MANUAL

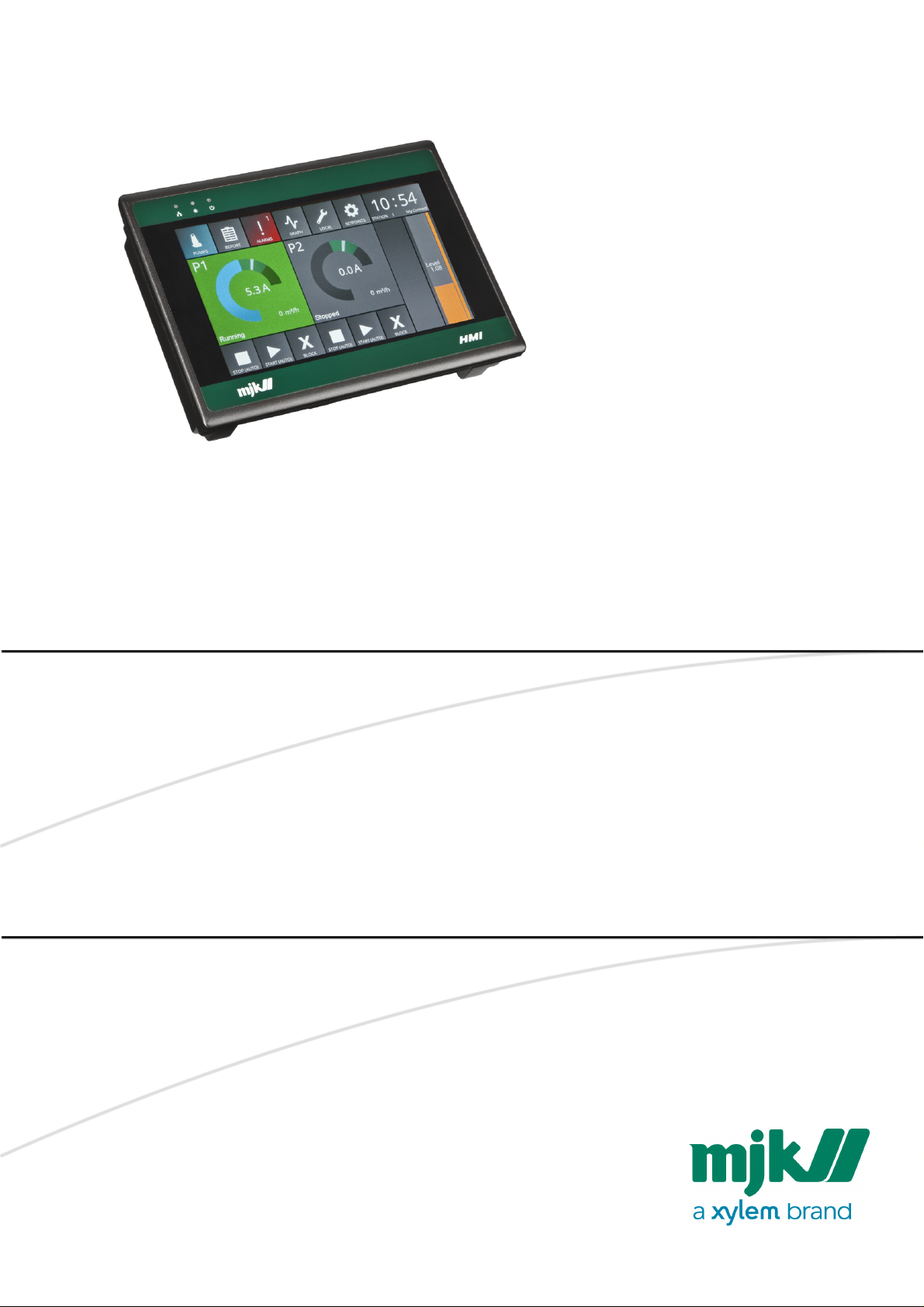

HMI display

MANUAL

HMI display

Your notes:

MANUAL

HMI display

2

Table of contents

MANUAL

HMI display

Introduction

Specifications & Order Numbers

................................................................................................................................... 6Order Numbers

................................................................................................................................... 7Dimensions

Electrical and mechanical mounting and connecting

................................................................................................................................... 9Mµ Connect / Connect RS485 CNET & INET

................................................................................................................................... 11Power Supply

Menu Screens and Operation

................................................................................................................................... 16Prerequisites

................................................................................................................................... 17Pumps, overview screen

................................................................................................................................... 22Report

................................................................................................................................... 23Alarms

................................................................................................................................... 24Graph

................................................................................................................................... 25Local

................................................................................................................................... 33Setpoints

4

5

8

12

3

MANUAL

Område

Telefon

e-mail

Europa

+45 45 56 06 56

mjk@mjk.com

Danmark

+45 45 56 06 56

mjk@mjk.dk

Norge

+47 69 20 60 70

mjk@mjk.no

Holland

+31 251 672171

mjknl@mjk.com

HMI display

Introduction

Thank you for choosing the MJK HMI Display unit.

MJK HMI Display are easy to install and operate, to get the most of the HMI Display, MJK recommends, reading this

manual to get familiar with the details regarding the touch display. The equipment must be treated and used

according to the guidelines provided by MJK Automation ApS, to ensure a stable operation and accurate

measurements.

Liability

MJK Automation ApS is liable according to the national regulations of Danish law on product liability. However, the

liability is reduced to coverage of MJK Automation ApS public liability insurance of products. Unless specifically

mentioned, MJK Automation ApS is not liable for loss of profits and working deficits or other indirect losses caused by

the product.

Changes

As our products are developed continuously, we reserve the right to make any alterations without prior notice.

Trademarks & acknowledgements

Mµ Connect, Connect, MagFlux, Chatter, SuSix, Oxix, pHix and Shuttle are ® registered trademarks for MJK

Automation ApS, Denmark. Expert and Instrument Link are ™ trademark for MJK Automation ApS, Denmark.

VLT® is registered trademark for Danfoss A/S.

Other trademarks are property of their respective owners.

MJK Automation ApS is a Xylem brand.

4

Specifications & Order Numbers

MJK HMI Display

Power supply

24V DC ±20%

Power consumption

400 m A@24V

Processor

32Bit RISC CPU 600MHz

Display

7” TFT / Resolution 800 x 480 pixels (W x H)

Memory

256MB / RAM 256MB

Brigtness

(cd/m2) 500 / Contrast Ratio 500:1 / 16.7M Colors

LED Back Light

Back Light Life Time >30.000 hrs

Touch Panel

4-Wire Resistive Type

External

Communication

CAN bus / CANopen Protocol / Modbus RTU

Interface

SD Card Slot SDHC

Audio Line Out - 3.5 mm jack x 1

USB Host USB 2.0 x 1 / USB Client USB 2.0 x 1

Ethernet Port 10/100 Base-T

COM Port COM1 (RS-232/RS-485 2W/4W), COM3(RS-232/RS-485 2W) Supports MPI 187.5K

Enclosure

IP66 front panel (O ring seal) / NEMA 4

Cabinet Material

Aluminum

Operating Conditions

-20°~50°C (-4°~122°F)

Storage Temperature

-20°~70°C (-4°~158°F)

Operation Humidity

10%~90% RH (non-condensing)

Weight

App. 0.9 kg.

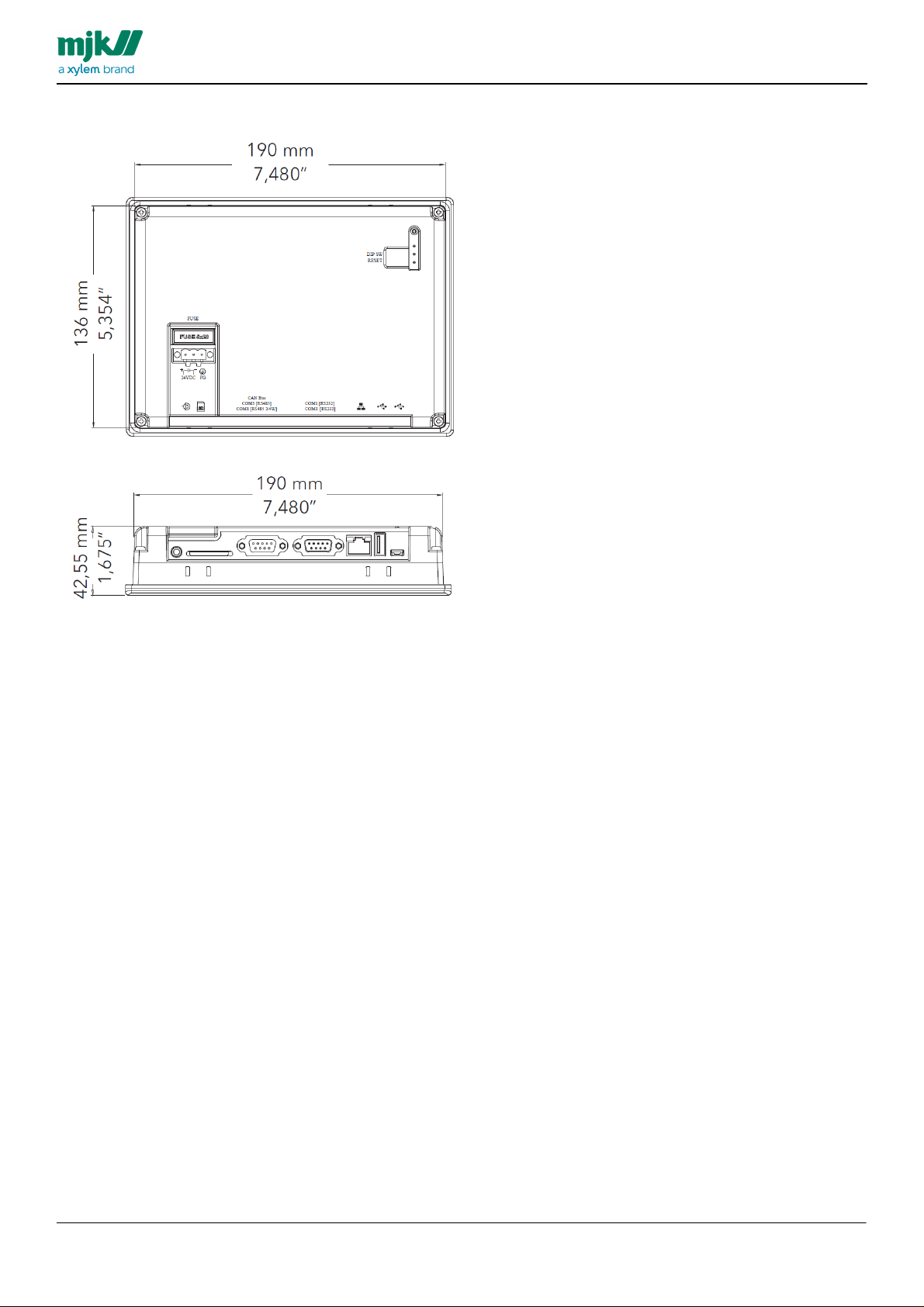

Dimensions Panel

Cutout

192 x 138 mm (W x H)

Approvals

Compilies with EN 55022:2006+A1:2007 , EN 61000-3-2:2006+A2:2009 .EN 61000-3-3:2008,

EN 55024:1998+A1:2001+A2:2003

Comply with FCC class A

MANUAL

HMI display

5

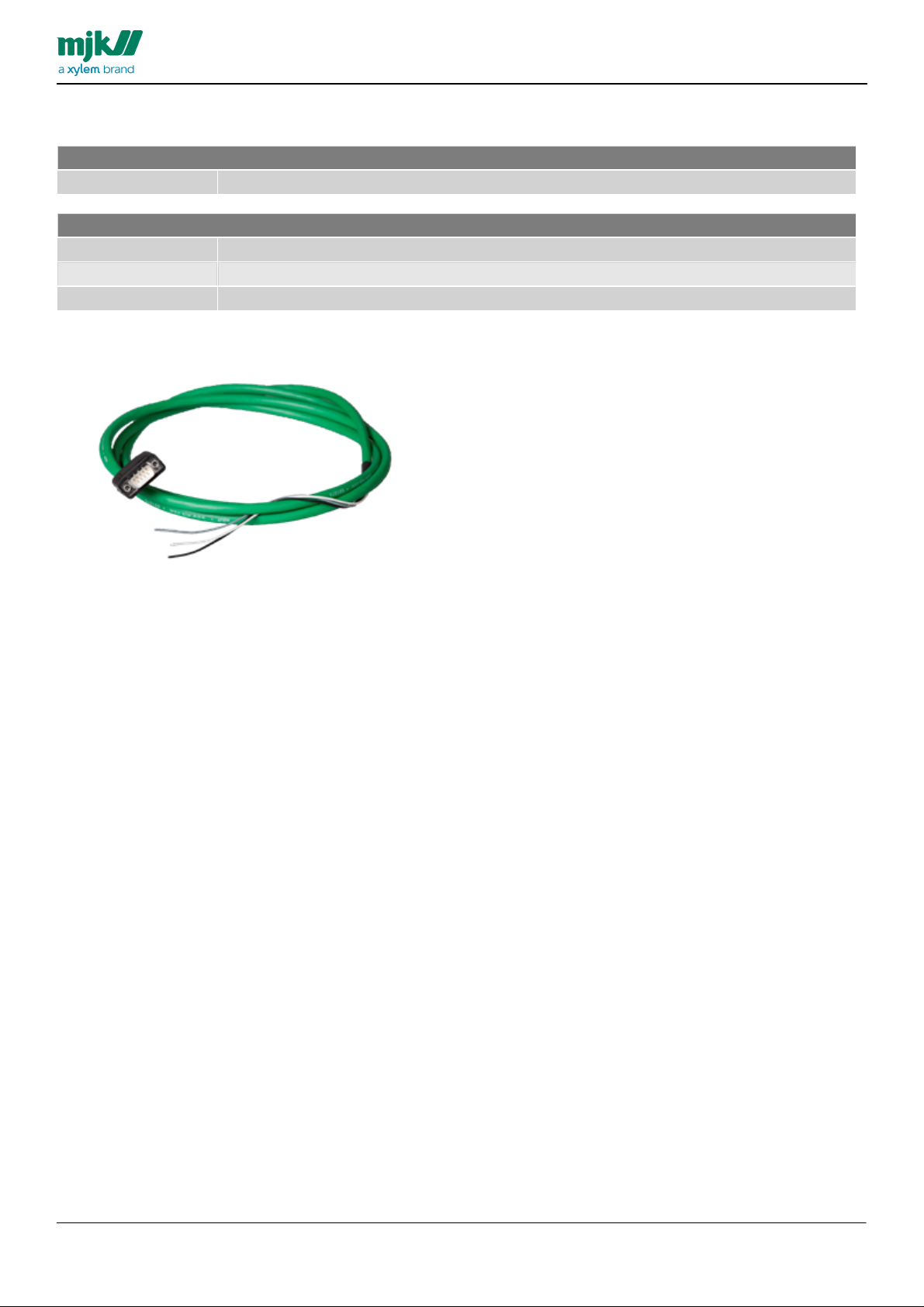

Order Numbers

MJK HMI Display

205410

HMI Display 7" Touch

Accessories

205205

Powersupply 100-240V AC to 24V DC/1.75 A

205506

Cable kit for Connect to HMI display, RS 485 cable, 2,5m, Inclusive blind lid for Connect.

205507

Cable kit for Mµ Connect to HMI display, RS 485 cable, 2,5m

MANUAL

HMI display

205507 Cable kit for Mµ Connect to HMI display, RS 485 cable, 2,5m

6

Dimensions

MANUAL

HMI display

7

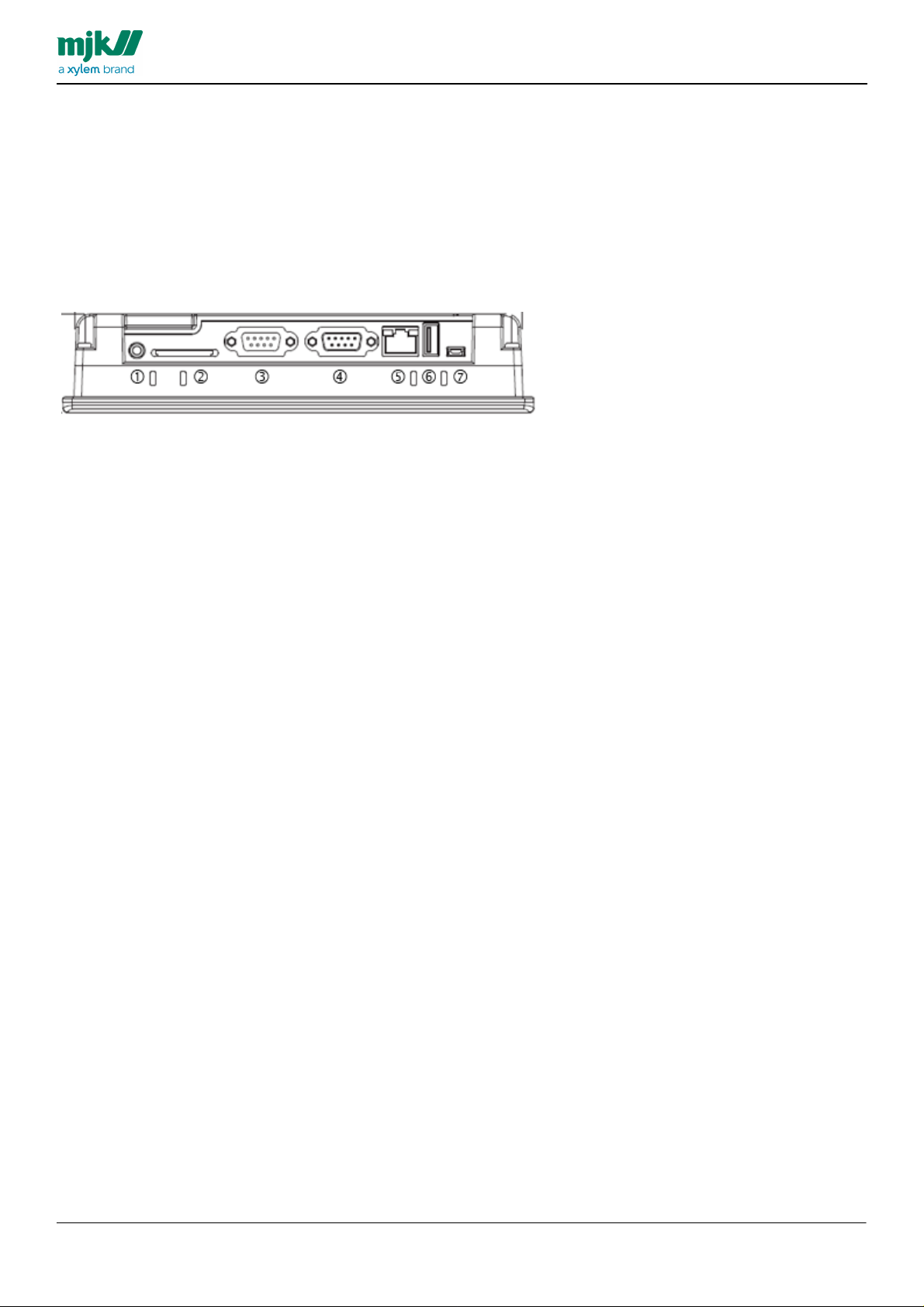

Electrical and mechanical mounting and connecting

The HMI display provides the following connection options:

1. Audio Line Out - 3.5 mm jack

2. SD Card Slot SDHC

3. COM1 RS-232 2W/4W

4. COM3 RS-485 2W Supports MPI 187.5K

5. Ethernet Port 10/100 Base-T

6. USB Host USB 2.0

7. USB Client USB 2.0

MANUAL

HMI display

8

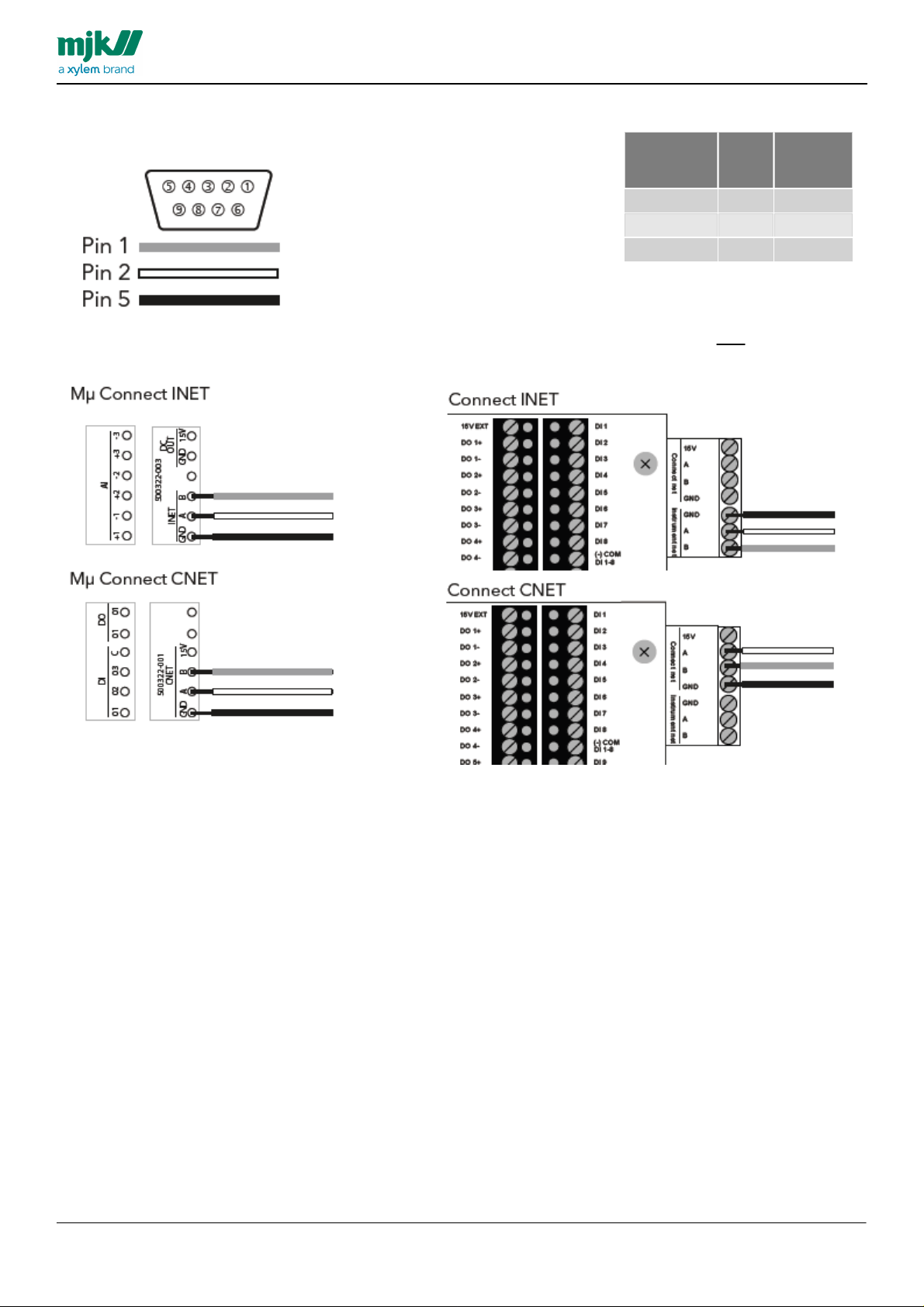

MANUAL

HMI C om 3 RS485

Port pin

9 Pin D-Sub

Female

Signal

Wire

color

1

B

Grey2A

White

5

GND

Black

Connecting to Mµ Connect device

Connecting to Connect device

HMI display

Mµ Connect / Connect RS485 CNET & INET

When the HMI display is connected using INET it cannot be used by additional units at an denne ikke bruges af andre

enheder simoultaneously.

9

The shown configuration for INET is for M µ Connect udevice, m ade in Connect Link

MANUAL

HMI display

10

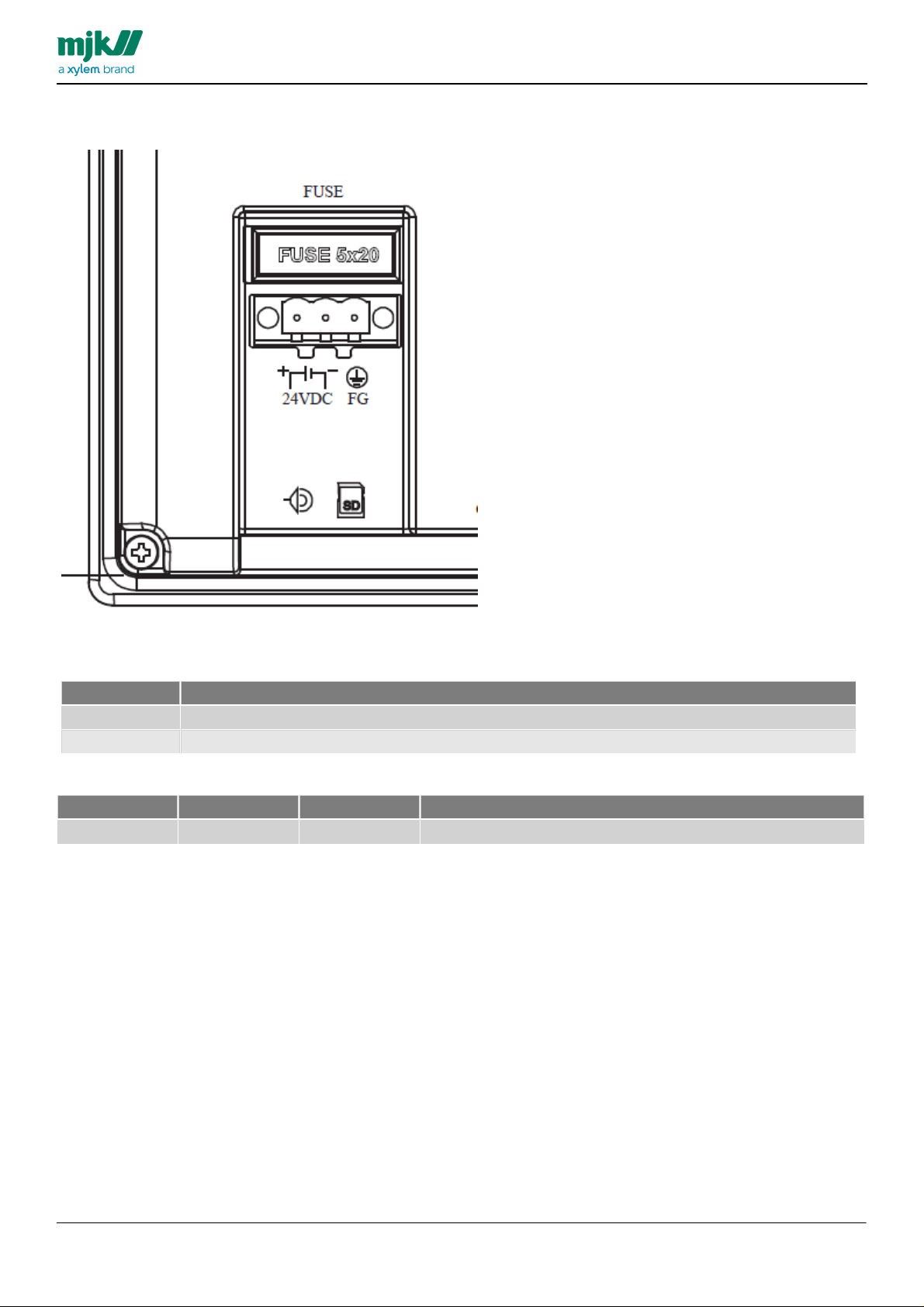

Power Supply

Terminal

Function

-

24 VDC minus

+

24 VDC plus

Power

Ampere

Order no.

Package

250 V

F 1,25A

5 x 20 mm

The HMI Display must be supplied with 24 VDC, Min. 400 mA

MANUAL

HMI display

Power Supply - 24 VDC

Internal Fuse

11

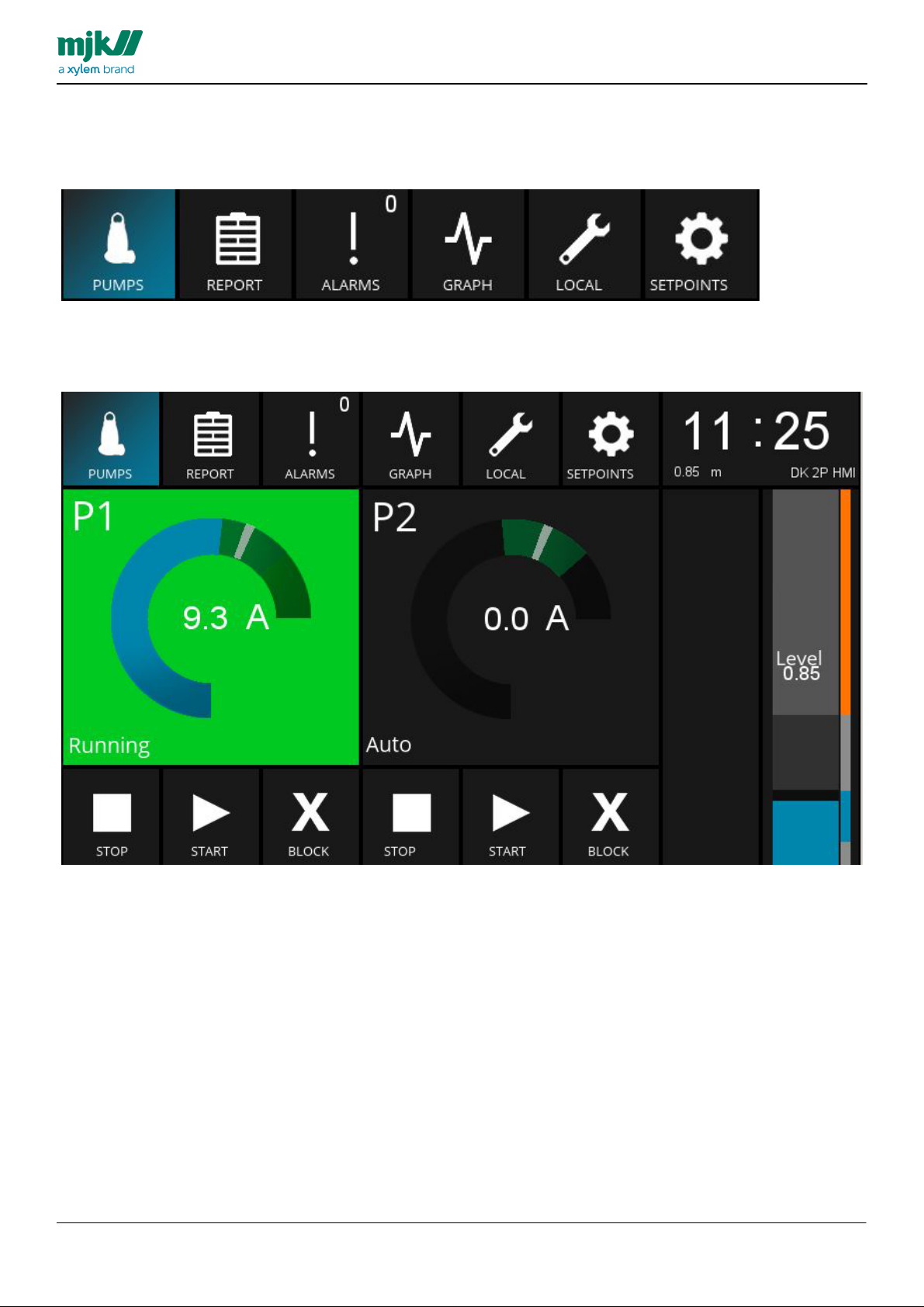

Menu Screens and Operation

The following pages will describes details regarding the individual sub menus and statuses.

The main screen is created to provide most necessary information when arriving to a pump station.

Besides the top bar and clock/date, the screen provides the pumpscreen, including easy readable information on the

capacity for the station, fro the individual pumps and the level of the well.

If the screen is black, press anywhere on the touchscreen to activate.

This chapter describes the individual overview screens and menus in the HMI Display.

HMI display provides 6 primary screens.

Pumps

MANUAL

HMI display

12

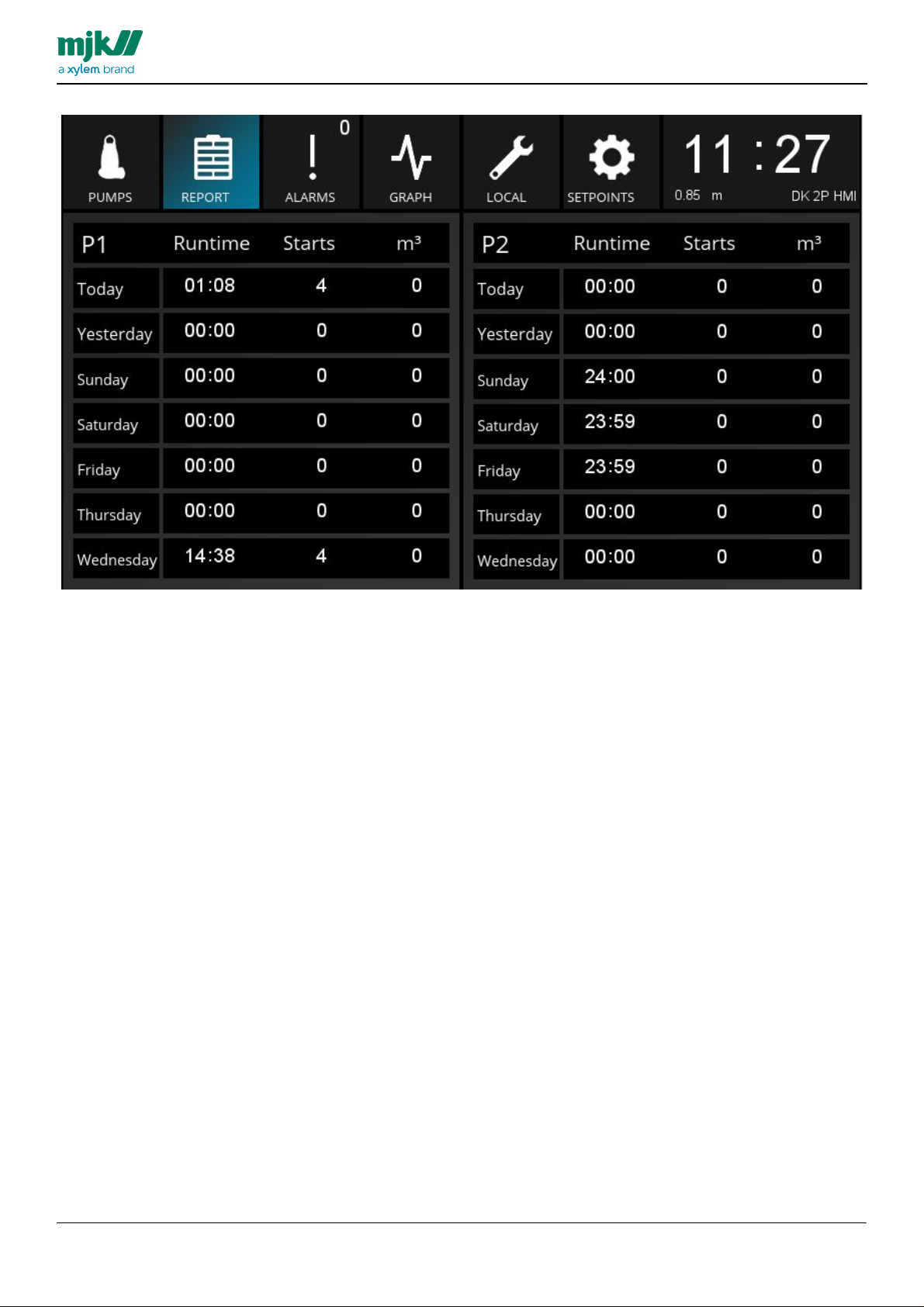

Report

The Report screen provides an overview of the capacity per pump, per day, making a simple evaluation of the

configuration the past week.

MANUAL

HMI display

13

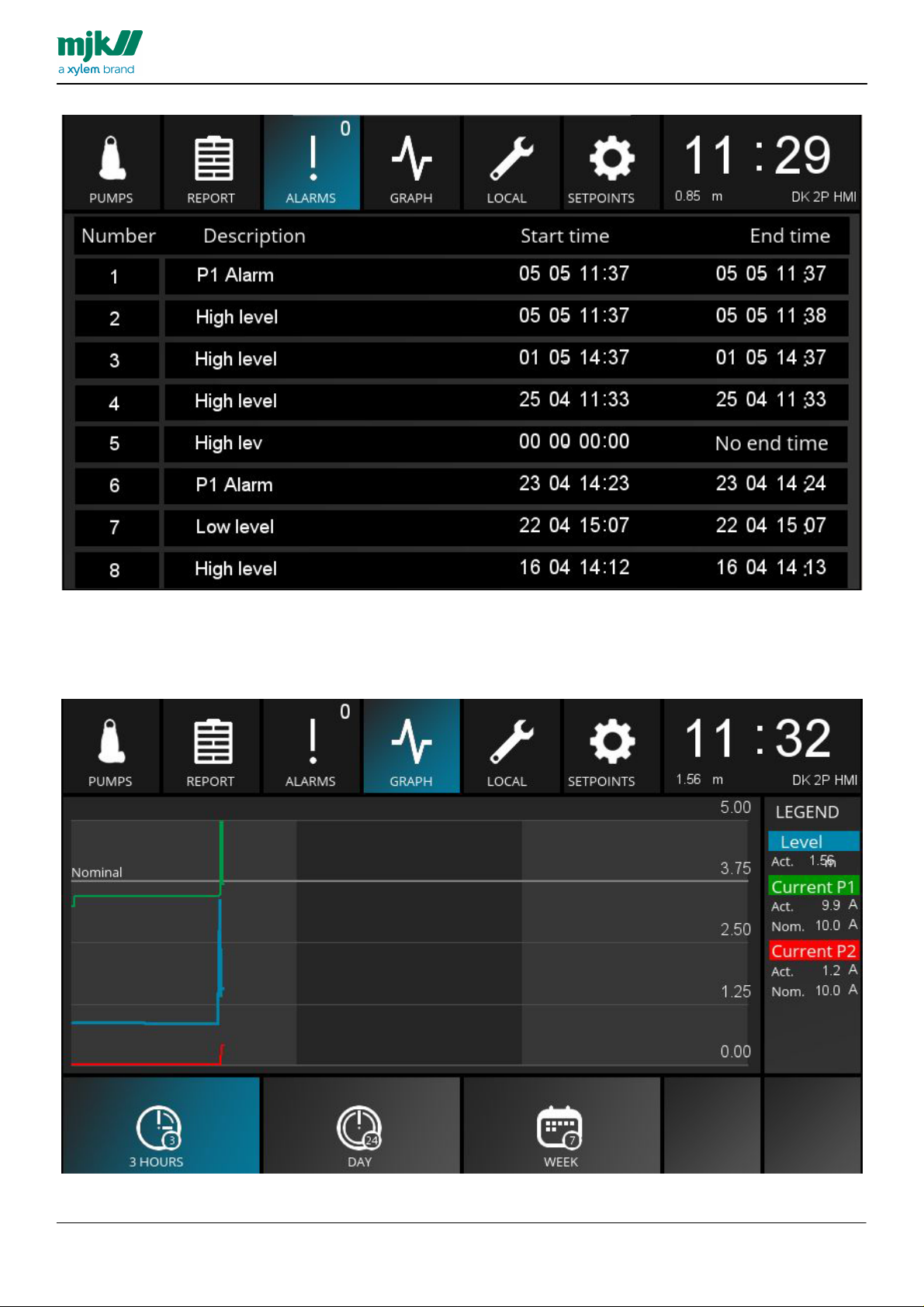

Alarms

The Alarm screen provides a list of the 8 most recent alarms from the station, including information in regards of the

state of the individual alarm.

The Graph screen provides a graphical view of the level of the well, as well as the power consumtion per pump..

MANUAL

HMI display

Graph

14

Local

The Local screen allows access to information and configuration of the station.

The Setpoint screen allows configuration of the functions of the HMI display includuing start/stop levels of station

and much more.

MANUAL

HMI display

Setpoints

15

Prerequisites

Analog Input

Signal Name

Scaling 4mA

Scaling 20mA

Device - type

units

Averaging

AI 1

Level

0

Depending on

the connected

device

Level

m, 2 decimals

0 sec.

AI 2

Power P1

0

Depending on

the connected

device

Other devices

A, 1 decimal

0 sec.

AI 3

Power P2

0

Depending on

the connected

device

Other devices

A, 1 decimal

0 sec.

Digital output

Signal Name

Relay function

Closing time

Seconds on

time

Delay

DO 1

Start / stop P1

NO- constant

0 sec.

0 sec.

DO 2

Start / stop P2

NO- constant

0 sec.

0 sec.

Virtual analog input

Signal Name

High Alarm

Low Alarm

VAI 3

Power P1 (Illustrated in

HMI)

In use, Yes

In use, Yes

This VAI is used for

Setpoint for upper

and lower limits in the

main screen ampere

view.

VAI 4

Power P2 (Illustrated

in HMI)

In use, Yes

In use, Yes

This VAI is used for

Setpoint for upper

and lower limits in the

main screen ampere

view.

The HMI configuration is created for operating the MJK Mµ Connect Pump Control 1 using control words.

Mµ Connect device must have firmware version 844008-013.

This FW contains e.g. 7 days history.

Control word in Pump control 1 must be activated.

The following I/O is permanently connected:

MANUAL

HMI display

Additional I/O can be wired

Besides this the following can be created:

16

MANUAL

The screen is divided in various elements described on the following pages.

HMI display

Pumps, overview screen

Pumps screen

This screen also serves as start screen, shows the status of the pumps and provides control of the pumps and options

of resetting alarms.

17

Pump element

When selecting this element a detailed screen for the individual pump is shown,

this screen provides the following options and informations:

MANUAL

HMI display

Pump element device window

The individual elements is shown on the following pages:

18

Pump element

Menu Item

Text

Defaul

t

Description

Background

color

The color of the background in this element will switch depending on the

operating condition of the pump.

The colors are similar to the colors used in most SCADA systems.

Pump operating

condition

Stopped

Grey

The pump is stopped

Pump operating

condition

Not

operating

Black

The pump is blocked

Pump operating

condition

Operating

green

The pump active (operating),

Pump operating

condition

Error

red

Error on the pump

Pump operating

condition

Blocked

Blue

The pump is blocked

Ampere meter

Blue

Orang

e

The Ampere meter illustrates the actual power consumption of the pump.

the green area is illustrating the safe range of 10% -/+ of the nominal current. This is

creating a simple visualization of the power consumption being acceptable.

If the acceptable range is exeeded the color will change from green to orange.

The grey line illustrates the acceptable range of nominal current, this value is

entered in SETPOINTS>Current

This will make it easy to evaluate if the actual power consumption is proportional to

the nominal current of the individual pump.

Ampere

numerical

Illustration

A

Numerical Ampere value of the powerconsumption of the individual pump.

Menu Item

Description

Stop

Stop the pump.

Start

Start the pump

Block

Block the pump. Press start to restart the pump.

When the pump is blocked, no alarms will be activated from the device to the SCADA system

MANUAL

HMI display

Betjeningsknapper

19

Operating data

Menu Item

Description

Runtime

Runtime today, yesterday, since last service and in total

Last service value can be reset in LOCAL>Readout values

Starts

Number of starts today, yesterday, after service and totals.

m3

The pumped volume today, yesterday and totals.

Menu Item

Valg

Default

Description

Alarm reset

Reset alarm button.

When pressing the button the active alarms will be reset.

MANUAL

HMI display

Reset Alarm

20

Level Element

Menu Item

Description

The Level element works as a shortcut to SETPOINTS>Pump Settings, in which e.g. the start/

stop levels can be adjusted.

Level,

Left area

The left bar illustrates the actual level of the well.

If the level is acceptable the color will blue.

If the level is below minimum requirements or above acceptable level the color will switch to orange

Level,

Right Area

The start/stop levels AND the high/low alarm limits is illustrated in this bar.

Orange illustrates the high/low alarm levels.

Grey illustrates the start and stop levels.

Blue illustrates the acceptable levels.

MANUAL

HMI display

21

Report

Menupunkt

Beskrivelse

Days

7 days is shown

Runtime

Runtime for the pumps in hours and minutes on the day

Starts

Number of starts per pump per day

m3

Pumped volume per pump per day.

The Report screen provides an overview of the operatiion of the pumps the past 7 days.

MANUAL

HMI display

22

Alarms

Menu Item

Description

Number

Order of the 8 most recent alarms

Description

Description of the type of alarm occured and text as Defined from I/O device

Start time

Start time of the alarm, if the alarm occured more than 24 hours ago, th edate will be shown as well

End time

End time of the alarm (if ended). if the alarm has ended more than 24 hours ago, the date will be

shown as well.

This screen provides an overview of the 8 most recent alarms

MANUAL

HMI display

23

Graph

Menu Item

Description

Graphs

Visual illustration of the level and power consumption per pump during a selected period.

The figures on the right side of the graph indicates a scaling of the level based on minimum and

maximum scaling of the level and current measurement.

The second graph (from the top), is the nominal value for the pumps. Hereby scaling their graphical

value.

Nominal graph

The nominal Graph is grey.

When a pump reaches its nominal current the graph will be on this line.

Alle pumper skaleres op mod denne linje. Derfor vises der alligevel grafer for pumper som kører med

forskellige nominalstrømme. Hermed undgår man at pumper med stærk afvigende nominalstrømme

falder væk fra denne graf.

Menu Item

Default

Description

Numeric indication of the values shown in the graph window

Level

Blue

Level value; the actual level of the well.

Current P1

Green

Current value Pump 1, actual value and nominal value.

Current P2

Red

Current value Pump 2, actual value and nominal value.

Menu Item

Description

3 Hours

Time span of 3 hours

Day

Time span of 24 hours

Week

Time span of one week

This screen provides a graphical illustration of the power consumption during selected periods.

MANUAL

HMI display

Legend

Time span selection

24

Local

Navigation Menu, left

Installation

Configuration of the station.

Readout values

Reset button regarding runtime and starts after service and overflow

volume.

XDM

Stores information of the data of the pump.

Display Properties

Select display language and more.

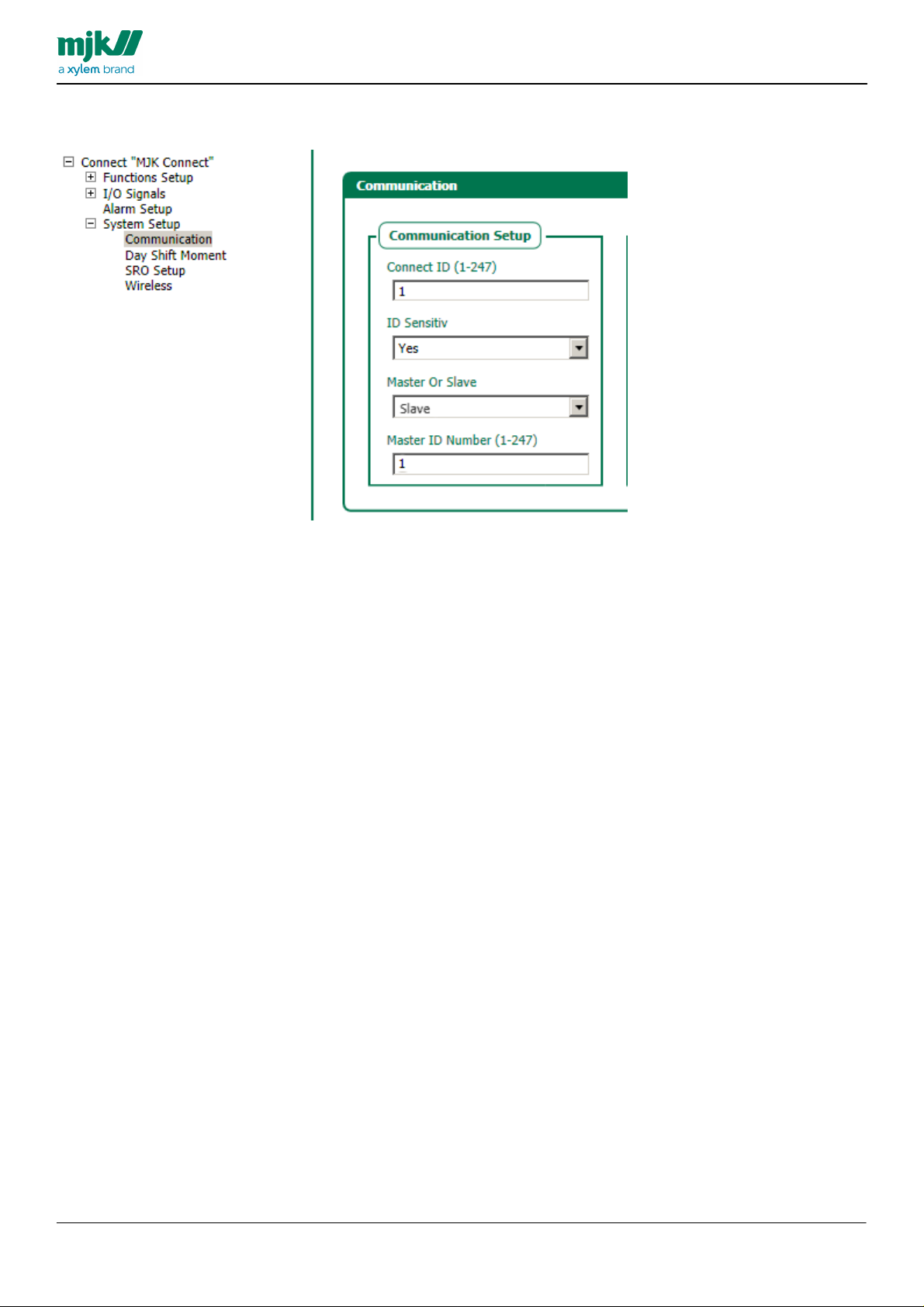

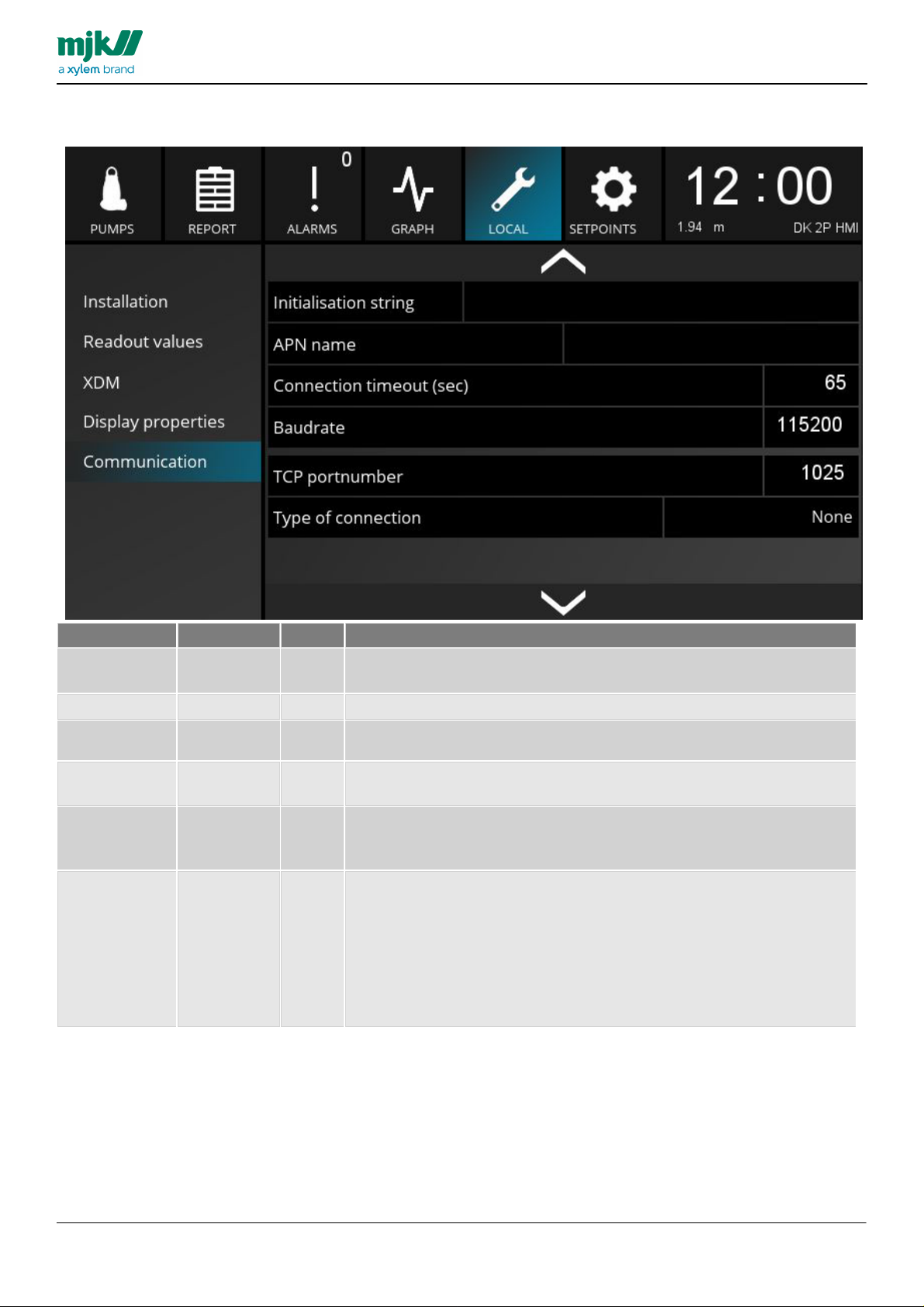

Communication

Adjust modem configuration and VNC.

Setup options in regards to the station configuration.

MANUAL

HMI display

Local screen contains 5 submenus.

25

Installation

Menu Item

Options

Default

Description

Station Name

Name of the station, this name will be shown beneith the clock.

Station Number

1-247

Station number (ID number in the SCADA system). This will also be shown beneith

the clock.

Time

hh:mm:

ss

Adjust the clock.

Date

ddmmyyyy

Adjust the date.

MANUAL

HMI display

26

Readout Values

Menu Item

Opti

ons

Default

Description

P1 Runtime

since last

service (h)

Reset P1 runtime since last service (shown in pump element)

P1 Starts since

last service

Reset P1 number of starts since last service (shown in pump element)

P2 Runtime

since last service

(h)

Reset P2 runtime since last service (shown in pump element)

P2 Starts since

last service

Reset P2 number of starts since last service (shown in pump element)

Starts, Reset

button

This will reset number of starts since service.

Starts, numeric

column

Number of starts since service can be adjusted in this column

Overflow

Overflow

volume today

Overflow volume m3.

Overløbsvolum

e yesterday

Overflow volume m3.

Counter

24-hour

counter actual

value

Actual value of 24 hour counter.

MANUAL

HMI display

27

XDM

Menu Item

Options

Default

Description

Pump type

Enter type of pump.

Impeller

Enter type of impeller.

kW

Enter kW for pump.

Nominal current

Nominal current for pump

Production year

Pump production year

Serial number

Pump serial number

Informations regarding the connected pumps

MANUAL

HMI display

28

Display Properties

Menu Item

Options

Default

Description

Language

English

Italian

Spanish

German

French

Swedish

Finnish

Portuguese

Norwegian

Danish

Danish

Choose language from the drop-down menu.

Brightness

Adjust by pressing + or -.

CPU load

display

Actual CPU load of the display.

Free space

display

Free space on the Display memory

MANUAL

HMI display

29

Communication

Menu Item

Options

Default

Description

Connection

status

Current status on the modem connection.

IP address SIM

card

Shows IP address provided by SIM card in modem.

Connection

strength CSQ

GSM/GPRS strength of connection.

Local – communication 1

Use the up/down arrows to switch between addtional communication screens

MANUAL

HMI display

30

Local – Communication 2

Menu Item

Options

Default

Description

Initiation string

Modem

Select to

adjust

Initiation string for modem.

APN name

Name of access point.

Connection

Timeout

0-9999 sec

15

Connection timeout in seconds. Press to adjust the value.

Baudrate

115200

Baud rate in the modem. Baud rate is the number of bits strasnferred per

second. Press to adjust the value.

TCP

portnumber

1025

TCP port number in the modem. This port number is used to establish TCP

connection. Press to adjust the port number.

This number is only used for TCP connections.

Type of

connection

None

TP6000

NIROS

RS232

RS485 no

termination

RS485 with

termination

None

MANUAL

HMI display

31

Local – Communication 3

Menu Item

Options

Default

Description

HMI IP address

Select to

adjust

IP address of the HMI Display.

This address is used when creating a VNC Connection from the HMI Display.

HMI ethernet

mask

Select to

adjust

HMI Display Ethernet mask.

HMI ethernet

gateway

address

Select to

adjust

HMI Display Ethernet gateway address.

HMI ethernet

port

Select to

adjust

HMI Display Ethernet port. This port is used to connect to the HMI Display.

VNC server

Turn on/off the VNC server.

When turned off, the HMI Display cannot be accessed remotely

Multiple VNC

Connection

Allow multiple VNC connections. When this is on, multiple devices cannot be

accessed remotely.

VNC password

Select to

adjust

Adjust the access code for VNC server. This code is only used when

accessing remotely

MANUAL

HMI display

32

Setpoints

Navigation Menu, Left

Level

Current

Pump Settings

Capacity

Overflow

Alarm Call

Miscellaneous

MANUAL

HMI display

Setpoint screen provides 7 submenus.

33

Level

Menu Item

Option

Default

Description

Level sensor at

20 mA

-99 - 999

Depen

ding on

sensor

Adjust level hight when level sensor provides 20 mA. Select to adjust.

Level sensor at

4 mA

-99 - 999

Depen

ding on

sensor

Adjust level hight when level sensor provides 4 mA. Select to adjust.

Level maximal

-99 - 999

Depen

ding on

sensor

Adjust setpoint limitation in relation to max level. Select to adjust.

Level minimal

-99 - 999

Depen

ding on

sensor

Adjust setpoint limitation in relation to max level. Select to adjust.

Level high alarm

Select to

adjust

Set level for high alarm

Level low alarm

Select to

adjust

Set level for high alarm

MANUAL

HMI display

34

Current

Menu Item

Option

Default

Description

P1 range current

measurement

0-9999 A

Depending

on

configuration

Adjust measuring range for current in ampere. The figure is the max value

for the pumps. Select to adjust.

P1 high current

0-9999 A

Depending

on

configuration

Adjust high current alarm value in ampere. select to adjust.

P1 low current

0-9999 A

Depending

on

configuration

Adjust low current alarm value in ampere. Select to adjust.

P1 nominal

current

0-9999 A

Depending

on

configuration

Adjust normal current value in ampere. Select to adjust.

MANUAL

HMI display

35

Current - 2

MANUAL

HMI display

sam e settings on P2

36

Pump configuration

Menu Item

Option

Default

Description

Number of

pumps

0-2

Depending on

configuration

Number of pumps connected in this installation. Depending on the

configuration used, it is possible to configure 1-2 or 3-4 pumps. This value

decided the number of pumps viewed in the display. Select to adjust.

Pumps

simultaneously

0-2

Depending on

configuration

The number of simultaneously running pumps allowed. Select to adjust.

Start level 1

Select to

adjust

The first start level for the pumps.

Stop level 1

Select to

adjust

The first stop level for the pumps.

Start level 2

Select to

adjust

The second start level for the pumps.

Stop level 2

Select to

adjust

The second stop level for the pumps.

MANUAL

HMI display

37

Pump configuration - 2

Menu Item

Option

Default

Description

P1 Alternation

On / Off

Depending on

configuration

Activate or de-activate pump alternation.

Select to adjust

P1 Maximum

runtime

0-9999

(Sec)

0

Maximum runtime for the pump in seconds. When the value is exceeded,

the station will send an alarm. Select to adjust.

P1 start delay

0-9999

(Sec)

0

Delay in seconds. Select to adjust.

Same for P2

MANUAL

HMI display

38

Pump configuration - 3

Menu Item

Option

Default

Description

Dynamic level offset

Select to

adjust

0,00

Level setpoint displacement.

Dynamic level start

time

hh:mm

00:00

Start time for setpoint displacement in hours and minutes. Select to

adjust.

Dynamic level stop

time

hh:mm

00:00

Stop time for setpoint displacement in hours and minutes. Select to

adjust.

Periodic pumping

by P1/P2

OFF/P1/

P2

OFF

Select the pump for periodic depth pumping. Select to adjust.

Periodic pumping

time

Select to

adjust

0

Adjust runtime (in seconds) for periodic depth pumping.

Periodic pump

(every xx starts)

Select to

adjust

0

Number of starts between periodic depth pumping.

MANUAL

HMI display

Delay of high-level signal (float-switch)

The delay is specified in seconds. Select to adjust.

39

Capacity

Menu Item

Option

Default

Description

Start level

capacity

measurement

Select to

adjust

Enter start level

Stop level

capacity

measurement

Select to

adjust

Enter stop level

Volume capacity

reading

Select to

adjust

Enter volume between start/stop level for capacity measurement

MANUAL

HMI display

40

Overflow

Menu Item

Option

Default

Description

Overflow

level 1

0,00 - 10,00 m

0,00

Overflow level in meters. Select to adjust

Overflow

capacity 1

0,0 - 9999,99 m3/h

0,0

Overflow capacity in m3/h. Select to adjust

MANUAL

HMI display

41

Alarm call

Menu Item

Option

Default

Description

Call type

0-4

0 - None

1 - PC (Scada)

2 - Telefon

3 - SMS

4 - GPRS

Phone number 1

Select to

adjust

Enter the number for the connection. This is relevant

This is relevant after selecting type in "Call type". This phone number is the

number that will receive the information*/data shipped from the HMI display.

Time between

calls

0-9999

(Min)

0

Adjust time, in minutes, between calls

Menu Item

Option

Default

Description

Station name

Select to

adjust

Station number

Select to

adjust

(ID no.)

Setup – Alarm call 1

MANUAL

HMI display

42

Setup – Alarmopkald 2

Menu Item

Valg

Default

Description

Alarm delay high

level

0-9999

(sec)

0

Enter number of seconds before sending high alarm.

Alarm delay low

level

0-9999

(sec)

60

Enter number of seconds before sending low alarm.

MANUAL

HMI display

43

Miscellaneous

Menu Item

Valg

Default

Description

Test alarm

On / Off

Start time for

test alarm

(hh:mm)

00:00

Time of day in hours and minutes

24-hour counter

alarmvalue

Select to

adjust

Alarm value for 24-hours counter.

Person on site

detection delay

Select to

adjust

Delay in seconds - when the panel is opened, the value is the number of seconds

before sending the alarm to the scada.

Person on site

alarm

On / Off

Off

See is a person on sie alarm is active or off. If active, this button can turn off the

alarm.

trend resolution

(sec)

30-3600

Seconds

30

Adjust the extended datalogger logging interval.

MANUAL

HMI display

44

Clock element.

Press the clock to read state of the connected Mµ Connect I/O.

MANUAL

HMI display

45

Status I/O signals

MANUAL

HMI display

Digital in/out

46

1) The tissue in plants that brings water upward from the roots;

2) a leading global water technology company.

We’re 12,000 people unified in a common purpose: creating innovative solutions

to meet our world’s water needs. Developing new technologies that will improve

the way water is used, conserved, and re-used in the future is central to our work.

We move, treat, analyze, and return water to the environment, and we help people

use water efficiently, in their homes, buildings, factories and farms. In more than

150 countries, we have strong, long-standing relationships with customers who

know us for our powerful combination of leading product brands and applications

expertise, backed by a legacy of innovation.

For more information on how Xylem can help you, go to www.xyleminc.com

MJK Automation A/S

Byageren 7

DK-2850 Nærum

Denmark

Tel +45 45 56 06 56

Fax +45 45 56 06 46

www.mjk.com

Connect, MµConnect, Chatter, MagFlux, Oxix, pHix compact, Shuttle and

SuSix

are registrered trademarks of MJK Automation A/S.

© 2013 Xylem, Inc.

Loading...

Loading...