INSTRUCTION MANUAL

IM102R05

Jet Pumps

INSTALLATION, OPERATION AND TROUBLESHOOTING MANUAL

Table of Contents

WARNING

WARNING

WARNING

DANGER

WARNING

WARNING

Table of Contents

SUBJECT PAGE

Selecting the Correct Jet Pump System ........................................................................................................................3

Preparing for Installation ............................................................................................................................................. 4

General Information - Piping ....................................................................................................................................... 4

Shallow Well Installation .............................................................................................................................................4

Deep Well Twin Pipe ...................................................................................................................................................5

Deep Well Packer System ............................................................................................................................................. 5

Deep Well Discharge Piping ......................................................................................................................................... 5

All Systems .................................................................................................................................................................. 6

Booster Systems ........................................................................................................................................................... 7

Seasonal Service ..........................................................................................................................................................7

Recommended Deep Well Jet Assemblies and Control Valve Settings ........................................................................8-9

Shallow Well Jet Assemblies For Convertible Pumps .................................................................................................... 9

Technical Data ......................................................................................................................................................10-11

Troubleshooting ........................................................................................................................................................12

Goulds Water Technology Limited Warranty .............................................................................................................12

SAFETY INSTRUCTIONS

TO AVOID SERIOUS OR FATAL PERSONAL INJURY OR MAJOR PROPERTY DAMAGE, READ

AND FOLLOW ALL SAFETY INSTRUCTIONS IN

MANUAL AND ON PUMP.

THIS MANUAL IS INTENDED TO ASSIST IN THE

INSTALLATION AND OPERATION OF THIS UNIT

AND MUST BE KEPT WITH THE PUMP.

This is a SAFETY ALERT SYMBOL.

When you see this symbol on the pump

or in the manual, look for one of the

following signal words and be alert to

the potential for personal injury or

property damage.

Warns of hazards that WILL cause

serious personal injury, death or major

property damage.

WARNING

Warns of hazards that CAN cause

serious personal injury, death or major

property damage.

CAUTION

Warns of hazards that CAN cause personal injury or property damage.

NOTICE: INDICATES SPECIAL INSTRUCTIONS

WHICH ARE VERY IMPORTANT AND MUST BE

FOLLOWED.

THOROUGHLY REVIEW ALL INSTRUCTIONS

AND WARNINGS PRIOR TO PERFORMING ANY

WORK ON THIS PUMP.

MAINTAIN ALL SAFETY DECALS.

Important notice: Read safety instructions before

proceeding with any wiring

All electrical work must be performed

by a qualified technician. Always follow

the National Electrical Code (NEC), or the Canadian

Electrical Code, as well as all local, state and provincial

codes. Code questions should be directed to your local

electrical inspector. Failure to follow electrical codes

and OSHA safety standards may result in personal injury or equipment damage. Failure to follow manufacturer’s installation instructions may result in electrical

shock, fire hazard, personal injury or death, damaged

equipment, provide unsatisfactory performance, and

may void manufacturer’s warranty.

Standard units are not designed for use

in hazardous liquids, or where flammable

gases exist. Well must be vented per local codes. See

specific pump catalog bulletins or pump nameplate for

all agency Listings.

Disconnect and lockout electrical power

before installing or servicing any electrical equipment. Many pumps are equipped with automatic thermal overload protection which may allow an

overheated pump to restart unexpectedly.

Never over pressurize the tank, piping

or system to a pressure higher than the

tank's maximum pressure rating. This will damage

the tank, voids the warranty and may create a serious

hazard.

Protect tanks from excessive moisture

and spray as it will cause the tank to rust

and may create a hazard. See tank warning labels and

IOM for more information.

2

SELECTING THE CORRECT

SELECTING THE CORRECT

JET PUMP SYSTEM

JET PUMP SYSTEM

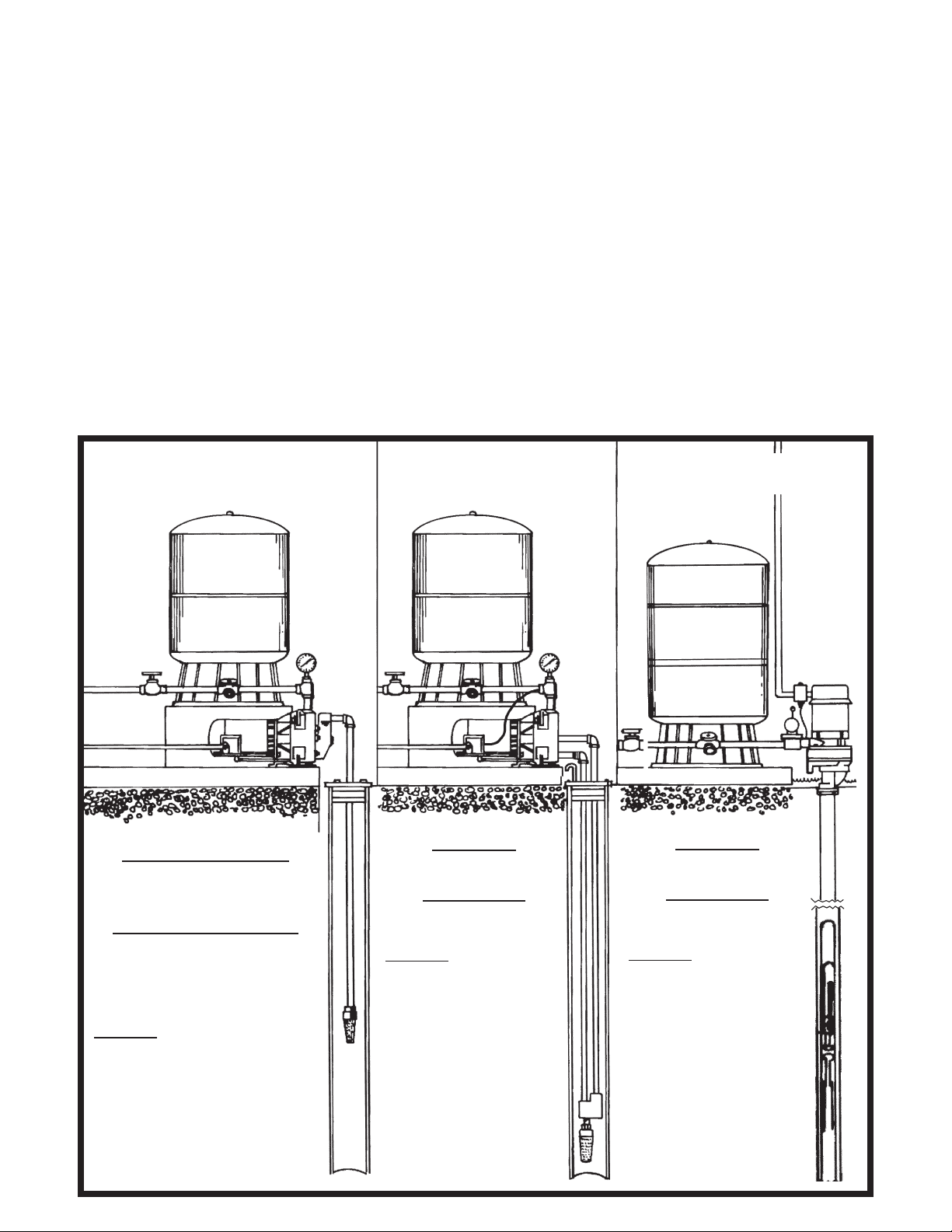

It is important to determine which jet pump system you

need. A jet pump is a centrifugal pump with a jet (ejector) assembly. Goulds Water Technology sells three types

of jet pumps:

Shallow Well Jet Pumps with built-in jet assemblies for

maximum lift of 25'. See Fig. 1

Convertible Jet Pumps can be used for Shallow wells (to

25'), with a bolt on shallow well adapter; or deep well

(over 25') applications with a jet assembly in the well.

See Fig. 1, 2 and 3.

Deep Well Jets should only be used on deep well (over

25') applications with the appropriate jet assembly.

See Fig. 2 and 3

Use a shallow well pump or a convertible pump with a

Shallow Well Adapter for wells with a maximum suction lift of 25'. This 25' includes actual vertical lift plus

friction loss in the suction piping. Shallow well systems

are identified by one (1) pipe going to the well, lake or

river. They are good for city water booster systems and

pumping from cisterns or tanks. See Typical Installations,

Figs. 1, 5 and 6.

Deep well jet pumps are used for lifts greater than 25'

and must have two pipes going to the well. There are two

types of deep well jet assemblies, twin-pipe and packer

systems. Deep well pumps come in both vertical and

horizontal designs and in single and multi-stage models.

See Typical Installation Drawing, Fig. 2 and 3.

Consult with your Professional Dealer or Distributor to

select the best pump system for your application.

• Liquid temperature must not exceed 140° F (60°C).

• Protect unit from freezing

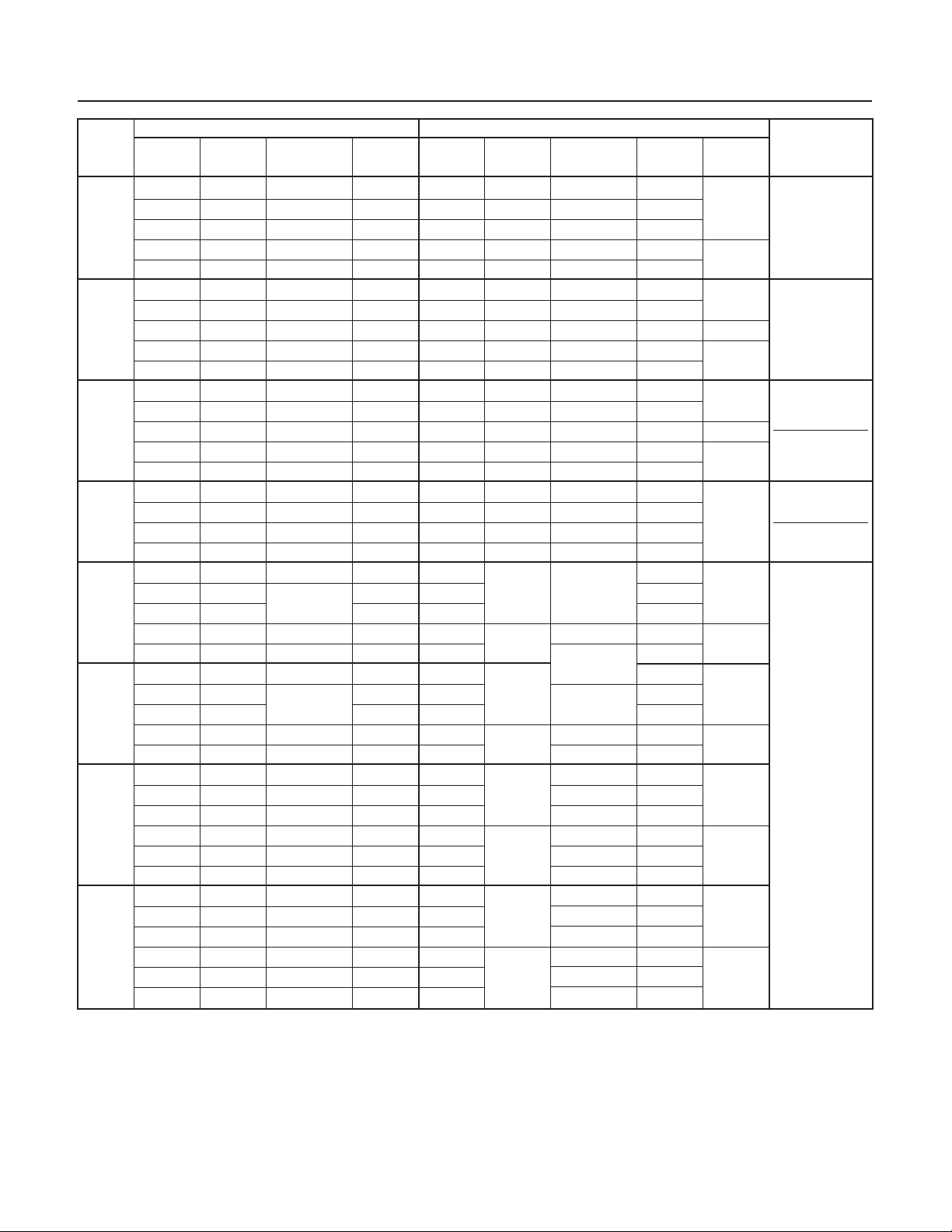

Typical Goulds Water Technology Jet Pump InstallationsTypical Goulds Water Technology Jet Pump Installations

SHALLOW WELL

SYSTEM

Shallow Well Only

J5S - J15S, JRS5 - JRS10

Convertible with

Shallow Well Adapter

J5 - J15, JRD5 - JRD10

➀ J5 with FH5H, J5 or JRD5

with FH5, J7 or JRD7 with FH7,

J10 or JRD10 with FH10,

J15 with FH15

Requires:

• Pump

• Tank

➀• Shallow Well Adapter (FH--)

(J+ and JRD only)

JS and JRS have built-in

jet assembly (shallow well

adapter).

TWIN PIPE

DEEP WELL SYSTEM

Vertical

SJ or VJ

Horizontal

J, JRD, HSJ

Requires:

• Pump

• Tank

• Twin Pipe

Jet Assembly

• Pressure

Control Valve

(order separately for

horizontal models,

supplied with vertical

pumps).

Fig. 2 Fig. 3Fig. 1

PACKER

DEEP WELL SYSTEM

Vertical

SJ or VJ

Horizontal

J, JRD, HSJ

Requires:

• Pump

• Tank

• Packer Adapter

(for well head)

• Packer Jet Assembly

• Pressure

Control Valve

(order separately for

horizontal models,

supplied with vertical

pumps).

3

Hazardous pressure can

cause personal injury or

property damage.

WARNING

Hazardous pressure can

cause personal injury or

property damage.

WARNING

PREPARING FOR INSTALLATION

PREPARING FOR INSTALLATION

Inspect the pump and the motor assembly for shipping

damage.

Insure that you have all of the parts required for a proper

installation. See component lists for different system

types. There are shallow well, convertible shallow well,

convertible deep well – twin pipe, convertible deep

well-packer, vertical deep well-twin pipe, vertical deep

well-packer, and booster systems. See Typical Installation

Drawings and Chart 1.

Check power supply voltage and select motor voltage.

Goulds ½ hp Jet pumps are factory pre-wired for 115

volts while ¾ hp and larger are pre-wired for 230 volts.

Motors from ½ hp to 1½ hp can operate on either 115

or 230 volts. The 2 hp motors operate only on 230 volts.

See Fig. 7.

Select a site where the pump and tank will not freeze.

The pump must be within 4' of the tank to prevent

switch chatter. There should be no filters or valves, other

than a wide open gate valve, between the pump and tank.

Fluid temperature must not exceed 140° F (60°C).

GENERAL INFORMATION - PIPING

GENERAL INFORMATION - PIPING

Always follow state and local plumbing codes. Goulds

Water Technology does not sell or specify pipe types or

materials, consult with your pipe supplier to determine

the best pipe for your installation. Pipes can be threaded, glued, soldered, or clamped to available fittings and

adapters. If using poly pipe with barbed connectors we

suggest you double clamp all fittings to prevent air leaks.

It is very important to eliminate high spots and dips in

suction piping as they will trap air and make the system

very hard to prime. Never route the piping up above and

then down to the pump suction. Suction piping should be

either straight from the well to the pump or should slope

upward to the pump. Pumps do not “hold” prime, piping

systems and check valves do. Go to the specific section

for your system type.

SHALLOW WELL INSTALLATION - start here

SHALLOW WELL INSTALLATION

To prevent over pumping a low yield well you can

throttle a jet pump using a ball valve in the suction line.

You should install a compound pressure/vacuum gauge

between the well and the valve. Do not throttle to more

than 22" Hg (25' lift).

In areas where freezing occurs make the transition from

vertical to horizontal below the frost line using a pitless

adapter, consult with your plumbing supplier for pitless

adapter information. In some areas they use a well seal

and a 90° elbow.

We recommend not using filters on the suction side of a

jet pump. Dirty filters increase the effective suction lift

on the pump and can starve the pump of water. This

will damage the impeller and diffuser which will affect

performance.

Install Shallow Well Adapter On Convertible Pump

Unpack the Goulds Water Technology “Shallow Well

Adapter”. Insure that the nozzle is installed in the adapter. Screw the venturi (long black tube) into the adapter.

Install the gasket and bolt the adapter to the front of the

pump using the four bolts provided. Tighten the bolts

evenly to insure proper sealing and alignment of the

venturi to the impeller. Do not over tighten the bolts. See

Chart 2.

Shallow Well Pump – jet is built-in, proceed to next step.

Attach Suction Piping To Pump

Install a barbed adapter into the 1¼" pump

suction if using poly pipe and double clamp the

fitting.

OR

Thread a pipe nipple and union into the suction port to

make a threaded pipe connection. Make sure the union is

clean and well seated. Any air leak will ruin performance

and the pump will not make pressure!

Discharge Piping

Install a tee or cross tee in the pump discharge. (They

are not supplied with the pump!) Install a pipe plug or a

pressure gauge into a reducer bushing in the top port of

the tee. This will be used as the priming port.

Suction Piping

The suction pipe should be at least as large as

the pump suction, typically 1¼". Use of smaller

pipe increases friction loss and increases effective suction lift. This will reduce flow and pressure. On offsets over 50' we recommend using

pipe larger than the pump suction. This will

reduce friction loss and improve performance.

Install a foot valve on the end of your drop pipe if the

well is 2" or larger. Lower the drop pipe with foot valve

into the well. It is best to keep it at least 5' off the bottom

of a clean well. If you set it lower you increase the chance of pulling debris into the screen or into the pump.

On sand points or driven wells you can install an in-line

check valve near the well head or at the pump and use

the well casing as the suction pipe. The closer the check

valve is to the well the easier the system will prime.

4

Cross Tee - the discharge line to the home attaches to

one port and the tank attaches to the other. This is called

an Off-Line Tank installation.

Tee - you can use one line to supply the house with the

tank tee installed off the line. This is called an On-Line

Tank Installation and is most common.

Note: Goulds Water Technology HydroPro Water System

tanks are shipped with a tank installation guide. Please

refer to it for more detailed tank instructions.

Do not place valves or filters between the pump and

tank, other than a fully open gate valve or “full port” ball

valve. The most common ball valves are not full port!

Most valves and filters will create excessive friction loss

and cause “switch chatter”. Switch chatter is a rapid OnOff cycling of not only the pressure switch but also the

motor. It will burn the points in the switch, the motor

points, and cause motor damage if not corrected. If for

Hazardous pressure can

cause personal injury or

property damage.

WARNING

Hazardous pressure can

cause personal injury or

property damage.

WARNING

Hazardous pressure can

cause personal injury or

property damage.

WARNING

any reason you must have fittings or filters between the

pump and tank and they cause switch chatter you should

move the pressure switch to the tank cross tee. Go To

“Install HydroPro Water Systems Tank” to Complete

Shallow Well Installation.

DEEP WELL TWIN PIPE – start here

DEEP WELL TWIN PIPE

Twin Pipe Suction Piping

A twin pipe jet assembly is used in wells 4" and larger.

Our 4" jet assemblies require a minimum 1¼" suction and

1" drive water pipe; 5" jets require a minimum 1½" suction and 1¼" drive water pipe. Use of smaller piping will

reduce performance in gpm and pressure. Offsets over

50' require larger pipes to reduce friction loss and

to obtain published performance.

Install Twin Pipe Jet Assembly

Check to make sure the nozzle is installed in

the jet assembly. Install the venturi tube in line

with the nozzle. On 4" jets attach the 1¼" suction and 1" pressure pipe to the jet assembly

female threads. On 5" jets the pipes should be

1½" and 1¼". Install a foot valve on the male

thread bottom port on the jet assembly or on

the end of a 34' tail pipe. The tail pipe prevents over

pumping a low yield well so the pump will not break

suction. See Tail Pipe in Technical Section.

Lower the jet assembly into the well. It should be set at

least 5' below the static water level. Keep the jet a few

feet off the well bottom to lessen the possibility of sucking debris into the jet. The connections at the well head

can be either a pitless adapter or a well seal. Priming will

be easier if you fill the pipes with water before attaching

the pump.

Connect the suction and pressure pipes to the threaded

connections on the face of the pump. This can be done

using unions and threaded pipe nipples, or barbed connectors with poly pipe. Always double clamp barbed

connectors. Make sure that the piping slopes upward to

the pump and that no point is above the pump suction.

On long offsets it is easier to prime the system if you fill

the pipes with water before connecting the pipes to the

pump. Go to Deep Well Discharge Piping.

DEEP WELL PACKER SYSTEM – start here

DEEP WELL PACKER SYSTEM

Packer Suction Piping

Packers use the area between the well casing

and the suction pipe as the drive water (pres-

sure) pipe. The 2" or 3" well casing must be

smooth and clean to insure a good seal with

the packer leathers or the system will leak and

not hold prime. The 2" packer requires 1¼"

threaded suction pipe and the 3" requires 1½".

On 2" packers only: Use the Goulds Water Technology

turned couplings part #64655 to connect the sections of

1¼" threaded pipe. This special diameter turned coupling

increases the clearance between the 2" well I.D. and the

O.D. of the coupling to allow the drive (pressure) water

to easily pass the couplings. Failure to use them will have

a negative impact on pump performance, both pressure

and gpm will decrease. The pump may easily lose prime

while pumping due to the restriction!

Using smaller than recommended pipe may reduce gpm

output. The longer the pipe the worse the affect.

Install Packer Assembly

To ease installation soak the 2" or 3" packer assembly in

warm water to make the leathers soft and pliable. DO

NOT lubricate them with grease, oil, or petroleum jelly!

The leathers must absorb water to seal the packer assembly against the well casing.

Check to make sure the nozzle is installed in the jet

assembly. Install the venturi tube in line with the nozzle.

Install a strainer (not supplied with packer assembly) on

the bottom port of the packer assembly or on the end of

a 34' tail pipe. The tail pipe prevents over pumping a low

yield well so the pump will not break suction. Attach the

packer assembly to the suction pipes using the Goulds

Water Technology’ turned couplings to connect the

sections. Insert the packer assembly into the well casing

and push it down. Attach the other pipe sections as

you lower the jet into the well. See Tail Pipe in Technical

Section.

Attach Suction Pipe To Packer Adapter

Packer systems always require a Packer Adapter at the

well head. The adapter makes the transition from vertical

to horizontal for horizontal pumps, and it connects vertical pump casings to the well casing and suction pipe. See

the list of Packer Adapters/Pump Models to see which

one your pump system requires. See Chart 1 for a list of

Packer Adapters/Pump Models.

After the jet assembly is inserted into the well, attach

the Packer Adapter to the top of the suction pipe. Screw

the top section of 1¼" male threaded suction pipe or a

threaded adapter into the 1¼" NPT female threaded hole

in the 2" packer adapter or a 1½" suction pipe into the 3"

packer adapter.

Make sure that the O.D. of the well casing is free of dirt

and burrs. With the gland bolts loosened the tapered seal

ring on the packer adapter should slide over the well

casing. After insuring that it is in place tighten the two

gland nuts to compress the seal ring and seal it to the

well casing O.D.

Install the pump by attaching it to the Packer Adapter

using the bolts and gaskets provided. Vertical models use

studs and nuts for ease of assembly.

DEEP WELL DISCHARGE PIPING

DEEP WELL DISCHARGE PIPING

All deep well jet pumps require back pressure to operate the jet assembly. To insure we

have the required back pressure or drive water

pressure we must use a pressure control valve

or some type of flow restrictor in the discharge

line. The valve must be located between the

pump and the first discharge port. It is best

to locate it as close to the pump as possible. Failure to

install and adjust a pressure control valve will result in

loss of prime during peak usage such as filling a washing

machine, bathtub or using outside hose bibs.

All ½ hp pumps can use a simple gas cock or full port ball

valve, such as our AV15.

5

All other horizontal deep well jet pumps, ¾ hp and

Hazardous pressure can

cause personal injury or

property damage.

WARNING

larger, should use an AV22KIT, or an AV22 and a JDW

tubing kit. The AV22 has a tapping to which you connect

the new, longer pressure switch tubing. This allows the

pressure switch to read the pressure on the outboard

side of the valve rather than in the pump casing. Remove

the straight or elbow compression fitting from the pump

casing. Use the pipe plug in the JDW or AV22KIT to plug

the hole in the pump casing. Remove the fitting from

the pressure switch. Cut the old tubing in half and slide

the compression fittings off the old tubing. Note that the

fitting will only slide in one direction. You can now reuse

the elbow compression fitting with the new tubing at the

pressure switch. Screw the new straight connector into

the AV22 and attach the tubing from the switch to the

AV22.

Vertical deep well pumps come with a built-in AV21 and

only need to be adjusted.

installation guide in the carton, please refer to it for more

detailed tank instructions. If you are using a tank from

another manufacturer please contact that company for

specific instructions on their tank.

Galvanized tanks are installed the same as pre-charged

tanks except they require an Air Volume Control (AVC)

to replenish air lost through absorption. The AVC requires connection to a vacuum port on the pump. The

suction side of the AVC must have a minimum 3" vacuum

for 15 seconds when the pump starts. Follow the instructions provided with the air volume control.

Priming a Shallow Well System

Priming means filling the pump and suction pipe with

water. Most shallow well jet pumps handle air well and

will evacuate air from the suction line but it may take

several minutes to prime depending on depth to water,

and pipe size and length.

After the pump is primed and flowing water at a steady

pressure you should open a few faucets and adjust the

pressure control valve to the pressure listed in the chart.

To increase pressure close the valve, AV15 or AV22, or

turn the AV21 screw clockwise. See Chart 1.

AV15

AV21

AV22

ALL SYSTEMS

ALL SYSTEMS

Fig. 4

Install HydroPro Water Systems Tank

While the tank is empty check the pre-charge

air pressure with a tire pressure gauge. The

tank pre-charge should be set 2 psi lower than

the pump cut-in (turn on) pressure. On Goulds

Water Technology HydroPro Water Systems

tanks the valve cap is the primary seal so be

sure to re-install the cap after checking air

pressure. Avoid frequent air checking as you lose 1 – 2

psi every time you check. Goulds Water Technology jet

pumps are all supplied with 30 – 50 psi standard pressure

switch settings.

Locate the tank on a firm, level surface.

A pressure relief valve is recommended for all systems,

and mandatory for systems producing over 100 psi. It

should be rated less than 100 psi but greater than the

system pressure near the tank.

Make the piping connection between the pump discharge

and the tank. Complete the piping by connecting to the

house plumbing.

Note: Goulds Water Technology only sells the HydroPro

Water System tanks. They are all shipped with a tank

6

VENT THE PUMP FOR EASIER PRIMING!

It is easier to prime a pump if you allow all the air to

escape from the pump and the pipes, the water cannot go

in unless the air can escape!

Remove the pipe plug or pressure gauge bushing in the

discharge tee to fill the pump with water. On shallow

well pumps you should remove the 1⁄8" pipe plug located

between the suction and discharge ports to allow air to

escape as you fill the casing with water. The port will be

located on either the top of the casing or the top of the

shallow well adapter. Fill the pump and as much of the

suction pipe as possible with water through the discharge

port.

Replace the 1⁄8" pipe plug and discharge gauge/bushing.

Open the faucet closest to the pump/tank a small amount

to allow air to escape the system. Do not open it too

much or the pump will expel too much water and you

will have to reprime the pump casing. On jobs with long

suction pipes you may have to add water to the pump

casing several times to complete the priming process.

Go to Power Motor.

Priming a Deep Well System

Priming a deep well system means filling the pump and

the suction/pressure pipes with water. Deep well single

stage and multi-stage pumps require a complete prime

before starting. Filling the pipes with water before installing the pump will make priming faster and easier.

VENT THE PUMP FOR EASIER PRIMING!

To insure a complete prime we recommend removing the

angled 1⁄8" vent plug located just above the suction pipe

on horizontal pumps. This will allow the air to easily

escape as water enters. Our horizontal convertible deep

well jets should be primed through a tee or the AV22 at

the pump discharge. The tee is not supplied by Goulds

Water Technology.

Our vertical deep well jet pumps have built-in pressure

control valves. Priming is done through the pressure

gauge port on the pressure control valve. Most verticals

have a vent plug located on the side of the motor adapter

that vents the seal cavity which is the high point inside

the pump. Removing this vent plug will make priming

much easier.

Power the Motor

STORAGE TANK

GATE

VALVE

CHECK

VALVE

JET PUMP

HYDRO-

PRO

TANK

DANGER

Hazardous voltage

can shock, burn or

cause death.

DANGER

Hazardous voltage

can shock, burn or

cause death.

The electrical supply must be a separate branch

circuit with a properly sized breaker or fuses.

All wiring must conform to National (NEC),

CSA, state, provincial, and local codes. Power

supply voltage, phase and controls must match

motor.

Attach the green or bare ground wire to either green

ground screw in the switch. It makes no difference which

Line terminal you attach the hot- L1 (usually Black)

and neutral- N (usually white) 115 volt wires to on the

switch. The same goes for a 230 volt hook-up, either

wire can go on either Line terminal. Re-install the switch

cover. NOTE: Motor voltage is NOT changed in the

pressure switch. See Fig. 7 in Technical Data.

NEVER RUN A PUMP DRY, DAMAGE WILL RESULT,

AND THE WARRANTY WILL BE VOIDED!

Check to insure that the motor is wired to match the

incoming voltage. All motors have a sticker near the

ALWAYS DISCONNECT AND LOCK-OUT

ALL ELECTRICAL POWER WHEN INSTALLING OR WORKING ON PUMPS,

MOTORS, OR SWITCHES. INSURE THE

POWER SUPPLY BREAKER IS OFF OR THE

DISCONNECT (WHERE USED) IS OFF.

pressure switch that identifies the pre-wired voltage. All

½ hp jet pumps are factory wired for 115 V, and ¾ hp

and larger are wired for 230V. The motor voltage must

be changed inside the motor cover, not in the pressure

switch. Make sure the breaker or disconnect is OFF

before entering the motor cover. All motors have a wir-

ing diagram on the cover label and it is also found in this

Remove the pressure switch cover. Attach the power

supply wires, either 115 or 230 depending on the motor

manual. See Motor Wiring Diagram, Fig. 7, in Technical

Data.

voltage, to the Line terminals of the pressure switch.

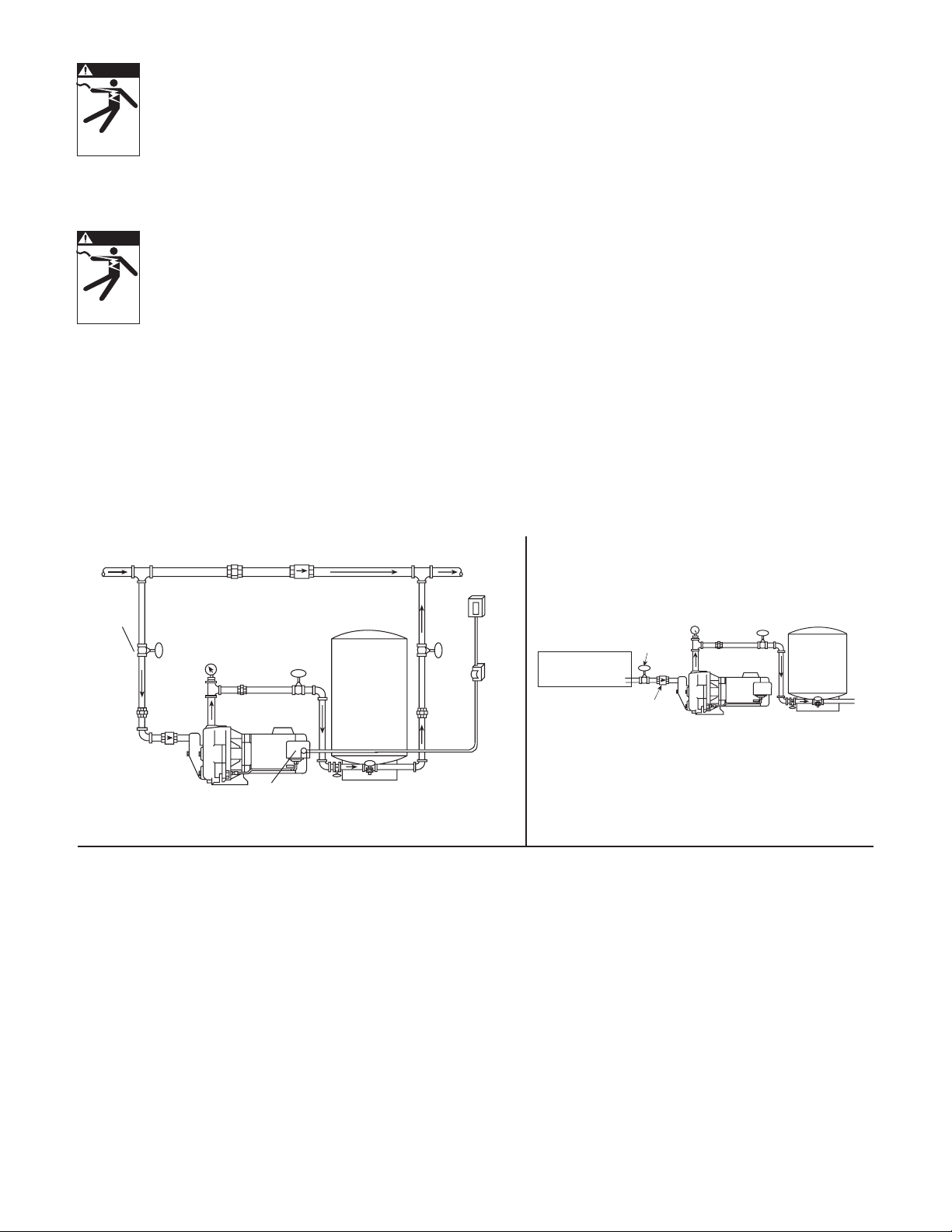

BOOSTER SYSTEMS

BOOSTER SYSTEMS

Use the basic instructions for either a Shallow Well or Convertible with Shallow Well Adapter. If a city water booster

system please plumb per Fig. 5

If pumping from a cistern or water tank plumb

per Fig. 6.

Use ow

control

or ball

valve on

suction to

throttle

pump. Must

be sized,

or set, to

load motor

below max.

nameplate

amps.

BALL

VALVE

UNION

UNION

GAUGE

UNION

WATER MAIN

PRESSURE

SWITCH

CHECK

VALVE

GATE

VALVE

RELIEF

VALVE

TO SIZE TANK

PROPERLY –

MATCH

DRAWDOWN

OF TANK TO

CAPACITY

OF PUMP.

MAIN POWER BOX

GATE

FUSE BOX

VALVE

OR

SWITCH

Fig. 6Fig. 5

SEASONAL SERVICE

SEASONAL SERVICE

It is necessary to drain the entire system where the pump,

tank, and piping will be subjected to freezing. Vertical

pumps have a drain plug located on the side of the pump

casing near the bottom of the pump. Horizontal pumps

may have two drain plugs, one on the casing (part where

pipes attach) and another on the motor adapter. They are

also located near the bottom of the pump. Multi-stage

pumps also have 1 or 2 drain plugs and they may require

you to tip the pump or blow compressed air in one hole

to get all the water out of the stages.

7

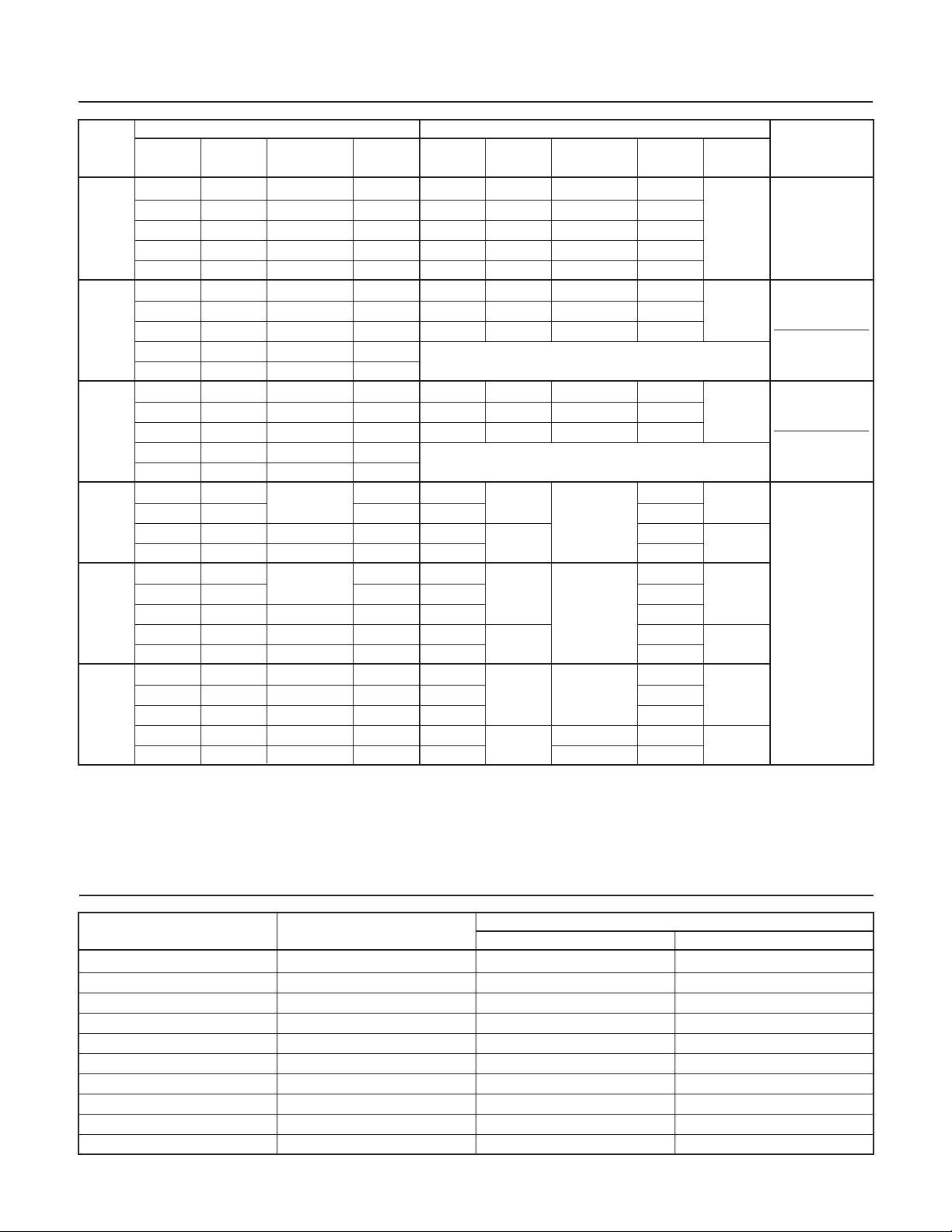

CHART 1

RECOMMENDED DEEP WELL JET ASSEMBLIES AND CONTROL VALVE SETTINGS

RECOMMENDED DEEP WELL JET ASSEMBLIES AND CONTROL VALVE SETTINGS

TWIN PIPE SYSTEMS (see g. 2) PACKER SYSTEMS (see g. 3)

PUMP

ASSEMBLY DIAMETER SETTING (PSI) TO JET ASSEMBLY DIAMETER SETTING (PSI) TO JET ADAPTER

FT4-13 4" 30 30-40 FP2-13 2" 30 30-40

FT4-31 4" 30 30-60 FP2-31 2" 30 30-60 AWJ2 AV15

J5 FT4-08 4" 30 60-90 FP2-08 2" 30 60-80 or

FT5-14 4½" 30 50-90 FP3-36 3" 30 30-70

— — — — FP3-24 3" 30 50-80

FT4-14 4" 28 30-60 FP2-40 2" 30 30-60 AWJ2

FT4-34 4" 29 70-90 FP2-47 2" 32 60-90 AV22KIT

J7 FT4-18 4" 30 90-110 — — — — — or

FT5-47 4½" 28 30-70 FP3-53 3" 27 30-70

FT5-48 4½" 40 70-110 FP3-54 3" 30 70-110

FT4-44 4" 31 30-60 FP2-48 2" 35 30-60

FT4-43 4" 33 60-80 FP2-43 2" 36 60-100

J10 FT4-18 4" 35 80-110 — — — — —

FT5-49 4½" 30 30-80 FP3-55 3" 28 30-80

FT5-11 4½" 32 80-120 FP3-14 3" 32 80-120

FT5-12 4½" 35 30-70 FP3-16 3" 34 30-60

— — — — FP3-21 3" 34 90-150

— — — — FP3-24 3" 39 100-170

FT4-48 4" 37 30-70 FP2-51 30-70

FP3-40 3" 36 30-80

FP3-42 40 80-130

FT4-47 4" 40 30-70 FP2-50 30-60

FP3-40 3" 40 30-90

FP3-49 43 90-150

FT4-45 4" 62 30-90 FP2-49 62 30-90

FT4-30 4" 65 90-130 FP2-30 2" 65 90-130 AWD2

SJ15 & FT4-29 4" 67 130-190 FP2-29 67 130-180

HSJ15 FP3-47 62 30-100

FP3-46 3" 64 100-150 AWD3

FP3-34 66 150-210

FT4-45 4" 76 30-100 FP2-49 76 30-100

FT4-30 4" 78 100-150 FP2-30 2" 78 100-150 AWD2

SJ20 & FT4-29 4" 80 150-200 FP2-29 80 150-200

HSJ20 FP3-47 75 30-110

FP3-46 3" 78 110-170 AWD3

FP3-34 80 170-230

JET MIN. WELL CONTROL VALVE DEPTH JET WELL CONTROL VALVE DEPTH PACKER CONTROL VALVE

MODEL

AWCJ3

AWCJ3

AWJ2

AWCJ3

FT5-11 4½" 40 70-140 FP3-18 3" 34 60-90

J15

SJ07 &

SJ10 &

NOTE: Offset adapters are available. See “Fittings” section of your Goulds Water Technology Jet and Sub Catalog or consult

your local distributor for information.

FT4-47 4" 40 70-90 FP2-50 2" 40 70-90 AWD2

FT4-06 4" 90-130 FP2-06 90-130

HSJ07

FT4-24 4" 43 70-110 FP2-07 2"

FT4-08 4" 110-150 FP2-08 110-150

HSJ10

60-110 AWD2

45

AWCJ3

AWD3

AWD3

RECOMMENDED

(see g. 4)

AV22KIT

AV22 and JDW

AV22KIT

AV22 and JDW

AV22KIT

AV22 and JDW

SJ - AV21 is built-in

HSJ - use AV22KIT

8

CHART 1 (continued)

RECOMMENDED DEEP WELL JET ASSEMBLIES AND CONTROL VALVE SETTINGS

RECOMMENDED DEEP WELL JET ASSEMBLIES AND CONTROL VALVE SETTINGS

TWIN PIPE SYSTEMS (see g. 2) PACKER SYSTEMS (see g. 3)

PUMP

JET MIN. WELL CONTROL VALVE DEPTH JET WELL CONTROL VALVE DEPTH PACKER CONTROL VALVE

MODEL

ASSEMBLY DIAMETER SETTING (PSI) TO JET ASSEMBLY DIAMETER SETTING (PSI) TO JET ADAPTER

FT3-09 3" 30 30-50 FP2-13 2" 30 30-50

FT4-13 4" 30 30-50 AV15

JRD5 FT4-31 4" 30 30-70 FP2-31 2" 30 30-60 AWJ2 or

FT4-08 4" 30 60-90 FP2-08 2" 30 60-80 AV22KIT

FT5-14 4½" 30 70-90

FT4-14 4" 27 30-60 FP2-40 2" 30 30-60

FT4-34 4" 29 60-90 FP2-47 2" 32 60-90 AWJ2

JRD7 FT4-18 4" 30 90-110

FT5-47 4½" 27 30-70 NA

FT5-48 4½" 30 70-110

FT4-44 4" 31 30-60 FP2-48 2" 35 30-60

FT4-43 4" 33 60-80 FP2-43 2" 36 60-100 AWJ2

JRD10 FT4-18 4" 35 80-110

FT5-49 4½" 28 30-80

FT5-11 4½" 32 80-120

FT4-46 4"

FT4-08 4" 60-90 FP2-08 23 60-90

VJ05

30-60 FP3-42 3" 30-60

60-100 FP3-09 60-100

FT4-47 4"

FT4-46 4" 60-90 FP2-47 2" 60-100 AWD2

VJ07 FT4-06 4" 40 90-110 FP2-09 34 100-120

FP3-40 3" 30-60

FP3-43 60-130

FT4-14 4" 34 30-90 FP2-48 30-60

FT4-09 4" 36 90-120 FP2-43 2" 36 60-100 AWD2

VJ10 FP2-08 100-120

FP3-40 3" 34 30-90

FP3-49 36 90-140

NOTE: Offset adapters are available. See “Fittings” section of your Goulds Water Technology Jet and Sub Catalog or consult

your local distributor for information.

30-60 FP2-38 2" 30-60

23

30-60 FP2-50 30-60

34

NA

AWD2

AWD3

AWD3

AWD3

RECOMMENDED

(see g. 4)

AV22KIT

AV22 and JDW

AV22KIT

AV22 and JDW

AV21 is built-in

CHART 2

SHALLOW WELL JET ASSEMBLIES FOR CONVERTIBLE PUMPS

SHALLOW WELL JET ASSEMBLIES FOR CONVERTIBLE PUMPS

ORDER NO.

J5 FH5 (std.) AN017 AD3731

J5 FH5H (high pres.) AN019 AD3528

JRD5 FH5JRD AN018 AD3731

J7, JRD7 FH7 AN018 AD3536

J10, JRD10 FH10 AN018 AD3538

J15 FH15 AN022 AD3542

HSJ07N FHSJ07 AN012 AD3432

HSJ10N FHSJ10 AN012 AD3437

HSJ15N FHSJ15 AN012 AD3439

HSJ20N FHSJ20 AN012 AD3448

PUMP MODEL

SHALLOW WELL ASSEMBLY INCLUDES

NOZZLE VENTURI

9

TECHNICAL DATA

DANGER

Hazardous voltage

can shock, burn or

cause death.

DANGER

Hazardous voltage

can shock, burn or

cause death.

TECHNICAL DATA

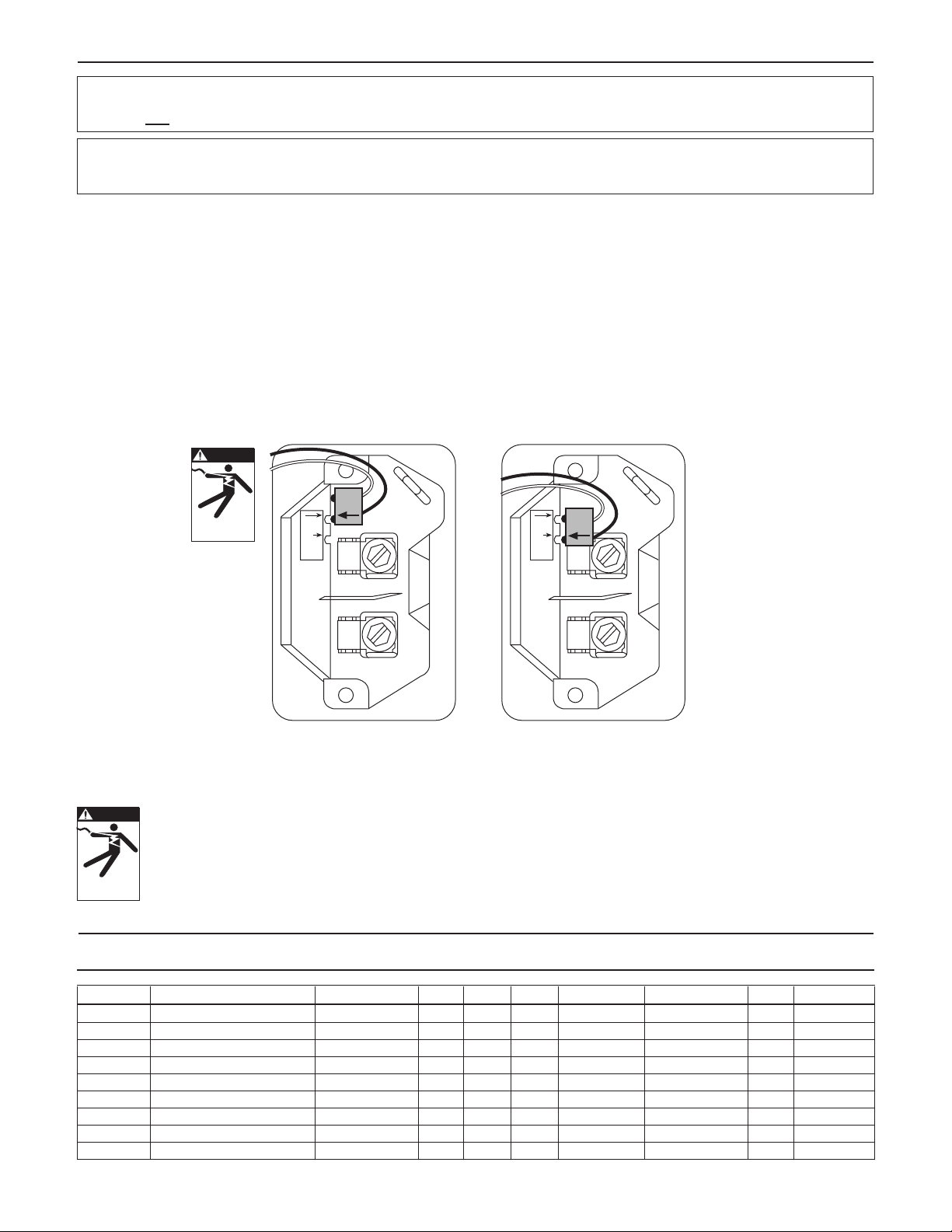

WARNING: DISCONNECT POWER SOURCE BEFORE CHECKING. DO NOT MAKE ANY CHANGES WITH

POWER ON.

VOLTAGE CHANGES ARE MADE INSIDE THE MOTOR COVER,

NOT IN THE PRESSURE SWITCH.

VOLTAGE CHANGE PROCEDURE AND TERMINAL BOARD DESIGN

A.O. Smith jet pump motors have a voltage plug to facilitate simple voltage changes from 115V to 230V. All ½ HP

motors are factory wired for 115V operation. If wired for 115V, operation at 230V will destroy the windings in a

matter of seconds and will not be covered by warranty. Larger HP motors are factory wired at 230V.

Terminal Board Design:

• L1 has two (2) male terminals, one switch wire is attached to one terminal.

• L2 has two (2) male terminals, one switch wire is attached to one terminal and when set up for 115V operation the

voltage plug is connected to the other.

• “A” has 1 male terminal, the voltage plug is always connected to “A”.

Voltage Change: failure to follow these instructions may damage the windings

• 115V - Place the Black voltage plug on the open L2 male terminal and the “A” terminal.

• 230V - Place the Black voltage plug only on the “A” male terminal. The 2nd L2 male terminal will be open.

230V

115V

A

L2

L1

230V

115V

A

L2

L1

Fig. 7

A.O. SMITH / CENTURY MOTOR TERMINAL BOARD AND VOLTAGE CHANGE PLUG

■ Pumps are Pre-Wired by HP:

• ½ hp wired for 115 volts

• ¾ hp - 1½ hp and larger wired for 230 volts

• 2 hp is 230 volt only

A.O. SMITH / CENTURY MOTOR DATA

GWT Number Where Used A.O. Smith Number HP Volts Phase Service Factor Max. Load Amps Watts Circuit Breaker

J04853L J5(S), GB C48A93A06 ½ 115/230 1 1.6 10.8/5.4 968 25/15

J05853L J7(S), GB, GT07, (H)SJ07, HSC07 C48A94A06 ¾ 115/230 1 1.5 14.8/7.4 1336 30/15

J06853L J10(S), GB, GT10, (H)SJ10, HSC10 C48A95A06 1 115/230 1 1.4 16.2/8.1 1592 30/20

J07858L J15(S), GB, GT15, HSJ15, HSC15 C48C53A06 1½ 115/230 1 1.3 22.0/11.0 1950 40/20

➀ J08854L HSJ20, GB, GT20, HSC20 K48A34A06 2 230 1 1.4 12.9 2100 25

J09853 XSH30, GT30 7-196427-20 3 230 1 1.15 13.3 3280 30

SFJ04860 JRS5, JRD5, JB05 C48C04A06 ½ 115/230 1 1.6 12.6/6.3 990 25/15

SFJ05860 JRS7, JRD7, JB07 C48C05A06 ¾ 115/230 1 1.5 14.8/7.4 1200 30/15

SFJ06860 JRS10, JRD10, JB10 C48C06A06 1 115/230 1 1.4 16.2/8.1 1400 30/20

➀ Effective July, 1998, 230 V only.

10

TECHNICAL DATA

TECHNICAL DATA

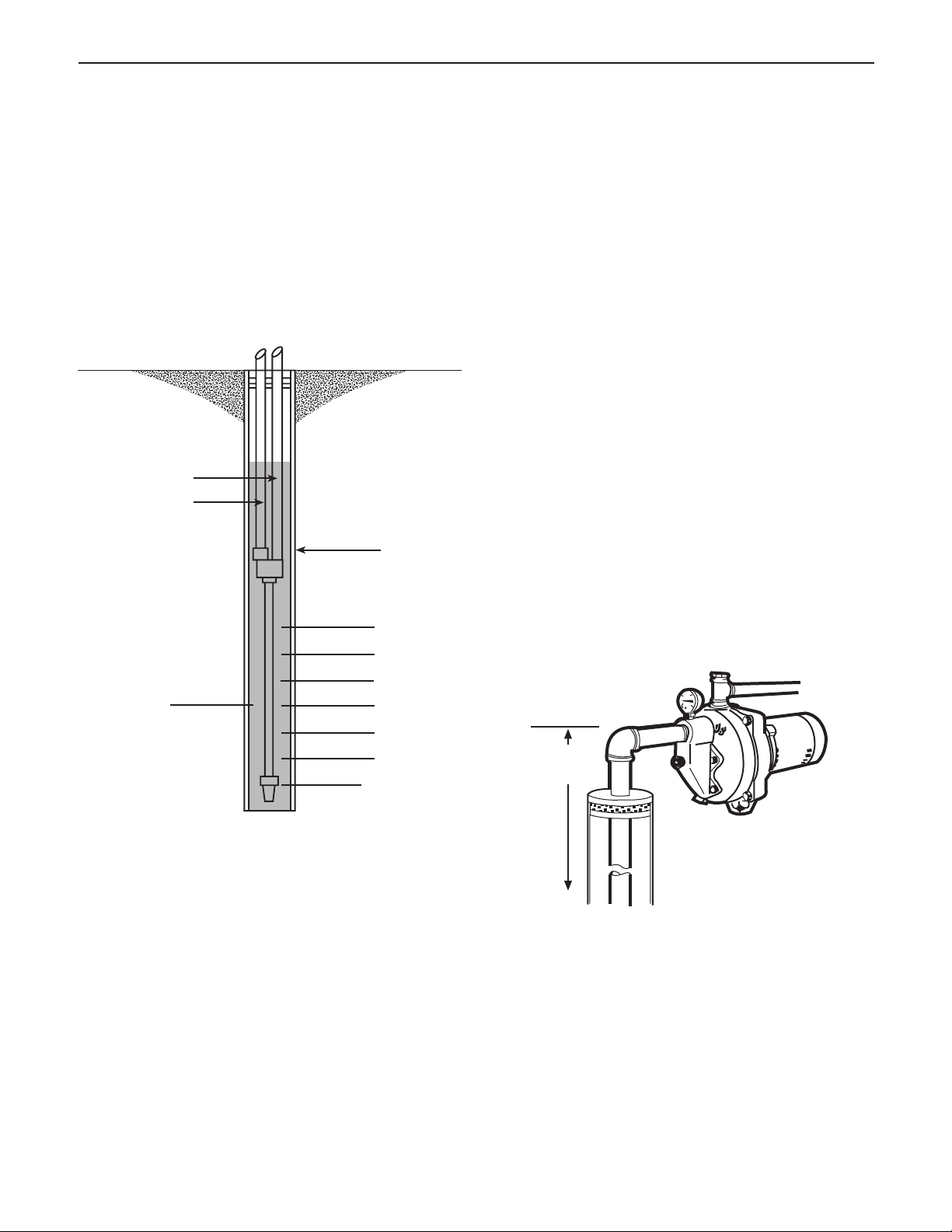

USE OF TAILPIPE ON

DEEP WELL JET PUMPS

If the capacity of a deep well jet pump exceeds the well

production, well drawdown will allow your pump to

break suction and lose prime. This can be overcome by

using a 34' tailpipe between the jet assembly and the foot

valve. Since the capacity of a pump falls off as the lift is

increased your well inflow and pump output will equalize

somewhere between the jet and foot valve. The drawing

shows the percentage of rated capacity you will get at

certain points. As in a normal situation the jet should be

set 5' below the static water level.

DRIVE PIPE

SUCTION PIPE

JET ASSEMBLY

STATIC LEVEL

100%

10' PIPE 80%

CHECKING SUCTION LIFT ON A

SHALLOW WELL

A vacuum gauge indicates Total Suction Lift (vertical lift

+ friction loss) in inches of mercury (Hg.). One inch (1")

on the gauge = 1.13 feet of total suction lift (based on a

pump at sea level). Practical suction lift at sea level is 25'

or 22" Hg. Deduct 1 ft. for each 1000 ft. above sea level.

Install the compound vacuum/pressure gauge in the 1⁄8"

hole in the shallow well adapter or the 1⁄8" hole between

the suction and discharge pipes on a dedicated shallow

well pump. This is the same hole that is used to connect

an air volume control.

Interpreting the gauge readings:

High Vacuum (22" or more)

• Suction pipe buried in mud

• Foot valve or check valve stuck closed

• Suction lift exceeds lift capability of pump

Low Vacuum or 0 vacuum

• Suction pipe not submerged

• Suction leak (check joints and especially unions)

Gauge needle fluctuates rapidly

• Gaseous well

• Air leak in suction line

• Well producing less than pump capacity (throttle a

ball valve in suction line do not exceed 22" Hg.) to

reduce pump capacity

TAIL PIPE

34 FT. WILL PREVENT

BREAKING SUCTION

Fig. 8

15' PIPE 70%

20' PIPE 57%

25' PIPE 40%

28' PIPE 25%

29' PIPE 17%

33.9' MAXIMUM

DRAW DOWN 0%

Vacuum

Gauge

22.6’

Vertical Lift

Plus Friction

Fig. 9

A reading of 20" on a vacuum gauge placed on the suc-

tion side of the pump would tell you that you have a

vacuum or suction lift of 22.6 ft.

20" x 1.13' = 22.6 ft.

11

Hazardous

voltage

DANGER

TROUBLESHOOTING

TROUBLESHOOTING

FAILURE TO DISCONNECT AND

LOCKOUT ELECTRICAL POWER

BEFORE ATTEMPTING ANY

MAINTENANCE CAN CAUSE SHOCK,

BURNS OR DEATH.

SYMPTOM

MOTOR NOT RUNNING

See Probable Cause – 1 through 5

LITTLE OR NO LIQUID DELIVERED BY PUMP

See Probable Cause – 6 through 11

PUMP DELIVERS WATER – WILL NOT SHUT OFF

See Probable Cause – 9 through 13

PUMP CYCLES EXCESSIVELY

See Probable Cause – 14 through 17

PROBABLE CAUSE

1. Motor thermal protector tripped

2. Open circuit breaker or blown fuse

3. Impeller binding

4. Wiring incorrect/check motor voltage setting

5. Defective motor

6. Pump not primed, inadequate suction pipe

submergence, air leak in suction pipe

7. Discharge or suction plugged, closed valve(s)

8. Low voltage causing reduced motor speed

9. Impeller worn or plugged, no jet assembly installed, or

jet plugged

10. System head too high

11. Suction lift or suction losses excessive

12. Pressure switch plugged, incorrectly adjusted

13. Leaks in discharge piping or at house

14. Defective suction check or foot valve

15. Water logged pressure tank

16. Pump farther than 5 feet from tank

17. High friction loss valves between pump and tank. (Use

only fully open gate valves)

GOULDS WATER TECHNOLOGY LIMITED WARRANTY

This warranty applies to all water systems pumps manufactured by Goulds Water Technology.

Any part or parts found to be defective within the warranty period shall be replaced at no charge to the dealer during the warranty period. The warranty period shall exist for a

period of twelve (12) months from date of installation or eighteen (18) months from date of manufacture, whichever period is shorter.

A dealer who believes that a warranty claim exists must contact the authorized Goulds Water Technology distributor from whom the pump was purchased and furnish complete

details regarding the claim. The distributor is authorized to adjust any warranty claims utilizing the Goulds Water Technology Customer Service Department.

The warranty excludes:

(a) Labor, transportation and related costs incurred by the dealer;

(b) Reinstallation costs of repaired equipment;

(c) Reinstallation costs of replacement equipment;

(d) Consequential damages of any kind; and,

(e) Reimbursement for loss caused by interruption of service.

For purposes of this warranty, the following terms have these definitions:

(1) “Distributor” means any individual, partnership, corporation, association, or other legal relationship that stands between Goulds Water Technology and the dealer in pur-

chases, consignments or contracts for sale of the subject pumps.

(2) “Dealer” means any individual, partnership, corporation, association, or other legal relationship which engages in the business of selling or leasing pumps to customers.

(3) “Customer” means any entity who buys or leases the subject pumps from a dealer. The “customer” may mean an individual, partnership, corporation, limited liability

company, association or other legal entity which may engage in any type of business.

THIS WARRANTY EXTENDS TO THE DEALER ONLY.

Xylem Inc.

2881 East Bayard Street Ext., Suite A

Seneca Falls, NY 13148

Phone: (866) 325-4210

Fax: (888) 322-5877

www.gouldswatertechnology.com

Goulds is a registered trademark of Goulds Pumps, Inc. and is used under license.

© 2012 Xylem Inc. IM102 Revision Number 5 May 2013

MANUAL DE INSTRUCCIÓN

IM102R05

Bombas de Inyección

MANUAL DE INSTALACIÓN, OPERACIÓN E IDENTIFICACIÓN Y RESOLUCIÓN DE PROBLEMAS

Índice

ADVERTENCIA

ADVERTENCIA

ADVERTENCIA

PRECAUCIÓN

ADVERTENCIA

ADVERTENCIA

ADVERTENCIA

Índice

TEMA PÁGINA

Cómo seleccionar el sistema de bomba de inyección correcto .................................................................................... 15

Cómo prepararse para la instalación .......................................................................................................................... 16

Información Géneral - Tuberías ................................................................................................................................. 16

Instalación para pozos poco profundos ...................................................................................................................... 16

Tubo doble para pozos profundos .............................................................................................................................. 17

Sistema de obturador para pozos profundos ..............................................................................................................17

Tubería de descarga para pozos profundos ................................................................................................................. 17

Todos los sistemas .....................................................................................................................................................18

Sistemas elevadores ...................................................................................................................................................19

Servicio de temporada ............................................................................................................................................... 19

Conjuntos de inyección y ajustes de válvulas de control para pozos profundos recomendados ..............................20-21

Conjuntos De Inyección Para Pozos Poco Profundos Para Bombas Convertibles ........................................................21

Datos técnicos ......................................................................................................................................................22-23

Identificación y resolución de problemas ...................................................................................................................24

Garantía limitada de Goulds Water Technology ......................................................................................................... 24

INSTRUCCIONES DE SEGURIDAD

PARA EVITAR LESIONES PERSONALES GRAVES O

AÚN FATALES Y SERIOS DAÑOS MATERIALES, LEA

Y SIGA TODAS LAS INSTRUCCIONES DE SEGURIDAD EN EL MANUAL Y EN LA BOMBA.

ESTE MANUAL HA SIDO CREADO COMO UNA

GUÍA PARA LA INSTALACIÓN Y OPERACIÓN DE

ESTA UNIDAD Y SE DEBE CONSERVAR JUNTO A

LA BOMBA.

Éste es un SÍMBOLO DE ALERTA DE

SEGURIDAD. Cuando vea este símbolo

en la bomba o en el manual, busque una

de las siguientes palabras de señal y esté

alerta a la probabilidad de lesiones perso-

PELIGRO

nales o daños materiales.

Advierte los peligros que CAUSARÁN

graves lesiones personales, la muerte o

daños materiales mayores.

Advierte los peligros que PUEDEN causar

graves lesiones personales, la muerte o

daños materiales mayores.

Advierte los peligros que PUEDEN causar

lesiones personales o daños materiales.

AVISO: INDICA INSTRUCCIONES ESPECIALES

QUE SON MUY IMPORTANTES Y QUE

SE DEBEN SEGUIR DE RETROCESO DE

DRENAJE; ESTOS SISTEMAS DEBEN

UTILIZAR OTROS MEDIOS FRANKLIN

ELECTRIC O EN UN MANUAL DEL

CÓDIGO N.E.C. (CÓDIGO ELÉCTRICO

NACIONAL DE LOS ESTADOS UNIDOS).

EXAMINE BIEN TODAS LAS INSTRUCCIONES Y

ADVERTENCIAS ANTES DE REALIZAR CUALQUIER TRABAJO EN ESTA BOMBA.

MANTENGA TODAS LAS CALCOMANÍAS DE

SEGURIDAD.

Aviso importante: Lea las instrucciones de seguridad

antes de proseguir con el cableado.

Todo el trabajo eléctrico debe ser realizado

por un técnico calificado. Siempre siga el

Código Eléctrico Nacional (NEC) o el Código Eléctrico

Canadiense, además de todos los códigos locales, estatales

y provinciales. Las preguntas acerca del código deben ser

dirigidas al inspector eléctrico local. Si se hace caso omiso

a los códigos eléctricos y normas de seguridad de OSHA,

se pueden producir lesiones personales o daños al equipo.

Si se hace caso omiso a las instrucciones de instalación del

fabricante, se puede producir electrochoque, peligro de

incendio, lesiones personales o incluso la muerte, daños

al equipo, rendimiento insatisfactorio y podría anularse la

garantía del fabricante.

Las unidades estándar no fueron diseña-

das para su uso en líquidos peligrosos o

donde existan gases inflamables. El pozo debe contar con

ventilación de acuerdo con los códigos locales. Vea los

boletines de catálogos de bombas específicos o la placa de

nombre de la bomba para todas las listas de agencias.

Desconecte y bloquee la corriente eléctrica

antes de instalar o dar servicio a cualquier

equipo eléctrico. Muchas bombas están equi-padas con

protección automática contra la sobrecarga térmica, la cual

podría permitir que una bomba demasiado caliente rearranque inesperadamente.

Nunca presurice demasiado el tanque, las

tuberías o el sistema a una presión superior

a la clasificación de presión máxima del tanque. El hacerlo

dañará el tanque, anula la garantía y puede crear un peligro

grave.

Proteja a los tanques contra humedad y

pulverización excesivas, ya que oxidarán al

tanque y pueden crear un peligro. Vea las etiquetas de advertencia o el manual del tanque para más información.

14

CÓMO SELECCIONAR EL SISTEMA DE

CÓMO SELECCIONAR EL SISTEMA DE

BOMBA DE INYECCIÓN CORRECTO

BOMBA DE INYECCIÓN CORRECTO

Es importante determinar qué sistema de bomba de

inyección usted necesita. Una bomba de inyección es una

bomba centrífuga con un conjunto de inyección (eyector). Goulds vende tres tipos de bombas de inyección.

Bombas de inyección para pozos poco profundos con

conjuntos de inyección incorporados para una elevación

máxima de 25 pies. Consulte la Fig. 1.

Bombas de inyección convertibles pueden utilizarse para

pozos poco profundos (hasta 25 pies) con un adaptador

empernado para pozo poco profundo o para aplicaciones

de pozos profundos (más de 25 pies) con un conjunto de

inyección en el pozo. Consulte las Figuras 1, 2 y 3.

Los inyectores para pozos profundos sólo deben usarse

en aplicaciones de pozos profundos (más de 25 pies) con

el conjunto de inyección apropiado. Consulte las Figuras

2 y 3.

Utilice una bomba para pozos poco profundos o una

bomba convertible con un adaptador para pozos poco

profundos en el caso de pozos con una elevación de

succión máxima de 25 pies. Este valor de 25 pies incluye

Instalaciones típicas de bombas de inyección Goulds Water Technology

Instalaciones típicas de bombas de inyección Goulds Water Technology

la elevación vertical real más la pérdida por fricción en

la tubería de succión. Los sistemas de pozos poco profundos se identifican por una (1) tubería que va al pozo,

lago o río. Son adecuados para los sistemas elevadores de

agua municipales y para bombear de cisternas o tanques.

Consulte las instalaciones típicas en las Figuras 1, 5 y 6.

Se utilizan bombas de inyección para pozos profundos

para elevaciones de más de 25 pies y deben tener dos

tuberías que vayan al pozo. Hay dos tipos de conjuntos de inyección para pozos profundos: los sistemas de

tubo doble y los sistemas de obturador. Las bombas para

pozos profundos se ofrecen en diseños tanto verticales

como horizontales y en modelos de una etapa y de etapas

múltiples. Consulte los dibujos de instalaciones típicas,

Figuras 2 y 3.

Consulte con su proveedor o distribuidor profesional

para seleccionar el mejor sistema de bomba para su

aplicación.

• La temperatura del líquido no debe exceder 140°F

(60°C).

• Proteja a la unidad contra la congelación

SISTEMA PARA POZOS

POCO PROFUNDOS

Pozo poco profundo

únicamente

J5S - J15S, JRS5 - JRS10

Convertible con adaptador

para pozo poco profundo

J5 - J15, JRD5 - JRD10

➀ J5 con FH5H, J5 o JRD5 con

FH5, J7 o JRD7 con FH7, J10 o

JRD10 con FH10, J15 con FH15

Se requiere:

• Bomba

• Tanque

➀ • Adaptador para pozo poco

profundo (FH—) (J+ y JRD

únicamente) JS y JRS tienen

un conjunto de inyección

incorporado (adaptador para

pozo poco profundo).

Fig. 1

SISTEMA DE TUBO

DOBLE PARA POZOS

PROFUNDOS

Vertical

SJ o VJ

Horizontal

J, JRD, HSJ

Se requiere:

• Bomba

• Tanque

• Conjunto de inyección

de tubo doble

• Válvula de control de

presión (ordene en

forma separada para

los modelos

horizontales, incluida

con las bombas

verticales).

Fig. 2

SISTEMA DE OBTURA-

DOR PARA POZOS PRO-

FUNDOS

Vertical

SJ o VJ

Horizontal

J, JRD, HSJ

Se requiere:

• Bomba

• Tanque

• Adaptador para

obturador (para el

cabezal del pozo)

• Conjunto de inyecto-

res de obturación

• Válvula de control de

presión (ordene en

forma separada para

los modelos horizon tales, incluida con las

bombas verticales).

Fig. 3

15

ADVERTENCIA

La tensión peligrosa

puede causar choques,

quemaduras o la

muerte.

ADVERTENCIA

La tensión peligrosa

puede causar choques,

quemaduras o la

muerte.

CÓMO PREPARARSE PARA LA

CÓMO PREPARARSE PARA LA

INSTALACIÓN

INSTALACIÓN

Inspeccione el conjunto de la bomba y el motor para

asegurar que no hayan sido dañados durante el envío.

Asegure que tenga todas las partes requeridas para

realizar una instalación apropiada. Consulte las listas de

componentes para los distintos tipos de sistemas. Hay

sistemas para pozos poco profundos, convertibles para

pozos poco profundos, convertibles para pozos profundos - de tubo doble, convertibles para pozos profundos con obturador, verticales para pozos profundos - de tubo

doble, verticales para pozos profundos - con obturador y

sistemas elevadores. Consulte los dibujos de instalación

típica y la tabla 1.

Verifique la tensión de la fuente de alimentación y seleccione la tensión del motor. Las bombas de inyección

Goulds de ½ HP vienen precableadas de fábrica para 115

voltios, mientras que las bombas de ¾ HP y de mayor

capacidad vienen precableadas para 230 voltios. Los

motores de ½ a 1½ HP pueden operar ya sea con 115 ó

230 voltios. Los motores de 2 HP operan sólo con 230

voltios. Consulte la Fig. 7.

Seleccione un lugar donde la bomba y el tanque no se

congelen. La bomba debe estar a menos de 4 pies del

tanque para evitar el chasquido del interruptor. No debe

haber filtros ni válvulas, excepto por una válvula de

compuerta completamente abierta, entre la bomba y el

tanque. La temperatura del uido no debe exceder 140°F

(60°C).

INFORMACIÓN GENERAL - TUBERÍAS

INFORMACIÓN GENERAL - TUBERÍAS

Siempre cumpla con los códigos de plomería estatales y

locales. Goulds Water Technology no vende ni especifica

tipos o materiales de tuberías, consulte con su proveedor

de tuberías para determinar cuál es la mejor para su

instalación. Los tubos pueden roscarse, pegarse, soldarse

o sujetarse con abrazadera a los accesorios y adaptadores

disponibles. Si se utiliza tubería de polietileno con conectores tipo arpón, le sugerimos que la sujete con doble

abrazadera a todos los accesorios para evitar las fugas de

aire. Es muy importante eliminar los puntos altos o las

caídas en la tubería de succión ya que atraparán aire y

dificultarán significativamente el cebado del sistema. La

trayectoria de la tubería nunca debe ascender sobre la

bomba y luego bajar a la succión de la bomba. La tubería

de succión debe ser ya sea recta desde el pozo a la bomba

o debe tener una inclinación ascendente hacia la bomba.

Las bombas no “retienen” el cebado, mientras que los

sistemas de tuberías y las válvulas de retención sí lo hacen. Vaya a la sección específica para su tipo de sistema.

INSTALACIÓN PARA POZOS POCO PRO-

INSTALACIÓN PARA POZOS POCO PRO-

FUNDOS - comience aquí

FUNDOS - comience aquí

Tuberías de succión

La tubería de succión debe ser al menos tan

grande como la succión de la bomba, típicamente de 1¼ pulg. El uso de una tubería más

pequeña aumenta la pérdida por fricción y

aumenta la elevación efectiva de la succión.

Esto reducirá el flujo y la presión. En derivaciones de más de 50 pies, recomendamos usar tubería

más grande que la succión de la bomba. Esto reducirá la

pérdida por fricción y mejorará el rendimiento.

Instale una válvula de aspiración en el extremo del tubo

de bajada si el pozo es de 2 pulg. o más. Baje el tubo de

bajada con la válvula de aspiración al interior del pozo.

Es mejor mantenerlos al menos a 5 pies del fondo de un

pozo limpio. Si los sitúa más abajo, hay mayor probabilidad de que lleguen residuos al filtro o al interior de la

bomba.

En áreas arenosas o pozos hincados usted puede instalar

una válvula de retención en línea cerca del cabezal del

pozo o en la bomba y utilizar el entubado del pozo como

16

tubería de succión. Mientras más cerca esté la válvula

de retención al pozo, más fácil será cebar. Para impedir

bombear en exceso un pozo de baja producción, usted

puede estrangular una bomba de inyección con una válvula de bola en la línea de succión. Usted debe instalar un

indicador compuesto de presión/vacío entre el pozo y la

válvula. No estrangule a más de 22 pulg. Hg (25 pies de

elevación).

En áreas donde ocurre congelación, haga la transición de

vertical a horizontal debajo del nivel de penetración de

la helada utilizando un adaptador sin depresión; consulte

con su proveedor de artículos de plomería para obtener

información acerca de un adaptador sin depresión. En

algunas áreas se utiliza un sello para pozo y un codo de

90º.

Nosotros recomendamos no usar filtros en el lado de

succión de una bomba de inyección. Los filtros sucios

aumentan la elevación ineficaz de succión en la bomba y

podrían impedir el flujo de agua a la bomba. Esto dañará

el impulsor y el difusor, lo cual afectará el rendimiento.

Instale un adaptador para pozos poco profundos en la

bomba convertible

Desempaque el “Adaptador para pozos poco profundos”

Goulds Water Technology. Asegure que la boquilla esté

instalada en el adaptador. Atornille el tubo Venturi (tubo

negro largo) en el adaptador. Instale la empaquetadura y

emperne el adaptador a la sección delantera de la bomba

con los cuatro pernos suministrados. Apriete los pernos

en forma pareja para asegurar un sellado apropiado y el

alineamiento del tubo Venturi y el impulsor. No apriete

demasiado los pernos. Consulte la Tabla 2.

Bomba para pozos poco profundos - el inyector está

incorporado, prosiga con el paso siguiente.

Conecte la tubería de succión a la bomba

Instale un adaptador tipo arpón a la succión de

1¼ pulg. de la bomba si está utilizando tubo

de polietileno y sujete el accesorio con doble

abrazadera.

O

Enrosque un niple de tubo y una unión en el

orificio de succión para hacer una conexión de

tubo roscado. Asegúrese de que la unión esté limpia y

bien asentada. ¡Cualquier fuga de aire arruinará el rendimiento y la bomba no acumulará presión!

Tuberías de descarga

Instale un perfil en T o una doble T en la descarga de la

bomba. (¡Estos no se suministran con la bomba!) Instale un tapón de tubería o un manómetro en un buje de

reducción en el orificio superior del perfil en T. Éste se

utilizará como el orificio de cebado.

Doble T - la tubería de descarga a la residencia se conecta

a un orificio y el tanque se conecta al otro. Esto se denomina instalación de tanque fuera de línea.

Perfil en T - usted puede utilizar una línea para abastecer

la residencia, con el perfil en T del tanque instalado

desde la línea. Esto se denomina instalación de tanque en

línea y es el tipo más común.

Nota: Los tanques Goulds Water Technology HydroPro

para sistemas de agua se envían con una guía para la

instalación del tanque. Por favor consúltela para obtener

instrucciones más detalladas sobre el tanque.

No coloque válvulas o filtros entre la bomba y el tanque,

excepto por una válvula de compuerta completamente

abierta o una válvula de bola de “orificio completo”. ¡Las

válvulas de bola más comunes no son de orificio completo! La mayoría de las válvulas y filtros crearán pérdida

por fricción excesiva y producirán “chasquido del interruptor”. El chasquido del interruptor es una secuencia de

encendido-apagado no sólo del interruptor por caída de

presión, sino que también del motor. Producirá quemaduras de los contactos del interruptor, los contactos

de motor y causará daños al motor si no se corrige. Si

por alguna razón debe tener accesorios o filtros entre la

ADVERTENCIA

La tensión peligrosa

puede causar choques,

quemaduras o la

muerte.

ADVERTENCIA

La tensión peligrosa

puede causar choques,

quemaduras o la

muerte.

ADVERTENCIA

La tensión peligrosa

puede causar choques,

quemaduras o la

muerte.

bomba y el tanque y estos causan chasquido del interruptor, debe mover el interruptor por caída de presión a la

doble T del tanque. Consulte la “instalación del tanque

HydroPro para sistemas de agua” para completar la instalación para pozos poco profundos.

TUBO DOBLE PARA POZOS PROFUNDOS

TUBO DOBLE PARA POZOS PROFUNDOS

- comience aquí

- comience aquí

Tubería de succión de tubo doble

Un conjunto de inyección de tubo doble se utiliza en

pozos de 4 pulgadas y más grandes. Nuestros conjuntos

de inyección de 4 pulgadas requieren como mínimo una

tubería de succión de 1¼ pulg. y una tubería motriz de

agua de 1 pulg.; los inyectores de 5 pulgadas requieren

como mínimo una tubería de succión de 1½ pulg. y una

tubería motriz de agua de 1¼ pulg. El uso de tuberías más pequeñas reducirá el rendimiento en gpm y la

presión. Las derivaciones de más de 50 pies requieren

tubos más grandes para reducir la pérdida por fricción y

obtener el rendimiento publicado.

Instale el conjunto de inyección de tubo doble

Verifique que la boquilla esté instalada en el

conjunto de inyección. Instale el tubo Venturi

en línea con la boquilla. En el caso de inyectores de 4 pulgadas, conecte la tubería de succión

de 1¼ pulg. y el tubo de presión de 1 pulg. a

las roscas hembra del conjunto de inyección. En

el caso de inyectores de 5 pulgadas, las tuberías deben ser

de 1½ pulg. y de 1¼ pulg. Instale una válvula de aspiración en el orificio inferior de rosca macho del conjunto

de inyección o en el extremo de un tubo de aspiración de

34 pies. El tubo de aspiración impide el bombeo excesivo

de un pozo de baja producción, de manera que la bomba

no interrumpa la succión. Consulte la información sobre

el tubo de aspiración en la sección técnica.

Baje el conjunto de inyección al pozo. Debe situarse

al menos 5 pies por debajo del nivel de agua estática.

Mantenga el inyector a unos pocos pies del fondo del

pozo para reducir la probabilidad de aspirar residuos al

interior del inyector. Las conexiones en el cabezal del

pozo pueden ser ya sea un adaptador sin depresión o un

sello para pozo. Será más fácil cebar si llena las tuberías

con agua antes de conectar la bomba.

Conecte las tuberías de succión y de presión a las conexiones roscadas en la cara de la bomba. Esto puede

hacerse utilizando uniones y niples roscados o conectores

tipo arpón en el caso de tuberías de polietileno. Siempre

sujete los conectores tipo arpón con doble abrazadera.

Asegúrese de que la tubería se incline hacia arriba hacia

la bomba y que no haya ninguna sección sobre la succión

de la bomba. En el caso de derivaciones largas, es más

fácil cebar el sistema si llena las tuberías con agua antes

de conectarlas a la bomba. Pase a la sección de tubería de

descarga para pozos profundos.

SISTEMA DE OBTURADOR PARA POZOS

SISTEMA DE OBTURADOR PARA POZOS

PROFUNDOS - comience aquí

PROFUNDOS - comience aquí

Tubería de succión del obturador

Los obturadores utilizan el área entre el entubado del

pozo y la tubería de succión como la tubería motriz de

agua (presión). El entubado del pozo de 2 ó 3 pulgadas

debe ser liso y limpio para asegurar un buen

sello con el material del obturador o el sistema

tendrá fugas y no retendrá el cebado. El obtu-

rador de 2 pulgadas requiere tubería de succión

roscada de 1¼ pulg. y el de 3 pulgadas requi-

ere tubería de 1½ pulg. Para obturadores de

2 pulgadas únicamente: Utilice acoplamientos

torneados Goulds Water Technology, parte #64655, para

conectar las secciones de tubería roscada de 1¼ pulg.

Este acoplamiento torneado de diámetro especial aumenta el espaciamiento entre el diámetro interior del pozo de

2 pulgadas y el diámetro exterior del acoplamiento para

permitir que el agua (presión) motriz pase con facilidad

por los acoplamientos. Si no se usa este tipo de acopla-

miento, se influenciará negativamente el rendimiento de

la bomba y tanto la presión como los gpm disminuirán.

¡La bomba puede perder cebado fácilmente durante el

bombeo debido a la restricción!

Si se utiliza tubería más pequeña que la recomendada,

podría reducirse la salida de gpm. Mientras más larga es

la tubería, peor es el efecto.

Instale el conjunto del obturador

Para facilitar la instalación, remoje el conjunto del obturador de 2 ó 3 pulgadas en agua tibia para que el material

se ponga blando y flexible. ¡NO lo lubrique con grasa,

aceite o gelatina de petróleo! El material debe absorber

agua para sellar el conjunto del obturador contra el entubado del pozo.

Verifique que la boquilla esté instalada en el conjunto de

inyección. Instale el tubo Venturi en línea con la boquilla.

Instale un colador (no incluido con el conjunto del obturador) en el orificio inferior del conjunto del obturador

o en el extremo de un tubo de aspiración de 34 pies.

El tubo de aspiración impide el bombeo excesivo de un

pozo de baja producción, de manera que la bomba no interrumpa la succión. Conecte el conjunto del obturador a

los tubos de succión utilizando los acoplamientos torneados Goulds Water Technology para conectar las secciones. Inserte el conjunto del obturador en el entubado del

pozo y empújelo hacia abajo. Conecte las otras secciones

de tubería a medida que baja el inyector al interior del

pozo. Consulte la información sobre el tubo de aspiración

en la sección técnica.

Conecte la tubería de succión al adaptador para el obturador

Los sistemas de obturadores siempre requieren un adaptador para el obturador en el cabezal del pozo. El adaptador sirve de transición de vertical a horizontal para las

bombas horizontales y conecta las carcasas de las bombas

verticales al entubado del pozo y a la tubería de succión.

Consulte la lista de modelos de adaptadores para obturadores/bombas para determinar cuál es el que su sistema

requiere. Consulte la lista de modelos de adaptadores

para obturadores/bombas en la Tabla 1.

Después de haber insertado el conjunto del obturador

en el pozo, conecte el adaptador para el obturador al extremo superior de la tubería de succión. Atornille la sección superior de la tubería de succión roscada macho de

1¼ pulgada o un adaptador roscado al agujero roscado

hembra NPT de 1¼ pulg. en el adaptador para obturador

de 2 pulgadas o una tubería de succión de 1½ pulg. en el

adaptador para obturador de 3 pulg.

Asegure que el diámetro exterior del entubado del tubo

no contenga suciedad o rebabas. Con los tornillos de

casquillo sueltos, el anillo de sello ahusado en el adaptador para el obturador debe deslizarse sobre el entubado

del pozo. Después de asegurarse de que esté en posición,

apriete las dos tuercas de casquillo para comprimir el

anillo de sello y sellarlo al diámetro exterior del entubado del pozo.

Instale la bomba conectándola al adaptador del obturador con los pernos y empaquetaduras suministrados. Los

modelos verticales utilizan pernos prisioneros y tuercas

para facilitar el montaje.

TUBERÍA DE SUCCIÓN PARA POZOS

TUBERÍA DE SUCCIÓN PARA POZOS

PROFUNDOS

PROFUNDOS

Todas las bombas de inyección para pozos

profundos requieren contrapresión para operar

el conjunto de inyección. Para asegurar que

exista la contrapresión o presión de agua motriz

requerida, debemos usar una válvula de control de presión o algún tipo de restricción de

flujo en la tubería de descarga. La válvula debe

situarse entre la bomba y el primer orificio de descarga.

Es mejor situarla lo más cerca posible de la bomba. Si no

se instala o no se ajusta una válvula de control de pre-

17

ADVERTENCIA

La tensión peligrosa

puede causar choques,

quemaduras o la

muerte.

sión, se producirá una pérdida de cebado durante el uso

máximo, tal como el llenado de una máquina lavadora, la

tina del baño o el uso de llaves de mangueras exteriores.

Todas las bombas de ½ HP pueden usar una llave de paso

de gas sencilla o una válvula de bola de orificio completo,

tal como nuestro modelo AV15.

Todas las demás bombas de inyección horizontales para

pozos profundos, de ¾ HP y más grandes, deben usar un

modelo AV22KIT, o AV22 y un juego de tubos JDW. El

modelo AV22 tiene una derivación a la cual se conecta

el tubo nuevo y más largo del interruptor por caída de

presión. Esto permite que el interruptor lea la presión

en el lado de afuera de la válvula y no en la carcasa de la

bomba. Retire el accesorio de compresión recto o acodado de la carcasa de la bomba. Utilice el tapón para tubo

en el modelo JDW o AV22KIT para tapar el agujero en

la carcasa de la bomba. Retire el accesorio del interruptor por caída de presión. Corte el tubo viejo por mitad y

deslice los accesorios de compresión fuera de dicho tubo.

Note que el accesorio sólo se deslizará en una dirección.

Ahora usted puede reutilizar el accesorio de compresión

acodado con el tubo nuevo en el interruptor por caída de

presión. Atornille el nuevo conector recto en el modelo

AV22 y conecte el tubo del interruptor al AV22.

Las bombas verticales para pozos profundos están

equipadas con un AV21 incorporado y sólo necesitan

ajustarse.

Después de haber cebado la bomba y que fluya agua a

una presión constante, debe abrir algunas llaves y ajustar

la válvula de control de presión a la presión especificada

en la tabla. Para aumentar la presión cierre la válvula

AV15 o AV22, o gire el tornillo del modelo AV21 en

sentido horario. Consulte la Tabla 1.

AV15

Fig. 4

TODOS LOS SISTEMAS

TODOS LOS SISTEMAS

AV21

AV22

Instalación de un tanque HydroPro para sistemas de

agua

Mientras el tanque está vacío, verifique la

presión de aire de precarga con un indicador

de presión para neumáticos. La precarga del

tanque debe fijarse 2 lbs./pulg. cuadrada más

bajas que la presión de encendido. En los

tanques Goulds Water Technology HydroPro

para sistemas de agua la tapa de la válvula es el

sello principal, así que asegúrese de reinstalarla después

de verificar la presión de aire. Evite verificar el aire con

demasiada frecuencia, ya que se pierde 1 a 2 lbs./pulg.

cuadrada cada vez que lo haga. Todas las bombas de

inyección Goulds Water Technology están equipadas con

interruptores por caída de presión estándar con valores

de 30 a 50 lbs./pulg. cuadrada.

Sitúe el tanque sobre una superficie firme y nivelada.

Se recomienda una válvula de alivio de presión para

todos los sistemas y es obligatoria para los sistemas que

producen más de 100 lbs./pulg. cuadrada. Su clasificación

debe ser de menos de 100 lbs./pulg. cuadrada, pero debe

ser superior a la presión del sistema cerca del tanque.

Haga la conexión de la tubería entre la descarga de la

bomba y el tanque. Complete la tubería conectándola a

las tuberías de la residencia.

18

Nota: Goulds Water Technology sólo vende los tanques

HydroPro para sistemas de agua. Se envían con una guía

de instalación del tanque en la caja de cartón; consulte

dicha guía para obtener instrucciones más detalladas

acerca de la instalación del tanque. Si usted está utilizando un tanque de otro fabricante, comuníquese con dicha

compañía para obtener instrucciones específicas acerca de

su tanque.

Los tanques galvanizados se instalan de la misma manera

que los tanques precargados, excepto que requieren un

control de volumen de aire (AVC) para reponer el aire

perdido por absorción. El control de volumen de aire

requiere una conexión a un orificio de vacío en la bomba.

El lado de succión de dicho control debe tener un

mínimo de 3 pulg. de vacío durante 15 segundos cuando

arranca la bomba. Siga las instrucciones incluidas con el

control de volumen de aire.

Cómo cebar un sistema para pozos poco profundos

Cebar significa llenar la bomba y la tubería de succión

con agua. La mayoría de las bombas de inyección para

pozos poco profundos manejan bien el aire y lo evacuarán de la tubería de succión, pero podría llevar varios

minutos cebar, dependiendo de la profundidad al agua y

el tamaño y largo de la tubería.

¡VENTILE LA BOMBA PARA FACILITAR EL CEBADO!

Es más fácil cebar una bomba si permite que todo el aire

se escape de la bomba y las tuberías; ¡no puede entrar

agua a menos que el aire pueda escapar!

Retire el tapón de la tubería o el buje del manómetro

en el perfil en T de descarga para llenar la bomba con

agua. En las bombas para pozos poco profundos, hay que

retirar el tapón para tubería de 1⁄8 pulg. situado entre los

orificios de succión y descarga para permitir el escape de

aire cuando llena la carcasa con agua. El orificio estará

situado ya sea en el extremo superior de la carcasa o en el

extremo superior del adaptador para pozo poco profundo. Llene la bomba y la tubería de succión lo más posible

con agua a través del orificio de descarga.

Reinstale el tapón para tubería de 1⁄8 pulg. y el indicador/

buje de descarga. Abra un poco la llave más cercana a

la bomba/tanque para permitir que se escape el aire del

sistema. No la abra demasiado o la bomba expulsará

demasiada agua y tendrá que cebar nuevamente la carcasa de la bomba. En proyectos con tubería de succión

larga podría ser necesario agregar agua a la carcasa de la

bomba varias veces para completar el proceso de cebado.

Consulte la sección de encendido del motor.

Cómo cebar un sistema para pozos profundos

Cebar un sistema para pozos profundos significa llenar

la bomba y las tuberías de succión/presión con agua. Las

bombas de una etapa y de etapas múltiples para pozos

profundos requieren un cebado completo antes del arranque. Si se llenan las tuberías con agua antes de instalar

la bomba, se facilitará y se acelerará el cebado.

¡VENTILE LA BOMBA PARA FACILITAR EL CEBADO!

Para asegurar un cebado completo, recomendamos retirar

el tapón angular de ventilación de 1⁄8 pulg. situado justo

arriba de la tubería de succión en las bombas horizontales. Esto permitirá que el aire escape fácilmente cuando

entra el agua. Nuestros inyectores horizontales convertibles para pozos profundos deben cebarse a través de un

perfil en T o la unidad AV22 en la descarga de la bomba.

El perfil en T no es suministrado por Goulds Water Technology.