INSTRUCTION MANUAL

MM-284D

Operation

The Ser

ies PSE-800 probe type LWCO’s provide

protection against low water conditions for residential

and commercial steam boiler applications. The control

uses patented technology to monitor changes in

water conductivity. When defined parameters are

exceeded, the new PSE-800 makes a decision to

shut the burner off based on the volatility/variability

SPECIFICA

A

utomatic reset after power outage

All models include a provision for adding an alarm or automatic

water feeder.

30 second Delay on Make (DOM)

10 second Delay on Break (DOB)

Contr

T

T

Humidity: 85% (non-condensing)

ol Unit

emperature Ratings:

emperature:

Storage: -40˚F to 135˚F (-40˚C to 57˚C)

Ambient: 32 F to 120 F (0 C to 4 C)

TIONS

oo

o

o

9

of the resistance readings. This new patented technology

provides the best protection possible without turning

off the boiler unless a low water condition exists. As

an added measure of safety, the control will turn off

the boiler if it recognizes an out-of-water condition

when the sensitivity threshold is exceeded.

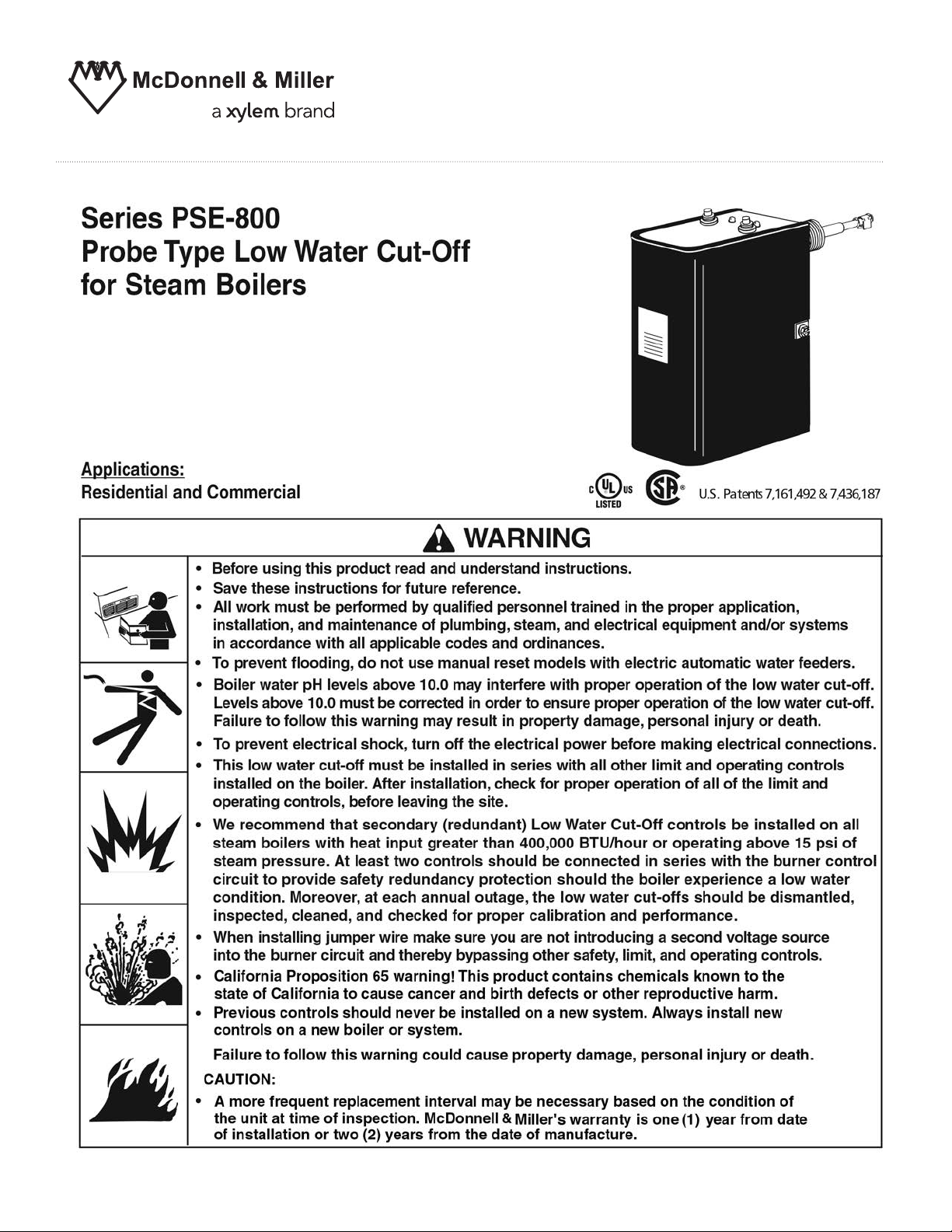

Green

(Power On)

Red

(Low Water)

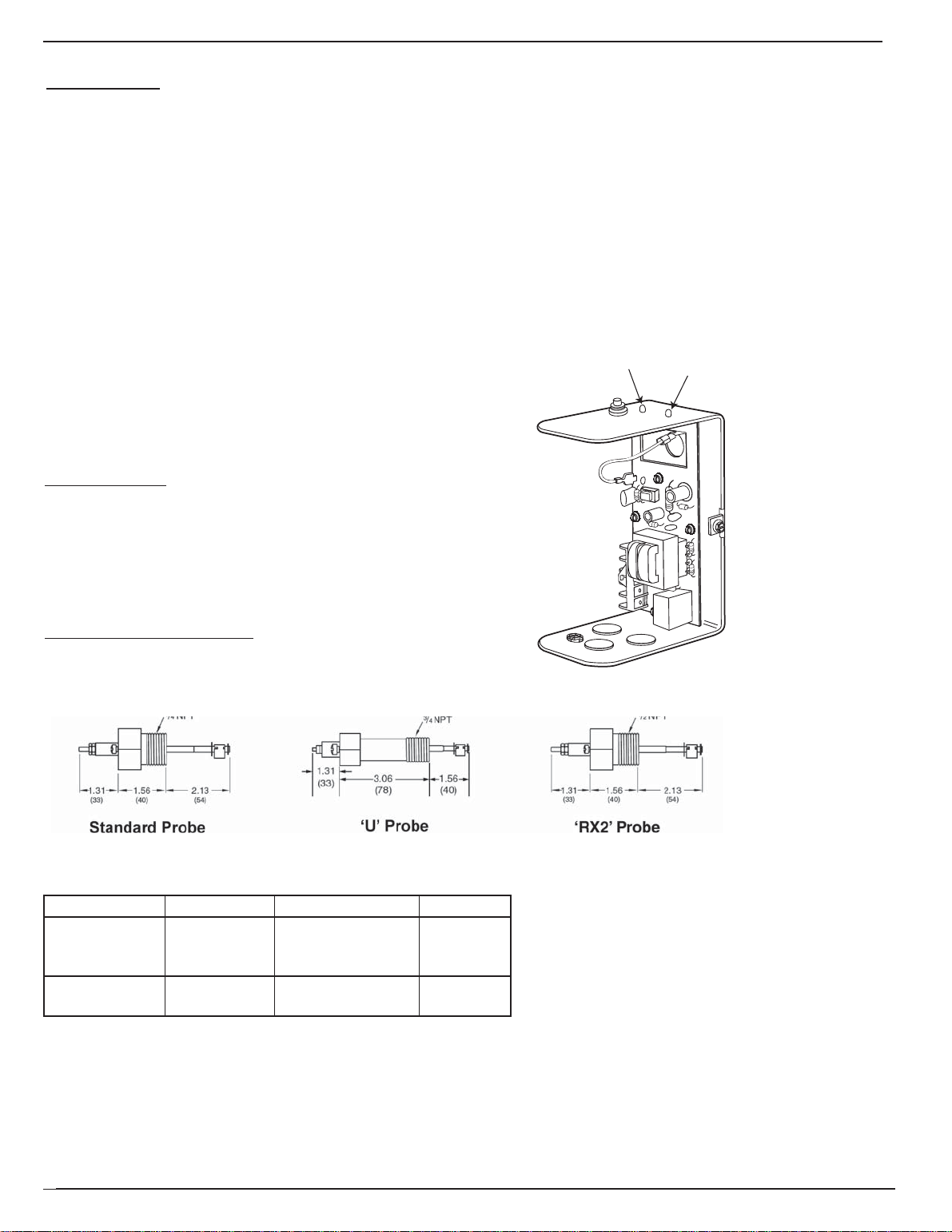

obe Specifications

Pr

Maxim

Pr

HZ: 50/60

Contr

1.7VA @ 24VAC

3.6VA @ 120VAC

Electrical Enclosure Rating: NEMA 1 General Purpose

um Steam Pressure: 15 psi (1.0 kg/cm

obe Sensitivity: 7,000 ohm

Model

PSE-802-24

PSE-802-U-24

PSE-802-RX2-24

PSE-801-120

PSE-801-U-120

ol Power Consumption:

Control Voltage Motor Switch Rating

24 VAC N/A 50VA

120 VAC 7.5 FLA 43.2 LRA 125VA

2

)

Pilot Rating

2

INST

T

ALLATION

OOLS NEEDED:

One (1) flathead screwdriver, and one (1) pipe wrench.

For Remote Installations a level and power drill will be required.

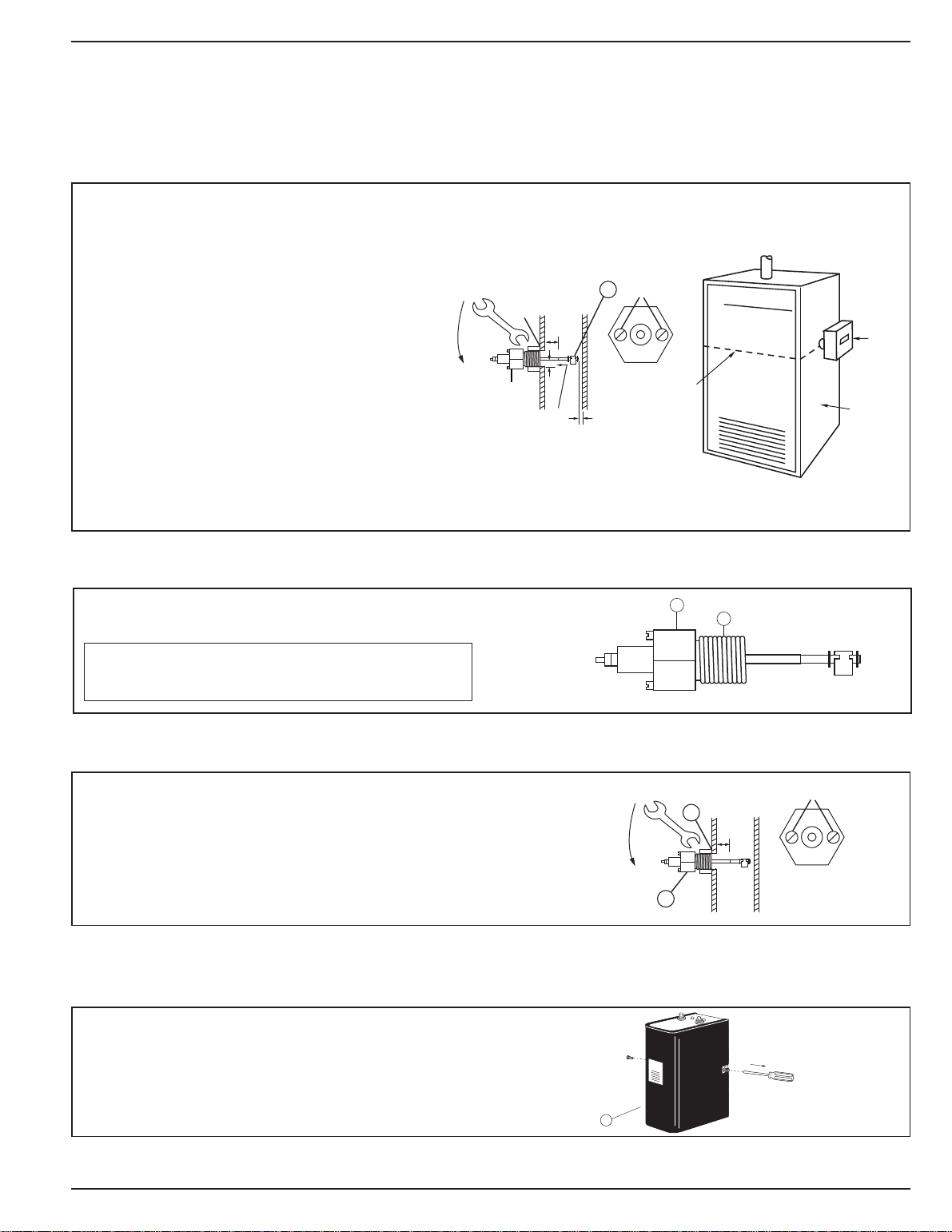

STEP 1 - Locating and Installing the Pr

a. Based on the f

For all Applications:

1. Refer to boiler manufacturers instructions to

determine suitable tapping for the probe.

2. Make sure probe is installed above minimum

safe water line as determined by the boiler

manufacturer.

3. Make sure that ends and sides of the probe

are at least 1/4” (6.4mm) from all internal

metal surfaces.

4. sure the probe is positioned to shut off

Make

the boiler before the water level falls below

the lowest visible part of the gauge

b. Sparingly, apply pipe sealant to the ext

threads (D) of the (A).

ollowing criteria locate a suitable position for the probe:

glass.

ernal

probe

obe

4

A

1/4"

3

(6mm)

1

1/4"

(6mm)

Minimum Safe

Water Level

(May vary

by boiler

manufacturer)

A

D

Control

Steam

Boiler

Probe

IMPORTANT: Do not use tape. Only use

04&%

pipe sealant.

c. Using a wrench, tighten the probe (A) into the

tapped connection (E) that w

as determined in Step

1 of these instructions. Tighten to 47 ft•lb (64 N•m).

NOTE: Be sure to align the probe so that the

mounting scre

STEP 2 - Installing Contr

ws (F) are in a horizontal position.

ol Box

a. Using a flathead screwdriver, loosen the two (2) screws

that secure the cover (G) to the control about 1-1/2

turns and remove cover.

F

E

A

G

3

STEP 4 - Contr

or all wire connections to the terminal block (M).

d. F

ol Wiring (continued)

1.Strip about 1/3" (8.5 mm) of insulation from the wire.

2.Loosen the terminal screw (N) but DO NOT

REMOVE. Move the wire clamping plate (P) back until the

plate touches the back side of the screw head.

3.Insert the stripped end of the wire under the wire clamping

plate (P) and securely tighten the terminal screw (N).

PSE-802 using Harness Connection

Connect plug (A) of wir

Wiring harness is pr

Do not use f

receptacle solder connections.

Check to make sure factory supplied jumper is installed

between terminals (H) and (C).

ing harness to receptacle (B).

TE

NO

ovided by boiler manufacturer.

UTION

CA

!

orce to insert plug. This may damage

N

P

M

B

A

PSE-802 using

Connect neutral wire (A) of 24 volt circuit to terminal (N).

•

Terminal Connections

• Connect hot wire (B) of 24 volt circuit to terminal (H).

• Connect wire (C) from beginning of Burner circuit

(thermostat, gas valve, limits, etc.) to terminal (B).

• Connect wire (D) from end of Burner circuit to terminal (N).

• Make sure factory provided jumper bar is connected to

terminal (H) and (C).

PSE-801 with 120

•

Connect Hot wire (A) of 120 volt circuit to terminal (H).

Volt Burner Circuit

• Connect Neutral wire (B) of 120 volt circuit to terminal (N).

• Connect wire (C) from beginning of Burner circuit (thermostat,

gas valve, limits, etc.) to terminal (B).

• Connect wire (D) from end of Burner circuit to terminal (N).

• Connect jumper wire (E) to terminals (H) and (C).

PSE-801 with 24

•

Connect hot wire (A) of 120 volt circuit to terminal (H) and

Volt Burner Circuit

transformer terminal (L1).

• Connect neutral wire ‘B’ of 120 volt circuit to terminal (N) and

transformer terminal (L2).

• Connect wire (C) from beginning of Burner circuit

(thermostat, gas valve, limits, etc.) to terminal (B).

• Connect wire (D) from end of Burner circuit to transformer

terminal (T2).

• Connect wire (E) from transformer terminal (T1) to

terminal (C).

120 V

CIRCUIT

OLT

120 V

CIRCUIT

24 V

OLT

POWER

CIRCUIT

OLT

B

B

A

H

N

A

H

N

E

B

JUMPER

BAR

N H C W B

A

D

N H C W B

B

D

N H C W B

1

L

2

L

24 V

TRANSFORMER

(BY OTHERS)

NH

OLT

B

URNER

CIRCUIT

URNER

B

CIRCUIT

1

T

B

T

2

CIRCUIT

E

E

URNER

D

C

C

C

INST

ALLATION COMPLETE

6

Xylem Inc.

8200 N. Austin Avenue

Morton Grove, Illinois 60053

Phone: (847) 966-3700

Fax: (847) 965-8379

www.mcdonnellmiller.com

McDonnell & Miller is a trademark of Xylem Inc. or one of its subsidiaries.

© 2014 Xylem Inc. MM-284D January 2014 Part No. 211630

Loading...

Loading...