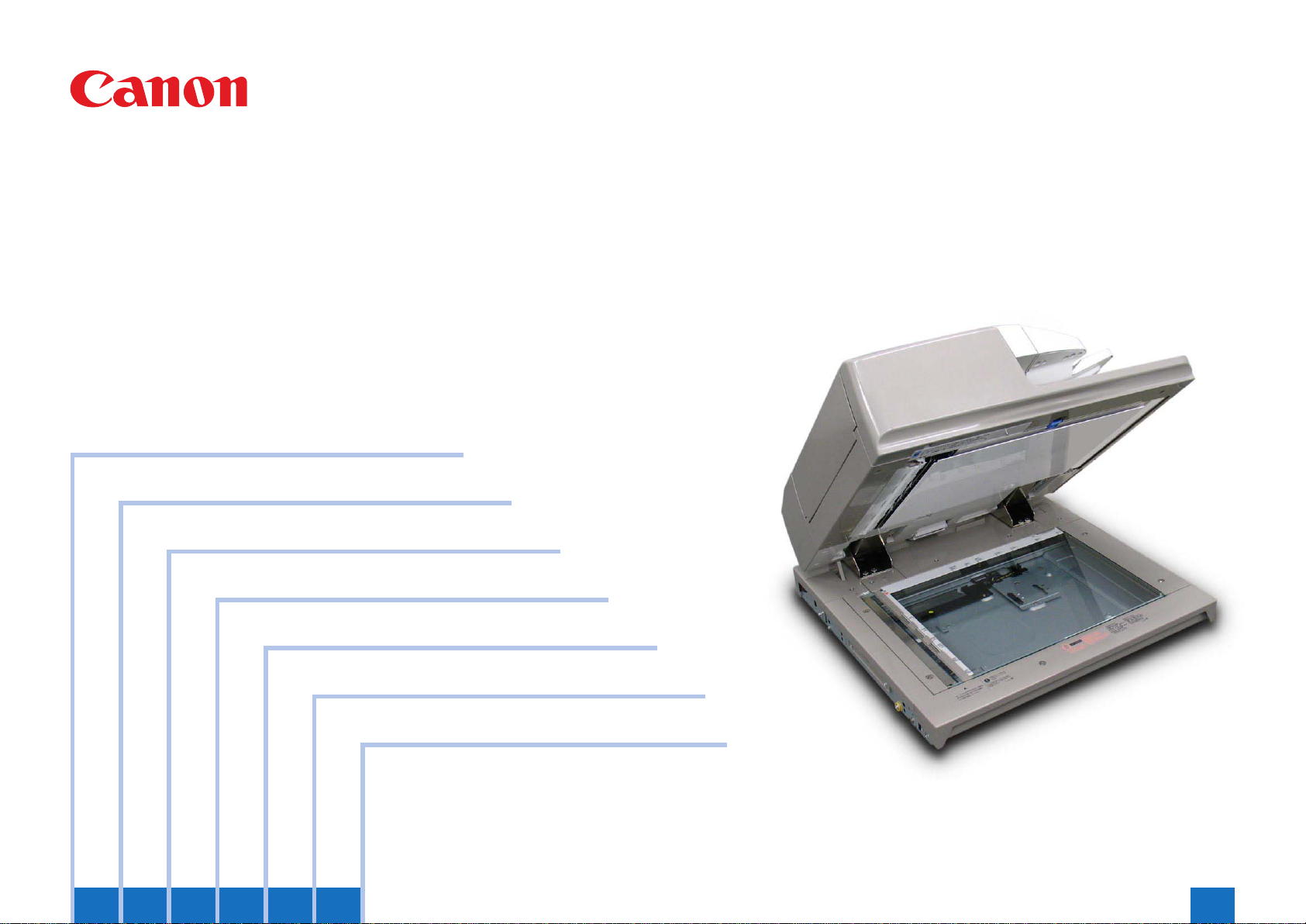

Canon F1 Service Manual

Duplex Color Image Reader - F1

Product Outline

Technology

Periodic Servicing

Parts Replacing and Cleaning

Adjustments

Installation

Appendix

Service Manual

April 11, 2013

Revision 0

654321

Application

This manual has been issued by Canon Inc. for qualied persons to learn technical theory,

installation, maintenance, and repair of products. This manual covers all localities where the

products are sold. For this reason, there may be information in this manual that does not

apply to your locality.

Corrections

This manual may contain technical inaccuracies or typographical errors due to improvements

or changes in products. When changes occur in applicable products or in the contents of this

manual, Canon will release technical information as the need arises. In the event of major

changes in the contents of this manual over a long or short period, Canon will issue a new

edition of this manual.

The following paragraph does not apply to any countries where such provisions are

inconsistent with local law.

Trademarks

The product names and company names used in this manual are the registered trademarks

of the individual companies.

Copyright

This manual is copyrighted with all rights reserved. Under the copyright laws, this manual may

not be copied, reproduced or translated into another language, in whole or in part, without the

written consent of Canon Inc.

(C) CANON INC. 2012

Caution

Use of this manual should be strictly supervised to avoid disclosure of condential

information.

Explanation of Symbols

The following symbols are used throughout this Service Manual.

Symbols Explanation Symbols Explanation

Check. Remove the claw.

Check visually. Insert the claw.

The following rules apply throughout this Service Manual:

1. Each chapter contains sections explaining the purpose of specic functions and the

relationship between electrical and mechanical systems with reference to the timing of

operation.

In the diagrams, represents the path of mechanical drive; where a signal

name accompanies the symbol, the arrow

indicates the direction of the

electric signal.

The expression "turn on the power" means ipping on the power switch, closing the

front door, and closing the delivery unit door, which results in supplying the machine with

power.

Check the noise. Use the bundled part.

Disconnect the connector. Push the part.

Connect the connector. Plug the power cable.

Remove the cable/wire

from the cable guide or wire

saddle.

Set the cable/wire to the

cable guide or wire saddle.

Remove the screw.

Tighten the screw.

Turn on the power.

2. In the digital circuits, '1' is used to indicate that the voltage level of a given signal is

"High", while '0' is used to indicate "Low". (The voltage value, however, differs from

circuit to circuit.) In addition, the asterisk (*) as in "DRMD*" indicates that the DRMD

signal goes on when '0'.

In practically all cases, the internal mechanisms of a microprocessor cannot be checked

in the eld. Therefore, the operations of the microprocessors used in the machines

are not discussed: they are explained in terms of from sensors to the input of the DC

controller PCB and from the output of the DC controller PCB to the loads.

The descriptions in this Service Manual are subject to change without notice for product

improvement or other purposes, and major changes will be communicated in the form of

Service Information bulletins.

All service persons are expected to have a good understanding of the contents of this Service

Manual and all relevant Service Information bulletins and be able to identify and isolate faults

in the machine.

Contents

1

Product Outline

Characteristic ------------------------------------------------------------------1-2

High Speed 2-Side Scan-at One Time (DADF) ---------------------------- 1-2

High Capacity Pickup Tray (DADF) ------------------------------------------- 1-2

Next Generation Scanner Unit (DADF/Reader) ---------------------------- 1-2

Specication --------------------------------------------------------------------1-3

Reader -------------------------------------------------------------------------------- 1-3

DADF --------------------------------------------------------------------------------- 1-4

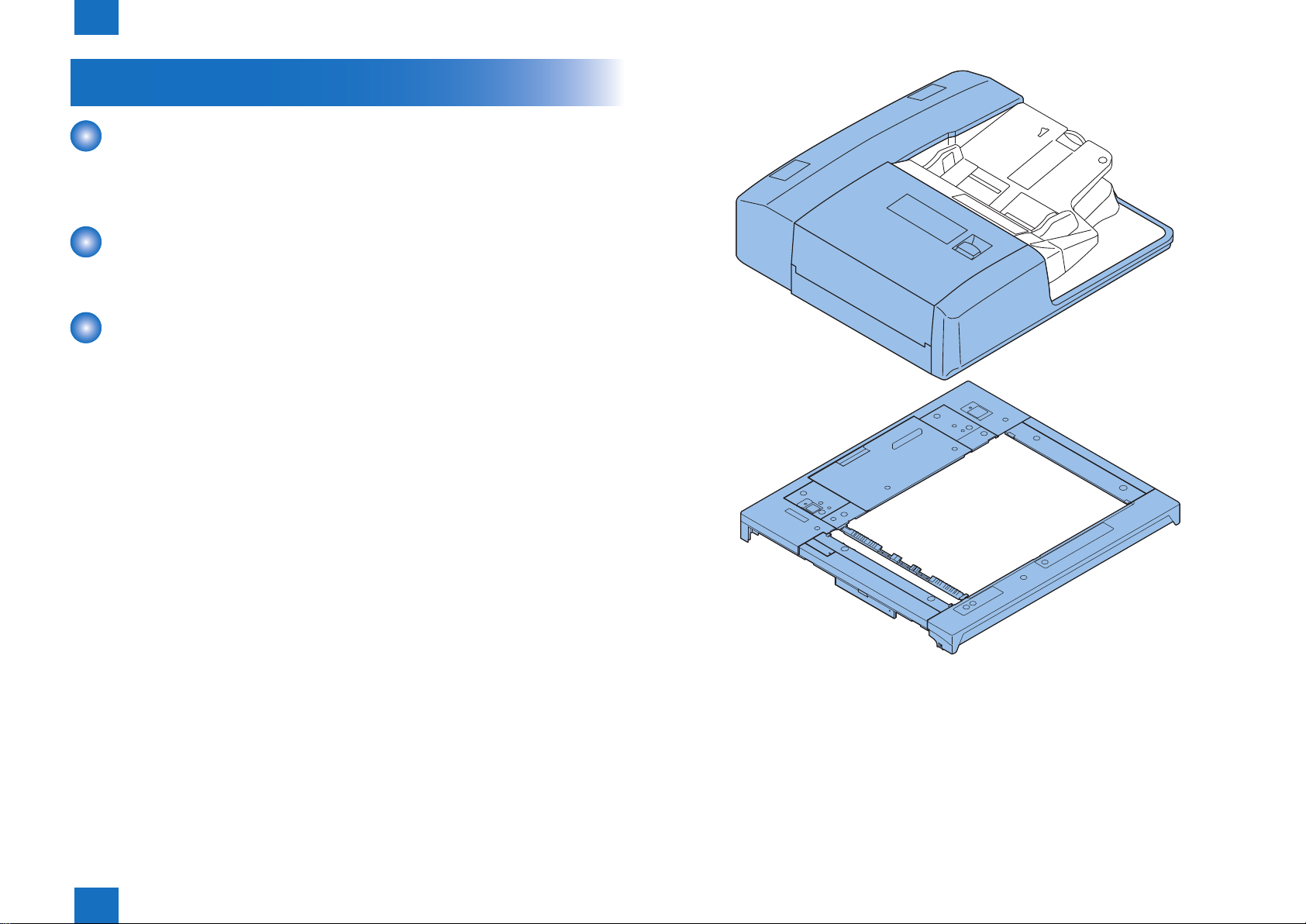

Names of Parts ----------------------------------------------------------------1-5

External View ----------------------------------------------------------------------- 1-5

Cross-section View ---------------------------------------------------------------- 1-6

Basic Operation ---------------------------------------------------------------1-6

Original Set Display --------------------------------------------------------------- 1-6

Option conguration ----------------------------------------------------------1-7

2

Technology

Basic conguration -----------------------------------------------------------2-2

Reader -------------------------------------------------------------------------------- 2-2

DADF --------------------------------------------------------------------------------- 2-7

Controls ------------------------------------------------------------------------ 2-18

Reader -------------------------------------------------------------------------------2-18

DADF --------------------------------------------------------------------------------2-32

Service Work ----------------------------------------------------------------- 2-57

Reader -------------------------------------------------------------------------------2-57

DADF --------------------------------------------------------------------------------2-58

3

Periodic Servicing

Periodic Servicing List -------------------------------------------------------3-2

Reader -------------------------------------------------------------------------------- 3-2

DADF --------------------------------------------------------------------------------- 3-4

4

Parts Replacing and Cleaning

Parts List (Reader) ------------------------------------------------------------4-2

External Covers (Reader) -------------------------------------------------------- 4-2

Main unit (Reader) ----------------------------------------------------------------- 4-2

List of Periodical Consumable Parts/Locations

for Periodical Cleaning (Reader) ----------------------------------------------- 4-3

Motor (Reader) --------------------------------------------------------------------- 4-3

Fan (Reader) ------------------------------------------------------------------------ 4-4

Sensor (Reader) ------------------------------------------------------------------- 4-4

PCB (Reader) ----------------------------------------------------------------------- 4-5

Connector Layout Drawing (Reader) ----------------------------------------- 4-6

Removing from the connection equipment (Reader)-----------------4-7

Removing the DADF + Reader Unit ------------------------------------------- 4-7

Major Unit (Reader) -------------------------------------------------------- 4-14

Removing the Scanner Unit (Reader) ---------------------------------------4-14

Removing the Reader Controller PCB ---------------------------------------4-16

External Auxiliary System (Reader) ------------------------------------ 4-18

Removing the Box Right Cover -----------------------------------------------4-18

Removing the Box Left Cover -------------------------------------------------4-18

Removing the Box Upper Cover ----------------------------------------------4-19

Removing the Upper Right Cover 1/Upper Left Cover ------------------4-19

Periodical Consumable Parts/Locations

for Periodical Cleaning (Reader)

Cleaning the Copyboard Glass (Large) -------------------------------------4-20

Cleaning the Copyboard Glass (Small) -------------------------------------4-21

Cleaning/Lubrication of the Scanner Rail -----------------------------------4-23

Parts List (DADF) ----------------------------------------------------------- 4-25

External Covers (DADF) --------------------------------------------------------4-25

Main Unit (DADF) -----------------------------------------------------------------4-25

List of Periodical Consumable Parts/Locations

for Periodical Cleaning (DADF) -----------------------------------------------4-26

---------------------------------------- 4-20

Solenoid (DADF) ------------------------------------------------------------------4-27

Motor (DADF) ----------------------------------------------------------------------4-27

Fan (DADF) ------------------------------------------------------------------------4-28

Lamps, Heaters, and Others (DADF) ----------------------------------------4-28

Sensor (DADF) --------------------------------------------------------------------4-29

PCB (DADF) -----------------------------------------------------------------------4-30

Connector Layout Drawing (DADF) ------------------------------------------ 4-31

Removing from the Connection Equipment (DADF) ---------------4-34

Removing the DADF -------------------------------------------------------------4-34

Major Units (DADF) --------------------------------------------------------- 4-36

Removing the DADF Scanner Unit -------------------------------------------4-36

Removing the Pickup Roller Unit ---------------------------------------------4-38

External Auxiliary System (DADF) -------------------------------------- 4-39

Removing the DADF Front Cover --------------------------------------------4-39

Removing the DADF Rear Cover ---------------------------------------------4-39

Installing the DADF White Sheet ----------------------------------------------4-40

Removing the Stamp Solenoid ------------------------------------------------ 4-41

Consumable parts for periodical replacement

and locations for cleaning (DADF)

Removing the Pickup Roller / Feed Roller ----------------------------------4-42

Removing the Separation Roller ---------------------------------------------- 4-44

Removing the Dust Collecting Sheets Type E -----------------------------4-45

Removing the Dust Collecting Sheets ---------------------------------------4-46

Removing the Stamp Cartridge -----------------------------------------------4-48

Cleaning the Back Surface of the Reading Glass ------------------------4-49

Cleaning the Post-separation Sensor 1/Post-separation Sensor 2

/Post-separation Sensor 3 ------------------------------------------------------4-50

Cleaning the Pullout Roller/Feed Roller 2/Lead Roller 1 --------------- 4-51

Cleaning the Registration Sensor/Lead Sensor/Registration Roller -4-53

Cleaning the Lead Roller 2/Lead Roller 3 ----------------------------------4-55

Cleaning the Delivery Roller/Delivery Sensor -----------------------------4-56

Height Adjustment ----------------------------------------------------------------4-57

5

Adjustments

-------------------------------------- 4-42

Overview ------------------------------------------------------------------------5-2

Reader -------------------------------------------------------------------------------- 5-2

DADF

--------------------------------------------------------------------------------- 5-3

Service mode backup ------------------------------------------------------------- 5-4

Adjustment Method -----------------------------------------------------------5-5

Measurement during Reader Controller PCB Replacement

and After RAM Clear -------------------------------------------------------------- 5-5

Processing after Scanner Unit Replacement ------------------------------- 5-7

Processing after Copyboard Glass Replacement ------------------------- 5-9

Preparation or Creation of Test Chart ----------------------------------------5-10

Angle Restriction Release (Opening Angle at 90 deg) ------------------ 5-10

Sensor Output Adjustment ------------------------------------------------------ 5-11

Tray Width Adjustment----------------------------------------------------------- 5-11

Tilt Adjustment ---------------------------------------------------------------------5-12

Height Adjustment ----------------------------------------------------------------5-12

Right Angle Adjustment ----------------------------------------------------------5-15

Registration Roller Wheel Skew Adjustment ------------------------------- 5-16

Stream Reading Adjustment --------------------------------------------------- 5-18

Side Registration Adjustment --------------------------------------------------5-19

Leading Edge Registration Adjustment--------------------------------------5-20

Magnication Adjustment -------------------------------------------------------5-21

White Level Adjustment ---------------------------------------------------------5-22

Hinge Pressure Adjustment ---------------------------------------------------- 5-22

6

Installation

How to check this installation procedure --------------------------------6-2

When using the parts included in the package ----------------------------- 6-2

Symbols in the illustration -------------------------------------------------------- 6-2

Product Name ------------------------------------------------------------------6-2

Point to Note About Installation

Checking the Contents

Contents of the Equipment ------------------------------------------------------ 6-3

Contents of the Host Machine -------------------------------------------------- 6-3

------------------------------------------------------6-3

--------------------------------------------6-2

Turning OFF the power of the host machine ---------------------------6-4

Installation Outline Drawing

Unpacking of the Reader Unit

Installation Procedure

Connecting this Machine --------------------------------------------------------- 6-6

------------------------------------------------6-4

---------------------------------------------6-4

--------------------------------------------------------6-6

Installing the Stamp Ink Cartridge --------------------------------------------6-15

Afxing Labels ---------------------------------------------------------------------6-17

Operation Check ------------------------------------------------------------ 6-17

Performing Auto Adjust Gradation

--------------------------------------6-18

Appendix

Service Tools --------------------------------------------------------------------- II

Special Tools --------------------------------------------------------------------------- II

List of Oils/Solvents ------------------------------------------------------------------ II

General Circuit Diagram -------------------------------------------------------III

Reader ---------------------------------------------------------------------------------- III

DADF (1/2) ---------------------------------------------------------------------------- IV

DADF (2/2) -----------------------------------------------------------------------------V

Product Outline

1

Characteristic

■

Specication

■

Names of Parts

■

Basic Operation

■

Option conguration

■

Product Outline

1

1

Product Outline > Characteristic > Next Generation Scanner Unit (DADF/Reader)

Characteristic

High Speed 2-Side Scan-at One Time (DADF)

• Maximum 200 ipm (2 side, B/W, 300 dpi).

• Color scan is also available, maximum 80 ipm (one side/2-side, 300 dpi).

High Capacity Pickup Tray (DADF)

• Maximum document loading is 300 sheets (80 g/m2 or lower).

Next Generation Scanner Unit (DADF/Reader)

• Adapting the reading sensor uniquely developed, allows low power consumption and high-

speed drive.

• Exposure to light by white color LED, enables low power consumption, size reducing, and

color balance improvement.

• Color aberration-free.

1-2

Product Outline > Characteristic > Next Generation Scanner Unit (DADF/Reader)

1

F-1-1

1-2

1

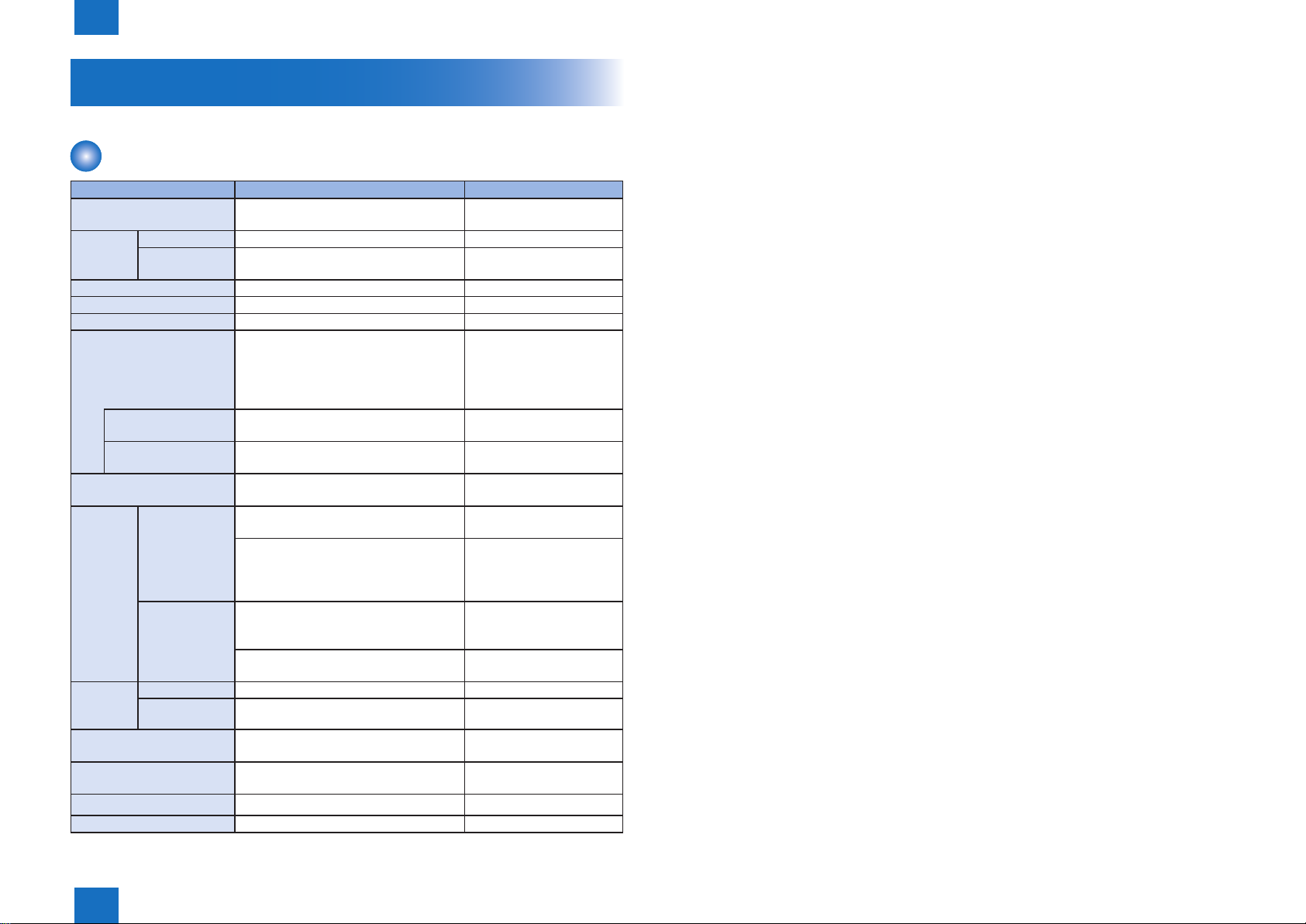

Product Outline > Specication > Reader

Specication

Following shows the specication list of this equipment.

Reader

Item Specication/function Remarks

Exposure system High-brightness white LED + reection

plate

Original

scan

Scanning resolution 600 dpi x 600 dpi SEND: 300 x 300 dpi

Gradation 256 gradations Carriage position detection Scanner unit HP sensor (SR2) Magnication change 25% to 400% Digital reproduction (Color:

Number of line of reading

sensor

Original

size

detection

Maximum

original

size

Power source DC 24.5V, DC 12.3V It is supplied by the

Dimension 635 x 590 x 72 (W x D x H mm) DADF is not counted for the

Weight Approx. 12 kg -

Option Reader heater -

Contents of description are subject to change due to product improvement etc.

In BOOK mode Scan by movement of scanner unit In DADF mode Scan by original stream reading with

scanner unit xed

In main scanning

direction

In sub scanning

direction

In BOOK mode Horizontal scanning direction: detection

In DADF mode Horizontal scanning direction:

In BOOK mode 297 mm x 431.8 mm In DADF mode 304.8 mm x 630 mm -

Image processing in main controller PCB -

Image processing in main controller PCB Some are processed by the

4 lines (R, G, B, B/W) -

by reading sensor (scanner unit)

Vertical scanning direction: detection by

reection sensor (original size sensor 1

(AB type) or original si ze sensor 2 (Inch

type)

detection by the original width volume/

photointerrupter on DADF

Vertical scanning direction: detection by

the photointerrupter on DADF

-

-

in case of 300 dpi or

less, scan reproduction

(double speed scan) is also

included).

reader controller PCB.

-

-

-

-

connected device.

height.

T-1-1

1-3

Product Outline > Specication > Reader

1

1-3

1

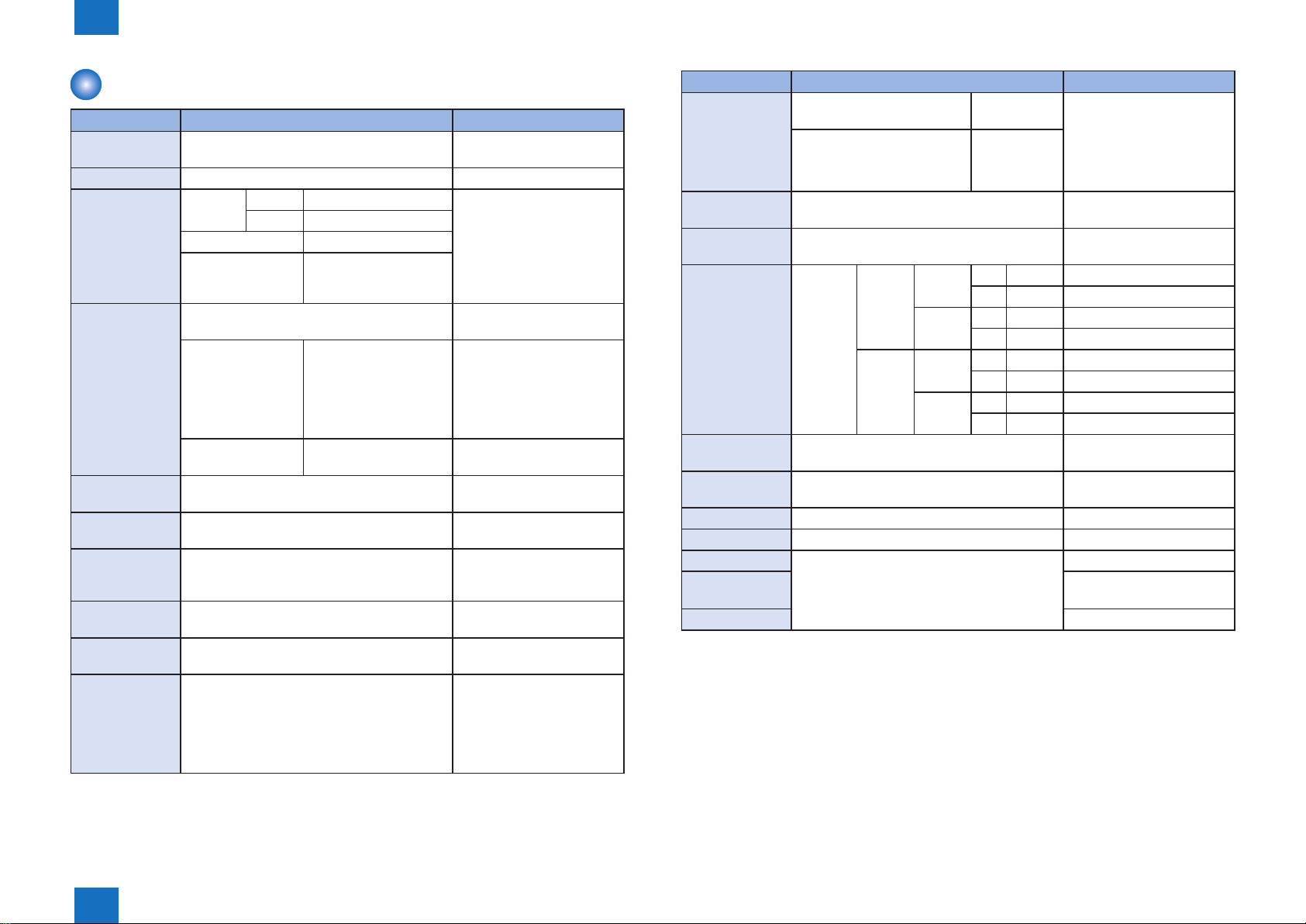

Product Outline > Specication > DADF

1-4

DADF

Item Specication Remarks

Original pickup

method

Type of original Sheet original -

Grammage of

original

Original size A3, A4, A4R, A5, A5R, B4, B5, B5R, B6R, LDR,

Setting direction

of original

Setting position of

original

Scanning method

of original

Separation

method of original

Feed mode of

original

Stacking capacity

of original tray

Auto pickup/delivery method Simultaneous 2-sided

scanning

1-sided A/B 38 to 220 g/m

Inch 50 to 220 g/m

2-sided 50 to 220 g/m

Color original 64 to 220 g/m

LGL, LTR, LTRR, STMT, STMTR

Feed direction 139.7 to 432 mm

(STMT to 17 inch)

* 432 to 630 mm

(refer to the remarks).

Width direction 128 to 304.8 mm

(B6R to 12 inch)

Original tray pickup: face-up stacking -

Original tray pickup: center reference -

Stream reading For simultaneous 2-sided

Retard separating method -

1-sided, 2-sided (simultaneous scanning) -

All sizes: 300 sheets

(in case of paper of 80 g/m

2

or lighter)

2

2

2

2

60 to 90 g/m2: If original

exceeds 432 mm, 1-sided,

1-sheet feeding.

64 to 220 g/m2 at B/W and

color mixed mode and if

original is B/W.

For B6, horizontal scanning

only

Since the original with 432 to

630 mm in feed direction is

larger than the original pickup

tray, user needs to hold it so

that the machine can scan

the original.

-

scanning, only the original of

432 mm or shorter.

- Grammage conversion for

original exceeding 80 g/m2.

- Folding original is subject to

height of 10 mm or shorter.

- 1 sheet stacking for original

exceeding 432 mm.

Item Specication Remarks

Mixed mode

function

Original size

detection function

Done stamp

function

Original

processing speed

Power source DC 24.5V, DC 5V It is supplied by the

Maximum power

consumption

Weight Approx. 27.4 kg -

Dimension 633 x 603 x 179 (W x D x H mm) -

Use condition Subject to connected device. -

Temperature

range

Humidity range -

Mix of same conguration

mode

Mix of different conguration

mode

Yes -

Yes -

Stream

scanning

180 W or less (including reader) Standby: 15 W or less

1-sided 600 dpi BW 120 ipm -

300 dpi BW 120 ipm -

2-sided 600 dpi BW 120 ipm -

300 dpi BW 200 ipm -

Yes - Original should be set at the

rear side.

Yes

CL 70 ipm -

CL 120 ipm -

CL 70 ipm -

CL 140 ipm -

- Assured combination for mix

with different conguration

AB type: A3/B4, B4/A4R, A4/

B5, B5R/A5R

connected device.

-

*1: Extra length mode is specied in Service Mode. Go through the following:

(Lv.2) COPIER > OPTION > USER > MF-LG-ST;

and select “1” (default: 0).

T-1-2

Product Outline > Specication > DADF

1

1-4

1

[4][8]

[3]

Product Outline > Names of Parts > External View > DADF

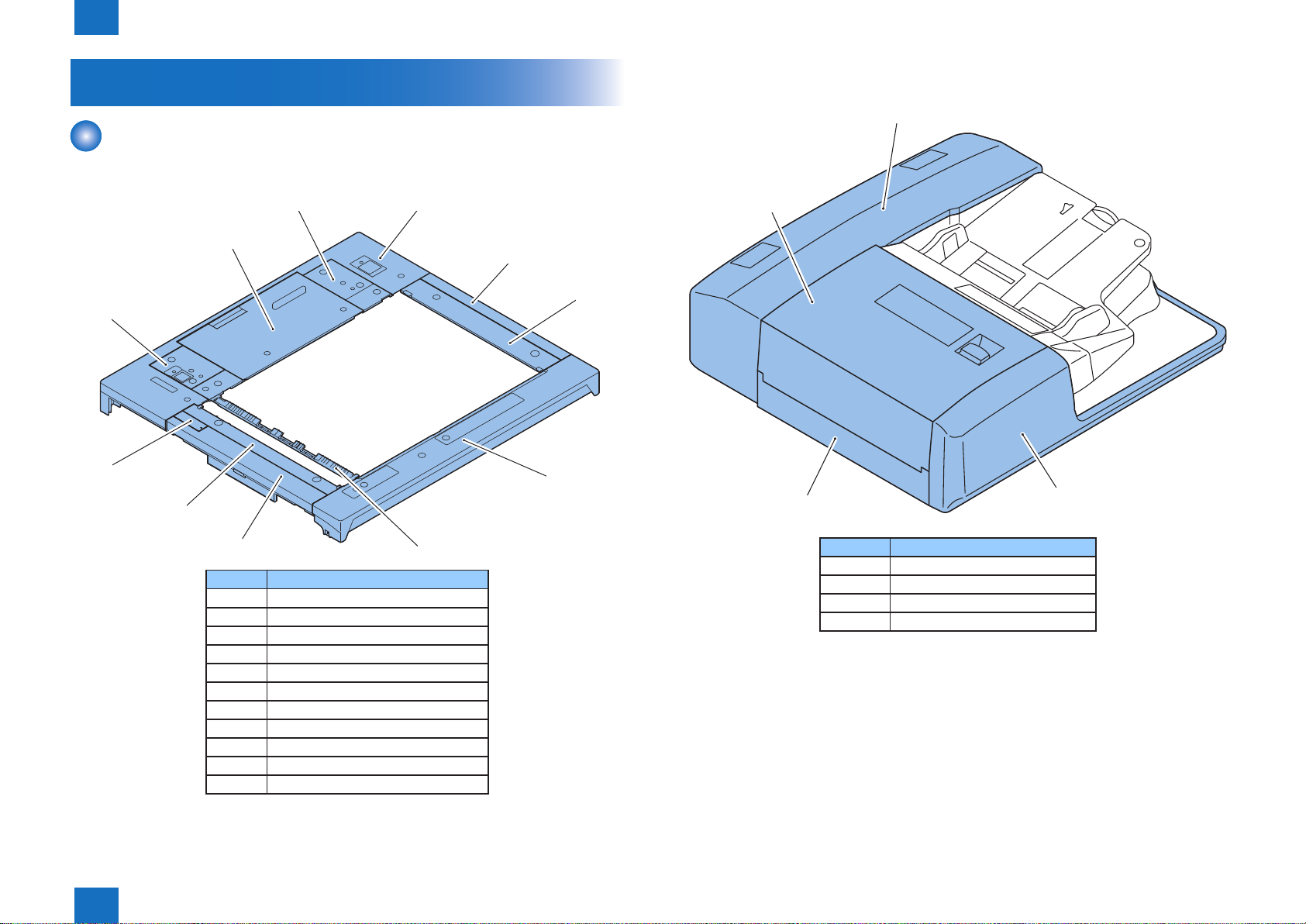

Names of Parts

External View

Reader

■

■

DADF

1-5

[4]

[9]

[11]

[5]

[7]

[2]

No.

[1] Front Cover

[2] Left Cover

[3] Right Cover

[4] Rear Cover

[5] PCB Cover

[6] Right Upper Panel

[7] Left Upper Panel

[8] DADF Base Right Cover

[9] DADF Base Left Cover

[10] Jump Base

[11] Left Upper Small Cover

[10]

[3]

[1]

[6]

F-1-2

[2]

No.

[1] Front Cover

[2] Left Cover

[3] Rear Cover

[4] Feeder Cover

[1]

F-1-3

T-1-3

Product Outline > Names of Parts > External View > DADF

1

1-5

1

Stream reading glass Copyboard glass

Scanner unit Pickup roller unit Original pickup tray

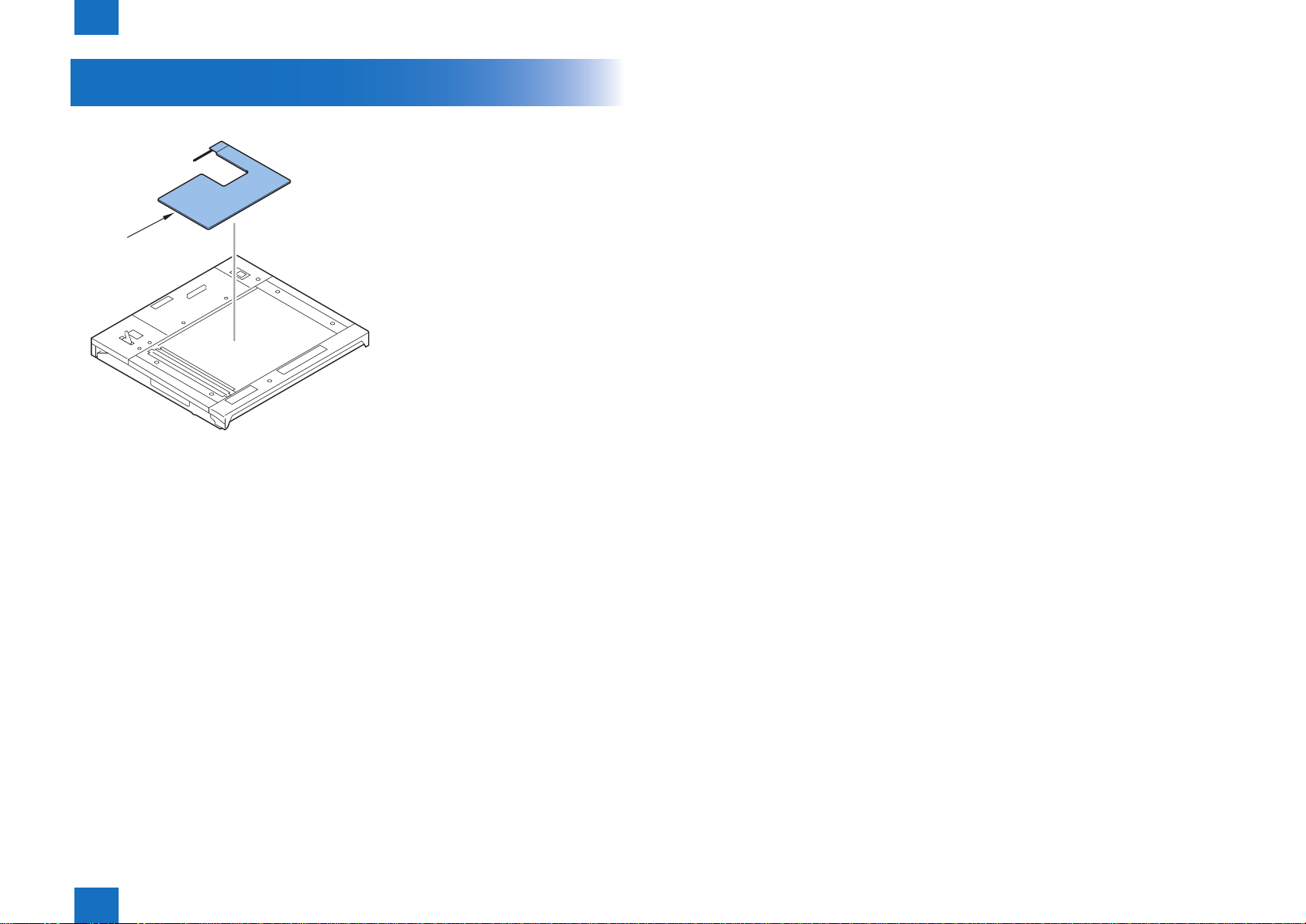

Product Outline > Basic Operation > Original Set Display

1-6

Cross-section View

Reader

■

Scanner unit

DADF

■

Basic Operation

Original Set Display

The original set display LED is activated when the original is set on the original pickup tray.

When a jam is detected while the original is scanned, the original set display LED starts

ashing.

Original set display

F-1-4

Scanning position

(front side)

Product Outline > Basic Operation > Original Set Display

(rear side)

1

Original delivery trayPath of originalScanning position

F-1-5

F-1-6

1-6

1

Product Outline > Option conguration

Option conguration

Followings are the options for the host machine.

Reader heater

1-7

F-1-7

Product Outline > Option conguration

1

1-7

Technology

2

Basic conguration

■

Controls

■

Service Work

■

2

Technology

2

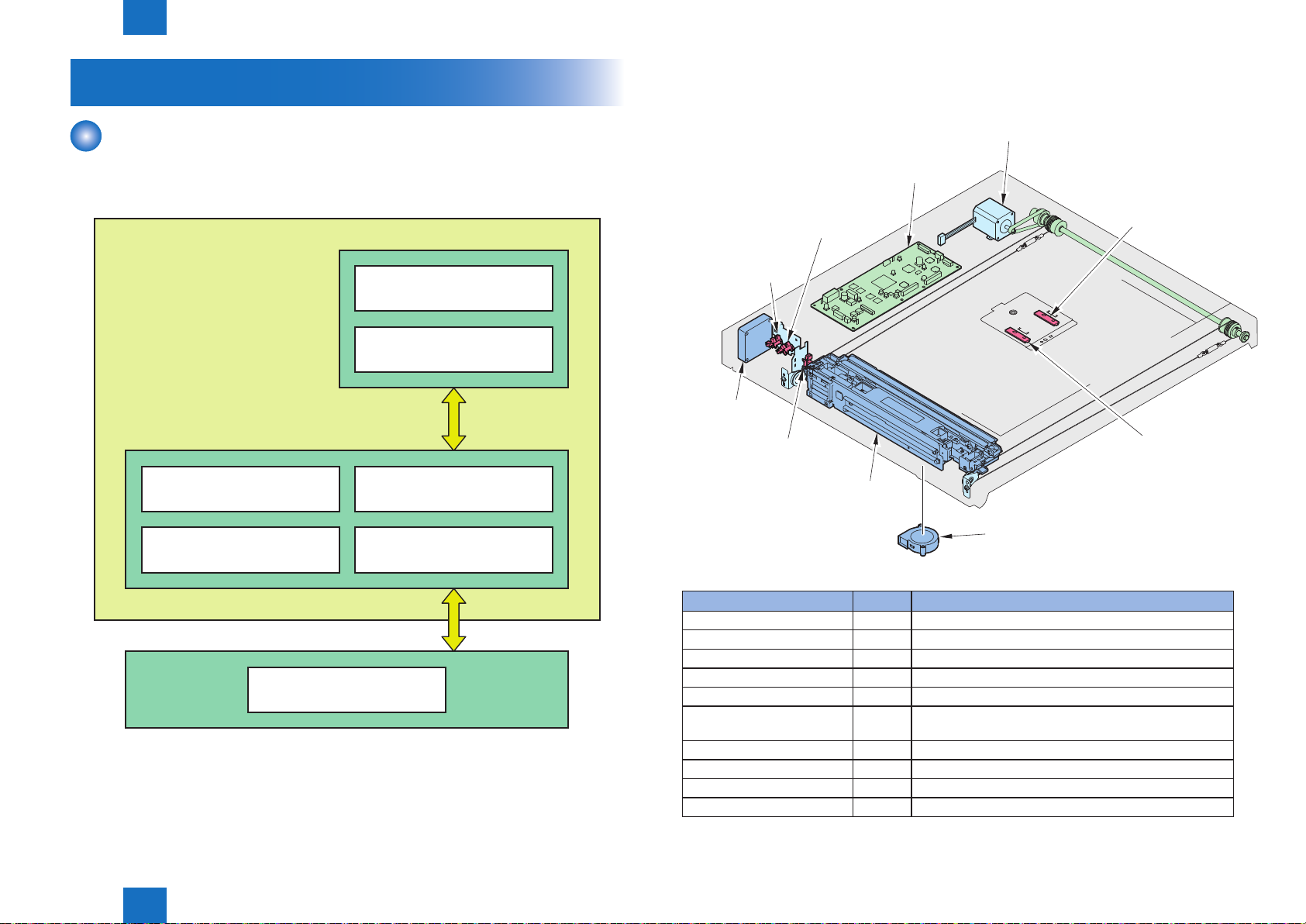

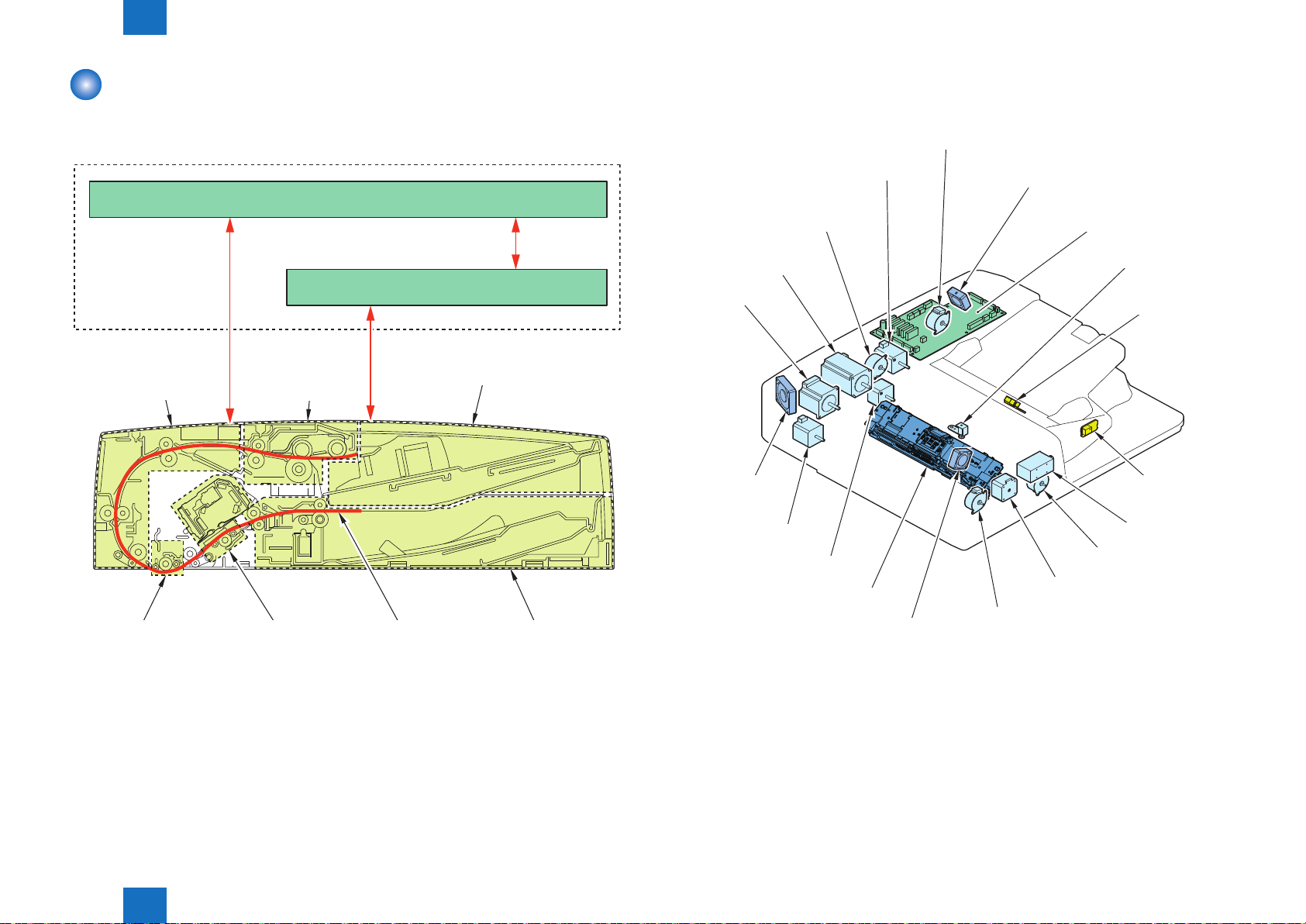

Scanner motor (M1)

Technology > Basic conguration > Reader > Parts conguration

Basic conguration

Reader

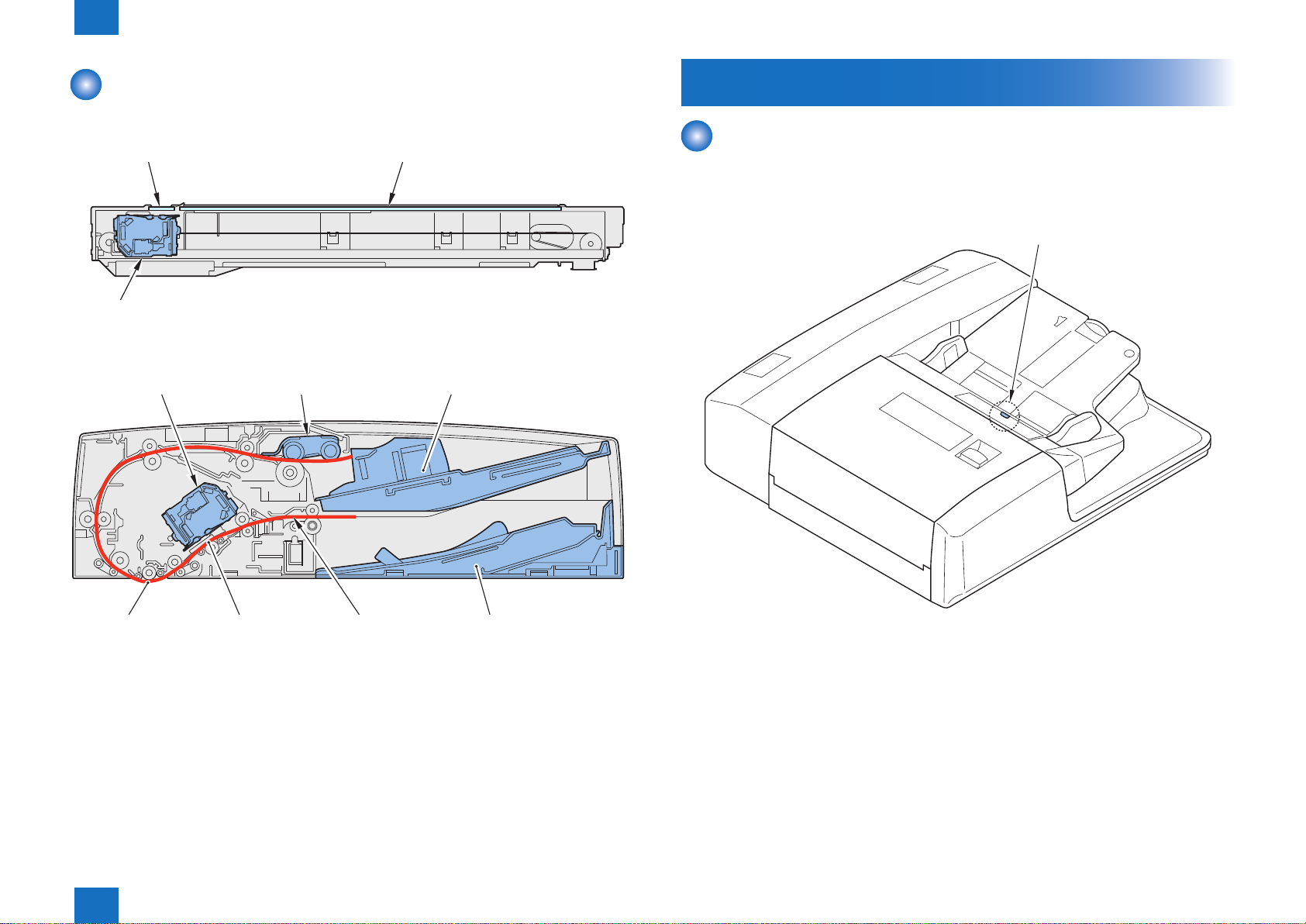

Parts conguration

■

Followings are the positions and names of main conguration parts.

2-2

Function conguration

■

Following is the list of functions.

Reader controller PCB

Scanner drive

Main controller PCB

Scanner unitReader unit

Image scanning

A/D conversion

Original size detection

Image processingDust detection

Magnification change

F-2-1

Reader controller PCB

DADF

open/closed

DADF

open/closed

sensor 1

(SR1)

Scanner unit

exhaust fan (FM1)

home position sensor

Component part Symbol Function/specication

Scanner motor M1 2 phase pulse motor: pulse control

Scanner unit exhaust fan FM1 Exhaustion of scanner unit

Scanner unit cooling fan FM2 Cooling of scanner unit

DADF open/closed sensor 1 SR1 DADF open detection (DADF is detected at 5 degree)

Scanner unit HP sensor SR2 Scanner unit HP detection

DADF open/closed sensor 2 SR3 DADF open detection (size detection timing is detected

Original size sensor 1 CF1 Size detection in sub scanning direction (AB type)

Original size sensor 2 CF2 Size detection in sub scanning direction (INCH type)

Scanner unit --- Image reading, analog image processing

Reader controller PCB PCB1 Control of entire reader, digital image processing

sensor 2

(SR3)

Scanner unit

(SR2)

Scanner unit

(PCB1)

Original size sensor 2

(CF2)

Original size sensor 1

(CF1)

Scanner unit

cooling fan (FM2)

when DADF is open at 25 degree.

F-2-2

T-2-1

Technology > Basic conguration > Reader > Parts conguration

2

2-2

2

Technology > Basic conguration > Reader > Reader controller PCB

2-3

Overview of power circuit

■

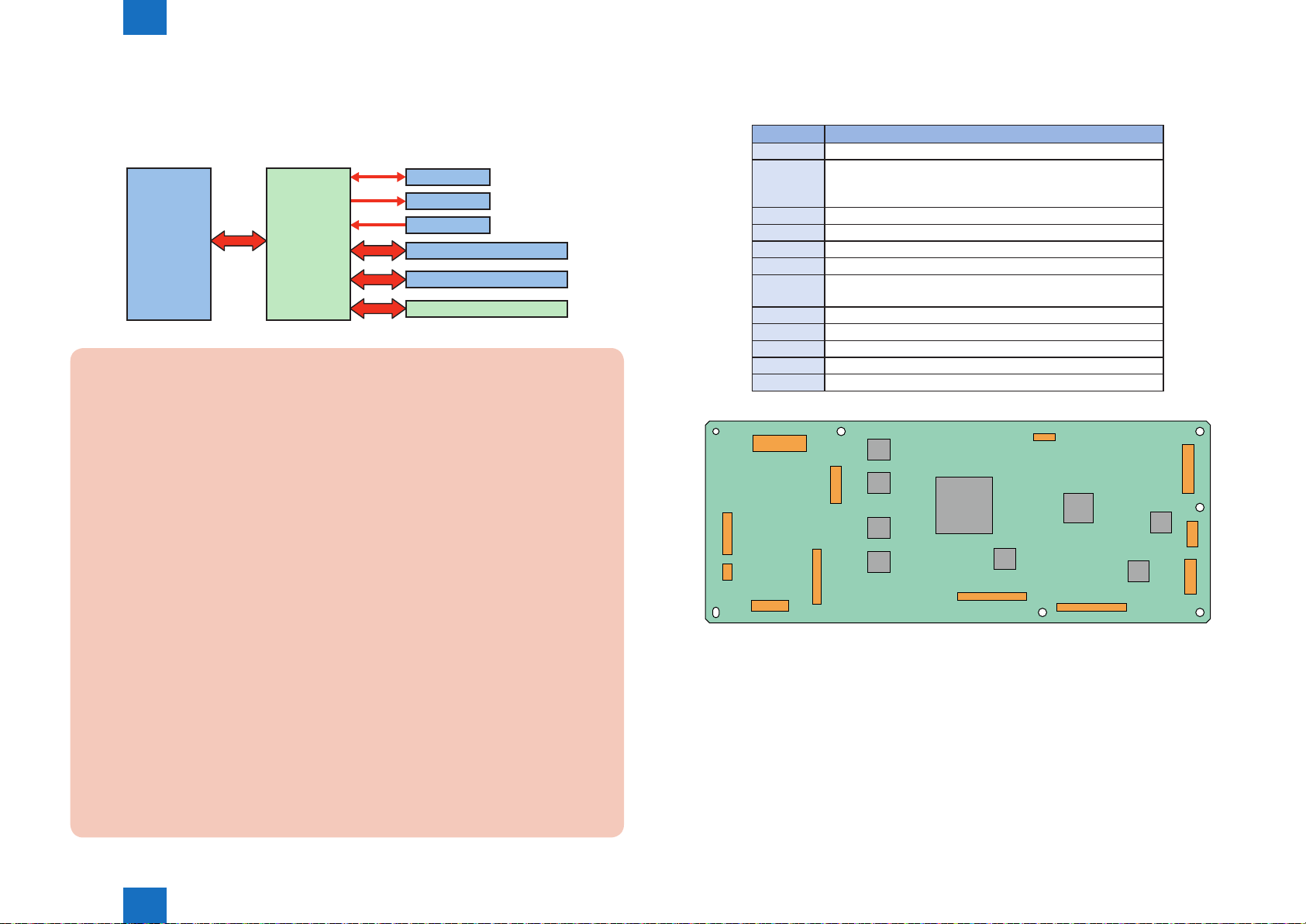

Control of the host machine is conducted at the reader controller PCB.

Reader controller PCB also controls the DADF driver PCB and DADF scanner unit.

Following is the relations of each electrical part.

Motor

Fan

Host

machine

Error Code

E270 (Error in the main scanning/sub scanning synchronization signal).

-0001 Sub scanning synchronization signal (VSYNC) is not properly transmitted from scanner

unit PCB (front side scanner unit), and this causes image failure or abnormal termination.

-0002 Sub scanning synchronization signal (VSYNC) is not transmitted due to the error in the

main scanning synchronization signal (HSYNC), and this causes image failure or abnormal

termination.

-0101 Sub scanning synchronization signal (VSYNC) is not properly transmitted from scanner

unit PCB (back side scanner unit), and this causes image failure or abnormal termination.

E280 (Communication error between reader controller PCB – scanner unit)

- 0001 If the communication is not started within the specied time between reader controller

PCB – front side scanner unit.

- 0101 If the communication is not started within the specied time between reader controller

PCB – back side scanner unit.

E400 (Communication error between reader controller PCB – DADF)

-0001, -0002

If reception error occurs during communication between reader controller PCB - DADF

Reader

controller

PCB

Sensor

Scanner unit (reader)

Scanner unit (DADF)

DADF driver PCB

F-2-3

Reader controller PCB

■

Following is the function conguration of reader controller PCB.

Jack No. Destination

J101 Host machine (for power supply)

J102 DADF open/closed sensor 1 (SR1)

Scanner unit HP sensor (SR2)

DADF open/closed sensor 2 (SR3)

J103 Scanner unit exhaust fan (FM1)

J104 DADF driver PCB (for communication)

J105 Scanner unit (DADF)

J106 Scanner unit (Reader)

J107 Original size sensor 1 (CF1)

Original size sensor 2 (CF2)

J108 Scanner motor (M1)

J109 Main controller PCB (for communication)

J110 (Connection with PC)

J111 DADF driver PCB (for power supply)

J112 Scanner unit cooling fan (FM2)

J101

J110

J111

IC

J102

J103

J112

J104

J105

J106

T-2-2

J109

J108

J107

F-2-4

E490 (Error caused by incorrect DADF type)

-0001 If a not-supported DADF type is installed.

E473 (DDI communication error)

-0000, -0003, -0004

If the reader controller PCB detects communication error between the main controller PCB and

the reader controller PCB.

Technology > Basic conguration > Reader > Reader controller PCB

2

2-3

2

Technology > Basic conguration > Reader > Scanner unit

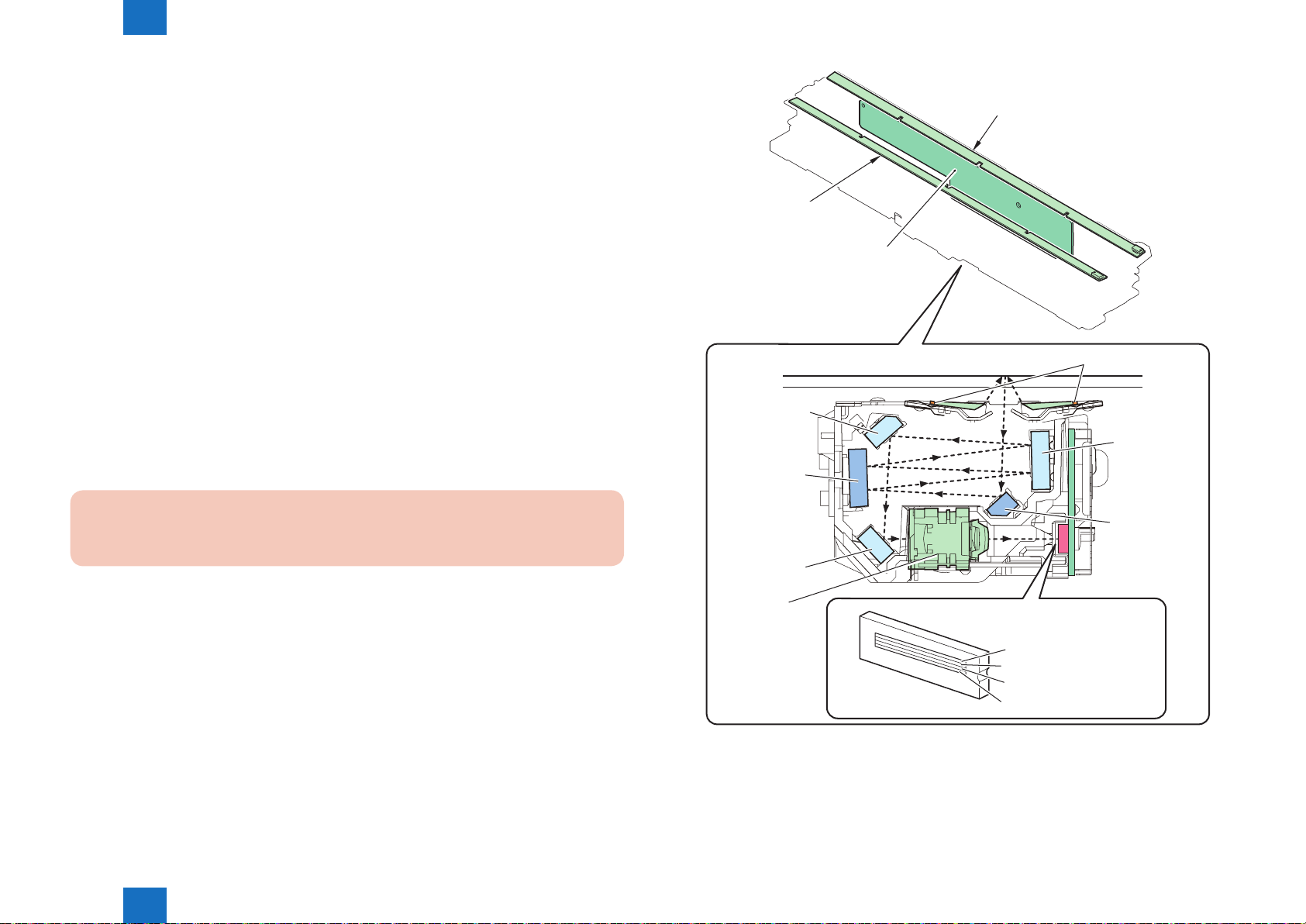

Scanner unit

■

Original exposure and scanning are performed by the integrated scanner unit of LED, mirror,

lens and reading sensor.

Light emitted from LED is reected by the original and reaches the reading sensor through

the 3 folding mirrors and 4 free curvature mirrors.

1. LED lamp unit

On LED lamp unit, the light is generated from the 2 LED lamp PCBs (LED chip: 54 pieces per

PCB).

Generated light is exposed to the original through the reection plate.

2. Free curvature mirror

Scanner unit is equipped with the 3 folding mirrors and 4 free curvature mirrors.

Free curvature mirror has symmetric facet in main scanning direction and asymmetric facet in

sub scanning direction against the optical axis.

2-4

Reader LED Lamp

PCB (Left)

Reader LED Lamp

PCB (Right)

Reader Scanner

Unit PCB

LED (light source)

3. Reading sensor

Reading sensor scans the image per 1image line.

Reading sensor has 4 lines (R, G, B, BW). At B&W scanning, it uses 1 line (B/W) and uses 3

lines (R, G, B) at color scanning.

Error code

E301 (insufcient light intensity)

-0001 The light intensity during front side shading is lower than the standard level

Mirror

No.4

Mirror

No.3

Mirror

No.2

Mirror

No.1

Mirror

No.5

Lens

CCD

[Red (R) line]

[Greeen (G) line]

[Blue (B) line]

[Black & white (B / W) line]

F-2-5

Technology > Basic conguration > Reader > Scanner unit

2

2-4

2

detection position

Technology > Basic conguration > Reader > Basic sequence

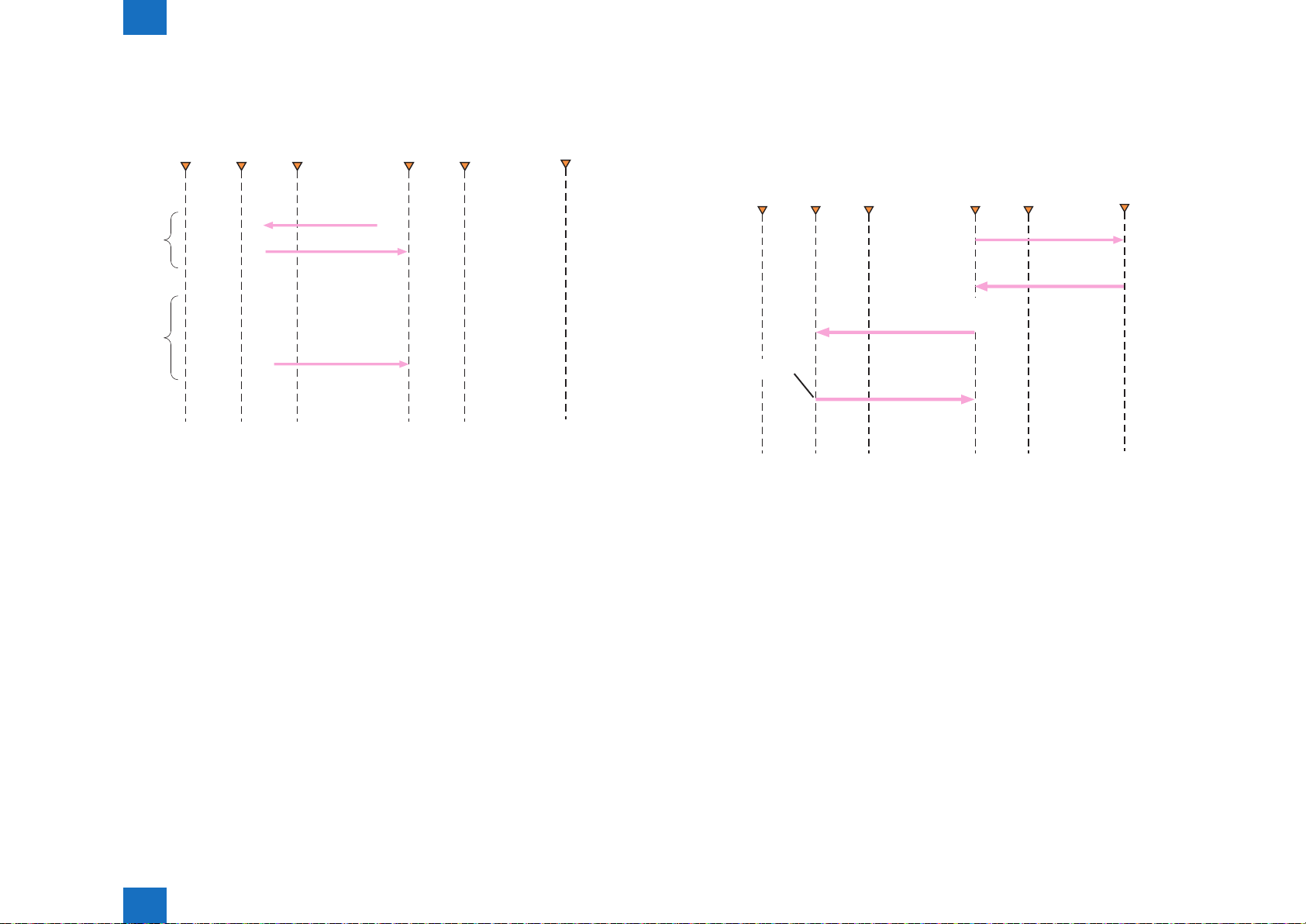

Basic sequence

■

Home position detection operation at power ON

●

Scan start

position

Stream

reading position

HPsensor

position

Shading

position

Image

leading edge

Original size

Original size detection operation

●

2-5

If the HP Sensor

is OFF when the

Main Power Switch

is ON

If the HP Sensor

is OFF when the

Main Power Switch

is ON

F-2-6

Scan start

position

30 sec timeout

HP search

operation

Stream

reading position

HP Sensor

position

Shading

position

Lamp ON

Lamp OFF

Image

leading edge

Copyboard is open

Original size

detection position

Copyboard is

closed

→Lamp ON

Original size

idntification

→Lamp OFF

F-2-7

Technology > Basic conguration > Reader > Basic sequence

2

2-5

2

detection position

Technology > Basic conguration > Reader > Basic sequence

2-6

At start key ON (Book mode/1 sheet original)

●

Scan start

position

If the original

size detection

started before

the 30-second

time-out

HP search

operation

If the original

size detection

started after

the 30-second

time-out

HP search

operation

Stream

reading position

Lamp ON

HP sensor

position

position

Lamp ON

Shading

Image

leading edge

Original size

detection position

Reading

completed

・Stop

position

Lamp OFF

Reading

completed

・Stop

position

Lamp OFF

F-2-8

At start key ON (DADF mode/1 sheet original)

●

Scan start

position

Change in read position of the original in order to

avoid dust during stream reading(5points)

Stream reading dust detection(5points)

HP search

operation

Stream

reading position

Scan Operation

HP sensor

position

Shading

start

position

Lamp ON

Shading

position

Image

leading

edge

Original size

F-2-9

Technology > Basic conguration > Reader > Basic sequence

2

2-6

2

DADF driver PCB (PCB1)

Disengaging

motor 2 (M7)

Glass shifting

motor (M9)

Disengaging

motor 1 (M6)

Delivery

motor (M5)

Registration

motor (M3)

Read motor (M4)

Feed motor (M2)

Pickup roller unit

lifter motor (M10)

Tray lifter motor (M8)

Pickup motor (M1)

Scanner unit

cooling fan (FM3)

Scanner unit

Read motor Motor

cooling fan (FM2)

Motor driver cooling fan (FM1)

Original Display

LED PCB (LED1)

Delivery Display

LED PCB (LED2)

Disengaging

solenoid (SL1)

Stamp solenoid

(SL2)

Technology > Basic conguration > DADF > Parts Conguration

DADF

Function Conguration

■

Functions are listed below:

Reader controller PCB

Parts Conguration

■

List of Major Electric Parts

●

2-7

- Controls

- Power supply

assembly

assembly (front side)

Original feed

assembly

Original scanning

Original pickup

assembly

assembly (rear side)

DADF driver PCB

Original pickup tray assembly

Path of original Original delivery assemblyOriginal scanning

F-2-10

F-2-11

2

Technology > Basic conguration > DADF > Parts Conguration

2-7

2

Technology > Basic conguration > DADF > Parts Conguration

2-8

Drive Conguration

●

This equipment is a device to feed the original solely for stream scanning.

This equipment has 10 motors and 1 solenoid as drive load.

There is also 1 scanner unit for the original (for the back side).

Code Name Role Remarks

M1 Pickup motor Drive of pickup roller, separation roller, feed

roller 1

M2 Feed motor Drive of pullout roller, feed roller 2 Speed control is active

M3 Registration motor Drive of registration roller PS constant speed

M4 Read motor Drive of lead roller 1/2/3 and platen roller 1/2 PS constant speed

M5 Delivery motor Drive of delivery roller Speed control is active

M6 Disengagement

motor 1

M7 Disengagement

motor 2

M8 Tray lifter motor Up/down movement of pickup lifter -

M9 Glass shift motor Shift of glass of scanning assembly for back side -

M10 Pickup roller unit

lifter motor

SL1 Disengagement

solenoid

The drive of this equipment is shown below.

Disengagement of lead roller 1

(releasing pressure)

Disengagement of lead roller 2

(releasing pressure)

Up/down movement of pickup roller unit (using

cam)

Disengagement of delivery roller -

M2 M1

M10M9M3

Speed control is active

-

-

-

T-2-3

List of Rollers

●

[1]

[2]

[3]

[4]

[5]

[6]

[7]

[8]

[9]

[10]

[11]

[12]

[13]

[14]

[15]

[16]

[17]

[18]

[19] [20] [21] [22] [23]

[1] Pickup roller [14] Platen roller 1 wheel 1

[2] Feed roller 1 [15] Lead roller 2 wheel

[3] Separation roller [16] Lead roller 2

[4] Pullout roller wheel [17] Platen roller 2 wheel 1

[5] Pullout roller [18] Platen roller 2

[6] Feed roller 2 [19] Platen roller 2 wheel 2

[7] Feed roller 2 wheel [20] Lead roller 3 wheel

[8] Registration roller wheel [21] Lead roller 3

[9] Registration roller [22] Delivery roller wheel

[10] Lead roller 1 [23] Delivery roller

[11] Lead roller 1 wheel

[12] Platen roller 1 wheel 2

[13] Platen roller 1

F-2-13

M7

Technology > Basic conguration > DADF > Parts Conguration

2

SL1

M8M5M4M6

F-2-12

2-8

2

Technology > Basic conguration > DADF > Parts Conguration

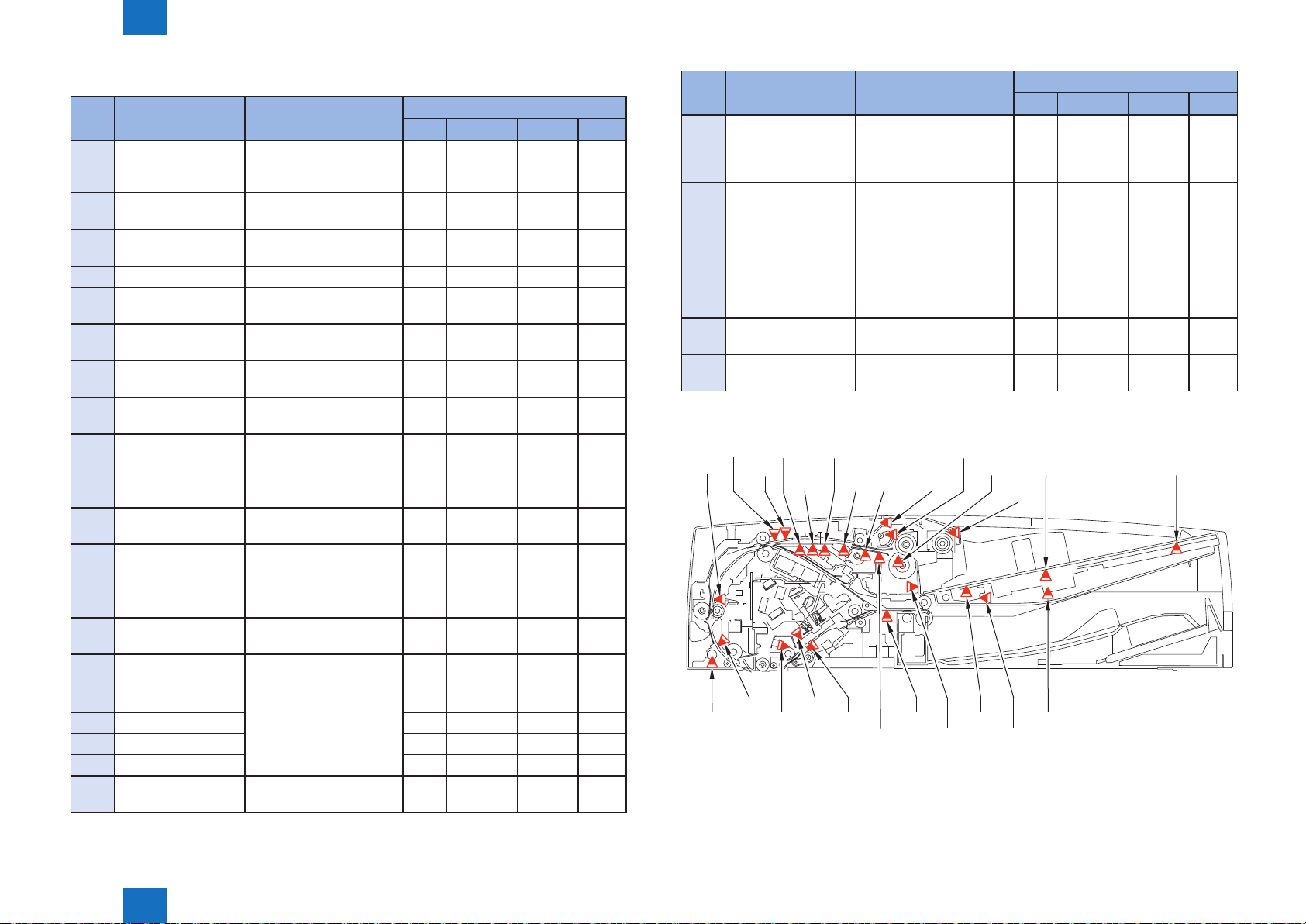

Sensor List

●

Code Name Detection content

SR1 Original sensor Presence/absence of

original on original pickup

tray

SR2 Post-separation

sensor 1

SR3 Post-separation

sensor 2

SR4 Delay sensor Feed delay Yes Yes Yes -

SR5 Lead sensor 2 Disengaged timing of lead

SR6 Paper surface sensor Top surface position at

SR7 AB/ Inch identication

sensor

SR8 LTR-R/ LGL

identication sensor

SR9 Tray open/closed

sensor

SR10 Cover open/closed

sensor

SR11 Glass shifting HP

sensor

SR12 Pickup roller unit lifter

HP sensor

SR13 Tray HP sensor Most lowered position of

SR15 Disengaging HP

sensor 1

SR16 Disengaging HP

sensor 2

SR17 Original size sensor 1 Original size in width

SR18 Original size sensor 2 - - - -

SR19 Original size sensor 3 - - - -

SR20 Original size sensor 4 - - - -

SR22 Leading edge position

sensor

Leading edge of original

just after the pickup

Leading edge of original

just after the pickup

roller 2

original pickup

Identication of A4R/LTRR

and A5R/STMTR

Identication of LTR-R/LGL

Open/close of original

pickup tray

Open/close of feeder cover

Position of scanning glass

Position of pickup roller

unit

original pickup tray (upper)

Engaging/disengaging of

lead roller 1 wheel

Engaging/disengaging of

lead roller 2 wheel

direction

Leading edge position of

original at feeding

Delay Stationary Residue Others

- - - -

- - - Yes

- - - Yes

Yes Yes Yes -

- - - -

- - - -

- - - -

- - - -

- - - Yes

- - - -

- - - Yes

- - - -

- - - Yes

- - -

- - - -

- - Yes -

Jam detection

Yes

Code Name Detection content

PCB2 Post-separation

sensor 3

PCB3 Registration sensor - Registration arch creation

PCB4 Lead sensor 1 - Disengaging timing of

PCB5 Delivery sensor Disengaging timing of

VR Original width volume Original size in width

SR20

PCB3

SR15

SR22 SR17

SR18 SR19

SR5

PCB4

SR11

- Leading edge position

just after the pickup

- Original size in feed

direction

timing

- Disengaging timing of

lead roller 1

lead roller 1/2

- Original size in feed

direction

delivery roller

direction

PCB2

SR4

SR16

SR3

SR10

PCB5

SR12

SR9

SR2 SR7

SR1

SR13

2-9

Jam detection

Delay Stationary Residue Others

Yes Yes Yes Yes

Yes Yes Yes -

Yes Yes Yes -

Yes Yes Yes -

- - - -

T-2-4

SR6

SR8

VR

F-2-14

Technology > Basic conguration > DADF > Parts Conguration

2

2-9

2

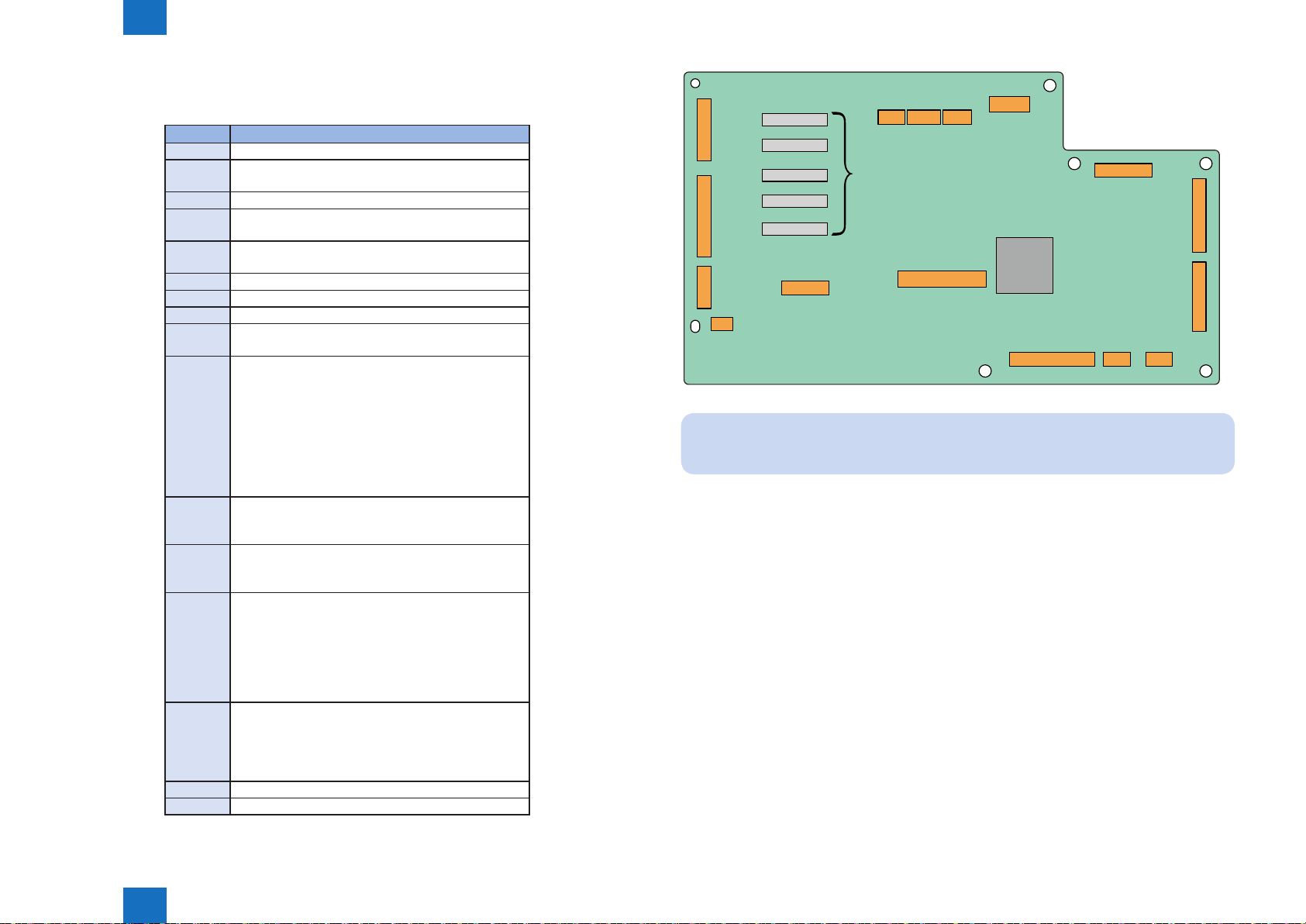

Technology > Basic conguration > DADF > DADF Driver PCB

DADF Driver PCB

■

Indicate the destination of the DADF driver PCB.

Jack No. Destination

J401 Reader controller PCB (for communication)

J402 Feed motor (M2)

Registration motor (M3)

J403 Pickup roller unit lifter motor (M10)

J404 Read motor cooling fan (FM2)

Motor driver cooling fan (FM1)

J405 Disengaging motor 1 (M6)

Disengaging solenoid (SL1)

J406 Pickup motor (M1)

J407 Read motor (M4)

J408 Delivery motor (M5)

J409 Disengaging motor 2 (M7)

Glass shifting motor (M9)

J410 Cover open/closed detection sensor (SR10)

Disengaging home position sensor 1 (SR15)

Original size sensor 1 (SR17)

Original size sensor 2 (SR18)

Original size sensor 3 (SR19)

Original size sensor 4 (SR20)

Leading edge position sensor (SR22)

Scanner unit cooling fan (FM3)

Original set display LED (LED)

J411 Lead sensor 2 (SR5)

Glass shifting home position sensor (SR11)

Disengaging home position sensor 2 (SR16)

J412 Registration sensor (PCB3)

Lead sensor 1 (PCB4)

Delivery sensor (PCB5)

J413 Post-separation sensor 1 (SR2)

Post-separation sensor 2 (SR3)

Delay sensor (SR4)

Paper surface sensor (SR6)

Tray open/closed sensor (SR9)

Pickup roller unit lifter home position sensor (SR12)

Post-separation sensor 3 (PCB2)

J414 Original sensor (SR1)

AB/ Inch identication sensor (SR7)

LTR-R/ LGL idencation sensor (SR8)

Tray home position sensor (SR13)

Original width volume (VR)

J416 Tray lifter motor (M8)

J418 Reader controller PCB (for power supply)

T-2-5

J403J408

J407

J416

Motor IC

J418

J402

J409

J405

IC

J406

J404

Note:

The scanner unit is connected to the reader controller PCB.

2-10

J401

J414

J413

J412J411J410

F-2-15

Technology > Basic conguration > DADF > DADF Driver PCB

2

2-10

2

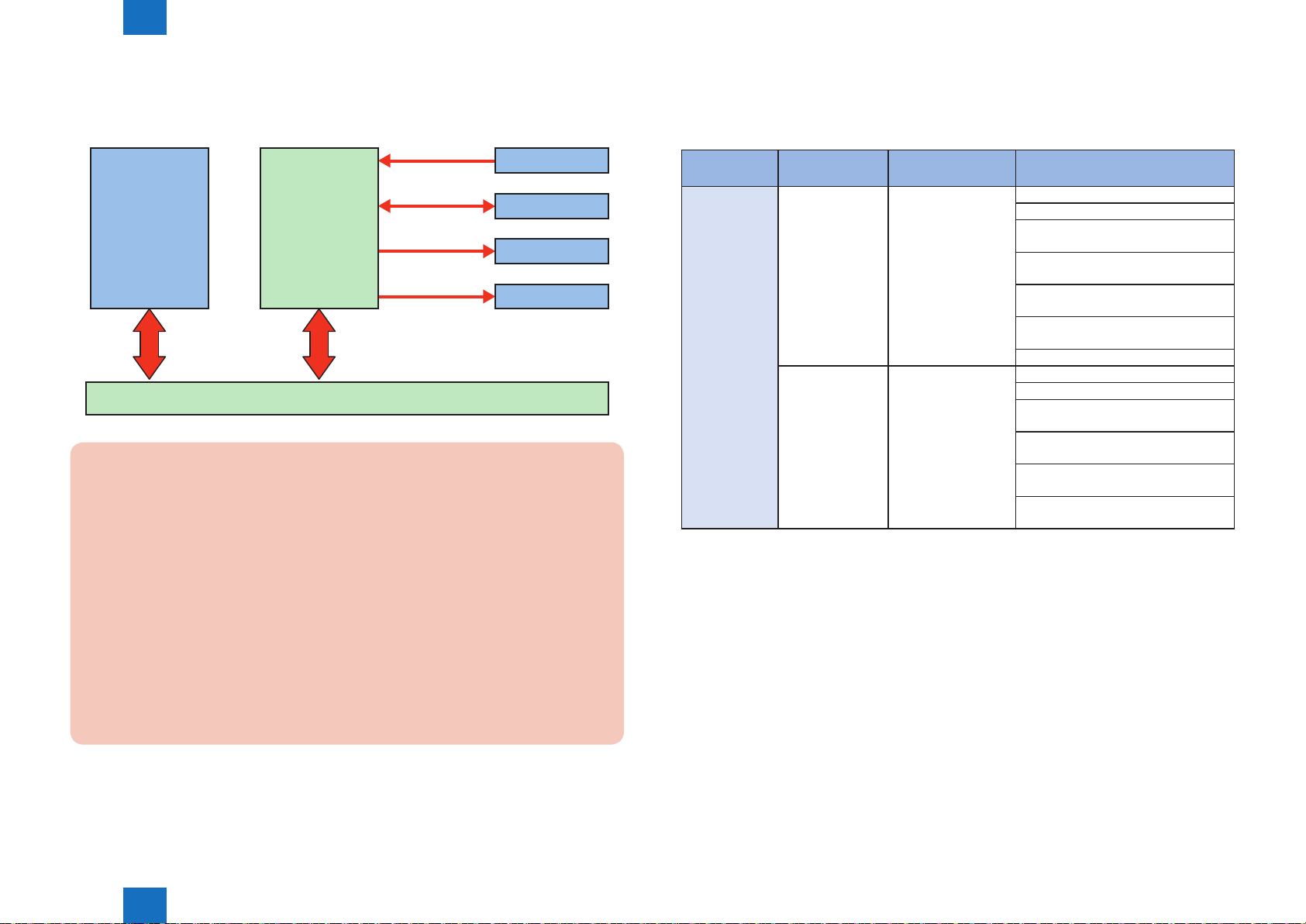

Technology > Basic conguration > DADF > Overview of Operation Mode

2-11

Electric Circuit Diagram

■

The control of this equipment is performed on the reader controller PCB.

Following shows the relation of each electrical parts.

Sensor

Scanner unit

Error code:

E270 (Error in the main scanning/sub scanning synchronization signal)

-0101 Sub scanning synchronization signal (VSYNC) is not properly transmitted from scanner

unit PCB (back side scanner unit), and this causes image failure or abnormal termination.

E280 (Communication error between reader controller PCB – scanner unit)

- 0101 If the communication is not started within the specied time between reader controller

PCB – back side scanner unit.

DADF driver

PCB

Reader controller PCB

Motor

Solenoid

Fan

F-2-16

Overview of Operation Mode

■

Overview

●

The operation mode of this equipment is classied as below.

Name of

operation mode

Normal rotation

pickup/delivery

The outline of the original ow is shown.

2-sided scanning

method

- Original is picked up

2-sided

simultaneous

scanning

Operation overview Applicable print mode

and is scanned by the

scanner unit in reader

side. And then, it is

delivered.

Original is picked up

and the front surface

is scanned by the

scanner unit in reader

side while back

surface is scanned

by the scanner unit in

DADF side.

And then, it is

delivered.

1-sided original -> 1-sided print

1-sided original -> 2-sided print

1-sided original with mix of same

conguration -> 1-sided print

1-sided original with mix of same

conguration -> 2-sided print

1-sided original with mix of different

conguration -> 1-sided print

1-sided original with mix of different

conguration -> 2-sided print

Extra long original -> 1-sided print

2-sided original -> 1-sided print

2-sided original -> 2-sided print

2-sided original with mix of same

conguration -> 1-sided print

2-sided original with mix of same

conguration -> 2-sided print

2-sided original with mix of different

conguration -> 1-sided print

2-sided original with mix of different

conguration -> 2-sided print

T-2-6

E400 (Communication error between reader controller PCB – DADF)

-0001 If check sum error occurs during communication between reader controller PCB - DADF.

-0002 If reception error occurs during communication between reader controller PCB - DADF.

E490 (Error caused by incorrect DADF type)

-0001 If a not-supported DADF type is installed.

Technology > Basic conguration > DADF > Overview of Operation Mode

2

2-11

2

Technology > Basic conguration > DADF > Overview of Operation Mode

2-12

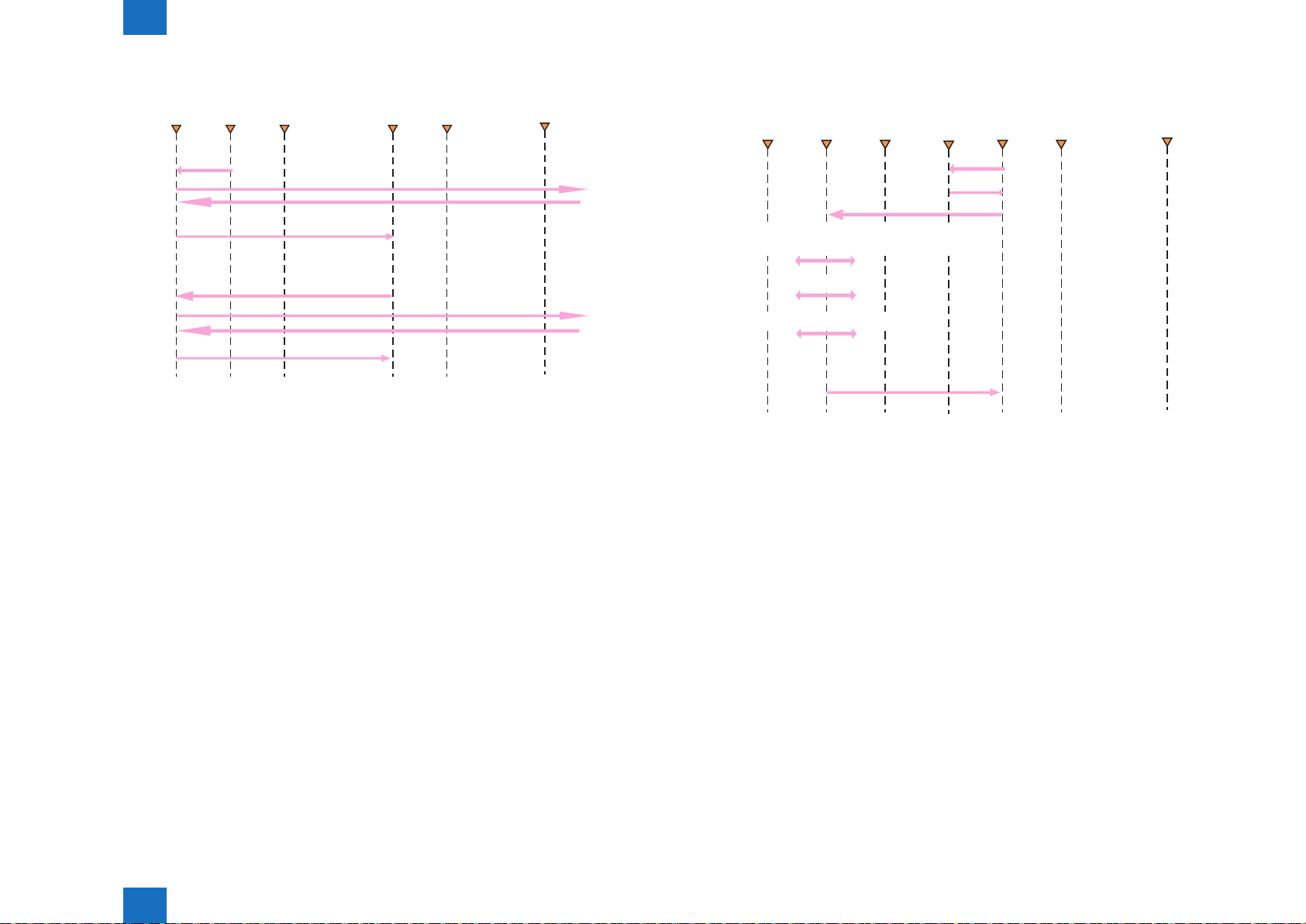

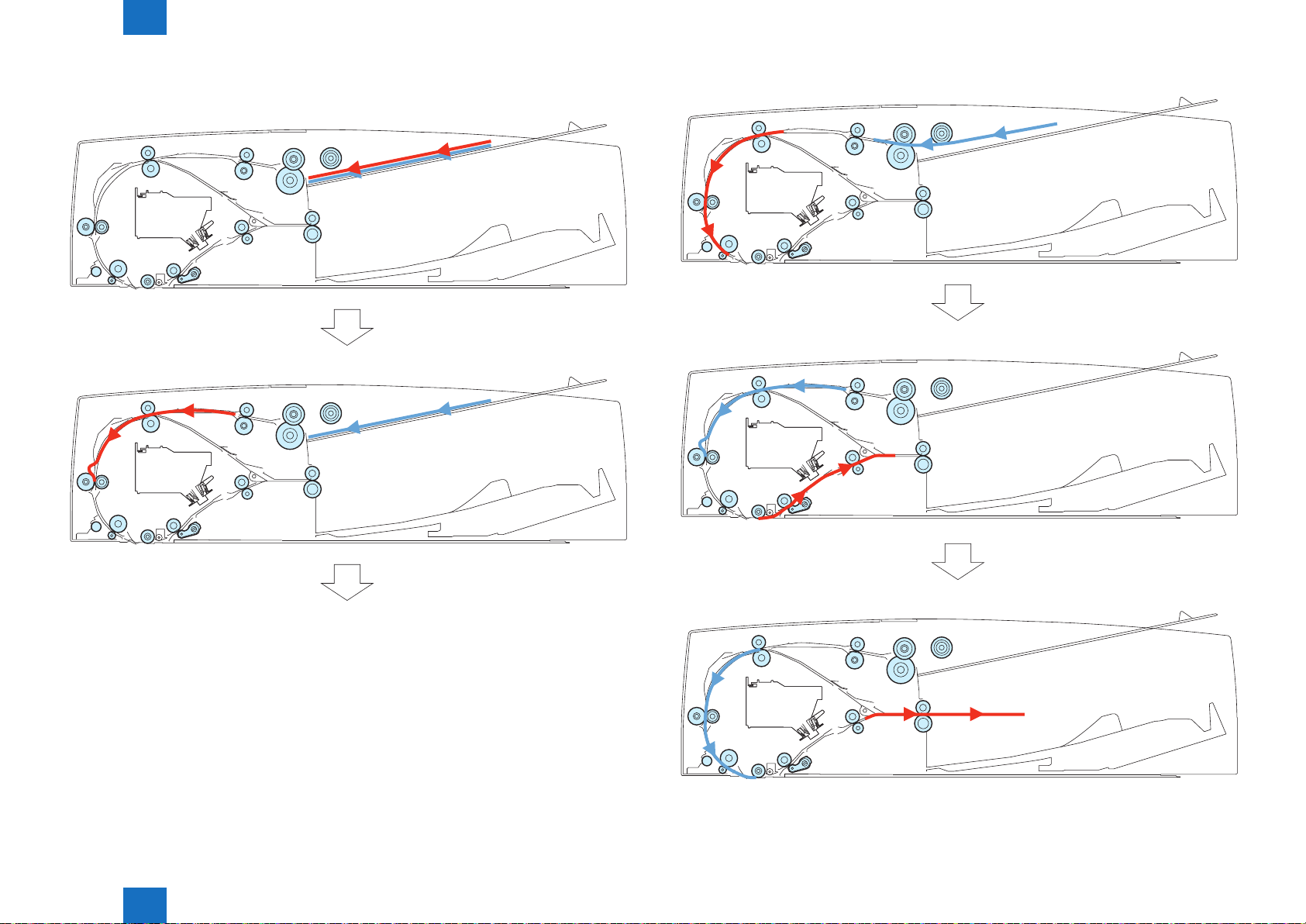

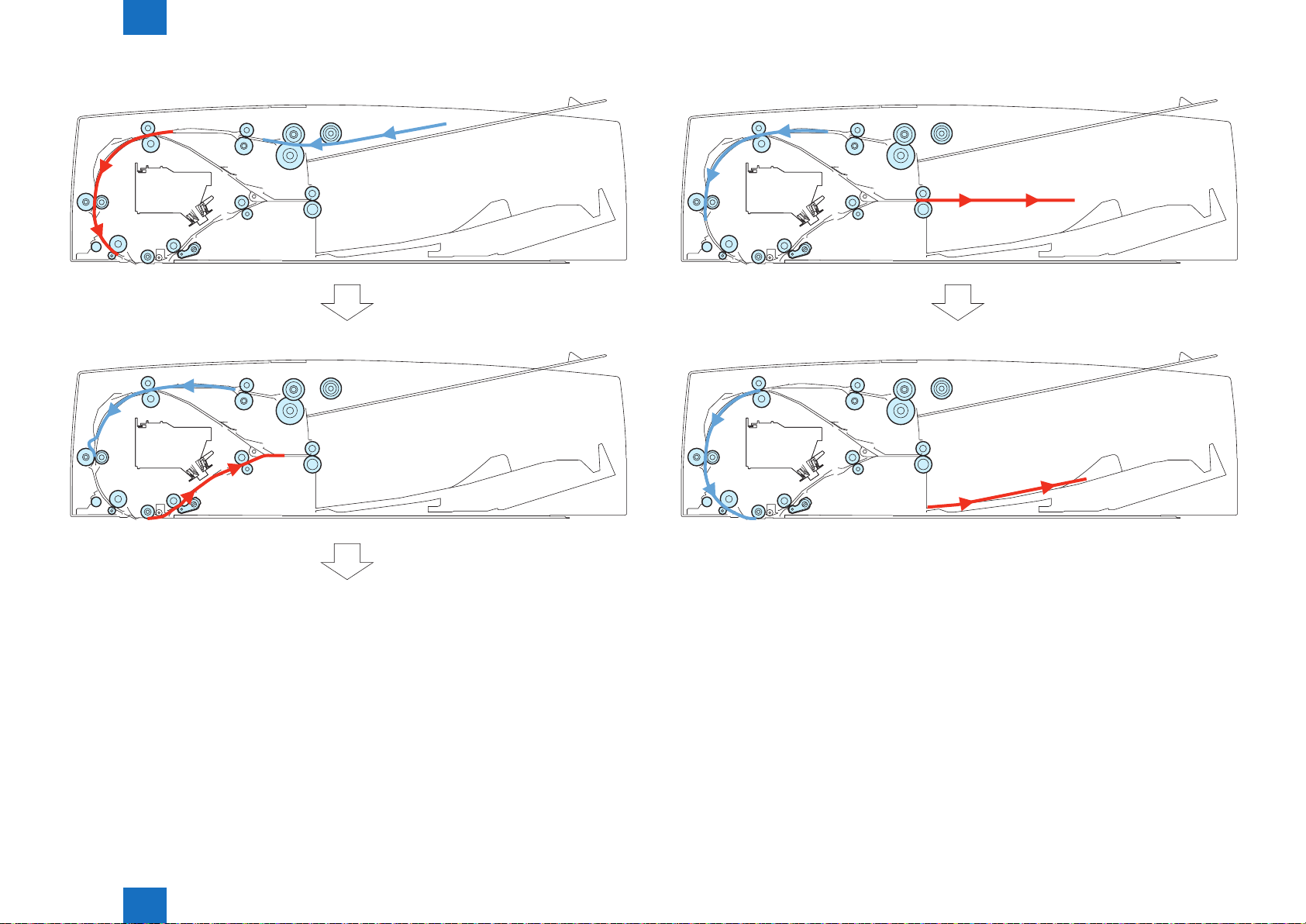

1-Sided Original (Small Size)

●

1) 1st side pickup

2) 1st side arch creation

3) 1st side feeding & 2nd side pickup

F-2-19

F-2-17

4) 2nd side arch creation

Technology > Basic conguration > DADF > Overview of Operation Mode

2

F-2-20

F-2-18

5) 2nd side scanning

F-2-21

2-12

2

Technology > Basic conguration > DADF > Overview of Operation Mode

2-13

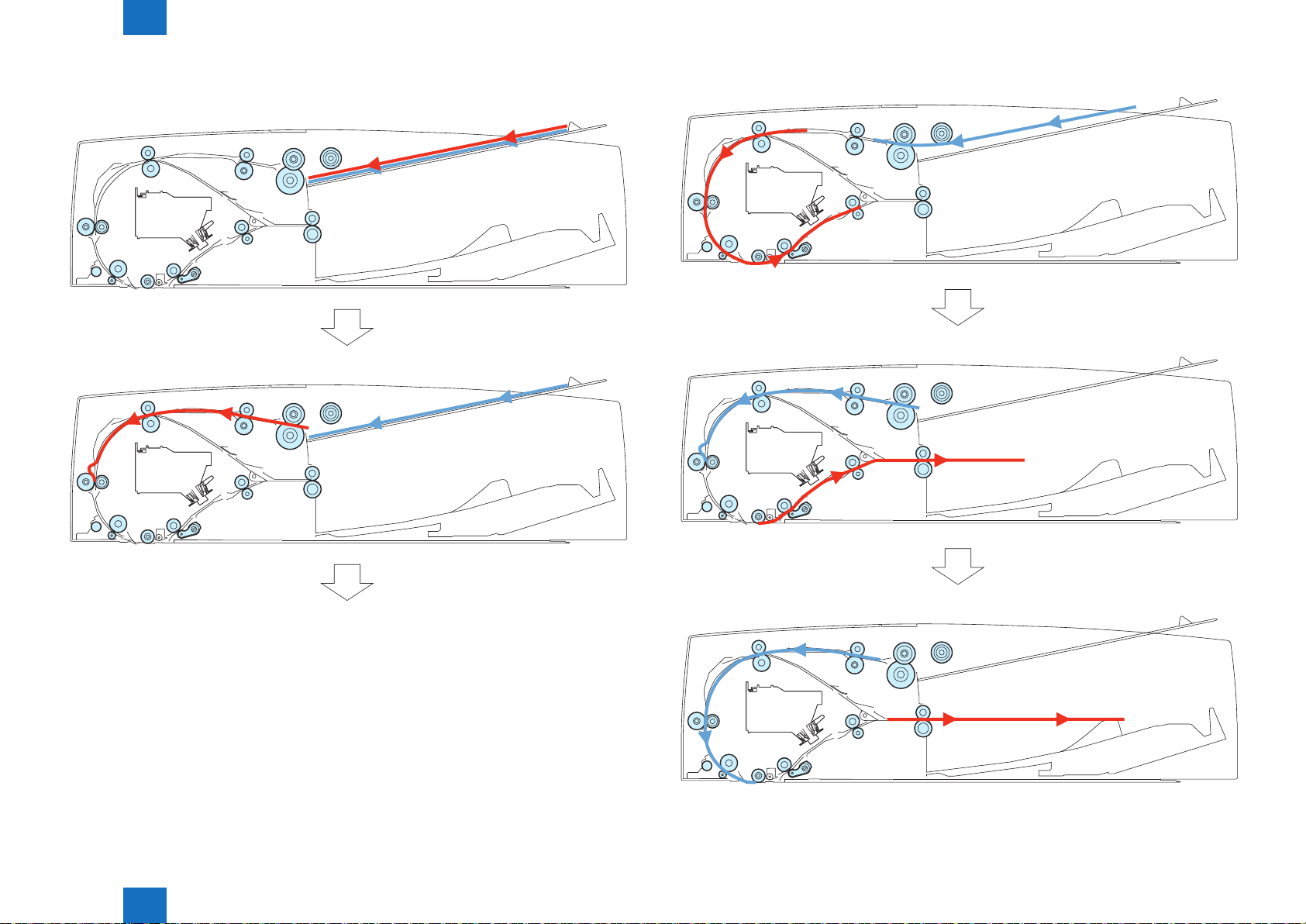

1-Sided Original (Large Size)

●

1) 1st side pickup

2) 1st side arch creation

3) 2nd side pickup

F-2-24

F-2-22

4) 2nd side arch creation

Technology > Basic conguration > DADF > Overview of Operation Mode

2

F-2-25

F-2-23

5) 2nd side scanning

F-2-26

2-13

2

Technology > Basic conguration > DADF > Overview of Operation Mode

2-14

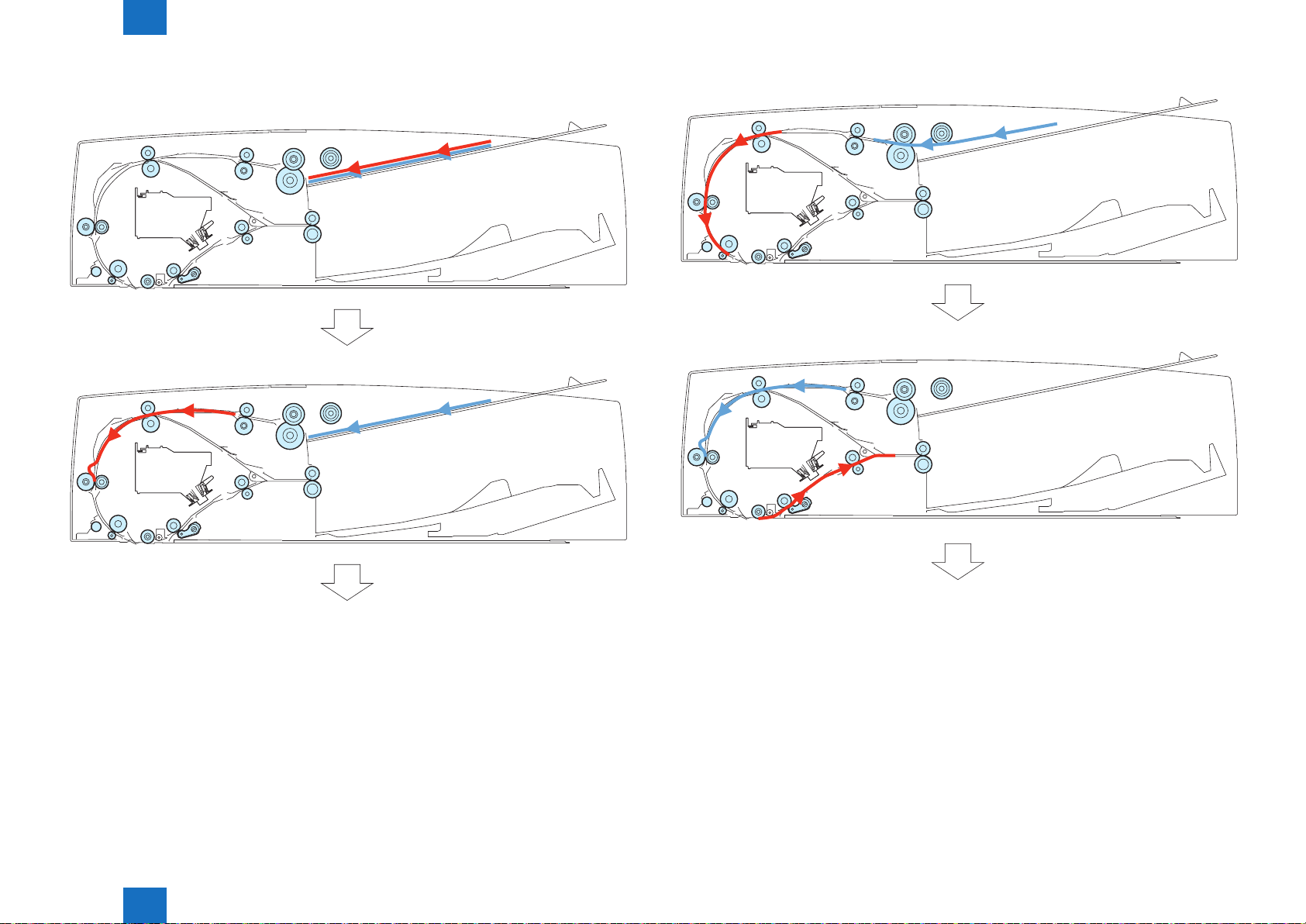

1-Sided Original with Mix of Same Conguration (Small Size)

●

1) 1st side pickup

2) 1st side arch creation

3) 1st side stop & 2nd side pickup

F-2-29

F-2-27

4) 2nd side arch creation

Technology > Basic conguration > DADF > Overview of Operation Mode

2

F-2-30

F-2-28

2-14

2

Technology > Basic conguration > DADF > Overview of Operation Mode

2-15

5) 2nd side stop (1st side is also stopped)

6) 2nd side scanning

F-2-31

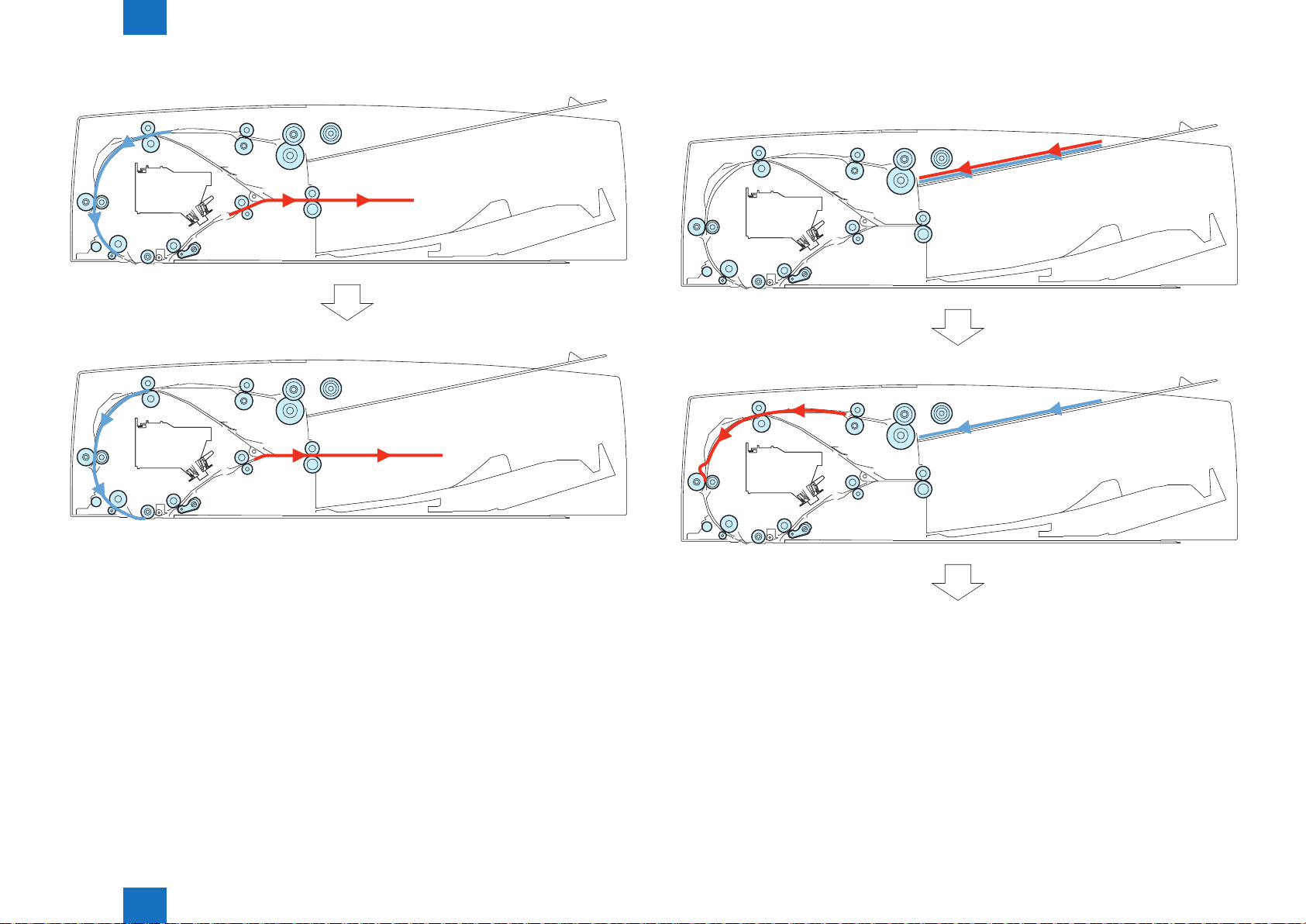

2-Sided Original (Simultaneous Scanning of Both Sides) (Small Size)

●

1) 1st side pickup

2) 1st side arch creation

F-2-33

Technology > Basic conguration > DADF > Overview of Operation Mode

2

F-2-32

F-2-34

2-15

2

Technology > Basic conguration > DADF > Overview of Operation Mode

2-16

3) 1st side feeding & 2nd side pickup

4) 2nd side arch creation

F-2-35

5) 2nd side feeding

F-2-37

6) 2nd side scanning

Technology > Basic conguration > DADF > Overview of Operation Mode

2

F-2-36

F-2-38

2-16

2

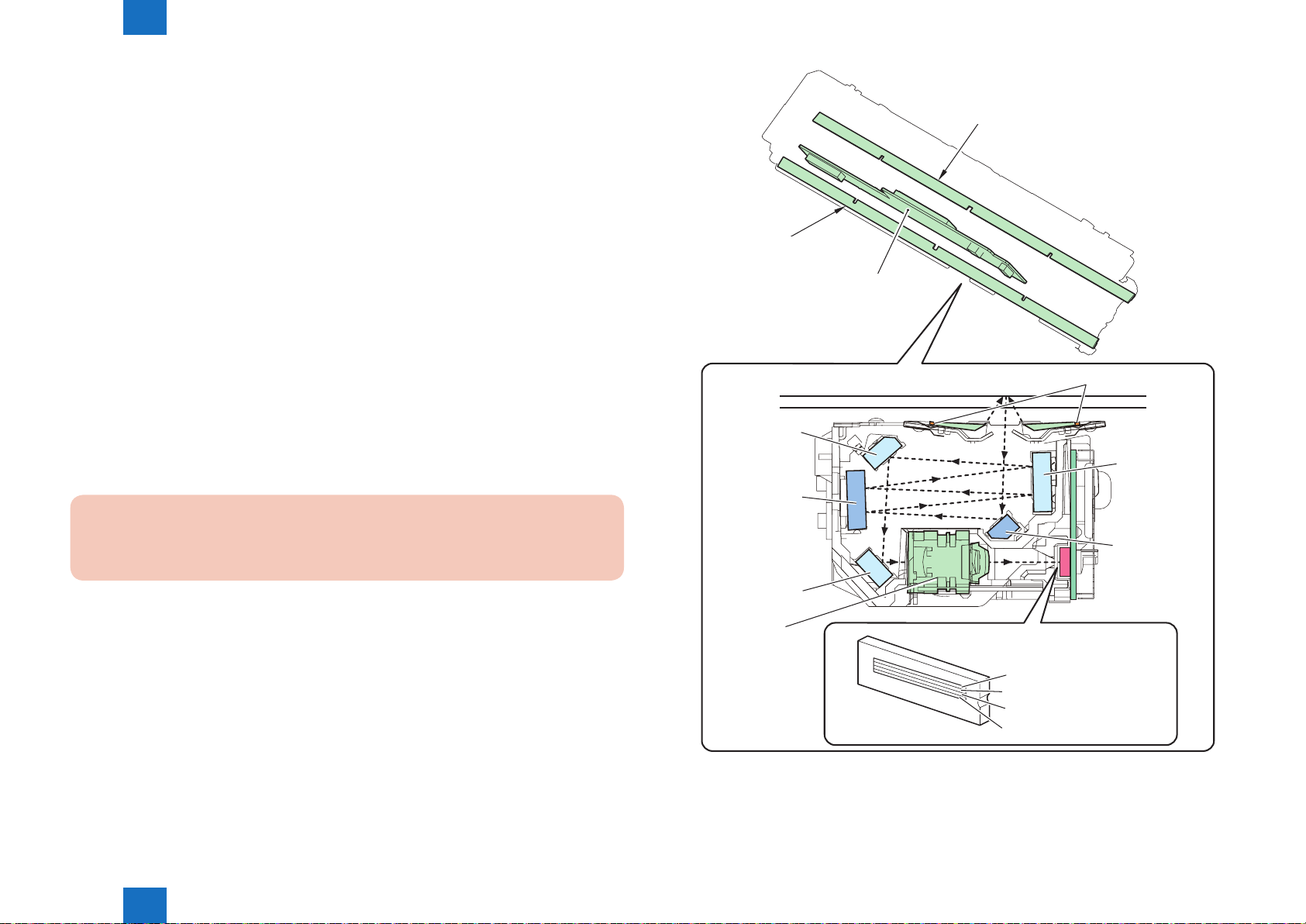

Technology > Basic conguration > DADF > Scanner Unit

Scanner Unit

■

For exposure and scanning of original, this equipment uses an integrated scanner unit

consists of the LED, the mirror, the lens and the reading sensor.

The light emitted from the LED is reected to the original, and then received by the reading

sensor through the 3 turndown mirrors and the 4 free curved mirrors.

a. LED lamp unit

The LED lamp unit emits light from 2 boards of LED lamp PCB (LED chip: 54 pc per board).

The emitted light is reected to the original through the reecting plate.

b. Free curved mirror

The scanner unit has 3 turndown mirrors and 4 free curved mirrors.

The free curved mirror is a mirror symmetric to the light shaft in main (horizontal) scanning

direction while dissymmetric in sub (vertical) scanning direction.

c. Reading sensor

The reading sensor performs scanning of image per image line.

The reading sensor has 4 lines (B/W, R, G, B), using 1 line (B/W) when scanning black/white

image and 3 lines (R, G, B) when scanning color image.

Error code

E301 (insufcient light intensity)

-0101 The light intensity during back side shading is lower than the standard level

2-17

DADF LED Lamp

PCB (Left)

DADF LED Lamp

PCB (Right)

DADF Scanner

Unit PCB

LED (light source)

Mirror

No.4

Mirror

No.3

Mirror

No.2

Mirror

No.1

Technology > Basic conguration > DADF > Scanner Unit

2

Mirror

No.5

Lens

CCD

[ Red (R) line]

[ Greeen (G) line]

[ Blue (B) line]

[ Black & white (B / W) line]

F-2-39

2-17

Loading...

Loading...