Page 1

25A Make-Up Water Feeder

For Receiving Tanks

For Residential and Commercial Applications

OPERATION

Maximum Body Pressure: 35 psi

Maximum Water Supply Pressure: 100 psi

WARNING

!

INSTRUCTION MANUAL

MM-318C

Series 25A

CAUTION

WARNING

• Before using this product read and understand instructions.

• Save these instructions for future reference.

• All work must be performed by qualified personnel trained in the proper application, installation, and maintenance of plumbing, steam, and electrical equipment and/or systems in

accordance with all applicable codes and ordinances.

• Drain water level down below feeder and let cool to 80˚F (27˚C) before servicing.

• If tank or receiver is pressurized relieve pressure to 0 psi (0 Bar) before servicing.

California Proposition 65 warning! This product contains chemicals known to the

•

!

state of California to cause cancer and birth defects or other reproductive harm.

Previous controls should never be installed on a new system. Always install new

•

controls on a new boiler or system.

Failure to follow this warning could cause property damage, personal inj ury or death.

CAUTION:

•

A more frequent replacement interval may be necessary based on the condition of

the unit at time of inspection. McDonnell Miller s warranty is one (1) year from date

&

of installation or two (2) years from the date of manufacture.

INSTALLATION –

TOOLS NEEDED:

Two (2) pipe wrenches, pipe dope, assorted fittings and lengths of 1” pipe.

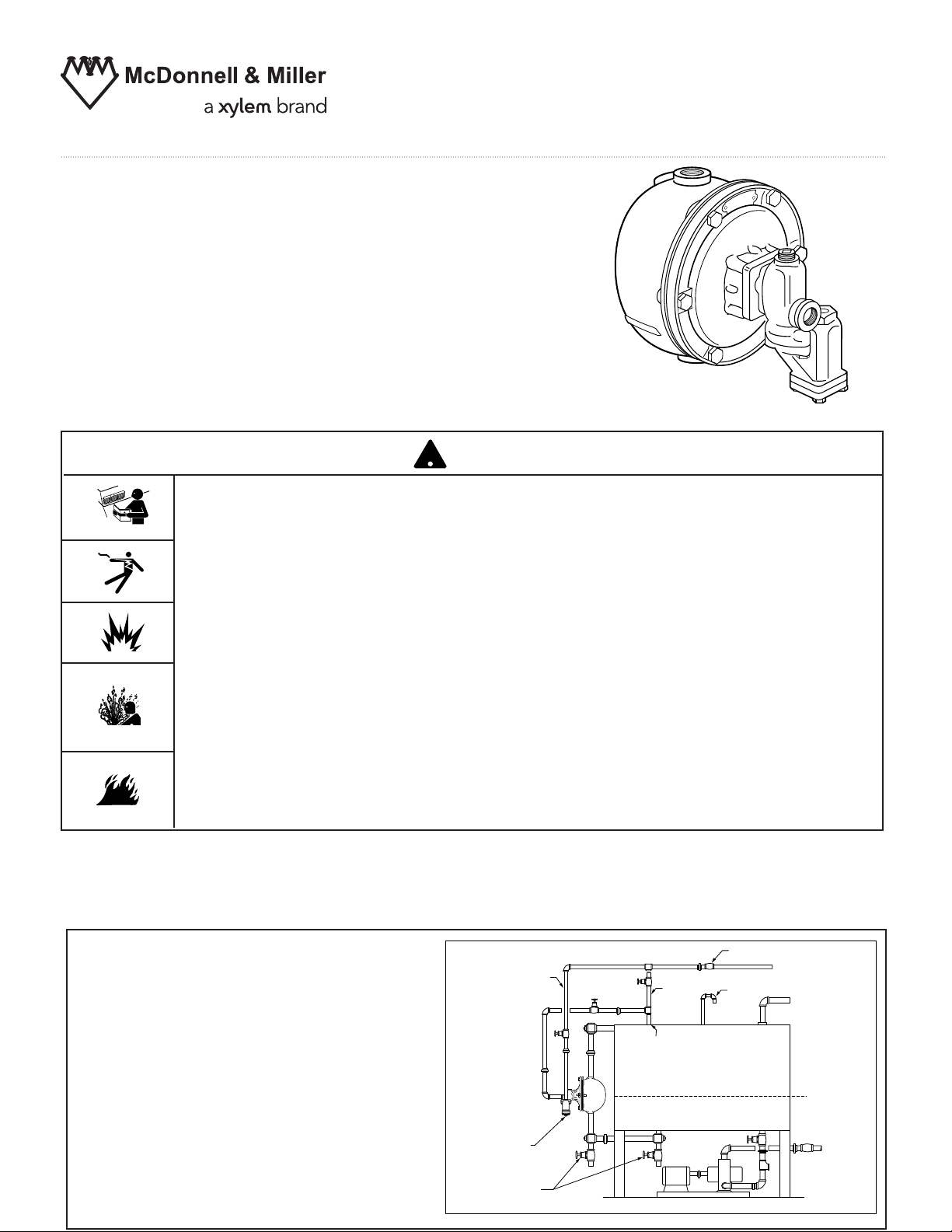

STEP 1 - Determine Location of the Feeder

'

a. The feeder is usually mounted one-

third (1/3) of the way up from the

bottom of the tank. This provides twothirds (2/3) of the tank for return

condensate.

3

/4’’ PIPE

OUT

STRAINER

BASKET ASS’Y

BLOW-OFF

VALVES

CHECK VALVE

WATER SUPPLY

BY PASS

DISCHARGE

IN

RECEIVER TANK

FEED PUMP

VENT

CONDENSATE

RETURN

2/3

1/3

PUMP

DISCHARGE

Page 2

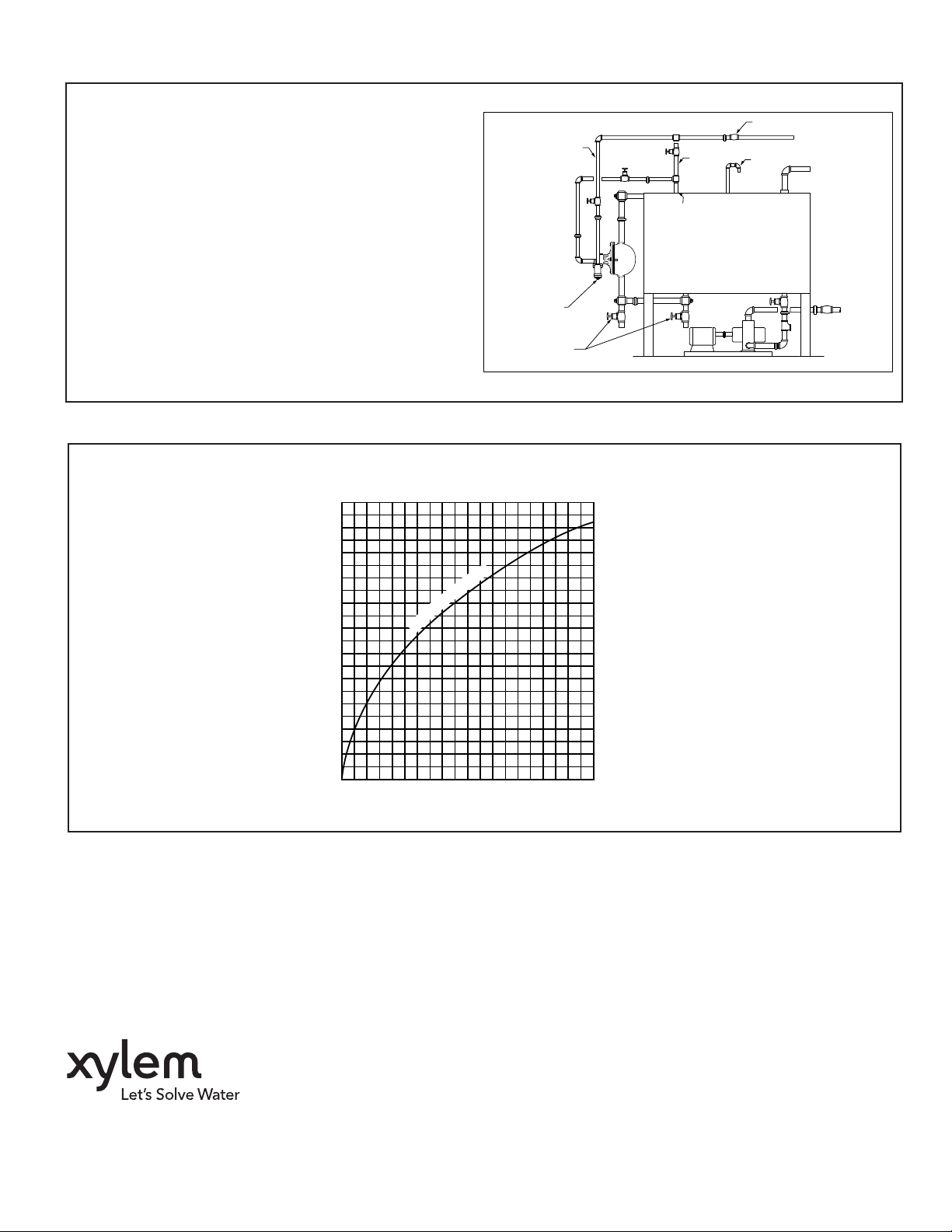

STEP 2 - Installation of Model 25A

a. Follow the diagram to the right for piping the

feeder to the tank and water supply. Remember

to leave room for servicing the water feeder.

• The discharge piping should be connected to

the top of the tank. The height of the discharge

piping should be as short as possible and use

minimum amount of fittings.

An air break can be used if code mandates one.

•

• There is not a positive seal between the valve

and the float chamber. If too much back

pressure is developed, the water from the

valve will go into the float chamber.

At all right angle turns in the equalizing

•

piping,

crosses should be used to facilitate inspection

and cleaning.

Capacity Curve No. 25A

3

/4’’ PIPE

OUT

STRAINER

BASKET ASS’Y

BLOW-OFF

VALVES

CHECK VALVE

WATER SUPPLY

BY PASS

DISCHARGE

IN

RECEIVER TANK

FEED PUMP

VENT

CONDENSATE

RETURN

PUMP

DISCHARGE

FEEDER DISCHARGE

(kg/hr.)

lbs./hr.

11,000(4990)

(4536)

10,000

9,000

(4082)

(3629)

8,000

C

(3175)

(2722)

(2268)

(1814)

(1361)

(907)

(454)

7,000

6,000

5,000

4,000

3,000

2,000

1,000

(0)

0

0psi 10 20 30 40 50 60 70 80 90 100

2

) (.7) (1.4) (2.1) (2.8) (3.5) (4.2) (4.9) (5.6) (6.3) (7.0)

(0)(kg/cm

WATER SUPPLY PRESSURE IN LBS. PER SQ. IN.

m

u

m

i

x

a

M

MAINTENANCE

SCHEDULE:

• Blow down weekly during heating season. Blow

down may have to be more frequent depending on

local water conditions and the amount of make-up

water.

BOILER

gpm

(lpm)

22

(83.27)

20

(75.70)

18

(68.13)

y

t

i

c

a

p

a

16

14

12

10

8

6

4

2

0

(60.56)

(52.99)

(45.42)

(37.85)

(30.28)

(22.71)

(15.14)

(7.57)

(0)

hp

(Kilowatts)

319

(238)

290

(216)

261

(195)

232

(173)

203

(151)

174

(130)

145

(108)

116

(86)

87

(65)

58

(43)

29

(22)

0

(0)

• Clean strainer at least twice during heating

season. Cleaning may have to be more frequent

depending on local water conditions and the

amount of make-up water.

• Replace control every 15 years.

Xylem Inc.

8200 N. Austin Avenue

Morton Grove, Illinois 60053

Phone: (847) 966-3700

Fax: (847) 965-8379

www.xyleminc.com/brands/mcdonnellmiller

McDonnell & Miller is a trademark of Xylem Inc. or one of its subsidiaries.

© 2013 Xylem Inc. MM-318C July 2013 Part No. 246732

Loading...

Loading...