Replacement Snap Switch Assembly

SWA-150S SWA-158S

SWA-150S-MD SWA-159S

For Series 150S and 157S Low

Water Cut-Off/Pump Controllers

(All Models)

INSTRUCTION MANUAL

MM-235E

Replacement Switch Assembly

WARNING

!

CAUTION

WARNING

• Before using this product read and understand instructions.

• Save these instructions for future reference.

• All work must be performed by qualified personnel trained in the proper application, installation, and maintenance of plumbing, steam, and electrical equipment and/or systems in

accordance with all applicable codes and ordinances.

• To prevent serious burns, the boiler must be cooled to 80˚F (27˚C) and the pressure must be

0 psi (0 bar) before servicing.

• To prevent electrical shock, turn off all sources of electrical power before servicing unit.

• This low water cut-off must be installed in series with all other limit and operating controls

installed on the boiler. After servicing unit, check for proper operation of all of the limit

and operating controls before leaving the site.

• We recommend that secondary (redundant) Low Water Cut-Off controls be installed on all

steam boilers with heat input greater than 400,000 BTU/hour or operating above 15 psi of

steam pressure. At least two controls should be connected in series with the burner

control circuit to provide safety redundancy protection should the boiler experience a

low-water condition. Moreover, at each annual outage, the low water cutoffs should be

dismantled, inspected, cleaned, and checked for proper calibration and performance.

• To prevent a fire, do not use this low water cut-off to switch currents over 7.4A, 1/3 Hp at

120 VAC or 3.7A, 1/3 Hp at 240 VAC, unless a starter or relay is used in conjunction with it.

Failure to follow this warning could cause property damage, personal injury or death.

For Model

Repl. Switch

Model & Part No.

150S

150S-B

150S-M*

150S-B-M*

150S-M-MD*

150S-B-M-MD*

157S

157S-A

157S-P

157S-R

157S-RL

157S-M*

157S-A-M*

157S-R-M*

157S-RB-M*

157S-RL-M*

157S-M-MD*

157S-M-RB-P-MD*

150S-MD

150S-B-MD

157S-MD

157S-P-MD

157S-R-MD

157S-RB-MD

157S-RB-P-MD

157S-RD-MD

157S-RLS-MD

158S

158S-M*

158S-M-MD*

159S

SWA-150S

310462

SWA-150S-MD

310464

SWA-158S

310468

SWA-159S

310470

2

Verify that you have the Correct Replacement Switch Assembly Model

IMPORTANT:

• Installation of an incorrect switch assembly could cause damage to the boiler and/or boiler system.

• Modification of the switch assembly before or after installation could cause damage to the boiler

and/or boiler system.

• Series 150S and 157S Replacement Snap Switch Assemblies are not interchangeable with Series 150 and 157 mercury

switch controls.

• Replacement Switch Assemblies are not interchangeable and must be selected and ordered for the specific control

model in which it will be installed.

Model SWA-150S

P/N 310462

Model SWA-159S

P/N 310470

September 2003 (03J)

and Older

NOTE: Models with (*) will require head replacement

if manufactured before September 2003 (03J)

October 2003 (03K)

and Newer

Model SWA-158S

P/N 310468

Model SWA-150S-MD

P/N 310464

Manual Reset Models

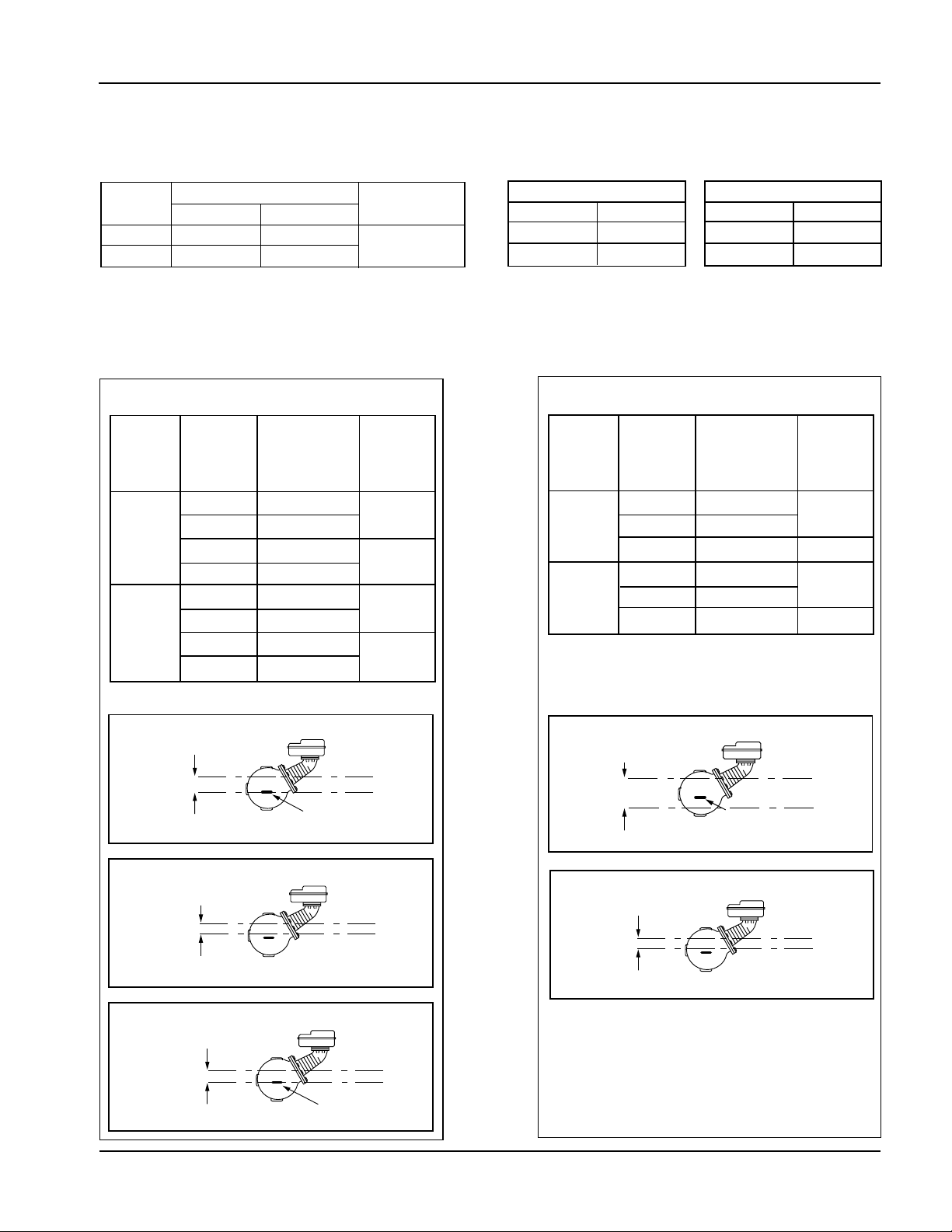

Pump Circuit Rating (Amperes)

Voltage Full Load Locked Rotor Pilot Duty

120 VAC 7.4 44.4

345 VA at

240 VAC 3.7 22.2

120 or 240 VAC

Approximate

Distance Above

Cast Line Differential

Setting In. (mm) In. (mm)

Pump Off

15

/16 (24)

5

/16 (8)

Pump On

5

/8 (16)

Burner On

5

/8 (16)

3

/8 (16)

Burner Off

1

/4 (6.4)

Pump Off 13/8 (41)

3

/4 (19)

Pump On

5

/8 (16)

Burner On

7

/8 (22)

7

/8 (22)

Burner Off 0 (0)

BURNER

“CUT-OFF LEVEL”

AT CAST LINE

BURNER OFF

BURNER ON

7

/8"

DIFFERENTIAL

(22mm)

PUMP

OFF

BURNER

OFF

BURNER

“CUT-OFF LEVEL”

AT CAST LINE

NORMAL BOILER

WATER LINE

1

3

/8"

DIFFERENTIAL

(35mm)

PUMP OFF

PUMP ON

3

/4"

DIFFERENTIAL

(19mm)

PUMP OFF

PUMP ON

3

/4"

DIFFERENTIAL

(19mm)

PUMP

OFF

BURNER

OFF

NORMAL BOILER

WATER LINE

1

13

/16"

DIFFERENTIAL

(46mm)

BURNER CUT-OFF LEVEL

3

/8

"

(9.5mm) BELOW

CAST LINE

OPERATION

3

Maximum Pressure: 150 psi (10.5 kg/cm2)

Electrical Ratings

Settings and Differential Pressures

Series 150S and 157S

150 psi (10.5 kg/cm

2

) Levels

150 psi (10.5 kg/cm

2

) Levels

0 psi

(0 kg/

cm2)

150 psi

(10.5 kg/

cm

2

)

Approximate

Distance Above

Cast Line Differential

Setting In. (mm) In. (mm)

Pump Off

15

/16 (24)

3

/8(16)

Pump On

9

/16 (14)

Burner Off 0 (0) N/A

Pump Off 17/16 (37)

3

/4 (19)

Pump On 11/16 (17)

Burner Off -

3/8 (-16)

N/A

Model 150S-MD and 157S-MD

0 psi

(0 kg/

cm

2

)

150 psi

(10.5 kg/

cm

2

)

Pressure

Pressure

Alarm Circuit Rating

Voltage Amps

120 VAC 1

240 VAC 1/2

Motor Horsepower

Voltage Hp

120 VAC

1/3

240 VAC 1/3

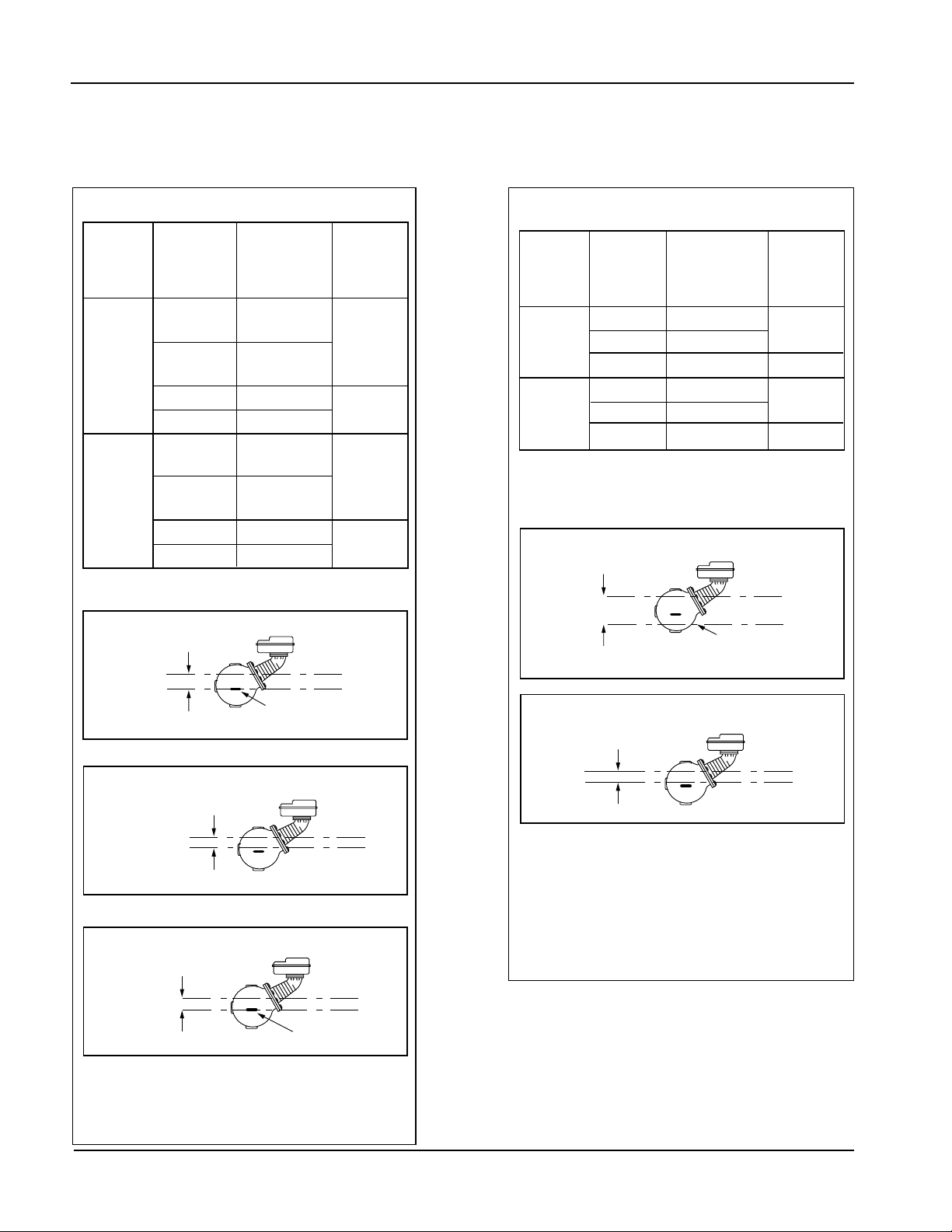

4

Approximate

Distance Above

Cast Line Differential

Setting In. (mm) In. (mm)

Motorized

15

/16 (24)

Valve Closed

5

/16 (8)

Motorized

5

/8 (16)

Valve Open

Burner On

5

/8 (16)

3

/8 (16)

Burner Off

1

/4 (6.4)

Motorized 13/8 (41)

3

/4 (19)

Valve Closed

Motorized

5

/8 (16)

Valve Open

Burner On

7

/8 (22)

7

/8(22)

Burner Off 0 (0)

BURNER

“CUT-OFF LEVEL”

AT CAST LINE

BURNER OFF

BURNER ON

7

/8"

DIFFERENTIAL

(22mm)

MOTORIZED

VALV E

CLOSED

BURNER

OFF

BURNER

“CUT-OFF LEVEL”

AT CAST LINE

NORMAL BOILER

WATER LINE

1

3

/8"

DIFFERENTIAL

(35mm)

MOTORIZED

VALV E

CLOSED

MOTORIZED

VALV E

OPEN

3

/4"

DIFFERENTIAL

(19mm)

NOTE: Due to the slower operation of some

motorized valves, complete valve opening

or closing will occur at slightly different levels than indicated above.

Model 158S

150 psi (10.5 kg/cm

2

) Levels

0 psi

(0 kg/

cm

2

)

150 psi

(10.5 kg/

cm

2

)

Pressure

Operation

Settings and Differential Pressures (continued)

150 psi

(10.5 kg/

cm

2

)

MOTORIZED

VALUE

OPEN

CLOSED

3

/4"

DIFFERENTIAL

(19mm)

MOTORIZED

VALV E

CLOSED

BURNER

OFF

NORMAL BOILER

WATER LINE

1

13

/16"

DIFFERENTIAL

(46mm)

BURNER CUT-OFF LEVEL

3

/8

"

(9.5mm) BELOW

CAST LINE

Approximate

Distance Above

Cast Line Differential

Setting In. (mm) In. (mm)

Pump Off

15

/16 (24)

3

/8(16)

Pump On

9

/16 (14)

Burner Off 0 (0) N/A

Pump Off 1

7

/16 (37)

3

/4 (19)

Pump On 11/16 (17)

Burner Off - 3/8 (-16)

N/A

Model 158S-MD

0 psi

(0 kg/

cm

2

)

Pressure

150 psi (10.5 kg/cm2) Levels

NOTE: Due to the slower operation of some

motorized valves, complete valve opening

or closing will occur at slightly different levels than indicated above.

5

PUMP #1

OFF

PUMP #1

ON

3

/4"

DIFFERENTIAL

(19mm)

PUMP #2 ON

AT CAST LINE

PUMP #2

ON

PUMP #2

OFF

7

/8"

DIFFERENTIAL

(22mm)

PUMP #1

OFF

PUMP #2

ON

PUMP #2 ON

AT CAST LINE

NORMAL BOILER

WATER LINE

1

3

/8"

DIFFERENTIAL

(35mm)

150 psi (10.5 kg/cm2) Levels

Approximate

Distance Above

Cast Line Differential

Setting In. (mm) In. (mm)

Pump #1 Off15/16 (24)

5

/16 (8)

Pump #1 On5/8 (16)

Pump #2 Off5/8 (16)

3

/8 (16)

Pump #2 On1/4 (6.4)

Pump #1 Off 13/8 (41)

3

/4 (19)

Pump #1 On5/8 (16)

Pump #2 Off7/8 (22)

7

/8 (22)

Pump #2 On

0 (0)

Model 159S

0 psi

(0 kg/

cm2)

150 psi

(10.5 kg/

cm

2

)

Pressure

Settings and Differential Pressures (continued)

Switch Level Ruler

Cut to actual size and attach

to piece of cardboard.

TOP

CUT HERE

3"

(76.2mm)

2"

(50.8mm)

1"

(25.4mm)

Casting

Cut-Off

Line

1"

(25.4mm)

PUMP

SWITCH

PUMP

CIRCUIT

TERMINALS

LOW WATER

CUT-OFF AND

ALARM SWITCH

ALARM

CIRCUIT

TERMINALS

LOW WATER

CUT-OFF

TERMINALS

6

3. Remove the cover (B).

4. Mark and remove the pump switch and

burner/alarm switch wires from terminal block.

1. Turn the boiler off.

A

2. Allow the boiler to cool to 80˚F (27˚C) and

release the boiler pressure to 0 psi (0 bar).

Drain water in the boiler to a level which is

below the float chamber (A).

INSTALLATION

SECTION 1 - Switch Bracket Replacement

• To prevent electrical shock, turn off the electrical power before making electrical connections.

• This low water cut-off must be installed in series with all other limit and operating controls installed on the

boiler. After installation, check for proper operation of all of the limit and operating controls, before leaving

the site.

Failure to follow this warning could cause electrical shock, an explosion and/or a fire, which could result in

property damage, personal injury or death.

!

WARNING

B

OFF

ON

Terminal Connection

Product Switch 1 2 3 4 5 6

150S/157S 2 Wire Blue Yellow

Pump

3 Wire Black White Red

Burner

158S 3 Wire Black White Red

Pump

3 Wire Black White Red

Burner

159S 2 Wire Blue Yellow

Pump

2 Wire Blue Yellow

Burner

Terminal Connection Reference Chart

7

C

D

5a. Locate the actuator assembly (C) and the two fillister head

screws (D) which secure it to the bearing of the control.

b. Clean the inspection lacquer out of the screw slots in the two fil-

lister head screws.

c. Remove the two screws holding the actuator assembly in place

using a flat head screwdriver. Remove actuator assembly and

place aside for reinstallation.

G

7a. Reattach the actuator assembly using the two fillister head

screws (G) and torque to 30 - 40 in. lb. (34.5 - 46 cm. kg.).

b. Apply a drop of the supplied adhesive to the threads of

each fillister head screw.

6a. Remove the two Torx®screws (E) holding the switch bracket

assembly in place using a flat head screwdriver or a Torx

®

T30 wrench.

b. Take the new switch bracket assembly out of the package

and place the bagged supplies to one side while discarding

the insert.

NOTE: Refer to the chart on page 2 to make sure you have

the proper switch bracket assembly for your control. The

switch bracket assemblies are not interchangeable.

c. Install the new switch bracket assembly (F) into the junction

box in the same orientation as the old switch bracket assembly (i.e. with arrows on the bracket pointing toward the terminal block).

d. Secure the new assembly with Torx

®

screws (E) and torque

to 80 - 140 in. lb. (92 - 161 cm. kg.).

9. Reattach the cover (H).

Proceed with normal operational checks of controls as described in Step 2 “Checking Switch Settings and

Adjusting Switch Setpoints at Operating Pressure”; or Section 3 “Checking Switch Settings at "0" Pressure”.

The pump or burner switch operating points should be within +/- 1/8" of those specified for your control.

H

SECTION 1 - Switch Bracket Replacement (continued)

E

F

8. Reconnect the pump switch and burner/ alarm switch wires

to terminal block as noted when disconnected and torque to

13 - 17 in. lb. ( 15 - 19.5 cm. kg.) (Refer to "Terminal

Connection Chart" on page 6 if unsure of proper switch to

terminal block wire connections).

Note:

Cover must be installed correctly as shown

8

INSTALLATION

SECTION 2 - Checking Switch Settings and Adjusting Switch Setpoints at

Operating Pressure

IMPORTANT: All switches have fixed differentials.

Adjustment of switches referred to in Step 2 and 3

are all based upon Pump Off and Burner Off setpoints. The Pump On and Burner On setpoints are

not adjustable.

We strongly recommend that you check the control at both the operating pressure and at 0 pressure. All boilers start at 0 psi regardless of the oper-

ating pressure.

The operating points will spread out as the pressure

goes up and shrink as the pressure goes down.

1. Cut out the "Switching Level Ruler" (page 5)

along the indicated lines.

RULER

I

LEVEL

2a. Hold the ruler against the side of the gauge glass in a position

so the “Cast Line” mark is on the same level as the Cast Line

on the float chamber of the control (I) (a carpenter's level should

be used to insure the cast line on the float chamber is

at the same level as the one on the ruler).

b. Once the ruler is properly positioned, tape it to the gauge glass.

3a. Bring boiler up to normal operating pressure and turn the

pump off.

b. Remove the cover (J).

J

(Not to Scale. Template

located on page 5).

2"

(50.8mm)

1"

(25.4mm)

1"

(25.4mm)

3"

(76.2mm)

Casting

Cut-Off

Line

BURNER

SWITCH

BURNER

SET SCREW

K

4b. If the cut-off point does not match the one

as shown in chart for the control (pages 3,

4, or 5) as measured on the "Switch Level

Ruler" dig the inspection lacquer out of the

socket in the set screw (K) above the burner

switch in the actuator assembly using an

awl.

c. Using an Allen wrench with a 5/64" hex, turn

the screw 1/4 turn:

- clockwise (if the “Burner Off” point is too

high when viewed from top)

- counterclockwise (if the “Burner Off” point

is too low when viewed from top)

- for manual reset units with date codes of

03K and newer, the set screw should be

turned opposite the above direction to

obtain desired results.

ADD ADHESIVE HERE

M

9

4d. Turn the pump back on, allowing the boiler

to fill with water.

e. Reset the burner switch (L) for manual

reset models once the pump shuts off.

BURNER

“CUT-OFF LEVEL”

AT CAST LINE

BURNER OFF

BURNER ON

4a. Slowly bring the boiler water level down to

the point at which the burner cuts off. If the

burner does not shut off automatically by the

time the water level reaches 3/8" (9.5mm)

below the cast line on the unit body, shut the

burner off manually.

4f. Repeat steps a. through d. as necessary to

match the Burner Off point specification for

your model.

g. Apply one drop of adhesive (furnished) to

the set screw threads (M) above the burner

switch in the actuator assembly.

4 - Setting the Operating Points of the Burner Switch

IMPORTANT: Where Pump On/Off and Burner On/Off are referenced in these instructions, Pump #1 On/Off

and Pump #2 Off/On should be substituted, respectively, for a 159S control, and Motorized Valve

Open/Closed can substitute for Pump On/Off for a 158S control.

L

NOTE

Manual reset units with date codes of 03K and newer require the cover to

be installed for proper operation of the manual reset mechanism.

PUMP

SWITCH

PUMP

SET SCREW

N

PUMP OFF

PUMP ON

BURNER

“CUT-OFF LEVEL”

AT CAST LINE

10

ADD ADHESIVE HERE

O

5b. If the Pump Off point does not match the one shown in chart for the

control (pages 3 and 4) and as measured on the "Switching Level

Ruler", dig the inspection lacquer out of the socket in the set screw

(N) above the pump switch in the actuator assembly using an awl.

c. Using an Allen wrench with a 5/64" hex, turn the screw 1/4 turn:

- clockwise (if the “Pump Off” point is too

high when viewed from top)

- counterclockwise (if the “Pump Off” point

is too low when viewed from top)

5d. Slowly drain the water in the boiler until the pump turns on.

Allow pump to fill the boiler and observe the point on the ruler

where the water level shuts off.

5e. Repeat steps 5a. through d. as necessary to match the

specified Pump Off point specification.

f. Apply one drop of adhesive (furnished) to the set screw threads

(O) above the pump switch in the actuator assembly.

PUMP OFF

PUMP ON

BURNER

“CUT-OFF LEVEL”

AT CAST LINE

5a. Slowly drain the water in the boiler until the

pump turns on. Allow pump to fill the boiler

and observe the point on the ruler where the

water level shuts off.

5 - Setting the Operating Points of the Pump Switch

IMPORTANT: Where Pump On/Off and Burner On/Off are referenced in these instructions, Pump #1 On/Off

and Pump #2 Off/On should be substituted, respectively, for a 159S control, and Motorized Valve

Open/Closed can substitute for Pump On/Off for a 158S control.

11

RULER

CAST

LINE

LEVEL

2. Hold the ruler against the side of the gauge glass in a position so

the Cast Line mark is on the same level as the cast line on the float

chamber of the control (a carpenter's level should be used to

insure the cast line on the float chamber is on the same plane as

the one on the marker).

3. Once the marker is properly positioned, tape it to the gauge glass.

PUMP OFF

PUMP ON

BURNER

“CUT-OFF LEVEL”

AT CAST LINE

4a. Drain the water level in the boiler until the pump turns on. Note the

level at which the pump turns on and then turns off. Verify that

pump settings are acceptable.

b. Turn the pump off.

BURNER

“CUT-OFF LEVEL”

AT CAST LINE

BURNER OFF

BURNER ON

5a. Drain the water level in the boiler until the burner turns off. Observe

the burner off point.

b. Turn the pump back on and observe the Burner On point as the

boiler fills with water. In the case of manual reset models, try resetting the burner switch as close as possible to the Burner On point

as shown in chart for the control and as measured on the switch

level ruler. Verify that burner settings are acceptable.

1. Find the "Switching Level Ruler" on page 5,

and cut it out along the indicated lines.

(Not to Scale. Template

located on page 5).

IMPORTANT: All switches have fixed differentials. Adjustment of switches referred to in Sections 2 and

3 are based upon Pump Off and Burner Off setpoints. The Pump On and Burner On setpoints are not

adjustable.

IMPORTANT: Where Pump On/Off and Burner On/Off are referenced in these instructions, Pump #1 On/Off

and Pump #2 Off/On should be substituted, respectively, for a 159S control, and Motorized Valve

Open/Closed can substitute for Pump On/Off for a 158S control.

7. Turn the boiler on.

O

FF

O

N

6. Re-attach the junction box cover (P).

J

INSTALLATION

SECTION 3 - Checking Switch Settings at 0 Pressure

2"

(50.8mm)

1"

(25.4mm)

1"

(25.4mm)

3"

(76.2mm)

Casting

Cut-Off

Line

NOTE

Manual reset units with date codes of 03K and newer require the cover to

be installed for proper operation of the manual reset mechanism.

Note:

Cover must be installed correctly as shown

MAINTENANCE

!

BLOW DOWN PROCEDURE:

SCHEDULE:

Blow down control as follows when boiler is

in operation.

• Daily if operating pressure is above 15 psi.

• Weekly if operating pressure is below 15 psi.

NOTE

More frequent blow-down may be necessary

due to dirty boiler water and/or local codes.

• Remove head assembly and inspect water

side components annually. Replace head

assembly if any of the internal components are

worn, corroded or damaged or if control no longer

operates properly.

• Inspect the float chamber and equalizing piping

annually. Remove all sediment and debris.

NOTE

The control may need to be inspected and

cleaned more frequently on systems where there

is the potential of excessive scale or sludge

build-up. This includes systems:

• With high raw water make-up

• With no condensate return

• With untreated boiler water

• Where significant changes have been

made to the boiler-water chemical

treatment process

• With oil in the boiler water

CAUTION

To prevent serious personal injury from steam

pipe blow down, connect a drain pipe to the

control opening to avoid exposure to steam

discharge.

Failure to follow this caution could cause

personal injury.

When blowing down a control at pressure, the blow

down valves should be opened slowly. The piping

needs to be warmed up and stagnant water in the

drain piping needs to be pushed out. Suddenly

opening a blow down valve causes steam to condense, which can create water hammer. Damage to

components can occur when water hammer occurs

due to improper blow down piping.

For these reasons, McDonnell & Miller recommends

a dual valve blow-down system for each control.

Blow down the control when the water in the boiler

is at its normal level and the burner is on.

NOTE: Refer to page 2 for switch operating points.

• Open upper valve (#1)

• Slowly open the lower valve (#2)

• Water in the sight glass should lower.

• As the water in the sight glass lowers, the

pump should turn on.

• As the water continues to lower in the sight

glass, the burner should turn off.

• Slowly close the lower valve (#2).

• Close the upper valve (#1)

• The water level in the sight glass should rise, first

turning on the burner and then turning off the pump.

NOTE: On manual reset models, the reset button

will need to be pressed after the water level has

been restored before the burner will operate.

Replace head mechanism every 5 years.

More frequent replacement may be required when

severe conditions exist.

Replacement parts are available from your local

authorized McDonnell & Miller Distributor.

The use of parts or components other than those

manufactured by McDonnell & Miller will void all

warranties and may affect the units compliance with

listings or regulating agencies.

Xylem Inc.

8200 N. Austin Avenue

Morton Grove, Illinois 60053

Phone: (847) 966-3700

Fax: (847) 965-8379

www.xyleminc.com/brands/mcdonnellmiller

McDonnell & Miller is a trademark of Xylem Inc. or one of its subsidiaries.

© 2012 Xylem Inc. MM-235E May 2012 Part No. 210369

NOTE

If this sequence of operation does not occur as

described, immediately close all the valves, turn off the

boiler and correct the problem. Inspection/cleaning of

the float mechanism may be required to determine why

the control was not working properly. Retest the control

after the problem has been identified and corrected.

Valve #1

Valve #2

Loading...

Loading...