Series 6667 Replacement

!

Mechanism

Model 6667 on 120 VAC or 24 VAC Systems

Model 6667MV on Millivolt or 24 VAC Systems

Used on Series 61, 67, 69, 767, 70, and 70-B

Low Water Cut-offs

OPERATION

Maximum Steam Pressure: 20 psi

INSTRUCTION MANUAL

MM-209D

Electrical Ratings

Voltage Full Load Locked Rotor Pilot Duty

120 VAC 7.4 44.4 125 VA at

240 VAC 3.7 22.2 120 or 240 VAC

57.5 VA at

120 or 240 VDC

On D.C. Service be sure to connect (+) positive

wire to terminal marked (2).

CAUTION

WARNING

• Before using product, read and understand instructions.

• Save these instructions for future reference.

• All work must be performed by qualified personnel trained in the proper application,

installation, and maintenance of plumbing and electrical equipment and/or systems in

accordance with all applicable codes and ordinances.

WARNING

Series 6667

®

Approved

• To prevent electrical shock, turn off the electrical power before making electrical

connections.

• To prevent serious burns bleed off all pressure and let boiler cool down to 80˚F (27˚C).

• Drain water level down below the control before taking the control out of the boiler.

Failure to follow this warning could cause property damage, personal injury or death.

2

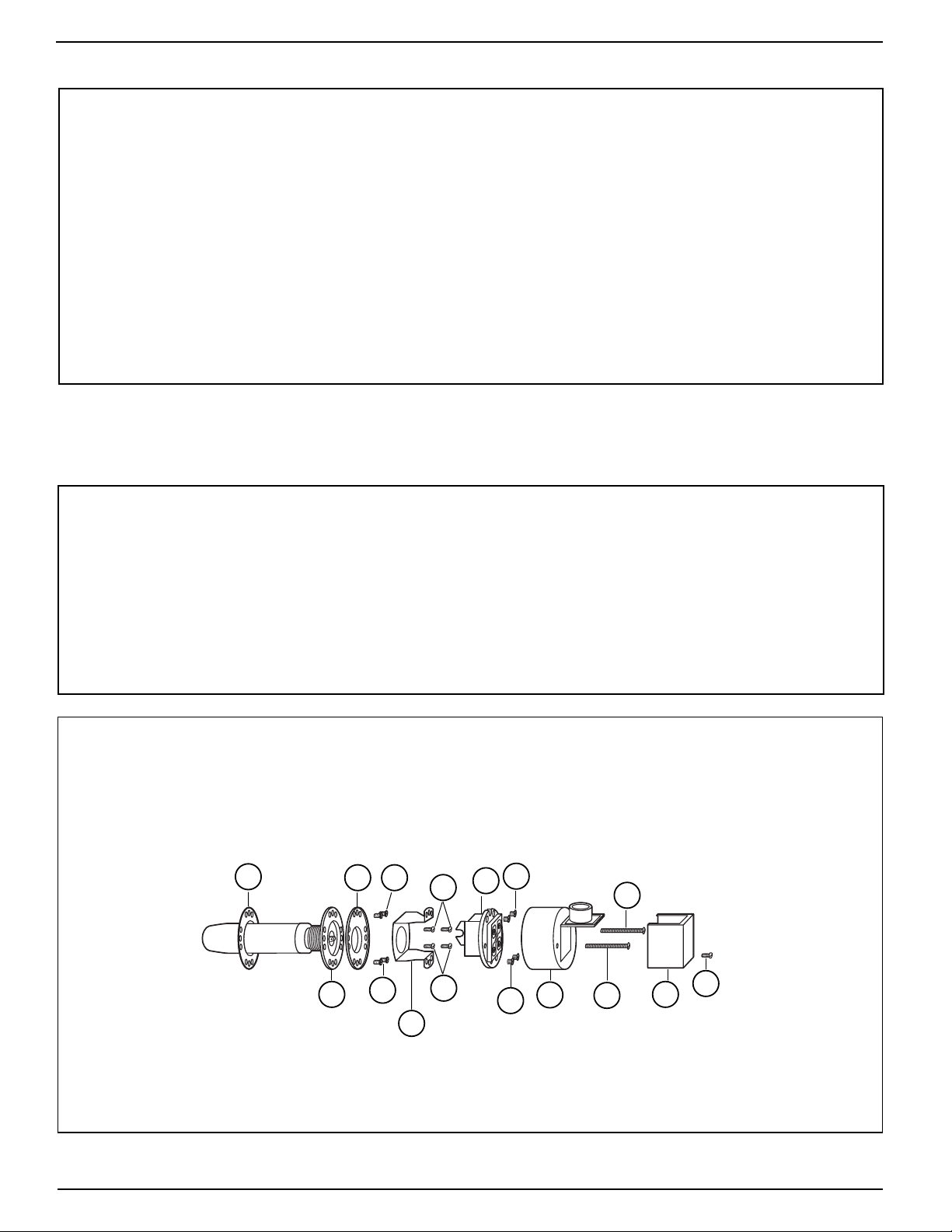

a. See figure 1. Turn off all electrical power to the boiler. (There may be more than one power

source to the boiler). Bleed off all pressure and let the boiler cool down to 80˚F (27˚C).

Drain water level in boiler down below the control. Remove screw (A) and cover (B). Tag all

wires for reconnection later. Disconnect wires from the terminals and remove conduit connection from housing (C). Remove two (2) screws (D) and switch housing (C).Remove four

(4) screws (E) and remove switch (F). Remove four (4) screws (G) and bracket (H).

Remove four (4) screws (J) and ring (K). The float and bellows assembly (L) can now be

removed. Clean the gasket surface and mount the new float and bellows assembly.

b. Disassemble the new 6667 by removing screw (A) and cover (B). Remove the two (2) nuts

on the back side of screws (D) and pull the assembly apart.

STEP 1 - Preparation

STEP 2 - Installation on 61, 67, 767, 70, and 70-B

For installing in a 69 Series see Step 3

a. See figure 1. Slip gasket (M) over float (L) and slide into body. Make sure that word TOP on

the bellow base is at the top. Align the holes in gasket (M) with holes in the body, float and

bellows assembly (L) and ring (K). Using four (4) screws (J) attach (L) and (K) to the body.

Attach bracket (H) using four (4) screws (G) to ring (K) and body. Install switch (F) into

bracket (H), making sure that the yoke on the switch fits around the roller in float and bellows assembly (L) and that the word TOP on the switch is at the top. Attach with four (4)

screws (E). Attach housing (C) using two (2) screws (D). Install conduit connector and

reconnect wires to their proper terminals. Install cover (B) using screw (A).

E

L

J

F

C

B

D

G

H

M

K J

G

E

D

A

Figure 1

3

a. Follow STEP 1-a.

STEP 3 - Installation on 69 Series

b. See figure 2. Remove eight (8) screws (N) and clamping ring (O). Mark position of float

shield (P) with respect to barrel casting (R). Inspect and clean float shield (P). Clean the

gasket surfaces, being careful not to scratch them. NOTE: On newer models the gasket

has been replaced with square cut rings (items (T) in figure 2). Place gasket (S) over float

shield (P) and insert the float shield (P) into barrel casting (R). Line up the marks that you

applied above. Using clamping ring (O) and eight (8) screws (N) secure the float shield (P)

to the barrel casting (R).

c. Follow STEP 2-a.

a. Run the control through several cycles of operation before leaving the job site.

STEP 4 - Testing

R

P

T

O

S

N

M

L

K

J

J

H

G

G

F

E

E

C

D

D

B

A

Figure 2

MAINTENANCE

TROUBLESHOOTING

SCHEDULE:

• Blow down weekly during heating season.

(On 61, 67, 767, 70 and 70B). Blow down

weekly if operating pressure is 15 psi or lower.

Blow down daily if operating pressure is 15 psi

or higher.

• Follow ASME Boiler and Pressure Vessel

Code - Section VI Paragraph 7.07G. It states

that the controls should be dismantled annually

by qualified personnel, to the extent necessary

to insure freedom from obstructions and proper

functioning of the working parts.

• Check for leaks at the gasket surfaces and

solder joints. Repair or replace components as

needed.

• Check all wiring for brittle or worn insulation.

• Replace control every 10 years.

Problem:

1. Control does not turn burner off on low water.

a. Cause: Build up of scale and sediment.

Test: Dismantle control and check for any

build up or any other obstructions that

would prevent the control from turning

off the burner. Don’t forget to check the

corrugations of the bellows.

Solution: Clean or replace as necessary.

b. Cause: Terminals 1 and 2 on the No. 11 switch

are not opening up on low water.

Test: With a continuity meter or ohm meter

check if terminals 1 and 2 open on low

water. If they do not open, take the switch

off the control and work it manually.

Solution: If terminals 1 and 2 do not open when

operated manually, replace the switch. If

they do open see item a. above.

Problem:

2. Control does not turn electric feeder off.

a. Cause: Build up of scale between the corruga-

tions of the bellows. On 69 units the float

shield could be tipped down.

Test: Dismantle the control and check for

scale build up between the bellow corrugations. On the 69 series control check

the float shield to make sure it is in the

proper position.

Solution: Clean or replace as necessary. On 69

series reposition the float shield.

Xylem Inc.

8200 N. Austin Avenue

Morton Grove, Illinois 60053

Phone: (847) 966-3700

Fax: (847) 965-8379

www.xyleminc.com/brands/mcdonnellmiller

McDonnell & Miller is a trademark of Xylem Inc. or one of its subsidiaries.

© 2012 Xylem Inc. MM-209D April 2012 Part No. 246776

Loading...

Loading...