WARNI

NG

C

A

U

T

I

O

N

!

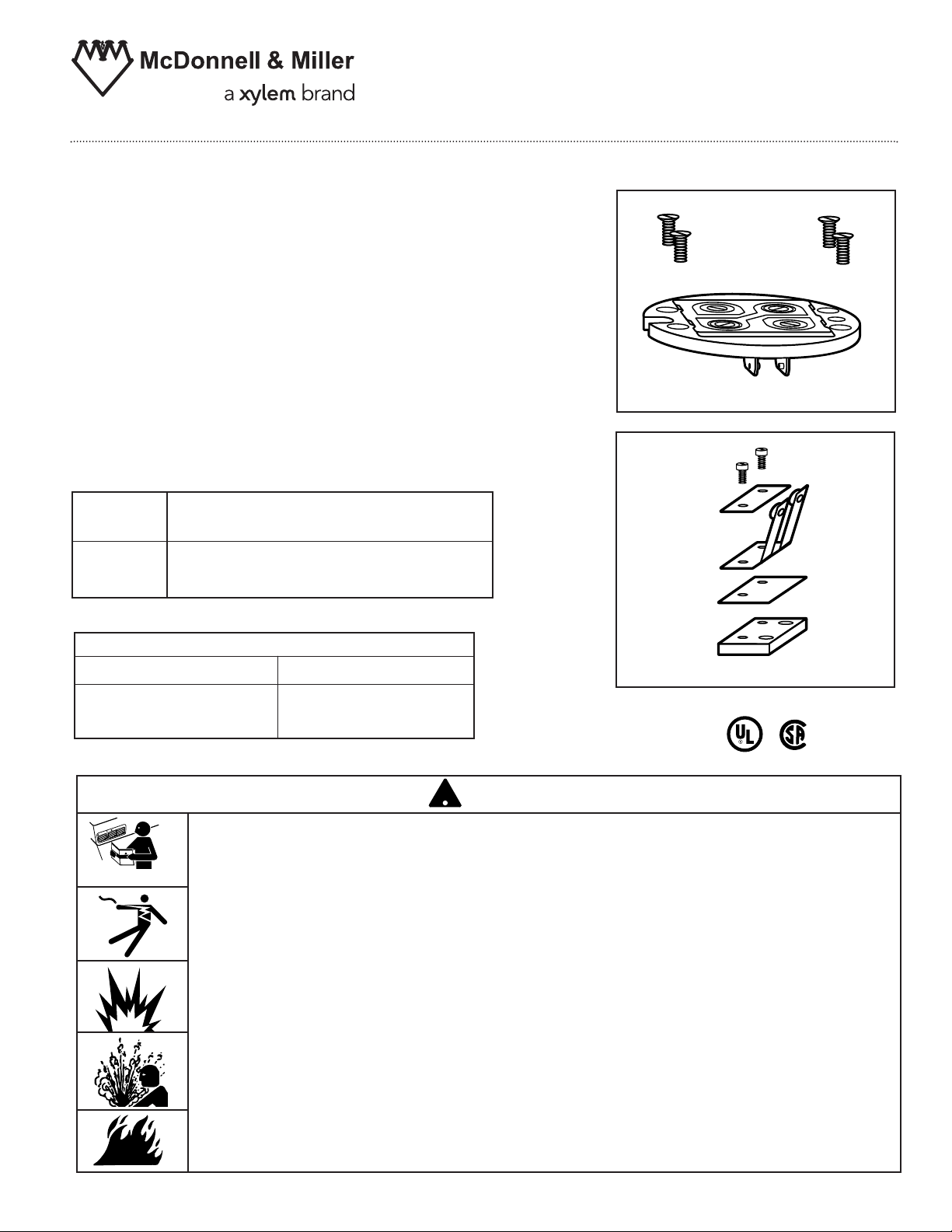

Replacement Pump and Burner

Switch Arm Contacts with

Terminal Panel

SA91-30B

SA91-30P

INSTRUCTION MANUAL

MM-714C

For installation on 5, 5-M, 7B or 7B-M

Switch Assemblies

Electrical Ratings

Models with 5 or 5-M Switch

Pump and Burner Switch Contact Ratings

Voltage Pilot Duty Only

120 VAC

345 VA

240 VAC

Models with 7B or 7B-M Switch

Switch Ratings

Burner Valve

120 VAC

345 VA 0 - 135 ohms @ 24 VAC

240 VAC

Terminal Panel

Switch Arm Contact

WARNING

• Before using this product read and understand instructions.

• Save these instructions for future reference.

• All work must be performed by qualified personnel trained in the proper

application, installation, and maintenance of plumbing, steam, and electrical

equipment and/or systems in accordance with all applicable codes and ordinances.

• To prevent a fire, do not exceed the switch contact rating.

Failure to follow this warning could cause property damage, personal injury or

death.

O

FF

O

N

STEP 1 - Removal and Replacement of Contacts and Terminal Panels

BURNER

SWITCH

LEVER

STOPS

A

C

E

TOWER

TUBE

FITTIN

G

H

U

B

S

WITC

H

H

O

U

S

IN

G

T

E

RMINA

L

CO

NNE

CT

IO

NS

S

WIT

C

H

C

O

V

E

R

P

U

MP

T

E

R

MIN

A

L

P

A

N

E

L

B

U

R

N

E

R

T

E

R

MIN

A

L

P

A

N

E

L

C

O

N

D

U

I

T

C

O

N

N

E

C

T

O

R

N

AM

EPLAT

E

NA

ME

P

L

A

TE

BASE

PLAT

E

B

D

!

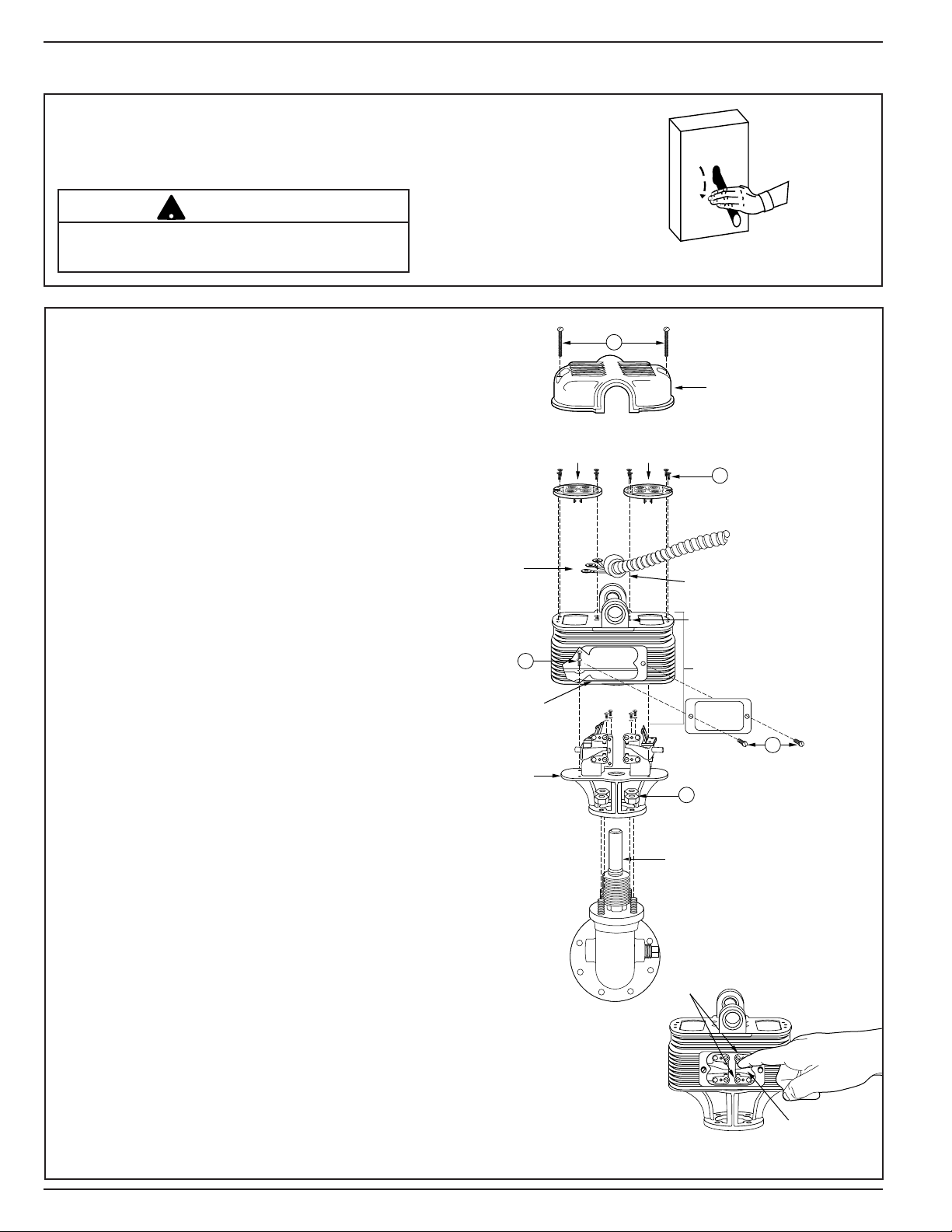

a. Turn power off to boiler and all controls.

Allow boiler to cool to 80˚F (27˚C) and

reduce the pressure to 0 psi (0 bar).

CAUTION

There may be more than one source of power to

the boiler.

b. Remove Switch Assembly, Terminal

Panels and Switch Housing

• Remove two screws (A) and lift off switch

cover.

• Identify terminal connections for rewiring

and then disconnect all wires from terminal

panels.

• Remove conduit connector and wire from

integral fitting hub.

• Remove four hex nuts (B) and carefully lift

switch assembly up and off tower tube.

• Remove two screws (C) and remove

nameplate.

• Loosen and remove four screws (E) that

hold pump and burner terminal panels in

place. Do not remove terminal panels at

this time.

• Reach through nameplate opening and hold

burner switch lever about midway

between upper and lower stops to move

contact arms into correct (upright) position.

With contact arms in upright position, carefully

remove burner terminal panel.

• Reach through nameplate opening and hold

pump switch lever about midway

between upper and lower stops to move

contact arms into correct (upright) position.

With contact arms in upright position, carefully

remove pump terminal panel.

• Loosen four screws (E) and carefully lift

switch housing up off base plate.

2

NOTCH

NOTCH

5 / 5-M

TERMINAL PANEL

ORIENTATION

24

1

BLUE RED

3

31

42

A

C

E

TOWER

TUBE

FITTIN

G

H

U

B

S

WITC

H

H

O

U

S

IN

G

T

E

RMINA

L

CO

NNE

CT

IO

NS

S

WIT

C

H

C

O

V

E

R

P

U

MP

T

E

R

MIN

A

L

P

A

N

E

L

B

U

R

N

E

R

T

E

R

MIN

A

L

P

A

N

E

L

C

O

N

D

U

I

T

C

O

N

N

E

C

T

O

R

N

AM

EPLAT

E

NA

ME

P

L

A

TE

BASE

PLAT

E

B

D

F

G

H

I

c. Remove and Replace Switch Arm Contacts

• Remove two screws (F) and lift off bus bar

(G), contact arms (H) and insulator (I).

• Place new insulator (I), contact arms (H) and

bus bar (G) in position and fasten with two

screws (F). Make sure the contact arm blades (H)

are in alignment and at right angle to insulator.

d. Replace Switch Housing, Switch

Assembly and Reconnect Wiring

• Replace switch housing and fasten to

base plate with four screws (E).

Move burner switch arms to upright position

•

by reaching through nameplate opening

and holding burner switch lever midway

between stops. Carefully set burner

terminal panel in position and fasten with

screws (D). Do not force. (See diagram at

lower right for proper orientation of

terminal panel).

Move pump switch arms to upright position

•

by reaching through nameplate opening

and holding pump switch lever midway

between stops. Carefully set pump

terminal panel in position and fasten with

screws (D). Do not force. (See diagram

at lower right for proper orientation of

terminal panel).

• Check visually to see that contact arms

are in proper position between terminal

panel contacts and move lever up and

down to see that switch operates freely

and smoothly.

• Carefully slide switch assembly over

tower tube and secure with four hex

nuts (B).

• Install conduit connector and wires to

the integral fitting hub on switch

assembly.

• Reconnect wiring to terminal panel in

exactly the same position as removed.

• Replace switch cover and fasten with

two screws (A).

• Replace nameplate and fasten with

two screws (C).

Proceed to Step 2 to Test Control

3

!

!

McDonnell & Miller

STEP 2 - Testing

– Dimensions shown are typical.

– The following testing procedure is only meant to serve as a verification of proper

operating sequence.

a. Turn on power to boiler and pump circuits.

With the boiler empty, the pump should turn on (5 or 5-M switch models) or the valve open

(7B or 7B-M switch models). The burner should remain off and boiler should begin to fill with water.

CAUTION

mmediately turn off all power if the burner turns on with no water in the gauge glass.

I

Investigate further before continuing procedure.

b. For Automatic Reset Models

When water level in the gauge glass is approximately 1 3/8” (35mm) above the horizontal cast line,

the burner should turn on.

For Manual Reset Models

When water level in the gauge glass is approximately 1 3/8” (35mm) above the horizontal cast line,

press the manual reset button and the burner should turn on.

c. For 5 or 5-M Switch Models

When water level in the gauge glass is approximately 2 1/8” (54mm) above the horizontal cast line,

the pump should turn off.

For 7B or 7B-M Switch Models

When water level in the gauge glass is approximately 2 11/16” (68mm) above the horizontal cast

line, the valve should be closed.

CAUTION

If pump does not turn off or valve close, turn off water supply to boiler. Investigate

further before continuing procedure.

d. With the water in the boiler at its normal level and burner on, SLOWLY open the blow-down valve

until it is fully open. As the water level in the gauge glass begins to drop, verify that the following

occurs.

For 5 or 5-M Switch Models

When water level drops to approximately 1 1/8” (29mm) above the horizontal cast line, the pump

should turn on.

When water level drops to the horizontal cast line, the burner should turn off.

For 7B or 7B-M Switch Models

As the water level drops, the valve should begin to open.

When the water level drops to approximately 7/8” (22mm) above the horizontal cast line, the valve

should be full open.

When the water level drops to the horizontal cast line, the burner should turn off.

e. Close the blow-down valve after burner turns off and restore water level to normal operating level.

f. Repeat testing procedure several times to ensure proper operation of control.

g. After testing and verification of control operation, the boiler can be returned to service.

Xylem Inc.

8200 N. Austin Avenue

Morton Grove, Illinois 60053

Phone: (847) 966-3700

Fax: (847) 965-8379

www.mcdonnellmiller

McDonnell & Miller is a trademark of Xylem Inc. or one of its subsidiaries.

© 2013 Xylem Inc. MM-714C January 2013 Part No. 210422

Loading...

Loading...