Page 1

Replacement Head Mechanism

!

150E-HD

Replacement head mechanisms can be installed without

disturbing existing equalizing connections or disassembly

of components, making repair simple and easy.

The Series 150E is a microprocessor based control

which utilizes the conductive properties of the boiler

water to operate relays. All units include redundant low

water cut-off and pump off features to guard against

shorted or fouled probe conditions.

INSTRUCTION MANUAL

MM-415C

Series 150E

WARNING

CAUTION

WARNING

• Before using this product read and understand instructions.

•Save these instructions for future reference.

• All work must be performed by qualified personnel trained in the proper application, instal-

lation, and maintenance of plumbing, steam, and electrical equipment and/or systems in

accordance with all applicable codes and ordinances.

•To prevent serious burns, the boiler must be cooled to 80˚F (27˚C) and the pressure must be

0 psi (0 bar) before servicing.

•To prevent electrical shock, turn off the electrical power before making electrical connections.

• This low water cut-off must be installed in series with all other limit and operating controls

installed on the boiler. After installation, check for proper operation of all of the limit and

operating controls, before leaving the site.

•We recommend that secondary (redundant) low water cut-off controls be installed on all

steam boilers with heat input greater than 400,000 BTU/hour or operating above 15 psi of

steam pressure. At least two controls should be connected in series with the burner control

circuit to provide safety redundancy protection should the boiler experience a low-water

condition. Moreover, at each annual outage, the low water cut-offs should be dismantled,

inspected, cleaned, and checked for proper calibration and performance.

•To prevent serious personal injury from steam blow down, connect a drain pipe to the control

opening to avoid exposure to steam discharge.

•To prevent a fire, do not use this low water cut-off to switch currents over 16A, 1 Hp at

120 VAC or 8A, 1 Hp at 240 VAC, unless a starter or relay is used in conjunction with it.

Failure to follow this warning could cause property damage, personal injury or death.

Page 2

SPECIFICATIONS

Maximum Pressure: 150 psi (10.5 kg/cm2)

ELECTRICAL RATINGS & SWITCH RATINGS

Supply Probe Full Load (Amps) Locked Rotor (Amps) Pilot Duty (VA) Motor (HP)

Voltage Voltage NO (NC), VAC NO (NC), VAC NO (NC), VAC NO (NC), VAC

120 VAC 5 VAC 16 (5.8), 120 96 (34.8), 120 470 (290), 120 1 (1/4), 120

50/60 HZ maximum 8 (2.9), 240 48 (17.4), 240 470 (290), 240 1 (1/4), 240

Burner Delay (DOB): 0 to 60 seconds (Field Adjustable)

Ambient Temp: 120˚F Max.

NOTE: The circuit board is protected with a sensor which will

shut down the unit if the temperature at the board exceeds

176˚F (80˚C). The board will reset when the temperature at

the board drops below 167˚F (75˚C).

FEATURES

Burner Relay Time Delay

There is a field-adjustable time delay (DOB) to prevent nuisance burner shut-down. The number of

seconds water needs to be off the bottom probe

before the burner relay is reactivated can be set

between 0 and 60 seconds.

Redundant Low Water Cut-Off

When the boiler water drops below the middle

probe, a 3 minute timing circuit will be activated. If

water does not return to the middle probe within

three minutes, the burner relay will reactivate. The

Red LED will flash once every second if this

condition occurs.

•Automatic Reset units will automatically reset

when the water level is restored to the middle

probe.

• The reset button on Manual Reset units will

have to be pressed after water is restored to

the middle probe.

NOTE: The timing circuit will automatically reset

if the water level is restored to the middle probe

within 3 minutes.

Redundant Pump Off

The pump relay will be activated after water drops

below the middle probe. If the water level is not

restored to the top probe within 3 minutes the pump

relay will be deactivated. After the pump relay is

deactivated, normal operation is resumed. Water

must again drop off the middle probe to activate the

pump relay. There is no LED signal for this

occurance.

CSD-1 Code Compliance

On Manual Reset units, if the control is in a low

water condition (burner relay deactivated) prior to

an interruption of power, the control will remain in a

low water condition when power is restored. The

reset button will need to be pressed when the water

level again covers the middle probe.

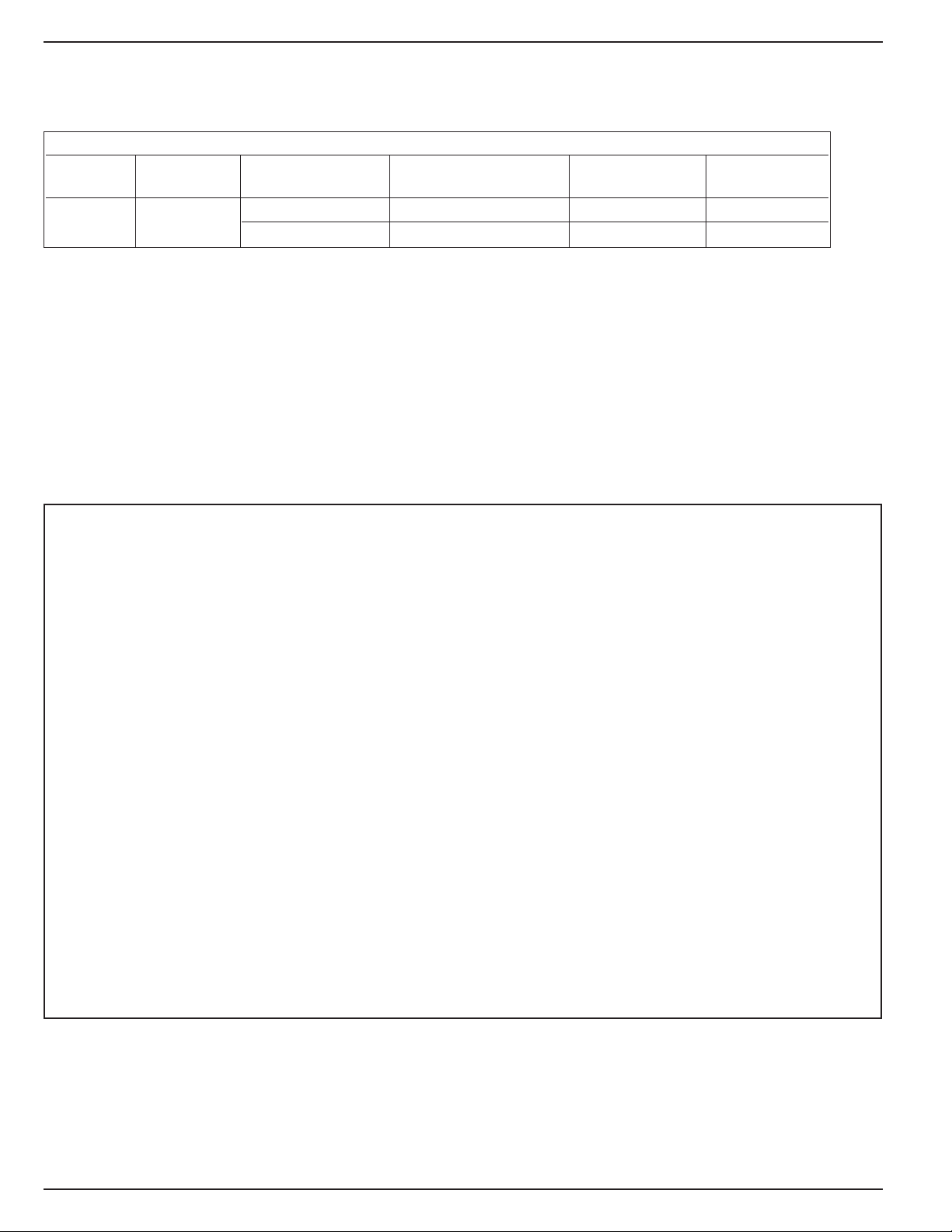

Adjustable Pump Differentials

2

Page 3

BURNER

CUT-OFF LEVEL

AT CAST LINE

(22mm)

BURNER OFF

BURNER ON

7

/8"

PUMP

OFF

BURNER

OFF

BURNER

CUT-OFF LEVEL

AT CAST LINE

2

1

/16"

(52 mm)

NORMAL BOILER

WATER LINE

1

3

/16"

(30 mm)

PUMP OFF

PUMP ON

NORMAL BOILER

WATER LINE

SWITCH SETTINGS:

BURNER

CUT-OFF LEVEL

AT CAST LINE

(22mm)

BURNER OFF

BURNER ON

7

/8"

PUMP

OFF

BURNER

OFF

BURNER

CUT-OFF LEVEL

AT CAST LINE

1

5

/8"

(41mm)

NORMAL BOILER

WATER LINE

3

/4" (19 mm)

PUMP OFF

PUMP ON

NORMAL BOILER

WATER LINE

Values are ±

3

/16” (6mm).

When the water level in the boiler drops below the

middle probe, the circuit is broken which will activate the pump relay. When the water level rises

above the top probe, the circuit is made and the

pump relay is deactivated.

The distance between the top and middle probes is

adjustable. By turning the flange one bolt hole

clockwise, the distance can be increased by 7/16”.

Approximate

Distance Above

Cast Line Differential

Setting In. (mm) In. (mm)

Pump Off 15/8 (41)

Pump On

Burner On

7

/8 (22)

7

/8 (22)

Burner Off 0 (0)

3

/4(19)

7

/8(22)

When the water level in the boiler drops below the

bottom probe, the circuit is broken which will deactivate the burner relay. When the water level is

restored to the middle probe, the burner relay will

be activated for auto reset controls only.

Flange in “B” PositionFlange in “A” Position

Approximate

Distance Above

Cast Line Differential

Setting In. (mm) In. (mm)

Pump Off 2

Pump On

Burner On

Burner Off 0 (0)

1

/16 (52)

7

/8 (22)

7

/8 (22)

3

/16(30)

1

7

/8(22)

Burner Off has adjustable 0-60 second time delay.

Burner Off has adjustable 0-60 second time delay.

3

Page 4

A

B

C

D

F

E

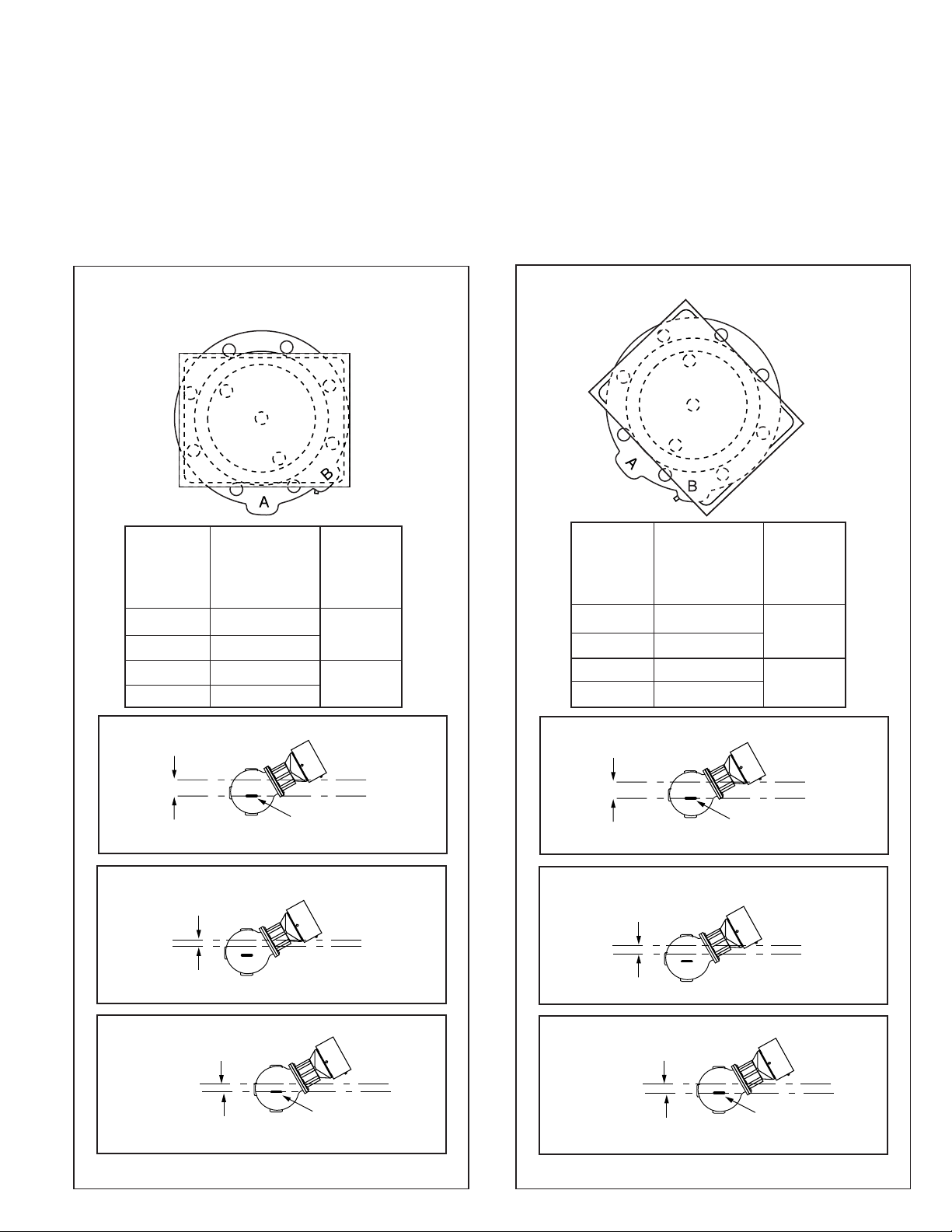

INSTALLATION –

!

!

A

B

C

D

TOOLS NEEDED:

One (1) pipe wrench, one (1) flatblade screwdriver, one (1) scraper, and one (1) 9/16" socket or wrench.

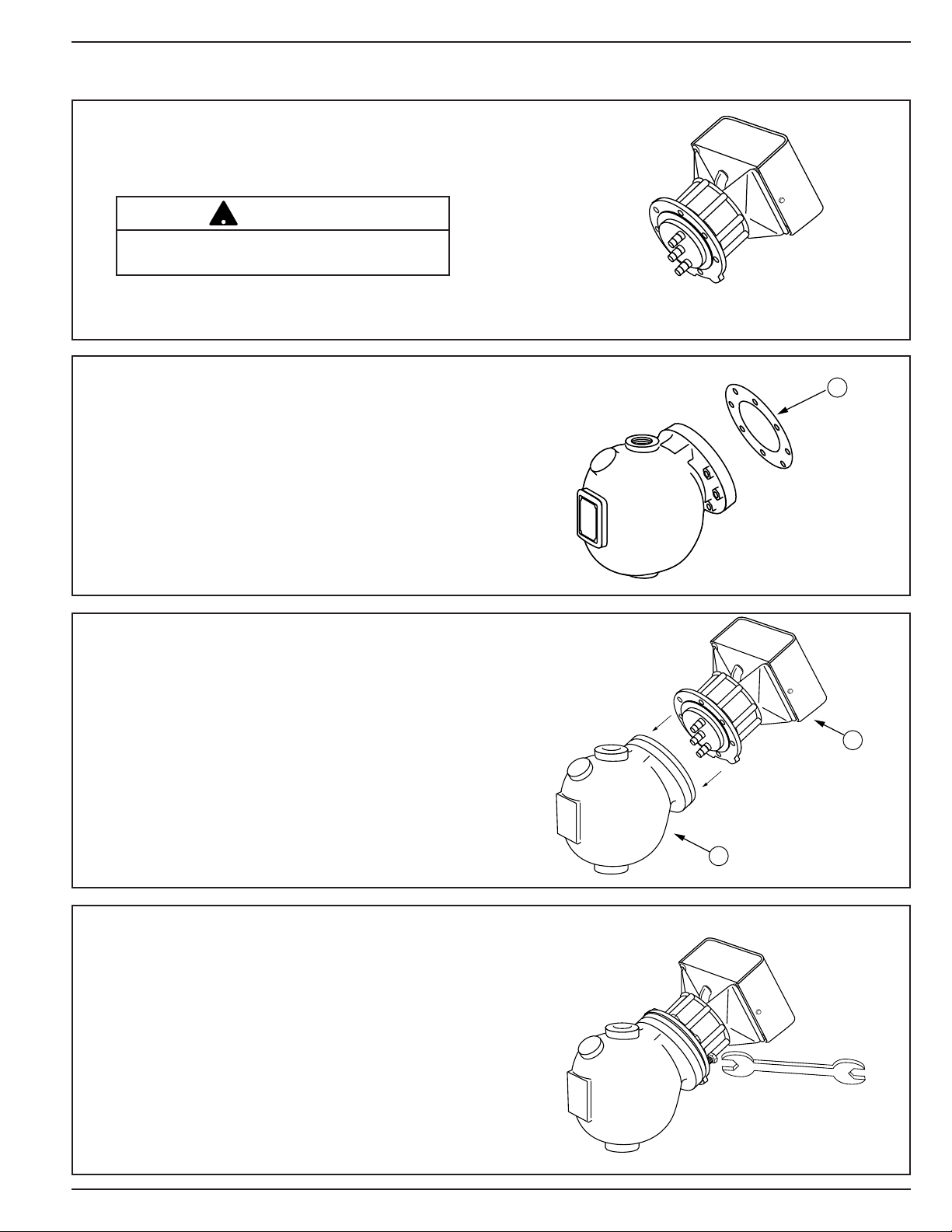

STEP 1 - Preparation

WARNING

•To prevent serious burns, the boiler must be cooled to 80˚F (27˚C) and the pressure must be 0 psi (0 bar)

before servicing.

•To prevent electrical shock, turn off the electrical power before disconnecting or making electrical connections.

Failure to follow this warning could cause property damage, personal injury or death.

a. Drain water in the boiler to a level

which is below the float chamber (A).

Allow the boiler to cool to 80˚F

(27˚C) and release the boiler pressure to 0 psi (0 bar).

b. Using a flatblade screwdriver, remove the

junction box cover (B). Disconnect, mark,

and remove the supply wires and conduit

connections.

CAUTION

There may be more than one source of

power to the control.

c. Remove the existing head mechanism (C)

from the body (D).

d. Using a scraper, remove the old gasket (E).

Clean all debris from the float chamber. The

gasket sealing surface (F) must be smooth

and clean.

4

Page 5

!

J

K

D

STEP 2 - Installing the Replacement Head Mechanism

a. Carefully remove the new replacement head

mechanism from the carton. Handle it carefully

to prevent damage to the probes.

CAUTION

If probes are loose and/or damaged, the control

may leak or not work properly.

b. Align the bolt holes of the new head gasket (J)

on the sealing surface of the control body.

c. Install the new replacement head (K) on the

body (D) by guiding the probes into the control

body and aligning the bolt holes.

NOTE: For increased pump differential locate

tab “B” down (see page 3 Flange Positioning).

d. Using a wrench, insert the eight (8) bolts and

tighten them to approximately 14-20 ft•lb

(19-27 N•m) in an alternating star pattern.

5

Page 6

Cover

A

BCOM

BNC

BNO

PCOM

PNC

PNO

N

H

BCOM

BNC

BNO

PCOM

PNC

PNO

N

H

60

30

Secs.

0

60

30

Secs.

0

B

Probe Wires

B

Control Box

B

B

Remote Mounting of the Control Box

Loosen screws (A) and remove cover.

• Disconnect probe wires (red, blue, yellow) from

circuit board.

• Remove 4 screws (B) connecting control box to

brackets, lifting control box from brackets.

6

Page 7

Probes

Cover Plate

Brackets

C

C

C

C

C

C

Offset Connector

• Remove 6 screws (C) connecting brackets

Upper Nut

and cover plate to probe housing.

• Remove offset connector from cover plate.

Disconnect wires from probes.

NOTE

Only loosen upper nut to remove probe wire.

7

Page 8

• Mount Control Box in a suitable location near

the boiler’s main electrical panel.

NOTE

Boiler sight glass must be visible from location of

Control Box and must be within 25 feet of Control

Box.

• Install electrical conduit between Probe

Housing and Control Box.

NOTE

Wire must be 18 AWG stranded with glass braided

silicone jacket (UL 3071) suitable for high temperature (200˚C) service.

NOTE

Refer to and follow local codes and standards

when selecting conduit and electrical fittings.

Wires from Probe Housing to Control Box must be

in their own conduit. If they are run in conduit with

other wires, there may be interference that can

affect the performance of the control.

• Pull four (4) wires through conduit.

8

Page 9

Screws

Plate Ground

Blue/Top

Yellow/Middle

Red/Bottom

Connect wires between Control Box and Probes

BCOM

BNC

BNO

PCOM

PNC

PNO

N

H

BCOM

BNC

BNO

PCOM

PNC

PNO

N

H

60

30

Secs.

0

60

30

Secs.

0

BCOM

BNC

BNO

PCOM

PNC

PNO

N

H

BCOM

BNC

BNO

PCOM

PNC

PNO

N

H

60

30

Secs.

0

60

30

Secs.

0

Probe wires

Control Box

Chassis Ground

as follows.

Pr

obes Control

Top/Blue Top/Blue

Middle/Yellow Middle/Yellow

Bottom/Red Bottom/Red

Plate Ground Chassis Ground

NOTE

Wire connections at Probes (1/4” Ring Terminal) and

Control Panel (22-18 Female Spade) must be made

with connectors suitable for high temperature (200˚C)

service.

• Attach cover plate to probe housing.

• Use knockout plug from probe housing to plug

the hole in the cover plate.

• Proceed to Electrical Wiring Section to complete

wiring to Burner and Pump/Valve circuits.

9

Page 10

STEP 4 - Electrical Wiring

!

L

BCOM

BNC

BNO

PCOM

PNC

PNO

N

H

BCOM

BNC

BNO

PCOM

PNC

PNO

N

H

60

30

Secs.

0

60

30

Secs.

0

BCOM

BNC

BNO

PCOM

PNC

PNO

N

H

0 60

30

Secs.

0

Probe Connections

Bottom

Red

Middle

Yellow

To p

Blue

0-60 Second Adjustable

Burner Off Delay

110 Volt Input

from Boiler

Circuit

Manual Reset

(If applicable)

Low Water

LED

Red

Powe r

LED

Green

Test

Switch

Burner

Te r minals

Pump

Te r minals

BCOM

BNC

BNO

PCOM

PNC

PNO

N

H

Probe LED's

K

WARNING

•To prevent electrical shock, turn off the electrical power before making electrical connections.

• This low water cut-off must be installed in series with all other limit and operating controls installed on the

boiler. After installation, check for proper operation of all of the limit and operating controls, before leaving

the site.

• Boiler manufacturer schematics should always be followed. In the event that the boiler manufacturer’s

schematic does not exist, or is not available from the boiler manufacturer, refer to the schematics provided

in this document.

Failure to follow this warning could cause electrical shock, an explosion and/or a fire, which could result in

property damage, personal injury or death.

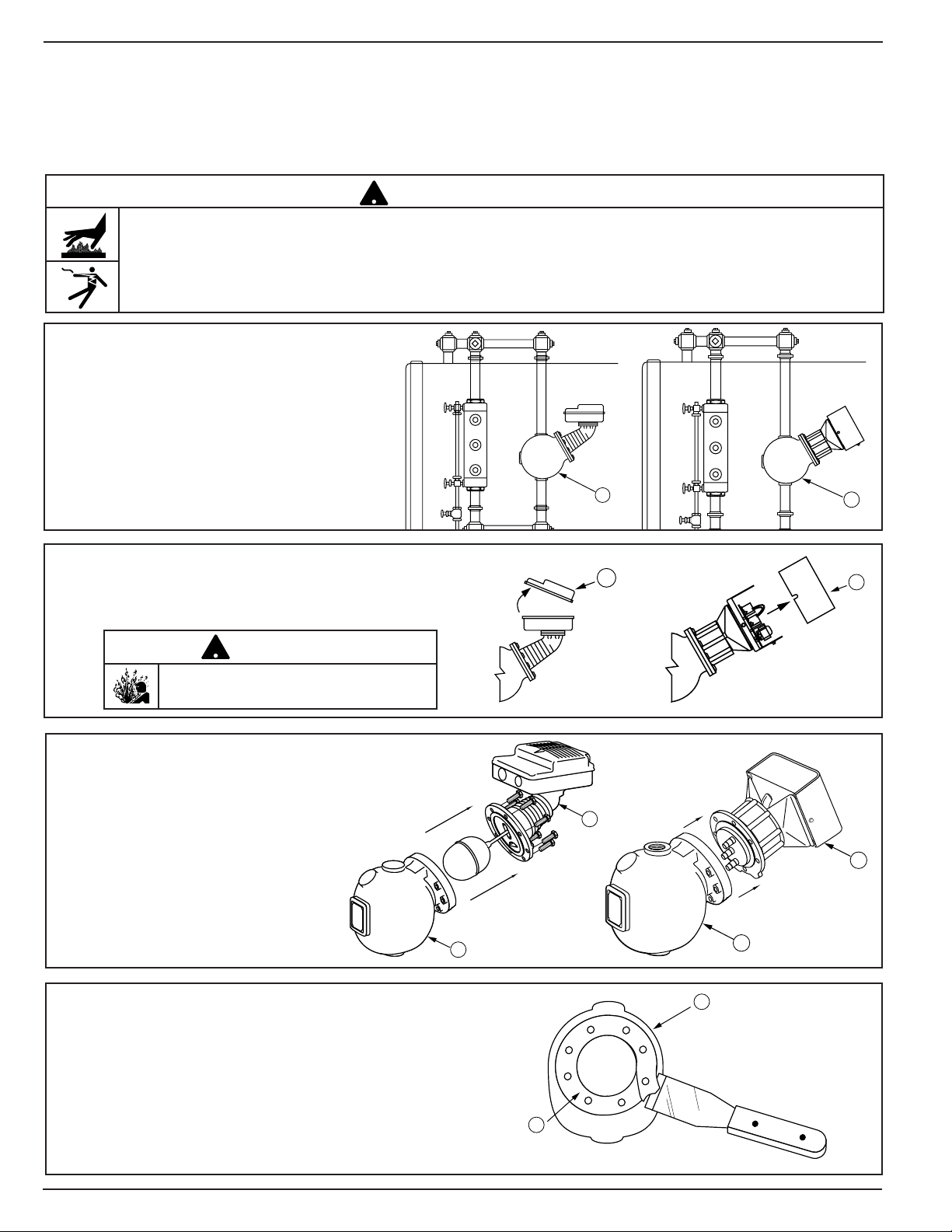

Cover Removal and Installation Procedure

a. To remove cover, use a flathead screwdriver to

loosen screws and remove the cover (K).

b. To reconnect cover, slide over brackets and tighten

screws using a flathead screwdriver.

c. Following the appropriate wiring diagram (refer to

page 11) based on your application requirements,

and using BX armored cable or Thinwall electrical

metal tubing connector fittings, make electrical

connections to the junction box (L).

IMPORTANT: There must be a minimum space

of 2” (13mm) between connector fittings and

electrical live metal parts.

Circuit Board Layout

10

Page 11

PUMP

OPERATION

BURNER

OPERATION

FROM BURNER OR ALARM

CONTROL CIRCUIT

TO ALARM

CONTROL CIRCUIT

TO BURNER

CONTROL CIRCUIT

FROM PUMP UP

CONTROL CIRCUIT

TO PUMP UP

CONTROL CIRCUIT

NEUTRAL

HOT

BCOM

BNC

BNO

PCOM

PNC

PNO

N

H

g

f

e

d

c

b

a

WIRING DIAGRAMS

PUMP 1

OPERATION

PUMP 2

OPERATION

FROM PUMP #1

CONTROL CIRCUIT

FROM PUMP #2

CONTROL CIRCUIT

TO PUMP #2

CONTROL CIRCUIT

TO PUMP #1

CONTROL CIRCUIT

NEUTRAL

HOT

BCOM

BNC

BNO

PCOM

PNC

PNO

N

H

f

e

d

c

b

a

VALV E

SPRING

CLOSED

BURNER

OPERATION

VALV E

DRIVE

TO OPEN

FROM VALVE

CONTROL CIRCUIT

TO VALVE

CONTROL CIRCUIT

NEUTRAL

HOT

BCOM

BNC

BNO

PCOM

PNC

PNO

N

H

d

c

b

a

FROM BURNER OR ALARM

CONTROL CIRCUIT

TO ALARM

CONTROL CIRCUIT

TO BURNER

CONTROL CIRCUIT

g

f

e

Low Water Cut-Off, Alarm and Pump Up Control

• Connect wire “a” from power supply to terminal “H”.

• Connect wire “b” from neutral supply to terminal “N”.

• Connect wire “c” from pump control circuit to terminal “PNO”.

• Connect wire “d” from pump control circuit to terminal “PCOM”.

• Connect wire “e” from burner control circuit to terminal “BNO”.

• Connect wire “f” from alarm control circuit to terminal “BNC”.

• Connect wire “g” from burner or alarm control circuit to terminal “BCOM”.

Dual Pump Control

• Connect wire “a” from power supply to terminal “H”.

• Connect wire “b” from neutral supply to terminal “N”.

• Connect wire “c” from pump #1 control circuit to terminal “PNO”.

• Connect wire “d” from pump #1 control circuit to terminal “PCOM”.

• Connect wire “e” from pump #2 control circuit to terminal “BNC”.

• Connect wire “f” from pump #2 control circuit to terminal “BCOM”.

Motorized Valve and Low Water Cut-Off

• Connect wire “a” from power supply to terminal “H”.

• Connect wire “b” from neutral supply to terminal “N”.

• Connect wire “c” from valve control circuit to terminal “PNO”.

• Connect wire “d” from valve control circuit to terminal “PCOM”.

• Connect wire “e” from burner control circuit to terminal “BNO”.

• Connect wire “f” from alarm control circuit to terminal “BNC”.

• Connect wire “g” from burner or alarm control circuit to terminal “BCOM”.

11

Page 12

STEP 5 - Testing

OFF

ON

!

IMPORTANT: Follow the boiler manufacturer’s start-up and operating instructions along with all applicable

codes and ordinances.

Exterior Lights

• Green light on: Unit has power

• Red light on: Boiler water dropped below the bottom probe for longer than the adjustable time delay

setting. The burner has shut down.

• Red light flashing every second: Boiler water was below the middle probe for more than three

minutes and the burner has shut down.

• Auto reset units will automatically reset when the boiler water returns to the middle probe.

• Manual reset units must be manually reset after boiler water returns to the middle probe.

• Red light and green light flashing alternately every 1/2 second. Probes are out of sequence.

Unit has shut down. Unit will automatically reset when condition has cleared or been corrected.

• Red light and green light flashing simultaneously every 1/2 second: The PCB is too hot and the unit

has shut down. The unit will automatically restart when the PCB has cooled sufficiently.

• When using the “TEST” button, the green light will flash once per second during the time delay interval.

The time delay setting can be determined by counting the number of flashes.

Interior Lights

Green Light – Shows status of top probe

Yellow Light – Shows status of middle probe

Red Light – Shows status of bottom probe

• If the light is on, the probe is in water and probe resistance is well below the threshold.

• If the light is flashing every 1/2 second, the probe is in water, but probe resistance is near (just below)

the threshold.

• If the light is flashing every 2 seconds, the probe is out of water, but probe resistance is near (just above)

the threshold.

• If the light is off, the probe is out of water and probe resistance is well above the threshold.

Procedure

Tu rn on power to the boiler and pump circuits. With the boiler empty, the

control will be activated (Green LED On) and the pump should turn on.

The burner should stay off (Red LED On).

NOTE: If Green and Red LED’s flash alternately, the probes are not connected in sequence. Turn off power and check probe wires for proper

connection.

WARNING

If the burner comes on, immediately turn the boiler off and make the

necessary corrections.

Failure to follow this warning could cause an explosion or fire and

result in property damage, personal injury or death.

12

Page 13

The boiler should begin to fill with water.

BCOM

BNC

BNO

PCOM

PNC

PNO

N

H

BCOM

BNC

BNO

PCOM

PNC

PNO

N

H

60

30

Secs.

0

60

30

Secs.

0

BCOM

BNC

BNO

PCOM

PNC

PNO

N

H

0 60

30

Secs.

0

Probe Connections

Bottom

Red

Middle

Yellow

Top

Blue

0-60 Second Adjustable

Burner Off Delay

110 Volt Input

from Boiler

Circuit

Manual Reset

(If applicable)

Low Water

LED

Red

Powe r

LED

Green

Test

Switch

Burner

Te r minals

Pump

Te r minals

BCOM

BNC

BNO

PCOM

PNC

PNO

N

H

Probe LED's

NOTE: If water does not start filling the boiler,

immediately turn off the the boiler and make

the necessary corrections.

For Automatic Reset Models:

When the water level reaches the level of the

middle probe, the burner circuit should be activated and the Red LED should turn off. (Pump

#2 should turn off with Dual Pump Applications).

For Manual Reset Models:

The reset button must be pushed to activate the

burner circuit when water reaches the level of the

middle probe.

When the water level rises to the level of the top

probe, the pump relay will be de-activated.

Depending on the application, this will either turn

off the pump or close a valve.

Adjusting Burner Delay (DOB)

The number of seconds that water must be off the

bottom probe before the burner will turn off is

adjustable from 0 to 60 seconds with the unit factory

set at 0 seconds. To adjust, turn the adjusting screw

clockwise using a small flatblade screwdriver to the

delay time desired.

NOTE

If the delay time is too long, the manual reset secondary LWCO may turn off the boiler before this control turns off the boiler. If this occurs, shorten the time

delay by turning the adjustment screw counter-clockwise from the new setting.

Follow the blow down procedure found on page 15

to verify operation.

INSTALLATION COMPLETE

13

Page 14

Troubleshooting

Green LED does not turn on.

• There may be no power to the unit. Check wiring

connected to ‘H’ and ‘N’ terminals on circuit board.

Verify that the control is being powered when the

boiler power is turned on.

Red & Green LEDs flash alternately every

1/2 second.

• The probes are out of sequence. Check probe

wires and connections.

• The control head flange is not installed properly.

“A” or “B” tabs must be installed at bottom of body.

Red & Green LEDs flash simultaneously every 1/2

second.

• The temperature at the circuit board is higher than

170˚F. Removing the control box cover may cool

the control enough for it to operate. If the control

works with the cover removed, the control box

should then be mounted remotely.

Pump does not turn off when water level is above

top probe.

• The probes may be fouled with dirt, scale or rust.

Remove head assembly to inspect probes.

•The wiring connections for the pump may not be

connected properly. Check wiring at terminals.

Pump does not turn on when water level is below

the middle probe.

• The probes may be fouled with dirt, scale or rust.

Remove head assembly to inspect probes.

•The wiring connections for the pump may not be

connected properly. Check wiring at terminals.

Burner does not turn off when water level is

below bottom probe.

• The probes may be fouled with dirt, scale or rust.

Remove head assembly to inspect probes.

•The wiring connections for the pump may not be

connected properly. Check wiring at terminals.

• Make sure the time delay is not causing delay of

burner off.

The 150E control does not turn off the burner

before the secondary (manual reset LWCO) turns

off the burner.

•The burner off time delay (DOB) may be set for too

long of a delay.

During operation, the burner does not turn off

when the water level is below the bottom probe.

•The burner off time delay (DOB) may be set for too

long of a delay.

• The boiler water may be priming or foaming. Clean

boiler water and/or consult with chemical treatment

specialist.

During operation, the burner turns off even when

the pump has turned on or the motorized valve

has opened.

• Pump capacity may not be sufficient or there may

be restrictions in the feedwater piping. Check pump

capacity and piping.

• The motorized valve stroke-to-open time may be

too long. Check valve motor timing.

14

Page 15

MAINTENANCE

Valve #1

Valve #2

!

BLOW DOWN PROCEDURE:

SCHEDULE:

Blow down control as follows when boiler is in

operation.

• Daily if operating pressure is above 15 psi.

•Weekly if operating pressure is below 15 psi.

NOTE

More frequent blow-down may be necessary due to

dirty boiler water and/or local codes.

Disassemble and inspect annually.

•

Inspect the float/probe chamber and equalizing

piping annually.

debris from chamber and/or equalizing piping.

• Inspect and clean probes. Use a non-abrasive

cloth to clean probes and water-side of

probe-mounting flange. Replace head mechanism

and probes if probes are worn, corroded or have

excessive coating of scale or rust that cannot be

easily cleaned off.

DO NOT REMOVE PROBES FROM FLANGE. Replace probe

flange assembly if probe PTFE insulation is broken, torn

or frayed.

The probes may need to be inspected and cleaned more

frequently on systems where there is the potential of

coating build-up on the probes.This includes systems:

• With high raw water make-up

• With no condensate return

• With untreated boiler water

• Where significant changes have been made to the

boiler-water chemical treatment process

• With oil in the boiler water

Replace head mechanism every 5 years.

More frequent replacement may be required when

severe conditions exist such as rapid switch

cycling, surging water levels and use of water

treatment chemicals.

Replacement parts are available from your

local authorized McDonnell & Miller

Distributor. The use of parts or components other

than those manufactured by McDonnell & Miller

will void all warranties and may affect the units

compliance with listing or regulating agencies.

Remove all sediment and

WARNING

NOTE

CAUTION

To prevent serious personal injury from steam

pipe blow down, connect a drain pipe to the

control opening to avoid exposure to steam

discharge.

Failure to follow this caution could cause

personal injury.

When blowing down a control at pressure, the blow

down valves should be opened slowly. The piping needs

to be warmed up and stagant water in the drain piping

needs to be pushed out. Suddenly opening a blow down

valve causes steam to condensate, which creates water

hammer. Damage to components can occur when water

hammer occurs due to improper blow down piping.

For these reasons, McDonnell & Miller recommends a

dual valve blow-down system for each control.

Blow down the low water cut-off when the water level is

at its normal level (pump/valve off) and the burner is on.

• Open the upper “Positive Shut-off Ball Valve” (#1).

• Slowly open lower “Throttling Gate Valve” (#2).

• With both valves open, the water level will drop in

the sight glass.

• When the water falls below the level of the middle

probe, the pump or valve should turn ON.

• When the water falls below the level of the bottom

probe, the burner should turn OFF. NOTE: The

Red LED will turn ON to indicate low water condition.

• Slowly close the lower “Throttling Gate Valve” (#2).

• The water level should begin to rise and the burner

should turn ON (Red LED turns off) when the level

is at the middle probe. The pump or valve should

turn OFF when the water level rises above the top

probe postion.

NOTE

If this sequence of actions does not occur, as

described, immediately close all valves, turn off the

boiler and correct the problem. To correct the problem,

inspection/cleaning of all probes may be required.

NOTE: On manual reset models, the red reset button will

need to be pressed after the water level is restored to the

level of the middle probe before the burner will operate.

• Close the upper valve “Positive Shut-off Ball Valve” (#1).

• Observe that the water level returns to its normal level

before leaving the site.

15

Page 16

Xylem

1) The tissue in plants that brings water upward from the roots;

2) a leading global water technology company.

We’re 12,500 people unified in a common purpose: creating innovative solutions

to meet our world’s water needs. Developing new technologies that will improve

the way water is used, conserved, and re-used in the future is central to our work.

We move, treat, analyze, and return water to the environment, and we help people

use water efficiently, in their homes, buildings, factories and farms. In more than

150 countries, we have strong, long-standing relationships with customers who

know us for our powerful combination of leading product brands and applications

expertise, backed by a legacy of innovation.

For more information on how Xylem can help you, go to www.xyleminc.com

Xylem Inc.

8200 N. Austin Avenue

Morton Grove, Illinois 60053

Phone: (847) 966-3700

Fax: (847) 965-8379

www.xyleminc.com/brands/mcdonnellmiller

McDonnell & Miller is a trademark of Xylem Inc. or one of its subsidiaries.

© 2012 Xylem Inc. MM-415C October 2012 Part No. 210497

Loading...

Loading...