Page 1

Series 851, 851-S and 847

Make-Up Water Feeders

Applications:

For receiver tanks in industrial or

commercial applications.

INSTRUCTION MANUAL

MM-320

C

Series 851

WARNING

!

• Before using this product read and understand the installation instructions.

• Save the installation instructions and these maintenance and replacement instructions

CAUTION

ARNING

W

for future reference.

• All work must be performed by qualified personnel trained in the proper application, installation, inspection, and maintenance of HVAC systems in accordance with all applicable

codes and ordinances.

Series 851-S

Series 847

California Proposition 65 warning! This product contains chemicals known to the

•

state of California to cause cancer and birth defects or other reproductive harm.

•

Previous controls should never be installed on a new system. Always install new

controls on a new boiler or system.

Failure to follow this warning could cause property damage, personal inj ury or death.

CAUTION:

•

A more frequent replacement interval may be necessary based on the condition of

the unit at time of inspection. McDonnell Miller s warranty is one (1) year from date

of installation or two (2) years from the date of manufacture.

!

&

'

Page 2

2

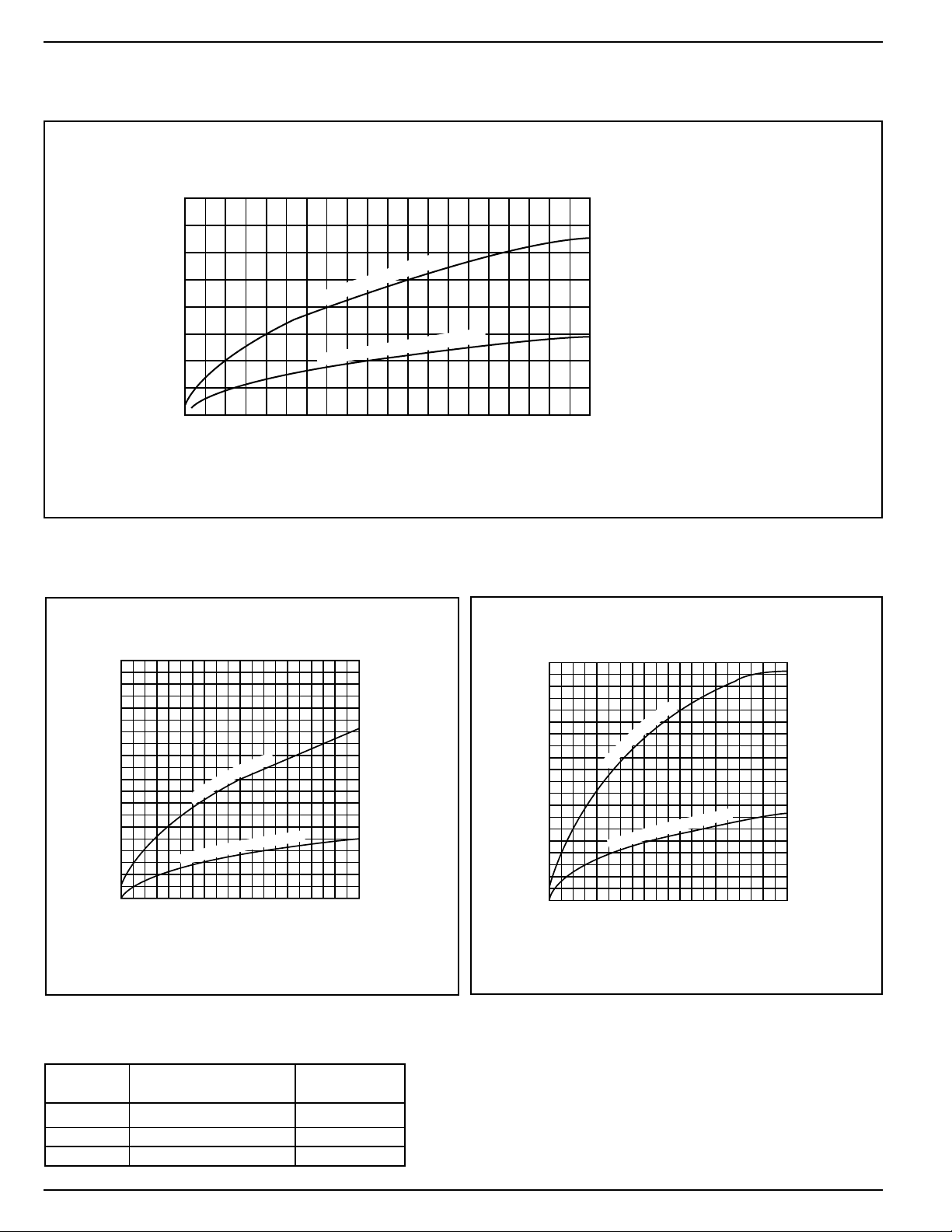

Capacities

DIFFERENTIAL PRESSURE IN POUNDS PER SQ. IN.

(Water pressure less boiler pressure)

4,000

lbs./hr.

BOILER

Btu/Hr.

(K-Calories/Hr.)

4,000,000

(15,800)

3,000,000

(11,900)

2,000,000

(7,900)

1,000,000

(4,000)

116

(1137)

87

(853)

58

(569)

29

(284)

16,000

12,000

8,000

4,000

000

BOILER

hp

(Kilowatts)

STEAM

Sq. Ft.

3,000

2,000

1,000

0

psi

(1814)

(kg/hr.)

(1361)

(907)

(454)

(0)

0102030405060708090100

(kg/cm

2

)

(0) (.7) (1.4) (2.1) (2.8) (3.5) (4.2) (4.9) (5.6) (6.3) (7.0)

C

a

p

a

c

i

t

y

a

t

S

w

i

t

c

h

C

u

t

-

O

f

f

M

a

x

i

m

u

m

C

a

p

a

c

i

t

y

C

a

p

a

c

i

t

y

a

t

S

w

i

t

c

h

C

u

t

-

O

f

f

M

a

x

i

m

u

m

C

apacity

FEEDER DISCHARGE

DIFFERENTIAL PRESSURE IN POUNDS PER SQ. IN.

(Water pressure less boiler pressure)

10,000

lbs./hr.

9,000

8,000

7,000

6,000

5,000

4,000

3,000

2,000

1,000

0

0psi 10 20 30 40 50 60 70 80 90 100

(0)(kg/cm

2

) (.7) (1.4) (2.1) (2.8) (3.5) (4.2) (4.9) (5.6) (6.3) (7.0)

(4536)

(kg/hr.)

STEAM

Sq.Ft.

BOILER

hp

(Kilowatts)

40,000

36,000

32,000

28,000

24,000

20,000

16,000

12,000

8,000

4,000

0

290

(2843)

261

(2559)

232

(2274)

203

(1990)

174

(1706)

145

(1421)

116

(1137)

87

(853)

58

(569)

29

(284)

0

(4082)

(3629)

(3175)

(2722)

(2268)

(1814)

(1361)

(907)

(454)

(0)

FEEDER DISCHARGE

DIFFERENTIAL PRESSURE IN POUNDS PER SQ. IN.

(Water pressure less boiler pressure)

10,000

lbs./hr.

9,000

8,000

7,000

6,000

5,000

4,000

3,000

2,000

1,000

0

0psi 10 20 30 40 50 60 70 80 90 100

(0)(kg/cm

2

) (.7) (1.4) (2.1) (2.8) (3.5) (4.2) (4.9) (5.6) (6.3) (7.0)

(4536)

(kg/hr.)

STEAM

Sq.Ft.

BOILER

hp

(Kilowatts)

40,000

36,000

32,000

28,000

24,000

20,000

16,000

12,000

8,000

4,000

0

290

(2843)

261

(2559)

232

(2274)

203

(1990)

174

(1706)

145

(1421)

116

(1137)

87

(853)

58

(569)

29

(284)

0

(4082)

(3629)

(3175)

(2722)

(2268)

(1814)

(1361)

(907)

(454)

(0)

M

a

x

i

m

u

m

C

a

p

a

c

i

t

y

C

a

p

a

c

i

t

y

a

t

S

w

i

t

c

h

C

u

t

-

O

f

f

Max. Water Supply Max. Valve

Series Pressure, psi Pressure, psi

851 150 35

851-S 100 35

847 150 25

Operation

Series 851

Series 847

Series 851-S

Page 3

3

INSTALLATION –

TOOLS NEEDED:

One (1) pipe wrench and one (1) socket wrench.

STEP 1 - Preparation

A

Drain the water in the receiving tank to a level

which is below the control opening (A). Allow the

boiler to cool to 80˚F (27˚C) and allow the

pressure to release to 0 psi (0 bar).

C

D

Use a socket wrench to secure the feeder (D)

to the receiver tank with the six

3

/8” - 16

bolts through mounting flange (C) and

tighten to 18 ft•lb (24 N•m).

STEP 2 - Install the Control Unit

Mounting Flange Dimensions

B.C.

O.D.

Float

O.D. B.C. C D Diameter

6

11

⁄16 (170) 53⁄4 (146) 67⁄16 (11.1) 43⁄4 (121)

Series 851, 851-S and 847

Dimensions, in. (mm)

“C” - number of mounting holes

“D” - size of mounting holes

Page 4

STEP 3 - Install the Piping

Piping the Valve on Series 847 and 851

a. Follow the drawing to the right for piping the

valve to boiler and city water supply. When

piping the valve remember to leave room for

servicing the valve. This will aid in troubleshooting the valve and piping in the future.

Piping the Valve on Series 851-S

a. Follow the drawing to the right for piping the

valve to the boiler and city water supply.

When piping the valve remember to leave

room for servicing the valve. This will aid in

troubleshooting the valve and piping in

the future.

Hand By-Pass Valve

By-pass

Hand By-Pass

Valve

CAUTION

Before turning

on city water

pressure be

sure to open

this valve

Swing Check Valve

Connect to return

header on boiler

side of all valves

Swing Check Valve

Strainer

Basket

Assembly

City Water

Supply

Supply

Valve

City Water

Supply

Supply To

Feeder

MAINTENANCE

SCHEDULE:

• Disassemble and inspect annually. Replace the

water feeder if it is worn, corroded, or if

components no longer operate properly.

• Replace control every 15 years. More frequent

replacement may be required when severe

conditions exist such as surging water levels and

use of water treatment chemicals.

By-pass

Connect to return

header on boiler

side of all valves

Strainer

Basket

Assembly

• Disassemble and inspect the strainer screen

annually. Thoroughly clean the strainer screen

or replace.

• Remove and inspect cartridge annually.

Thoroughly clean by rinsing with clear water

or replace.

Xylem Inc.

8200 N. Austin Avenue

Morton Grove, Illinois 60053

Phone: (847) 966-3700

Fax: (847) 965-8379

www.xyleminc.com/brands/mcdonnellmiller

McDonnell & Miller is a trademark of Xylem Inc. or one of its subsidiaries.

© 2013 Xylem Inc. MM-320C July 2013 Part No. 210528

Loading...

Loading...