Page 1

Model FS8-WG-SL

Flow Switch

INSTRUCTION MANUAL

MM-611 CC

C

Page 2

Page 3

PTFE

PTFE

Page 4

4

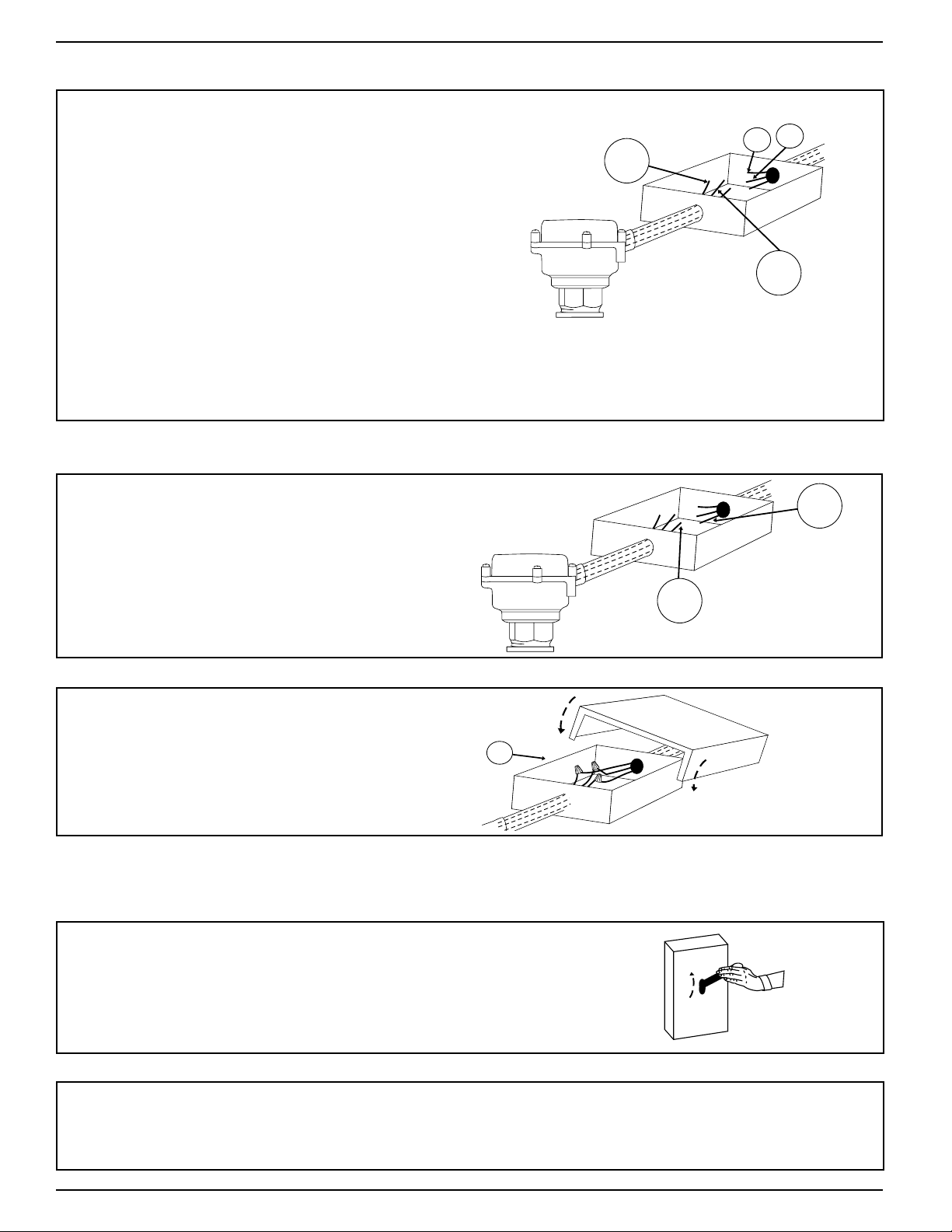

STEP 5 - Making Electrical Connections

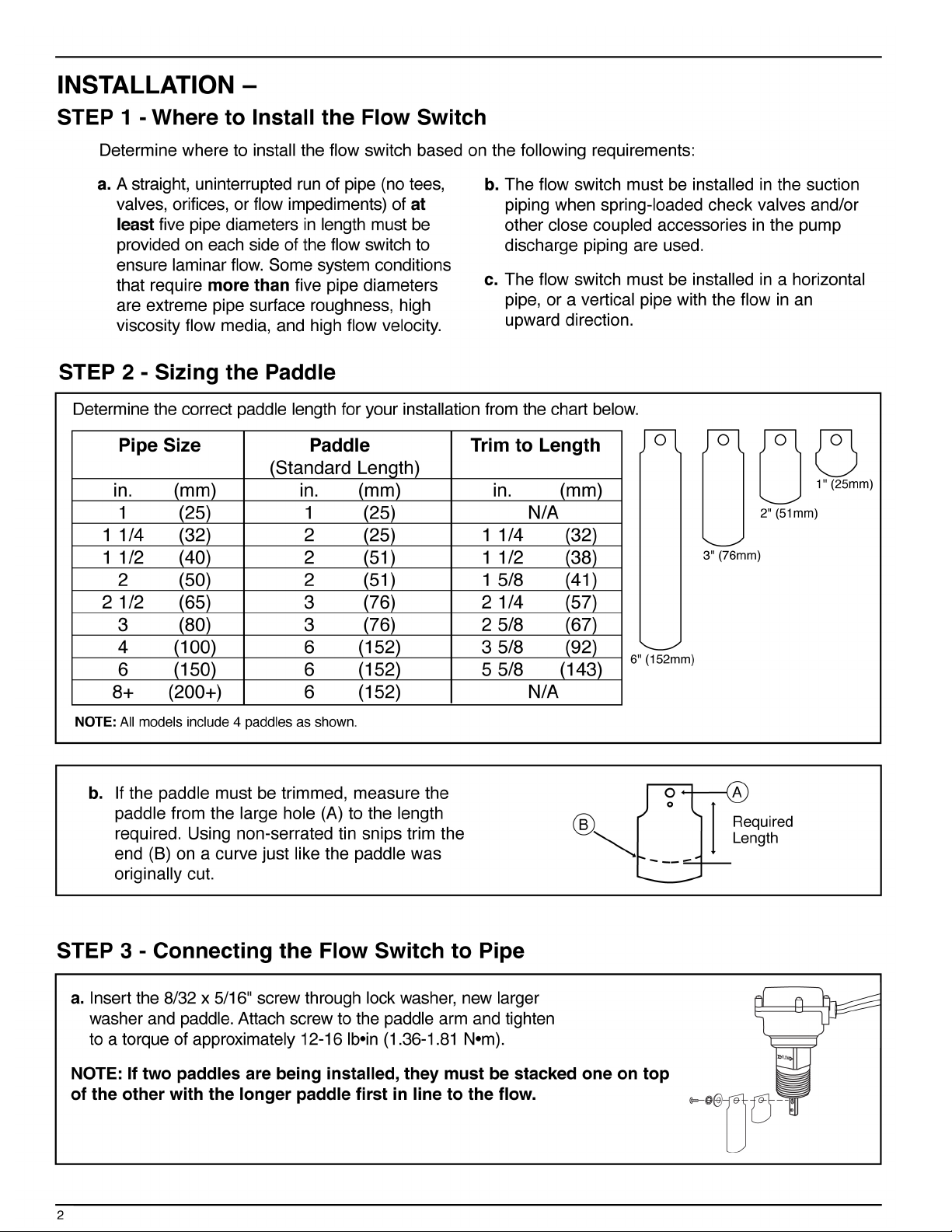

a. Apply pipe sealing compound or PTFE tape

to the threads (U) of a 1/2” (15mm) NPT pipe.

b. Insert the three (3) wires (V) extending from

the flow switch adapter (W) into the pipe (X).

V

X

W

c. Insert the pipe (X) into the adapter (W) and

finger tighten.

X

W

d. Place a pipe wrench (Y) on the pipe (X) and

another pipe wrench (Z) on the adapter (W).

While keeping the adapter (W) stationary,

tighten the pipe (X) into it.

Y

X

Z

W

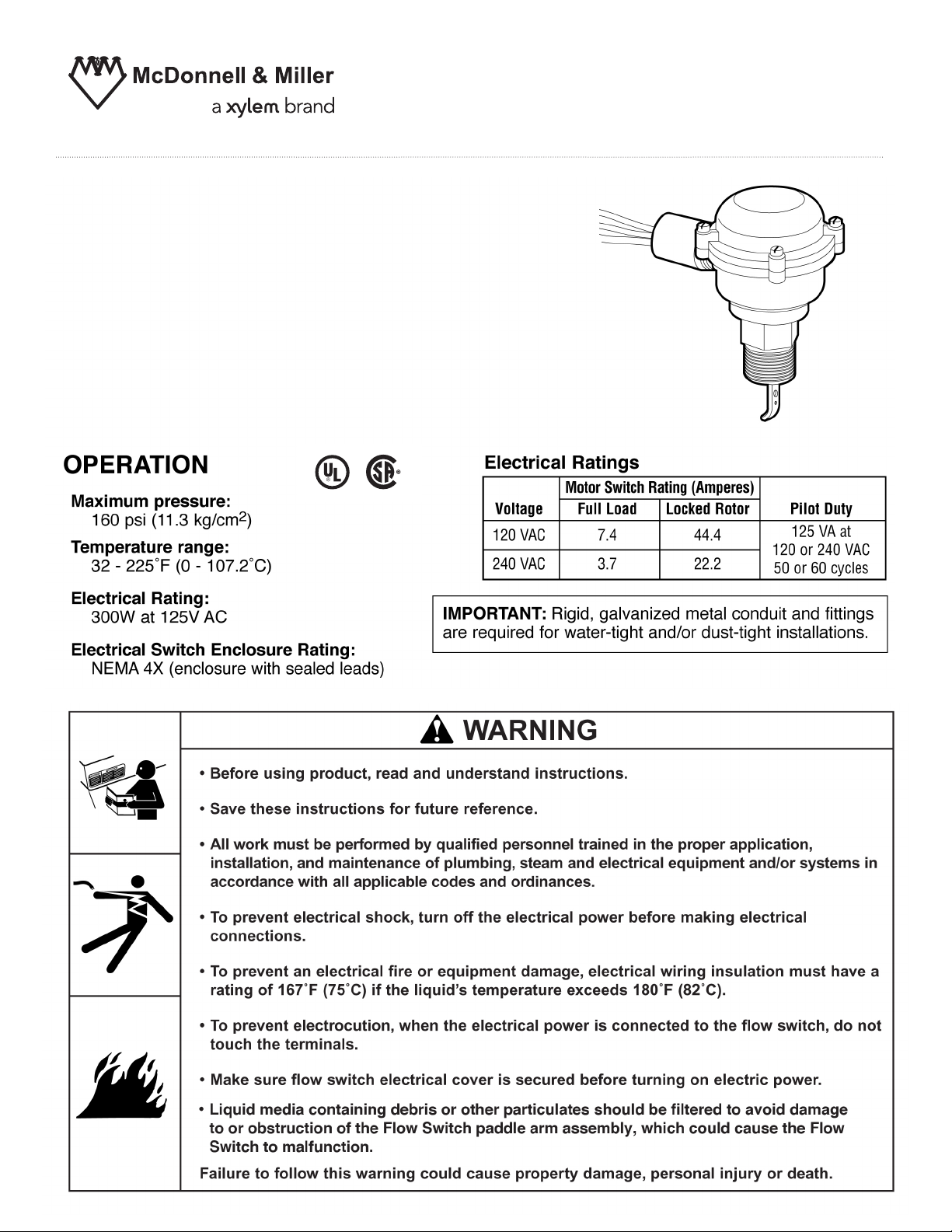

c. Insert the flow switch (Q) into the pipe tee (L)

or pipe half coupling (N), depending on your

installation. Turn the flow switch (Q) two (2)

or three (3) revolutions by hand.

d. Place a 1 3/8” (35mm) open end box wrench

(R) on the hex (S) and tighten the flow switch

(Q). The final position of the flow arrow on the

side of the hex (T) must be parallel to the pipe

and in the same direction as the flow.

FLOW

Q

R

T

S

Q

Q

L

PTFE

N

U

Page 5

5

STEP 5 - continued

e. Verify that the paddle’s full range of motion

(AA) is unobstructed. Some system piping

disassembly may be required.

AA

• To prevent electrical shock, turn off the electrical power before making electrical connections.

• To prevent an electrical fire or equipment damage, electrical wiring insulation must have a

rating of 167°F (75°C) if the liquid’s temperature exceeds 180°F (82°C).

Failure to follow this warning could cause property damage, personal injury or death.

!

WARNING

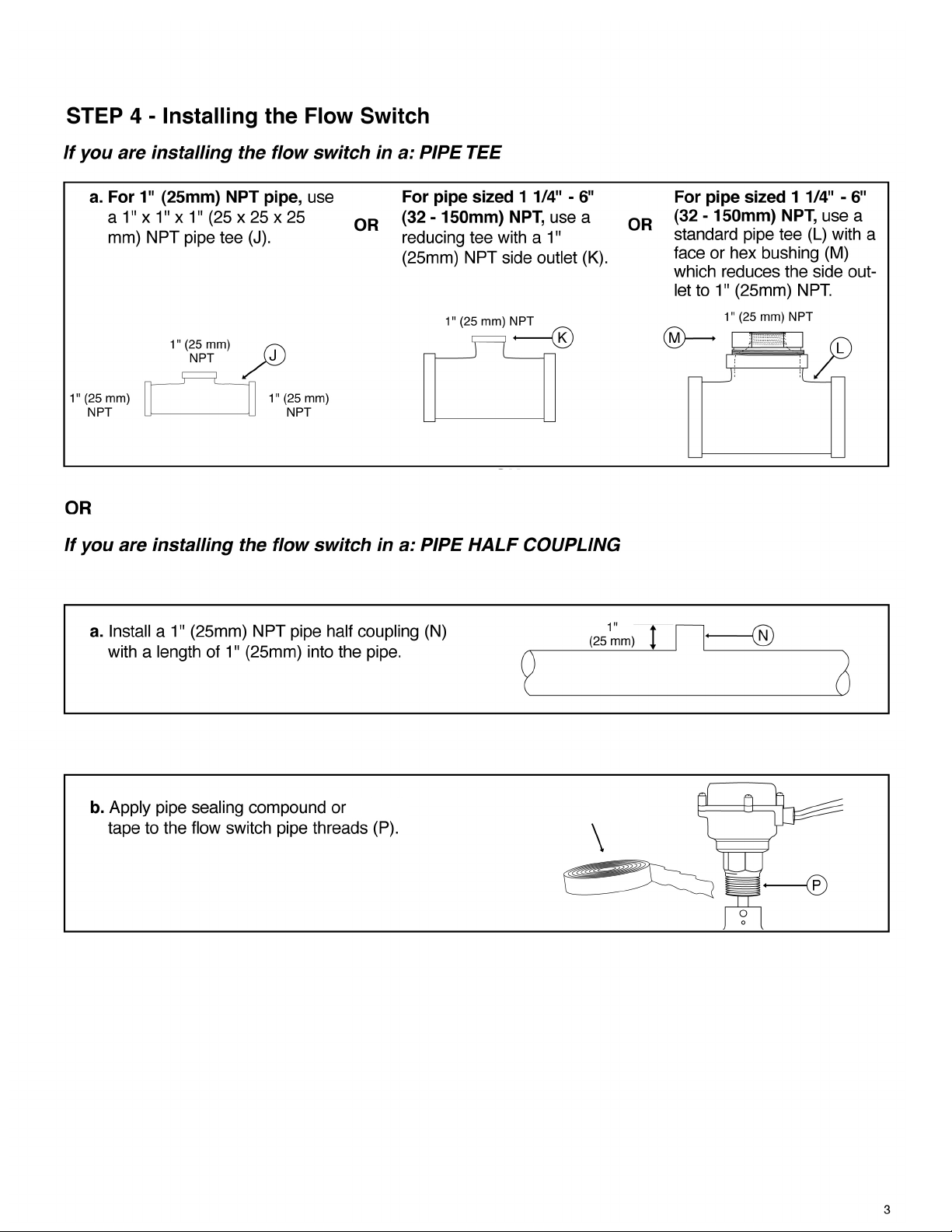

f. Insert the pipe (X) into the appropriate elec-

trical junction box (CC) and secure it.

CC

X

g. Based on the mode of operation (Flow or No Flow)

required for your application, complete the appropriate corresponding step (g.1 or g.2).

g.1.

For FLOW Mode of Operation

If the flow switch will be used to actuate a signal,

alarm, or other device when flow occurs, connect the

yellow flow switch wire (DD) to the appropriate wire

from that device (EE). Cap with a wire nut and seal

with electrical tape.

If the flow switch will also be used to actuate another

device when no flow occurs, connect the blue flow

switch wire (FF) to the appropriate wire from that

device (GG). Otherwise, cap the blue wire (FF)

with a wire nut and seal with electrical tape.

FF

blue

GG

DD

yellow

EE

COMMON

NORMALLY

OPEN

NORMALLY

CLOSED

Page 6

h. Connect the red flow switch wire (HH) to the

“Hot” power supply wire (JJ). Cap with a wire

nut and seal with electrical tape.

HH

red

JJ

“Hot”

i. Cover and properly secure the electrical

junction box (CC).

CC

a. Turn on the electrical power to the flow switch.

Initiate flow through the flow switch.

OFF

ON

b. Observe the device being activated by the flow switch, or measure the flow rate

to determine if the flow switch is activating when desired. If the flow switch isn ’t

activating when desired, follow Step 7 to adjust the sensitivity .

STEP 6 - Testing

6

For all installations

STEP 5 - continued

g.2. For NO FLOW Mode of Operation

If the flow switch will be used to actuate a signal,

alarm, or other device when no flow occurs, connect

the blue flow switch wire (FF) to the appropriate wire

from that device (EE). Cap with a wire nut and seal

with electrical tape.

If the flow switch will also be used to actuate another

device when flow occurs, connect the yellow flow

switch wire (DD) to the appropriate wire from that

device (GG). Otherwise, cap the yellow wire (DD)

with a wire nut and seal with electrical tape.

FF

blue

GG

DD

yellow

EE

Page 7

OFF

ON

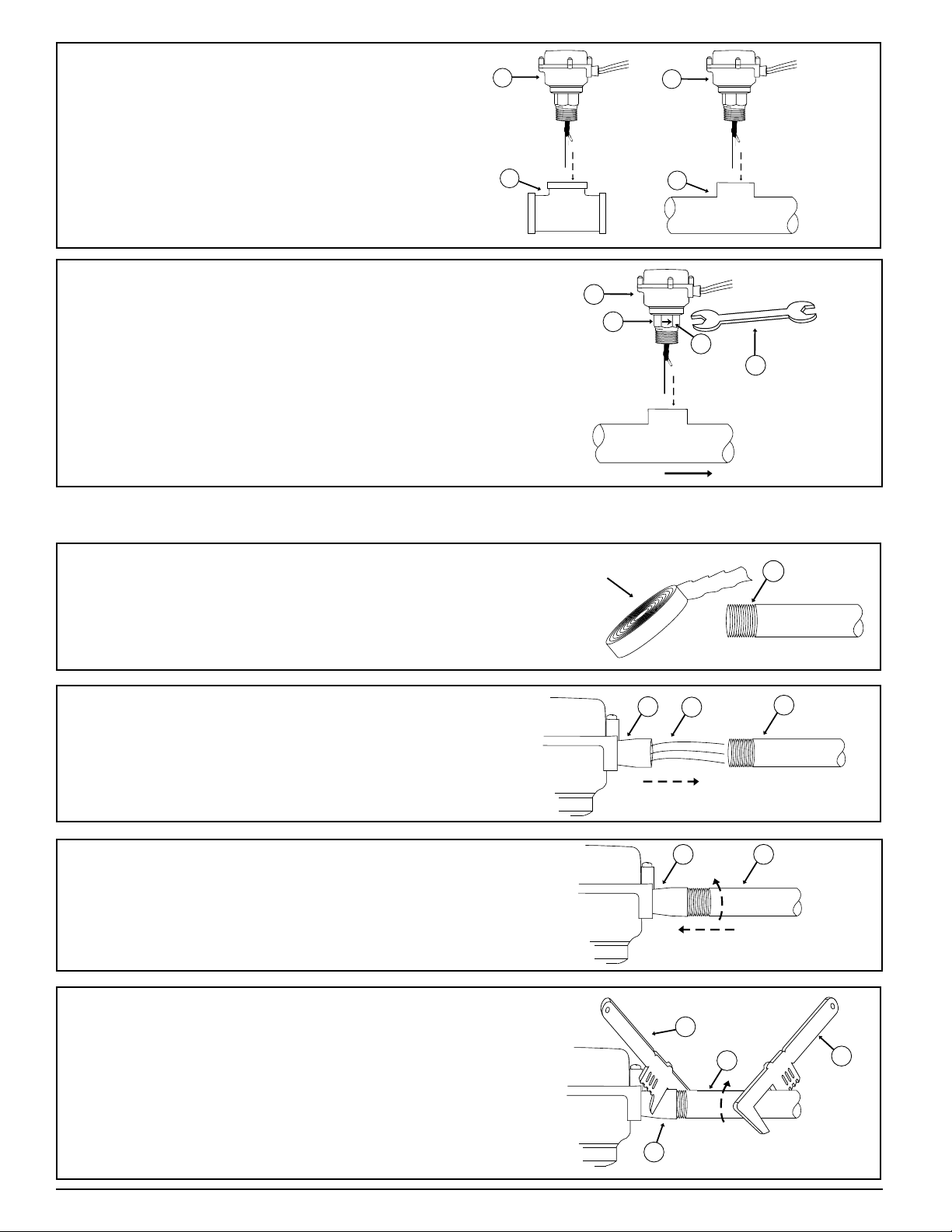

a. Disconnect the electrical power to the flow switch.

STEP 7 - Adjusting the Flow Rate (only necessary if operation

above minimum flow velocities is required)

• To prevent electrical shock, turn off the electrical power before making electrical connections.

• To prevent electrocution, when the electrical power is connected to the flow switch, do not

touch the terminals, or the red, blue or yellow flow switch wires.

Failure to follow this warning could cause property damage, personal injury or death.

!

WARNING

7

KK

LL x 4

MM

b. Using a flathead screwdriver (KK), unscrew the four (4)

cover screws (LL) and remove the cover (MM).

NN

COMMON

NORMALLY

OPEN

NORMALLY

CLOSED

c. Using a flathead screwdriver, turn the adjusting

screw (NN) several turns clockwise.

LL x 4

MM

S

d. Place the cover (MM) on the flow switch (S)

and insert the four (4) cover screws (LL).

PP

LL x 4

e. Using a torque screwdriver (PP), tighten the four (4)

cover screws (LL) to a torque of 10 lb. •in (1.13 N•m).

Page 8

Xylem Inc.

8200 N. Austin Avenue

Morton Grove, Illinois 60053

Phone: (847) 966-3700

Fax: (847) 965-8379

www.xyleminc.com/brands/mcdonnellmiller

McDonnell & Miller is a trademark of Xylem Inc. or one of its subsidiaries.

Loading...

Loading...