Lowara Servitec Degassing Unit

1

Installation, Operating and

Maintenance Instructions

Declaration of Conformity

Lowara pumps UK declare that the Servitec degassing unit conforms to the requirements of the Machinery

Safety Directive 89/392/EEC.

Conforming to the UK Health & Safety Requirements S.I. 1992 No 3073 S.I. 1994 No 2063

Water supply (Water fittings) regulations 1999

Simple pressure vessel directive 87/404/EEC

Code of practice for heating and chilled water systems BS7074 (parts 1, 2 & 3)

Signed: Position: Engineering manager Date: 14-08-12 Revision

Clive Willmott

Introduction

This leaflet contains information to enable the safe installation and operation of the products mentioned above.

The following instructions must be read and understood by all persons responsible for the installation, operation

and maintenance of this product.

Warning Symbols

Safety instructions where noncompliance would affect safety.

Safety instruction where electrical hazard is involved.

Safety instruction where noncompliance could cause damage to the equipment.

Instruction for safe us

This product has been designed for collecting and boosting rain water in non potable water

installations to the operating conditions shown.

This product should not be installed until this leaflet has been studied carefully.

Handling, transportation and installation of this equipment should only take place with the proper

use of lifting equipment.

This product must be stored in a frost-free dry environment.

Noise Emission

This equipment operates at a noise level lower than 70dBA.

Installation

The Lowara Servitec unit is despatched mounted on a wooden pallet and covered in a protective film, it is

recommended that the unit be retained in the protective packaging until the product is to be

installed. The unit will arrive pre-packaged and wired ready for installation.

This product has been fully run tested at our works under simulated site conditions. The unit

should be thoroughly checked for physical damage that may have been caused during transit.

If the unit is found to have damage it must be reported immediately and should not be installed.

The unit must be sited in a clean well ventilated area with good all round access, two fixing holes are

provided in the back plate allowing the unit to be wall mounted.

Electrical Connections

The cable used for the incoming supply must be of adequate size to carry the motor full load current. This is

shown on the duty plate. All non power caballing should be limited to 2.5mm².

All connections must be made using the appropriate wiring drawings for the equipment being

installed, with particular attention being paid to the supply voltages.

The supply voltage is shown on the set duty plate.

Never operate this product with the control panel front cover removed.

It is essential that this equipment is earthed to the building earth system.

Pumps operate at 230v 50Hz

All wiring should be arranged such that it enters the control section through the appropriate cable glands.

2

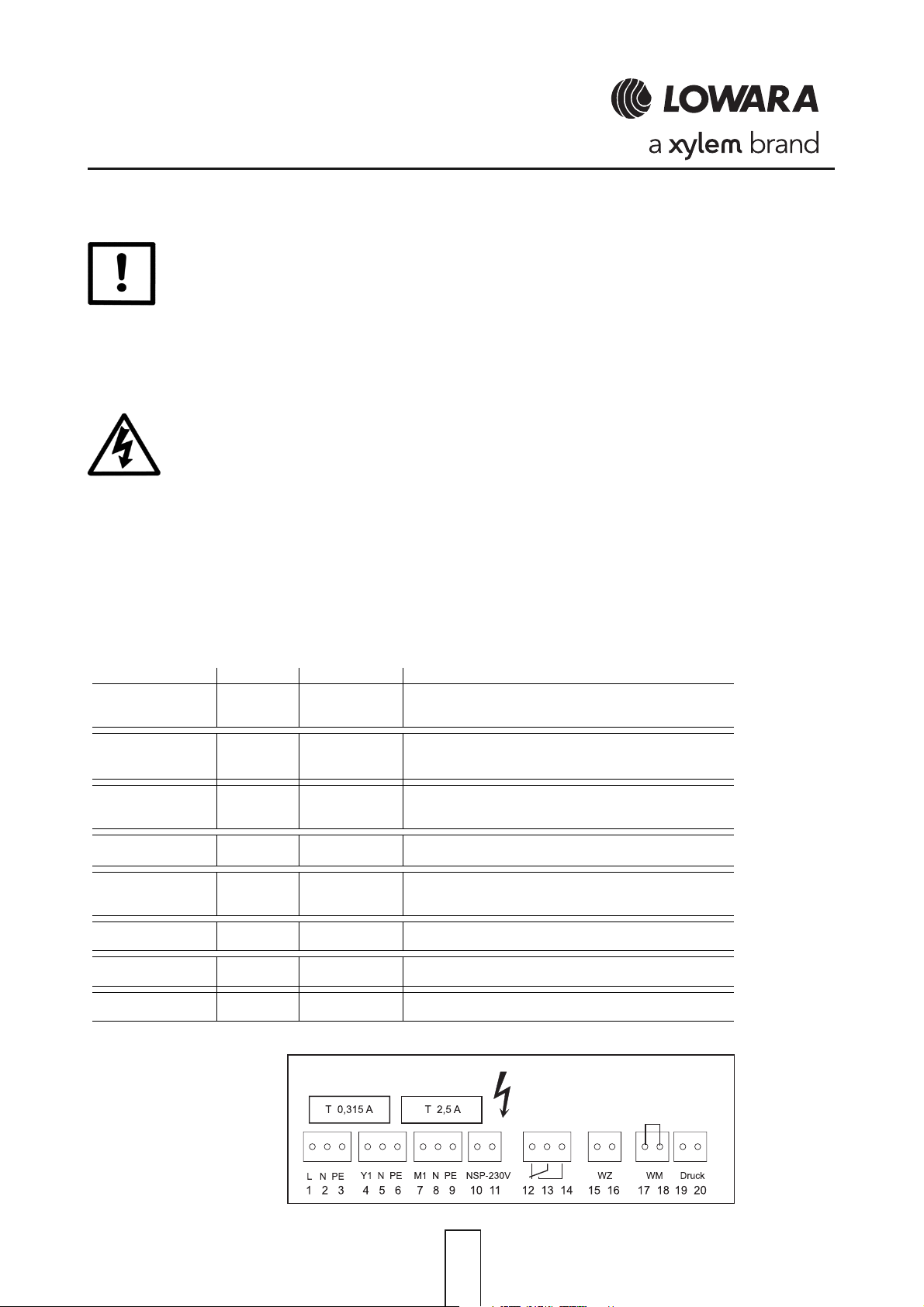

Terminal Diagram

Designation

Supply 1 PE

(230 V)

Make-up motorized

ball valve

Pump 7 M1

External make-up

control

Common message 12 NC

(fl oating)

Not confi gured 15 +24 V DC

Water shortage 17 +24 V DC

switch 18 E1

Pressure measurement transducer

Terminal Signal Note

2 N ’servitec’ is fully wired with a shock-proof plug

3L

4Y1

5 N connected

6PE

8 N connected

9PE

10

11

13 COM wire on site (optional)

14 NO

16 E1

19 +18 V

20 AE

Fuse

Electronics

only for ’servitec levelcontrol’ mode

230 V wire on site

not wired up

not connected

connected

Fuse

Motor

(jumper)

Important:

Despite removing the mains plug, 230 V

may still be present at terminal 10, 11 12,

13 and 14, and at parts of the circuit board.

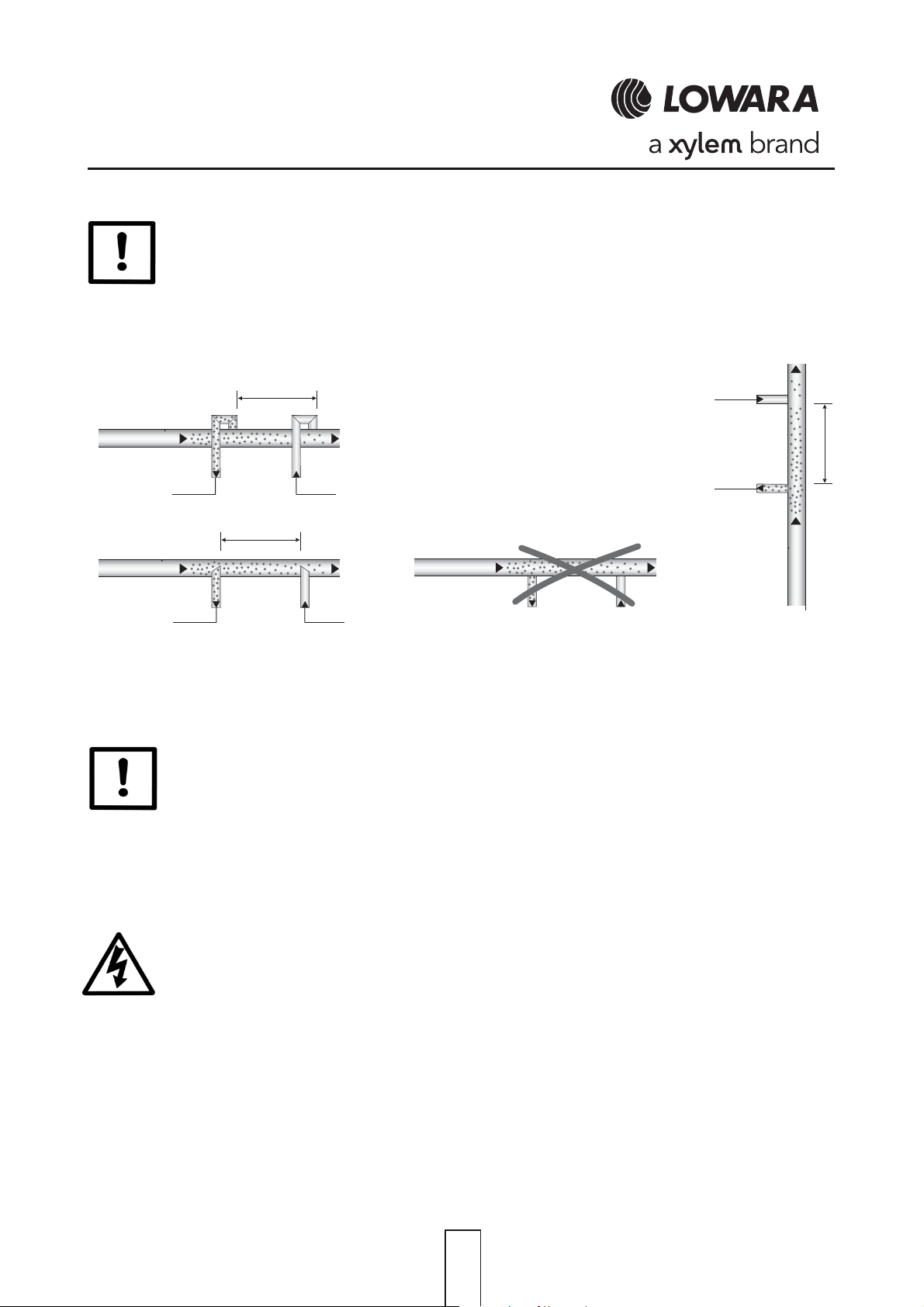

System Connections

Connect the Lowara Servitec system inlet port (marked 1) to the return leg of the circulating

system maximum temperature 70˚C, connect the system outlet port (marked 2) down stream of

the inlet port, minimum distance 500mm The connections to the main pipe should be made at the

top or side of the pipe not the bottom, this is to prevent dirt being transferred to the Servitec.

3

Make up water

Make up water is generally provided by a separate pressurisation unit placed in the system and

will work independently of the Lowara Servitec unit. In this case the water make up (port 3) can be

blanked off and not used. It is possible to connect a basic fill unit to the system for water make

which can be controlled by the Servitec unit, in this case the fill unit outlet should be connected the

Servitec make up port (Marked 3) maximum pressure 6 bar. The appropriate electrical connections

will also need to be made.

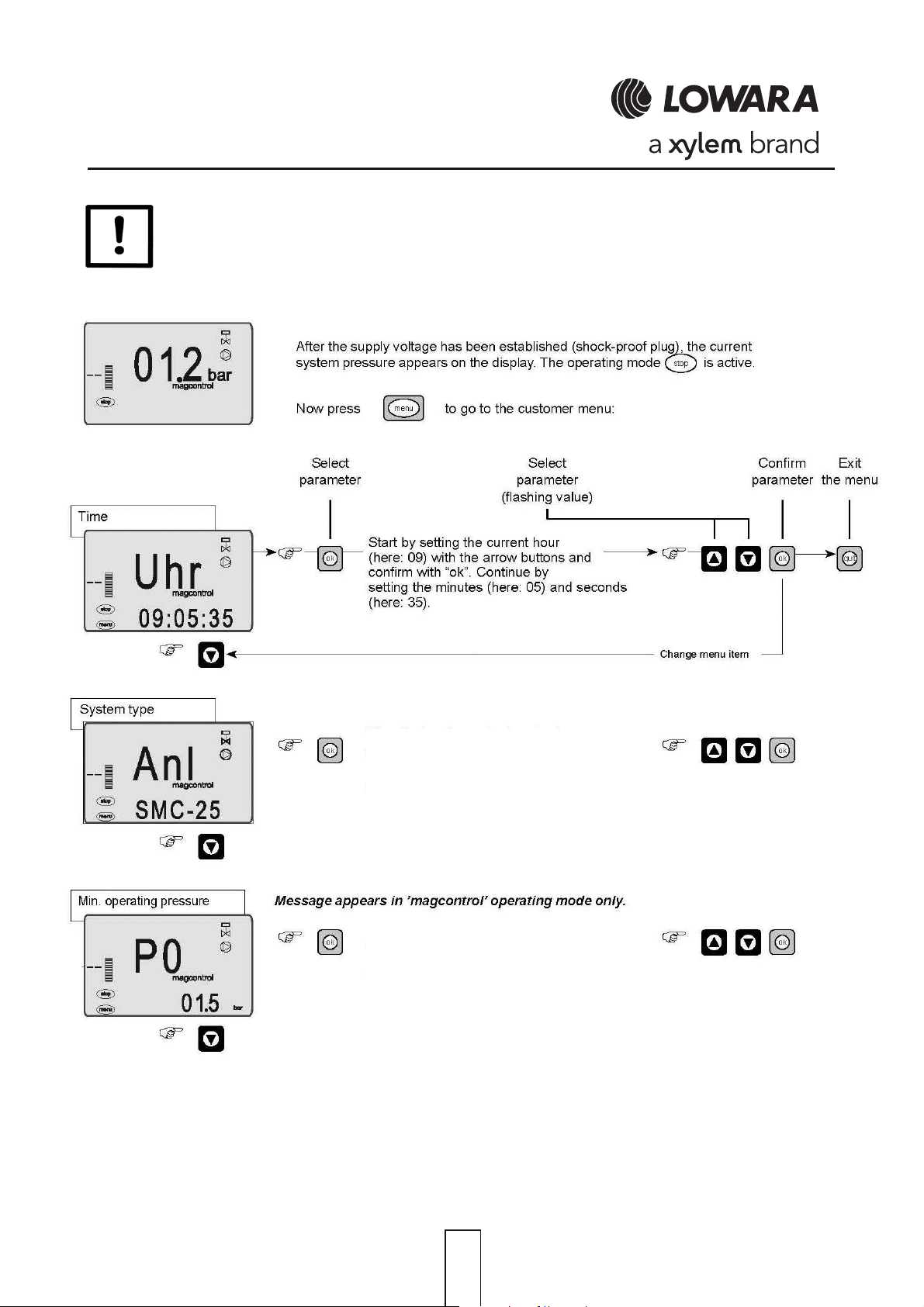

Initial start up

1. Check that the electrical connections are all made in accordance with local bylaws.

2. Check that the system connections have been made and the isolation valves are open.

3. Check that the pipe lines to the Servitec have been cleaned and are clear of any debris that

may have accumulated during installation.

Parameter Settings

The Lowara Servitec has two parameter setting levels, one is for service use and is password protected, and the

second is for customer use and is not protected.

During initial start up the customer parameters must be set to the system specific conditions.

From above

Main current V

circuit water

Rich in

gas

From below as an

immersion tube

Main current V

circuit water

Rich in

gas

t500

t500

Low in

gas

Low in

gas

Butt-welded from the

bottom not permitted

At the side

(horizontal and vertical

assembly possible)

Low in

gas

Rich in

gas

Main current V

circuit water

t500

4

Specific system set points

The display shows the ’servitec’ type

selected; ’servitec magcontrol’ or ’servitec

levelcontrol’. The system type can be

specified here Select levelcontrol

System fill pressure

5

Select continuous gassing time

And confirm with OK button

Select the degassing program

Confirm with OK button

Select the degassing program

Confirm with OK button

6

Configure the setting here for whether a water

meter is to be evaluated, e.g. when using

Lowara ‘fillset’ with contact meter.

0 Only alarm = Factory settings

1 Alarm messages

7

The last 20 errors including error code (e.g.

ER01, page 11) are shown here as well as the

relevant operating hours until the message

occurs. E01 is the most recent error, E20 is

the oldest.

8

General description

’Servitec 30’ is a degassing and make-up station. It can be

used in a wide range of system conditions. The main field

of application is heating and cooling circuits and wherever

air problems in the form of dissolved or free gases cause

problems in systems.

The ’servitec’ vacuum spray-tube degassing system removes up to 90 % of the dissolved gases from the system

water.

Vacuum degassing of a part flow of the circuit water takes

place according to an optimized schedule using selectable

degassing programs.

A part flow of the circuit water is sprayed through the

nozzle (7). The vacuum is created by the pump (6).

The large surface area of the sprayed water and the

intense vacuum result in the extremely high degassing

performance. The degassed water is returned to the

system. There the water is again able to dissolve gases.

The gases separated in the pump (6) are expelled using

the dipstick-tube degassing unit (5). This degassing

interval is repeated and free as well as dissolved gases

are removed from the circuit water.

Degassing interval

The degassing interval is a time-controlled, pre-programmed process that consists of the degassing time,

expulsion time, and idle time. The time periods can only

be changed in the service menu by Reflex Service.

The degassing intervals are repeated according to the

continuous degassing mode (standard = 5 h a day) or

interval degassing mode (standard = 16 x a day).

Injection time

The pump (6) starts. A vacuum (dependent on temperature) can be read off the displaY after a short time. This is

possible because the pump (6) draws more water from the pump casing than is able to flow in via the pressure supply

port with nozzle (7). Spraying via the nozzle commences as soon as the vacuum begins to be established.

The water level in the pump casing (6) drops continuously while the pump (6) is running. The timing program and pressure setting have been selected so that the pump does not become low in water.

Expulsion time

The pump (6) switches off. The water continues to be sprayed into the pump casing by the system pressure (at least 0.5

bar). The water column in the pump casing rises gradually during the expulsion time.

The vacuum is still maintained during this phase of the interval. At the end of the expulsion phase, the rising water

column compresses the removed gas within a few seconds, expelling it into the atmosphere via the dipstick-tube

degassing unit (5)

Idle time

This is followed by the idle time during which redegassing takes place.

Make-up

In the case of the ’servitec 30’, the pressure in the heating or cooling system is registered and monitored with the help of

the pressure transducer (8). If the fill pressure drops below pF = p0 + 0.2 bar, make-up degassing is activated until

pF = p0 + 0.3 bar has been reached. Time (20 min default setting), cycle (3 in 2 hours) and volume monitoring are active

during this process.

The motorized ball valve (2) opens during make-up. During pump operation, a pressure of approx. - 0.6 bar is set in the

pump casing (pressure indicator display). In the event of a cyclical pump stop, the system pressure is checked and made

up if necessary.

2

5

6

8

7

Mode of Operation

9

Automatic Mode

Automatic Mode

successfully completed. If you are in automatic mode, you can select

from three degassing programs, if required. System monitoring is active

with all three programs. Make-up takes place automatically. Selection in

customer menu.

Continuous degassing – Intensive degassing following start-up and

repairs.

The degassing cycles are executed successively for the set

continuous degassing time (basic setting: 5 h). The controller then

automatically proceeds with interval degassing. In the case of water

systems, at least half the system volume should flow through the

’servitec’ unit once during start-up. Based on a system volume of

8 m

3

, this is equivalent to approx. 22 h of continuous degassing. In

systems that are particularly rich in gas, a continuous degassing

period of 48 h is completely sufficient. As a result of the subsequent

interval degassing, 10,000 intervals are made per year. This number

per year must not be exceeded in order to avoid unnecessary wear to

the ’servitec’. The controller registers the total number of intervals that

have passed.

Interval degassing – Economy mode in automatic mode

After 8 intervals (standard), a break (standard 23 h) is observed

before the next 8 degassing intervals are started. This program is

automatically started upon completion of continuous degassing or can

be selected manually for systems already degassed. Interval

degassing then starts at 08:00 each day.

No degassing – Only make-up

The system water is not degassed. This operating mode is practical

during summer operation or if general degassing of the system water

is not required.

Manual mode may only be be used after the initial start-up has been

completed. This operating mode is primarily a means of performing

functional checks of the pump and the make-up solenoid valve.

Select the pump or motorized ball valve,

activate the flashing symbol with the “ok”

button.

Pump starts/motorized ball valve opens.

Pressing the “ok” button again stops the

pump or closes the motorized ball valve.

Alternatively, the “quit” button can also be

pressed directly. The pump and motorized ball valve then switch off after each

other.

Stop Mode

In stop mode, ’servitec 30’ is without function except for indication in the

LCD display. Operation monitoring does not take place. The pump is shut

off. The adjacent display appears when the “stop” button is pressed.

10

Messages are indicated on the display by the “info” symbol. At the same time, “Er” and the relevant

error code (e.g. Er 06) are shown on the info display. If there are several messages present, these may

be displayed using the symbols.

Most of the messages are automatically acknowledged once the cause has been remedied (see

table). Errors such as “Make-up time 06” or “Make-up cycle 07” must be acknowledged manually.

For remote transmission, it is possible to use the floating changeover switch for the common message.

In the customer menu, you can select whether only those messages characterized as alarms or all

messages should be output using the floating contact.

Messages

9

9

11

It is often of great use to know the sequence for assessing

a message or understanding the cause. The information in

the error memory can aid this (→ a. customer menu).

Scroll to the error memory display

This displays the last 20 errors with information from the

error code (e.g. ER01) as well as the corresponding

operating hour to the time that the message occurred.

Error sequence E01 is the mostrecent error; E20 is

the oldest error.

If the error memory is called up the most recent error (01) is

shown

To scroll through the error memory use:

To quite the error memory use:

Maintenance instructions

Disassembly

Maintenance work should only be carried out by specialists. As a reminder of the annual maintenance, the message

“SrV” is shown in the display after a year of operation. This can be acknowledged with the “quit” button.

Leak test

– Check for external leaks

– Seal, if required

Clean dirt trap

– Clean the “blue ball valve” of the dirt trap (3)

Perform vacuum test

– p. 5

Function test of pump, motorized ball valve

– p. 9

Prior to disassembly of the ’servitec 30’ system or pressurized

parts, these must be depressurized on the fresh water and system sides.

1. On-site valves must be shut off to ’servitec 30’

2. Run the controller in “manual mode” page 9 and open motorized

ball valve (2) until pressure equalization with the atmosphere is achieved.

Lowara UK Limited

Millwey Rise Industrial Estate

Axminster, Devon EX13 5HU - UK

Tel: 01297 630230

Fax: 01297 630270

e-mail: lowaraukenquiries@xyleminc.com

http://www.lowara.co.uk

http://completewatersystems.com

Lowara is a trademark of Xylem Inc. or one of its subsidiaries.

© 2011 Xylem, Inc.

Lowara reserve the right to make modifications without prior notice.

C

ode. UKLIT0103 P10/12

Loading...

Loading...