Canon MP450, MP170 User Manual

PIXMA MP170 PIXMA MP450

SERVICE

MANUAL

Canon

Copyright 2005, Canon U.S.A. This technical publication is the proprietary and confidential information of Canon U.S.A. which shall be retained for reference purposes by Authorized Service Facilities of Canon U.S.A. Its unauthorized use is prohibited.

PIXMA MP170

PIXMA MP450

SERVICE MANUAL

Revision 0

QY8-13AH-000

COPYRIGHT©2005 CANON INC. CANON PIXMA MP170/PIXMA MP450 082005 XX 0.00-0

Scope

This manual has been issued by Canon Inc., to provide the service technicians of this product with the information necessary for qualified persons to learn technical theory, installation, maintenance, and repair of products. The manual covers information applicable in all regions where the product is sold. For this reason, it may contain information that is not applicable to your region.

Revision

This manual could include technical inaccuracies or typographical errors due to improvements or changes made to the product. When changes are made to the contents of the manual, Canon will release technical information when necessary. When substantial changes are made to the contents of the manual, Canon will issue a revised edition.

The following do not apply if they do not conform to the laws and regulations of the region where the manual or product is used:

Trademarks

Product and brand names appearing in this manual are registered trademarks or trademarks of the respective holders.

Copyright

All rights reserved. No parts of this manual may be reproduced in any form or by any means or translated into another language without the written permission of Canon Inc., except in the case of internal business use.

Copyright © 2005 by Canon Inc. CANON INC.

Inkjet Device Quality Assurance Div. 2

451, Tsukagoshi 3-chome, Saiwai-ku, Kawasaki-shi, Kanagawa 212-8530, Japan

I. MANUAL OUTLINE

This manual consists of the following three parts to provide information necessary to service the PIXMA MP170 / MP450:

Part 1: Maintenance

Information on maintenance and troubleshooting of the PIXMA MP170 / MP450

Part 2: Technical Reference

New technology and technical information such as FAQ's (Frequently Asked Questions) of the PIXMA MP170 / MP450

Part 3: Appendix

Block diagrams and pin layouts of the PIXMA MP170 / MP450

Reference:

This manual does not provide sufficient information for disassembly and reassembly procedures. Refer to the graphics in the separate Parts Catalog.

II. TABLE OF CONTENTS

Part 1: MAINTENANCE

1. MAINTENANCE

1-1. Adjustment, Periodic Maintenance, Periodic Replacement Parts, and Replacement Consumables by Service Engineer

1-2. Customer Maintenance

1-3. Product Life

1-4. Special Tools

1-5. Serial Number Location

2. LIST OF ERROR DISPLAY / INDICATIONS

2-1. Operator Call Errors

2-2. Service Call Errors

2-3. Warnings

2-4. Troubleshooting by Symptom

3. REPAIR

3-1. Notes on Service Part Replacement (and Disassembling / Reassembling) 3-2. Special Notes on Repair Servicing

3-3. Adjustment / Settings

(1)Paper feed motor adjustment

(2)Main chassis and carriage rail adjustment

(3)Document pressure sheet adjustment

(4)Grease application

(5)Waste ink counter setting

(6)User mode

(7)Service mode

Service test print

EEPROM initialization

Waste ink counter reset

Destination settings

Button and LCD test

3-4. Verification Items

(1)Service test print

(2)EEPROM information print

Part 2: TECHNICAL REFERENCE

1. NEW TECHNOLOGIES

2. CLEANING MODE AND AMOUNT OF INK PURGED

3. PRINT MODE

3-1. Resolution in Printing via Computer (Print on One or Both Sides of Paper, BK Cartridge, Monochrome Mode)

3-2. Resolution in Printing via Computer (Print on One or Both Sides of Paper, BK and CL Cartridges, Monochrome Mode)

3-3. Resolution in Printing via Computer (Print on One or Both Sides of Paper, BK and CL Cartridges, Color Mode)

3-4. Resolution in Printing via Computer (Print on One or Both Sides of Paper, CL Cartridge, Color or Monochrome Mode)

3-5. Resolution in Borderless Printing (Print on One or Both Sides of Paper, BK and CL Cartridges or CL Cartridge Only, Color or Monochrome Mode)

3-6. Resolution in Direct Printing

3-7. Resolution in Copying (Copy on One or Both Sides of Paper, Color or Monochrome Mode) 4. FAQ (Problems Specific to the MP170 / MP450 and Corrective Actions)

Part 3: APPENDIX

1. BLOCK DIAGRAM

2. CONNECTOR LOCATION AND PIN LAYOUT

2-1. Main Board

2-2. MP450 Operation Panel Board L

2-3. MP450 Operation Panel Board R

2-4. MP170 Operation Panel Board

2-5. Card Slot Board (Card Slot Unit)

2-6. Carriage Board (Print Head Connector)

3. SPECIFICATIONS

Part 1

MAINTENANCE

1. MAINTENANCE

1-1. Adjustment, Periodic Maintenance, Periodic Replacement Parts, and Replacement Consumables by Service Engineer

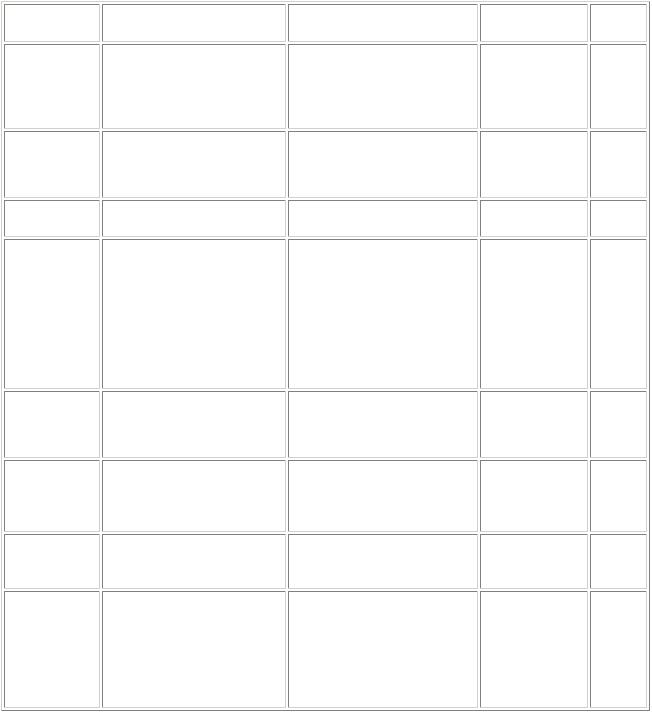

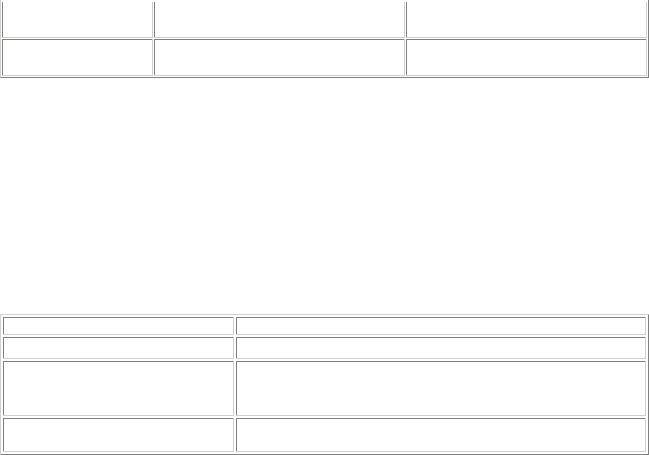

(1) Adjustment |

|

|

|

Adjustment |

Timing |

Purpose |

Tool |

EEPROM |

At logic board ass'y replacement |

To initialize settings other than |

None. |

initialization |

|

the following: |

|

(EEPROM |

|

- USB serial number |

|

settings) |

|

- Destination setting |

|

- Waste ink counter

Approx.

time

1 min.

Destination |

At logic board ass'y replacement |

To set the destination. |

None. |

1 min. |

settings |

|

|

|

|

(EEPROM |

|

|

|

|

settings) |

|

|

|

|

LCD language |

At logic board ass'y replacement |

To set the language to be |

None. |

1 min. |

settings |

|

displayed on the LCD. |

|

|

Waste ink |

- At bottom case unit |

To reset the waste ink counter. |

None. |

1 min. |

counter |

replacement |

|

|

|

resetting |

MP170: QM2-2800-000 |

|

|

|

(EEPROM |

MP450: QM2-2814-000 |

|

|

|

settings) |

- At ink absorber replacement |

|

|

|

|

MP170: QY5-0149, QC1- |

|

|

|

|

6014 |

|

|

|

|

MP450: QY5-0151, QC1- |

|

|

|

|

6014 |

|

|

|

Document |

- At document cover unit |

To adjust the pressure sheet to fit |

None. |

1 min. |

pressure sheet |

replacement |

in place to the four corners of the |

|

|

position |

- At scanning unit replacement |

platen glass when the cover is |

|

|

adjustment |

|

closed |

|

|

Print head |

- At print head replacement |

To ensure accurate dot placement. |

- Machine buttons |

2 min. |

alignment |

- At logic board ass'y |

|

- Computer |

|

|

replacement |

|

(settings via the |

|

|

- At carriage unit replacement |

|

MP driver) |

|

Paper feed |

At paper feed motor unit |

To adjust the belt tension. |

None. |

2 min. |

motor position |

replacement |

(Position the paper feed motor so |

|

|

adjustment*1 |

|

that the belt is stretched tight.) |

|

|

Grease |

- At carriage unit replacement |

- To maintain sliding properties |

- FLOIL KG- |

1 min. |

application |

- At bottom case unit |

of the carriage, cap blade unit, |

107A (QY9- |

|

|

replacement |

and eject rollers. |

0057) |

|

|

- At platen replacement |

|

- MOLYKOTE |

|

|

- At eject roller replacement |

|

PG641 (CK- |

|

|

- At cap blade unit replacement |

|

0562) |

|

|

- |

|

|

|

*1: Red screws of paper feed motor

The red screws securing the paper feed motor may be loosened only at replacement of the paper feed motor unit.

1-1

(2) Periodic maintenance

No periodic maintenance is necessary.

(3) Periodic replacement parts

There are no parts in this machine that require periodic replacement by a service engineer.

(4) Replacement consumables

There are no consumables that require replacement by a service engineer.

1-2. Customer Maintenance

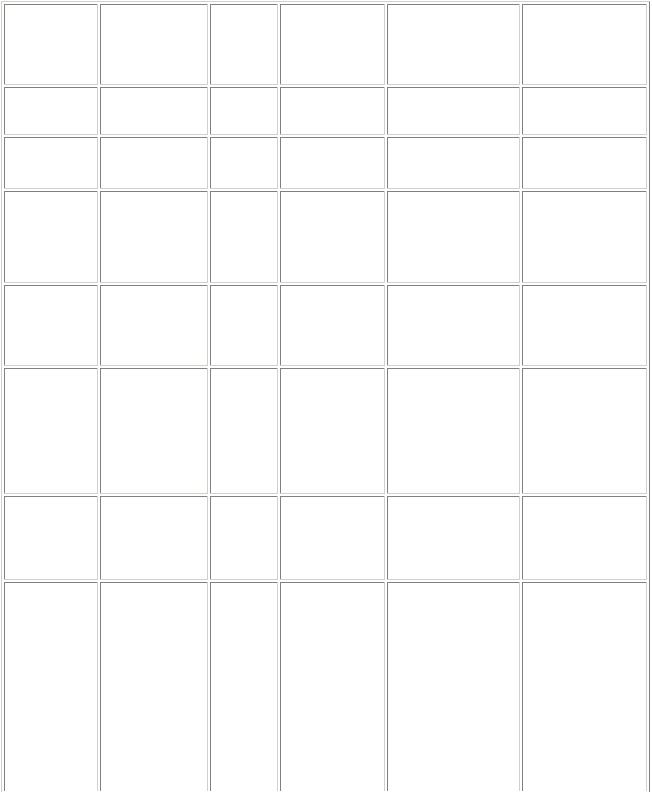

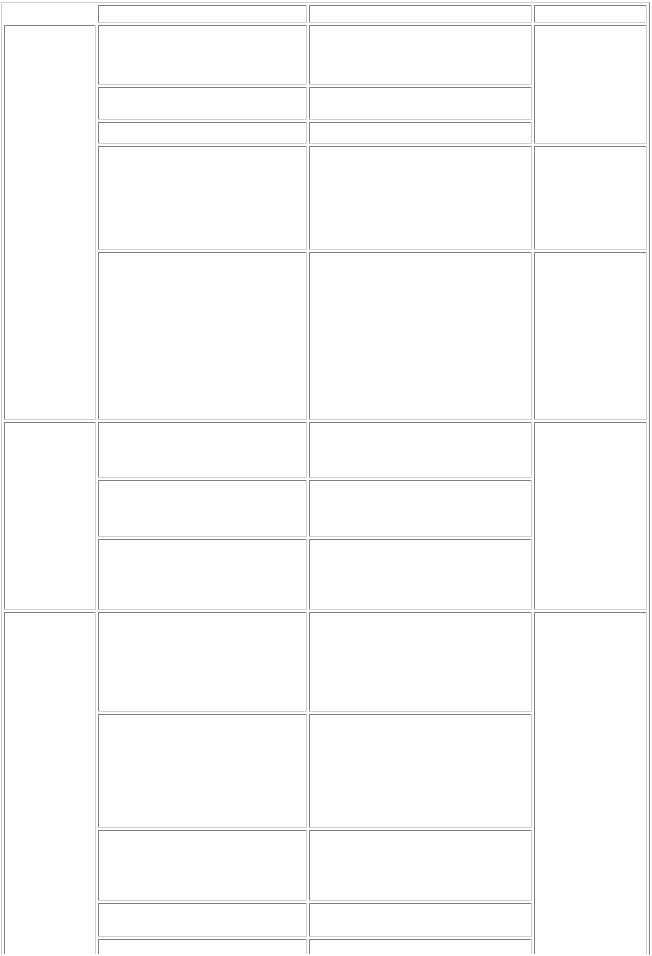

Adjustment |

Timing |

Purpose |

Tool |

Approx. |

|

time |

|||||

|

|

|

|

||

Print head |

When print quality is not |

To ensure accurate dot |

- Machine buttons |

3 min. |

|

alignment |

satisfying. |

placement. |

(automatic |

|

|

|

|

|

alignment by |

|

|

|

|

|

scanning the head |

|

|

|

|

|

alignment sheet) |

|

|

|

|

|

- Computer (manual |

|

|

|

|

|

alignment via the |

|

|

|

|

|

MP driver) |

|

|

Print head |

When print quality is not |

To improve nozzle conditions. |

- Machine button |

1 min. |

|

cleaning |

satisfying. |

|

- Computer (settings |

|

|

|

|

|

via the MP driver) |

|

|

Print head deep |

When print quality is not |

To improve nozzle conditions. |

- Machine button |

2 min. |

|

cleaning |

satisfying, and not improved by |

|

- Computer (settings |

|

|

|

print head cleaning. |

|

via the MP driver) |

|

|

Ink cartridge |

When an ink cartridge becomes |

----- |

----- |

2 min. |

|

replacement |

empty. (No ink error) |

|

|

|

Paper feed roller |

When paper does not feed |

cleaning |

properly. |

Bottom plate |

When the back side of the paper |

cleaning |

is smeared |

To clean the paper feed rollers.

To clean the platen ribs.

Machine button |

2 min. |

- Machine button |

1 min. |

-Computer (settings via the MP driver)

1-3. Product Life

(1) Machine

Specified print volume (I) or the years of use (II), whichever comes first.

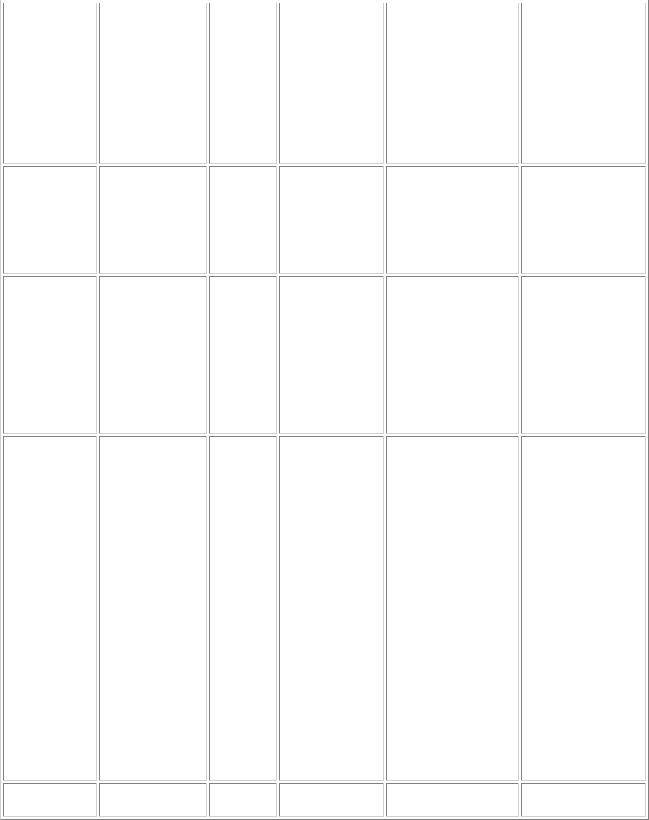

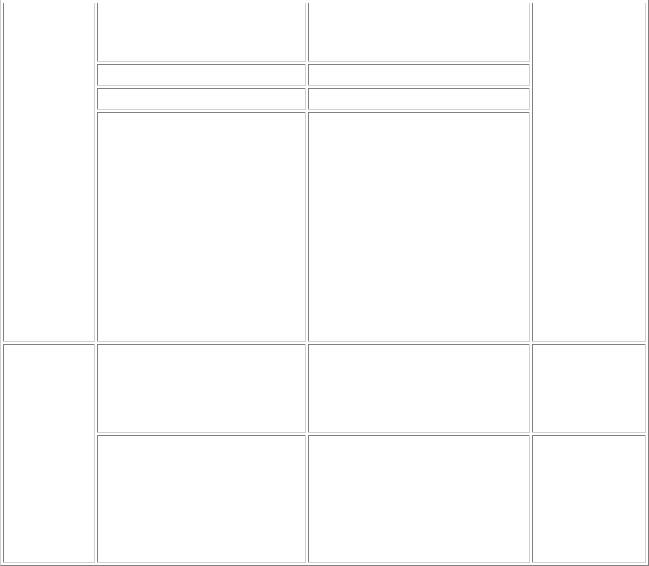

(I) Print volume

|

|

MP170 / MP450 |

|

|

8,000 pages |

Black |

1,500 character pattern |

4,000 pages |

Color |

A4, 7.5% duty per color pattern |

3,200 pages |

|

A4, 30 % duty per color pattern |

160 pages |

|

4 x 6, 30 % duty per color pattern |

400 pages |

|

Postcard, 30 % duty per color pattern |

240 pages |

(II) Years of use

5 years of use

1-2

(2) Ink cartridge (ink tank with nozzles) (target value)

1,500 character pattern

plain paper, standard mode (BK)

ISO JIS-SCID No. 5

plain paper, standard mode (BK)

ISO JIS-SCID No. 5

plain paper, standard mode (CL)

Digital camera 24 images PP-101 4x6

Standard |

High capacity |

|||

BK |

CL |

BK |

CL |

|

PG-40 |

CL-41 |

PG-50 |

CL- |

|

51 |

||||

|

|

|

||

490 pages |

- |

750 pages |

- |

|

760 pages |

- |

1,170 pages |

- |

|

- |

190 pages |

- |

320 |

|

pages |

||||

|

|

|

||

- |

100 pages |

- |

180 |

|

pages |

||||

|

|

|

||

1-4. Special Tools

Name |

Tool No. |

Application |

Remarks |

MOLYKOTE |

QY9-0035-000 |

To be applied to the chassis. |

In common with |

PG-641 |

|

|

other models. |

FLOIL |

QY9-0057-000 |

To be applied to the sliding portion of |

In common with |

KG-107A |

|

the carriage, and the platen link. |

other models. |

1-5. Serial Number Location

On the chassis (visible when the scanning unit is open).

To the table of contents |

To the top |

<Part 1: 1.MAINTENANCE>

<Part 1: 1.MAINTENANCE>

1-3

2. LIST OF ERROR DISPLAY / INDICATIONS

Errors and warnings are displayed by the following ways:

1)Operator call errors are indicated by the Alarm LED lit. (In the service mode, the Alarm LED blinks to indicate errors.)

Service call errors are indicated by the number of cycles the Alarm and Power LEDs blink.

2)Errors and warnings are displayed on the LCD on the operation panel.

3)Warnings are displayed on the MP driver Status Monitor.

2-1. Operator Call Errors (by Alarm LED Lit in Orange)

MP450 LCD |

MP170 LCD |

There is no |

LOAD PAPER |

paper. |

|

The paper is |

PAPER JAMMED |

jammed. |

|

Ink has run out. |

CHECK INK |

Replace the ink |

U041 |

cartridge and |

|

close the cover. |

|

U041 |

|

The following |

CHECK INK |

ink cartridge |

U051 / U059 |

cannot be |

|

recognized. |

|

U051 / U059 |

|

The following |

CHECK INK |

ink cartridge |

U052 |

cannot be |

|

recognized. |

|

U052 |

|

The following |

CHECK INK |

ink cartridge |

U053 |

cannot be |

|

recognized. |

|

U053 |

|

The waste ink |

WASTE INK |

absorber is |

NEAR FULL |

almost full. |

|

Alarm LED |

|

|

|

blinking in |

|

|

|

orange (in |

Error [Error code] |

Solution |

Remarks |

the service |

|

|

|

mode only) |

|

|

|

2 times |

No paper. (ASF) |

Set the paper in the |

|

|

[1000] |

ASF, and press the OK |

|

|

|

button. |

|

3 times |

Paper jam. [1300] |

Remove the jammed |

|

|

|

paper, and press the OK |

|

|

|

button. |

|

- |

No ink. [1600] |

Replace the empty ink |

Pressing the OK |

|

|

cartridge(s), or press |

button will exit the |

|

|

the OK button. |

error without ink |

|

|

|

cartridge replacement, |

|

|

|

however, ink may run |

|

|

|

out during printing. |

5 times |

Ink cartridge not |

Confirm that the ink |

|

|

installed. [1401] |

cartridges are for this |

|

|

Ink cartridge not |

model, install them |

|

|

for this model |

properly, then close the |

|

|

installed. [1485] |

scanning unit. |

|

15 times |

Ink cartridge not |

Re-install the |

|

|

installed. [1682] |

applicable ink cartridge |

|

|

|

(s) properly, and close |

|

|

|

the scanning unit. |

|

|

|

Or, with the ink |

|

|

|

cartridges installed, |

|

|

|

turn the machine off |

|

|

|

and on again. |

|

4 times |

Improper |

Re-install the |

|

|

installation of an |

applicable ink cartridge |

|

|

ink cartridge. |

(s) properly, and close |

|

|

[1687] |

the scanning unit. |

|

- |

|

|

|

Incompatible device detected.

The following ink may have

run out.

U161

An ink cartridge that was once empty is

installed.

U162

Failed to scan head alignment sheet.

Cover is open.

MP450: QY5-0151)

For platen ink absorber

|

|

|

replacement, |

|

|

|

replace |

|

|

|

- the ink absorber |

|

|

|

(QC1-6014) |

|

|

|

, and |

|

|

|

- the ink absorber kit |

|

|

|

(MP170: QY5-0149 |

|

|

|

MP450: QY5-0151). |

INCOMPATIBLE |

- |

The connected |

Remove the cable |

CAMERA |

|

digital camera or |

between the camera and |

|

|

digital video |

the machine, press the |

|

|

camera does not |

Stop/Reset button, then |

|

|

support Camera |

re-connect the cable. |

|

|

Direct Printing. |

|

|

|

[2001] |

|

CHECK INK |

- |

Remaining ink |

U161 |

|

amount unknown. |

U162 |

|

[1685/1686] |

|

|

A once-used ink cartridge (except the one which has been used until just before replacement) is

installed.

Replace the applicable ink cartridge with a new one, or press the OK button.

Pressing the OK button will exit the error without ink cartridge replacement, however, the function to detect the remaining ink amount is disabled.

HEAD |

- |

Failed in scanning |

Press the OK button to |

ALIGNMENT |

|

the print head |

exit the error, and do |

ERROR |

|

alignment sheet. |

the print head |

|

|

|

alignment again (from |

|

|

|

printing of the print |

|

|

|

head alignment sheet), |

|

|

|

while confirming the |

|

|

|

following: |

|

|

|

- Set A4 or LTR size |

|

|

|

plain paper. |

|

|

|

- Confirm that the print |

|

|

|

head alignment sheet |

|

|

|

is printed properly |

|

|

|

(no smear or non- |

|

|

|

ejection of ink). |

|

|

|

- Fill in all the |

|

|

|

applicable boxes in |

|

|

|

the printed sheet. |

|

|

|

- Place the sheet on the |

|

|

|

platen glass in the |

|

|

|

correct position and |

|

|

|

orientation. |

COVER IS OPEN |

- |

Scanning unit |

Close the scanning unit. |

|

|

open. [1200] |

|

*1: The main waste ink absorber is separate from the platen waste ink absorber. In servicing, replace the waste ink absorber which becomes full.

[See Section 3-3. Adjustment / Settings, (7) Service mode, for details.]

1-5

2-2. Service Call Errors (by Cyclic Blinking in Orange (Alarm LED) and Green (Power LED), or Alarm LED Lit in Orange)

Cycles of blinking in |

|

Solution |

orange (Alarm LED) and |

Error [Error code] |

(Replacement of listed parts, which are |

green (Power LED) |

|

likely to be faulty) |

2 times |

Carriage error [5100] |

- Carriage unit (QM2-2136) |

|

|

- Timing slit strip film (QC1-6015) |

|

|

- Logic board ass'y (MP170 QM2-3210, |

|

|

MP450 QM2-3231)*1 |

|

|

- Carriage motor (QM2-3165) |

3 times |

Paper feed error [6000] |

- Timing sensor ass'y (QM2-3167) |

|

|

- Timing slit disk film (QC1-4962) |

|

|

- Feed roller ass'y (QL2-0905) |

|

|

- Platen (QC1-6013) |

|

|

- Logic board ass'y (MP170 QM2-3210, |

|

|

MP450 QM2-3231)*1 |

|

|

- Paper feed motor (QM2-3166) |

4 times |

Purge unit error [5C00] |

- Carriage unit (QM2-2136) |

|

|

- Timing slit strip film (QC1-6015) |

|

|

- Logic board ass'y (MP170 QM2-3210, |

|

|

MP450 QM2-3231)*1 |

|

|

- Carriage motor (QM2-3165)- Carriage |

|

|

motor (QM2-3165) |

5 times |

ASF (cam) sensor error [5700] |

- Drive ass'y (QM2-2130) |

|

|

- PE sensor ass'y (QM2-3168) |

|

|

- Pressure roller ass'y (QM2-3336) |

6 times |

Internal temperature error [5400] |

- Logic board ass'y (MP170 QM2-3210, |

|

|

MP450 QM2-3231)*1 |

7 times |

Waste ink absorber full [5B00]*2 |

Main waste ink absorber: |

|

|

- Bottom case unit (MP170 QM2-2800, |

|

|

MP450 QM2-2814)*3 |

|

|

- Ink absorber kit (MP170 QY5-0149, |

|

|

MP450 QY5-0151) |

|

|

Platen waste ink absorber: |

|

|

- Ink absorber (QC1-6014) |

|

|

- Ink absorber kit (MP170 QY5-0149, |

|

|

MP450 QY5-0151) |

8 times |

Cartridge temperature rise error [5200] |

- Print head |

|

|

- Logic board ass'y (MP170 QM2-3210, |

|

|

MP450 QM2-3231)*1 |

9 times |

EEPROM error [6800] |

- Logic board ass'y (MP170 QM2-3210, |

|

|

MP450 QM2-3231)*1 |

13 times |

Paper feed position error [6B00] |

- Paper feed motor (QM2-3166) |

|

|

- Paper feed belt (QC1-5194) |

|

|

- Logic board ass'y (MP170 QM2-3210, |

|

|

MP450 QM2-3231)*1 |

15 times |

USB Host VBUS overcurrent [9000] |

- Logic board ass'y (MP170 QM2-3210, |

|

|

MP450 QM2-3231)*1 |

17 times |

Motor driver error [6D00] |

- Logic board ass'y (MP170 QM2-3210, |

|

|

MP450 QM2-3231)*1 |

20 times |

Other hardware error [6500] |

- Logic board ass'y (MP170 QM2-3210, |

|

|

MP450 QM2-3231)*1 |

22 times |

Scanner error [5010] |

- Scanner unit (MP170 QM2-2798, MP450 |

|

|

QM2-2812) |

|

|

- Logic board ass'y (MP170 QM2-3210, |

|

|

MP450 QM2-3231)*1 |

1-6

Continuous alternate |

ROM error |

- Logic board ass'y (MP170 QM2-3210, |

blinking |

|

MP450 QM2-3231)*1 |

Lights in orange |

RAM error |

- Logic board ass'y (MP170 QM2-3210, |

|

|

MP450 QM2-3231)*1 |

*1: Before replacement of the logic board ass'y, check the waste ink amount, and re-set the waste ink amount value in the replaced logic board.

[See Section 3-3. Adjustment / Settings, (7) Service mode, for details.]

*2: The main waste ink absorber is separate from the platen waste ink absorber. In servicing, replace the waste ink absorber which becomes full.

[See Section 3-3. Adjustment / Settings, (7) Service mode, for details.]

*3: Reset the waste ink counter when replacing the bottom case unit. The main and platen waste ink counters can be reset separately.

[See Section 3-3. Adjustment / Settings, (7) Service mode, for details.]

2-3. Warnings

Machine (displayed on the LCD): |

|

Displayed warning |

Remarks |

Low ink |

|

Print head temperature rise |

If the print head temperature is high when the scanning unit is opened, the |

|

warning is displayed.*1 |

|

When the print head temperature falls, the warning is released. |

Protection of excess rise of the print head |

If the print head temperature exceeds the specified limit, a Wait is inserted |

temperature |

during printing, |

*1: If the warning is displayed, the carriage does not move to the ink cartridge replacement position when the scanning unit is opened.

1-7

2-4. Troubleshooting by Symptom

Symptom The power does not turn on.

Symptom The power does not turn on.

The power turns off immediately after power-on.

Strange noise.

Printing stops mid-way.

Nothing is displayed on the LCD.

Faulty operation

Solution |

Remarks |

Replace the |

|

- AC adapter, or |

|

- logic board ass'y*1. |

|

Remove foreign material, or attach a |

|

removed part if any. |

|

Replace the logic board ass'y*1. |

|

-Confirm the connection of the operation panel, scanner unit, and the logic board ass'y.

-Replace the

-operation panel, or

-logic board ass'y.

A portion of the LCD is not displayed.

Multiple sheets feed.

Paper does not feed.

Paper feed problems

Paper feeds at an angle.

No printing, or no color ejected.

Printing is faint, or white lines appear on printouts even after print head cleaning.

Line(s) not included in the print data appears on printouts.

Paper gets smeared.

A part of a line is missing on printouts.

Unsatisfactory

-Perform the button and LCD test in the service mode, and confirm that the LCD is displayed without any segments missing.

-Confirm the connection of the operation panel, scanner unit, and the logic board ass'y.

-Replace the

-operation panel, or

-logic board ass'y.

Replace the

-drive unit, or

-pressing plate ass'y.

Remove foreign material, or replace the

-drive unit, or

-pressing plate ass'y.

Remove foreign material, or adjust the paper guide, or replace the

-drive unit, or

-pressing plate ass'y.

Replace the

-ink cartridge*2,

-logic board ass'y*1,

-drive unit, or

-cap blade unit.

Remove and re-install the ink cartridges, or replace the

-ink cartridge*2,

-cap blade unit,

-purge unit, or

-logic board ass'y*1.

Feed several sheets of paper, perform bottom plate cleaning, or

clean the paper path with cotton swab or cloth.

Replace the ink cartridge(s)*2.

1-8

print quality |

Color hue is incorrect. |

Printing is incorrect.

No ejection of black ink.

Graphic or text is enlarged on printouts.

Replace the

- ink cartridge*2, or perform print head alignment.

Replace the logic board ass'y*1. Replace the ink cartridge(s)*2.

When enlarged in the carriage movement direction, clean grease or oil off the timing slit strip film, or replace the

|

|

- timing slit strip film, |

|

|

- carriage unit, or |

|

|

- logic board ass'y*1. |

|

|

When enlarged in the paper feed |

|

|

direction, clean grease or oil off the |

|

|

timing slit disk film, or replace the |

|

|

- timing slit disk film, |

|

|

- timing sensor unit, or |

|

|

- logic board ass'y*1. |

|

No scanning. |

- Confirm the connection between the |

|

|

scanner unit and the logic board ass'y. |

|

|

- Replace the |

|

|

- scanner unit, or |

|

|

- logic board ass'y. |

Faulty scanning |

Streaks or smear on the scanned |

- Clean the platen glass. |

image. |

- Confirm the connection between the |

|

|

|

scanner unit and the logic board ass'y. |

|

|

- Replace the |

|

|

- scanner unit, |

|

|

- logic board ass'y, or |

|

|

- document pressure sheet. |

*1: Before replacement of the logic board ass'y, check the waste ink amount, and re-set the waste ink amount value on the replaced logic board.

[See Section 3-3. Adjustment / Settings, (7) Service mode, for details.]

*2: Replace the print head only after the print head deep cleaning is performed 2 times, and when the problem persists.

To the table of contents |

To the top |

<Part 1: 2. LIST OF ERROR DISPLAY / INDICATION>

<Part 1: 2. LIST OF ERROR DISPLAY / INDICATION>

1-9

3. REPAIR

3-1. Notes on Service Part Replacement (and Disassembling / Reassembling)

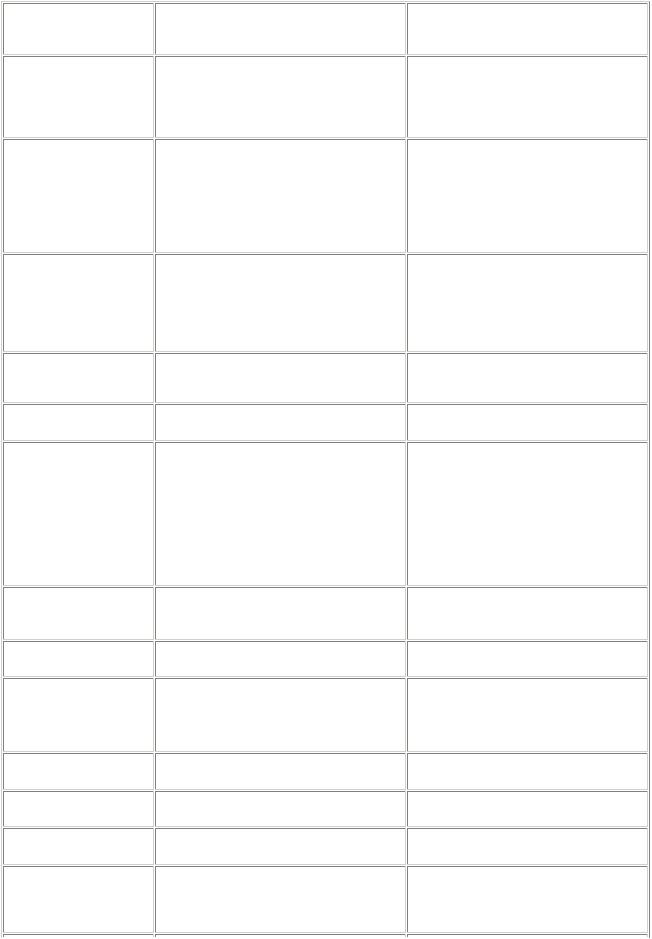

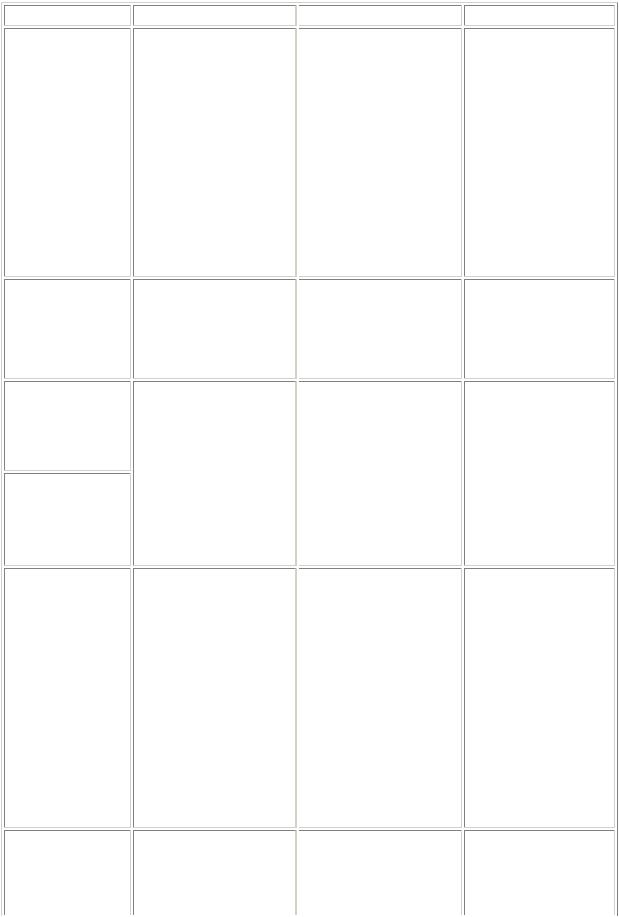

Service part

Logic board ass'y MP170: QM2-3210 MP450: QM2-3231

Ink absorber

QC1-6014

Bottom case unit MP170: QM2-2800 MP450: QM2-2814

Ink absorber MP170: QY5-0149 MP450: QY5-0151

Carriage unit

QM2-2136

Paper feed motor unit QM2-3166

Notes on replacement*1

-Before removal of the logic board ass'y, remove the power cord, and allow for approx. 1 minute (for discharge of capacitor's accumulated charges), to prevent damage to the logic board ass'y.

-Before replacement, check the waste ink amount, and re-set the waste ink amount data in the replaced logic board ass'y.

[See 3-3. Adjustment / Settings, (7) Service mode, for details.]

Platen waste ink absorber

Adjustment / settings

After replacement:

1.Initialize the EEPROM.

2.Set the waste ink data.

3.Set the destination in the EEPROM.

4.Set the LCD language.

[See 3-3. Adjustment / Settings, (7) Service mode, for details of 1 to 4.]

5.Perform the print head alignment in the user mode.

After replacement:

Operation check

-EEPROM information print

-Service test print

-Printing via parallel or USB connection

-Direct printing from a digital camera

-Direct printing from a memory card

-Print Beam printing

-Service test print

1. Reset the platen waste ink

|

counter. |

|

|

[See 3-3. Adjustment / |

|

|

Settings, (7) Service |

|

|

mode, for details.] |

|

Main waste ink absorber |

After replacement: |

- Service test print |

|

1. Reset the main waste ink |

- Printing on thick paper |

|

counter. |

|

|

[See 3-3. Adjustment / |

|

|

Settings, (7) Service |

|

|

mode.] |

|

|

2. Adjust the head-to-paper |

|

|

distance. |

|

|

[See 3-3. Adjustment / |

|

|

Settings, (7) Service |

|

|

mode.] |

|

The red screws on both sides of the main chassis securing the carriage shaft are allowed to be loosened only when replacing the carriage or removing the main chassis.

Before removing the screws, mark the original screw position, and re-fasten them

at the original position.

At replacement: |

- Printing on thick paper |

1.Apply grease to the sliding portions.

[See 3-3. Adjustment / Settings, (4) Grease application.]

2.Adjust the distance between the carriage shaft and the platen.

[See 3-3. Adjustment / Settings, (2) Main chassis and carriage rail adjustment.]

3.Perform the print head alignment in the user mode.

-The red screws securing the paper feed motor are allowed to be loosened. (DO NOT loosen any other red screws.)

At replacement:

1. Adjust the paper feed motor.

[See 3-3. Adjustment /

1-10

Document pressure plate ass'y

QM2-2809

Document pressure sheet

QC1-7588

Scanner base unit MP170: QM2-2798 MP450: QM2-2812 Timing slit strip film QC1-4962

Timing slit disk film QC1-4833

*1: General notes:

Settings, (1) Paper feed motor adjustment.]

At sheet or unit replacement:

1. Adjust the document pressure sheet.

[See 3-3. Adjustment / Settings, (3) Document pressure sheet adjustment.]

- Upon contact with the film, |

After replacement: |

- Service test print |

wipe the film with ethanol. 1. Perform the print head |

|

|

- Confirm no grease is on the |

alignment in the user |

|

film. (Wipe off any grease |

mode. |

|

thoroughly with ethanol.) |

|

|

- Do not bend the film

-Make sure that the flexible cables and wires in the harness are in the proper position and connected correctly. [See 3-2. Special Notes on Repair Servicing, (1) Flexible cable and harness wiring, connection, for details.]

-Do not drop the ferrite core, which may cause damage.

-Protect electrical parts from damage due to static electricity.

-Before removing a unit, after removing the power cord, allow the machine to sit for approx. 1 minute (for capacitor discharging to protect the logic board ass'y from damages).

-Do not touch the timing slit strip film and timing slit disk film. No grease or abrasion is allowed.

-Protect the units from becoming soiled with ink.

-Protect the housing from scratches.

-Exercise caution with the red screws, as follows:

i.The red screws of the paper feed motor may be loosened only at replacement of the paper feed motor unit (DO NOT loosen them in other cases).

ii.Except for carriage replacement, DO NOT loosen the red screws (which secures the carriage shaft positioning) on both sides of the main chassis.

After replacement of the carriage, print on thick paper to confirm that the distance between the carriage shaft and the platen is proper, and there is no contact of the ink cartridges to the paper.

If the ink cartridges contact the paper, adjust the carriage shaft, while referring to [3-3. Adjustment / Settings, (2) Main chassis and carriage rail adjustment.]

To the table of contents |

To the top |

<Part 1: 3. REPAIR, 3-1>

<Part 1: 3. REPAIR, 3-1>

1-11

3-2. Special Notes on Repair Servicing

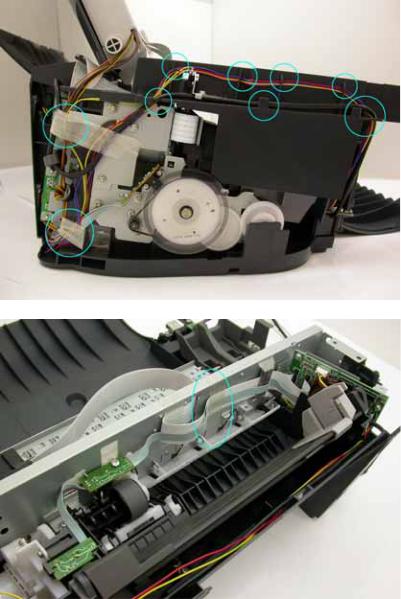

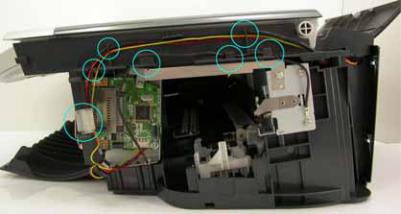

(1) Flexible cable and harness wiring, connection

Be careful of wiring of the flexible cables and harness. Improper wiring or connection may cause breakage of a line, leading to ignition or emission of smoke.

(I) Logic board ass'y, PictBridge connector, and IrDA board wiring

1-12

(II) Card board wiring

To the table of contents |

To the top |

>

<Part 1: 3. REPAIR, 3-2>

<Part 1: 3. REPAIR, 3-2>

1-13

3-3. Adjustment / Settings

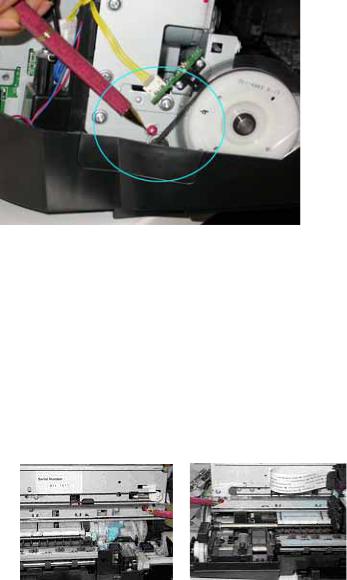

(1) Paper feed motor adjustment

Perform the following adjustments when the paper feed motor unit is replaced: 1) When removing the screws, mark the 6 screw holes.

2)When installing the motor, position each screw to the mark, and fasten them.

3)After replacement, be sure to perform the service test print, and confirm that no strange noise or faulty print operation (due to dislocation of the belt or gear, or out-of-phase motor, etc.) occurs.

Note: The red screws securing the paper feed motor may be loosened only at replacement of the paper feed motor unit. DO NOT loosen them in other cases.

(2) Main chassis and carriage rail adjustment

[Carriage rail adjustment]

Perform the following adjustments when the carriage unit is replaced:

1) Before loosening the red screws, mark the boss position beside the screw.

2)In attaching the carriage rail, make sure that the boss fits into the hole and to the mark made in step 1), then fasten the screws.

3)Be sure to perform the confirmation test detailed below; confirm that the print quality is proper and the ink cartridges are not contacting the paper.

[Main chassis adjustment]

After installing the main chassis, be sure to perform the confirmation test detailed below; confirm that the print quality is proper and the ink cartridges are not contacting the paper.

<Confirmation test>

Using Photo Paper Pro, and with the paper thickness lever set to the left position (normal position), print an image and confirm that the print quality is proper, and the ink cartridges are free from contacting the paper.

If the print quality is not proper, or an ink cartridge contacts the paper, adjust the head-to-paper distance in the following procedures:

1-14

Loading...

Loading...