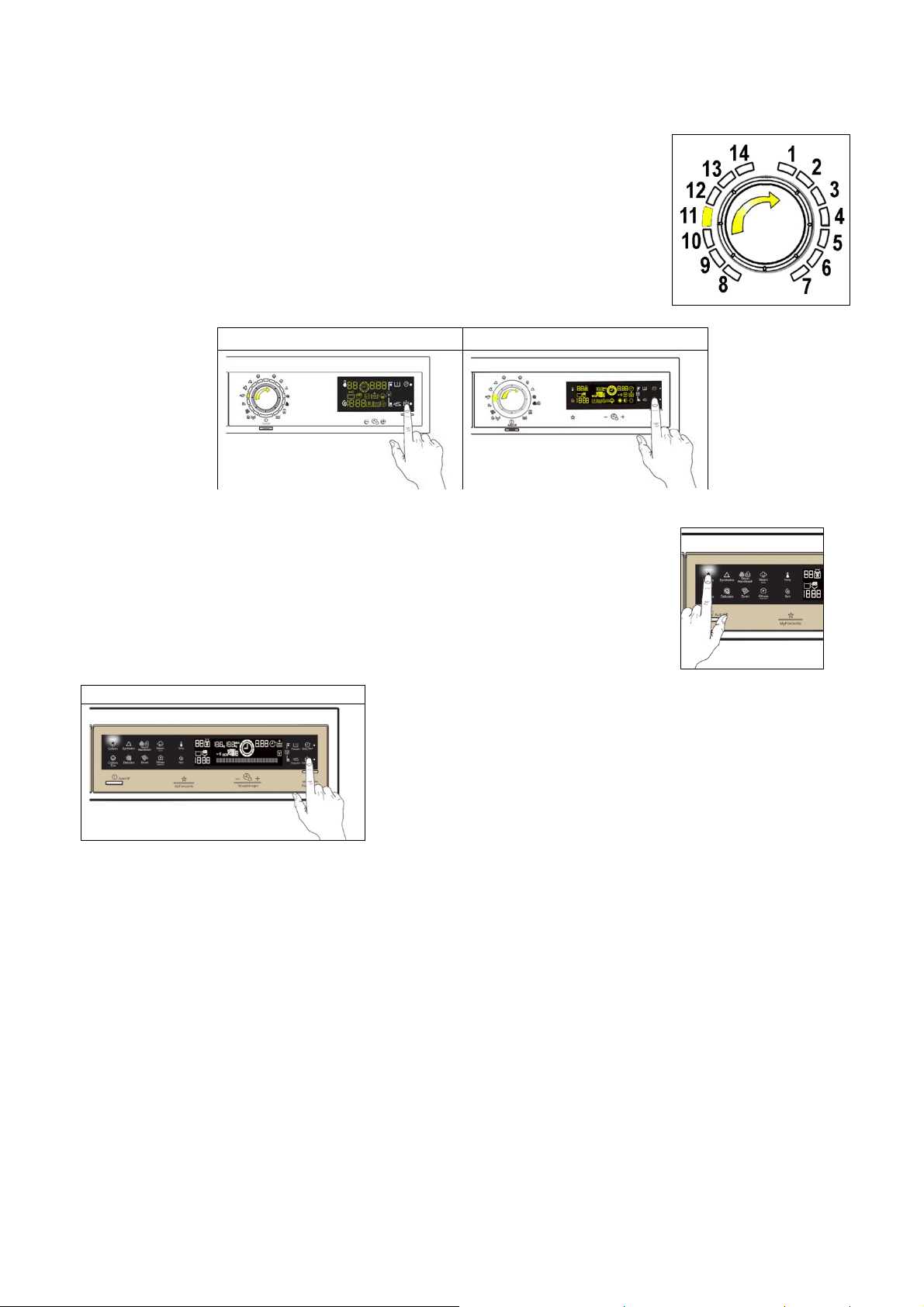

4.1 Accessing diagnostics

The operations listed below must be carried out within 7 seconds.

TC 3 TC 2 TC 1

Do not start the procedure with your fingers over the combination sensors

1. Switch on the appliance using the ON/OFF button. The first LED lights up.

2. Simultaneously press the START/PAUSE button and the nearest option sensor (as shown in the

diagram).

3. Hold your fingers over the sensors until the LEDs and symbols begin to flash in sequence (approximately

3 seconds).

In the first position, the operation of the sensors, the LEDs and the groups of symbols shown on the LCD

display is checked;

For the TC3 and TC2 styling:

When the programme selector is turned in a clockwise direction, the operation of the various components is

diagnosed and the alarms are read (see diagnostic test on the next page).

For the TC1 styling:

Since there is no selector with which to perform the diagnostics of the various components and the alarm

reading, the two sensors shown in the figure below are used (the top one is used to move forward

progressively and the bottom one to move backwards in the same way). Concurrently, the function performed

is described in the text line (see diagnostic test on page 11).

Next Previous

During this phase, if any combination of sensors (except the one for diagnosis) is pressed, all the option

combinations stored will be deleted (Extra rinse, Buzzer disable, etc.).

4.2 Quitting the diagnostics system

→ To exit the diagnostic cycle, switch the appliance off, then back on and then off again.

Guide to diagnostics of electronic controls EWM10931

2012 TS/DT-mdm FCPD-dp 9/79 599 75 27-46 Rev.00

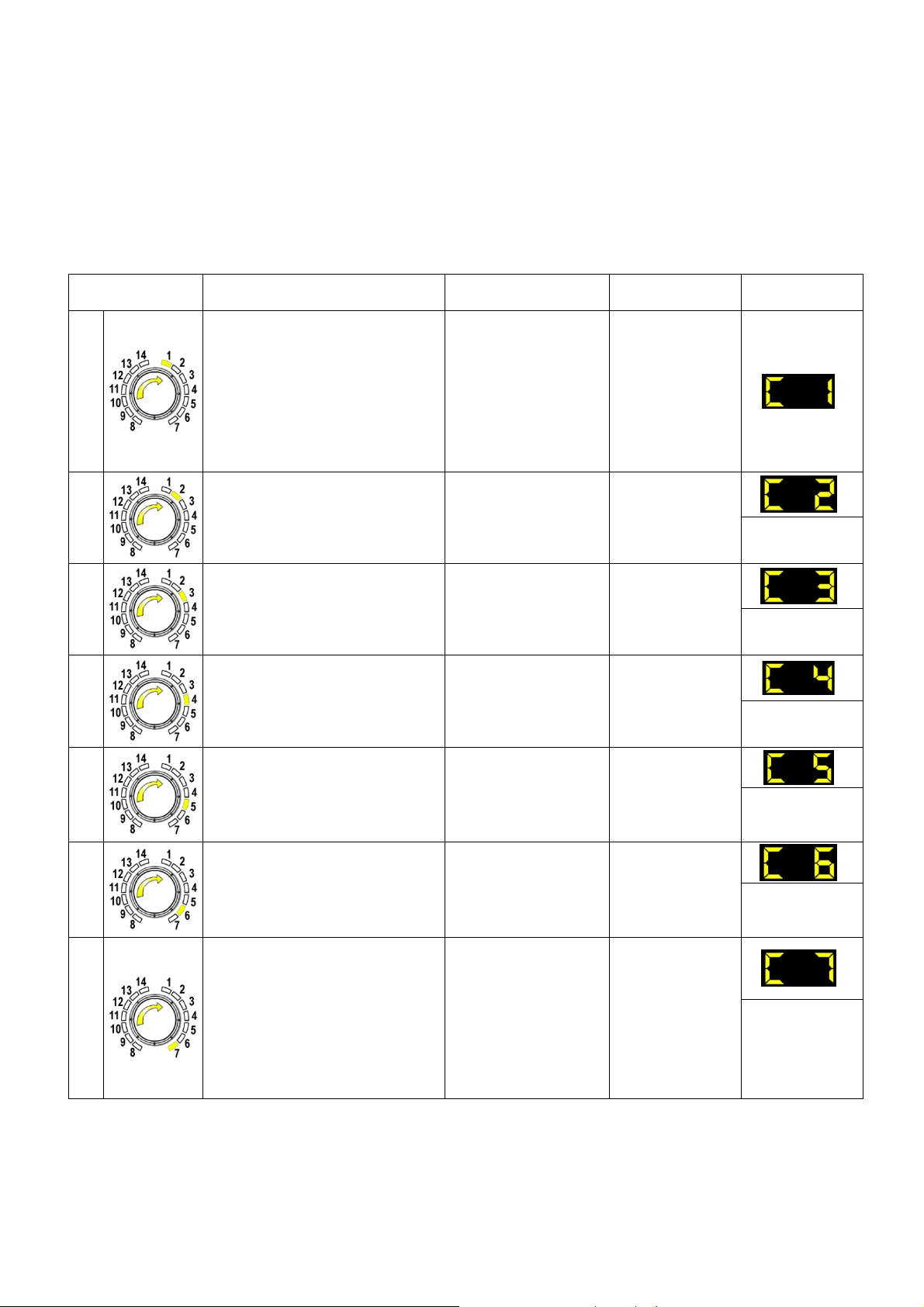

4.3 Phases of the diagnostics test

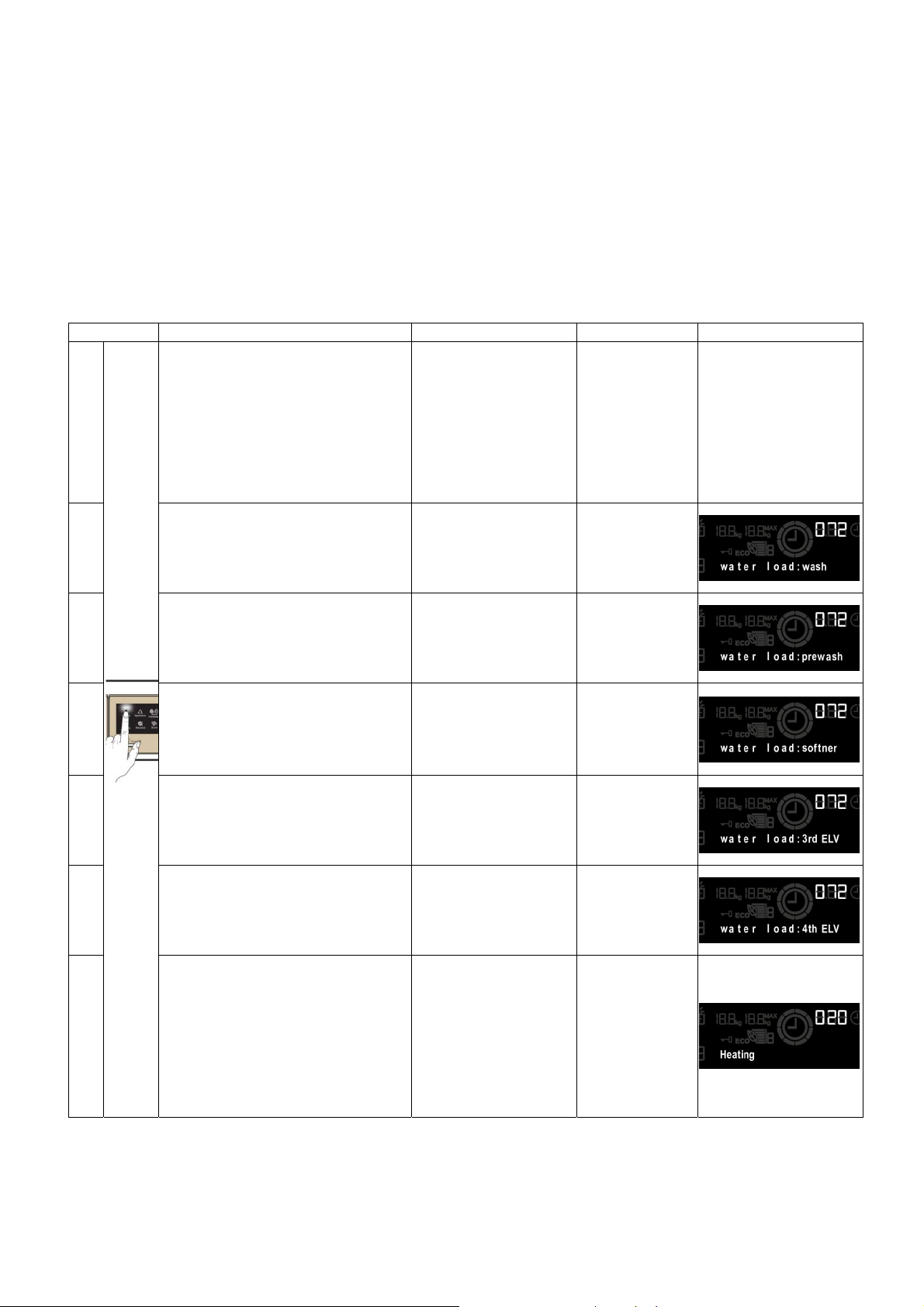

4.3.1 TC3-TC2 styling

Irrespective of the type of PCB and the configuration of the programme selector, after entering the diagnostic

mode, turn the programme selector dial clockwise to perform the diagnostic cycle for the operation of the

various components and to read any alarms.

Concurrently, a selector control code is shown on the LCD display, which indicates for two seconds the

description in the last column of the table below.

(all alarms are enabled in the diagnostic cycle).

Selector

position

Components activated Working conditions Function tested LCD display

1

- The LEDs, groups of symbols

in the LCD screen and the

backlight of the display are

turned on in sequence

- Touch a sensor to turn on the

group of icons in the LCD

screen or the corresponding

LED and the buzzer sounds at

the same time

Always active

User interface

functioning

2

- Door safety interlock

- Wash solenoid valve

Door closed

Water level below

anti-flooding level

Maximum time 5 mins.

Water fill to wash

compartment

Water level in

the tub (mm)

3

- Door safety interlock

- Pre-wash solenoid valve

Door closed

Water level below

anti-flooding level

Maximum time 5 mins.

Water fill to pre-

wash

compartment

Water level in

the tub (mm)

4

- Door safety interlock

- Solenoid valve pre-wash

and wash

Door closed

Water level below

anti-flooding level

Maximum time 5 mins.

Water fill to

conditioner

compartment

Water level in

the tub (mm)

5

- Door safety interlock

- Third solenoid valve

Door closed

Water level below

anti-flooding level

Maximum time 5 mins.

Water fill to third

solenoid valve

compartment

Water level in

the tub is

displayed (mm)

6

- Door safety interlock

- Fourth solenoid valve

(hot water where featured)

Door closed

Water level below

anti-flooding level

Maximum time 5 mins.

Water fill to

fourth solenoid

valve

compartment

Water level in

the tub is

displayed (mm)

7

- Door safety interlock

- Wash solenoid valve, if the

water in the tub is not enough

to cover the heating element

- Heating element

- Weight sensor (if there is one,

an extra litre of water is

loaded)

- Circulation pump

Door closed

Water level above the

heating element

Maximum time

10 mins up to 90°C (*)

Reheating

Circulation

Temperature in

°C measured

using the NTC

probe

Guide to diagnostics of electronic controls EWM10931

2012 TS/DT-mdm FCPD-dp 10/79 599 75 27-46 Rev.00

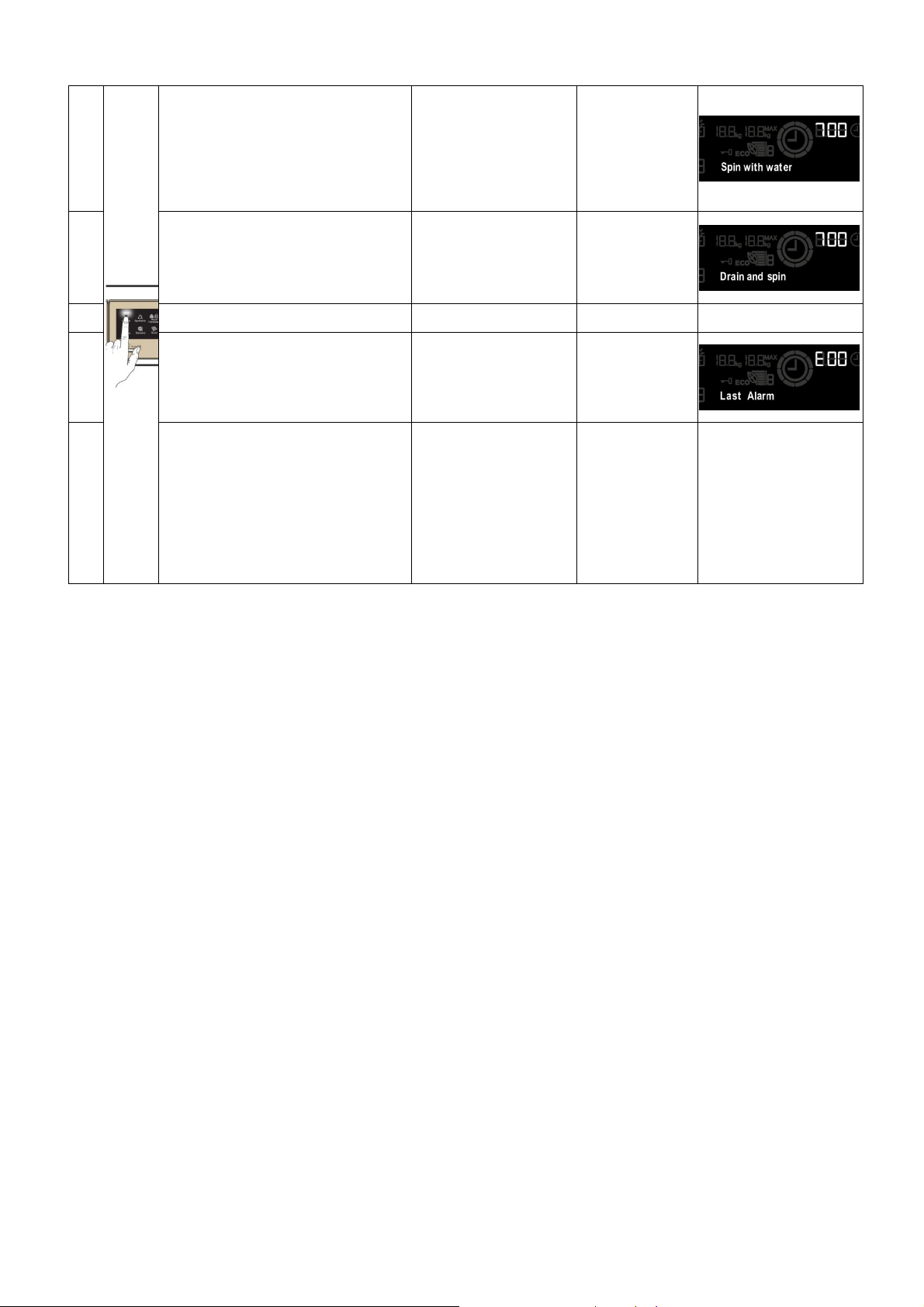

8

- Door safety interlock

- Wash solenoid valve, if the

water in the tub is not enough

to cover the heating element

- Motor (55 rpm clockwise,

55 rpm anti-clockwise,

250 rpm pulse)

Door closed

Water level above the

heating element

Check for leaks

from the tub

Drum speed in

rpm/10

9

- Door safety interlock

- Drain pump

- Motor up to 650 rpm then at

maximum spin speed (**)

Door closed

Water level lower

than anti-boiling level

for spinning

Drain, calibration

of analogue

pressure switch

and spin

Drum speed in

rpm/10

10

- Door safety interlock

- Drain pump

- Power fan

- Condensation solenoid valve

- Drying heating element

Door closed

Water level below

anti-boiling level

Maximum time

10 minutes

Drying

Displays the air

temperature

alternating

detection by

the two NTC

probes

11

- Reading/Deleting the last alarm ----- ----

12

÷

14

- The LEDs, groups of symbols

in the LCD screen and the

backlight of the display are

turned on in sequence

- Touch a sensor to turn on the

group of icons in the LCD

screen or the corresponding

LED and the buzzer sounds at

the same time

Always active

User interface

functioning

(*) In most cases, this time is sufficient to check the heating. H owever, the time can be increased by repeating the phase without draining

the water: pass f or a moment to a different phase of the diagnostic cycle and then back to the heating control phase (if the temperatur e is

higher than 80°C, heating does not take place).

(**) The check at the maximum speed occurs without control of the A.G.S. and no garments must be inside the appliance.

Guide to diagnostics of electronic controls EWM10931

2012 TS/DT-mdm FCPD-dp 11/79 599 75 27-46 Rev.00

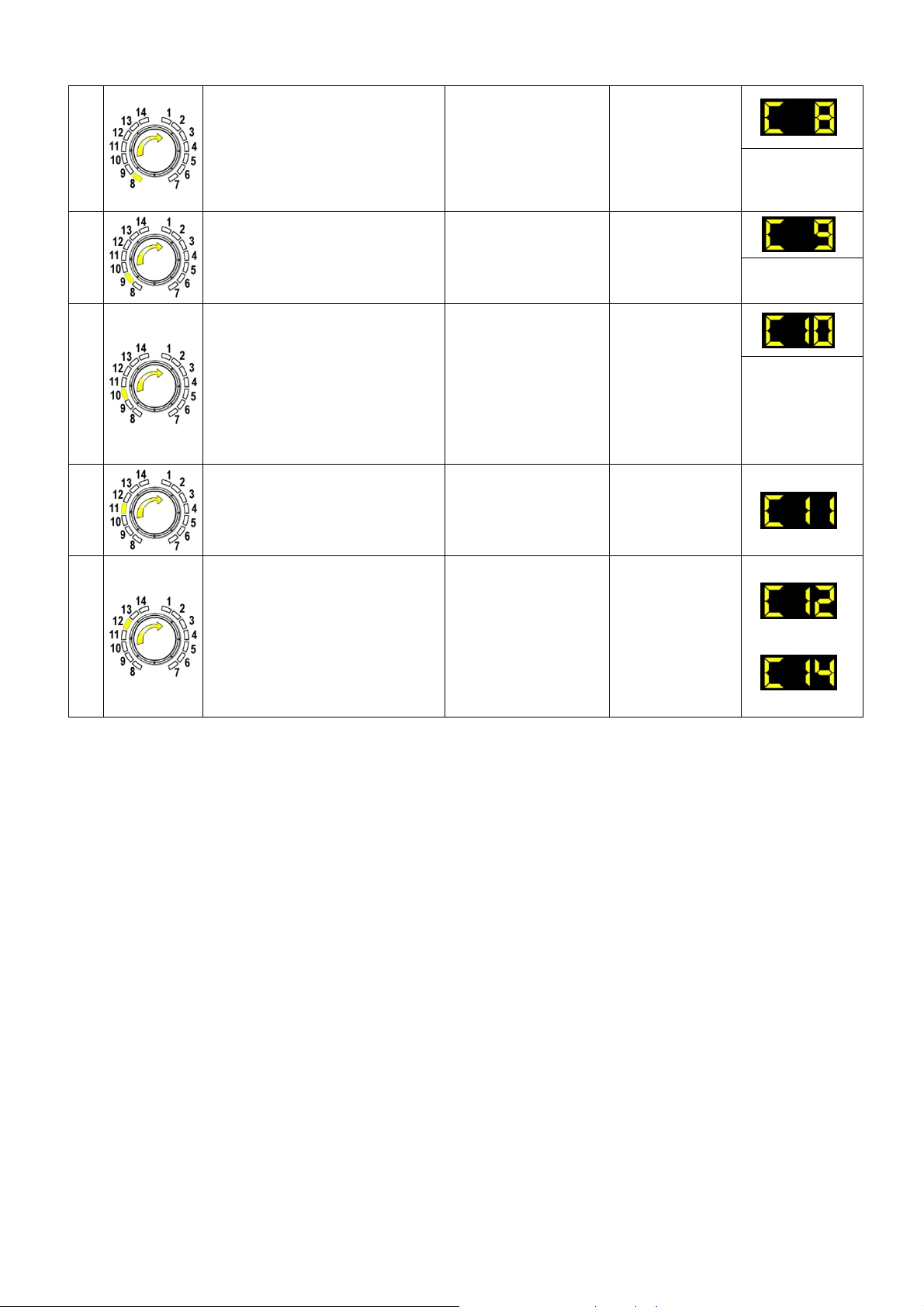

4.3.2 TC1 styling

Irrespective of the type of circuit board and the configuration of the programmes, after entering the diagnostic

mode, touch the sensor to the left of the display (as shown in the figure) to perform the diagnostic cycle for the

operation of the various components and to read any alarms.

The LCD display shows the function checked in the middle (see third column) and at the top right, using the

three digits:

¾ the water level in the tub, during the solenoid valve activation phases.

¾ the temperature in degrees °C, during the heating phases.

¾ the drum revolutions in rpm/10, during the phases when the motor is powered.

(all alarms are enabled in the diagnostic cycle)

Location Components activated Working conditions Function tested LCD display

1

- The LEDs are turned on in

sequence, as are the symbol

groups of the LCD display and

its backlight

- Touch a sensor to turn on the

group of icons in the LCD

screen or the corresponding

LED and the buzzer sounds at

the same time

Always active

User interface

functioning

2

- Door safety interlock

- Wash solenoid valve

Door closed

Water level below

anti-flooding level

Maximum time 5 mins.

Water fill to

wash

compartment

3

- Door safety interlock

- Pre-wash solenoid valve

Door closed

Water level below

anti-flooding level

Maximum time 5 mins.

Water fill to

pre-wash

compartment

4

- Door safety interlock

- Solenoid valve

pre-wash and wash

Door closed

Water level below

anti-flooding level

Maximum time 5 mins.

Water fill to

conditioner

compartment

5

- Door safety interlock

- Third solenoid valve

Door closed

Water level below

anti-flooding level

Maximum time 5 mins.

Water fill to

third solenoid

valve

compartment

6

- Door safety interlock

- Fourth solenoid valve (hot water

where featured)

Door closed

Water level below

anti-flooding level

Maximum time 5 mins.

Water fill to

fourth solenoid

valve

compartment

7

- Door safety interlock

- Wash solenoid valve, if the

water in the tub is not enough to

cover the heating element

- Heating element

- Weight sensor (if there is one,

an extra litre of water is loaded)

- Circulation pump

Door closed

Water level above the

heating element

Maximum time

10 mins up to 90°C (*)

Reheating

Circulation

Guide to diagnostics of electronic controls EWM10931

2012 TS/DT-mdm FCPD-dp 12/79 599 75 27-46 Rev.00

8

- Door safety interlock

- Wash solenoid valve, if the

water in the tub is not enough to

cover the heating element

- Motor (55 rpm clockwise,

55 rpm anti-clockwise,

250 rpm pulse)

Door closed

Water level above

the heating element

Check for leaks

from the tub

9

- Door safety interlock

- Drain pump

- Motor up to 650 rpm then at

maximum spin speed (**)

Door closed

Water level lower

than anti-boiling level

for spinning

Drain,

calibration of

analogue

pressure switch

and spin

10

----- ----- ----- -----

11

- Reading/Deleting the last alarm ----- ----

12

÷

14

- The LEDs, groups of symbols in

the LCD screen and the

backlight of the display are

turned on in sequence

- Touch a sensor to turn on the

group of icons in the LCD screen

or the corresponding LED and

the buzzer sounds at the same

time

Always active

User interface

functioning

(*) In most cases, this time is sufficient to check the heating. H owever, the time can be increased by repeating the phase without draining

the water: pass f or a moment to a different phase of the diagnostic cycle and then back to the heating control phase (if the temperatur e is

higher than 80°C, heating does not take place).

(**) The check at the maximum speed occurs without control of the A.G.S. and no garments must be inside the appliance.

Guide to diagnostics of electronic controls EWM10931

2012 TS/DT-mdm FCPD-dp 13/79 599 75 27-46 Rev.00

5 ALARMS

5.1 Displaying the alarms to the user

When a problem occurs in the appliance, the LCD display shows a “WARNING”:

− in stylings TC3 and TC2 with a code (in the three digits, where the time until the end of the cycle is

represented).

− in styling TC1, a message is shown (in the text line).

This information ceases to be displayed when the problem is repaired/solved. The buzzer then emits a

sound (three short “beeps”every 20” for 5 minutes). This does not occur for alarm EH0.

TC 3 TC 2

TC 1

The alarms displayed to the user are listed below and can also be eliminated by the user:

TC3 / TC2 TC1

E10 - Water fill difficulty (tap closed) Check the tap

E20 - Drain difficulty (

f

ilter dirty) Check the drain filter

E40 - Door open Check the door

EF0 - Excessive detergent Excessive detergen

t

EH0 -

V

oltage or frequency outside normal values Unstable frequency or voltage

While the alarm listed below:

TC3 / TC2 TC1

EF0 - Water leakage (Aqua Control System) Caution: water

The intervent ion of a service engineer is required.

The other alarms are displayed by a code.

The alarms are enabled during the execution of the washing programme. With the exception of alarms

associated w ith the configuration and the power supply voltage/frequency, whic h ar e also displayed dur ing

the programme selec tion phase.

The door can normally be opened (except where specified) when an alarm condition has occurred, on

condition that:

• The level of the water in the tub is below a certain level.

• The water temperature is lower than 55°C.

• The motor has stopped.

Certain alarm conditions require a drain phase to be performed before the door can be opened for safety

reasons:

• Cooling water fill if the temperature is greater than 65°C.

• Drain until the analogue pressure switch is on empty, during a max. 3 minute interval.

Guide to diagnostics of electronic controls EWM10931

2012 TS/DT-mdm FCPD-dp 14/79 599 75 27-46 Rev.00

5.2 Reading the alarms

The last three alarms stored in the FLASH memory of the PCB can be

displayed:

5.2.1 TC3-TC2 styling

• Enter the diagnostic mode (para. 3.1).

• Irrespective of the type of PCB and configuration, turn the programme

selector knob clockwise to the eleventh position the last alarm is displayed.

• To display previous alarms, touch the sensor closest to the START/PAUSE

sensor in sequence (as shown in the figure).

• To return to the last alarm, touch the START/PAUSE sensor.

5.2.2 TC1 styling

• Enter the diagnostic mode (para. 3.1).

• Irrespective of the type of circuit board and configuration, using the sensor

shown in the figure, go to the eleventh position and the last alarm is

displayed.

• To display previous alarms, touch the sensor closest to the START/PAUSE

sensor in sequence (as shown in the figure below).

• To return to the last alarm, touch the START/PAUSE sensor.

TC 1

5.3 Rapid reading of alarms

It is possible to display the last alarm even if the selector is not in the eleventh diagnostics position or if the

appliance is in normal operating mode (for example when performing a wash programme):

→ Touch the START/PAUSE sensor and the nearest option sensor simultaneously (as if you were

entering DIAGNOSTIC mode) and hold for at least 2 seconds: the LCD display shows the last alarm.

The alarm will continue to be displayed until a sensor is touched.

The alarm reading system is as described in para. 4.2.

While the alarm is being displayed, the appliance continues to perform the cycle or, if in the programme

selection phase, it stores the previously selected options.

TC 3 TC 2

Guide to diagnostics of electronic controls EWM10931

2012 TS/DT-mdm FCPD-dp 15/79 599 75 27-46 Rev.00

5.4 Deleting the last alarm

It is good practice to cancel the alarms stored:

• after reading the alarm codes, to check whether the alarm re-occurs during the diagnostic cycle

• after repairing the appliance, to check whether it re-occurs during testing

TC 3 TC 2

1. Enter the diagnostic mode (para. 3.1).

2. Turn the selector clockwise until the eleventh LED lights up.

3. Simultaneously press the START/PAUSE sensor and the nearest option sensor (as

shown in the diagram).

4. Keep your fingers over the sensors until the LCD display shows “E00” (at least

5 seconds).

TC 1

1. Enter the diagnostic mode (para. 3.1).

2. Irrespective of the type of circuit board and configuration, touch the sensor (shown in

fig. a) to go to the eleventh position and the alarm is displayed.

3. Simultaneously press the START/PAUSE sensor and the nearest option sensor

(as shown in fig. b).

4. Keep your fingers over the sensors until the LCD display shows “E00” (at least

5 seconds).

N.B. With this operation all the alarms stored are deleted.

Fig. a Fig. b

Guide to diagnostics of electronic controls EWM10931

2012 TS/DT-mdm FCPD-dp 16/79 599 75 27-46 Rev.00

5.5 ALARM SUMMARY TABLE

Alarm Description Possible faul

t

Machine status/a

c

tion Rese

t

Page

E00

E11 Water fill difficulty during washing

Tap closed or water pressure too low; drain pipe improperly

positioned; water fill solenoid valve faulty; leaks from water circuit on

pressure switch; pressure switch faulty; wiring faulty; main PCB

faulty.

Cycle is paused with door locked START/RESET 20

E13 Water leaks

Drain pipe improperly positioned; water pressure too low

Water fill solenoid valve faulty; water circuit on pressure switch is

leaking/clogged; pressure switch faulty.

Cycle is paused with door locked START/RESET 22

E21

Drain difficulty during washing

Drain pipe kinked/clogged/improperly positioned; drain filter

clogged/dirty; wiring faulty; pressure switch faulty; drain pump rotor

blocked; drain pump faulty; main PCB faulty.

Cycle is paused

(after 2 attempts)

START

ON/OFF

RESET

24

E23

Faulty triac for drain pump Wiring faulty; drain pump faulty; main PCB fault.

Safety drain cycle - Cycle stops with

door open

RESET 26

E24

Drain pump triac “sensing” circuit

faulty

Main circuit board faulty.

Safety drain cycle - Cycle stops with

door unlocked

RESET 28

E31

Malfunction in electronic pressure

switch circuit

Wiring; Electronic pressure switch; Main PCB. Cycle stops with door locked RESET 28

E32

Calibration error of the electronic

pressure switch

Drain pipe kinked/clogged/improperly positioned; solenoid valve

faulty; drain filter clogged/dirty; drain pump faulty; leaks from pressure

switch hydraulic circuit; pressure switch faulty;

Wiring; main PCB.

Cycle is paused START/RESET 29

E35

Overflow

Water fill solenoid valve faulty; leaks from water circuit on pressure

switch; wiring faulty; pressure switch faulty; main PCB faulty.

Cycle interrupted. Safety drain cycle.

Drain pump continues to operate (5 min.

on, then 5 min. off. etc.)

RESET 30

E38

Internal pressure chamber is

clogged (water level does not

change for at least 30 sec. of drum

rotation)

Motor belt broken; water circuit on pressure switch clogged. Heating phase is skipped RESET 31

E41

Door open

Check whether the door is closed properly;

Wiring faulty; door safety interlock faulty;

Main circuit board faulty.

Cycle is paused START/RESET 32

E42 Problems with door lock

Wiring faulty; door safety interlock faulty;

Electrical current leak between heating element and ground; main

PCB faulty.

Cycle is paused START/RESET 34

E43

Faulty triac supplying power to door

delay system

Wiring faulty; door safety interlock faulty;

Main circuit board faulty.

(Safety drain cycle)

Cycle blocked

RESET 36

E44

Faulty sensing by door delay system Main circuit board faulty.

(Safety drain cycle)

Cycle blocked

RESET 37

E45

Faulty sensing by door delay system

triac

Main circuit board faulty.

(Safety drain cycle)

Cycle blocked

RESET 37

Guide to diagnostics of electronic controls EWM10931

2012 TS/DT-mdm FCPD-dp 17/79 599 75 27-46 Rev.00

Alarm Description Possible faul

t

Machine status/a

c

tion Rese

t

Page

E52

No signal from motor tachometric

generator

Wiring faulty; Motor faulty;

Inverter board faulty.

Cycle stops with door locked

(after 5 attempts)

ON/OFF

RESET

38/40

E57

Inverter is drawing too much current

(

>15 A)

Wiring faulty on inverter for motor; inverter PCB faulty; motor faulty.

Cycle stops with door locked

(after 5 attempts)

ON/OFF

RESET

42

E58

Inverter is drawing too much current

(

>4.5 A)

Motor malfunction (overload); Wiring faulty on inverter faulty; motor

faulty; inverter PCB faulty.

Cycle stops with door locked

(after 5 attempts)

ON/OFF

RESET

44

E59

No signal from tachometric

generator for 3 seconds

Wiring faulty on inverter for motor; inverter PCB faulty; motor faulty.

Cycle stops with door locked

(after 5 attempts)

ON/OFF

RESET

46

E5A

Overheating on heat dissipator for

Inverter

Overheating caused by continuous operation or ambient conditions

(let appliance cool down); Inverter PCB faulty. NTC open (on the

Inverter PCB).

Cycle stops with door locked

(after 5 attempts)

ON/OFF

RESET

48

E5C Input voltage is too high

Input voltage is too high (m easure the grid voltage); Inverter PCB

faulty.

Cycle stops with door locked

(after 5 attempts)

ON/OFF

RESET

49

E5d

Data transfer error between Inverter

and main PCB

Line interference; wiring faulty; faulty main PCB or inverter PCB. ----------------

ON/OFF

RESET

50

E5E

Communication error between

Inverter and main PCB

Faulty wiring between main PCB and inverter PCB; Inverter PCB

faulty; Main PCB faulty.

Cycle blocked

(after 5 attempts)

ON/OFF

RESET

51

E5F

Inverter PCB fails to start the motor Wiring faulty; Inverter PCB faulty; Main PCB faulty.

Cycle stops with door open

(after 5 attempts)

ON/OFF

RESET

51

E5H

Input voltage is lower than 175 V Wiring faulty; Inverter PCB faulty.

Cycle stops with door locked

(after 5 attempts)

ON/OFF

RESET

52

E62

Overheating during

w

ashing

(temperature higher than 88°C for

more than 5 min.)

Wiring faulty; NTC probe for wash cycle faulty; Heating element

faulty; Main PCB faulty.

Safety drain cycle

Cycle stops with door open

RESET 53

E66

Heating element power relay faulty

(inconsistency between sensing and

K2 relay status)

Main PCB faulty.

Safety water fill

Cycle stops with door closed.

ON/OFF

RESET

54

E68 Current leak to the ground Current leakage between heating element and ground. The heating phase is skipped START/RESET 55

E69 Heating element interrupted

Wiring faulty; Heating element for washing interrupted (thermal fuse

open); Main PCB faulty.

----------------

START

ON/OFF

RESET

56

E6

A

Heating relay sensing faulty Main circuit board faulty. Cycle stops with door locked RESET 57

E6H

Heating element power relay faulty

(inconsistency between sensing and

K1 relay status)

Wiring faulty; Earth-leakage between heating element and earth;

Main PCB faulty.

Safety water fill

Cycle stops with door closed.

ON/OFF

RESET

57

E71

NTC probe fo

r

wash cycle faulty

(short-circuited or open)

Wiring faulty; NTC probe for wash cycle faulty;.

Main circuit board faulty.

The heating phase is skipped START/RESET 58

E74

NTC probe for wash cycle

improperly positioned

Wiring faulty; NTC probe for wash cycle improperly positioned; NTC

probe faulty; Main PCB faulty.

The heating phase is skipped RESET 59

E83

Error in reading selector Main PCB faulty (Incorrect configuration data). Cycle cancelled START/RESET 60

Guide to diagnostics of electronic controls EWM10931

2012 TS/DT-mdm FCPD-dp 18/79 599 75 27-46 Rev.00

Alarm Description Possible faul

t

Machine status/a

c

tion Rese

t

Page

E86 Selector configuration error Display board. ----------------

START

ON/OFF

RESET

60

E87

Display board microprocessor faulty If this continues, replace the display board. No action to be taken

START

ON/OFF

RESET

60

E91

Communication error between main

PCB and display

Wiring faulty; Control/display PCB faulty;

Main circuit board faulty; Inverter PCB faulty; Weight sensor faulty.

---------------- RESET 61

E92

Communication inconsistency

between main PCB and display

(incompatible versions)

Incorrect control/display PCB;

Incorrect PCB (does not correspond to the model).

Cycle blocked ON/OFF 62

E93

Appliance configuration error Main PCB faulty (incorrect configuration data). Cycle blocked ON/OFF 62

E94

Incorrect configuration of washing

cycle

Main PCB faulty (incorrect configuration data). Cycle blocked ON/OFF 62

E97

Inconsistency between programme

selector and cycle configuration

Main PCB faulty (incorrect configuration data). Cycle blocked RESET 62

E98

Communication error between main

PCB - Inverter

Incompatibility between main PCB and Inverter. Cycle blocked ON/OFF 62

E9C

Display board configuration error Display board faulty. ----------------

START

ON/OFF

RESET

63

E9E

Display board sensor/touch key

faulty

Display board faulty. ---------------- ON/OFF 63

EC1

Electronically controlled valve

blocked with operating flowmeter

Wiring faulty; Solenoid valve faulty/blocked, Main PCB faulty.

Cycle stops with door locked

Drain pump continues to operate (5 min.

on, then 5 min. off. etc.)

RESET 64

EC2

Data transfer error between Weight

sensor and main PCB.

Wiring faulty; Weight sensor faulty, PCB faulty. No action to be taken START/RESET 65

EC3

Problems with weight sensor (no

signal or outside the limits)

Wiring faulty; Weight sensor faulty; Main PCB faulty. ---------------- START/RESET 66

EF1

Drain filter clogged

(drain phase too long)

Drain filter clogged/dirty;

Drain hose blocked/kinked/too high.

Warning displayed at the end of cycle START/RESET 67

EF2

Overdosing of detergent (too much

foam during drain phases)

Excessive detergent dosing; Drain hose kinked/blocked;

Drain filter clogged/dirty.

Warning displayed after 5 attempts or

by the specific LED

RESET 67

EF3

Aqua control system intervention Water leaks onto base frame; Aqua control system faulty. Appliance drains ON/OFF RESET 67

EF4

Water fill pressure too low, no signal

from flowmeter and electronically

controlled valve is open

Tap closed, water fill pressure too low. ---------------- RESET 67

EF

5

Unbalanced load Final spin phases skipped. ---------------- START/RESET 67

EF6 Reset If it continues, replace the main board. No action to be taken ---------------- 68

EH1

Supply frequency of appliance

outside the limits

Problem with the power supply network (incorrect/disturbed); Main

PCB faulty.

Wait for nominal frequency conditions ON/OFF 68

Guide to diagnostics of electronic controls EWM10931

2012 TS/DT-mdm FCPD-dp 19/79 599 75 27-46 Rev.00

Alarm Description Possible faul

t

Machine status/a

c

tion Rese

t

Page

EH2

Supply voltage too high

Problem with the power supply network (incorrect/disturbed); Main

PCB faulty.

Wait for nominal voltage conditions ON/OFF 68

EH3 Supply voltage too low

Problem with the power supply network (incorrect/disturbed); Main

PCB faulty.

Wait for nominal voltage conditions ON/OFF 69

EH4

0 Watt relay malfunction Main circuit board faulty. ----------------

ON/OFF

RESET

69

EHE

Inconsistency between FCV relay

(in the main board) and safety

“sensing” circuit

Faulty wiring; Main circuit board faulty.

Safety drain cycle

Cycle stops with door open

RESET 69

EHF

Safety sensing circuit faulty (wrong

input voltage to microprocessor)

Main circuit board faulty.

Safety drain cycle

Cycle stops with door open

RESET 69

Guide to diagnostics of electronic controls EWM10931

2012 TS/DT-mdm FCPD-dp 20/79 599 75 27-46 Rev.00

5.6 Notes on the behaviour of certain alarms

Configuration alarm E93: when this alarm rings (when turned on) the machine blocks and the alarm code appears on the display provided the relevant

configuration part is intact.

It will not be possible to access diagnostics mode and the only available option is to turn the appliance off.

Configuration alarm E94: and the code can be viewed from the display.

The diagnostics mode cannot be accessed and the “quick alarm viewing” mode cannot be used.

Alarms EH1-EH2-EH3: in the event of problems with the supply voltage, the appliance remains in alarm status until the mains frequency or voltage returns to

acceptable values or the appliance is switched off (ON/OFF button). Only the “H” alarm family is displayed if the problem occurs while the appliance is

working normally, the code is shown simultaneously on the display.

The diagnostics mode cannot be accessed and the “quick alarm viewing” mode cannot be used: the alarm can only be read in full when the situation has

normalised.

Alarms E51- E52: all the alarms are displayed during diagnostic testing: normally, when shifting from one control phase to another, the appliance quits the

alarm mode and executes the selected phase. This is not the case for alarms E51 (motor power supply TRIAC short-circuiting) and E52 (no signal from motor

tachometric generator): the only possibility to exit the alarm situation is to rotate the programme switch to the “0” position (reset) for the TC2 and TC3 stylings,

while for the TC1 styling press the ON/OFF button.

Guide to diagnostics of electronic controls EWM10931

2012 TS/DT-mdm FCPD-dp 21/79 599 75 27-46 Rev.00

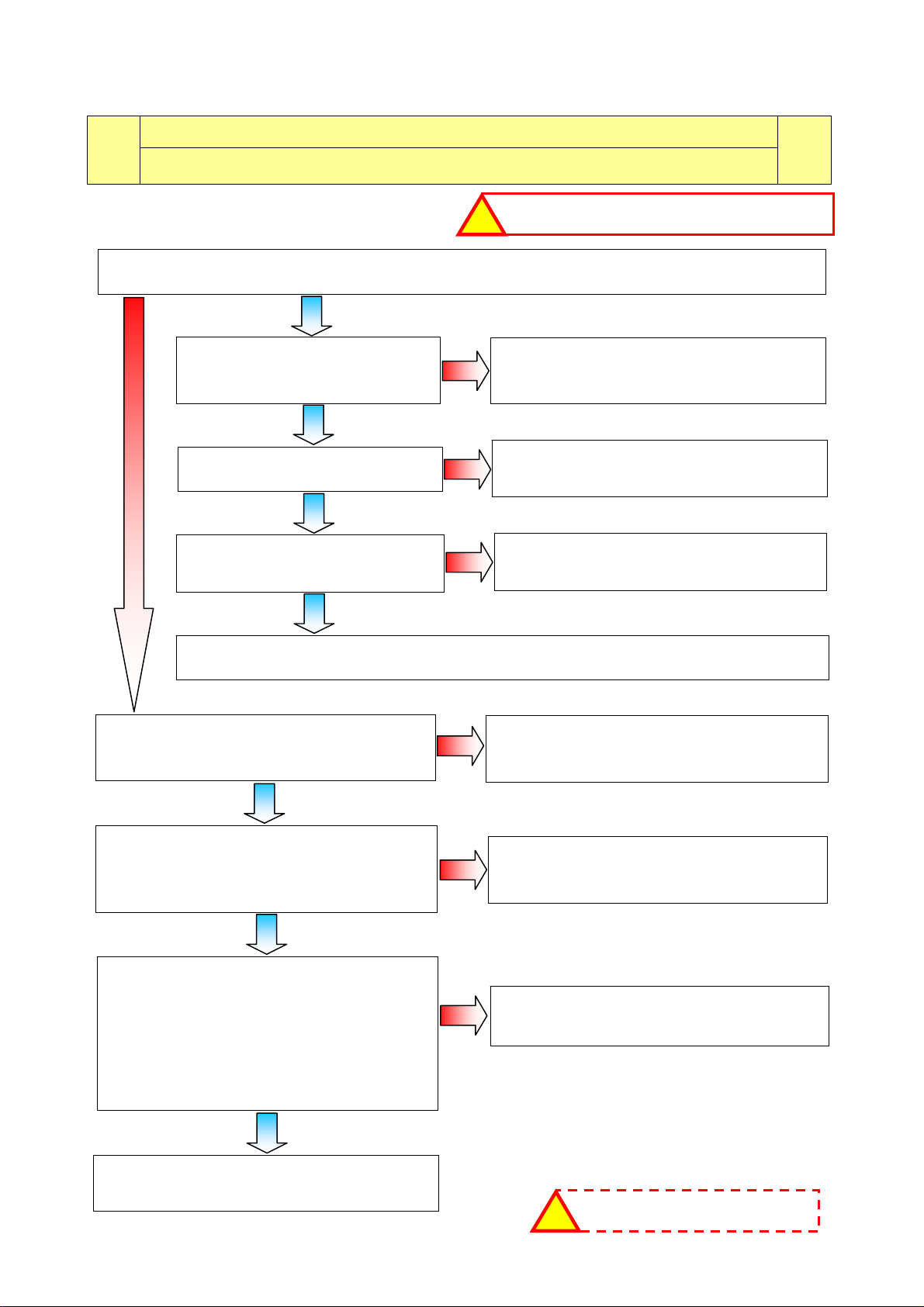

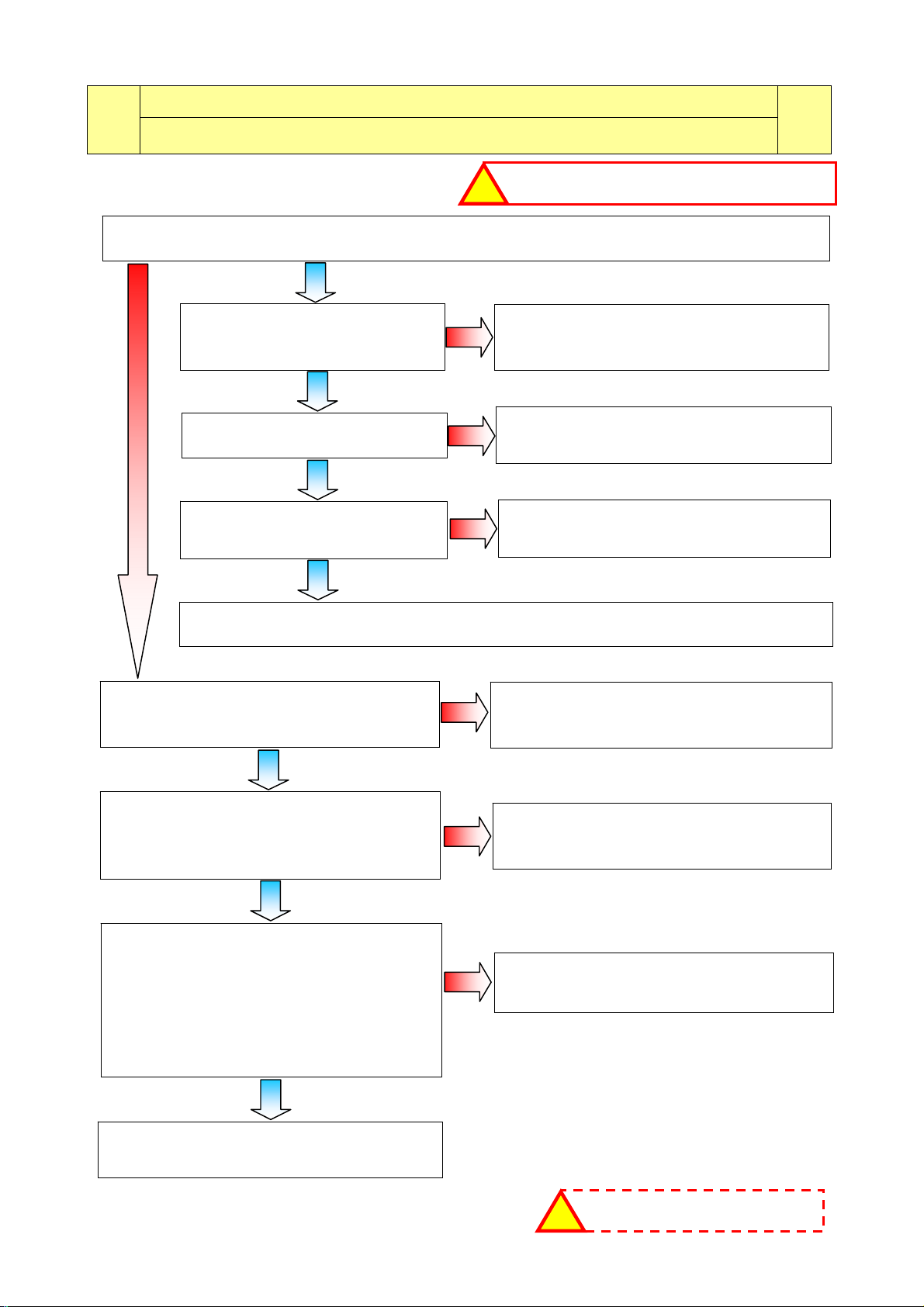

6 CANNOT ACCESS THE DIAGNOSTICS PROGRAMME

6.1 None of the LEDs on the circuit board light up

NO

NO

NO

NO

MAIN CIRCUIT

BOARD

DISPLAY BOARD

GENERAL EARTHING

J1

Are the power supply cable and the connection

on the main board (connector J1) working

properly?

Replace/repair the power supply cable, check

the connection.

Is the communication wiring between the main

board (connector J4) and the display board

(connectors J2 and J3) working properly? (insert

and remove)

Replace/repair wiring.

Does the ON/OFF button function mechanically?

Replace/repair the button or replace the display

board.

Change the main circuit board.

Is the appliance working correctly?

Replace display board.

Run the diagnostics programme.

Y

E

S

Y

E

S

Y

E

S

Y

E

S

Guide to diagnostics of electronic controls EWM10931

2012 TS/DT-mdm FCPD-dp 22/79 599 75 27-46 Rev.00

Run the diagnostic cycle and fill all the trays with water (phases 2,3,4,5,6).

Are all the trays filling with water?

7 TROUBLESHOOTING BASED ON ALARM CODES

E11

E11: Water fill difficulty during washing

E11

Maximum water fill time for every level of the pressure switch

(the time is reset every time the level is achieved)

Checks to perform:

Repair the drain circuit and repeat the

diagnostic cycle to check for any further alarms.

Repair the water circuit of the pressure switch

and repeat the diagnostic cycle to check for

any further alarms.

Replace the main circuit board and repeat the diagnostic cycle to check for any further alarms.

Is the drain tube positioned

correctly and not causing the siphon

effect? (fig. 1)

Is the pressure switch's water circuit

efficient (leaking/clogged)?

(fig. 2)

Check whether the tap is open, if the water

pressure is too low and make sure the tubes are

connected and not kinked.

Is one or are all the solenoid valves not

working?

Replace the solenoid valve and repeat the

diagnostic cycle to check for any further alarms.

Is the resistance measurement of the solenoid

valve approximately 3.5÷4.5 KΩ? (Measure it

directly on the solenoid valve without wiring)

-(see fig. 3)-

Replace/repair the wiring and repeat the

diagnostic cycle to check for any further alarms.

Reconnect the connector and measure

approximately 3.5÷4.5 KΩ on the solenoid valve

wiring connector on the circuit board side

(fig. 4): Between J7-1 and J7-3 wash

Between J7-4 and J7-6 pre-wash

Between J8-1 and J8-3 third solenoid valve

Between J8-4 and J8-6 hot water

Is the solenoid valve wiring ok?

Replace the main circuit board and repeat the

diagnostic cycle to check for any further alarms.

Repair the water circuit and repeat the

diagnostic cycle to check for any further alarms.

Is the washing machine's water

circuit efficient (leaking)?

Y

E

S

NO

Y

E

S

Y

E

S

Y

E

S

Y

E

S

NO

NO

NO

N

O

NO

NO

Y

E

S

Y

E

S

Check that all the connectors ar e correctly inserted

!

If there are burns on the circuit board,

see page 77

!

Guide to diagnostics of electronic controls EWM10931

2012 TS/DT-mdm FCPD-dp 23/79 599 75 27-46 Rev.00

E11

MAIN CIRCUIT

BOARD

3.5÷4.5 K

3.5÷4.5 K

WASHING

PRE-

WASHING

HOT

WATER

3rd

SOLENOID

V

ALVE

Fig. 3

J16 J13

J15

J10

J11 J4 J8

J7 J6

J12

J5

J3

J9

J1

Fig. 4

If there are burns on the circuit board,

see page 77

!

Fig. 1

Fig.

2

Fig. 2

Guide to diagnostics of electronic controls EWM10931

2012 TS/DT-mdm FCPD-dp 24/79 599 75 27-46 Rev.00

Run the diagnostic cycle and fill all the trays with water (phases 2,3,4,5,6).

Are all the trays filling with water?

E13

E13: Water leaks

E13

Maximum overall water fill time exceeded (sum of all water fills between one drain phase

and the next to avoid exceeding the maximum volume).

Checks to perform:

Repair the drain circuit and repeat the

diagnostic cycle to check for any further alarms.

Repair the water circuit of the pressure switch

and repeat the diagnostic cycle to check for

any further alarms.

Replace the main circuit board and repeat the diagnostic cycle to check for any further alarms.

Is the drain tube positioned

correctly and not causing the siphon

effect? (fig. 1)

Is the pressure switch's water circuit

efficient (leaking/clogged)?

(fig. 2)

Check whether the tap is open, if the water

pressure is too low and make sure the tubes are

connected and not kinked.

Is one or are all the solenoid valves not

working?

Replace the solenoid valve and repeat the

diagnostic cycle to check for any further alarms.

Is the resistance measurement of the solenoid

valve approximately 3.5÷4.5 KΩ? (Measure it

directly on the solenoid valve without wiring)

-(see fig. 3)-

Replace/repair the wiring and repeat the

diagnostic cycle to check for any further alarms.

Reconnect the connector and measure

approximately 3.5÷4.5 KΩ on the solenoid valve

wiring connector on the circuit board side

(fig. 4): Between J7-1 and J7-3 wash

Between J7-4 and J7-6 pre-wash

Between J8-1 and J8-3 third solenoid valve

Between J8-4 and J8-6 hot water

Is the solenoid valve wiring ok?

Replace the main circuit board and repeat the

diagnostic cycle to check for any further alarms.

Repair the water circuit and repeat the

diagnostic cycle to check for any further alarms.

Is the washing machine's water

circuit efficient (leaking)?

Y

E

S

NO

Y

E

S

Y

E

S

Y

E

S

Y

E

S

NO

NO

NO

N

O

NO

NO

Y

E

S

Y

E

S

Check that all the connectors ar e correctly inserted

!

If there are burns on the circuit board,

see page 77

!

Loading...

Loading...