Page 1

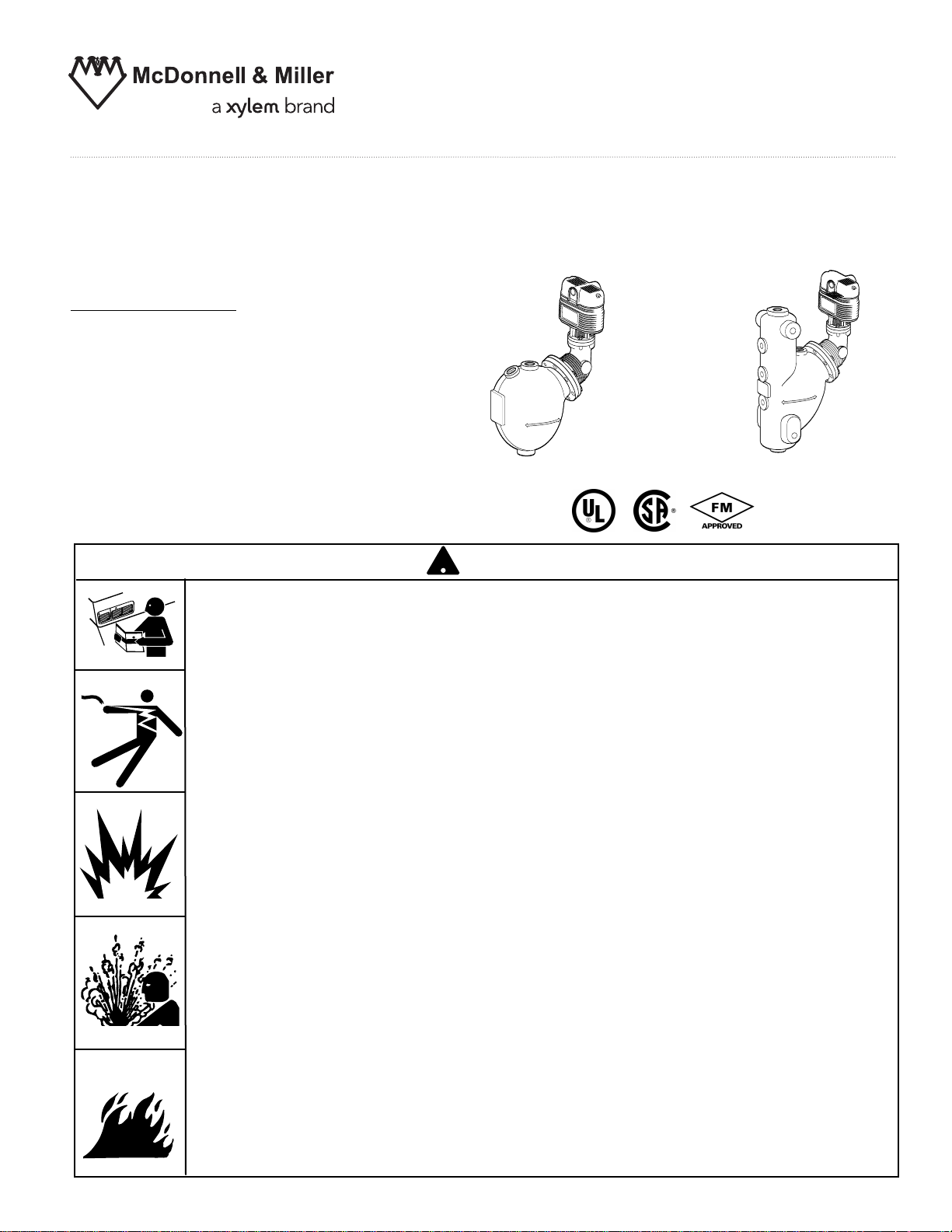

Series 93/193 and Series 94/194

WARNING

CAUTION

!

Low Water Cut-Off/Pump Controllers

For Steam Boilers and Level Control Applications

Typical Applications:

– Primary or secondary pump controller/

low water fuel cut-off

for steam boilers

– Motorized valve controller

– Proportional valve controller

– Low water cut-off

– High water cut-off

– Alarm actuation

Series 93 or Series 94

INSTRUCTION MANUAL

MM-404J

Series 193 or Series 194

WARNING

• Before using this product read and understand instructions.

• Save these instructions for future reference.

• All work must be performed by qualified personnel trained in the proper application, installation, and maintenance of plumbing, steam, and electrical equipment and/or systems in

accordance with all applicable codes and ordinances.

• To prevent serious burns, the boiler must be cooled to 80˚F (27˚C) and the pressure must be

0 psi (0 bar) before servicing.

• To prevent electrical shock, turn off the electrical power before making electrical connections.

• This low water cut-off must be installed in series with all other limit and operating controls

installed on the boiler. After installation, check for proper operation of all of the limit and

operating controls, before leaving the site.

We recommend that secondary (redundant) Low Water Cut-Off controls be installed on all

•

steam boilers with heat input greater than 400,000 BTU/hour or operating above 15 psi of

steam pressure. At least two controls should be connected in series with the burner

control circuit to provide safety redundancy protection should the boiler experience a

low-water condition. Moreover, at each annual outage, the low water cutoffs should be

dismantled, inspected, cleaned, and checked for proper calibration and performance.

• To prevent serious personal injury from steam blow down, connect a drain pipe to the control

opening to avoid exposure to steam discharge.

• To prevent a fire, do not exceed the switch contact rating.

California Proposition 65 warning! This product contains chemicals known to the

•

state of California to cause cancer and birth defects or other reproductive harm.

Previous controls should never be installed on a new system. Always install new

•

controls on a new boiler or system.

Failure to follow this warning could cause property damage, personal inj ury or death.

CAUTION:

•

A more frequent replacement interval may be necessary based on the condition of

the unit at time of inspection. McDonnell Miller s warranty is one (1) year from date

of installation or two (2) years from the date of manufacture.

!

&

'

Page 2

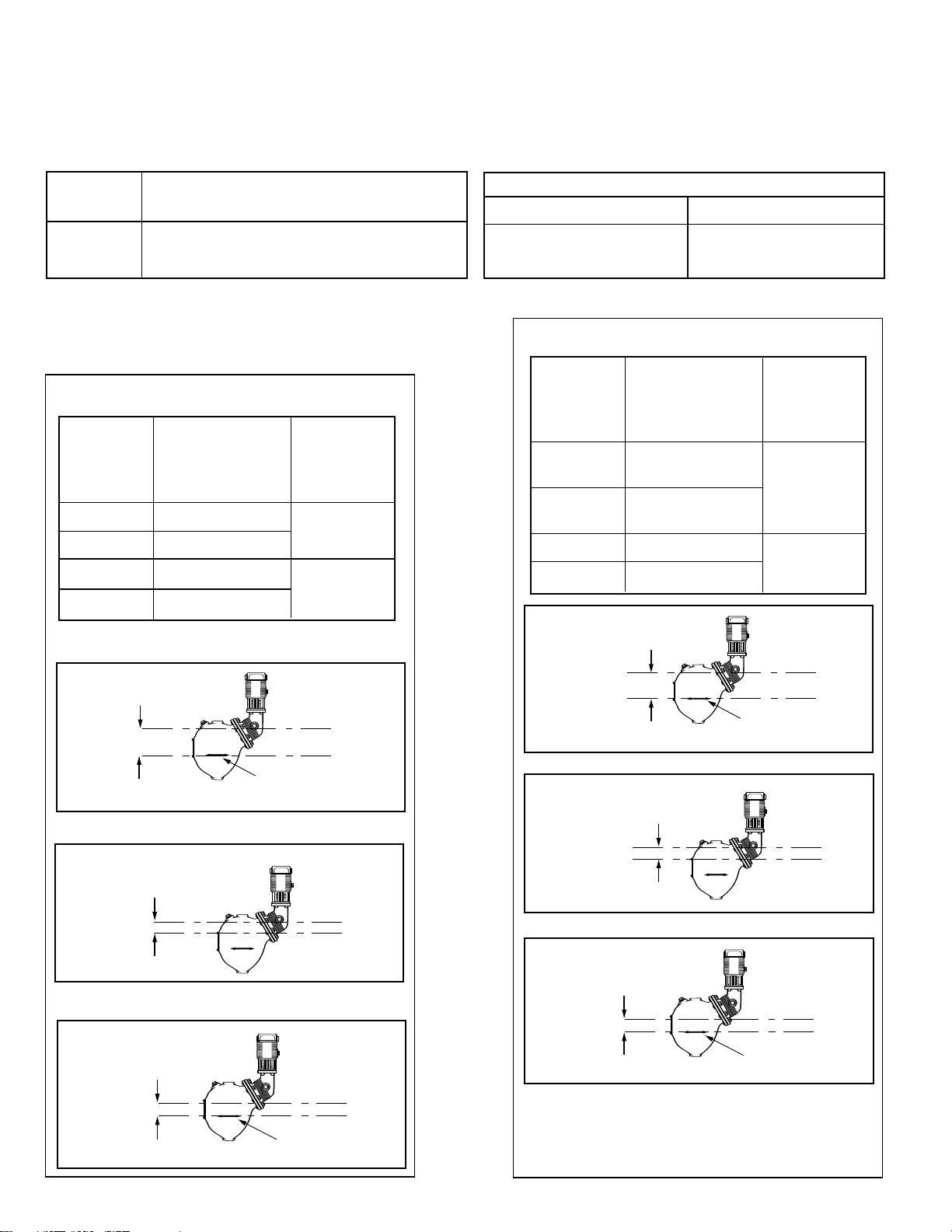

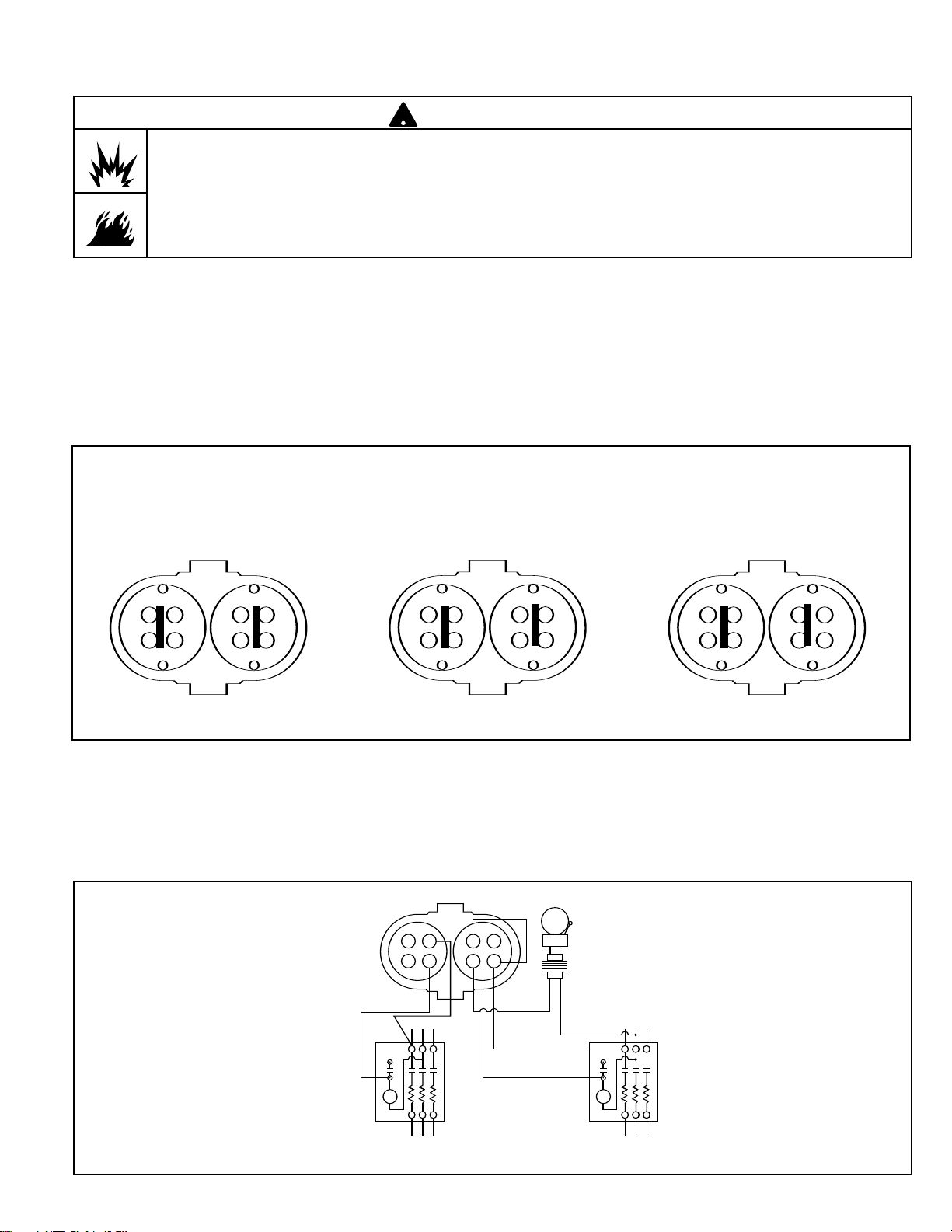

OPERATION

PUMP

OFF

BURNER

OFF

BURNER

“CUT-OFF LEVEL”

AT CAST LINE

2

3

/16"

(56mm)

PUMP OFF

PUMP ON

(27mm)

1

1

/16"

BURNER

“CUT-OFF LEVEL”

AT CAST LINE

BURNER OFF

(35mm)

BURNER ON

1

3

/8"

BURNER

“CUT-OFF LEVEL”

AT CAST LINE

BURNER OFF

(35mm)

BURNER ON

1

3

/8"

MOTORIZED

VALVE

CLOSED

BURNER

OFF

BURNER

“CUT-OFF LEVEL”

AT CAST LINE

2

3

/16"

(56mm)

MOTORIZED

VALVE

CLOSED

MOTORIZED

VALVE

OPEN

(27mm)

1

1

/16"

W

A

R

N

I

N

G

C

A

U

T

ION

!

®

Electrical Ratings

Models with 5 or 5-M Switch

Maximum Pressure:

Series 93/193: 150 psi (10.5 kg/cm

Series 94/194: 250 psi (17.6kg/cm

Models with 7B or 7B-M Switch

2

)

2

)

Pump and Burner Switch Contact Ratings

Voltage Pilot Duty Only

120 VA

C

345 VA

240 VAC

Switch Settings

1

/8

Values are ±

Models with 5 or 5-M Switches

Setting In. (mm) In. (mm)

Pump Off 23/

Pump On 11/8(29)

Burner On 13/8(35) 13/8(35)

Burner Off 0

” (3mm)

Approximate

Distance Above

Cast Line Differential

(56) 11/16(27)

16

Switch Ratings

Burner Valve

120 VAC

VA 0 - 135 ohms @ 24 VAC

345

240 VAC

Models with 7B or 7B-M Switches

Approximate

Distance Above

Cast Line Differential

Setting In. (mm) In. (mm)

Valve Full 23/

16

(56) 11/16(27)

Closed

Valve Full 11/8(29)

Open

Burner On 13/8(35) 13/8(35)

Burner Off 0

2

NOTE: Due to the slower operation of some

motorized valves, complete valve opening or

closing may occur at slightly different

levels than indicated above.

Page 3

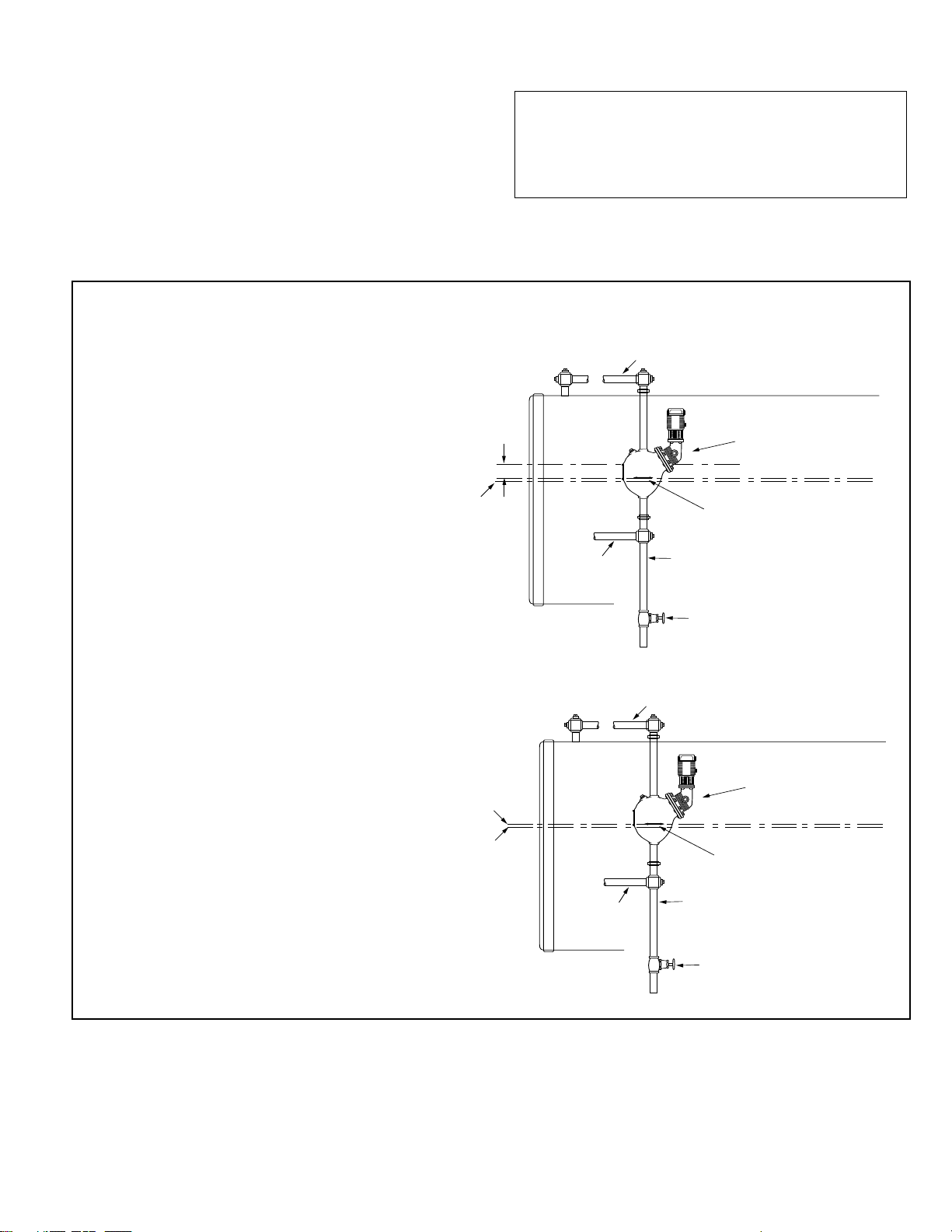

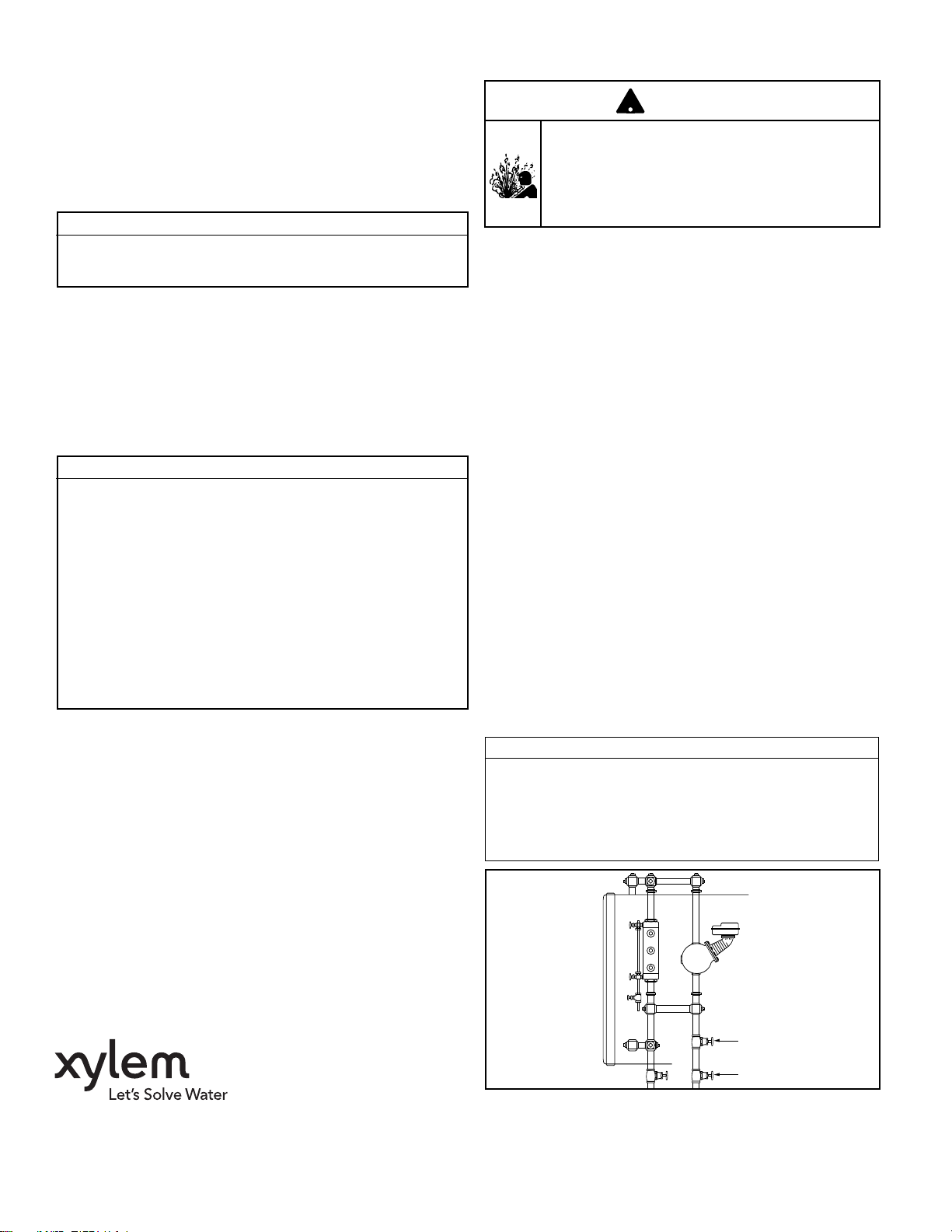

INSTALLATION –

11/2"

STEAM EQUALIZING PIPE

V

ERTICAL EQUALIZING PIPE

BLOW DOWN VALVE

NORMAL BOILER WATER LINE

AS A PRIMARY

LOW WATER CUT-OFF/PUMP

CONTROLLER

BURNER “CUT-OFF LEVEL”

A

T CAST LINE

LOWEST

PERMISSIBLE

W

ATER LEVEL

WATER

EQUALIZING

PIPE

STEAM EQUALIZING PIPE

VERTICAL EQUALIZING PIPE

BLOW DOWN VALVE

AS A SECONDARY

LOW WATER CUT-OFF/PUMP

CONTROLLER

BURNER “CUT-OFF LEVEL”

AT CAST LINE

LOWEST

PERMISSIBLE

WATER LEVEL

BURNER OFF

WATER

EQUALIZING

PIPE

TOOLS NEEDED:

o (2) pipe wrenches, one (1) flathead screw

Tw

driver, and pipe thread dope.

IMPORTANT: Follow the boiler manufacturer's

uctions along with all applicable codes and

instr

ordinances for piping, blow-down valve, water

gauge glass, tri-cock and electrical requirements.

STEP 1 - Determine the Position of the Low Water Cut-Off/Pump Controller

If the control will be the primary low

water fuel cut-off, size the steam (top) and

ater (bottom) equalizing pipe lengths so

w

that the horizontal cast line on the body is

1 1/2” (38mm) belo

water level, but not lower than the lowest

e permissible water level, as deter-

saf

mined by the boiler manufacturer.

If the control will be the secondary low

water fuel cut-off, size the steam (top) and

ater (bottom) equalizing pipe lengths so

w

that the horizontal cast line on the body is

at or above the lowest safe permissible

water le

vel, as determined by the boiler

manufacturer.

w the boiler’s normal

OR

3

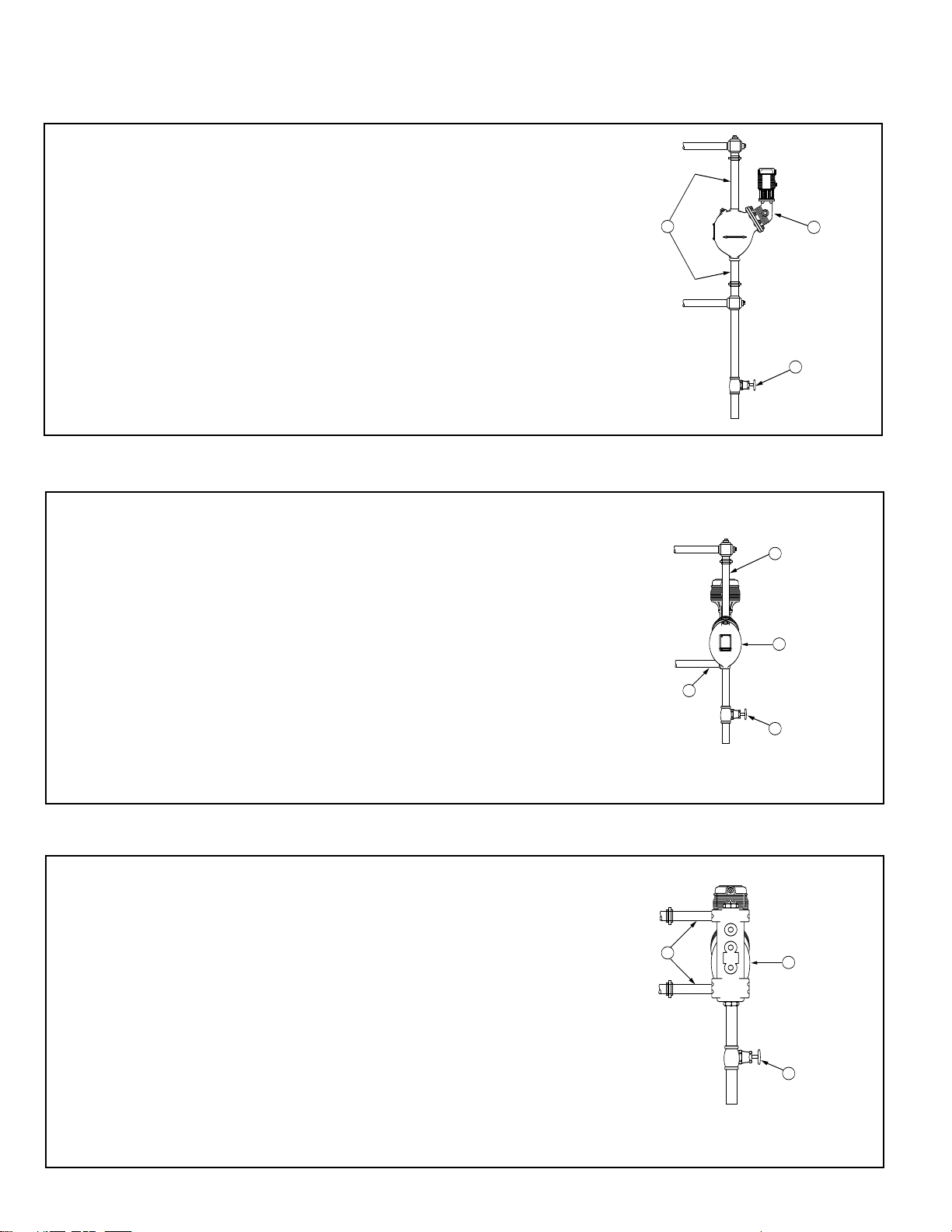

Page 4

A

B

C

STEP 2 - Installing the Low Water Cut-Off/Pump Controller

A

E

C

D

A

C

G

11/2"

STEAM EQUALIZING PIPE

V

ERTICAL EQUALIZING PIPE

BLOW DOWN VALVE

NORMAL BOILER WATER LINE

AS A PRIMARY

LOW WATER CUT-OFF/PUMP

CONTROLLER

BURNER “CUT-OFF LEVEL”

A

T CAST LINE

LOWEST

PERMISSIBLE

W

ATER LEVEL

WATER

EQUALIZING

PIPE

STEAM EQUALIZING PIPE

VERTICAL EQUALIZING PIPE

BLOW DOWN VALVE

AS A SECONDARY

LOW WATER CUT-OFF/PUMP

CONTROLLER

BURNER “CUT-OFF LEVEL”

AT CAST LINE

LOWEST

PERMISSIBLE

WATER LEVEL

BURNER OFF

WATER

EQUALIZING

PIPE

For Series 93/193 or 94/194 (except 94-A, 193-D and 193-G Models)

a. Mount and pipe the control (A) on vertical equalizing

pipes (B) at the required ele

vation as determined in

Step 1.

Install a full-ported blow-down valve (C) directly

w the lower cross.

belo

NOTE:

1” (25mm) NPT tappings are provided on Series

93/193 controls.

1 1/4” (32mm) NPT tappings are provided for Series

94/194 controls and 193-B Model.

For 94-A and 193-G Models

a. Mount and pipe the control (A) with a vertical upper

(D) and horizontal lower (E) equalizing piping at the

required ele

Install a full-ported blow-down valve (C) on the low

body connection.

vation as determined in Step 1.

er

NOTE:

1 1/4” (32mm) NPT tappings are provided for 94-A

Model control.

1” (25mm) NPT tappings are provided for 193-G

Model control.

For 193-D Models

a. Mount and pipe the control (A) with a horizontal

upper and lower (G) equalizing piping at the

vation as determined in Step 1.

required ele

Install a full-ported blow-down valve (C) on the lo

body connection.

NOTE:

1” (25mm) NPT tappings are provided for 193-D

Model control.

wer

4

Page 5

STEP 3 - Removing Float Blocking Plugs and Dowels

I

H

I

H

!

CAUTION

The plug and rod must be reinstalled before control is shipped installed on the

boiler, and removed after boiler is placed and installed.

Failure to follow this caution may damage the float and operating mechanism.

a. Using a pipe wrench, remove the float blocking plugs (I)

and dowels (H) from the control as sho

b. Using a pipe wrench, screw the pipe plugs provided with

control into the open tappings

.

wn below.

Series 193 / 194

Series 93 / 94

5

Page 6

STEP 4 - Installing a Water Gauge Glass and Tri-Cocks

C

UT-OFF LEVEL

CUT-OFF

LEVEL

3"

3"

B

D

F

E

C

K

L

JH

GAUGE GLASS

(TYPICAL)

TRI-COCK

(TYPICAL)

I

H

I

H

!

NOTE: A separate water column for installation of

gauge glass and tri-cocks may be required for boilers

a. Determine pipe size of tri-cock and

sight glass tappings for the control

being installed including center

distance of sight glass tappings.

NOTE:

These items are not provided with

control and must be purchased

separately

with a Series 93 or Series 94 control. Follow the

manufacturer’s instructions to install the water column.

Tri-Cock Gauge Glass Tapping Gauge Glass Tapping

Tapping Pipe Size Center Distance

Unit B C D E F H J K L

193

193-A

193-B

193-D

193-G

194

194-A

194-B

1

⁄2 (15)

1

⁄2 (15)

3

⁄4 (20)

1

⁄2 (15)

1

⁄2 (15)

1

⁄2 (15)

1

⁄2 (15)

3

⁄4 (20)

1

⁄2 (15)

1

⁄2 (15)

3

⁄4 (20)

1

⁄2 (15)

1

⁄2 (15)

3

⁄4 (20)

1

⁄2 (15)

1

⁄2 (15)

3

⁄4 (20)

1

⁄2 (15)

1

⁄2 (15)

1

⁄2 (15)

1

⁄2 (15)

3

⁄4 (20)

1

⁄2 (15)

1

⁄2 (15)

1

⁄2 (15) 111⁄2 (292)

1

⁄2 (15) 111⁄2 (292)

1

⁄2 (15) 111⁄2 (292)

1

⁄2 (15) 115⁄8 (295)

1

⁄2 (15)

3

⁄4 (20)

1

⁄2 (15)

3

⁄4 (20)

1

⁄2 (15) 123⁄4 (324)

3

⁄4 (20) 123⁄4 (324)

1

⁄2 (15) 127⁄8 (327)

3

⁄4 (20) 127⁄8 (327)

b. Install tri-cocks and gauge glass following

manufacturer’s instructions.

6

Page 7

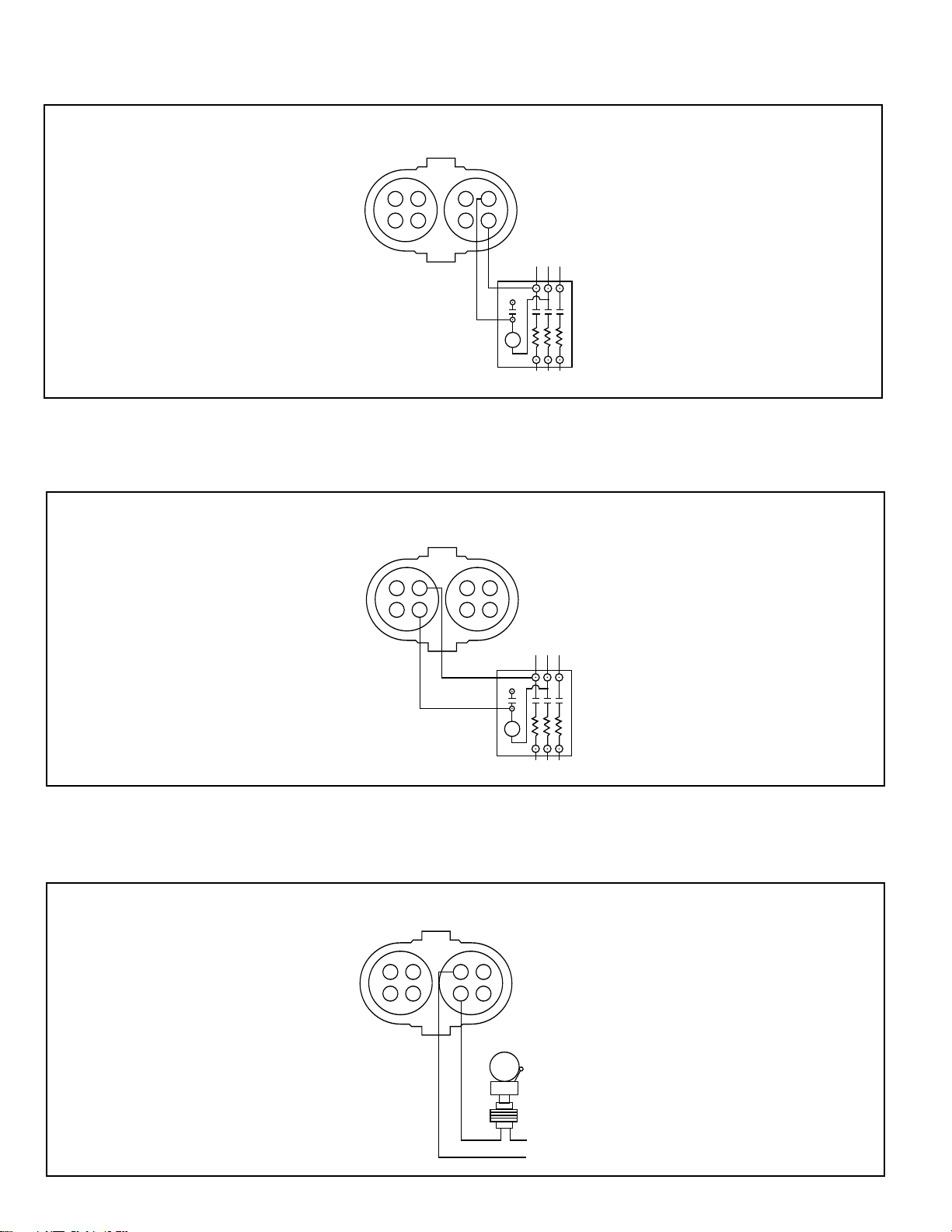

STEP 5 - Electrical Wiring

!

2 4

1 3

BLUE

BOILER FEED PUMP OFF–

BURNER ON–ALARM OFF

BOILER FEED PUMP ON–

BURNER ON–ALARM OFF

BOILER FEED PUMP ON–

BURNER OFF–ALARM ON

RED

3 1

4 2

2 4

1 3

BLUE RED

3 1

4 2

2 4

1 3

B

LUE RED

3 1

4 2

BLUE

NO. 5

SWITCH

TO BURNERTO PUMP

LINE

123

4

4

3

RED

LINE

ALARM

TRANS.

• To prevent electrical shock, turn off the electrical power before making electrical connections.

• This low water cut-off must be installed in series with all other limit and operating controls installed on the

boiler. After installation, check for proper operation of all of the limit and operating controls, before leaving

the site.

Failure to follow this warning could cause electrical shock, an explosion and/or a fire, which could result in

property damage, personal injury or death.

Wiring Diagrams

WARNING

NOTE: The following diagrams are provided for reference only.

If available, manufacturer’s wiring diagrams

should always be followed to connect the device

being operated.

Switch Operation

For Series 93/193 or 94/194 with 5 or 5-M Switch

Red switch terminals 1 and 2 are for burner circuit contacts, terminals 3 and 4 are for the low level alarm

circuit contacts.

Blue switch terminals 3 and 4 are for feeder/pump control contacts, terminals 1 and 2 are for high level

alarm circuit contacts.

Pump Control, Low Water Cut-Off and Alarm

7

Page 8

L

OW WATER CUT-OFF CIRCUIT

B

LUE

N

O. 5

S

WITCH

B

URNER

STARTER

1

2

R

ED

LINE

Low Water Cut-Off Only

PUMP CONTROL CIRCUIT

BLUE

NO. 5

SWITCH

PUMP

STARTER

4

3

RED

LINE

ALARM CIRCUIT

BLUE

NO. 5

SWITCH

ALARM

TRANS.

NEUTRAL

3

4

RED

LINE

!

2 4

1 3

BLUE

BOILER FEED PUMP OFF–

BURNER ON–ALARM OFF

BOILER FEED PUMP ON–

BURNER ON–ALARM OFF

BOILER FEED PUMP ON–

BURNER OFF–ALARM ON

RED

3 1

4 2

2 4

1 3

BLUE RED

3 1

4 2

2 4

1 3

B

LUE RED

3 1

4 2

BLUE

NO. 5

SWITCH

TO BURNERTO PUMP

LINE

123

4

4

3

RED

LINE

ALARM

TRANS.

Pump Control Only

Low Water Alarm Only

8

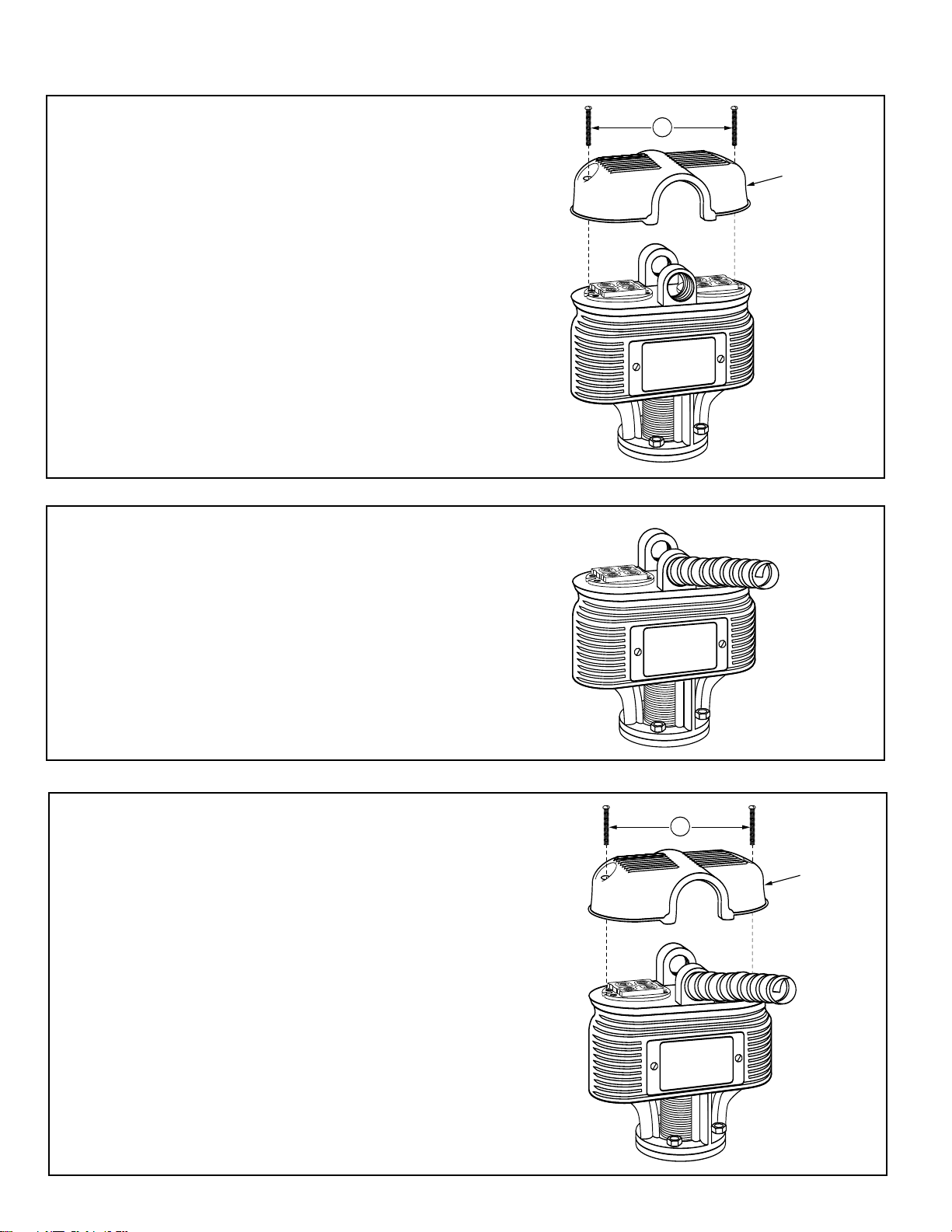

Page 9

TO BURNER

LINE

13

4

432

1

COMMON

CLOSING CIRCUIT

OPENING CIRCUIT

NO. 7B

SWITCH

BLUE

RED

2 4

1 3

BLUE

BURNER ON–ALARM OFF

VALVE CLOSED

BURNER ON–ALARM OFF

VALVE OPEN

BURNER OFF–ALARM ON

VALVE OPEN

RED

3 1

4

2 4

1 3

BLUE

RED

3 1

4

2 4

1 3

BLUE

RED

3 1

4

For Series 93/193 or 94/194 with 7B or 7B-M

Red terminals 1 and 2 are the burner circuit contacts, terminals 3 and 4 are the low level alarm circuit

contacts.

Blue terminal 3 is the common contact, terminals 1 and 4 are the output contacts.

NOTE: The 7B switch is a 135 ohm potentiometer slide

wire control for use with an electric valve operator with

the same rating.

Proportional Control, Low Water Cut-Off and Alarm

9

Page 10

A

SWITCH

COVER

A

SWITCH

COVER

Wiring Connections

TO BURNER

LINE

13

4

432

1

COMMON

CLOSING CIRCUIT

OPENING CIRCUIT

NO. 7B

SWITCH

BLUE

RED

2 4

1 3

BLUE

BURNER ON–ALARM OFF

VALVE CLOSED

BURNER ON–ALARM OFF

VALVE OPEN

BURNER OFF–ALARM ON

VALVE OPEN

RED

3 1

4

2 4

1 3

BLUE

RED

3 1

4

2 4

1 3

BLUE

RED

3 1

4

a. Remove two screws (A) and lift off switch

cover.

b. Connect BX armored cable or Thinwall electrical

metal tubing to the integral fitting hub. Connect

wires to terminals following appropriate wiring

diagram from pages 8 and 9 for your application.

NOTE: Follow local codes and standards when

selecting the types of electrical fittings and conduit

to connect to control.

c. Replace switch cover and fasten with two

screws (A).

10

Page 11

STEP 6 - Testing

!

!

TROUBLESHOOTING

– Dimensions shown are typical.

– The following testing procedure is only meant to serve

as a verification of proper operating sequence.

a. Turn on power to boiler and pump circuits.

With the boiler empty, the pump should turn on (5

or 5-M switch models) or the valve open (7B or

7B-M switch models). The burner should remain off

and boiler should begin to fill with water.

CAUTION

Immediately turn off all power if the burner turns on

with no water in the gauge glass. Investigate further

before continuing procedure.

b. For Automatic Reset Models

When water level in the gauge glass is approximately

1 3/8” (35mm) above the horizontal cast line, the

burner should turn on.

For Manual Reset Models

When water level in the gauge glass is approximately

1 3/8” (35mm) above the horizontal cast line, press

the manual reset button and the burner should turn on.

c. For 5 or 5-M Switch Models

When water level in the gauge glass is approximately

2 3/16” (56mm) above the horizontal cast line, the

pump should turn off.

For 7B or 7B-M Switch Models

When water level in the gauge glass is approximately

2 3/16” (56mm) above the horizontal cast line, the

valve should be closed.

CAUTION

If pump does not turn off or valve close, turn off

water supply to boiler. Investigate further before

continuing procedure.

d. With the water in the boiler at its normal level and

burner on, SLOWLY open the blow-down valve

until it is fully open. As the water level in the gauge

glass begins to drop, verify that the following occurs.

For 5 or 5-M Switch Models

When water level drops to approximately 1 1/8”

(29mm) above the horizontal cast line, the pump

should turn on. When water level drops to the hori

zontal cast line, the burner should turn off.

For 7B or 7B-M Switch Models

As the water level drops, the valve should begin to

open. When the water level drops to approximately

1 1/8” (29mm) above the horizontal cast line, the

valve should be full open.

When the water level drops to the horizontal cast

line, the burner should turn off.

e. Close the blow-down valve after burner turns off

and restore water level to normal operating level.

f. Repeat testing procedure several times to ensure

proper operation of control.

g. After testing and verification of control operation,

the boiler can be returned to service.

Erratic operation of the control is the most common symptom

that occurs. Erratic operation can be defined as pump and/or

burner switches not switching at proper levels. Refer to the

following list of items to check if the control is not operating

properly.

1. Float Ball is Crushed

Crushed floats are typically caused by improper blowdown. Drain piping from blow-down valve to drain should

be checked for proper pitch and the blow-down procedure

followed when blowing down the control. Purchase and

install a new float ball after investigating and correcting

the problem.

2. Float Ball is Filled with Water

The seam weld on the float can sometimes deteriorate.

This can be caused by the type of chemical treatment

used in the boiler. While this is a rare occurrence, the

chemical treatment supplier should be consulted to determine if a reaction could occur. Purchase and install a new

float ball after investigating and correcting the problem.

3. Float Arm Springs are Bent

The pivot springs located on either side of the float rod

should be flat and straight. If they become bent, the usual

cause is mishandling of the unit during installation or

improper blow-down.The control should never be picked

up by the float ball or allowed to hang from the bowl by the

float. Drain piping from blow-down valve to drain should be

checked for proper pitch and the blow-down procedure

followed when blowing down control. Purchase and install

new control or head mechanism after investigating and

correcting the problem.

4. Switch Contact Springs Broken

The contact springs can break if the electrical rating is

exceeded. Purchase and install new switch assembly or

head mechanism after investigating and correcting the

problem.

5. Switch Contact Springs Misaligned

Misalignment of the contact arms is usually associated

with damage to the control during shipment or installation.

Purchase and install new switch assembly or head

mechanism after investigating and correcting the problem.

6. Internal (Wetted) Parts Dirty

The internal parts can operate improperly if dirt, scale or

rust is allowed to build. This condition can be a result of

not blowing down the control as recommended and/or

improper boiler water chemical treatment. Purchase and

install new control or head mechanism after investigating

and correcting the problem.

11

Page 12

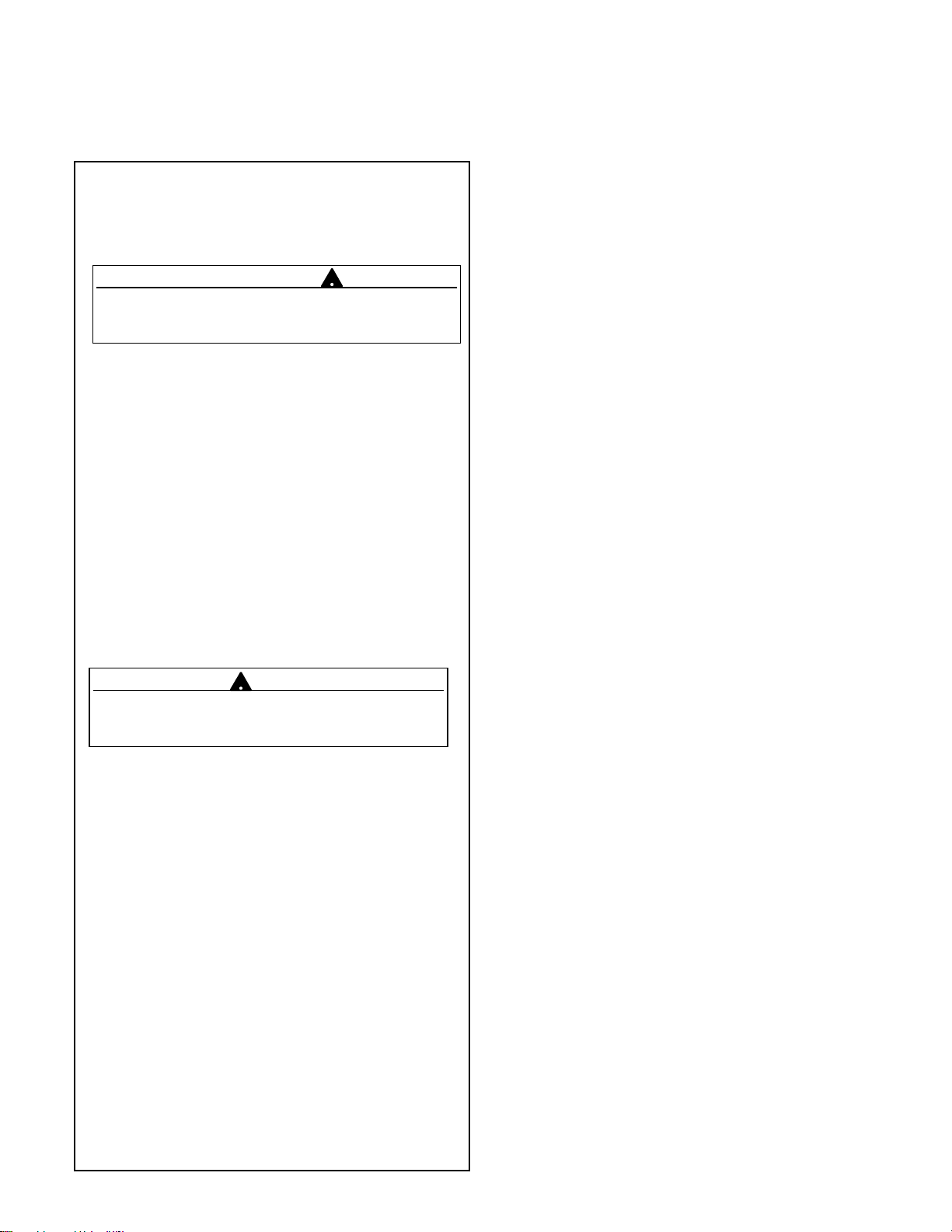

MAINTENANCE

!

Valve #2

Valve #1

!

!

BLOW DOWN PROCEDURE:

SCHEDULE:

Blow down control as follows when boiler is

in operation.

• Daily if operating pressure is above 15 psi.

• Weekly if operating pressure is below 15 psi.

NOTE

More frequent blow-down may be necessary

due to dirty boiler water and/or local codes.

• Remove head assembly and inspect water

side components annually. Replace head

assembly if any of the internal components are

worn, corroded or damaged or if control no longer

operates properly.

• Inspect the float chamber and equalizing piping

annually. Remove all sediment and debris.

NOTE

The control may need to be inspected and

cleaned more frequently on systems where there

is the potential of excessive scale or sludge

build-up. This includes systems:

• With high raw water make-up

• With no condensate return

• With untreated boiler water

• Where significant changes have been

made to the boiler-water chemical

treatment process

• With oil in the boiler water

CAUTION

To prevent serious personal injury from steam

pipe blow down, connect a drain pipe to the

control opening to avoid exposure to steam

discharge.

Failure to follow this caution could cause

personal injury.

When blowing down a control at pressure, the blow

down valves should be opened slowly. The piping

needs to be warmed up and stagnant water in the

drain piping needs to be pushed out. Suddenly

opening a blow down valve causes steam to

condense, which creates water hammer. Damage to

components can occur when water hammer occurs

due to improper blow down piping.

For these reasons, McDonnell & Miller recommends

a dual valve blow-down system for each control.

Blow down the control when the water in the boiler

is at its normal level and the burner is on.

NOTE: Refer to page 2 for switch operating points.

• Open upper valve (#1)

• Slowly open the lower valve (#2)

• Water in the sight glass should lower.

• As the water in the sight glass lowers, the

pump should turn on.

• As the water continues to lower in the sight

glass, the burner should turn off.

• Slowly close the lower valve (#2).

• Close the upper valve (#1)

• The water level in the sight glass should rise, first

turning on the burner and then turning off the pump.

NOTE: On manual reset models, the reset button

will need to be pressed after the water level has

been restored before the burner will operate.

Replace head mechanism every 5 years.

More frequent replacement may be required when

severe conditions exist.

Replacement parts are available from your local

authorized McDonnell & Miller Distributor.

The use of parts or components other than those

manufactured by McDonnell & Miller will void all

warranties and may affect the units compliance with

listings or regulating agencies.

Xylem Inc.

8200 N. Austin Avenue

Morton Grove, Illinois 60053

Phone: (847) 966-3700

Fax: (847) 965-8379

www.xyleminc.com/brands/mcdonnellmiller

McDonnell & Miller is a trademark of Xylem Inc. or one of its subsidiaries.

© 2013 Xylem Inc. MM-404J July 2013 Part No. 246043

NOTE

If this sequence of operation does not occur as

described, immediately close all the valves, turn off the

boiler and correct the problem. Inspection/cleaning of

the float mechanism may be required to determine why

the control was not working properly. Retest the control

after the problem has been identified and corrected.

Loading...

Loading...