Deutz B FM 1008 F Service Manual

Workshop Manual B/FM 1008/F

cardiagn.com

© 2001 / 0297 9984

cardiagn.com

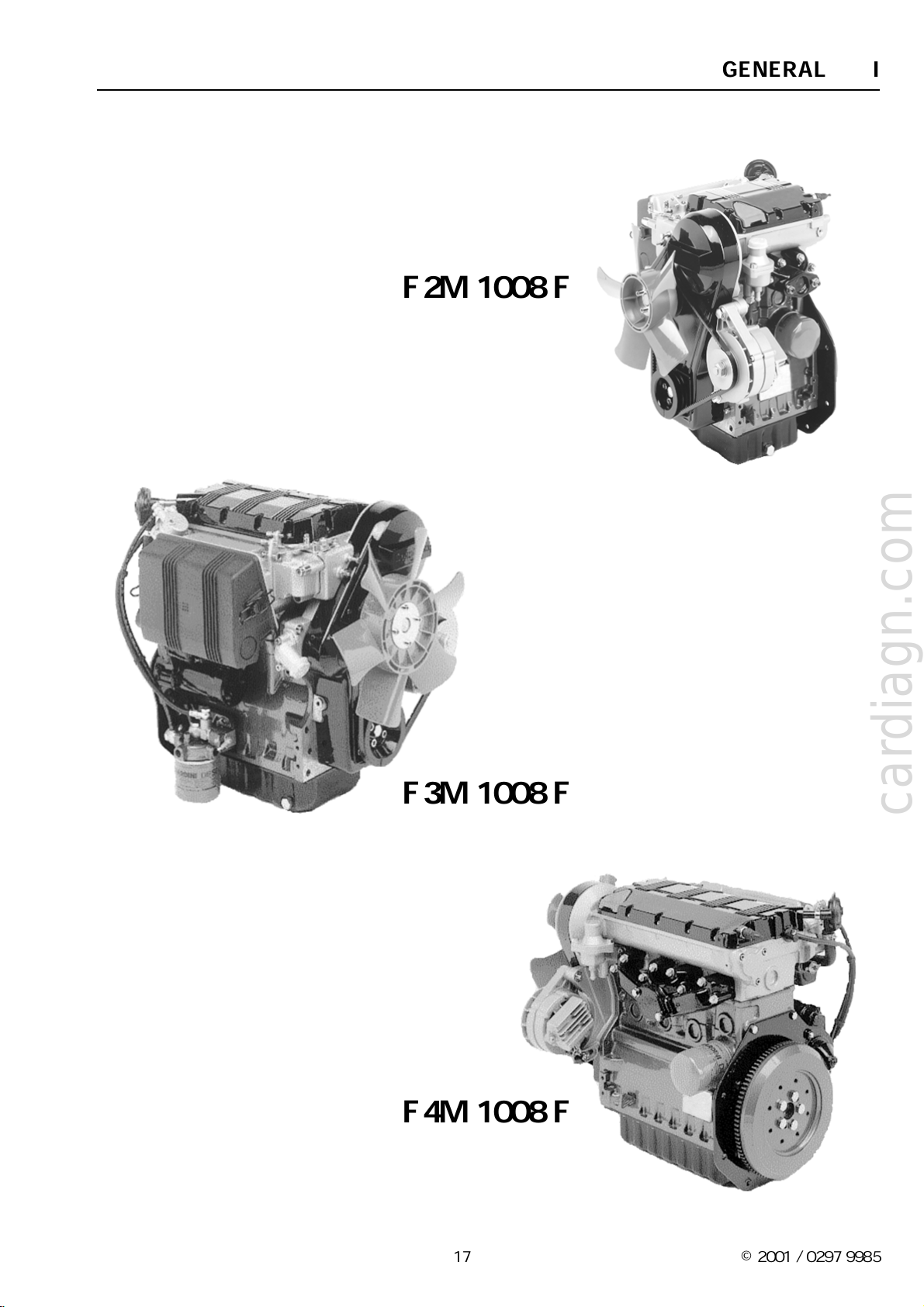

Workshop Manual F2M 1008

cardiagn.com

F3M 1008

F4M 1008

BF4M 1008

F2M 1008 F

F3M 1008 F

F4M 1008 F

0297 9985 en

In view of continuous design improvements or changes, the technical spe-

cifications and the illustrations shown in this Workshop Manual are subject to

alteration. Reprinting and reproduction, in part or in whole, are subject to our

written approval.

© 2001 / 0297 9985

© 2001 / 0297 9985

cardiagn.com

F O R E W O R D

cardiagn.com

R

eliable engine operation is dependent on properly executed repairs as well as adjustment work.

This Workshop Manual describes the appropriate operations for any repair and adjustment work on the

engine and engine components. It is presumed that this work will be carried out by qualified personnel.

The Manual has been laid out to ensure quick comprehension of the contents, i. e illustrations have been

placed adjacent to the brief text passages to clearly show the working operations.

Aspects of operation and maintenance are dealt with in the respective Operation Manual.

For spare parts orders the respective spare parts catalogue should be referred to.

This Workshop Manual is not subject to engineering change service and is valid until next issue.

Therefore please refer to the information in our Technical Circulars when carrying out repairs.

General information:

- Please read carefully and observe the instructions given in this Workshop Manual to

avoid accidents and ensure that your engine always functions properly and reliably.

- Make sure that this Workshop Manual is readily available for all those carrying out repairs

or adjustments and that the contents are well understood.

- Non-compliance with these repair instructions may result in malfunction and engine

damage as well as personal injuries for which the manufacturer shall not accept any

liability.

- The accident prevention regulations and all other generally recognized regulations on

safety and occupational medicine are to be observed.

- A prerequisite for successful repair is that all required equipment, hand and special tools

are available and in perfect working order.

- Optimal operation economy, reliability and durability of the engine can only be ensured

when genuine parts of DEUTZ AG are used.

- Engine components such as springs, clamps, snap rings, etc. may cause injury if not

handled with care.

- Engine repairs must be carried out in accordance with intended use as defined by the

equipment manufacturer. For conversions, only parts approved by DEUTZ AG for a

specific purpose should be used.

© 2001 / 0297 9985

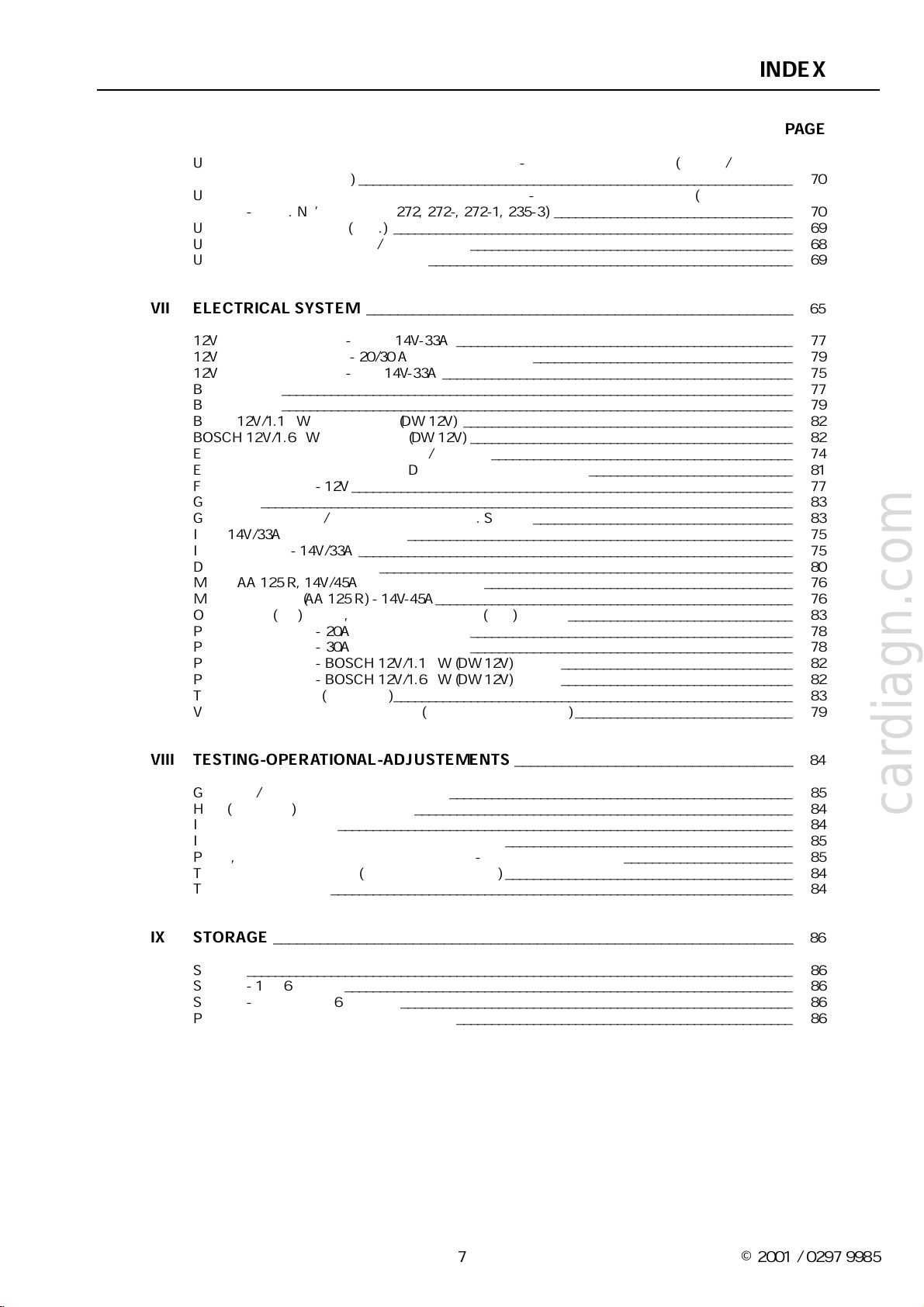

INDEX

cardiagn.com

This manual contains pertinent information regarding the repair of DEUTZ water-cooled, indirect

injection Diesel engines type

INDEX PAGE

B/FM 1008/F

.

TROUBLESHOOTING CHART - B/FM 1008/F SERIES ____________________________________

SAFETY AND W

ARNING DECALS - SAFETY INSTRUCTIONS _____________________________

I GENERAL ___________________________________________________________________

POWER RATINGS FOR B/FM 1008/F GENSET SPEC DIESEL ENGINES ______________________ 13

B/FM 1008 SERIES - TECHNICAL SPECIFICATIONS AND

CAPACITIES F2/3/4M 1008, BF4M 1008 __________________________________________________ 14

FLUID CAPACITIES (STANDARD) F2/3/4M 1008, BF4M 1008 ________________________________ 14

FM 1008 F SERIES - TECHNICAL SPECIFICATIONS AND CAPACITIES F2/3/4M 1008 F __________ 16

FLUID CAPACITIES (STANDARD) F2/3/4M 1008 F__________________________________________ 16

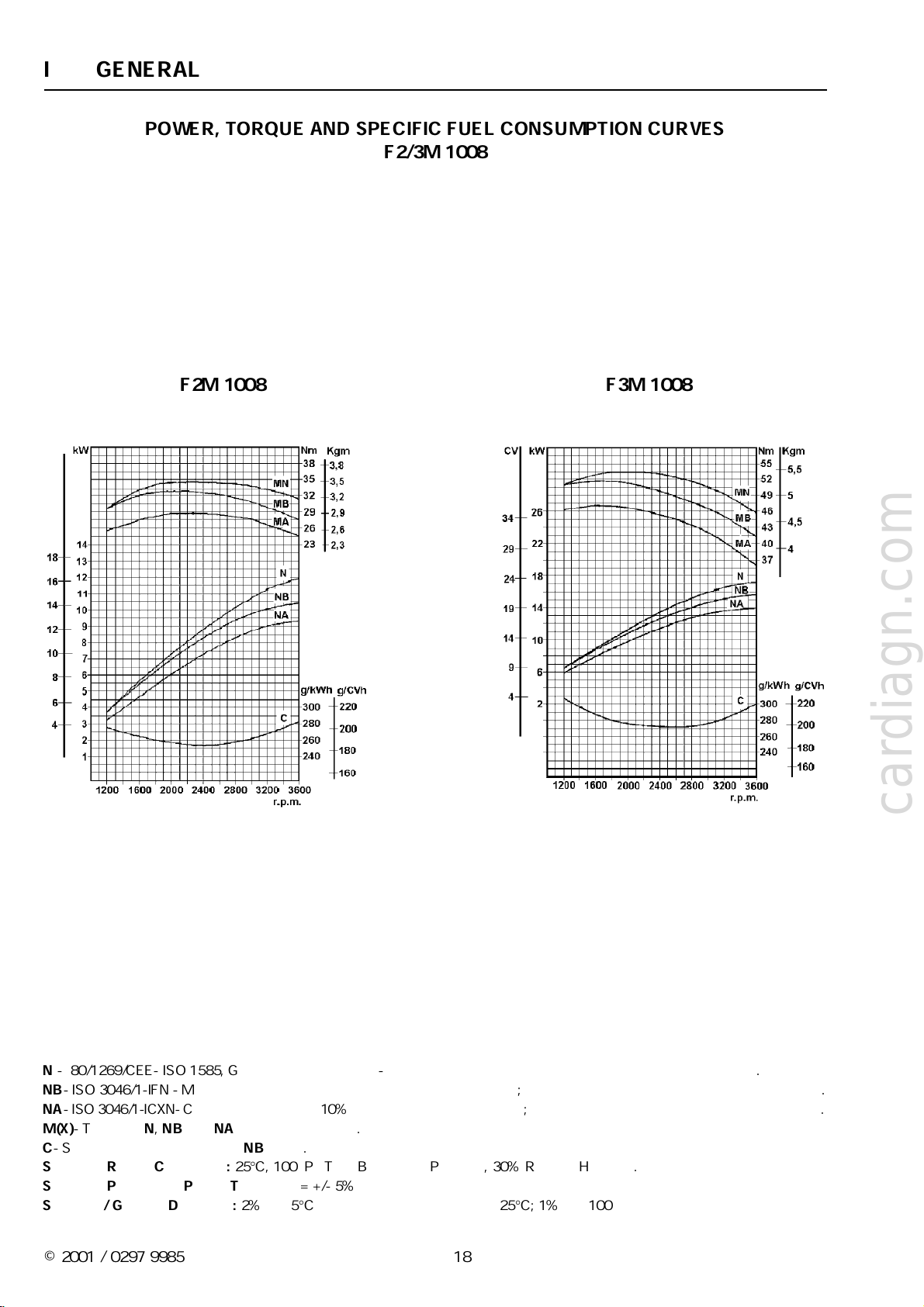

POWER, TORQUE AND SPECIFIC FUEL CONSUMPTION CURVES F2/3M 1008_______________ 18

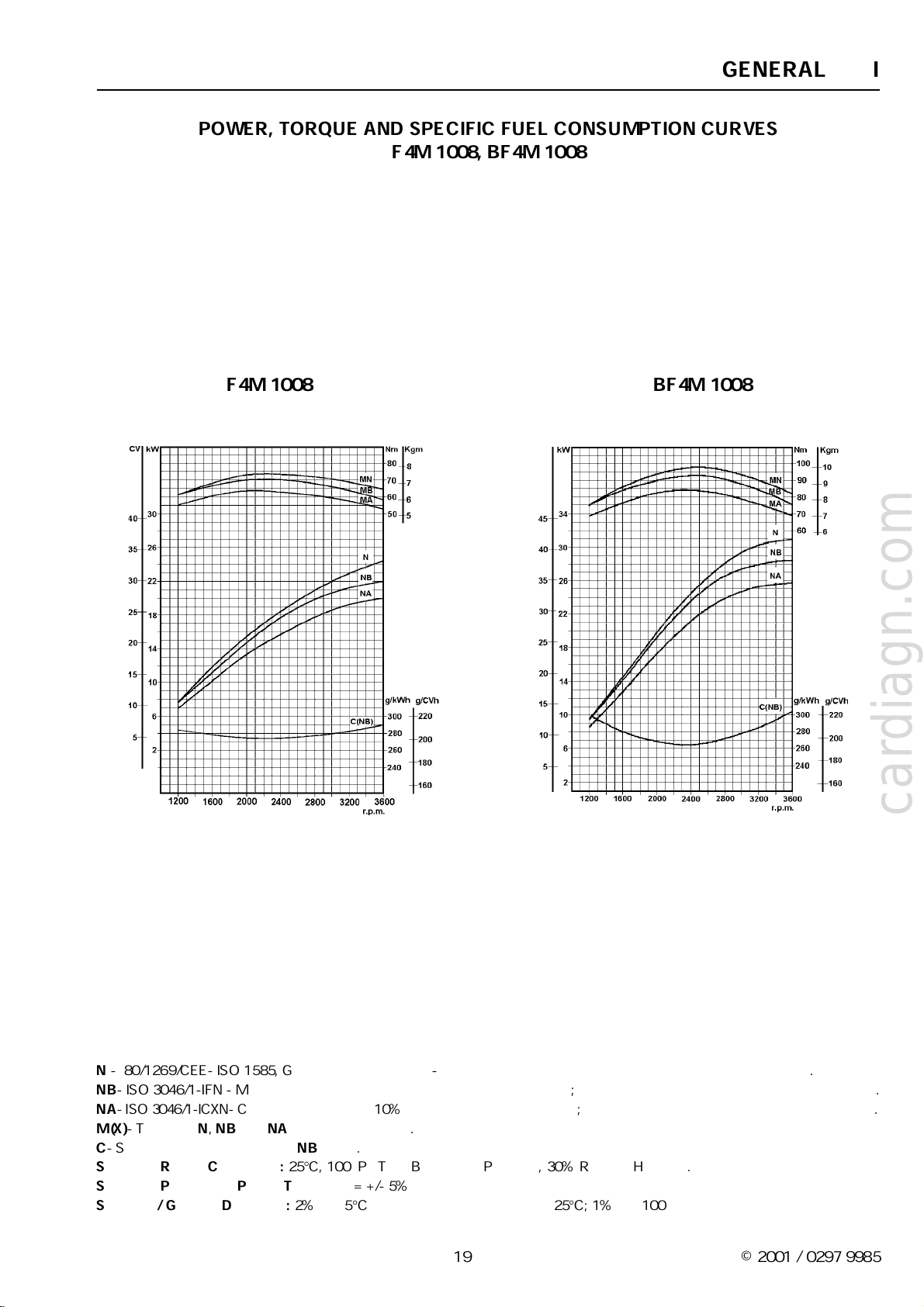

POWER, TORQUE AND SPECIFIC FUEL CONSUMPTION CURVES B/F4M 1008 ______________ 19

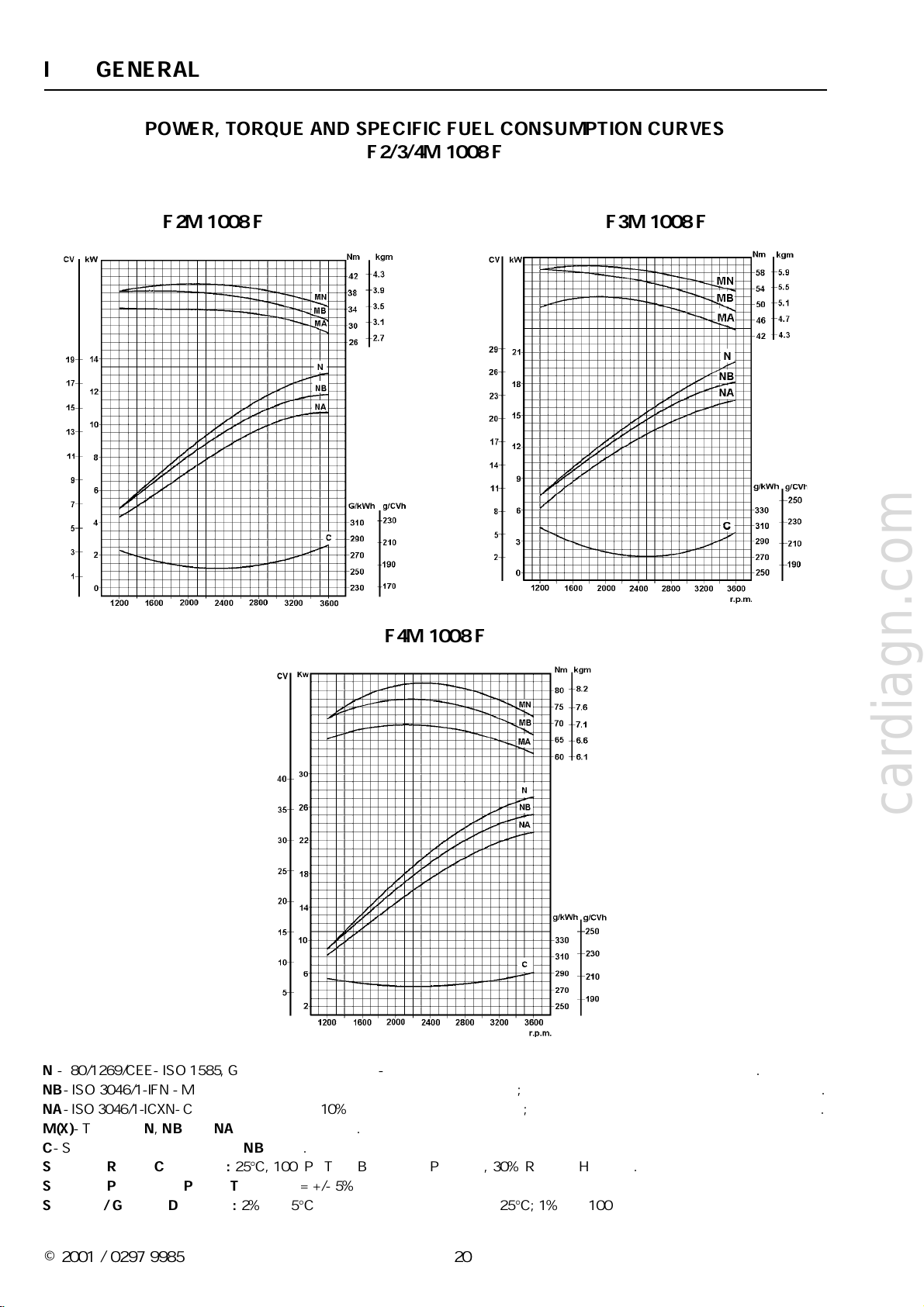

POWER, TORQUE AND SPECIFIC FUEL CONSUMPTION CURVES F2/3/4M 1008 F ___________ 20

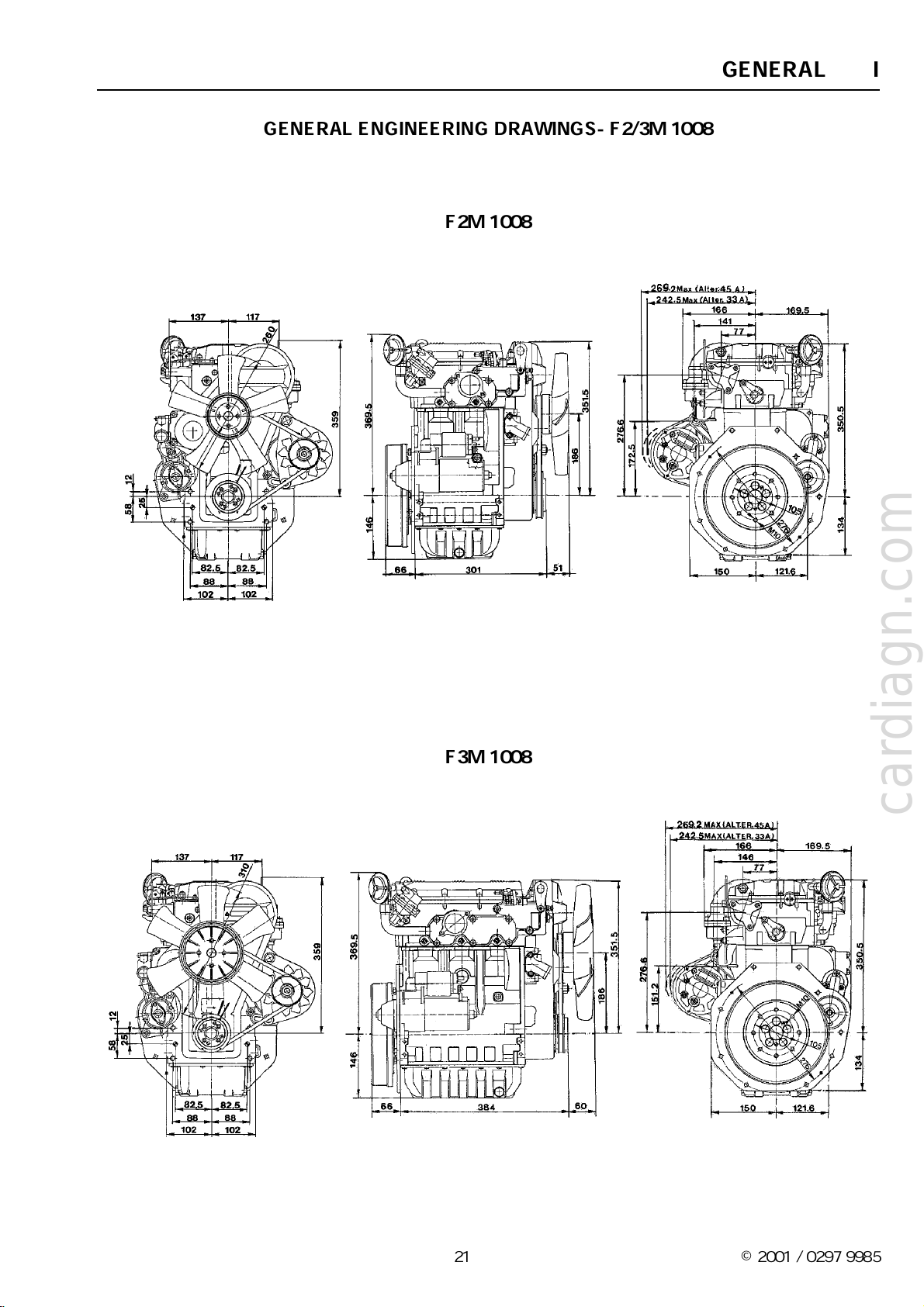

GENERAL ENGINEERING DRAWINGS - F2/3M 1008 _______________________________________ 21

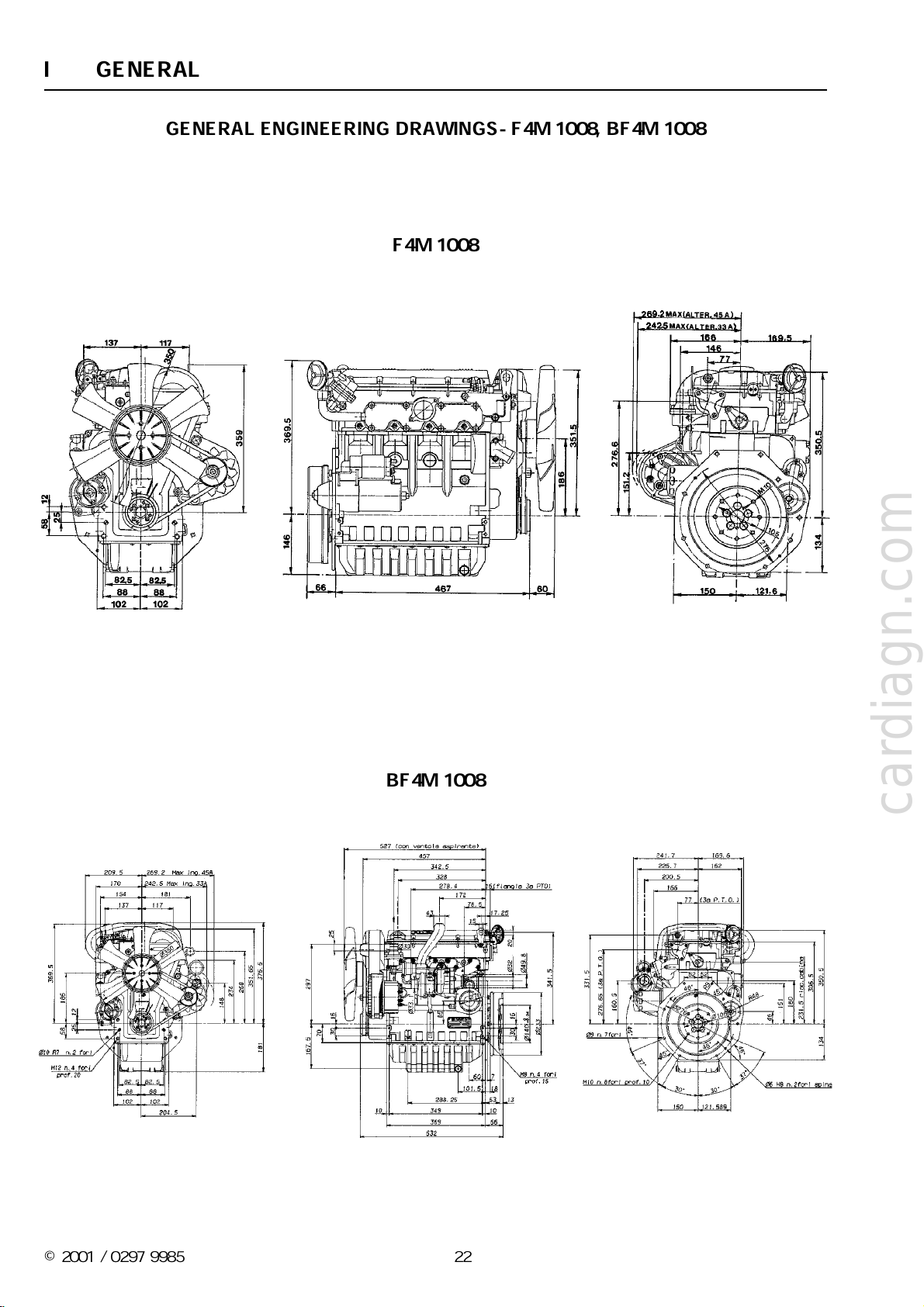

GENERAL ENGINEERING DRAWINGS - B/F4M 1008_______________________________________ 22

GENERAL ENGINEERING DRAWINGS - F2/3/4M 1008 F ___________________________________ 23

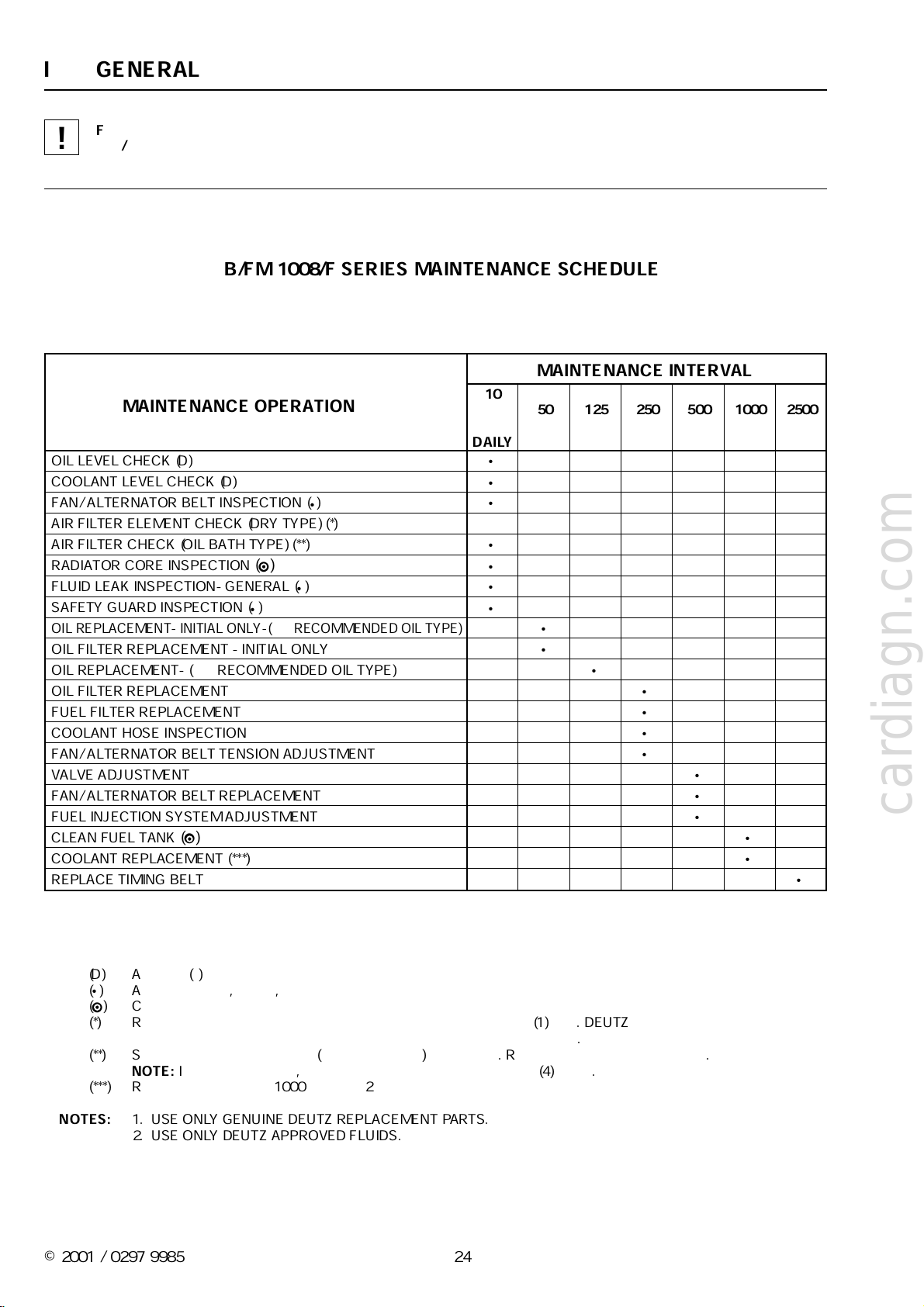

B/FM 1008/F SERIES MAINTENANCE SCHEDULE _________________________________________ 24

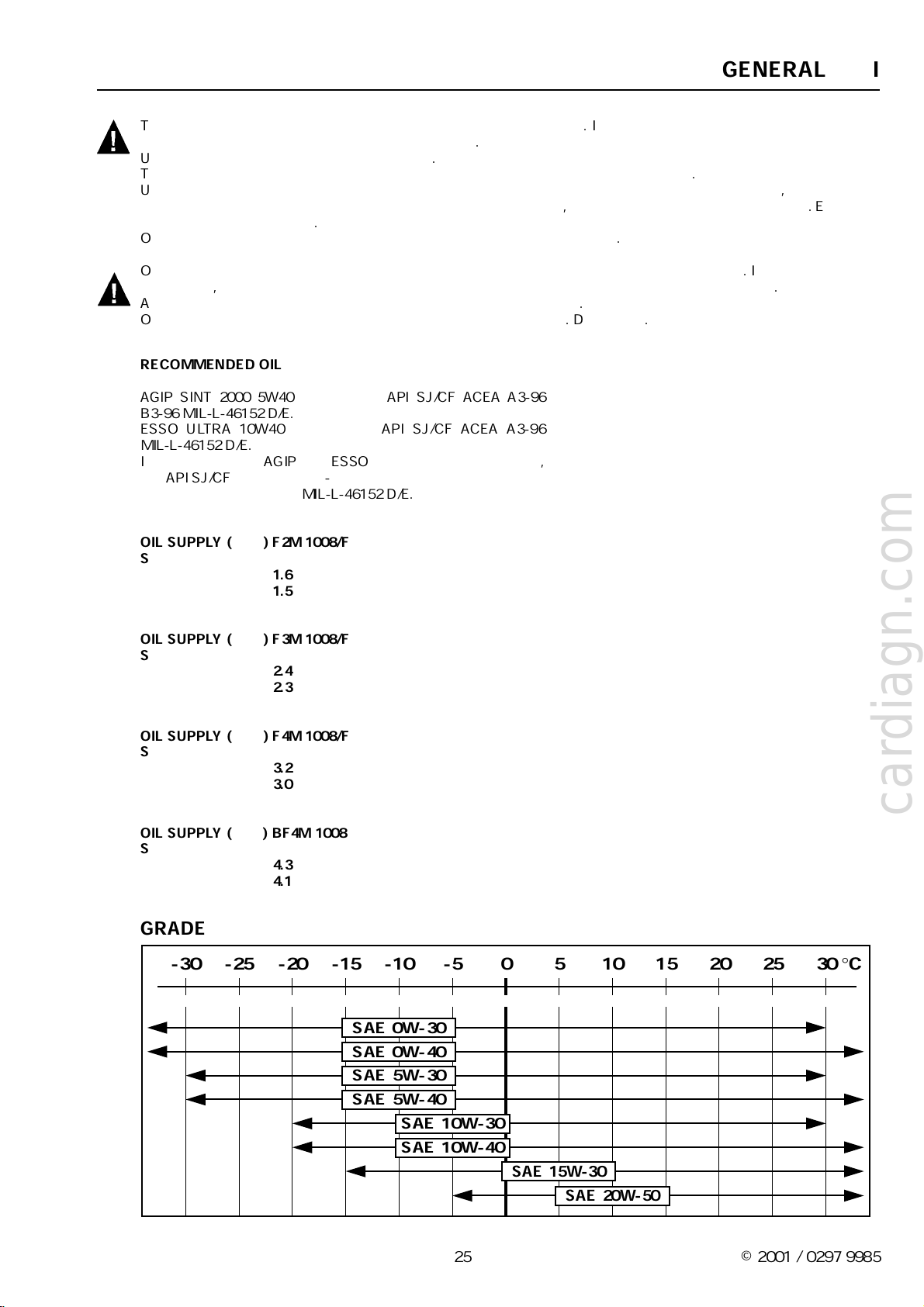

RECOMMENDED OIL___________________________________________________________________ 25

DIESEL FUEL SPECIFICATIONS _________________________________________________________ 26

ANTI-FREEZE / COOLANT SPECIFICATIONS / DETAILS - B/FM 1008/F SERIES _______________ 27

DRIVING TORQUES FOR STANDARD SCREWS ___________________________________________ 28

SEALANT AND THREAD LOCK LOCATIONS/DETAILS ______________________________________ 28

CRITICAL TORQUE SPECIFICATIONS ____________________________________________________ 29

SPECIAL TOOLS _______________________________________________________________________ 30

9

10

12

II DISASSEMBLY- REASSEMBLY________________________________________________

Air filter support - (intake manifold) ______________________________________________________

Air restriction switch ___________________________________________________________________ 31

Alternator / cooling fan drive belt ________________________________________________________ 32

Camshaft journal / support bore specifications____________________________________________ 43

Camshaft journal / support measurement ________________________________________________ 43

Camshaft lobe measurement procedure__________________________________________________ 43

Camshaft lobe specifications ___________________________________________________________ 44

Camshaft removal / replacement ________________________________________________________ 43

Camshaft timing pulley ________________________________________________________________ 35

Connecting bearing / rod cap installation _________________________________________________ 52

Connecting rod / connecting rod bearings specifications ____________________________________ 50

Connecting rod alignment ______________________________________________________________ 51

Connecting rod-piston assembly balance ________________________________________________ 51

Cooling fan ___________________________________________________________________________ 32

Cooling fan support ___________________________________________________________________ 33

Crankcase vacuum regulator valve (B/FM 1008/F) _________________________________________ 40

Crankshaft end play ___________________________________________________________________ 55

Crankshaft journal inspection / measurement _____________________________________________ 56

Crankshaft journal specifications ________________________________________________________ 57

Crankshaft lubrication drillings-typical ___________________________________________________ 56

Crankshaft pulley _____________________________________________________________________ 33

Crankshaft seals - front and rear ________________________________________________________ 56

2001 / 0297 9985

4©

31

32

INDEX

cardiagn.com

PAGE

Crankshaft timing pulley _______________________________________________________________ 35

Cylinder class

Cylinder head installation_______________________________________________________________ 53

Cylinder head removal _________________________________________________________________ 44

Cylinder head tightening procedure- F4M 1008/F, BF4M 1008 ______________________________ 53

Cylinder head tightening procedure- F2/3M 1008/F________________________________________ 53

Cylinder inspection / dimensional specifications __________________________________________ 49

Cylinder surface finish _________________________________________________________________ 49

Dry type air filter- standard engine mounted ______________________________________________ 31

Exhaust manifold______________________________________________________________________ 32

Flywheel / ring gear____________________________________________________________________ 33

Front / rear main bearing caps / bearings_________________________________________________ 54

Fuel rail ______________________________________________________________________________ 41

Fuel tank - (optional accessory) _________________________________________________________ 33

General piston notes __________________________________________________________________ 48

Governor fork _________________________________________________________________________ 38

Governor springs______________________________________________________________________ 38

Head gasket selection/ installation ______________________________________________________ 52

Hydraulic drive components- no. 3 pto___________________________________________________ 57

Hydraulic pump pto- (no. 3 pto) _________________________________________________________ 57

Idler pulley ___________________________________________________________________________ 35

Injection pump control rod _____________________________________________________________ 41

Limiting speed governor _______________________________________________________________ 39

Main and connecting rod bearings ______________________________________________________ 57

Main bearing caps / bearings- center ____________________________________________________ 54

Main bearing clearance ________________________________________________________________ 54

No. 2 pto (crankshaft pulley) with “ringfeder”- F4M 1008/F, BF4M 1008 ______________________ 34

Oil bath air filter _______________________________________________________________________ 31

Oil pan removal / installation ____________________________________________________________ 47

Oil pump assembly ____________________________________________________________________ 39

Oil pump assembly to the engine________________________________________________________ 39

Oil pump inspection ___________________________________________________________________ 39

Piston / connecting rod disassembly and piston inspection _________________________________ 48

Piston / connecting rod installation ______________________________________________________ 51

Piston balance ________________________________________________________________________ 48

Piston class, weight imbalance and genuine Deutz markings _______________________________ 48

Piston cooling jets- BF4M 1008 _________________________________________________________ 54

Piston protrusion ______________________________________________________________________ 52

Piston removal ________________________________________________________________________ 48

Piston ring assembly location ___________________________________________________________ 50

Piston ring end gap____________________________________________________________________ 50

Piston ring to piston land clearance _____________________________________________________ 50

Piston wrist pin installation / retaining snap ring ___________________________________________ 51

Precision speed governor -(gensets) _____________________________________________________ 38

Pre-combustion chamber installation ____________________________________________________ 47

Pre-combustion chamber removal_______________________________________________________ 47

Pre-combustion chamber ring nut _______________________________________________________ 47

Pre-combustion chamber-overview ______________________________________________________ 46

Rocker arm assembly__________________________________________________________________ 42

Speed governor _______________________________________________________________________ 38

Speed governor reassembly ____________________________________________________________ 39

Thrust bearings _______________________________________________________________________ 55

Thrust surface specifications-crankshaft end _____________________________________________ 55

play corrections _______________________________________________________________________ 55

Timing belt / timing pulley arrangement __________________________________________________ 34

Timing belt cover______________________________________________________________________ 34

Timing belt installation- timing procedure ________________________________________________ 36

Timing belt removal ___________________________________________________________________ 35

Timing belt tension procedure __________________________________________________________ 36

Timing belt tensioning procedure- setup _________________________________________________ 36

Timing pulley - reference marks _________________________________________________________ 36

Undersized bearings- rod and main _____________________________________________________ 57

Unit injector check valve _______________________________________________________________ 41

Unit injector removal / installation _______________________________________________________ 42

Valve / rocker cover ___________________________________________________________________ 40

________________________________________________________________________ 49

5 ©

2001 / 0297 9985

INDEX

cardiagn.com

Valve / rocker cover gasket _____________________________________________________________ 40

Valve

adjustment ______________________________________________________________________ 41

Valve guide installation guidelines and post installation valve/valve guide specifications________ 45

Valve guides / valve guide bore _________________________________________________________ 45

Valve recess and seat sealing width _____________________________________________________ 46

Valve removal_________________________________________________________________________ 44

Valve seats ___________________________________________________________________________ 46

Valve specifications ___________________________________________________________________ 45

Valve springs _________________________________________________________________________ 45

Valve stem seal installation _____________________________________________________________ 44

Valve timing angles ____________________________________________________________________ 37

Valve timing confirmation_______________________________________________________________ 37

PAGE

III TURBOCHARGER ___________________________________________________________

Turbochar

Turbocharger components _____________________________________________________________ 58

Turbocharger pressure testing __________________________________________________________ 58

Turbocharger waste gate adjustement-bench method _____________________________________ 59

ger identification _____________________________________________________________ 58

IV LUBRICATION SYSTEM ______________________________________________________

Lubrication system ____________________________________________________________________ 60

Oil pick-up screen and oil drain back tube________________________________________________ 61

Oil pump specification _________________________________________________________________ 61

Oil filter ______________________________________________________________________________ 62

Oil pressure testing ____________________________________________________________________ 62

V COOLING SYSTEM __________________________________________________________

B/FM 1008/F cooling system schematic _________________________________________________ 63

Cooling system pressure check/radiator cap inspection _____________________________________ 64

Coolant pump details __________________________________________________________________ 64

Thermostat ___________________________________________________________________________ 64

VI FUEL SYSTEM_______________________________________________________________

Barrel and plunger detail- (typical) curr

unit injectors (example- 6590-285) ______________________________________________________ 69

Barrel and plunger detail- early unit injectors (typical) ______________________________________ 69

Early unit injectors_____________________________________________________________________ 71

Engine timing reference marks __________________________________________________________ 72

Equalization tool installation, plumbing ___________________________________________________ 73

Fuel filter assembly ____________________________________________________________________ 65

Fuel rate adjustment details ____________________________________________________________ 73

Fuel system schematic ________________________________________________________________ 65

Fuel system special tools ______________________________________________________________ 67

Fuel transfer pump ____________________________________________________________________ 65

Fuel transfer pump push rod protrusion __________________________________________________ 65

Injector ______________________________________________________________________________ 65

Injector nozzle protrusion ______________________________________________________________ 70

Late/ intermediate unit injectors _________________________________________________________ 71

Static injection test instrumentation- early unit injectors _____________________________________ 71

Static timing adjustment _______________________________________________________________ 72

Tdc determination and static injection timing checking ______________________________________ 71

Unit injector __________________________________________________________________________ 68

Unit injector components ______________________________________________________________ 68

Unit injector delivery equalization- preparation ____________________________________________ 73

Unit injector delivery equalization- preparation (cont.) ______________________________________ 73

Unit injector fire ring ___________________________________________________________________ 70

Unit injector plunger reassembly ________________________________________________________ 68

ent ________________________________________________ 69

58

60

63

65

2001 / 0297 9985

6©

INDEX

cardiagn.com

PAGE

Unit injector popping pressure testing and adjustment

intermediate unit injectors) ______________________________________________________________ 70

Unit injector popping pressure testing and adjustment- high pressure procedure (early unit

injectors- all ref. No’s other than 272, 272-, 272-1, 235-3) __________________________________ 70

Unit injector reassembly (cont.) _________________________________________________________ 69

Unit injector ring nut removal / replacement ______________________________________________ 68

Unit injector test stand specifications ____________________________________________________ 69

- low pressure procedure (current /

VII ELECTRICAL SYSTEM _______________________________________________________

12V electrical schematic-marelli 14V-33A ________________________________________________ 77

12V electrical schematic - 20/30 A flywheel alternator _____________________________________ 79

12V electrical schematic-iskra 14V-33A __________________________________________________ 75

Battery sizing _________________________________________________________________________ 77

Battery sizing _________________________________________________________________________ 79

Bosch 12V/1.1 kW starter motor (DW 12V) _______________________________________________ 82

BOSCH 12V/1.6 kW starter motor (DW 12V) ______________________________________________ 82

Electrical system service precautions / warning ___________________________________________ 74

Engine side wiring harness for the Deutz supplied control panel _____________________________ 81

Flywheel alternator - 12V _______________________________________________________________ 77

Glow plug ____________________________________________________________________________ 83

Glow plug controller / relay with coolant temp. Sensor _____________________________________ 83

Iskra 14V/33A performance curve _______________________________________________________ 75

Iskra alternator - 14V/33A ______________________________________________________________ 75

Deutz supplied control panel ___________________________________________________________ 80

Marelli AA 125 R, 14V/45A performance curve ____________________________________________ 76

Marelli alternator (AA 125 R) - 14V-45A___________________________________________________ 76

Oil pressure (low) switch, coolant temperature (high) switch ________________________________ 83

Performance curve - 20A flywheel alternator ______________________________________________ 78

Performance curve - 30A flywheel alternator ______________________________________________ 78

Performance curve - BOSCH 12V/1.1 kW (DW 12V) starter _________________________________ 82

Performance curve - BOSCH 12V/1.6 kW (DW 12V) starter _________________________________ 82

Temperature sensor (thermistor)_________________________________________________________ 83

Voltage regulator connection details (flywheel alternator only) _______________________________ 79

65

VIII TESTING-OPERATIONAL-ADJUSTEMENTS ____________________________________

Governor / unit injector rack adjustment

High (maximum) speed adjustment ______________________________________________________ 84

Idle speed adjustment _________________________________________________________________ 84

Injection pump control rod stroke limit adjustment_________________________________________ 85

Power, torque device and speed adjustments-dynamometer method ________________________ 85

Torque device adjustment (without dynamometer) _________________________________________ 84

Torque device details __________________________________________________________________ 84

_________________________________________________ 85

IX STORAGE ___________________________________________________________________

Storage ______________________________________________________________________________ 86

Storage - 1 to 6 months ________________________________________________________________ 86

Storage - in excess of 6 months ________________________________________________________ 86

Preparing the engine for use after storage ________________________________________________ 86

84

86

7 ©

2001 / 0297 9985

NOTE

cardiagn.com

2001 / 0297 9985

8©

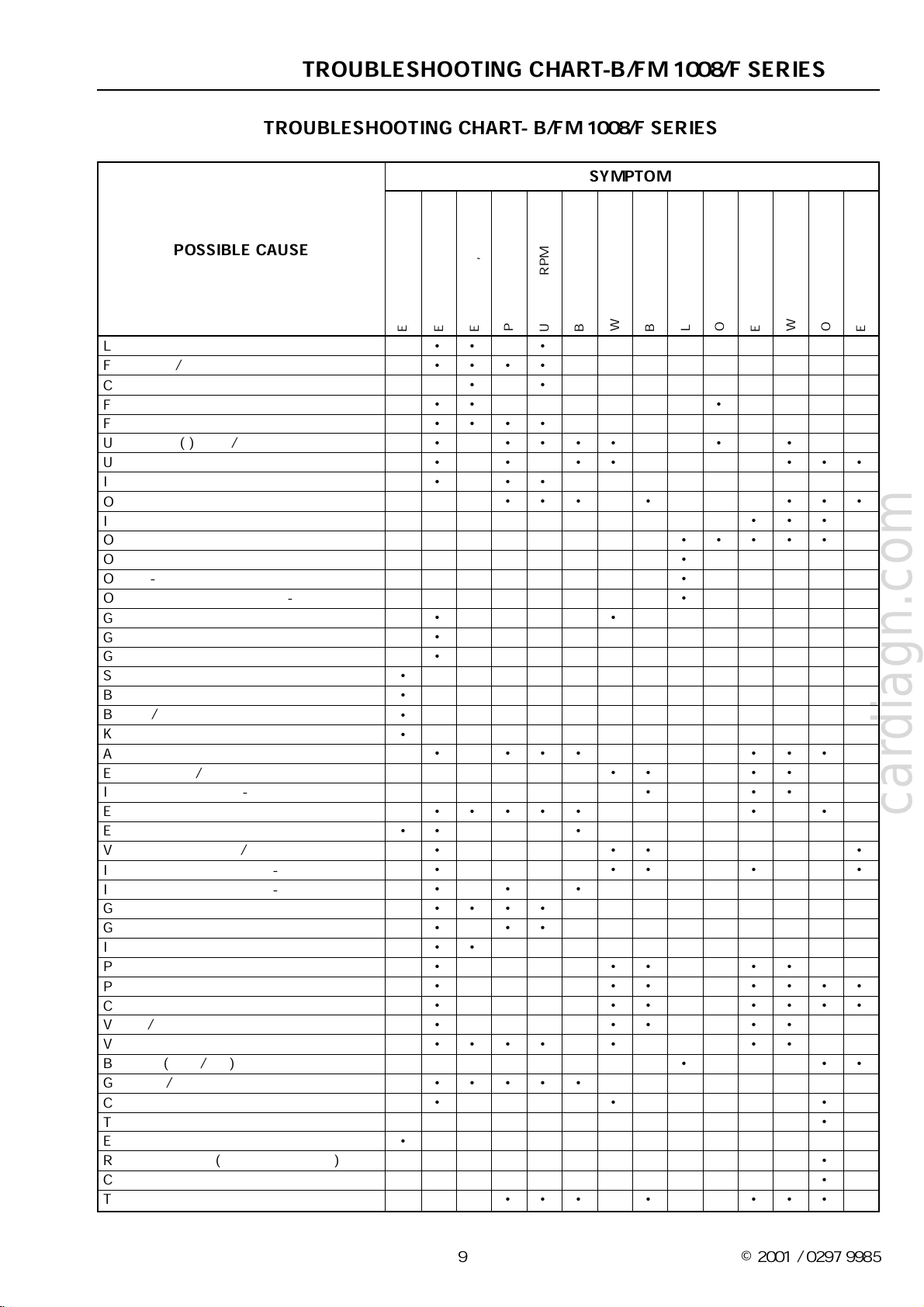

SYMPTOM

TROUBLESHOOTING CHART- B/FM 1008/F SERIES

Engine knocks

Engine will not crank

Engine does not start

Engine starts, but stops

Poor acceleration

White smoke

Unsteady RPM

Black smoke

Blue smoke

Low oil pressure

Oil level rising

Excessive oil consumption

Wet exhaust

Overheating

• • •

• • • •

• •

• • •

• • • •

• • • • • • •

• • • • • • •

• • •

• • • • • • •

• • •

• • • • •

•

•

•

• •

•

•

•

•

•

•

• • • • • • •

• • • •

• • •

• • • • • • •

• • •

• • • •

• • • • •

• • •

• • • •

• • •

• •

• • • • •

• • • • • • •

• • • • • • •

• • • • •

• • • • • • •

• • •

• • • • •

• • •

•

•

•

•

• • • • • • •

cardiagn.com

POSSIBLE CAUSE

TROUBLESHOOTING CHART-B/FM 1008/F SERIES

Low fuel level

Fuel supply/ return lines clogged

Clogged fuel tank vent

Fuel pump faulty

Fuel entrained with air

Unit injector(s) faulty/ worn

Unit injector settings incorrect

Injection pump rack sticking

Oil level too high

Improper oil viscosity

Oil diluted by fuel

Oil pressure relief valve faulty

Oil pick-up tube clogged

Oil pump air entrained at pick-up tube

Glow plugs faulty

Glow plug controller faulty

Glow plug relay inoperable

Starter defective

Battery voltage too low

Battery / battery cable connections corroded

Key switch defective

Air filter clogged

Excessive idle / light load operation

Incomplete engine run-in

Engine overloaded

Excessive parasitic load

Valve lash insufficient / excessive

Injection timing out of spec- advanced

Injection timing out of spec- retarded

Governor linkage adjustment incorrect

Governor spring fatigued or defective

Idle rpm too low

Piston rings worn or stuck

Piston worn or damaged

Cylinders worn or damaged

Valves / valve guides worn

Valves sticking

Bearings (main / rod) worn

Governor / governor linkage malfunction

Cylinder head gasket damaged

Thermostat stuck or malfunctioning

Engine seized

Radiator clogged (external or internal)

Coolant pump faulty

Turbocharger faulty

9 ©

2001 / 0297 9985

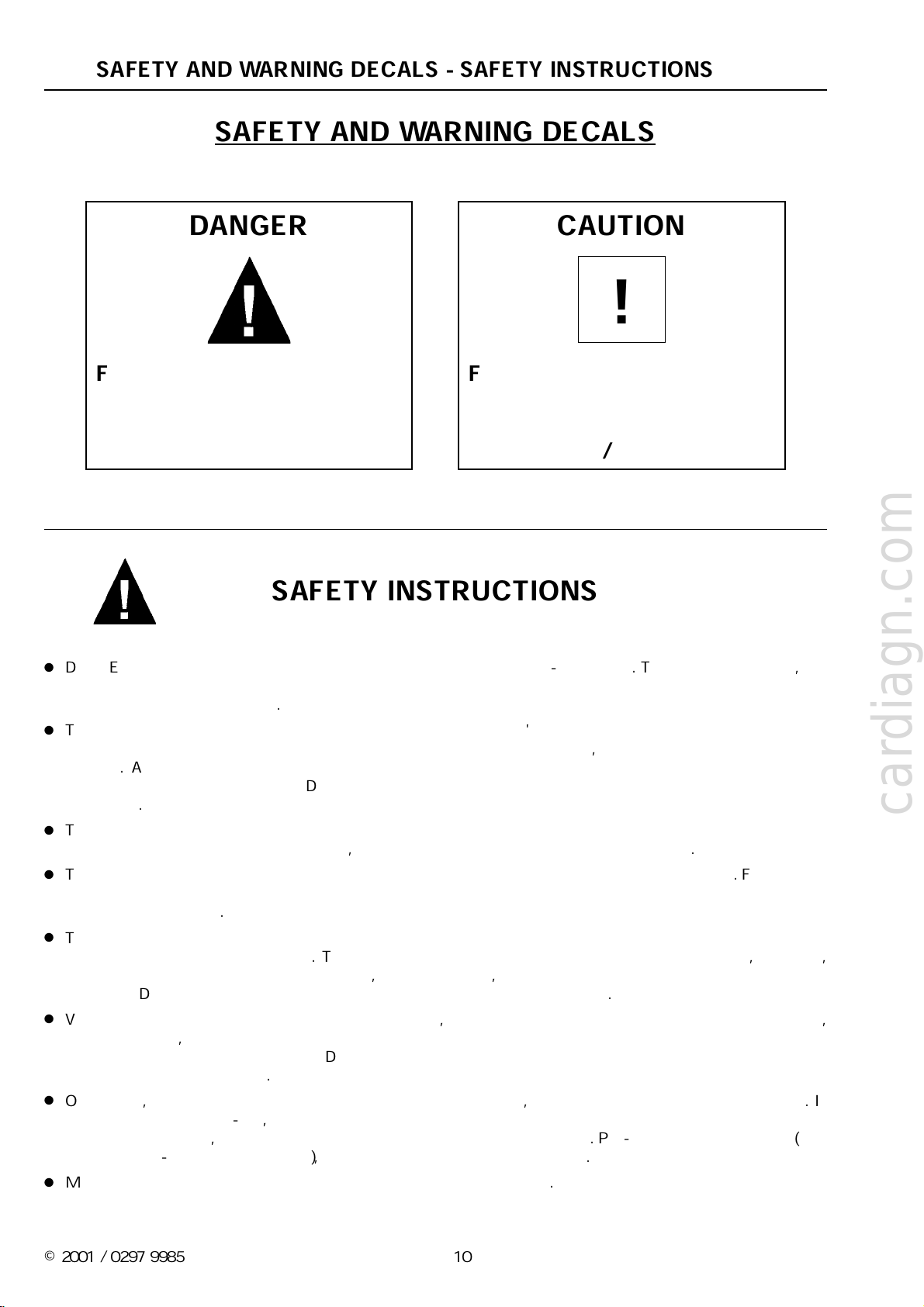

SAFETY AND WARNING DECALS - SAFETY INSTRUCTIONS

Failure to comply with the

instructions could result in

damage to persons and

property

Failure to comply with the

instructions could lead to

technical damage to the

machine and/or system

DANGER

SAFETY AND WARNING DECALS

CAUTION

SAFETY INSTRUCTIONS

●

Deutz Engines are built to supply their performances in a safe and long-lasting way. To obtain these results, it is

essential for users to comply with the servicing instructions given in the relative manual along with the safety

recommendations listed below.

●

The engine has been made according to a machine manufacturer's specifications and all actions required to

meet the essential safety and health safeguarding requisites have been taken, as prescribed by the current laws

in merit. All uses of the engine beyond those specifically established cannot therefore be considered as

conforming to the use defined by Deutz which thus declines all liability for any accidents deriving from such

operations.

●

The following indications are dedicated to the user of the machine in order to reduce or eliminate risks

concerning engine operation in particular, along with the relative routine maintenance work.

●

The user must read these instructions carefully and become familiar with the operations described. Failure to do

this could lead to serious danger for his personal safety and health and that of any persons who may be in the

vicinity of the machine.

●

The engine may only be used or assembled on a machine by technicians who are adequately trained about its

operation and the deriving dangers. This condition is also essential when it comes to routine and, above all,

extraordinary maintenance operations which, in the latter case, must only be carried out by persons specifically

trained by Deutz and who work in compliance with the existing documentation.

●

Variations to the functional parameters of the engine, adjustments to the fuel flow rate and rotation speed,

removal of seals, demounting and refitting of parts not described in the operation and maintenance manual by

unauthorized personnel shall relieve Deutz from all and every liability for deriving accidents or for failure to

comply with the laws in merit.

●

On starting, make sure that the engine is as horizontal as possible, unless the machine specifications differ. In

the case of manual start-ups, make sure that the relative actions can take place without the risk of hitting walls

or dangerous objects, also considering the movements made by the operator. Pull-starting with a free cord (thus

excluding self-winding starting only), is not permitted even in an emergency.

●

Make sure that the machine is stable to prevent the risk of overturning.

!

cardiagn.com

2001 / 0297 9985

10©

SAFETY AND WARNING DECALS - SAFETY INSTRUCTIONS

cardiagn.com

●

Become familiar with how to adjust the rotation speed and stop the engine.

●

Never start the engine in a closed place or where there is insufficient ventilation. Combustion creates carbon

monoxide, an odourless and highly poisonous gas. Lengthy stays in places where the engine freely exhausts

this gas can lead to unconsciousness and death.

●

The engine must not operate in places containing inflammable materials, in explosive atmospheres, where there

is dust that can easily catch fire unles specific, adequate and clearly indicated precautions have been taken and

have been certified for the machine.

●

To prevent fire hazards, always keep the machine at least one meter from buildings or from other machinery.

●

Children and animals must be kept at a due distance from operating machines in order to prevent hazards

deriving from their operation.

●

Fuel is inflammable. The tank must only be filled when the engine is off. Thoroughly dry any spilt fuel and move

the fuel container away along with any rags soaked in fuel or oil. Make sure that no soundproofing panels made

of porous material are soaked in fuel or oil. Make sure that the ground or floor on which the machine is standing

has not soaked up any fuel or oil.

●

Fully tighten the tank plug each time after refuelling. Do not fill the tank right to the top but leave an adequate

space for the fuel to expand.

●

Fuel vapour is highly toxic. Only refuel outdoors or in a well ventilated place.

●

Do not smoke or use naked flames when refuelling.

●

The engine must be started in compliance with the specific instructions in the operation manual of the engine

and/or machine itself. Do not use auxiliary starting aids that were not installed on the original machine (e.g.

Startpilot’).

●

Before starting, remove any tools that were used to service the engine and/or machine. Make sure that all

guards have been refitted.

●

During operation, the surface of the engine can become dangerously hot. Avoid touching the exhaust system in

particular.

●

Before proceeding with any operation on the engine, stop it and allow it to cool. Never carry out any operation

whilst the engine is running.

●

The coolant fluid circuit is under pressure. Never carry out any inspections until the engine has cooled and even

in this case, only open the radiator plug or expansion chamber with the utmost caution, wearing protective

garments and goggles. If there is an electric fan, do not approach the engine whilst it is still hot as the fan could

also start operating when the engine is at a standstill. Only clean the coolant system when the engine is at a

standstill.

●

When cleaning the oil-cooled air filter, make sure that the old oil is disposed of in the correct way in order to

safeguard the environment. The spongy filtering material in oil-cooled air filters must not be soaked in oil. The

reservoir of the separator pre-filter must not be filled with oil.

●

The oil must be drained whilst the engine is hot (oil T ~ 80°C). Particular care is required to prevent burns. Do not

allow the oil to come into contact with the skin.

●

Make sure that the drained oil, the oil filter and the oil it contains are disposed of in the correct way in order to

safeguard the environment.

●

Pay attention to the temperature of the oil filter when the filter itself is replaced.

●

Only check, top up and change the coolant fluid when the engine is off and cold. Take care to prevent fluids

containing nitrites from being mixed with others that do not contain these substances since "Nitrosamine",

dangerous for the health, can form. The coolant fluid is polluting and must therefore be disposed of in the correct

way to safeguard the environment.

●

During operations that involve access to moving parts of the engine and/or removal of rotating guards,

disconnect and insulate the positive wire of the battery to prevent accidental short-circuits and to stop the

starter motor from being energized.

●

Only check belt tension when the engine is off.

●

Only use the eyebolts installed by Deutz to move the engine. These lifting points are not suitable for the entire

machine; in this case, the eyebolts installed by the manufacturer should be used.

11 ©

2001 / 0297 9985

All pertinent information needed for engine identification and spare parts ordering can be accessed from the engine

data plate. Additionally, the maximum engine speed, “K” number and approval codes are included on the engine

data plate. The location of the data plate, as shown below, is identical for all DEUTZ B/FM 1008/F industrial

engines. Please supply the engine data plate information to your Authorized DEUTZ Distributor or Dealer when

ordering replacement parts or when making technical inquiries.

I GENERAL

cardiagn.com

2001 / 0297 9985

12©

GENERAL I

cardiagn.com

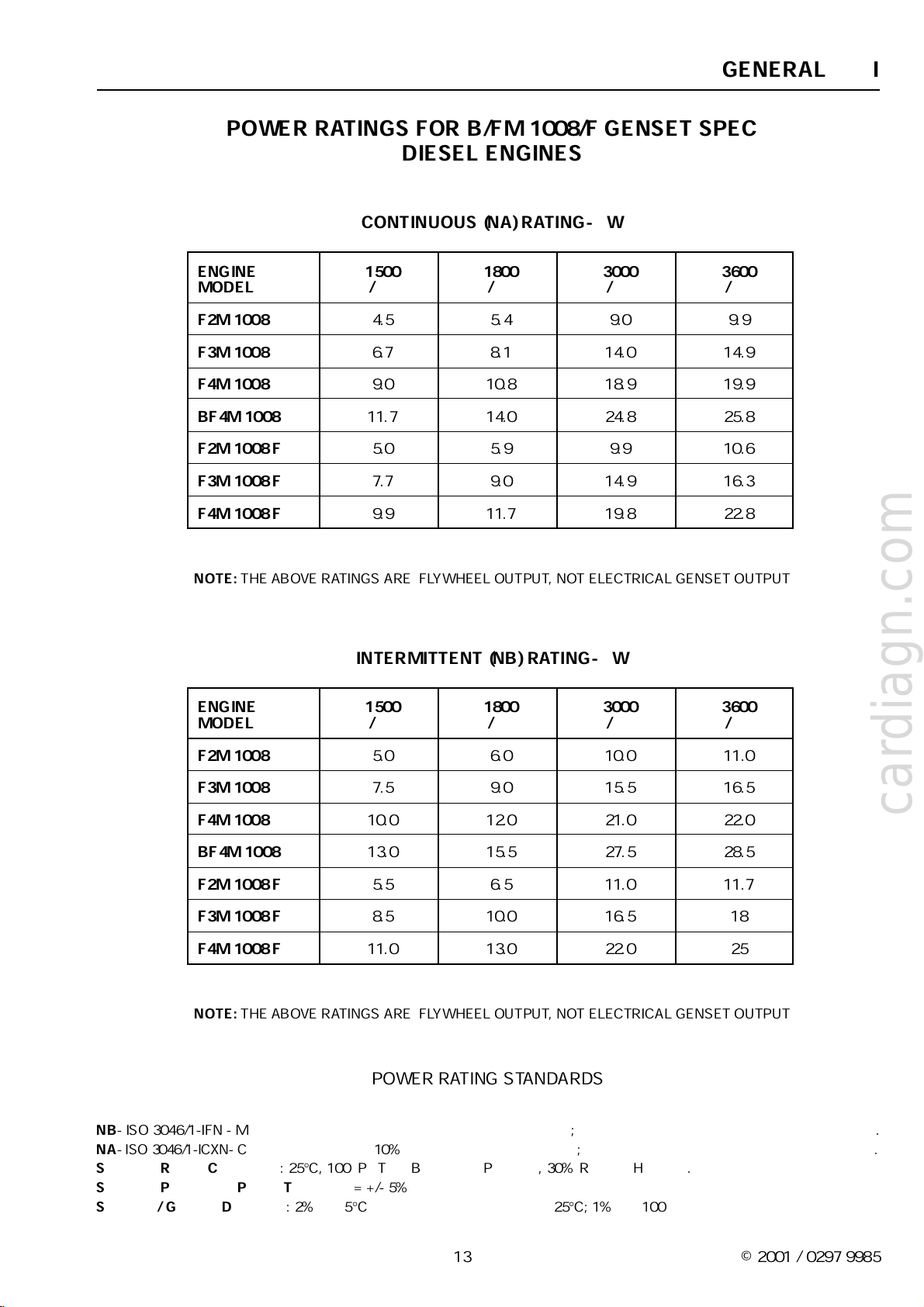

POWER RATINGS FOR B/FM 1008/F GENSET SPEC

DIESEL ENGINES

CONTINUOUS (NA) RATING- kW

ENGINE 1500 1800 3000 3600

MODEL r/min r/min r/min r/min

F2M 1008

F3M 1008

F4M 1008

BF4M 1008

F2M 1008 F

F3M 1008 F

F4M 1008 F

NOTE:

THE ABOVE RATINGS ARE FLYWHEEL OUTPUT, NOT ELECTRICAL GENSET OUTPUT

4.5 5.4 9.0 9.9

6.7 8.1 14.0 14.9

9.0 10.8 18.9 19.9

11.7 14.0 24.8 25.8

5.0 5.9 9.9 10.6

7.7 9.0 14.9 16.3

9.9 11.7 19.8 22.8

INTERMITTENT (NB) RATING- kW

ENGINE 1500 1800 3000 3600

MODEL r/min r/min r/min r/min

F2M 1008

5.0 6.0 10.0 11.0

F3M 1008

F4M 1008

BF4M 1008

F2M 1008 F

F3M 1008 F

F4M 1008 F

NOTE:

THE ABOVE RATINGS ARE FL

7.5 9.0 15.5 16.5

10.0 12.0 21.0 22.0

13.0 15.5 27.5 28.5

5.5 6.5 11.0 11.7

8.5 10.0 16.5 18

11.0 13.0 22.0 25

YWHEEL OUTPUT, NOT ELECTRICAL GENSET OUTPUT

POWER RATING STANDARDS

NB

- ISO 3046/1-IFN - Maximum intermittent rating with no overload capacity; operation with constant speed and variable load.

NA

-

ISO 3046/1-ICXN- Continuous rating with 10% intermittent overload allowed; operation with constant speed and constant load.

Standard Rating Conditions

Standard Production Power Tolerance

Standard/ General Derations

: 25°C, 100kPa Total Barometric Pressure, 30% Relative Humidity.

= +/- 5%

: 2% per 5°C increase in temperature over 25°C; 1% per 100m over mean sea level

13 ©

2001 / 0297 9985

I GENERAL

cardiagn.com

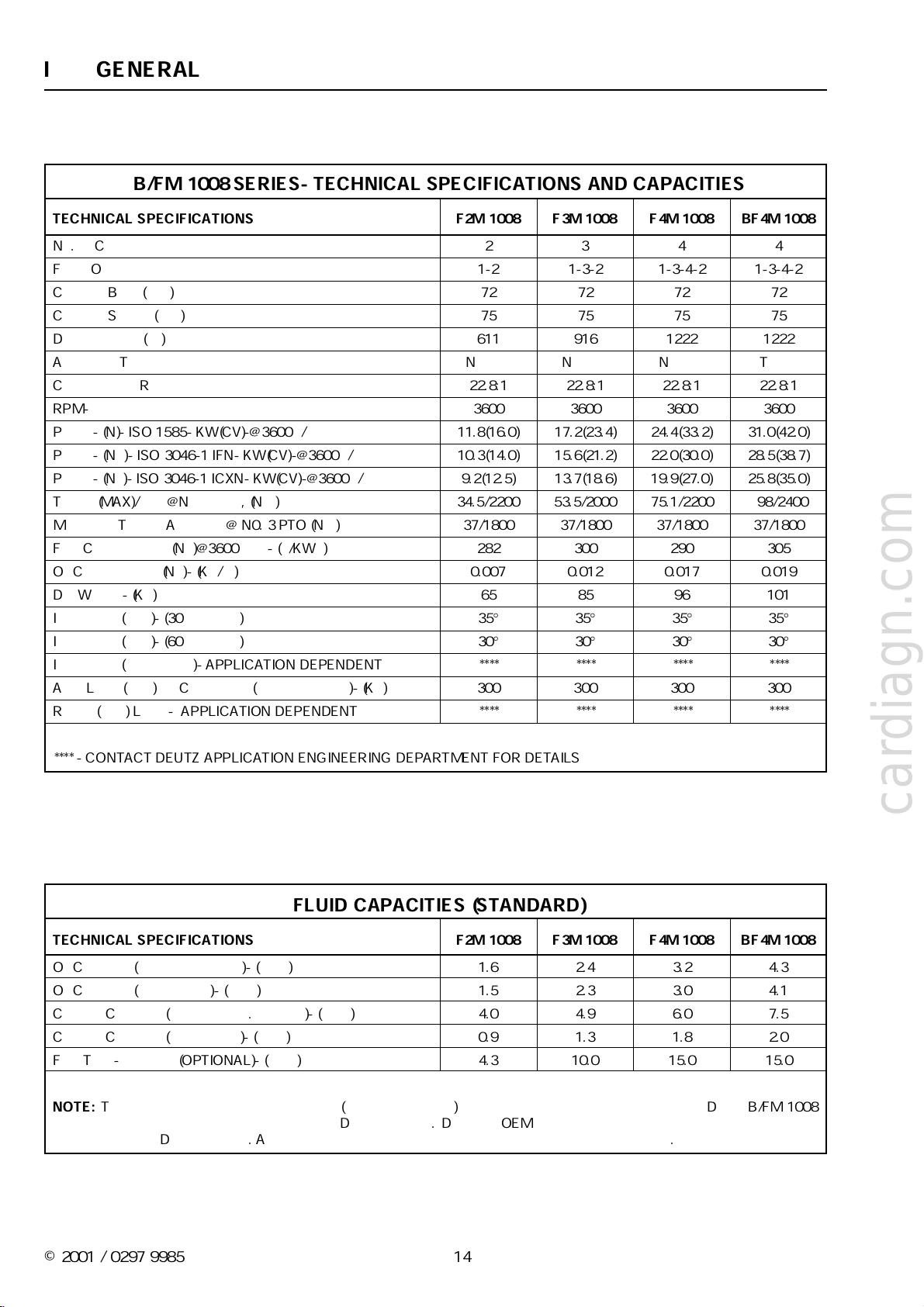

B/FM 1008 SERIES- TECHNICAL SPECIFICATIONS AND CAPACITIES

TECHNICAL SPECIFICATIONS F2M 1008

No. of Cylinders 2 3 4 4

Firing Order 1-2 1-3-2 1-3-4-2 1-3-4-2

Cylinder Bore (mm) 72 72 72 72

Cylinder Stroke (mm) 75 75 75 75

Displacement (cc) 611 916 1222 1222

Aspiration Type Natural Natural Natural Turbo

Compression Ratio 22.8:1 22.8:1 22.8:1 22.8:1

RPM- maximum 3600 3600 3600 3600

Power- (N)- ISO 1585- KW(CV)-@3600 r/min 11.8(16.0) 17.2(23.4) 24.4(33.2) 31.0(42.0)

Power- (Nb)- ISO 3046-1 IFN- KW(CV)-@3600 r/min 10.3(14.0) 15.6(21.2) 22.0(30.0) 28.5(38.7)

Power- (Na)- ISO 3046-1 ICXN- KW(CV)-@3600 r/min 9.2(12.5) 13.7(18.6) 19.9(27.0) 25.8(35.0)

Torque(MAX)/rpm @Nb output, (Nm) 34.5/2200 53.5/2000 75.1/2200 98/2400

Maximum Torque Available @ N0. 3 PTO (Nm) 37/1800 37/1800 37/1800 37/1800

Fuel Consumption (Nb)@3600 rpm- (g/KWh) 282 300 290 305

Oil Consumption (Na)- (Kg/hr) 0.007 0.012 0.017 0.019

Dry Weight- (Kg) 65 85 96 101

Inclination (max)- (30 seconds) 35

Inclination (max)- (60 seconds) 30

Inclination (continuous)- APPLICATION DEPENDENT **** **** **** ****

Axial Load (max) on Crankshaft (both directions)- (Kg) 300 300 300 300

Radial (side) Load - APPLICATION DEPENDENT **** **** **** ****

°

°

F3M 1008 F4M 1008 BF4M 1008

35

30

°

°

35

30

°

°

35

30

°

°

**** - CONTACT DEUTZ APPLICATION ENGINEERING DEPARTMENT FOR DETAILS

FLUID CAPACITIES (STANDARD)

TECHNICAL SPECIFICATIONS F2M 1008 F3M 1008 F4M 1008 BF4M 1008

Oil Capacity (including oil filter)- (liters) 1.6 2.4 3.2 4.3

Oil Capacity (less oil filter)- (liters) 1.5 2.3 3.0 4.1

Coolant Capacity (including std. radiator)- (liters) 4.0 4.9 6.0 7.5

Coolant Capacity (engine only)- (liters) 0.9 1.3 1.8 2.0

Fuel Tank-standard (OPTIONAL)- (liters) 4.3 10.0 15.0 15.0

NOTE:

The above cooling system capacities (including radiator) assume that the radiator fitted to your Deutz B/FM 1008

series diesel engine is the standard Deutz radiator. Different OEM machines may or may not be fitted with a

standard Deutz radiator. Always refer to your equipment documentation for capacity details.

2001 / 0297 9985

14©

F2M 1008

F3M 1008

F4M 1008

BF4M 1008

cardiagn.com

GENERAL I

15 ©

2001 / 0297 9985

I GENERAL

cardiagn.com

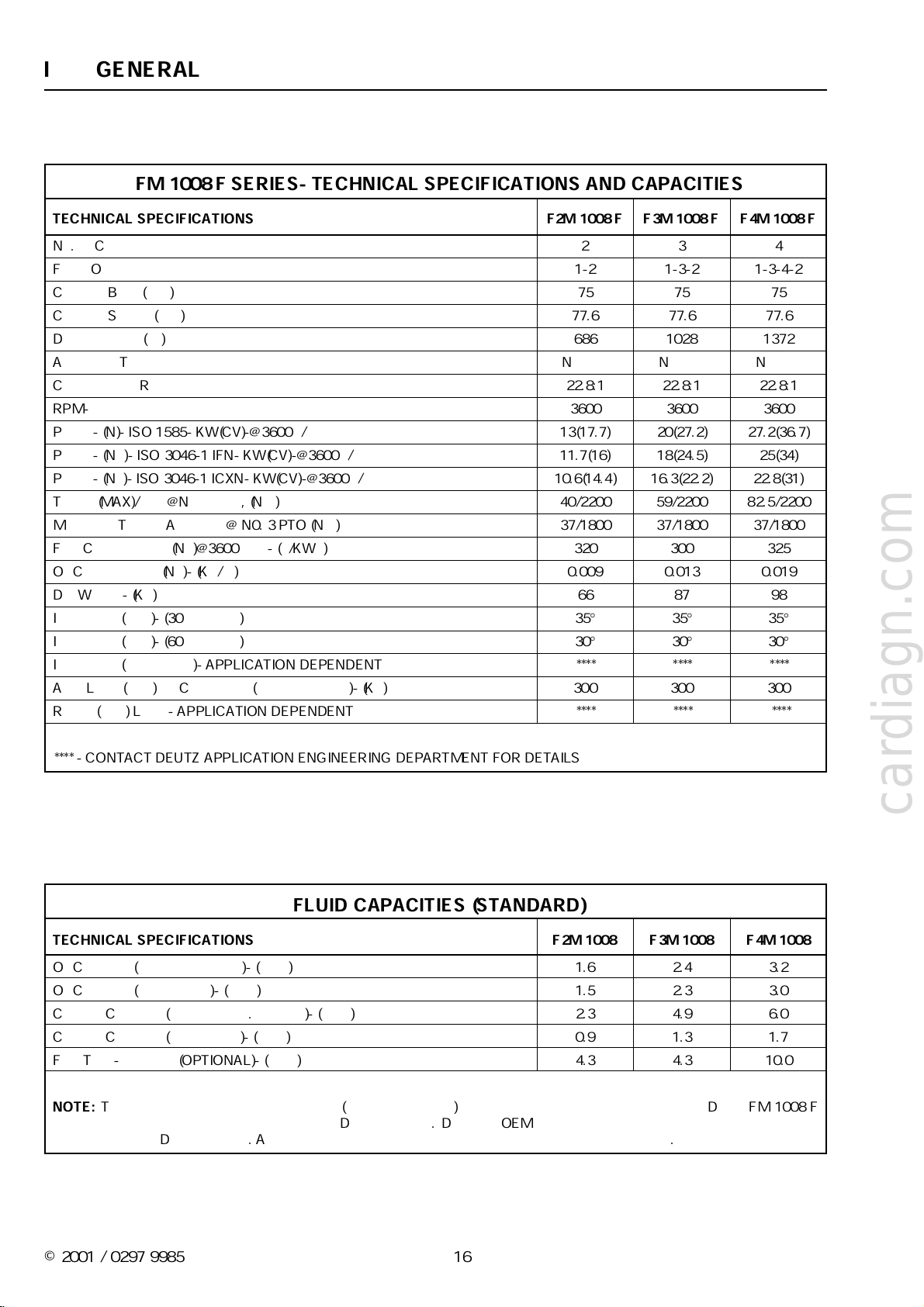

FM 1008 F SERIES- TECHNICAL SPECIFICATIONS AND CAPACITIES

TECHNICAL SPECIFICATIONS F2M 1008 F

No. of Cylinders 2 3 4

Firing Order 1-2 1-3-2 1-3-4-2

Cylinder Bore (mm) 75 75 75

Cylinder Stroke (mm) 77.6 77.6 77.6

Displacement (cc) 686 1028 1372

Aspiration Type Natural Natural Natural

Compression Ratio 22.8:1 22.8:1 22.8:1

RPM- maximum 3600 3600 3600

Power- (N)- ISO 1585- KW(CV)-@3600 r/min 13(17.7) 20(27.2) 27.2(36.7)

Power- (Nb)- ISO 3046-1 IFN- KW(CV)-@3600 r/min 11.7(16) 18(24.5) 25(34)

Power- (Na)- ISO 3046-1 ICXN- KW(CV)-@3600 r/min 10.6(14.4) 16.3(22.2) 22.8(31)

Torque(MAX)/rpm @Nb output, (Nm) 40/2200 59/2200 82.5/2200

Maximum Torque Available @ N0. 3 PTO (Nm) 37/1800 37/1800 37/1800

Fuel Consumption (Nb)@3600 rpm- (g/KWh) 320 300 325

Oil Consumption (Na)- (Kg/hr) 0.009 0.013 0.019

Dry Weight- (Kg) 66 87 98

Inclination (max)- (30 seconds) 35

Inclination (max)- (60 seconds) 30

Inclination (continuous)- APPLICATION DEPENDENT **** **** ****

Axial Load (max) on Crankshaft (both directions)- (Kg) 300 300 300

Radial (side) Load - APPLICATION DEPENDENT **** **** ****

°

°

F3M 1008 F F4M 1008 F

35

30

°

°

35

30

°

°

**** - CONTACT DEUTZ APPLICATION ENGINEERING DEPARTMENT FOR DETAILS

FLUID CAPACITIES (STANDARD)

TECHNICAL SPECIFICATIONS F2M 1008 F3M 1008 F4M 1008

Oil Capacity (including oil filter)- (liters) 1.6 2.4 3.2

Oil Capacity (less oil filter)- (liters) 1.5 2.3 3.0

Coolant Capacity (including std. radiator)- (liters) 2.3 4.9 6.0

Coolant Capacity (engine only)- (liters) 0.9 1.3 1.7

Fuel Tank-standard (OPTIONAL)- (liters) 4.3 4.3 10.0

NOTE:

The above cooling system capacities (including radiator) assume that the radiator fitted to your Deutz FM 1008 F

series diesel engine is the standard Deutz radiator. Different OEM machines may or may not be fitted with a

standard Deutz radiator. Always refer to your equipment documentation for capacity details.

2001 / 0297 9985

16©

GENERAL I

F2M 1008 F

F3M 1008 F

F4M 1008 F

cardiagn.com

17 ©

2001 / 0297 9985

I GENERAL

cardiagn.com

POWER, TORQUE AND SPECIFIC FUEL CONSUMPTION CURVES

F2M 1008 F3M 1008

F2/3M

1008

N

- 80/1269/CEE- ISO 1585, Gross automotive rating- intermittent operation with variable speed and variable load.

NB

- ISO 3046/1-IFN - Maximum intermittent rating with no overload capacity; operation with constant speed and variable load.

ISO 3046/1-ICXN- Continuous rating with 10% intermittent overload allowed; operation with constant speed and constant load.

NA

-

M(X)

- Torque at N,NB and NA ratings respectively.

C

- Specific fuel consumption at NB rating.

Standard Rating Conditions:

Standard Production Power Tolerance

Standard/ General Derations:

2001 / 0297 9985

25°C, 100kPa Total Barometric Pressure, 30% Relative Humidity.

= +/- 5%

2% per 5°C increase in temperature over 25°C; 1% per 100m over mean sea level

18©

GENERAL I

cardiagn.com

POWER, TORQUE AND SPECIFIC FUEL CONSUMPTION CURVES

F4M 1008, BF4M 1008

F4M 1008 BF4M 1008

N

- 80/1269/CEE- ISO 1585, Gr

NB

- ISO 3046/1-IFN - Maximum intermittent rating with no overload capacity; operation with constant speed and variable load.

ISO 3046/1-ICXN- Continuous rating with 10% intermittent overload allowed; operation with constant speed and constant load.

NA

-

M(X)

- Torque at N,NB and NA ratings respectively.

C

- Specific fuel consumption at NB rating.

Standard Rating Conditions:

Standard Production Power Tolerance

Standard/ General Derations:

oss automotive rating- intermittent operation with variable speed and variable load.

25°C, 100kPa Total Barometric Pressure, 30% Relative Humidity.

= +/- 5%

2% per 5°C increase in temperature over 25°C; 1% per 100m over mean sea level

19 ©

2001 / 0297 9985

I GENERAL

cardiagn.com

POWER, TORQUE AND SPECIFIC FUEL CONSUMPTION CURVES

F2M 1008 F F3M 1008 F

F2/3/4M

1008 F

F4M 1008 F

N

- 80/1269/CEE- ISO 1585, Gross automotive rating- intermittent operation with variable speed and variable load.

NB

- ISO 3046/1-IFN - Maximum intermittent rating with no overload capacity; operation with constant speed and variable load.

ISO 3046/1-ICXN- Continuous rating with 10% intermittent overload allowed; operation with constant speed and constant load.

NA

-

M(X)

- Torque at N,NB and NA ratings respectively.

C

- Specific fuel consumption at NB rating.

Standard Rating Conditions:

Standard Production Power Tolerance

Standard/ General Derations:

25°C, 100kPa Total Barometric Pressure, 30% Relative Humidity.

= +/- 5%

2% per 5°C increase in temperature over 25°C; 1% per 100m over mean sea level

2001 / 0297 9985

20©

GENERAL ENGINEERING DRAWINGS- F2/3M 1008

cardiagn.com

F2M 1008

GENERAL I

F3M

1008

21 ©

2001 / 0297 9985

I GENERAL

cardiagn.com

GENERAL ENGINEERING DRAWINGS- F4M 1008, BF4M 1008

F4M 1008

BF4M

1008

2001 / 0297 9985

22©

GENERAL ENGINEERING DRAWINGS- F2/3/4M 1008 F

cardiagn.com

GENERAL I

F2M 1008

F3M 1008 F

F

F4M 1008 F

23 ©

2001 / 0297 9985

I GENERAL

!

(D) Add fluid(s) as required

(•) After inspection, adjust, r

epair or replace as required

(●) Clean as often as required

(*) Replace air filter after air filter restriction switch indication or one(1) year. DEUTZ does not

recommend the removal of air filter elements for purposes of inspection.

(**) Service oil bath filter element (upper and lower) as required. Replace reservoir oil as required.

NOTE:

In dusty conditions, service the oil bath air filter every four(4) hours.

(***) Replace coolant every 1000 hours or 2 years

NOTES:

1. USE ONLY GENUINE DEUTZ REPLACEMENT PARTS.

2. USE ONLY DEUTZ APPROVED FLUIDS.

MAINTENANCE OPERATION

OIL LEVEL CHECK (D)

•

COOLANT LEVEL CHECK (D)

•

FAN/ ALTERNATOR BELT INSPECTION (•)

•

AIR FILTER ELEMENT CHECK (DRY TYPE) (*)

AIR FILTER CHECK (OIL BATH TYPE) (**)

•

RADIATOR CORE INSPECTION

(●)

•

FLUID LEAK INSPECTION- GENERAL (•)

•

SAFETY GUARD INSPECTION (•)

•

OIL REPLACEMENT- INITIAL ONLY-(see RECOMMENDED OIL TYPE)

•

OIL FILTER REPLACEMENT - INITIAL ONLY

•

OIL REPLACEMENT- (see RECOMMENDED OIL TYPE)

•

OIL FILTER REPLACEMENT

•

FUEL FILTER REPLACEMENT

•

COOLANT HOSE INSPECTION

•

FAN/ ALTERNATOR BELT TENSION ADJUSTMENT

•

VALVE ADJUSTMENT

•

FAN/ ALTERNATOR BELT REPLACEMENT

•

FUEL INJECTION SYSTEM ADJUSTMENT

•

CLEAN FUEL TANK (

●

)

•

COOLANT REPLACEMENT (***)

•

REPLACE TIMING

BELT

•

MAINTENANCE INTERVAL

10

hours

or

DAILY

see note

50

hours

125

hours

250

hours

500

hours

1000

hours

2500

hours

cardiagn.com

Failure

and/or system

to carry out the operations described in the table may lead to technical damage to the machine

B/FM 1008/F SERIES MAINTENANCE SCHEDULE

2001 / 0297 9985

24©

GENERAL I

0 5 10 15 20 25 30°C-5-10-15-20-25-30

SAE 0W-30

SAE 0W-40

SAE 5W-30

SAE 5W-40

SAE 10W-30

SAE 10W-40

SAE 15W-30

SAE 20W-50

cardiagn.com

The engine could be damaged if allowed to operate with insufficient oil. It is also dangerous to add too much oil as its

combustion could sharply increase the rotation speed.

Use a suitable oil in order to protect the engine.

The lubrication oil influences the performances and life of the engine in an incredible way.

Use of an inferior quality oil or failure to regularly change the oil will increase the risk of piston seizure, may make the

compression rings jam and will lead to rapid wear on the cylinder liner, the bearings and all other moving parts. Engine life

will also be notably reduced.

Oil viscosity must suit the ambient temperature in which the engine operates.

Old oil can cause skin cancer if repeatedly left in contact with the skin and for long periods of time. If contact with the oil

is inevitable, you are advised to thoroughly wash your hands with soap and water as soon as possible.

Appropriate protective gloves etc should be wore during this operation.

Old oil is highly polluting and must be disposed of in the correct way. Do not litter.

RECOMMENDED OIL

SINT 2000 5W40 specification API SJ/CF ACEA A3-96

AGIP

B3-96 MIL-L-46152 D/E.

ESSO ULTRA 10W40 specification API SJ/CF ACEA A3-96

MIL-L-46152 D/E.

In countries where AGIP and ESSO products are not available,

use API SJ/CF oil for gasoline-fuelled engines or oil that complies

with military specification MIL-L-46152 D/E.

OIL SUPPLY (liters) F2M 1008/F

Standard oil sump

filter included 1.6

filter excluded 1.5

OIL SUPPLY (liters) F3M 1008/F

Standard oil sump

filter included 2.4

filter excluded 2.3

OIL SUPPLY (liters) F4M 1008/F

Standard oil sump

filter included 3.2

filter excluded 3.0

OIL SUPPLY (liters) BF4M 1008

Standard oil sump

filter included 4.3

filter excluded 4.1

GRADE

25 ©

2001 / 0297 9985

Loading...

Loading...