SenTix® ORP 900

ORP electrode

ba75845e01 08/2009

Operating manual

SenTix

Note

The latest version of the present operating manual can be found on the

Internet under www.WTW.com.

12

Copyright © Weilheim 2009, WTW GmbH

Reprinting - even as excerpts - is only allowed with the explicit written

authorization of WTW GmbH, Weilheim.

Printed in Germany.

ba75845e01 08/2009

SenTix General information

General information

Automatic sensor

recognition

The sensor electronics with the stored sensor data is in the connecting head

of the electrode. The data include, among other things, the sensor type and

series number. The data is recalled by the meter when the sensor is

connected and is used for measurement and for measured value documentation.

The digital transmission technique guarantees the failure-free communication with the meter even with long connection cables. If the sensor firmware

is enhanced by WTW, it can be updated via the meter.

Technical data

General data Reference electrolyte 3 mol/l KCl, Ag+free

Junction Ceramic

Measurement and

application

characteristics

Electrode material and

shape

mV measuring range - 1250.0 ... + 1250.0

Allowed temperature range 0 ... 100 °C (32 ... 212 ° F)

Typical application Laboratory

Platinum / circle

Shaft dimensions,

material, electrical

connection

Connection cable Length 1.5 m

Accuracy of the

IDS measuring

technique

Shaft length 120 mm

Shaft diameter 12 mm

Shaft material Glass

Combination electrode con-

nection

Meter connection Digital plug

Diameter 4.3 mm

Smallest allowed

bend radius

Plug type Socket, 4 pins

Measured parameter Accuracy (± 1 digit)

U [mV] ± 0.2

Fixed cable

Fixed installation: 20 mm

Flexible use: 60 mm

ba75845e01 08/2009

13

Commissioning, measuring, checking SenTix

Refilling

opening

Commissioning, measuring, checking

Note

For ORP electrodes with platinum electrode, please follow the instructions in

Abschnitt A

Commissioning Prepare the electrode for measuring as follows:

z Open the refilling opening for the reference electrolyte solution. Depend-

ing on the model, the stopper of the refilling opening is an elastomer stopper or a slider.

The refilling opening must always be open during measurement!

CTIVATING PLATINUM ELECTRODES.

General rules for

measuring

z Remove the watering cap from the electrode tip. Possible salt deposits in

the area of the watering cap do not affect the measuring characteristics

and can easily be removed with deionized water.

Note

Please keep the watering cap. It is required for the electrode to be stored.

Always keep the watering cap clean.

z Connect the combination electrode to the meter.

z Measure with the electrode according to the operating manual of the meter

and observe the following rules while doing so:

z Make sure the refilling opening for the reference electrolyte solution is

open.

z Avoid the carryover of sample solution from one measurement to the next

as follows:

– Shortly rinse the sample beakers with the solution the beakers are to

be filled with next.

– Between measurements, rinse the electrode with the solution that fol-

lows. Alternatively, you can also rinse the electrode with deionized water and then carefully dab it dry.

z Immerse the electrode in the solution in a vertical or slightly tilted position.

14

z Make sure the immersion depth is correct. The junction must be complete-

ly submersed in the solution. The junction is in the area of the bottom end

of the shaft (see arrow).

ba75845e01 08/2009

SenTix Commissioning, measuring, checking

Conversion to

normal hydrogen

electrode

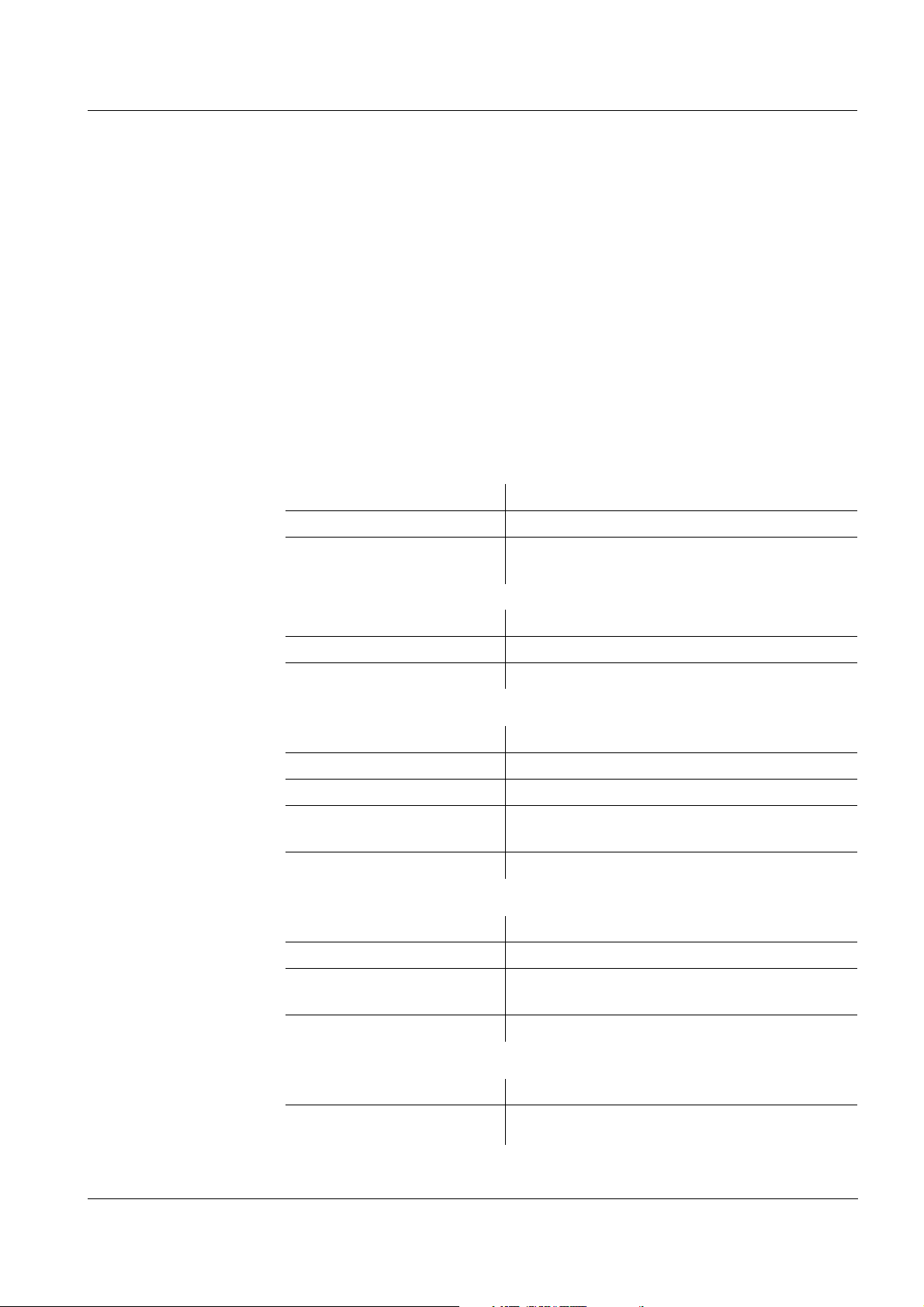

T (°C) T (°F) U

0 32 +224 35 95 +200

SenTix

®

ORP 900

At the same time, the level of the reference electrolyte must be at least 2

cm above the level of the solution.

U

= U

H

with: U

Meas

H

U

Meas

U

Ref

+ U

Ref

= ORP, referring to the normal hydrogen electrode

= Measured ORP

= Voltage of the reference system compared to the normal

hydrogen electrode

U

is temperature dependent and can be taken from the following table (see

Ref

also DIN 38404-6):

SenTix

[mV] T (°C) T (°F) U

Ref

®

ORP 900 SenTix® ORP 900

Ref

[mV]

5 41 +221 40 104 +196

10 50 +217 45 113 +192

15 59 +214 50 122 +188

20 68 +211 55 131 +184

25 77 +207 60 140 +180

30 86 +203

ba75845e01 08/2009

15

Aging SenTix

Storage

During short

measuring breaks

Overnight or

longer

Immerse the electrode in the reference electrolyte with the refilling opening

open.

Electrode Reference electrolyte WTW model

(see page 19)

SenTix

Prior to the next measurement, shortly rinse the electrode with the test

sample or deionized water.

Insert the clean electrode into the watering cap filled with reference

electrolyte and shut the refilling opening.

Note

During longer storing periods, salt sediments may develop on the watering

cap. They do not affect the measuring characteristics and can easily be removed with deionized water when the electrode is put into operation again.

®

ORP 900 3 mol/l KCl, Ag+free KCl-250 (250 ml)

Aging

Every ORP electrode undergoes a natural aging process. Extreme operating

conditions can considerably shorten the lifetime of the electrode. These are:

z Strong acids or lyes, hydrofluoric acid, organic solvents, oils, fats, bro-

mides, sulfides, iodides, proteins

z High temperatures

z High changes in pH and temperature.

The warranty does not cover failure caused by measuring conditions and

mechanical damage.

16

ba75845e01 08/2009

SenTix Aging

KCl-250

Maintenance and cleaning

During operation, a small amount of reference electrolyte leaks through the

junction from the electrode into the test sample. If the level of reference

electrolyte becomes too low with time, refill it through the refilling opening.

Refilling the

reference

electrolyte

Refilling is very easy using a dropping bottle. Proceed as follows:

z Cut off the tip of the dropping bottle at a right angle until the opening in the

tip can be seen

z Open the refilling opening of the electrode

z Press the tip of the dropping bottle into the refilling opening while turning

it slightly

z Pump several small quantities of the reference electrolyte into the stem

using the dropper bottle

z Pull the dropping bottle out of the refilling opening while turning it slightly

as necessary.

ba75845e01 08/2009

17

Activating platinum electrodes SenTix

Cleaning Remove water-soluble contamination by rinsing with deionized water. Re-

move other contamination as follows:

Contamination Cleaning procedure

Fat and oil Rinse with water containing household wash-

ing-up liquid

Lime and hydroxide deposits Rinse with citric acid (10 % by weight)

Protein Immerse in pepsin cleaning solution PEP/pH

for approx. 1 hour.

Note:

Make sure the level of the reference

electrolyte is above that of the cleaning solution.

After cleaning Rinse the electrode with deionized water.

First-time

activation during

installation and as

required

Activation during

very long set-up

times

Activating platinum electrodes

For first-time activation use the activation powder from the SORT/RH reagent

set (component of the SORT/RH reagent set). Immerse the moist (but not

dripping) platinum electrode into the activation powder and rotate the

electrode several times in the powder. Then remove the activation powder

under flowing water with a soft brush (e.g. toothbrush).

When changing from oxidizing to reducing test solutions and vice versa this

can result in set-up times that can take significantly more than an hour. In this

case pretreatment (activation) of the platinum surface can shorten the set-up

time. The type of pretreatment (reducing or oxidizing) is based on the pH value and the ORP voltage (U

timated for the first measurement.

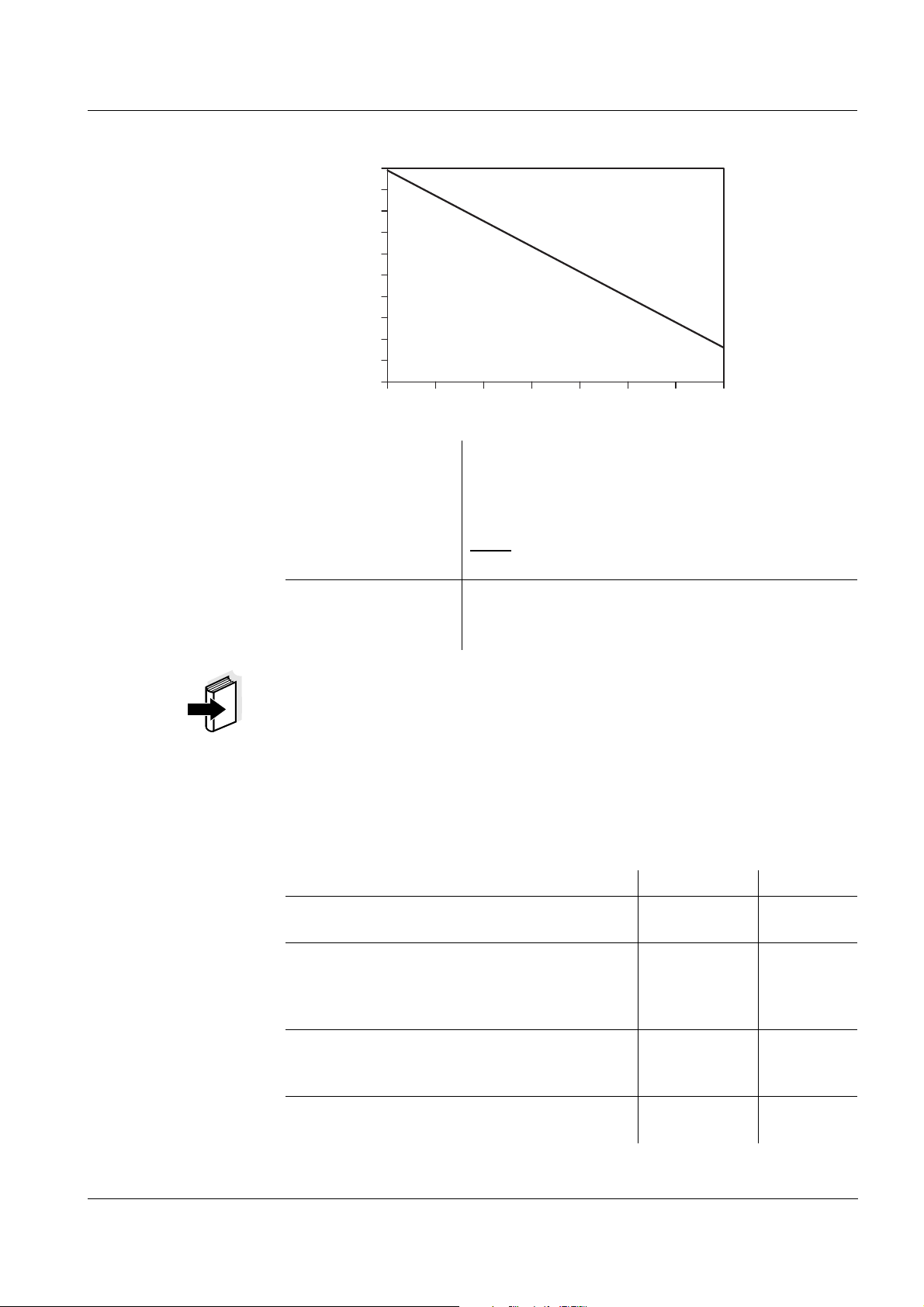

The type of pretreatment can then be determined using the following diagram

where U

is based on the normal hydrogen electrode:

H

) of the test solution where the latter must be es-

H

18

ba75845e01 08/2009

SenTix Wear parts and accessories

1000

800

600

400

200

20481012146

0

pH value

U

H

in mV

oxidizing pretreatment

reducing pretreatment

Oxidizing pretreatment

Immerse the platinum electrode for two to three

days in a sulfuric acid chlorine solution. Chlorine

powder for producing the solution is included in the

SORT/RH reagent set.

Note:

The diaphragm must not be immersed in the

chlorine solution!

Reducing pretreatment

When the electrode is ready for the test immerse it

in the RH 28 ORP buffer solution and wait for a stable measured value.

Note

Detailed information on activating platinum electrodes, such as how to produce the chlorine solution, is given in the WTW application report entitled R

GENERATING ORP ELECTRODES. The application report is included in the

SORT/RH reagent set.

Wear parts and accessories

Description Model Order no.

Reference electrolyte solution 3 mol/l KCl,

+

Ag

free (250 ml)

Reagent set for regenerating ORP platinum

electrodes

,consisting of 10 g activation powder and 30 g

chlorine powder

ORP buffer solution for checking ORP electrodes

= 427 mV, bottle of 250 ml

U

H

Pepsin cleaning solution,

3 bottles of 250 ml each

KCl-250 109 705

SORT/RH 109 730

RH 28 109 740

PEP/pH 109 648

E-

ba75845e01 08/2009

19

Wear parts and accessories SenTix

20

ba75845e01 08/2009

Loading...

Loading...