ITT

Commercial Water Systems

CentriPro

TM

CentriPro

FloStandard

SIMPLEX PUMP CONTROL PANEL

Installation and Operation Manual

CentriPro is a brand of ITT

Residential and Commercial Water.

www.centripro.com

Engineered for life

ITT

OWNER’S INFORMATION

Pump Model No:

__________________________

Commercial Water Systems

Pump Serial No:

CENTRIPRO

________________________________

Control Model No:

Dealer Phone No:

Date of Purchase:

_________________________

__________________________

__________________________

Control Panel Serial No:

Dealer:

Installation Date:

________________________________________

_________________________

_______________________________

CURRENT READINGS AT SETUP

1Ø 3Ø L1 L2 L3

Amps: Amps:

Volts: Volts:

MOTOR INFORMATION

______________________________________

HP:

____________________________________

Volts:

_________________________________________

RPM:

Service Factor:

_________________________________

Frequency:

Enclosure:

________________________________

Phase:

2

________________________________________

_____________________________________

ITT

CENTRIPRO

Commercial Water Systems

TABLE OF CONTENTS

Safety Instructions ............................................................................................................................. 4

Pre-Installation Checks ...................................................................................................................... 4

Pump Control Panels and Wiring ....................................................................................................... 5

Wiring and Grounding ...................................................................................................................... 5

Selecting Control Panels ....................................................................................................................5

Warning Pump Control Panels and Switches .....................................................................................5

Panel Operation ................................................................................................................................5

Check Rotation ..................................................................................................................................5

Combination Starter and Overload Relay ..........................................................................................7

Controller Functions ..........................................................................................................................8

Specifications

General Specifications ............................................................................................................... 8

Electrical ................................................................................................................................... 8

Interpreting Model Numbers ............................................................................................................. 9

Suggested Fuse, Wire, and Conduit Sizes ................................................................................ 11

Schematics ...................................................................................................................................... 12

Recommended Spare Parts For Five Years Of Operation ..................................................................22

Limited Warranty .............................................................................................................................24

3

ITT

CENTRIPRO

daNgER

WARNING

CAUTION

WARNING

WARNING

WARNING

daNgER

daNgER

WARNING

Commercial Water Systems

saFETY INsTRUCTIONs

TO AVOID SERIOUS OR FATAL PERSONAL

INJURY OR MAJOR PROPERTY DAMAGE,

READ AND FOLLOW ALL SAFETY

INSTRUCTIONS IN MANUAL AND ON

PUMP.

THIS MANUAL IS INTENDED TO ASSIST

IN THE INSTALLATION AND OPERATION

OF THIS UNIT AND MUST BE KEPT WITH

THE PUMP.

This is a SAFETY ALERT

SYMBOL. When you see this

symbol on the pump or in the

manual, look for one of the

following signal words and

be alert to the potential for

personal injury or property

damage.

Warns of hazards that WILL

cause serious personal injury,

death or major property

damage.

Warns of hazards that CAN

cause serious personal injury,

death or major property

damage.

Warns of hazards that CAN

cause personal injury or

property damage.

NOTICE: INDICATES SPECIAL

INSTRUCTIONS WHICH ARE

VERY IMPORTANT AND MUST BE

FOLLOWED.

THOROUGHLY REVIEW ALL

INSTRUCTIONS AND WARNINGS

PRIOR TO PERFORMING ANY WORK

ON THIS PUMP.

MAINTAIN ALL SAFETY DECALS.

All electrical work must be per-

formed by a qualified technician.

Always follow the National Electrical Code (NEC),

or the Canadian Electrical Code, as well as all

local, state and provincial codes. Code questions

should be directed to your local electrical inspector. Failure to follow electrical codes and OSHA

safety standards may result in personal injury or

equipment damage. Failure to follow manufacturer’s installation instructions may result in electrical

shock, fire hazard, personal injury or death, damaged equipment, provide unsatisfactory performance, and may void manufacturer’s warranty.

See specific pump and motor name-

plates for all agency Listings.

Check motor nameplate and Flo-

Standard nameplate for all electrical ratings.

The FloStandard fixed-speed pump

panel may have safety devices that

will stop the motor in the event of electrical,

mechanical load or external faults. This does not

remove power to the panel.

The FloStandard may have an auto

reset feature in the event of faults,

which can result in the pump motor restarting

unexpectedly. You must remove all main power to

the pump and motor before attempting a repair.

PRE-INsTallaTION ChECks

Open all cartons and inspect for

shipping damage. Report any damage to you supplier or shipping carrier immediately.

Verify that all equipment is the correct voltage and

phase. Warranty does not cover damage caused

by connecting pumps and controls to an incorrect

power source (voltage/phase supply).

Record the model numbers and serial numbers

from the pumps and control panel on the front of

this instruction manual for future reference. Give

it to the owner or place it in the plastic protective

pocket inside the panel cabinet when finished with

the installation.

4

ITT

CENTRIPRO

WARNING

WARNING

WARNING

WARNING

WARNING

Commercial Water Systems

PUmP CONTROl PaNEls aNd WIRINg

NOTE: CONSULT MOTOR AND

PUMP MANUALS FOR SPECIFIC

WIRING INSTRUCTIONS.

WIRINg aNd gROUNdINg

IMPORTANT NOTICE: Read

Safety Instructions before proceed-

ing with any wiring.

Use only stranded copper wire to pump/motor and ground. The ground wire must be

at least as large as the power supply wires.

Wires should be color coded for ease of

maintenance and troubleshooting.

Install wire and ground according to the

National Electrical Code (NEC), or the

Canadian Electrical Code, as well as all local,

state, and provincial codes.

Disconnect and lockout electrical power before performing any service or installation.

All splices must be waterproof. If using splice

kits follow manufacturer’s instructions.

Seal all panel connections tightly from gases

or moisture present which may damage electrical components.

FAILURE TO PERMANENTLY

GROUND PUMP, MOTOR,

AND CONTROLS BEFORE CONNECTING

TO POWER CAN CAUSE SHOCK, BURNS, OR

DEATH.

sElECTINg CONTROl PaNEls

MATCH EQUIPMENT TO

POWER SUPPLY: It is important

always to match the pump motor voltage, phase,

and HP ratings to your control panel and power

supply. Record the motor nameplate HP, voltage

and phase in the Owner Information table on the

cover page. Make sure that the power supply, motor nameplate, and panel nameplate data match.

Incorrect voltage or phase can cause fire, motor

and control damage and voids the warranty.

WaRNINg PUmP CONTROl PaNEls

aNd sWITChEs

It is important to use the wiring

diagrams furnished in the manual

and to wire all connections as indicated. Please

refer to Figure 1 on page 4 and pages 9-12.

Motor Lead Connections: Locate the terminal

block labeled T1, T2, T3 and ground screw.

Connect wires to terminal block and route wires

through one of the knock out ports on the bottom

of the panel. There is room allowed to wire with

service loops to avoid wire strain.

Input Power Cable Installation: The main power

cable is connected to the terminal block labeled

L3, L2, and L1. Room is allowed in the panel to

wire with service loops to avoid wire strain.

PaNEl OPERaTION

Operation is with a Hand/Off/Auto (HOA) threeposition switch on the panel cover. The pump may

be started and stopped at the panel cover by setting the switch to the Hand (manual start) or Off

positions. When the three-position switch is in the

Auto position, start and stopping is controlled only

by the wired remote contact or control device.

ChECk ROTaTION

Always verify correct rotation. Correct rotation

is usually indicated on the pump casing. Motor

direction is reversible. Consult pump and motor

manuals for specific instructions.

A full three-phase supply consisting of three individual transformers or one three-phase transformer is recommended. “Open” delta or wye connections using only two transformers can be used,

but are more likely to cause poor performance,

overload tripping or early motor failure due to

current unbalance.

Check the current in each of the three motor leads

and calculate the current unbalance as explained

below.

• If the current unbalance is 2% or less, leave

the leads as connected.

5

ITT

CENTRIPRO

Commercial Water Systems

• If the current unbalance is more than 2%,

current readings should be checked on each

leg using each of the three possible hook-ups.

Roll the motor leads across the starter in the

same direction to prevent motor reversal.

To calculate percent of current unbalance (see,

Example below):

1. Add the three-line amp values together.

2. Divide the sum by three, yielding average

current

3. Pick the amp value, which is furthest from

the average current (either high or low).

4. Determine the difference between this amp

value (furthest from average) and the average.

5. Divide the difference by the average. Multi-

ply the result by 100 to determine percent of

unbalance.

Current unbalance should not exceed 5% at service factor load or 10% at rated input load. If the

unbalance cannot be corrected by rolling leads, the

source of the unbalance must be located and corrected. If, on the three possible hookups, the leg

farthest from the average stays on the same power

lead, most of the unbalance is coming from the

power source.

Contact your local power company to resolve

imbalance.

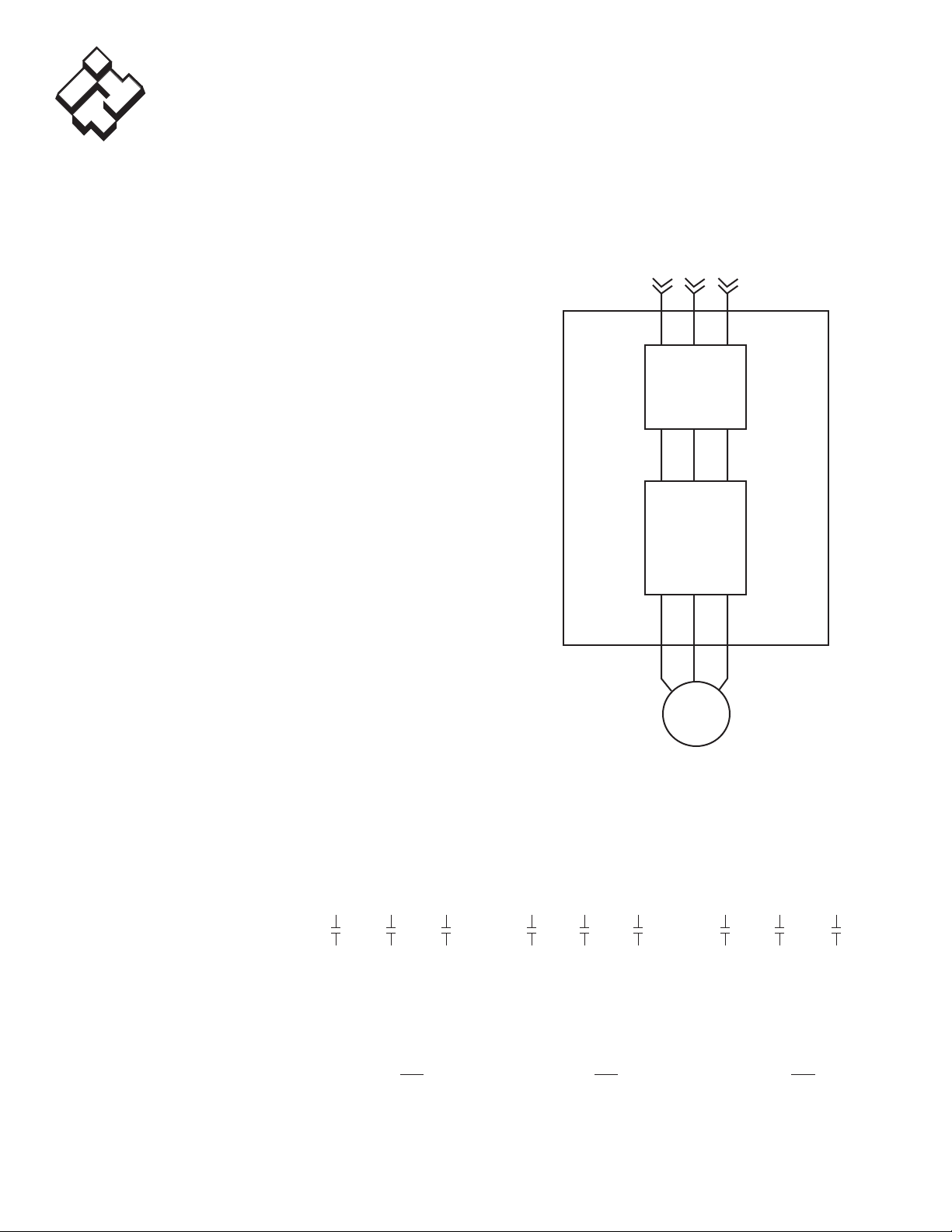

Main Power Supply

L1 L2 L3

Disconnect

‡

Starter

T1 T2 T3

Motor

‡ Class J Fuses are not included. Supplied by other vendors.

Figure 1 – Panel Connection Points

Hookup 1 Hookup 2 Hookup 3

Starter Terminals L1 L2 L3 L1 L2 L3 L1 L2 L3

Motor Leads T3 T1 T2 T2 T3 T1 T1 T2 T3

Example:

T3 = 51 amps T2 = 50 amps T1 = 50 amps

T1 = 46 amps T3 = 48 amps T2 = 49 amps

T2 = 53 amps T1 = 52 amps T3 = 51 amps

Total = 150 amps Total = 150 amps Total = 150 amps

÷ 3 = 50 amps ÷ 3 = 50 amps ÷ 3 = 50 amps

– 46 = 4 amps – 48 = 2 amps – 49 = 1 amps

4 ÷ 50 = .08 or 8% 2 ÷ 50 = .04 or 4% 1 ÷ 50 = .02 or 2%

6

ITT

CENTRIPRO

Commercial Water Systems

COmbINaTION sTaRTER aNd

OvERlOad RElaY

FloStandard is furnished with a combination

starter and overload relay to protect the motor from overload during start-up or operation.

Panels designed for use on three phase power also

incorporate circuitry that will protect motors from

phase loss or phase imbalance, in addition to overload during start-up or operation.

Figure 2 – Starter/Overload Relay

The following are field adjustments and indications

are available and can be referenced from Figure 2

above:

• Setting Based on Motor Service Factor: For

continuous-rated motors having a service

factor (SF) of 1.0, set the current adjustment

dial to 90% of the motor’s full-load current

(MFLC). For continuous-rated motors having

a service factor of 1.15 to 1.25, set the FLA

dial indicator current to the MFLC.

• Visible Trip Indication: A viewing window on

the front of the solid-state overload relay provides visible trip indication. A yellow marker

appears when the device is tripped.

When the overload relay detects motor current in

excess of 125% of the current adjustment dial setting, the overload contacts open and the optional

auxiliary contacts change state (N.O. contacts

close and N.C. contacts open). The time required

for the overload relay to trip depends upon:

• Current value.

• Time elapsed since last trip.

The phase loss/phase imbalance circuitry can

detect a phase loss and initiate a trip within three

seconds. Phase loss detection extends to a phase

loss in either the primary or the secondary of a

wye-delta or delta-wye transformer. The circuitry

also detects a phase imbalance and initiates a trip

when any phase current drops 25% below or rises

25% above the average of the three phase currents.

Reset Bar: The overload relay is reset by depressing the reset bar on the front of the device. Since

the overload relay trip function is of the “tripfree” design, it cannot be overridden by holding

down the reset bar.

Overload Relay Power On Light: A red LED

indicates that the power necessary to operate the

overload relay protective circuitry is present. This

power is derived from the current flowing in the

motor leads. When sufficient power is extracted to

enable normal operation, the LED blinks. It blinks

faster as the current being monitored increases.

Functional Test: To test for proper operation

of the overload contacts, de-energize the starter

and disconnect the control circuit power. With a

small, flat-blade screwdriver, slide the TEST switch

located on the bottom of the overload relay to the

right. This operates the trip mechanism, opening

the N.C. overload contacts at terminals 95 and 96.

Verify proper operation of the overload contacts,

and then reset the device by depressing the red

RESET bar. Reconnect the control circuit power

and reenergize the starter as required.

Inspecting and Replacing Contacts: Discoloration

and slight pitting do not harm contacts. Do not file

contacts; this wastes contact material. Replace contacts only when worn thin. To inspect or replace

contacts, disconnect all power. Do not remove any

wiring. Loosen the four captive screws holding

the contact actuator to the contact block. Lift the

contact actuator to expose the contacts. Manually

operate the contactor or starter with a screwdriver

by pushing down the contact carrier. There is a

step on the outside of the contact carrier suitable

for this use. Replacement starter contacts may be

obtained from a local electrical supply house.

7

ITT

CENTRIPRO

Commercial Water Systems

Loss of Phase/Phase Imbalance: The overload

relay has phase loss and phase imbalance monitoring circuitry. Loss of phase or a phase imbalance

of 25% or more of the average of the three phases

will result in a trip. Disconnect the unit from the

main power supply, find and correct cause for

phase loss of phase imbalance. Possible causes

would be blown fuse(s) or loose wiring connections. Reset the overload relay with the reset bar

on the front of the combination starter. Restart the

pump.

CONTROllER FUNCTIONs

FloStandard is designed to accept a variety of

inputs to function as a pump controller. Pressure

Switches, Level Sensors, Flow Switches, etc. can

be used as a dry contact signal to automatically

start and stop the pump. Caution should be used

to prevent pump cycling when utilizing remote

controllers.

sPECIFICaTIONs

GENERAL SPECIFICATIONS:

Enclosure Type

Outdoor Use

Operating Temperature 4º F to 122º F

Storage Temperature 20º F to 149º F

Humidity 0-95% non-condensing

ELECTRICAL:

Voltage Input

Voltage

Input Line Frequency 50/60 Hz +/- 2 Hz

Line Voltage / 115 Volts

Control Voltage AC with control power

transformer option

Overload Capacity

current for 60 seconds

NEMA 3R Suitable for

+/- 10% Rated Panel

125% of rated RMS

Overload Class 10 or 20

Adjustable setting for

Time Overload 125% of rated motor

current

Agency Listing UL508A or equivalent

8

ITT

CENTRIPRO

Commercial Water Systems

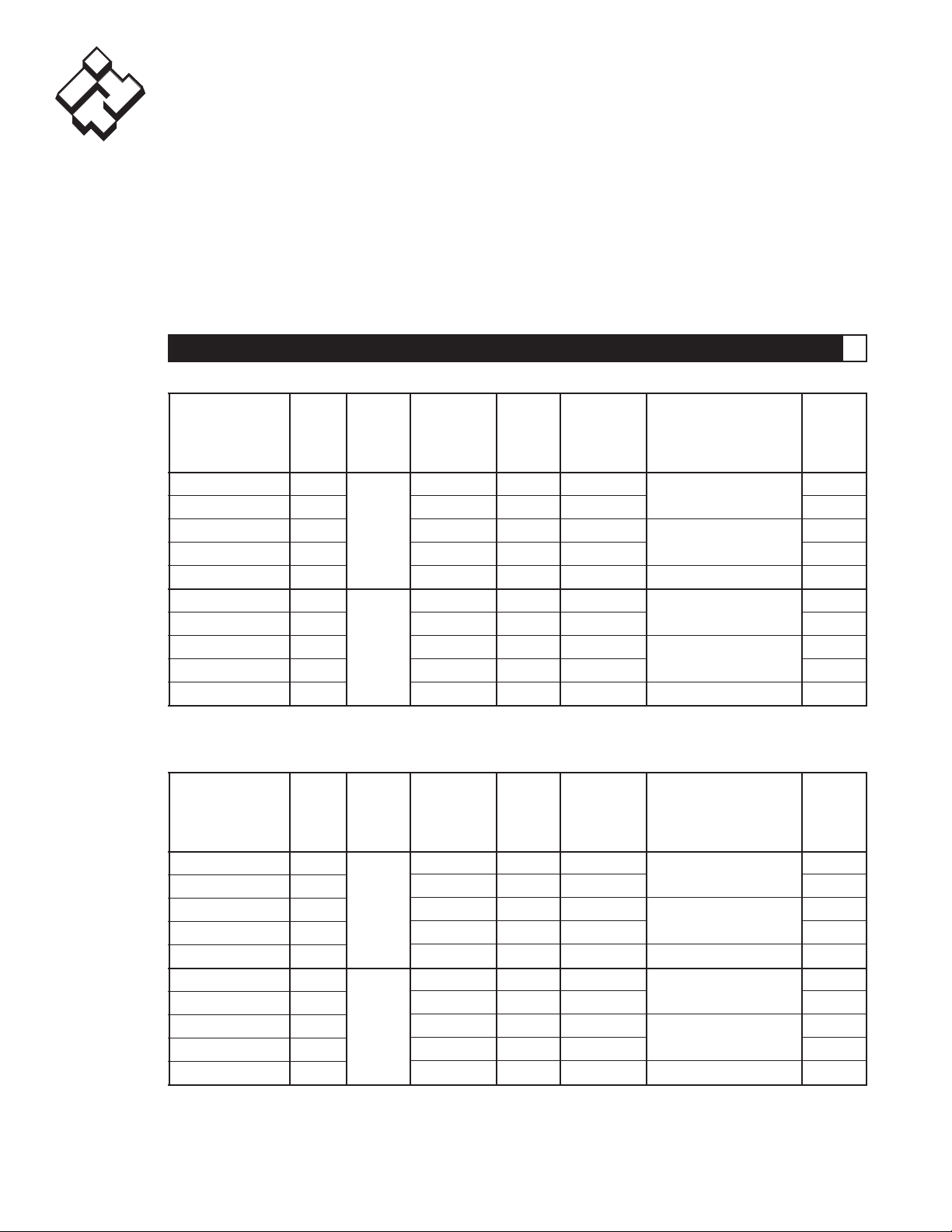

INTERPRETINg mOdEl NUmbERs

The model number of the FloStandard appears on the shipping carton label and on the technical data

label affixed to the panel. The information provided by the model number is shown below:

FloStandard™ Simplex Pump Control Panels J

Units supplied with Class 20 adjustable Overload Protection (For Above Ground Pumps)

Order Max. Input

Number HP Voltage

(Amps)

FV2070027A1 7½ 1 27 30

FV2015045A2 15 2 45 60 55

FV2030090A3 30 230 3 90 100

FV2050130A4 50 4 135 200 170

FV2100311A5 100 5 270 400 73”H x 22”W x 18”D 440

FV4010018B1 10 1 27 30

FV4025045B2 25 2 45 60 55

FV4050090B3 50 460 3 90 100

FV4100200B4 100 4 135 200 170

FV4200311B5 200 5 270 400 73”H x 22”W x 18”D 440

‡Class J fuses are not supplied.

Units supplied with Class 10 Overload Protection (For Submersible Pumps)

Order Max. Input

Number HP Voltage

(Amps)

FV2070027A1T 7½ 1 27 30

FV2015045A2T 15 2 45 60 55

FV2030090A3T 30 230 3 90 100

FV2050130A4T 50 4 135 200 170

FV2100311A5T 100 5 270 400 73”H x 22”W x 18”D 440

FV4010018B1T 10 1 27 30

FV4025045B2T 25 2 45 60 55

FV4050090B3T 50 460 3 90 100

FV4100200B4T 100 4 135 200 170

FV4200311B5T 200 5 270 400 73”H x 22”W x 18”D 440

‡Class J fuses are not supplied.

Starter

Starter

Max. Fuse

NEMA

NEMA

Max. holder Enclosure Weight

Amps Size Size lbs.

Size

Max. Fuse

Max. holder Enclosure Weight

Amps Size Size lbs.

Size

‡

36”H x 16”W x 9”D

45”H x 20”W x 11”D

36”H x 16”W x 9”D

45”H x 20”W x 11”D

‡

36”H x 16”W x 9”D

45”H x 20”W x 11”D

36”H x 16”W x 9”D

45”H x 20”W x 11”D

40

111

40

111

40

111

40

111

9

ITT

Commercial Water Systems

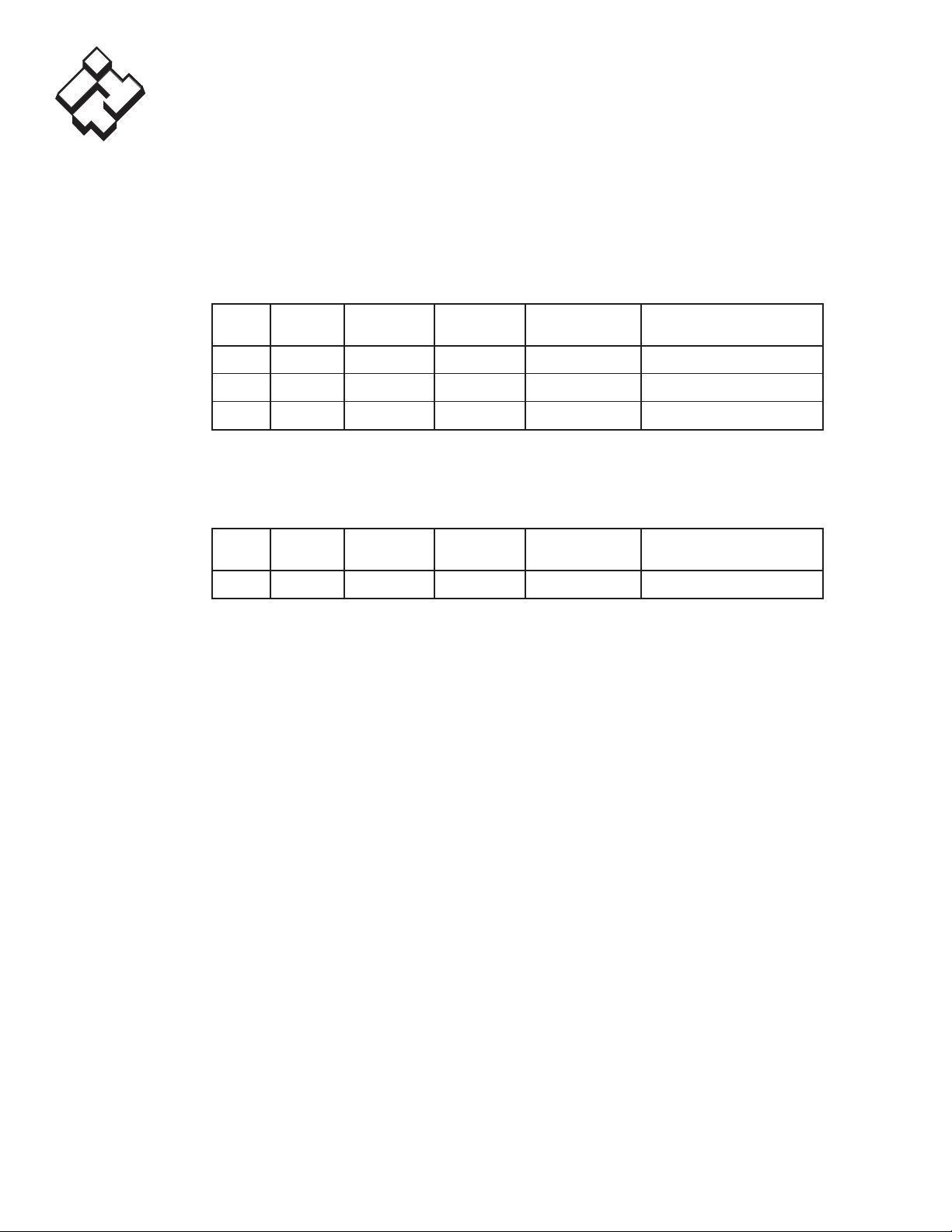

Units supplied with Class 10 Overload Protection with

Pump Monitor (777) and Lightning Protection

CENTRIPRO

Order Max. Input

Number HP Voltage

(Amps)

FV2070027A1W 7½ 1 27 30

FV2015045A2W 15 2 45 60 55

FV2030090A3W 30 230 3 90 100

FV2050130A4W 50 4 135 150 170

FV2100311A5W 100 5 270 400 73”H x 22”W x 18”D 440

FV4010018B1W 10 1 27 30

FV4025045B2W 25 2 45 60 55

FV4050090B3W 50 460 3 90 100

FV4100200B4W 100 4 135 200 170

FV4200311B5W 200 5 270 400 73”H x 22”W x 18”D 440

‡Class J fuses are not supplied.

Accessories sold separately. Field installation required.

FloStandard™ Simplex Pump Control Panels J

Note: Recommended class “R” Fuse Type, dual element, time delay (not Included).

Starter

Max. Fuse

NEMA

Max. holder Enclosure Weight

Amps Size Size lbs.

Size

‡

36”H x 16”W x 9”D

45”H x 20”W x 11”D

36”H x 16”W x 9”D

45”H x 20”W x 11”D

40

111

40

111

Option Description Weight (Lbs)

FSCT 120 V Control Transformer 7

FSSP Surge/Lightning Protection

FSPP Pump Monitor (777) Includes class 10 overload 2

FSTC Time Clock†

FSPH Condensation Header†

FSGN Green Run Light†

FSRN Red Alarm Light†

FSOP Class 10 Overload Protection†

†Requires control transformer option FSCT. For specials or other options, consult factory.

1

10

ITT

sUggEsTEd FUsE, WIRE aNd CONdUIT sIzEs

CENTRIPRO

Commercial Water Systems

208 Volt

HP Fuse Wire Conduit

3 17.5 14 0.50

5 30 10 0.50

7½ 40 8 0.75

10 50 8 0.75

15 80 6 1.00

20 100 4 1.00

25 125 3 1.25

30 150 2 1.25

NOTE:

Fuses are for main disconnect. Recommended dual element, time-delay type fuse.

Wire is copper, type “THW,” 75º C.

All sizes are recommended only and are not a substitute for hiring a local electrician to properly size

according to NEC and local codes.

230 Volt

HP Fuse Wire Conduit

3 15 14 0.50

5 25 12 0.50

7½ 35 10 0.50

10 45 8 0.75

15 70 6 1.00

20 90 4 1.00

25 110 4 1.00

30 125 3 1.25

460 Volt

HP Fuse Wire Conduit

5 12 14 0.50

7½ 17.5 14 0.50

10 25 12 0.50

15 35 10 0.50

20 45 8 0.75

25 60 8 0.75

30 70 6 1.00

40 90 6 1.00

50 110 4 1.00

60 125 3 1.25

11

ITT

sChEmaTICs

CENTRIPRO

Commercial Water Systems

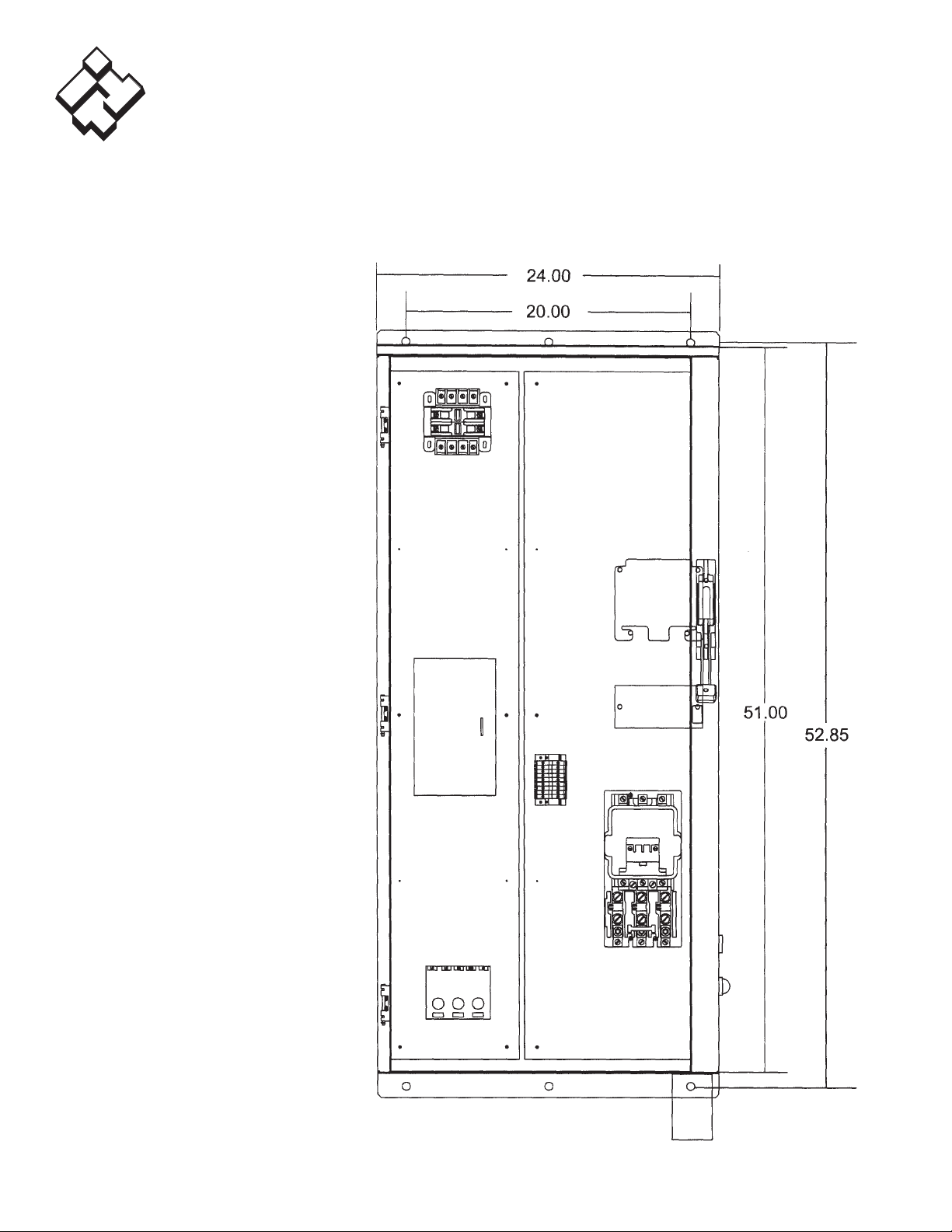

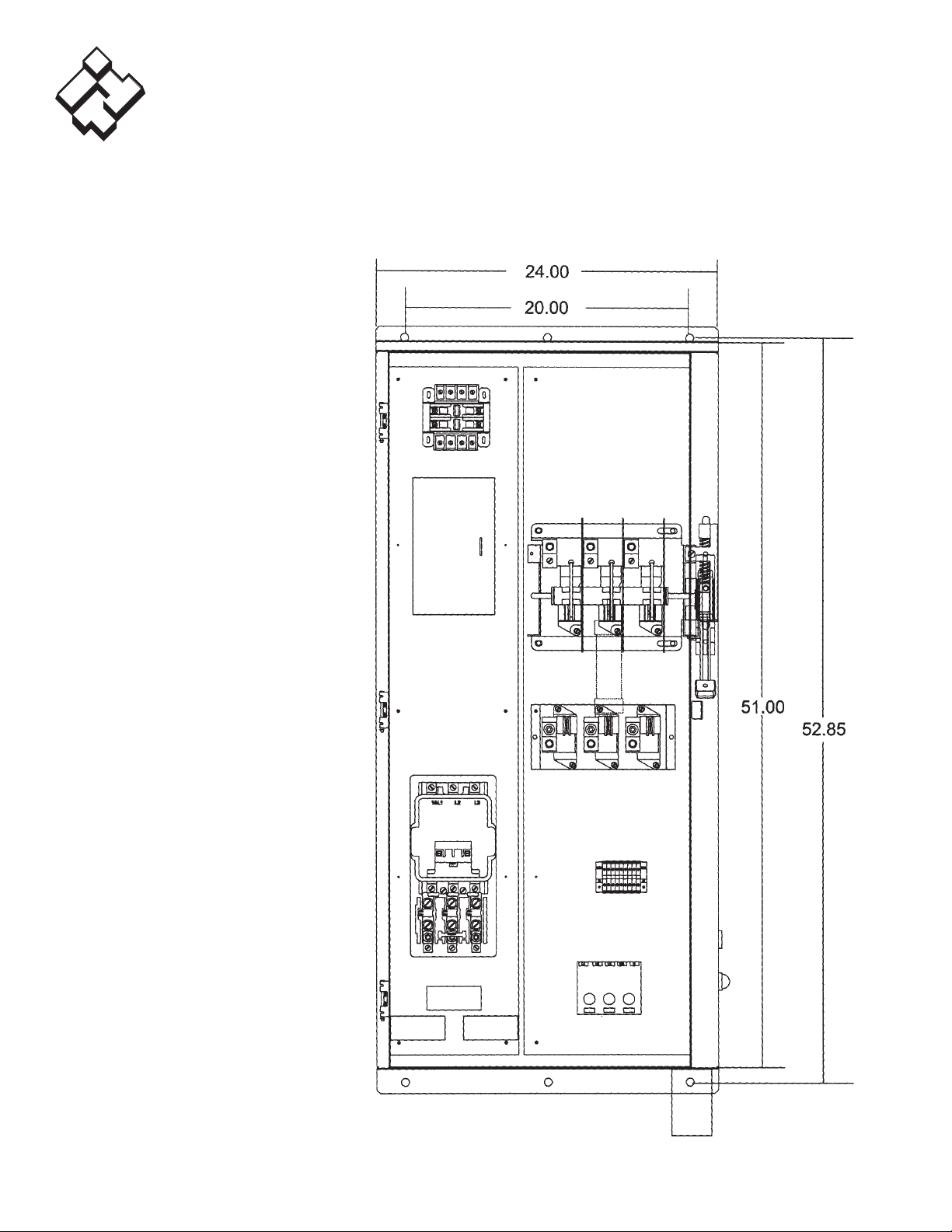

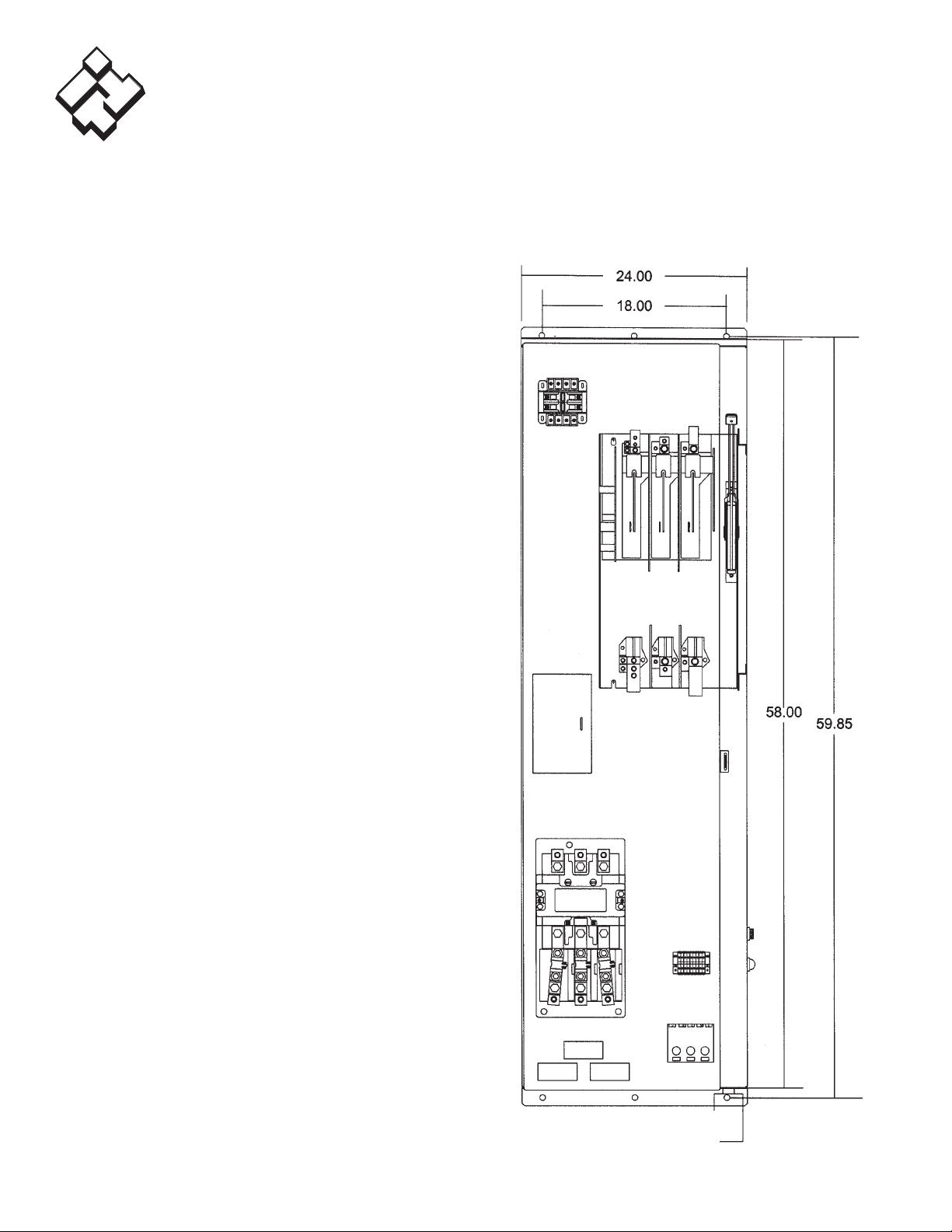

SIZE 1 & 2 PUMP PANEL

WITH OPTIONS INSTALLED

TIMECLOCK, CPT WITH

FUSING, RUN PILOT LIGHT

SYMCOM PUMP SAVER,

LIGHTNING ARRESTOR.

APPROXIMATE SHIPPING

WEIGHT 65 POUNDS.

Figure 3 – Size 1 and 2 Pump Panel Dimensions

12

ITT

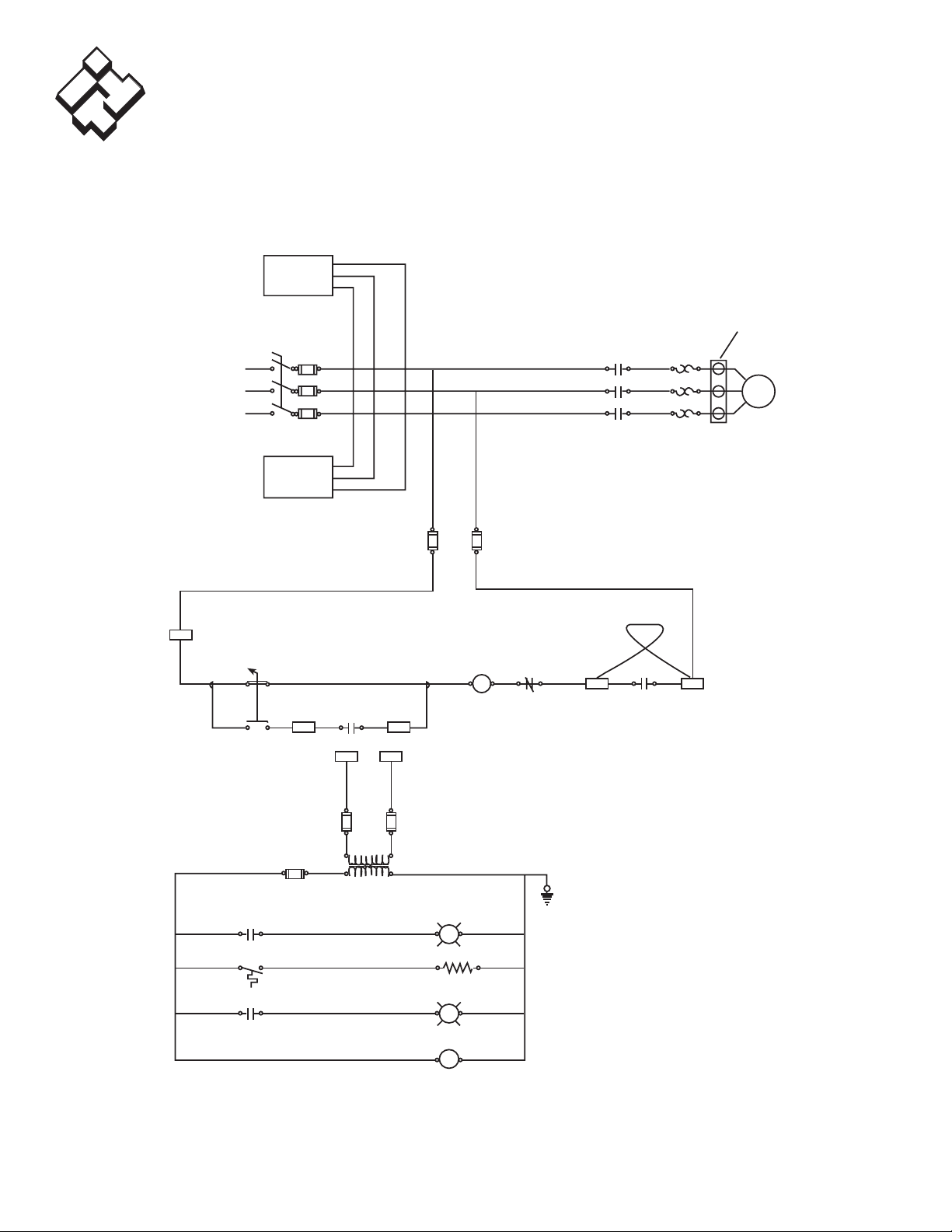

CENTRIPRO

M1 OL1

L1 T1 L1 T1

M1

L2 T2 L2 T2

L3 T3 L3 T3

PUMP 1

ROUTE MOTOR LEADS

THROUGH PUMPSAVER OR CT’S IF PROVIDED

ROUTE MOTOR LEADS

THROUGH PUMPSAVER

IF PROVIDED (AS REQUIRED)

L1

L2

L3

PUMP

SAVER

L1

L2

L3

PUMPSAVER

ORDER KIT #FSPP

MAIN DISCONNECT

SEE PART

NUMBER

RJ 1-3

LA

LIGHTING

ARRESTOR

LIGHTING ARRESTOR

ORDER KIT #FSSP

FU43AFU5

3A

1

4 2

H A

O

2 3

X00

X00

TC-1

M1

X2

X2A

OL 1-1 OL 1-1

X2A X2

YELLOW JUMPER

FACTORY INSTALLED

REMOVE IF

PUMPSAVER IS USED

1 X2

FU61AFU7

FNQR1

FU8

FNM11/4

120VAC

100VA

CPT PART #FSCT

M1

G

OL

R

TC

GREEN RUN LIGHT PART #FSGN*

* REQUIRES CPT

CONDENSATION HEATER PART #FSPH*

* REQUIRES CPT

RED ALARM LIGHT PART #FSRN*

* REQUIRES CPT

TIME CLOCK PART #FSTC*

* REQUIRES CPT

Commercial Water Systems

Loops through A, B & C

5 HP 15.2 FLA FRNR25 1 2

75 HP 96 FLA FRNR30 1 2

Figure 4 – Simplex Panel with Accessories Size 1, 2 and 3

CT Size Chart (CTs must be installed in the field for selected HP)

Size 1 240VAC

HP FLA Fuse Size

‡ The number of loops may differ from the number of conductors through the current transformers.

Always double check based on HP and FLA.

Number of Number of Conductors

13

‡

ITT

CENTRIPRO

Commercial Water Systems

CT Size Chart (CTs must be installed in the field for selected HP)

Size 1 480VAC

Loops through A, B & C

5 HP 7.6 FLA FRSR15 3 4

7.5 HP 11FLA FRSR20 2 3

10 HP 14FLA FRSR20 1 2

Loops through A, B & C

10 HP 28FLA FRNR40 0 1

HP FLA Fuse Size

‡ The number of loops may differ from the number of conductors through the current transformers.

Always double check based on HP and FLA.

HP FLA Fuse Size

Number of Number of Conductors

Size 2 240VAC

Number of Number of Conductors

‡

‡

15 HP 42FLA FRSR250 0 1

‡ The number of loops may differ from the number of conductors through the current transformers.

Always double check based on HP and FLA.

Size 2 480VAC

Loops through A, B & C

15 HP 21FLA FRSR35 1 2

20 HP 27FLA FRSR40 0 1

25 HP 34FLA FRSR50 0 1

HP FLA Fuse Size

‡ The number of loops may differ from the number of conductors through the current transformers.

Always double check based on HP and FLA.

Number of Number of Conductors

‡

14

ITT

sChEmaTICs

CENTRIPRO

Commercial Water Systems

SIZE 3 PUMP PANEL WITH

OPTIONS INSTALLED

TIMECLOCK, CPT WITH

FUSING, RUN PILOT LIGHT

SYMCOM PUMPSAVER,

LIGHTNING ARRESTOR.

APPROXIMATE SHIPPING

WEIGHT 150 POUNDS.

Figure 5 – Size 3 Dimensions

15

ITT

CENTRIPRO

Commercial Water Systems

CT Size Chart (CTs must be installed in the field for selected HP)

Size 3 240VAC

Loops through A, B & C

25 HP 68FLA FRNR100 0 1

30 HP 80FLA FRNR150 0 1

Loops through A, B & C

30 HP 40FLA FRSR60 0 1

40 HP 52FLA FRSR80 0 1

HP FLA Fuse Size

‡ The number of loops may differ from the number of conductors through the current transformers.

Always double check based on HP and FLA.

HP FLA Fuse Size

Number of Number of Conductors

Size 3 480VAC

Number of Number of Conductors

‡

‡

50 HP 65FLA FRSR100 0 51

‡ The number of loops may differ from the number of conductors through the current transformers.

Always double check based on HP and FLA.

16

ITT

sChEmaTICs

CENTRIPRO

Commercial Water Systems

SIZE 4 PUMP PANEL WITH

OPTIONS INSTALLED

TIMECLOCK, CPT WITH

FUSING, RUN PILOT LIGHT

SYMCOM PUMPSAVER,

LIGHTNING ARRESTOR.

APPROXIMATE SHIPPING

WEIGHT 150 POUNDS.

Figure 6 – Size 4 Dimensions

17

ITT

CENTRIPRO

M1 OL1

L1 T1 L1 T1

M1

L2 T2 L2 T2

L3 T3 L3 T3

PUMP 1

ROUTE MOTOR LEADS

THROUGH PUMPSAVER OR CT’S IF PROVIDED

ROUTE MOTOR LEADS

THROUGH PUMPSAVER

IF PROVIDED (AS REQUIRED)

L1

L2

L3

PUMP

SAVER

L1

L2

L3

PUMPSAVER

ORDER KIT #FSPP

MAIN DISCONNECT

SEE PART

NUMBER

RJ 1-3

LA

LIGHTING

ARRESTOR

LIGHTING ARRESTOR

ORDER KIT #FSSP

FU43AFU5

3A

1

4 2

H A

O

2 3

X00

X00

TC-1

M1

X2

X2A

OL 1-1 OL 1-1

X2A X2

YELLOW JUMPER

FACTORY INSTALLED

REMOVE IF

PUMPSAVER IS USED

1 X2

FU61AFU7

FNQR1

FU8

FNM11/4

120VAC

100VA

CPT PART #FSCT

M1

G

OL

R

TC

GREEN RUN LIGHT PART #FSGN*

* REQUIRES CPT

CONDENSATION HEATER PART #FSPH*

* REQUIRES CPT

RED ALARM LIGHT PART #FSRN*

* REQUIRES CPT

TIME CLOCK PART #FSTC*

* REQUIRES CPT

Commercial Water Systems

Figure 7 – Simplex Panel with Accessories Size 4 and 5

18

ITT

CENTRIPRO

Commercial Water Systems

CT Size Chart (CTs must be installed in the field for selected HP)

Size 4 480VAC

Loops through A, B & C

60 HP 77FLA FRSR100 No CT 0 1

75 HP 96FLA FRSR150 100:5 4 5

100 HP 124FLA FRSR170 150:5 4 5

HP FLA Fuse Size CT Size

‡ The number of loops may differ from the number of conductors through the current transformers.

Always double check based on HP and FLA.

Size 4 240VAC

Loops through A, B & C

50 HP 130FLA FRNR200 150:5 4 5

HP FLA Fuse Size CT Size

‡ The number of loops may differ from the number of conductors through the current transformers.

Always double check based on HP and FLA.

Number of Number of Conductors

Number of Number of Conductors

‡

‡

19

ITT

sChEmaTICs

CENTRIPRO

Commercial Water Systems

SIZE 5 PUMP PANEL WITH OPTIONS INSTALLED TIMECLOCK, CPT WITH FUSING,

RUN PILOT LIGHT SYMCOM PUMPSAVER,

LIGHTNING ARRESTOR. APPROXIMATE

SHIPPING WEIGHT 300 POUNDS.

Figure 8 – Size 5 Dimensions

20

ITT

CENTRIPRO

Commercial Water Systems

CT Size Chart (CTs must be installed in the field for selected HP)

Size 5 480VAC

Loops through A, B & C

125 HP 156FLA FRSR200 150:5 4 5

150 HP 180FLA FRSR250 200:5 4 5

200 HP 240FLA FRSR350 300:5 4 5

HP FLA Fuse Size CT Size

‡ The number of loops may differ from the number of conductors through the current transformers.

Always double check based on HP and FLA.

Size 5 240VAC

Loops through A, B & C

75 HP 193FLA FRNR300 200:5 4 5

HP FLA Fuse Size CT Size

Number of Number of Conductors

Number of Number of Conductors

‡

‡

100 HP 248FLA FRNR350 300:5 4 5

‡ The number of loops may differ from the number of conductors through the current transformers.

Always double check based on HP and FLA.

21

ITT

CENTRIPRO

Commercial Water Systems

RECOmmENdEd sPaRE PaRTs FOR FIvE YEaRs OF OPERaTION

• A set of spare main and control voltage fuses.

• A set of replacement contactors for the starter.

22

ITT

NOTEs

CENTRIPRO

Commercial Water Systems

23

ITT

Commercial Water Systems

CentriPro

TM

CENTRIPRO LIMITED WARRANTY

This warranty applies to all water systems pumps manufactured by CentriPro.

Any part or parts found to be defective within the warranty period shall be replaced at no charge to

the dealer during the warranty period. The warranty period shall exist for a period of twenty-four (24)

months from date of installation or thirty (30) months from date of manufacture, whichever period is

shorter.

A dealer who believes that a warranty claim exists must contact the authorized CentriPro distributor

from whom the pump was purchased and furnish complete details regarding the claim. The distributor

is authorized to adjust any warranty claims utilizing the CentriPro Customer Service Department.

The warranty excludes:

(a) Labor, transportation and related costs incurred by the dealer;

(b) Reinstallation costs of repaired equipment;

(c) Reinstallation costs of replacement equipment;

(d) Consequential damages of any kind; and,

(e) Reimbursement for loss caused by interruption of service.

For purposes of this warranty, the following terms have these definitions:

(1) “Distributor” means any individual, partnership, corporation, association, or other legal

relationship that stands between CentriPro and the dealer in purchases, consignments or

contracts for sale of the subject pumps.

(2) “Dealer” means any individual, partnership, corporation, association, or other legal

relationship which engages in the business of selling or leasing pumps to customers.

(3) “Customer” means any entity who buys or leases the subject pumps from a dealer. The

“customer” may mean an individual, partnership, corporation, limited liability company,

association or other legal entity which may engage in any type of business.

CentriPro, FloStandard and the ITT Engineered Blocks Symbol

are registered trademarks and tradenames of ITT Corporation.

SPECIFICATIONS ARE SUBJECT TO CHANGE WITHOUT NOTICE.

IM192R00 August, 2006

© 2006 ITT Corporation

Engineered for life

THIS WARRANTY EXTENDS TO THE DEALER ONLY.

Loading...

Loading...