AEG MC9-MV9, MC13-MV13 Manual

Handbook Handbok Handbuch Manuel

MAXIMA

MC9-SA, MV9-BA, MC13-SA, MC13-BA, MV13-SA

Box 938, SE-671 29 Arvika,

Sweden

Tel 0570-744100 * +46 570 744100

Fax 0570-744250 * +46 570 744250

36 23 199-01 (F)

Product safety

Application

The cabinet is meant for packaged chilled foodstuffs and shall not be used for storage of other products.

Design and testing

The cabinet is CE-marked and complies with valid EU-directives (low voltage directive and electro magnetic compatibility directive). All cabinets have been tested regarding electrical earthing and insulation. They have also been tested (pressure tested) regarding the evaporator and condenser. The cabinet has been test run regarding function and leakage.

Service and repair

Service and repair (except cleaning) must only be made by persons qualified to carry out service work on the product and who knows the function and design of the cabinet. These are responsible that the safety is not impaired. Special notice should be attended to

∙earth connection

∙insulation resistance

∙exchanged components must be equivalent with the original component

When servicing the refrigerant circuit please note that

∙the work must only be done by persons with certified competence, and in accordance with national regulations.

∙the refrigerant must not be discharged to the atmosphere

∙Discharging and charging of refrigerant must be made through the schrader valve, with the refrigerant in liquid phase

∙Charging with another refrigerant than the stated must not be made without the approval of Carrier.

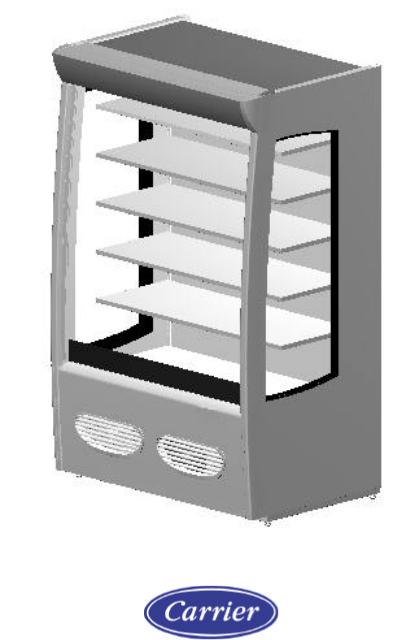

MC9/13

MV9/13

Description of function

Operation

The refrigeration is made with the help of fin coils in the bottom and fan assisted air circulation. The airs is sucked in through the grille in front of the bottom shelf and is discharged cooled partly through the perforation in back and ceiling plates and partly through the air supply in front of the ceiling plate. The evaporator fans (M2.1) are in operation continuously.

The temperature is controlled by a thermostat (S1, see page 9) which controls both timer (S4) and also the relay (K1). The control of the timer means defrost interval based on the compressor operation time. The relay then controls the compressor (M1) and the condenser fans (M2.2). At compressor operation the air circulates in the machine compartment through the air supply grille, passes condenser and is discharged at the back. When the compressor standstill this flow is reversed in order to clean the condenser surface.

Temperature, pressure and flow for the system during operation when the thermostat cuts-out are shown on page 8.

Defrost

The frost is melted with the help of air circulation from the evaporator fans, which operates also during defrost.

Defrost is initiated by the defrost timer, which via the relay cuts out the compressors. Defrost is terminated by the defrost timer when the set time has elapsed.

Defrost to some extent also takes place when the thermostat disconnects the compressors. At defrost the product temperature rises with some degree.

Settings

(Set values see "Technical Data")

Operating thermostat

The thermostat is set using the knob in the thermostat house, so that the knob figure points to the index on the panel plate.

36 23 199-01 (F) |

2 |

Common reasons for disturbances in operation

Temperature too high

∙Mains fuse blown due to other equipment also being connected.

∙Influence of draught and/or heating sources? See page 4

∙Overloaded?

∙Dust laden condenser?

∙Air circulation blocked? See page 4

∙Condenser fan defective?

∙Operation sensor defective (or incorrect set)?

∙Defective relay?

∙Compressor has a defective start relay?

∙Compressor defective?

Defrost problems

∙Defective defrost sensor (no defrost)?

∙The thermostat is set colder than pos. 3?

Summary of warranty conditions

Faults occurring during the warranty period are covered by the warranty with the exception of;

∙Transport damages and fair wear and tear

∙Adjustment of thermostat and timer

∙Fuses, fluorescent tubes, starters or similar

∙Problems in connection with an incorrect installation, abnormal use and non-maintenance.

Repair instruction

Replacement of compressor

∙Move the service pipe with the schrader valve to the new compressor

∙Always exchange the drier

Replacement of thermostat

∙Carefully lift and remove the front glass.

∙Loosen the 3 screws, placed in the slot for the front glass.

∙Loosen the 2 screws under the lower front.

∙Remove the front.

∙Remove the sealing of the bulb tube, and which is inserted at the back of the cabinet.

∙Pull out the bulb tube.

∙Loosen the thermostat knob.

∙Loosen the 2 cables on the thermostats left side.

∙Loosen and remove the old thermostat.

∙Mount the new thermostat.

∙Put back the 2 cables.

∙Put back the thermostat knob.

∙Insert the bulb tube through the right hole. Bend the tube a little upwards and follow the ceiling until the tube comes out on the back of the cabinet.

36 23 199-01 (F) |

3 |

MC9/13

MV9/13

∙Insert the bulb tube in the plastic tube until it reaches the bottom.

∙Seal the bulb tube with i.e. silicone to avoid humidity to reach it.

∙Remount in reverse order according to the first 4 points.

Replacement of fluorescent tube end wall

∙Loosen the light sheet by loosening the 4 screws holding it.

∙Twist loose the fluorescent tube.

∙Remount in reversed order.

Replacement of fluorescent tube in light box

∙Loosen the light box by loosening the 3 screws on the roof holding the light box.

∙Pull carefully apart the quick connection and remove the light box.

∙Loosen the 2 screws, underneath the light box, which holds the end wall of the light box.

∙Loosen the end wall.

∙Loosen the screw, underneath the box, which holds the opal sheet.

∙Pull gently out the opal sheet.

∙Twist loose the fluorescent tube.

∙Remount in reversed order.

Replacement of horizontal fluorescent tube

∙When exchanging the horizontal fluorescent tube, it has to be replaced by a fluorescent tube with a protective film.

Replacement of mains cable

∙Loosen the lower front (see replacement of thermostat)

∙Loosen the 2 screws holding the mains cable.

∙Loosen the mains cable from the plinth.

∙Fasten one thread or similar in the mains cable (to simplify the reassemble).

∙Pull out the mains cable from the back of the cabinet.

∙Fix the thread in the new mains cable.

∙Pull the thread from the front of the cabinet.

∙Remount in reversed order.

Replacement of condenser fan

∙Loosen the lower front (see replacement of thermostat).

∙Loosen the compressor by loosening the 3-spring pins.

∙Lift the compressor carefully a little outward.

∙Loosen the fan (4 screws).

∙Loosen the cable from the plinth.

∙Remove the fan.

∙Remount in reversed order.

Loading...

Loading...