CentriPro

IM182

ITT

Residential & Commercial Water Systems

CentriPro

BALANCED FLOW®

SUBMERSIBLE PUMP CONTROLLER

Installation, Operation and Troubleshooting Manual

CentriPro is a brand of ITT Corporation.

www.goulds.com

Engineered for life

®

Owner’s Information

Owner’s Information

Table of Contents

Table of Contents

Controller Model Number:

Controller Serial Number:

Pump Model Number:

Pump Serial Number:

Motor Model Number:

Motor SFA:

Tank Serial Number:

Dealer:

Dealer Telephone Number:

Installation Date:

Wire Lengths (Feet)

Service Entrance to Controller:

Controller to Well:

Top of Well to Motor:

Incoming Voltage:

NOTICE: RECORD THE MODEL NUMBERS

AND SERIAL NUMBERS FROM THE

PUMP AND CONTROLLER IN THIS

INSTRUCTION MANUAL FOR FUTURE

REFERENCE. GIVE IT TO THE OWNER

OR AFFIX IT TO THE CONTROLLER

WHEN FINISHED WITH THE

INSTALLATION.

SUBJECT PAGE

1. Safety Instructions ..................................................... 3

Typical Installation ..................................................... 3

Ratings ...................................................................... 4

Required Materials .................................................... 4

2. Installation ................................................................ 4

Controller .................................................................. 4

Pump and Piping ........................................................ 4

Splicing Drop Cable to Motor Leads .......................... 4

Wiring Pressure Transducer ........................................ 5

Motor Wires .............................................................. 5

Input Power ............................................................... 5

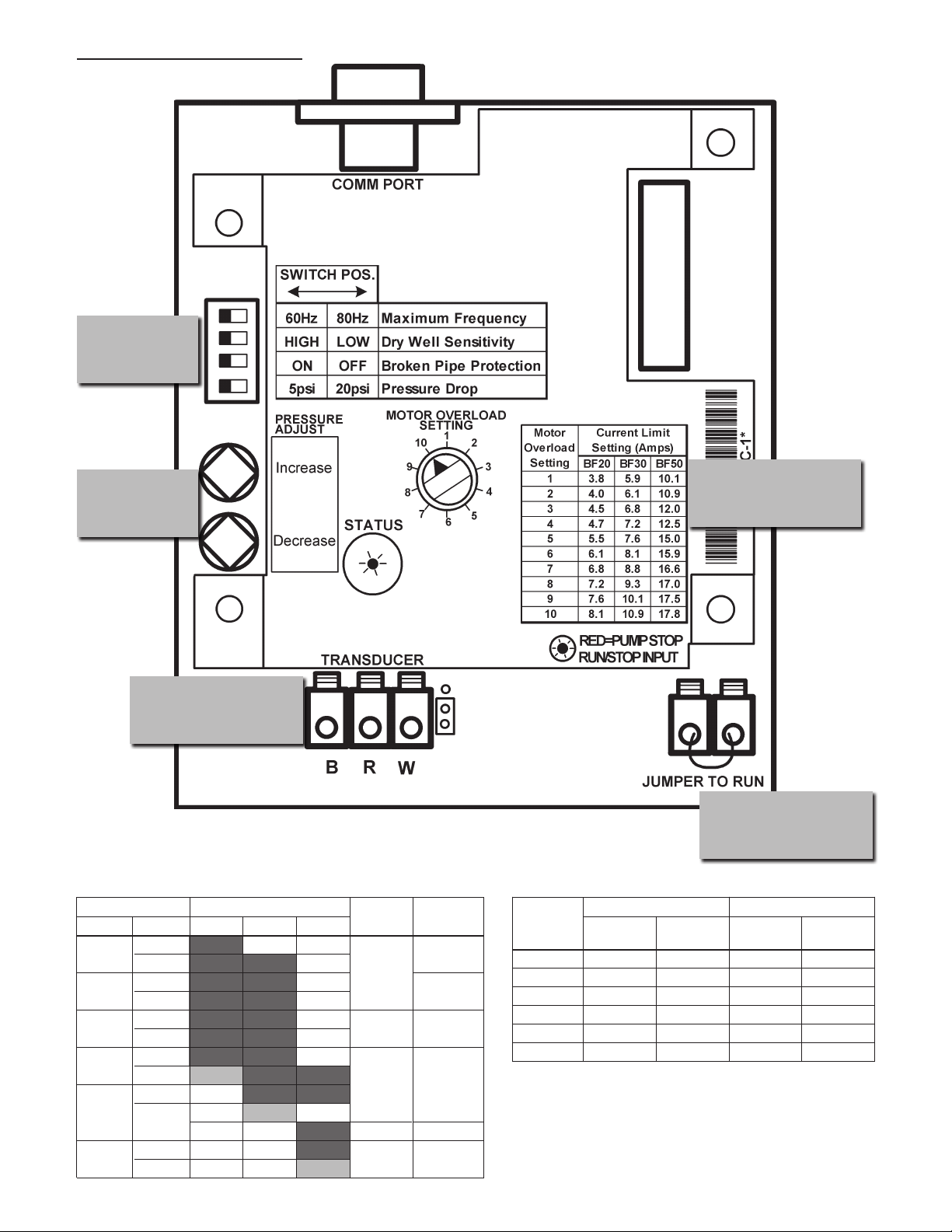

User Interface Board .................................................. 8

3. Installer Pre-Start Selections ...................................... 6

Maximum Frequency (Speed) Switch ......................... 6

Dry Well Sensitivity ................................................... 6

Broken Pipe Protection .............................................. 6

Pressure Drop ............................................................ 6

Motor Overload Setting Dial ..................................... 6

Pressure Adjustment Pushbuttons ............................... 6

Controller Status Indicator ........................................ 6

Purging System .......................................................... 6

Checking Rotation ..................................................... 6

Checking for Leaks .................................................... 7

Switch Input .............................................................. 7

Table 4: Wire Sizing ................................................... 9

4. Troubleshooting ................................................. 10-12

Limited Warranty ........................................................ 12

Water Ends and CentriPro Motors include these extra data labels. Please attach them to the inside cover of the

Balanced Flow Controller for future pump and motor identification.

®

Submersible Pump

33GS15

www.goulds.com

CentriPro

Motor: M30432/300C313

3.00 HP

FLA: 9.2 SFA: 10.1 LRA: 59

SF: 1.15 Hz: 60

Volts: 230 PH: 3

PLEASE USE THIS CONTROLLER INSTALLATION, OPERATION AND TROUBLESHOOTING

MANUAL (IOM) IN CONJUNCTION WITH THE PUMP IOM. THE CONTROLLER IOM COVERS THE

CONTROLLER ELECTRICAL INSTALLATION AND ANY SPECIAL INSTALLATION PROCEDURES

REQUIRED WITH VARIABLE SPEED CONTROLLERS.

ITT WILL NOT BE RESPONSIBLE FOR ANY DAMAGES TO AN INSTALLATION WHERE THE PRESSURE

RELIEF VALVE IS ALLOWED TO DISCHARGE INTO A FINISHED LIVING SPACE OR TO OTHERWISE

DAMAGE A CUSTOMERS PROPERTY. PLUMBING SAFETY DEVICES SUCH AS PRESSURE RELIEF

VALVES TO AN APPROPRIATE DRAIN IS THE RESPONSIBILITY OF THE INSTALLER AND IS OUT OF

OUR CONTROL.

2

DANGER

WARNING

CAUTION

WARNING

WARNING

WARNING

WARNING

1: SAFETY INSTRUCTIONS

WARNING

1: SAFETY INSTRUCTIONS

TO AVOID SERIOUS OR FATAL PERSONAL INJURY

OR MAJOR PROPERTY DAMAGE, READ AND

FOLLOW ALL SAFETY INSTRUCTIONS IN MANUAL

AND ON EQUIPMENT.

THIS MANUAL IS INTENDED TO ASSIST IN THE

INSTALLATION AND OPERATION OF THIS UNIT AND

MUST BE KEPT WITH THE UNIT.

This is a SAFETY ALERT SYMBOL.

When you see this symbol on the pump,

the controller or in the manual, look for

one of the following signal words and

be alert to the potential for personal

injury or property damage.

Warns of hazards that WILL cause

serious personal injury, death or major

property damage.

Warns of hazards that CAN cause serious

personal injury, death or major property

damage.

Warns of hazards that CAN cause

personal injury or property damage.

NOTICE: INDICATES SPECIAL

INSTRUCTIONS WHICH ARE

VERY IMPORTANT AND MUST BE

FOLLOWED.

THOROUGHLY REVIEW ALL INSTRUCTIONS

AND WARNINGS PRIOR TO PERFORMING ANY

WORK ON THIS CONTROLLER.

MAINTAIN ALL SAFETY DECALS.

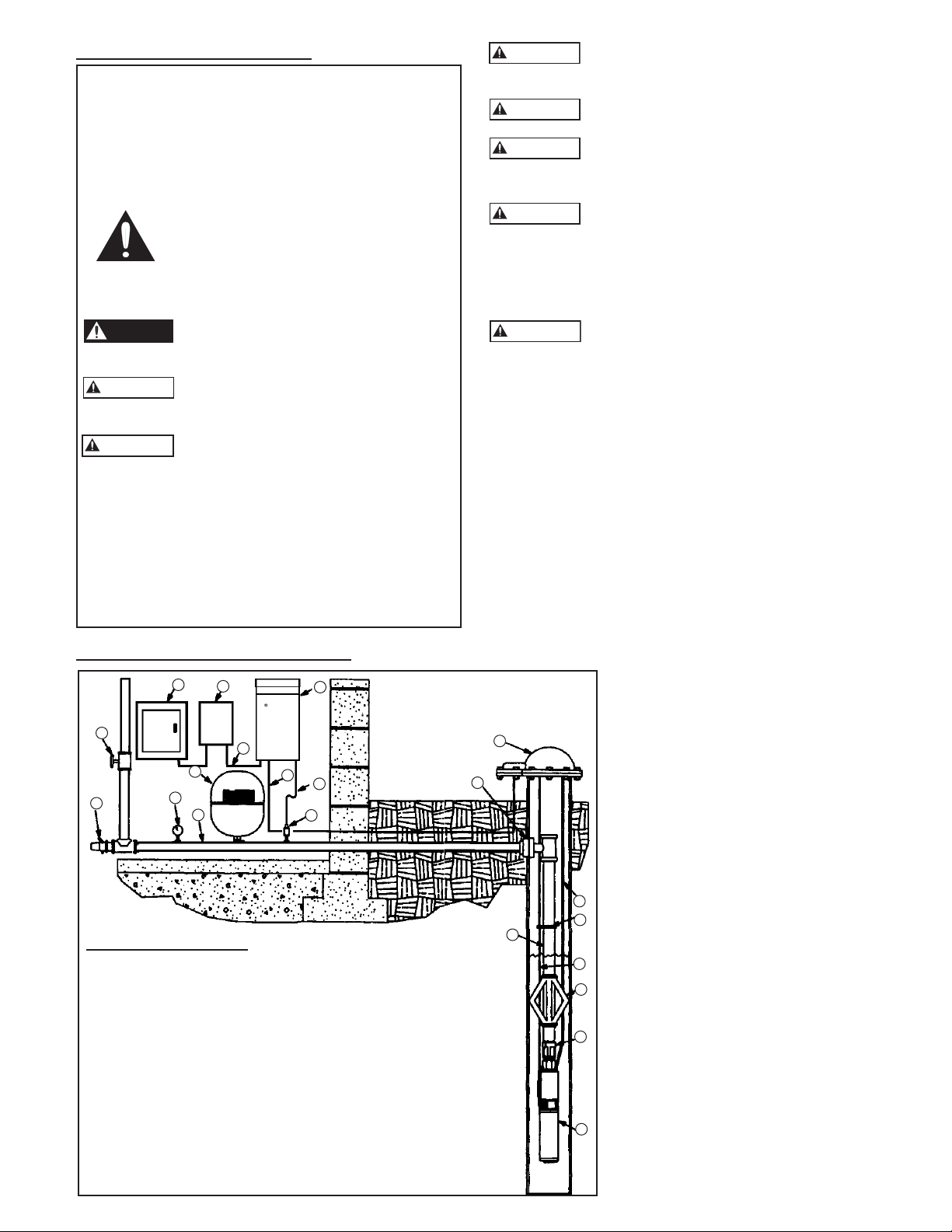

TYPICAL INSTALLATION

TYPICAL INSTALLATION

This controller is not designed for use

around swimming pools, open bodies of

water, hazardous liquids, or where flammable gases exist.

Do not use GFCI input power. This will

cause nuisance faults.

Disconnect and lockout electrical power

before installing or servicing any

electrical equipment.

ELECTROCUTION HAZARD.

CONTROLLER INPUT GROUND

TERMINAL (GND) AND ALL EXPOSED METAL

PIPING, INCLUDING PRESSURE TRANSDUCER

CASE, MUST BE CONNECTED TO THE SERVICE

ENTRANCE GROUND TERMINAL.

All electrical work must be performed

by a qualified technician. Always follow

the National Electrical Code (NEC), or the Canadian

Electrical Code, as well as all local, state and provincial

codes. Code questions should be directed to your local

electrical inspector. Failure to follow electrical codes and

OSHA safety standards may result in personal injury or

equipment damage. Failure to follow manufacturer’s

installation instructions may result in electrical shock,

fire hazard, personal injury or death, damaged

equipment, unsatisfactory performance, and may void

manufacturer’s warranty.

NOTICE: Some installations pull a vacuum on the

transducer when the system is drained. The new controller

is designed to protect against up to 17” Hg. of vacuum

on the transducer. An optional Gauge Guard, order

no. 6K210, will protect the transducer from a vacuum

condition.

11

20

17

13

16

15

10

19

9

4

12

14

PARTS DESCRIPTION:

1) Pump and Motor 10) Power Supply Cable

2) Check Valve (built-in 11) Service Entrance

on some models) 12) Pressure Sensor Cable

3) Torque Arrestor (optional) with drip loop

4) Pump Power Cable 13) Diaphragm Tank

with Splice Kit 14) Pressure Transducer

5) Electrical Tape 15) Pressure Gauge

(Cable to Pipe) 16) Relief Valve

6) Safety Rope (optional) 17) Shut-Off Valve

7) Well Cap / Seal 18) Drop Pipe

8) Pitless Adapter 19) Lateral Pipe

9) Controller 20) Electrical Disconnect

7

8

6

5

18

4

3

2

1

3

Ratings

WARNING

CAUTION

CAUTION

CAUTION

WARNING

CAUTION

Refer to serial number label on enclosure.

Required Materials

• BF Pump Controller with Transducer and Transducer Wire

• Pump (water end)

(see Speed Selector Switch for 60 Hz or 80 Hz Operation)

• Motor: 230 V, three phase (3Ø), 3450 RPM

• Pressure Relief Valve – piped to a drain for safety

• Pressure Gauge – for setting system pressure

• Heat Shrink Kit – one required for each underwater or

underground splice (mandatory)

• Tank Tee or (2) ¼" NPT Female pipe fittings for pressure

sensor and pressure gauge connections

• Pipe and fittings – as necessary per each system

• Disconnect Switch: 230 V, 2 pole, properly sized

(see Controller, Breaker, Generator Sizing Table)

• Copper Wire: Minimum 75ºC rated wire, double

jacketed is recommended but not mandatory

(see Wire Sizing table)

• Tank: diaphragm style tank

(see Tank Sizing Section and Chart)

2: INSTALLATION

2: INSTALLATION

Determine where the Controller, Pressure Tank and

Transducer will be located before starting the installation.

Controller

The controller is rated NEMA 3R (Raintight) so it may be

located outdoors. It must be mounted vertically. Locate

the enclosure in a shaded area where the temperature

stays within 0ºF to +122ºF (-18ºC to +50ºC). Since the

controller is designed for outdoor mounting it may be

located at the wellhead.

Opening Controller Cover

Lay the controller on a flat surface or hang

on wall before removing the cover screw.

Failure to do so may result in dropping and damaging the

unit. Once screw is removed, lift the cover up and out to

remove. There is a locking tab on the bottom of the unit to

accommodate a padlock if so desired.

Mounting Controller

Three screws are provided for mounting the enclosure.

Using the enclosure as a guide, select a mounting location.

First install the top screw in the mounting surface leaving

the head of the screw approximately 1⁄8" from the surface.

Hang the enclosure on this screw. Finish by installing the

two bottom screws and tightening the top screw. Be sure

to leave a minimum of 6" of clearance on each side of the

controller to ensure proper cooling.

EXPLODING TANK CAN INJURE OR

KILL.

Always protect the tank from over pressure by installing

a pressure relief valve large enough to limit the system

pressure below the maximum working pressure of the tank.

Install the tank at a point in the system where the maximum

possible system pressure cannot exceed the maximum

working pressure of the tank. Install the pressure relief valve

at the tank.

Avoid property damage caused by pressure

relief valve opening. Pipe the pressure relief

valve discharge to a drain or other location so that property

damage and flooding will not occur.

Locate the tank and transducer where they

will not freeze.

Ensure the system pressure setting does not exceed the

maximum working pressure of the tank.

For optimum performance, as a minimum, we recommend

using the same size pipe as the pump discharge between the

pump and the tank. Smaller diameter pipe may severely limit

the maximum capacity of the system. On long runs, larger

pipe may be beneficial for optimum performance and flow.

If using a torque arrestor, install it on the

discharge pipe before connecting pipe to

the discharge head.

Diaphragm Tank Sizing and Pre-Set Pressure

Recommendations:

Diaphragm type (captive air) tanks are required on these

systems.

Table 1: Tank Sizing Selection

Maximum

Pump GPM

10 2 V6P TP6P

23 4.5 V15P TP15P

41 8.2 V25P TP25P

70 13.9 V45 TP45

100 19.9 V60 TP60

Use Total Tank Volume, not drawdown volume, to select

the proper tank size. The total tank volume should be

approximately 20% of the pump’s maximum flow. For

example, when using a 10 gpm pump the system requires a

2 gallon (total volume) tank.

The tank sizing recommendations are field proven to

prevent objectionable pressure drops on start-up and

provide smooth operation for the majority of variable speed

pump systems.

Recommended Tanks

Total Volume Order No. or Order No.

For a 5 PSI Pressure Drop Set-up:

Set the tank pressure, while tank is empty of water, to 20 psi

below the desired system pressure setting. Ex. for a 50 psi

system pressure, charge the tank to 30 psi.

Pump and Piping

Do not install any valves, flow control

devices or filters between the pressure

transducer and the pump. It is allowable to run branches

off the pipe between the pump and transducer as long

as no flow restricting devices are between the pump and

transducer.

NOTICE: The terms Transducer and Pressure Sensor are

equal and interchangeable.

4

For a 20 PSI Pressure Drop Set-up:

Start with the tank pre-charge set 30 psi below the set

point, this setting may need minor adjustment for optimum

performance as all systems and piping are slightly different.

Splicing Drop Cable To Motor Leads

The underwater connection where the drop cable connects

to the motor wires must be done using a waterproof heat

shrink kit. To make the connection, first strip the wires

½" and place the heat shrink tubes over the wires. Then,

CAUTION

connect the wires using the crimps. Finish by shrinking the

CAUTION

CAUTION

WARNING

CAUTION

tubes over the crimps heating from the center outward.

The sealant in the tube will flow out the ends making a

watertight seal. If a heat shrink tube is burnt or split, the

connection will need to be remade.

Vinyl electrical tape is not acceptable for

underwater splices when using variable

speed drives due to the high potential for leakage to ground

through taped joints. Failure to use a waterproof heat shrink

kit will void the warranty.

Before installing the motor in the well, the drop cable must be

connected to the motor wires. Refer to the wire size chart when

selecting wire size for the drop cable. See Wire Sizing Table.

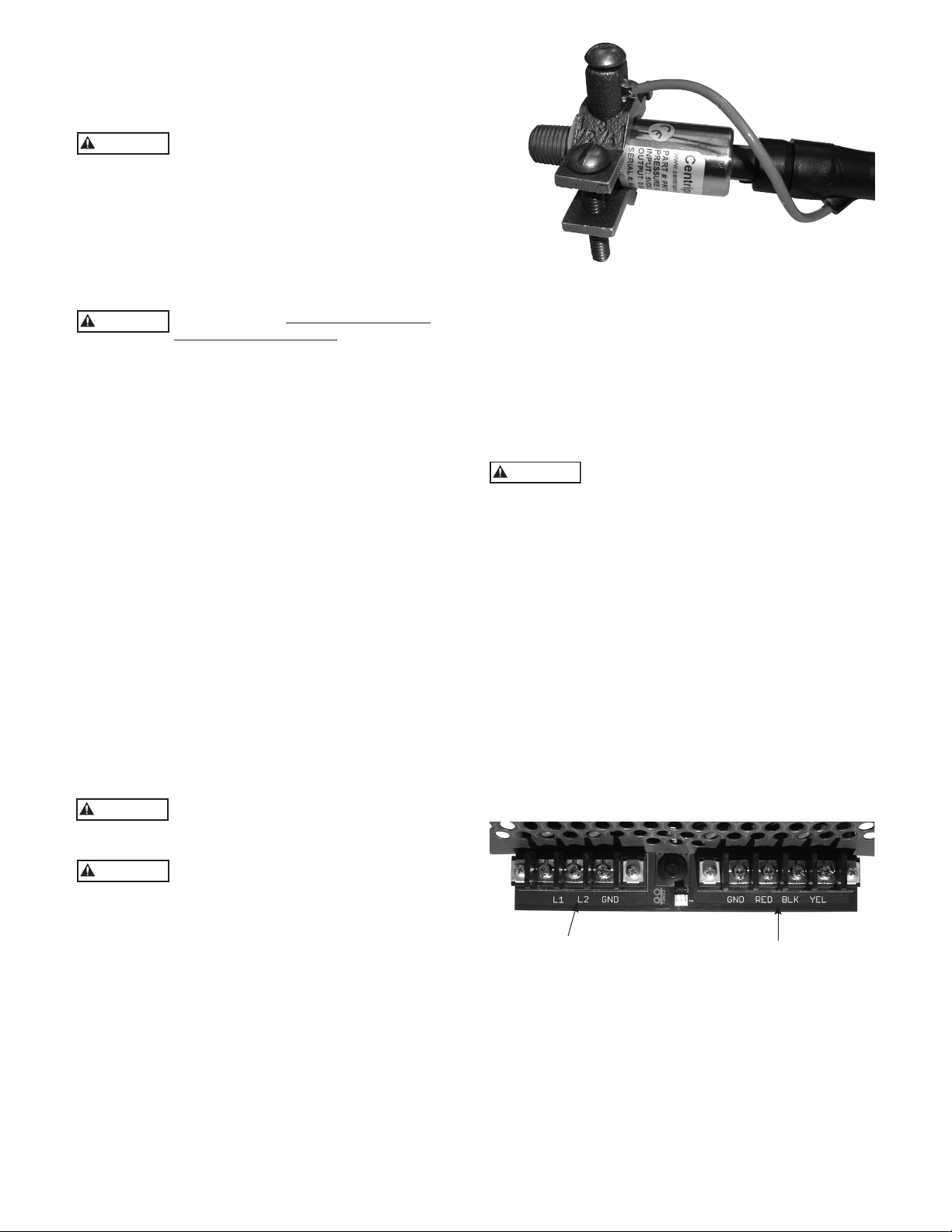

Figure 1: Transducer Grounding

Wiring Pressure Transducer

Transducer wires must never be in same

conduit with power wires. There should

always be a minimum of 12" between transducer wires

and power wires. Failure to separate these wires can cause

controller malfunctions.

The pressure transducer cable is pre-wired at the factory. If

desired, the length of the cable can be changed. The cable

can also be put in conduit to protect against damage.

To change the length of the transducer cable:

• Cable length cannot exceed 200'.

• Disconnect transducer wires from terminal block by pushing

down on tabs at rear of block one at a time and pulling the

wires out of the terminal.

• Splice additional cable to transducer wire, cut off excess as

required.

• Reconnect wires to terminal block. Be sure wire colors match

labels on circuit board (B = Black, R = Red, W = White).

To put the transducer cable in conduit, do the following:

Disconnect the cable from the terminal block and remove

the cable strain relief in the bottom of the enclosure.

Starting at the enclosure, run flexible or rigid ½" conduit to

where the transducer is located. The last few feet of conduit

adjacent to the transducer will need to be flexible. The

conduit must be well supported – NO stress can be placed

on the pressure transducer connector. Use a strain relief

bushing to seal around the pressure transducer connector.

After reconnecting the transducer wires to

the terminal block and ground terminal, tug

on each wire individually to ensure they are tight.

Any exposed metal in the system piping,

including transducer case, must be grounded

to the service entrance per NFPA 70: National Electrical

Code, Article 250.

The transducer cable has a Green ground wire and a ground

clamp supplied to facilitate grounding the transducer. See

Figure 1.

Motor Wires – See Table 4

NOTE: A MINIMUM OF 75ºC COPPER WIRE IS MANDATORY.

Refer to the Table 4 for wire sizing and maximum wire

lengths. Charts are designed to limit voltage drop to 5%.

Figure 2 shows the terminal block where the motor and

input wires connect. The protective cover on the terminal

block snaps off and on. Attach the motor wires to the

terminals according to colors marked on circuit board:

GND = Green, RED = Red, BLK = Black, YEL = Yellow.

Reversing any two leads on RED/BLK/YEL will change the

direction of motor rotation. Later during start-up you may

need to change motor rotation.

Input Power

SHOCK OR ELECTROCUTION

HAZARD

Connect a ground wire from the service panel to the

terminal marked GND. Controller has high leakage to

ground. Controller ground terminal must be connected to

the service entrance ground terminal. Failure to do so will

result in high voltage being present on the controller chassis.

Connect two “hot” wires from the 2 pole circuit breaker to

the terminals marked L1 and L2.

The input power system used must be a grounded power

system. The voltage measured from L1 to L2 must be in the

range of 196Vac to 265Vac. The voltage measured from

L1 to GND must be equal to the voltage measured from

L2 to GND. These voltages must be within the range of

120Vac +/- 10%. Reduced input voltage will reduce system

performance.

Do not use a Ground Fault Circuit Interruptor (GFCI) with

this product or nuisance tripping will result.

Incoming Power

Figure 2: Wiring Connections

NOTE: IT MAY BE NECESSARY TO PLACE A DISCONNECT SWITCH IN FRONT OF AND WITHIN SIGHT

OF THE CONTROLLER – CONSULT LOCAL CODES.

Wires to Motor

Size wire for worst case scenarios (low voltage) and stay

within the charts recommendations. Insure that the wire is

rated for direct burial and/or submergence.

5

3. INSTALLER PRE-START SELECTIONS

WARNING

WARNING

3: INSTALLER PRE-START SELECTIONS

DRIVE SETTINGS AND PROTECTION

Maximum Frequency (Speed) Switch

The Maximum Frequency switch sets the maximum

frequency (motor speed) the controller uses to energize the

motor to either 60 or 80 Hz.

• 60 Hz - Use for matched pump-motor combinations

where the motor HP and pump HP are the same.

Example: 2 HP WE and 2 HP Motor

• 80 Hz - Use for mis-matched pump-motor combinations

where motor HP is larger than the pump HP (typically 2x

larger).

Example: 1 HP WE and 2 HP Motor

• The unit is factory pre-set at 60 Hz.

Dry Well Sensitivity

Selections are High or Low. This function protects the

system from running dry. The selection depends on

several conditions and pump size.

Start with the sensitivity on high and test by running

pump at various flows. If a dry well fault is triggered,

switch to low setting. The unit is factory pre-set at high.

Restart times in minutes are: 1, 10, 20, 30, 60, 60 and

repeating every 60 minutes thereafter.

Example: 1st fault shuts down for 1 minute, next fault

shuts down for 10 minutes, then 20, etc.

• See Table 3 or the motor nameplate for Motor Amperage

ratings. The controller limits the output current to the

value selected by this dial. It does this by lowering the

frequency and voltage. If the current does not come

within the selected value by the time the frequency is at

40Hz, the controller will shut down and indicate Bound

Pump error (4 red blinks).

PRESSURE ADJUSTMENT

Pressure Adjustment Pushbuttons

The INCREASE and DECREASE pushbuttons are used

to set the desired pressure. To adjust pressure, press and

hold (do not tap) the button until the desired pressure is

obtained. It may take a full minute to adjust the pressure

from maximum to minimum, please be patient. Pressure can

only be changed when the pump-motor is running.

Controller Status Indicator (Light Visible Through

Window in Cover)

The controller status indicator light has 3 possible modes:

• Solid green = Standby, pump not running. There is no

water flow or the SWITCH INPUT is open.

• Blinking green = Pump running. There is flow (possibly a

leak) and the SWITCH INPUT terminals are connected to

each other (closed).

• Red = Error/Fault. Light will blink to indicate a particular

fault. See Troubleshooting Section for Fault Codes.

Broken Pipe Protection

ON Position - Used for constant pressure systems. The

drive will turn off if the system pressure drops 20 PSI

below the system set point pressure for a minimum of

30 seconds. This fault must be manually reset, it will not

clear automatically, this may prevent property damage if

a pipe breaks.

OFF Position - Use for open discharge situations such as

flushing a tank, filling a pond or tank, or whenever the

system pressure will be 20 psi or more below the system

set point pressure.

Pressure Drop – 5 PSI or 20 PSI

The pressure drop before the pump restarts can be set to

the standard 5 PSI or to 20 PSI.

The 20 PSI setting results in fewer starts for systems with

leaks. It is recommended for irrigation systems. It will

require a tank pre-charge adjustment. See Tank Sizing.

CURRENT LIMIT PROTECTION

Motor Overload Setting Dial

Failure to properly adjust the Motor

Overload Setting before applying power may

damage the motor or wire and void the warranty.

• Use Table 2 to determine which controller and setting to

use. Note that some 200V motors require upsizing to the

next larger controller.

• Set the Motor Overload - Turn the dial pointer to align

with the motor’s service factor amps (SFA) as listed on

the Motor Overload / Current Limit chart. Choose the

amperage value from the Current Limit Settings chart

on UIB that is closest to the SFA listed on the motor

nameplate but not higher.

Purging System

Open a valve and turn power on to the controller. If

the system pressure is below the factory preset pressure

setting (50 psi), the status light will begin blinking green

indicating that pump is running. The controller hums

when it is running. This is normal.

It is common for the pump to be air bound at

first, especially with shallow wells. In this case, the

controller will begin testing for a dry well (refer to the

troubleshooting section for a description of Dry Well

Detection).

Once the water is flowing, be sure to open all valves to

purge air from the system.

Checking Rotation

It is possible that the motor is rotating in

the wrong direction. The pump will work

but will have greatly reduced performance if rotating

backwards.

To check rotation, perform the following test:

Connect an amp probe to one of the power supply

wires. Run the system with several valves open and note

the pressure and amps. Leave the valves open, turn the

power off, and wait 5 minutes for the hazardous voltages

to discharge.

Swap red and black motor leads where they connect to

the controller terminal block (NOT L1 and L2).

Turn power back on and let the system pressure

stabilize. Again note the pressure and amps. Whichever

wire position provided the most pressure/flow is the

correct wire position. If there was little difference in the

pressure/flow, then whichever had the lower amp reading

is the correct wire position.

Turn the power off, wait 5 minutes and swap the wires

back if necessary.

6

Replace the plastic protective covers on the terminal

DANGER

DANGER

block.

Checking for leaks

Constant pressure systems utilizing small tanks run

whenever there is demand. Even small leaks can prevent

a pump from turning off. To check for leaks, close all

valves, turn power off to the controller, and note the

pressure displayed on the pressure gauge. Tap the gauge

to ensure you get an accurate reading.

Wait ten minutes and check the gauge again tapping to

prevent the needle from sticking. If the pressure dropped

then the system may have a leak*.

*If a system is pressurized after having been unpressurized, it will continue to expand for several

minutes. This expansion causes the pressure to drop

and can be misinterpreted as a leak. Allow a system to

stabilize for 10 minutes under pressure before

performing the aforementioned leak test.

A spring check valve placed on the pump side of the

tank and transducer will often improve the ability of the

system to shut down.

SWITCH INPUT

Optional Switch Input and Switch Input

Status Light

Log onto www.centripro.com, click on Goulds Pumps or

Red Jacket, click on Electrical Controls Water, click on

Balanced Flow for more detailed examples on using the

Switch Input.

Electrocution Hazard. Opening SWITCH

INPUT does not de-energize controller

or any of its outputs. Always treat wire terminals of this

controller as energized until power supply to the controller

has been removed for 5 minutes.

SWITCH INPUT - for connection of an external switch

or control device used to start and stop the pump. Devices

such as an over-pressure switch, level (float) switch or any

other non-powered switch (time delay, flow, etc.) can be

connected to this input.

The Switch Input terminals have a Jumper Wire installed at

the factory (do not confuse the jumper wire on the Switch

Input with the Transducer Jumper next to the Transducer

Connection Terminals, see Transducer Jumper below).

The Switch Input terminals must be connected (closed) for

the pump to operate. If they are not connected the Switch

Input Status Light (visible inside the enclosure) will be Solid

RED and the Controller Status Light will be Solid GREEN

indicating that the pump-motor is off. Remove the Jumper

Wire when connecting a float or over-pressure switch:

CONSTANT PRESSURE SYSTEM - with an Over-Pressure

Switch:

• Connect two wires from the Load and Lead connections

of a pressure switch to provide over-pressure protection.

In the event the pressure transducer fails, this will prevent

high pressure from damaging piping.

• The over-pressure switch cut-out setting must be a mini-

mum of 10 PSI higher than the system set point pressure.

• Set the over-pressure switch cut-out 5 - 10 PSI lower than

the pressure relief valve (PRV) pop-off pressure. This will

turn the system off before the pressure relief valve opens.

• Ex. On a system with a 50 PSI set point, set the over-pressure switch cut-out at 60 PSI with a typical PRV setting of

75 PSI. In the event the transducer fails at high pressure

the switch will turn the system off before the PRV pops.

• Typical UIB Settings For This Type System:

• 60 or 80 Hertz (depends on pump/motor)

• Dry Well - High (switch to low if it trips while pumping

water)

• Broken Pipe - On

• Pressure Drop - 5 PSI

• Transducer - Connected

• Transducer Jumper - Bottom Position (Factory Setting)

• Pressure Switch Connected to Switch Input

FLOAT SWITCH OPERATION - Filling a Pond or Tank

(Non-Constant Pressure System):

• Connect two wires from a float (level) switch to fill or

empty a tank, pond, etc. The pump will run when the

level switch contacts close. The maximum switch wire

length tested is 200’. The pump will run at maximum

speed when the float switch is closed.

• Typical UIB Settings For This Type System:

• 60 or 80 Hertz (depends on pump/motor)

• Dry Well - High (switch to low if it trips while pumping

water)

• Broken Pipe - Off

• Pressure Drop - 5 or 20 PSI

• Transducer - Not Connected

• Transducer Jumper - Top Position (Installer Must Move)

• Float Switch Connected to Switch Input

FLOAT SWITCH OPERATION - Filling a Pond or Tank

and Constant Pressure System:

• Connect two wires from a float (level) switch to fill or

empty a tank or pond and a pressurized system. The

maximum switch wire length tested is 200’. The pump

will operate at various speeds and try to maintain the set

point pressure. If piping is large and it cannot maintain

set point pressure it will operate at maximum speed.

• Typical UIB Settings:

• 60 or 80 Hertz (depends on pump/motor)

• Dry Well - High (switch to low if it trips while pumping)

• Broken Pipe - On (switch to off if pressure drops by 20

PSI or more)

• Pressure Drop - 5 PSI

• Transducer - Connected

• Transducer Jumper - Bottom Position (Factory Setting)

• Float Switch Connected to Switch Input

Transducer Jumper

Explosion Hazard. Keep jumper in bottom

position whenever a pressure transducer is

used. Failure to do so may cause a pressure transducer error

to be ignored and an over-pressure hazard to result.

For applications not requiring a pressure transducer such

as level control, the transducer can be removed. When

the transducer is not used, the Transducer Jumper must be

placed in the top position to prevent a sensor error. Never

place the jumper in the top position when using a pressure

transducer.

7

USER INTERFACE BOARD

USER INTERFACE BOARD

Drive

Settings /

Protection

Pressure

Adjustment

Current Limit Dial

(Motor Overload

Protection)

Pressure

Transducer

Connection

TRANSDUCER

JUMPER

Switch Input (Over

Figure 3: UIB (User Interface Board)

Pressure Protec-

tion, Level Control)

Table 2: Controller, Breaker, Generator Sizing Table 3: Service Factor Amps 3 Phase Motors

3 Phase Motor Controller Model ② Circuit Generator ④

HP Voltage ① BF20 BF30 BF50 Breaker ③ (VA)

¾ 230

200

1 230

200

230

1½

200

2 230

200

230

3

40

5 230

200

8100

200

15

20

30

50

2900

3500

4400

6100

13300

8

230 Volt, 3Ø 200 Volt, 3Ø

HP

CentriPro Franklin CentriPro Franklin

SFA SFA SFA SFA

¾ 4.0 3.8 4.5 4.4

1 4.7 4.7 5.5 5.4

1½ 6.1 5.9 7.2 6.8

2 7.6 8.1 8.8 9.3

3 10.1 10.9 12 12.5

5 17.5 17.8 20.2 20.5

NOTES:

① Motor Nameplate must be the same as supply voltage.

② Shaded areas indicate which controller models can be used with which

motors. Lighter shading indicates combinations where controller will limit

peak performance to 85% of catalog value for pump/motor.

③ Circuit Breaker or Dual Element Time Delay Fuse Size (Amps) protecting

branch circuit supplying controller.

④ Minimum size of single phase 240 V generator required.

Table 4: Wire Sizing

Maximum Cable Lengths in Feet to Limit Voltage Drop to 5% for 230 V Systems ①

Service Entrance to Controller

Controller Motor

Input

½ 366 583 925 1336 2107 3345 4175 5267 6637 8364

¾ 279 445 706 1020 1608 2552 3186 4019 5065 6383 8055

1 226 360 571 824 1300 2064 2576 3250 4095 5161 6513 8201

230V

1½ * 286 455 657 1036 1644 2052 2589 3262 4111 5188 6533 8236 9710

1 PH

2 * * 331 478 754 1197 1495 1886 2376 2995 3779 4759 5999 7073 8455 9852

3 * * 246 355 561 890 1111 1401 1766 2225 2808 3536 4458 5256 6283 7321 8343

5 * * * 218 343 545 680 858 1081 1363 1720 2165 2730 3219 3847 4483 5109 6348

Controller to Motor

Controller Motor

Input

½ 905 1442 2290 3306 5213 8276

¾ 690 1100 1748 2523 3978 6316 7884 9945

1 558 890 1413 2040 3216 5106 6375 8041

230V

1½ 445 709 1126 1625 2562 4068 5078 6406 8072

3 PH

2 324 516 820 1184 1866 2963 3699 4666 5879 7410 9351

3 241 384 609 880 1387 2202 2749 3467 4369 5506 6949 8750

5 * 235 373 539 849 1348 1683 2123 2675 3372 4255 5358 6755 7964 9520

① Reduce lengths by 13% for 200 V systems. * Wire does not meet the N.E.C. ampacity requirement.

② Lengths in bold require 90º C wire. Shading indicates 40º C maximum ambient.

Copper Wire Size 75ºC Insulation Exposed to a Maximum of 50ºC (122ºF) Ambient Temperature ②

HP

14 12 10 8 6 4 3 2 1 1/0 2/0 3/0 4/0 250 300 350 400 500

Copper Wire Size 75ºC Insulation Exposed to a Maximum of 50ºC (122ºF) Ambient Temperature ②

HP

14 12 10 8 6 4 3 2 1 1/0 2/0 3/0 4/0 250 300 350 400 500

The lengths in each of the Wire Sizing tables represent 100% of the allowable voltage drop when motor is

running at full load. When sizing wire, the voltage drop of each wire segment must be included. The total

must not exceed 100% of the allowable drop. Take for example a 1.5 HP motor with a distance from Service

Entrance to Controller of 100' and 500' between the Controller and Motor.

• Service Entrance to Controller = 100' of 10 AWG (100/455) = 22 % (455' is from the S.E. to

Controller chart)

• Controller to Motor = 500' of 12 AWG (500/709) = 71 % (709' is from the Controller to

Motor chart)

Total Drop (must be ≤ 100%) 93 %

If the distance from the Controller to Motor was 600' (600/709) = 85% + 22% = 107%, we would need to

use #10 wire for that segment, ex. 600/1126 = 53% + 22% (for 100' of #10) = 75% which is acceptable.

It is also acceptable to use different wire sizes for the Buried and Well sections of wire.

Table 5: Possible Combinations for TRANSDUCER, JUMPER AND SWITCH INPUT

Scenario

Transducer Position Input Status Indicator Indicator

Bottom Open Disabled Solid Green Solid Red

Constant

pressure operation

else solid green

Level or pressure

switch control

* See description of Maximum Speed Switch and Motor Overload Setting Switch for their effect on Full Speed value.

Pressure Jumper Switch Controller Status Switch Status

Connected

Top Open Disabled Solid Green Solid Red

Not

Connected

Bottom Closed Constant pressure

Top Closed Run Full Speed* Blinking green Off

Blinking green if flow

Off

9

4: TROUBLESHOOTING

4: TROUBLESHOOTING

The status light described in Section 3 Installer Pre-Start Selections is used to indicate system status i.e. running,

stopped, or faulted. When faulted, the status light will be red. The error code is the number of quick flashes followed

by a 1 second pause. The number of flashes can be any number from 2 to 8. The error code will be repeated until

cleared. Some errors will clear themselves with time. Others must be cleared manually by turning the power off for 1

minute. The following table describes the various errors that can occur.

NO LIGHT

Flashes Controller Status Description

None Low/No Input Voltage Check the input voltage to the controller. Measure the voltage between

L1 and L2 using an AC Voltmeter. This voltage should be greater

than 190Vac.

GREEN LIGHT CODES

Flashes Controller Status Description

Constant Standby/Low Voltage Constant Green Light indicates the pump is off. The system is in Standby

mode when there is no flow in the system and the pressure setting has been

reached. The system is in a Low Voltage condition when the line input

voltage drops below 190VAC.

Blinking Pump Running Flashing Green Light indicates the pump is running.

RED LIGHT CODES

Flashes

This information is to be used by professional installers or qualified

Constant Controller Error Internal controller fault. Replace controller.

2 Blinks Dry Well This fault can be caused by:

• Water supply level in well falls below suction inlet of pump.

• Plugged suction screen.

• Restriction in pipe between pump and pressure sensor.

• Air bound pump – see “Purging System”

• Incorrect setting of “MAXIMUM SPEED” switch. Be sure to set the

“MAXIMUM SPEED” switch to 80 Hz when using mismatched pumps

(water ends) and motors.

• Incorrect setting of “MOTOR OVERLOAD SETTING (SFA)” switch.

Ensure the Motor Overload Setting (SFA) Switch is not set higher than the

Service Factor Amps (SFA) listed on the motor nameplate.

In systems where the motor operates at less than Service Factor Amps the

controller may show a false “dry well” fault. See Dry Well Sensitivity Section.

If problems persists, please verify supply capacity.

The controller will automatically restart according to the chart below.

Dry Well Fault Reset table:

Fault 1 (Start Point) - resets after 1 minute

Fault 2 - resets after 10 minutes

Fault 3 - resets after 20 minutes

Fault 4 - resets after 30 minutes

Fault 5 - resets after 60 minutes

Will repeat every 60 minutes, when the system cycles Off the

Dry Well will default back to the start point.

Controller Status

Controller Action

To clear the fault, turn off

power to the controller, wait

1 minute, turn on power to

the controller. If fault persists

contact installer.

The controller will

automatically restart according

to the table shown on the right.

If fault persists contact installer.

Fault Description

personnel only.

Table 6: Fault Blink Codes (continued on next page)

10

WARNING

RED LIGHT CODES

Flashes Controller Status Description

3 Blinks Sensor Fault This fault can be caused by:

• Disconnected sensor. Disconnect sensor from sensor cable connector and

The controller will not run

if the signal from the

sensor is disconnected or out

of tolerance. The controller

will automatically restart when

the signal is within tolerance. If

fault persists contact installer.

reconnect to ensure a good connection.

• Disconnected sensor cable lead inside the controller. Check for loose wires

where the sensor cable connects to the circuit board by tugging on each wire.

• Broken wire in the sensor cable.

• Miswired sensor cable. Check that the wires are connected to the correct terminals on the sensor connector. The correct location of the wires is indicated

on the circuit board. B=Black, R=Red, W=White.

• Failed sensor. With the sensor cable connected to the circuit board, measure

the DC voltage between the black and white wires of the sensor cable at

the sensor connector. The voltage measured should be between 0.5Vdc and

4.5Vdc depending on the system pressure, see chart below.

• A vacuum on the sensor (transducer) of 17" Hg or more will cause a sensor

fault, eliminate the vacuum.

5

4.5

4

3.5

3

2.5

2

1.5

Transducer Output (Volts DC)

1

0.5

0

0 25 50 75 100 125 150 175 200

Sensor Output vs. Applied Pressure

Pressure (PSI)

100 PSI Sensor

200 PSI Sensor

4 Blinks Pump or Motor Bound This fault can be caused by:

• Installing a 1Ø motor - system requires a 3Ø, 200 or 230 V motor.

• Mechanical binding from debris in pump.

• Electrical failure of the motor.

• Incorrect setting of “MOTOR OVERLOAD SETTING (SFA)” switch.

A false “bound pump” error will be displayed if the switch is set too low.

Verify the error by turning power to controller off for 1 minute and then on.

The controller will try to restart the

motor three times before displaying

this fault. To clear the fault, turn off

power to the controller, wait 1 minute, turn on power to the controller.

If fault persists contact installer.

Pump/Motor must be checked if fault persists.

5 Blinks Short Circuit This fault can be caused by:

• Electrical failure of the motor.

• Electrical failure of wiring between controller and motor.

Verify the error by turning power to controller off for 1 minute and then on.

If error persists, motor and wiring between controller and motor must be

checked. Turn power off for 5 minutes. Remove the three motor wires from

the terminal block. Check wiring and motor for shorting phase to phase and

phase to ground. Refer to motor’s manual for information on resistance

readings.

If this fault is detected while

the pump is running, the

controller will attempt to restart

three times before displaying this

fault. To clear the fault, turn off

power to the controller, wait 1 minute, turn on power to the controller.

If fault persists contact installer.

6 Blinks Ground Fault This device does not provide personnel protection against

shock. This function is intended for equipment protection

only.

This fault can be caused by:

• Electrical failure of the motor

• Electrical failure of wiring between controller and motor.

• Miswiring of motor cable.

The controller will not restart

if displaying this fault. To clear

the fault, turn off power to the

controller, wait 1 minute, turn

on power to the controller. If

fault persists contact installer.

Verify the error by turning power to controller off for 1 minute and then on.

If error persists, motor and wiring between controller and motor must be

checked. Turn power off and wait 5 minutes. Remove the three motor wires

and ground wire from the terminal block. Check wiring and motor for

shorting phase to ground using a megohmmeter (“megger”). A reading less

than 200K Ohms indicates faulty insulation in the motor cable or motor.

Test each to determine fault location.

Table 6: Fault Blink Codes (continued on next page)

11

ITT

CentriPro

Flashes Controller Status Description

7 Blinks Temperature This fault can be caused by:

• High ambient temperature. The maximum ambient temperature

rating is 122º F (50º C).

• Low ambient temperature. The minimum ambient temperature

rating is -4º F (-20º C).

Check for a fan failure. The fan will turn on when the temperature

inside the controller reaches 140º F (60º C). The fan will turn on for

1 second each time the controller starts the motor. If the fan never

turns on, check fan connections and replace as needed. Ensure that

the external fan intake filter is not blocked or clogged. It can be

removed for cleaning and replacements are available.

8 Blinks Open Lead This fault can be caused by:

• Disconnected or broken wire between the controller and motor.

Verify the error by turning power to controller off for 1 minute and

then on. If error persists, motor and wiring between controller and

motor must be checked. Turn power off for 5 minutes. Remove the

three motor wires from the terminal block. Using an ohmmeter,

measure the resistance from phase to phase. A disconnected or

broken wire will be indicated by a high resistance reading (20 ohms

or higher).

9 Blinks Broken Pipe This fault can be caused by:

• Pressure 20 PSI below set point for 30 seconds. May be a broken

pipe or tripped pressure relief valve. If 20 PSI or more pressure

drop for 30 seconds is normal for the system, switch the broken

pipe protection off or change system to prevent the pressure drop.

The controller will auto-

matically restart when the

temperature reaches an

acceptable level. If fault

persists contact installer.

The controller will not

restart if displaying this

fault. To clear the fault, turn

off power to the controller,

wait 1 minute, turn on pow-

er to the controller. If fault

persists contact installer.

The controller will not

restart if displaying this

fault. To clear the fault, turn

off power to the controller,

wait 1 minute, turn on pow-

er to the controller. If fault

persists contact installer.

Table 6: Fault Blink Codes (continued from previous page)

Residential & Commercial Water Systems

RED LIGHT CODES

This warranty applies to the Balanced Flow Series Controller manufactured by CentriPro.

Any part or parts found to be defective within the warranty period shall be replaced at no charge to the dealer during the warranty period. The warranty pe-

riod shall exist for a period of twenty-four (24) months from date of installation or thirty (30) months from date of manufacture, whichever period is shorter.

A dealer who believes that a warranty claim exists must contact the authorized CentriPro distributor from whom the equipment was purchased and furnish

complete details regarding the claim. The distributor is authorized to adjust any warranty claims utilizing the CentriPro Customer Service Department.

The warranty excludes:

(a) Labor, transportation and related costs incurred by the dealer; (d) Consequential damages of any kind; and,

(b) Reinstallation costs of repaired equipment; (e) Reimbursement for loss caused by interruption of service.

(c) Reinstallation costs of replacement equipment;

For purposes of this warranty, the following terms have these definitions:

(1) “Distributor” means any individual, partnership, corporation, association, or other legal relationship that stands between CentriPro and the dealer in

purchases, consignments or contracts for sale of the subject equipment.

(2) “Dealer” means any individual, partnership, corporation, association, or other legal relationship which engages in the business of selling or leasing equip-

ment to customers.

(3) “Customer” means any entity who buys or leases the subject equipment from a dealer. The “customer” may mean an individual, partnership, corporation,

limited liability company, association or other legal entity which may engage in any type of business.

CentriPro and the ITT Engineered Blocks Symbol are

registered trademarks and tradenames of ITT Corporation.

SPECIFICATIONS ARE SUBJECT TO CHANGE WITHOUT NOTICE.

CENTRIPRO LIMITED WARRANTY

THIS WARRANTY EXTENDS TO THE DEALER ONLY.

®

IM182 Revision 12 February, 2010

Copyright (c) 2010 ITT Corporation

Engineered for life

ITT

CentriPro

Sistemas de Residential y Commercial Water

CentriPro

BALANCED FLOW® CONTROLADOR DE

BOMBA SUMERGIBLE

Manual de instalación, operación y localización de fallas

CentriPro es una marca de

fábrica de ITT Corporation.

www.goulds.com

Engineered for life

®

Información del propietario

Información del propietario

Índice

Índice

Número de modelo del controlador:

Número de serie del controlador:

Número de modelo de la bomba:

Número de serie de la bomba:

Número de modelo del motor:

SFA del motor:

Número de serie del tanque:

Comerciante:

Nº telefónico del comerciante:

Fecha de instalación:

Longitud de los cables (pies)

Entrada de servicio al controlador:

Controlador al pozo:

Superficie del pozo al motor:

Voltaje de entrada:

ATENCIÓN: REGISTRE EL NÚMERO DE LOS MOD-

ELOS Y LOS NÚMEROS DE SERIE DE

LA BOMBA Y EL CONTROLADOR DE

ESTE MANUAL DE INSTRUCCIONES

PARA REFERENCIAS FUTURAS.

DÉSELO AL PROPIETARIO O FÍJELO

AL CONTROLADOR CUANDO HAYA

CONCLUIDO LA INSTALCIÓN.

TEMA PÁGINA

1. Instrucciones de seguridad .........................................15

Generalidades .........................................................15

Instalación típica .......................................................15

Potencia de servicio ...................................................16

Materiales necesarios ................................................16

2. Instalación ...............................................................16

Controlador .............................................................16

Montaje del controlador ............................................16

Bomba y tubería .......................................................16

Empalme del cable de bajada con los conductores

del motor ............................................................17

Cableado del transductor de presión .......................17

Cables del motor ...................................................... 17

Corriente de entrada ...............................................17

3. Selecciones de prearranque del instalador ...............18

Configuración y protección del motor.....................18

Protección con límite actual ....................................18

Ajuste de presión ....................................................18

Entrada del interruptor ........................................... 19

Placa de interfaz del usuario ....................................21

4. Resolución de problemas ...................................23-25

Garantía limitada .........................................................26

Los terminales de agua y los motores CentriPro incluyen estas etiquetas de datos adicionales. Colóquelas en la cubierta

interna del Controlador de flujo equilibrado para una futura identificación de la bomba y el motor.

®

Bomba sumergible

33GS15

www.goulds.com

CentriPro

Motor: M30432/300C313

3,00 HP

FLA: 9,2 SFA: 10,1 LRA: 59

SF: 1,15 Hz: 60

Voltios: 230 PH: 3

LE PEDIMOS QUE USE EL MANUAL DE INSTALACIÓN, OPERACIÓN Y RESOLUCIÓN DE PROBLEMAS

(IOM) DE ESTE CONTROLADOR JUNTO CON EL IOM DE LA BOMBA. EL IOM DEL CONTROLADOR

ABARCA LA INSTALACIÓN ELÉCTRICA DEL CONTROLADOR Y CUALQUIER PROCEDIMIENTO

ESPECIAL DE INSTALACIÓN REQUERIDO CON CONTROLADORES DE VELOCIDAD VARIABLE.

ITT NO SERÁ RESPONSABLE DE NINGÚN DAÑO PRODUCIDO EN UNA INSTALACIÓN DONDE SE

PERMITA QUE LA VÁLVULA DE ALIVIO DE PRESIÓN SE DESCARGUE EN UN ESPACIO HABITABLE

TERMINADO O SE DAÑE DE ALGÚN OTRO MODO LA PROPIEDAD DE UN CLIENTE. LOS DISPOSITIVOS DE SEGURIDAD DE PLOMERÍA COMO VÁLVULAS DE ALIVIO DE PRESIÓN A UN DRENAJE APROPIADO SON RESPONSABILIDAD DEL INSTALADOR Y ESTÁN FUERA DE NUESTRO CONTROL.

14

ADVERTENCIA

ADVERTENCIA

PELIGRO

ADVERTENCIA

CUIDADO

ADVERTENCIA

ADVERTENCIA

1: INSTRUCCIONES DE SEGUIRDAD

ADVERTENCIA

1: INSTRUCCIONES DE SEGURIDAD

PARA EVITAR LESIONES PERSONALES GRAVES O

FATALES O DAÑOS SIGNIFICATIVOS A LA PROPIEDAD,

LEA Y RESPETE TODAS LAS INSTRUCCIONES DE

SEGURIDAD EN EL MANUAL Y EN EL EQUIPO.

LA FINALIDAD DE ESTE MANUAL ES AYUDAR EN LA

INSTALACIÓN Y OPERACIÓN DE ESTA UNIDAD Y SE

DEBE GUARDAR EL MISMO CON LA UNIDAD.

Este es un SÍMBOLO DE ALERTA DE

SEGURIDAD. Cuando vea este símbolo en

la bomba en el controlador o en el manual,

busque una de las siguientes palabras de

señal y esté alerta ante la posibilidad de

lesiones personales o daños materiales.

Advierte los peligros que CAUSARÁN

lesiones corporales graves, la muerte o

daños materiales importantes.

Advierte los peligros que PUEDEN causar

lesiones corporales graves, la muerte o

daños materiales importantes.

Advierte acerca de riesgos que PUEDEN

causar lesiones corporales o daños

materiales.

AVISO: INDICA QUE EXISTEN INSTRUCCIONES

ESPECIALES QUE SE DEBEN SEGUIR YA

QUE SON MUY IMPORTANTES.

EXAMINE MINUCIOSAMENTE TODAS LAS INSTRUCCIONES Y ADVERTENCIAS ANTES DE REALIZAR ALGÚN TRABAJO EN ESTE CONTROLADOR.

MANTENGA TODAS LAS CALCOMANÍAS DE

SEGURIDAD.

INSTALACIÓN TÍPICA

INSTALACIÓN TÍPICA

11

20

9

Este controlador no fue diseñado para utilizarse cerca de albercas, cuerpos abiertos de

agua, líquidos peligrosos ni donde existan gases inflamables.

No usar potencia de entrada GFCI. Esto

provocará fallas molestas.

Desconecte y bloquee la energía eléctrica

antes de instalar o realizar servicios en algún

equipo eléctrico.

PELIGRO DE ELECTROCUCIÓN. EL

TERMINAL DE CONEXIÓN A TIERRA

(GND) DE LA ENTRADA DEL CONTROLADOR Y

TODAS LAS TUBERÍAS DE METAL EXPUESTAS, LO

QUE INCLUYE LA CAJA DEL TRANSDUCTOR DE

PRESIÓN, DEBEN ESTAR CONECTADOS AL TERMINAL DE CONEXIÓN A TIERRA DE LA ENTRADA DE

SERVICIO.

Un técnico calificado debe encargarse de realizar

todos los trabajos eléctricos. Siempre cumpla

con las normas del National Electrical Code [Código oficial

estadounidense para instalaciones eléctricas] (NEC), o el Canadian Electrical Code [Código canadiense para las instalaciones

eléctricas], al igual que con todos los códigos nacionales, estatales

y provinciales. Las preguntas acerca de los códigos deberán

remitirse al inspector electricista de su zona. El incumplimiento

de los códigos de electricidad y las normas de seguridad OSHA

puede causar lesiones corporales o daños al equipo. El incumplimiento de las instrucciones de instalación establecidas por

el fabricante puede producir una descarga eléctrica, peligro de

incendio, lesiones corporales o la muerte, daños en el equipo,

desempeño deficiente y pueden anular la garantía del fabricante.

AVISO: Algunas instalaciones hacen vacío en el transductor

cuando se drena el sistema. El nuevo controlador está

diseñado para proteger contra un máximo de 17” Hg.

de vacío en el transductor. Un Protector de indicadores

opcional, no. de pedido 6K210, protege

el transductor contra el vacío.

17

13

16

15

10

4

12

19

14

7

8

DESCRIPCIÓN DE LAS PIEZAS:

1) Bomba y motor 10) Cable de suministro de energía

2) Válvula de control 11) Entrada del servicio

(incorporada en 12) Cable sensor de presión con

algunos modelos) bucle de goteo

3) Limitador de torque (opcional) 13) Tanque de diafragma

4) Cable de energía de la bomba 14) Transductor de presión

con juego de empalme 15) Manómetro

5) Cinta aislante (cable a tubería) 16) Válvula de seguridad

6) Cuerda de seguridad 17) Válvula de cierre

(opcional) 18) Tubería de descarga

7) Tapa / sello del pozo 19) Tubería lateral

8) Adaptador sin agujero

9) Controlador 20) Desconexión eléctrica

6

5

18

4

3

2

1

15

Clasificaciones

ADVERTENCIA

ADVERTENCIA

Consulte la etiqueta con el número de serie en la caja.

Materiales requeridos

• Controlador de bomba BF con transductor y cable de

transductor

• Bomba (terminal de agua) (ver interruptor de selección de

velocidad para una operación de 60 Hz u 80 Hz)

• Motor: 230 V, trifásico (3Ø), 3450 RPM

• Válvula de alivio de presión – conectada a un drenaje por

cuestiones de seguridad

• Indicador de presión – para establecer la presión del sistema

• Kit de termocontracción – se exige uno por cada empalme

submarino o subterráneo (obligatorio)

• Conexión en T para el tanque o (2) accesorios hembra para

tubería de ¼" NPT para conexiones del sensor de presión y

el indicador de presión.

• Tubería y accesorios – según sea necesario para cada sistema

• Interruptor de desconexión: 230 V, 2 polos, de tamaño

correcto ((ver Tabla de tamaños de controlador, disyuntor y

generador)

• Cable de cobre: Como mínimo un cable certificado para

soportar hasta 75°C, se recomienda que sea de doble

camisa, pero no es obligatorio (ver Tabla de tamaños de

cables)

• Tanque: tanque de diafragma

(Ver la Sección y el Cuadro de Tamaños de tanques)

2: INSTALACIÓN

2: INSTALACIÓN

Determinar dónde estarán ubicados el Controlador, el

Tanque de presión y el Transductor antes de comenzar la

instalación.

Controlador

El controlador está clasificado como NEMA 3 R (a prueba

de lluvia), por lo que puede ser colocado en el exterior. Debe

montarse en posición vertical. Ubique la caja en un área

sombreada donde la temperatura se mantenga en un rango

de 0°F a +122°F (-18°C a +50°C). Dado que el controlador

está diseñado para ser montado en el exterior, puede estar

ubicado en la cabeza del pozo.

Cómo abrir la cubierta del controlador

PRECAUCIÓN

remover el tornillo de la cubierta. De no hacerlo, la unidad

puede caerse y dañarse. Una vez removido el tornillo, levante

la cubierta hacia arriba y hacia afuera para removerla. Hay

una pestaña de cierre en la parte inferior de la unidad para

colocar un candado si usted lo desea.

Coloque el controlador en una superficie

plana o cuélguelo de una pared antes de

Montaje del controlador

Se suministran tres tornillos para montar la caja.

Usando la caja como guía, seleccione una ubicación de

montaje. Primero instale el tornillo superior en la superficie

de montaje dejando la cabeza del tornillo a aproximadamente

1/8” de la superficie. Cuelgue la caja de este tornillo. Finalice

la tarea instalando los dos tornillos inferiores y ajustando el

tornillo superior. Asegúrese de dejar un mínimo de 6” de

espacio libre a cada lado del controlador para garantizar una

refrigeración correcta.

Bomba y tubería

No instale válvulas, dispositivos de control

de flujo o filtros entre el transductor

de presión y la bomba. Está permitido hacer correr

derivaciones de la tubería entre la bomba y el transductor

siempre y cuando no haya dispositivos de restricción de

flujo entre la bomba y el transductor.

AVISO: Los términos Transductor y Sensor de presión son

sinónimos e intercambiables.

LA EXPLOSIÓN DE UN TANQUE PUEDE

PROVOCAR LESIONES O LA MUERTE.

Siempre proteja el tanque de sobreexposición instalando

una válvula de alivio de presión que sea lo suficientemente

grande como para limitar la presión del sistema por debajo

de la presión efectiva máxima del tanque. Instale el tanque

en un punto del sistema en que la presión máxima posible

del sistema no pueda exceder la presión efectiva máxima del

tanque. Instale la válvula de alivio de presión en el tanque.

PRECAUCIÓN

Evite daños a la propiedad causados por la

abertura de la válvula de alivio de presión.

Entube la descarga de la válvula de alivio de presión a

un drenaje u otro lugar, de modo de evitar daños a la

propiedad e inundaciones.

PRECAUCIÓN

Ubique el tanque y el transductor en donde

no se puedan llegar a congelar.

Asegúrese de que la configuración de la presión del sistema

no exceda la presión efectiva máxima del tanque.

Para un desempeño óptimo, recomendamos usar como

mínimo una tubería del mismo tamaño que la descarga de

la bomba entre la bomba y el tanque. Una tubería de menor

diámetro puede limitar severamente la capacidad máxima

del sistema. En recorridos largos, una tubería de mayor

tamaño puede ser beneficiosa para un desempeño y un flujo

óptimos.

PRECAUCIÓN

Si utiliza un limitador de torque, instálelo en

la tubería de descarga antes de conectar la

tubería al cabezal de descarga.

Recomendaciones sobre el tamaño del tanque de diafragma y

la presión preestablecida:

En estos sistemas, se requieren tanques de diafragma (aire

cautivo).

Tabla 1: Selección de tamaños de tanque

GPM máximo

de la bomba

10 2 V6P TP6P

23 4.5 V15P TP15P

41 8.2 V25P TP25P

70 13.9 V45 TP45

100 19.9 V60 TP60

Use el Volumen total del tanque, no el volumen de vaciado,

para seleccionar el tamaño de tanque correcto. El volumen

total del tanque debe ser aproximadamente el 20% del

flujo máximo de la bomba. Por ejemplo, cuando se usa

una bomba de 10 gpm, el sistema requiere un tanque de 2

galones (volumen total).

Se ha verificado en el campo que las recomendaciones sobre

el tamaño del tanque previenen caídas de presión objetables

en el arranque y logran una operación libre de problemas

para la gran mayoría de los sistemas de bombas de velocidad

variable.

Tanques recomendados

Volumen total No. de pedido o No. de pedido

16

Para una configuración con una caída de presión

ADVERTENCIA

de 5 PSI:

Configure la presión del tanque, mientras el tanque esté

vacío de agua, 20 psi por debajo de la configuración deseada

de la presión del sistema. Por Ej., para una presión de

sistema de 50 psi, cargue el tanque hasta 30 psi.

Para una configuración con una caída de presión

de 20 PSI:

Comience con la carga previa del tanque 30 psi por debajo

del punto fijado, es posible que esta configuración necesite

ajustes menores para un desempeño óptimo, ya que todos

los sistemas y las tuberías son ligeramente diferentes.

Empalme del cable de bajada con los conductores

del motor

La conexión subacuática en la que el cable de bajada se

conecta con los cables del motor se debe realizar utilizando

un kit de termocontracción a prueba de agua. Para realizar

la conexión, pele los cables ½" y coloque los tubos de

termocontracción sobre los cables. Luego, conecte los cables

usando los terminales eléctricos. Finalice colocando los

tubos de termocontracción por encima de los terminales y

calentando del centro hacia afuera. El sellador en el tubo

fluirá hacia los extremos formando un sello a prueba de agua.

Si el tubo de termocontracción se quema o se parte, será

necesario volver a realizar la conexión.

PRECAUCIÓN

motores de velocidad variable debido al alto potencial de

pérdidas a tierra a través de uniones encintadas. Si no se

utiliza un kit de termocontracción a prueba de agua, se

invalidará la garantía.

Antes de instalar el motor en el pozo, el cable de bajada debe

ser conectado a los cables del motor. Consulte el cuadro de

tamaño de cables al seleccionar el tamaño de cable para el

cable de bajada. Ver Tabla de tamaños de cables.

La cinta aisladora no es aceptable para

empalmes subacuáticos cuando se utilizan

transductor. Es necesario que los últimos pies del conducto

hasta el transductor sean flexibles. El conducto debe tener

buen soporte: NO se puede ejercer presión sobre el conector

del transductor. Utilice una boquilla del relevador de tensión

para sellar alrededor del conector del transductor de presión.

PRECAUCIÓN

y el terminal de conexión a tierra, tire de cada cable

individualmente para asegurarse de que estén bien ajustados.

PRECAUCIÓN

contar con conexión a tierra a la entrada de servicio, según

NFPA 70: Código Nacional de Electricidad, Artículo 250.

El cable del transductor viene con un cable a tierra Verde y

una abrazadera de conexión a tierra para facilitar la tarea de

conectar el transductor a tierra. Ver Figura 1.

Después de reconectar los cables del

transductor al bloque de terminales

Todo metal expuesto en las tuberías del

sistema, incluida la caja del transductor, debe

Cables del motor – Vea la tabla 4

AVISO: ES OBLIGATORIO USAR CABLE DE COBRE DE

UN MÍNIMO DE 75°C

Consulte la Tabla 4 para ver los tamaños de cable y las longitudes máximas de cables. Los cuadros están diseñados para

limitar la caída de voltaje a un 5%.

Elija el tamaño del cable para las peores situaciones (baja

tensión) y manténgase dentro de las recomendaciones de los

cuadros. Asegúrese de que el cable esté clasificado para un

entierro directo y/o para ser sumergido.

Cableado del transductor de presión

PRECAUCIÓN

ergía. Siempre debe haber un mínimo de 12” entre los cables

de transductor y los cables de energía. La falta de separación

de estos cables puede causar defectos de funcionamiento en el

controlador.

El cable del transductor de presión es precableado en fábrica.

Si usted lo desea, se puede modificar la longitud del cable.

También se puede colocar el cable en un conducto para protegerlo contra daños.

Para cambiar la longitud del cable del transductor:

• La longitud del cable no puede superar los 200'.

• Desconecte los cables del transductor del bloque de terminales presionando hacia abajo las pestañas en la parte

trasera del bloque de a una y sacando los cables del terminal.

• Empalme el cable adicional al cable del transductor, corte el

exceso según se requiera.

• Reconecte cables al bloque de terminales. Asegúrese de que los

colores de los cables correspondan a las etiquetas en la placa

de circuito (B = negro, R = rojo, W = blanco).

Para colocar el cable del transductor en un conducto, haga

lo siguiente: Desconecte el cable del bloque de terminales

y remueva el relevador de tensión del cable de la parte

inferior de la caja. Comenzando por la caja, lleve el conducto

flexible o rígido de ½" hasta el lugar en el que está ubicado el

Los cables del transductor nunca deben estar

en el mismo conducto con otros cables de en-

Figura 1: Conexión a tierra del transductor

La Figura 2 muestra el bloque de terminales donde se

conectan el motor y los cables de entrada. La cubierta protectora en el bloque de terminales se quita y se coloca a presión.

Unir los cables del motor con los terminales según los colores

marcados en la placa de circuito: GND = Verde, RED =

Rojo, BLK = Negro, YEL = Amarillo. Revertir dos conductores cualesquiera en RED/BLK/YEL cambiará la dirección de

rotación del motor. Luego durante el arranque es posible que

tenga que cambiar la rotación del motor.

Corriente de entrada

PELIGRO DE DESCARGA O ELECTROCUCIÓN

Conecte un cable a tierra del panel de servicio al terminal

marcado GND. El controlador tiene una alta fuga de corriente a tierra. El terminal a tierra del controlador debe estar

conectado al terminal de conexión a tierra de la entrada de

servicio. De no ser así, habrá un alto voltaje en el chasis del

controlador. Conecte dos cables “calientes” del disyuntor de

2 polos a los terminales marcados L1 y L2.

El sistema de corriente de entrada debe ser un sistema eléctrico con conexión a tierra. El voltaje medido entre L1 y L2

debe estar en el rango de 196Vac a 265Vac. El voltaje medido

17

ADVERTENCIA

entre L1 y GND debe equivaler al voltaje medido entre L2 y

GND. Estos voltajes deben estar dentro del rango de 120Vac

+/- 10%. Un voltaje de entrada reducido reducirá el rendimiento del sistema.

No use un Interruptor de Circuito de Fuga a Tierra

(GFCI, por su sigla en inglés) con este producto, ya que se

produciría una disyunción molesta.

Corriente de entrada

Figura 2: Conexiones de cableado

AVISO: PUEDE SER NECESARIO COLOCAR UN IN-

TERRUPTOR DE DESCONEXIÓN FRENTE A

Y A LA VISTA DEL CONTROLADOR: CONSULTE LOS CÓDIGOS LOCALES.

3. SELECCIONES DE PREARRANQUE DEL

3: SELECCIONES DE PREARRANQUE DEL

INSTALADOR

INSTALADOR

Cables al motor

CONFIGURACIÓN Y PROTECCIÓN DEL

MOTOR

Interruptor de frecuencia (velocidad) máxima

El interruptor de Frecuencia máxima establece la frecuencia

máxima (velocidad del motor) que el controlador usa para

dar energía al motor a 60 u 80 Hz.

• 60 Hz - Usada para combinaciones de bomba-motor en

las que el HP del motor y el HP de la bomba son iguales.

Por ejemplo: WE de 2 HP y motor de 2 HP

• 80 Hz - Usada para kits combinaciones de bomba-motor

en las que el HP del motor es mayor que el HP de la

bomba (generalmente el doble). Ejemplo: WE de 1 HP y

motor de 2 HP

• La unidad está preconfigurada en fábrica a 60 Hz.

Sensibilidad a pozo seco

Las selecciones son Alta o Baja. Esta función protege

al sistema de operar en seco. La selección depende de

diversas condiciones y del tamaño de la bomba.

Comience con la sensibilidad en alta y pruébela haciendo

funcionar la bomba con distintos flujos. Si salta una falla

por pozo seco, seleccione sensibilidad baja. La unidad

está preconfigurada en fábrica con la sensibilidad alta.

Los tiempos de reinicio en minutos son: 1, 10, 20, 30,

60, 60 y repitiendo cada 60 minutos a partir de ese

momento.

Ejemplo: La primera falla apaga el sistema por 1 minuto,

la siguiente falla lo apaga por 10 minutos, luego 20, etc.

Protección contra tuberías rotas

Posición de ENCENDIDO - Usada para sistemas a

presión constante. El motor se apagará si la presión

del sistema cae 20 PSI por debajo del punto de ajuste

de presión del sistema por un mínimo de 30 segundos.

Esta falla debe ser restablecida manualmente, no se

borrará automáticamente, esto puede prevenir daños a la

propiedad si se rompe una tubería.

Posición de APAGADO - Use esta posición para

18

situaciones de descarga abierta como la purga de un

tanque, el llenado de un pozo o tanque, o en casos en los

que la presión del sistema vaya a estar 20 PSI o más por

debajo del punto de ajuste de presión del sistema.

Caída de presión – 5 PSI o 20 PSI

La caída de presión antes de que la bomba se reinicie se

puede configurar en el estándar de 5 PSI o en 20 PSI.

La configuración de 20 PSI provoca menos arranques

en sistemas con pérdidas. Se recomienda para sistemas

de irrigación. Requerirá un ajuste del tanque previo a la

carga. Ver Tamaños de tanques.

PROTECCIÓN CON LÍMITE ACTUAL

Indicador de configuración de sobrecarga del

motor

Si no se ajusta correctamente la Configura-ción de

sobrecarga del motor antes de aplicar

energía, se pueden provocar daños al motor

o el cable y así invalidar la garantía.

• Use la Tabla 2 para determinar qué controlador y qué

configuración utilizar. Tenga en cuenta que algunos

motores de 200V requieren el uso de un controlador que

sea un tamaño más grande.

• Configure la sobrecarga del motor - Gire la aguja del

indicador para que quede alineada con el amperaje de

factor de servicio (SFA) del motor según lo indicado en

la cuadro de Sobrecarga del motor / Límite actual. Elija

el valor de amperaje del cuadro de Configuración de

límite actual en UIB que esté más cerca del SFA que figura

en la placa de identificación del motor, pero que no sea

superior a él.

• Consulte la Tabla 3 o la placa de identificación del motor

para ver las clasificaciones de Amperaje del motor. El

controlador limita la corriente de salida hasta el valor

seleccionado por este indicador. Lo hace reduciendo la

frecuencia y el voltaje. Si la corriente no se encuentra

dentro del valor seleccionado cuando la frecuencia llega

a 40 Hz, el controlador apagará el sistema e indicará un

error de Bomba limitada (4 parpadeos rojos).

AJUSTE DE PRESIÓN

Botones pulsadores de ajuste de presión

Los botones pulsadores de INCREMENTAR y DISMINUIR

se usan para establecer la presión deseada. Para ajustar

la presión, presione y mantenga presionado (no dé un

golpecito) el botón hasta obtener la presión deseada. Puede

llevar un minuto entero ajustar la presión del máximo al

mínimo, así que le pedimos que tenga paciencia. La presión

solo se puede modificar cuando la bomba-el motor está

funcionando.

Indicador de estado del controlador (Luz visible a

través de la ventana en la cubierta)

La luz indicadora de estado del controlador tiene 3 modos posibles:

• Verde fijo = En modo de espera, la bomba no está en

funcionamiento. No hay flujo de agua o la ENTRADA

DEL INTERRUPTOR está abierta.

• Verde titilante = La bomba está funcionando. Existe

flujo (posiblemente una pérdida) y los terminales de la

ENTRADA DEL INTERRUPTOR están conectados entre

sí (cerrados).

• Rojo = Error/Falla. La luz titilará para indicar una falla

ADVERTENCIA

en particular. Consulte la Sección de Resolución de

problemas para ver los Códigos de fallas.

Purga del sistema

Abra una válvula y encienda el controlador. Si la presión del

sistema está por debajo de la configuración de presión preestablecida en fábrica (50 psi), la luz de estado comenzará a

titilar en color verde para indicar que la bomba está funcionando. El controlador zumba cuando está funcionando. Esto

es normal.

Es común que la bomba sufra un atascamiento por aire al

principio, especialmente en el caso de pozos superficiales.

De ser así, el controlador comenzará a buscar un pozo seco

(consulte la sección de resolución de problemas para obtener

una descripción de la Detección de pozo seco).

Una vez que el agua comience a fluir, asegúrese de abrir todas

las válvulas para purgar el aire del sistema.

Control de la rotación

Es posible que el motor esté rotando en la dirección con-

traria. La bomba funcionará, pero tendrá un

rendimiento muy reducido si rota al revés.

Para controlar la rotación, realice la siguiente prueba:

Conecte un amperímetro a uno de los cables de suminis-

tro eléctrico. Haga funcionar el sistema con varias válvulas

abiertas y observe la presión y el amperaje. Deje las válvulas

abiertas, apague la electricidad y espere 5 minutos para que se

descarguen los voltajes peligrosos.

Intercambie los conductores rojos y negros del motor en

el lugar en que se conectan con el bloque de terminales del

controlador (NO L1 y L2).

Vuelva a encender la electricidad y deje que se estabilice la

presión del sistema. Vuelva a observar la presión y el amperaje. La posición de cables que suministró la mayor presión/

flujo es la posición correcta de los cables. Si hubo poca diferencia en la presión/flujo, la posición con la menor lectura de

amperaje es la posición correcta.

Apague la electricidad, espere 5 minutos y vuelva a intercambiar los cables de ser necesario.

Reemplace las cubiertas protectoras de plástico del bloque de

terminales.

Búsqueda de pérdidas

Los sistemas de presión constante que utilizan tanques pequeños funcionan siempre que haya demanda. Aun pequeñas

pérdidas pueden evitar que una bomba se apague. Para buscar

pérdidas, cierre todas las válvulas, apague la electricidad del

controlador y observe la presión mostrada en el indicador de

presión. Dé un golpecito en el indicador para asegurarse de

obtener una lectura exacta.

Espere diez minutos y controle nuevamente el indicador

dando un golpecito para evitar que la aguja se pegue. Si la

presión cayó, es posible que el sistema tenga una pérdida*.

*Si un sistema es presurizado después de haber sido despresurizado, seguirá expandiéndose durante varios minutos. Esta expansión hace que la presión caiga y puede ser

malinterpretada como una pérdida. Permita que el sistema

se estabilice por 10 minutos bajo presión antes de realizar la

prueba de pérdida mencionada anteriormente.

Una válvula de verificación de resorte colocada en el lado

del tanque y el transductor que alberga la bomba a menudo

mejorará la capacidad del sistema de apagarse.

ENTRADA DEL INTERRUPTOR

Entrada del interruptor y luz de estado de la

entrada del interruptor opcionales

Conéctese a www.centripro.com, haga clic en Goulds

Pumps o Red Jacket, haga clic en Electrical Controls Water,

y luego en Balanced Flow para obtener ejemplos más

detallados de cómo usar la Entrada del interruptor.

PELIGRO

cidad al controlador o cualquiera de sus salidas. Siempre

manipule los terminales de cables de este controlador como

si tuvieran electricidad hasta que hayan pasado 5 minutos

desde que se quitó la fuente de energía del controlador.

ENTRADA DEL INTERRUPTOR - para la conexión de

un interruptor o un dispositivo de control externo utilizado

para arrancar y detener la bomba. Se pueden conectar

dispositivos como un interruptor de sobrepresión, un

interruptor de nivel (flotador) o cualquier otro interruptor

sin alimentación (temporizador, flujo, etc.) a esta entrada.

Los terminales de Entrada del interruptor vienen con un

Cable de acoplamiento instalado en fábrica (no confunda

el cable de acoplamiento en la entrada del interruptor con

el Puente de conexión del transductor que está al lado de