Page 1

Instructions for changing a grinder pump cutter / cutter ring.

IM174R00

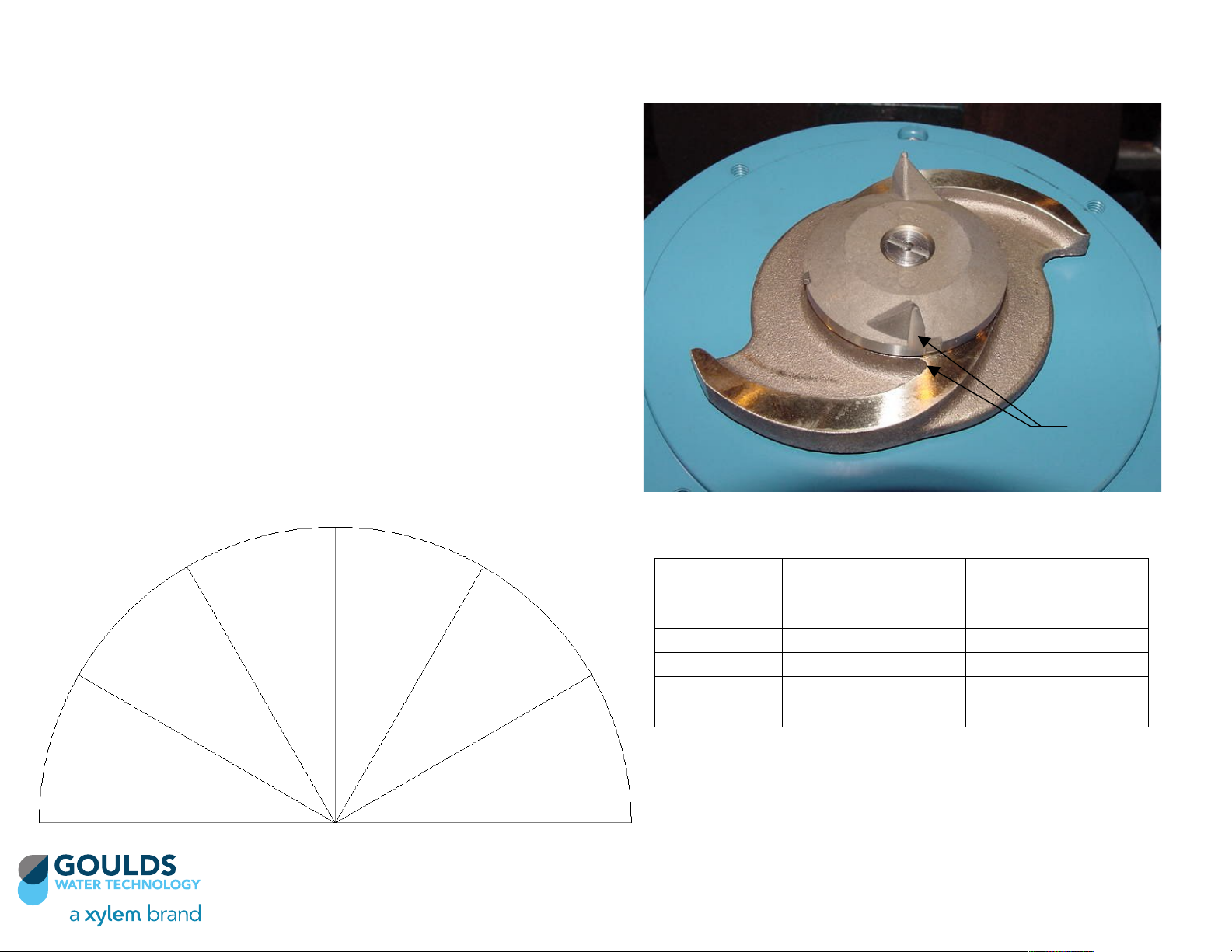

120°

150°

1. Thread impeller onto motor shaft and hand tighten holding the shaft with

screwdriver.

2. Thread cutter onto shaft and seat on impeller – do not tighten.

3. Check for alignment of the cutter to the impeller (per Picture).

Remove cutter and shim as necessary to align cutter blades with impeller

vanes (per Table and/or Template). Use screwdriver to hold shaft and

tighten cutter by tapping with plastic hammer.

4. Place casing on bearing housing and locate discharge opposite cord set

entry, secure w/ cap screws.

5. Check cutter to cutter ring clearance using .002” shim stock.

Adjust casing position with plastic hammer to ensure cutter

rotates freely. as ALIGN

6. Run dry for 10 seconds and recheck cutter to cutter ring clearance as

performed above.

SHIM

ANGLE OFFSET

(DEG.)

SHIM THICKNESS

(IN.)

0 - 30°

NO SHIM

BLUE

30 - 60°

.005”

BROWN

60 - 90°

.010”

PINK

90 - 120°

.015”

YELLOW

120 - 150°

.020”

Loading...

Loading...