INSTRUCTION MANUAL

IM132

RSPA (FSPA) & RJSP

Self-Priming Centrifugal Pumps

INSTALLATION, OPERATION AND MAINTENANCE INSTRUCTIONS

Table of Contents

Table of Contents

SUBJECT PAGE

Safety Instructions ....................................................................................................................................................... 3

Description and Specifications ..................................................................................................................................... 3

Piping Suction .............................................................................................................................................................3

Piping Discharge..........................................................................................................................................................3

Wiring and Grounding ................................................................................................................................................3

Rotation ......................................................................................................................................................................4

Operation ....................................................................................................................................................................4

Maintenance................................................................................................................................................................4

Disassembly ..........................................................................................................................................................4 & 7

Reassembly ...........................................................................................................................................................5 & 7

Troubleshooting ..........................................................................................................................................................5

Electrical Data ............................................................................................................................................................. 6

Repair Parts ..........................................................................................................................................................6 & 8

Engineering Data ......................................................................................................................................................... 6

Red Jacket Water Products Limited Warranty .............................................................................................................. 9

Español instrucciones ...........................................................................................................................................10-18

Version française ..................................................................................................................................................19-28

2

WARN ING

Hazardous voltage

can shock, burn or

cause death.

DANGER

CAUTION

Hazardous fluids can

cause personal injury

or property damage.

WARNING

Safety Instructions

Safety Instructions

TO AVOID SERIOUS OR FATAL PERSONAL INJURY OR MAJOR PROPERTY DAMAGE, READ AND

FOLLOW ALL SAFETY INSTRUCTIONS IN MANUAL

AND ON PUMP.

This is a SAFETY ALERT SYMBOL. When

you see this symbol on the pump or in the

manual, look for one of the following signal

words and be alert to the potential for personal injury or property damage.

Warns of hazards that WILL cause serious

personal injury, death or major property

damage.

WARNING

NOTICE: Indicates special instructions which are very

important and must be followed.

THIS MANUAL IS INTENDED TO ASSIST IN THE

INSTALLATION AND OPERATION OF THIS UNIT

AND MUST BE KEPT WITH THE PUMP.

THOROUGHLY REVIEW ALL INSTRUCTIONS AND

WARNINGS PRIOR TO PERFORMING ANY WORK

ON THIS PUMP.

MAINTAIN ALL SAFETY DECALS.

NOTICE: INSPECT UNIT FOR DAMAGE AND

REPORT ALL DAMAGE TO THE CARRIER

OR DEALER IMMEDIATELY. DO NOT USE

PUMP IF DAMAGE IS SUSPECTED.

Warns of hazards that CAN cause serious

personal injury, death or major property

damage.

Warns of hazards that CAN cause personal

injury or property damage.

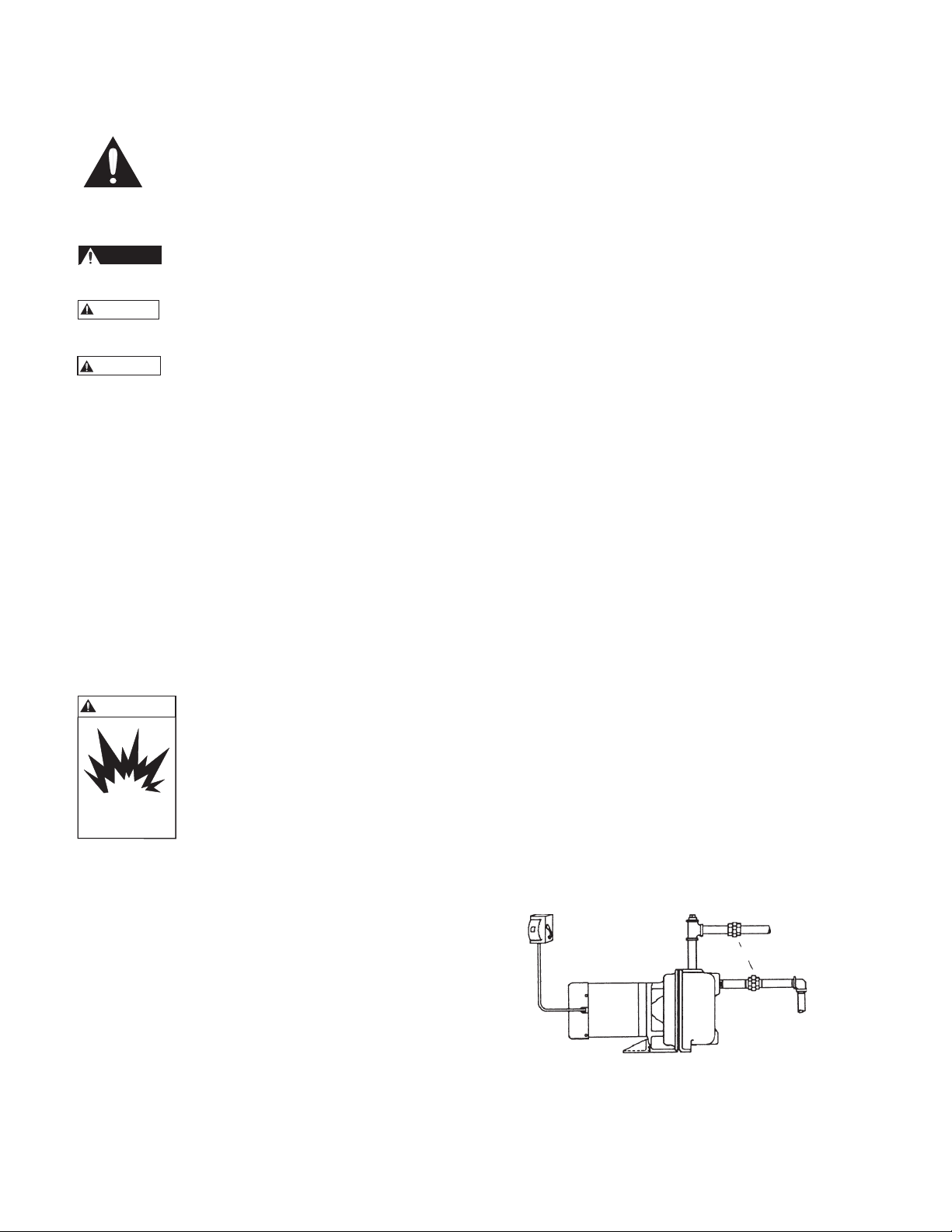

UNITS NOT DESIGNED FOR USE

WITH HAZARDOUS LIQUIDS OR

FLAMMABLE GASES.

Piping

Piping

• Pump MUST be installed horizontally on a solid flat

surface, with discharge on top.

• Allow adequate space for servicing and ventilation.

Protect the unit from weather and water damage due to

rain or flooding or freezing temperatures.

• Piping should be no smaller than the suction and dis-

charge connections and kept short as possible, avoiding

unnecessary fittings to minimize friction losses.

• All piping MUST be independently supported and

MUST NOT place any piping loads on the pump.

NOTICE: DO NOT FORCE PIPING INTO PLACE

AT PUMP SUCTION AND DISCHARGE

CONNECTIONS.

• All pipe joints MUST be airtight.

• The use of Teflon

for ALL pipe joints.

SUCTION

™

tape, or equivalent, is recommended

• Total suction lift, including elevation and pipe friction

loss, should not exceed 25 feet of head.

• Install an airtight union in the suction line close to the

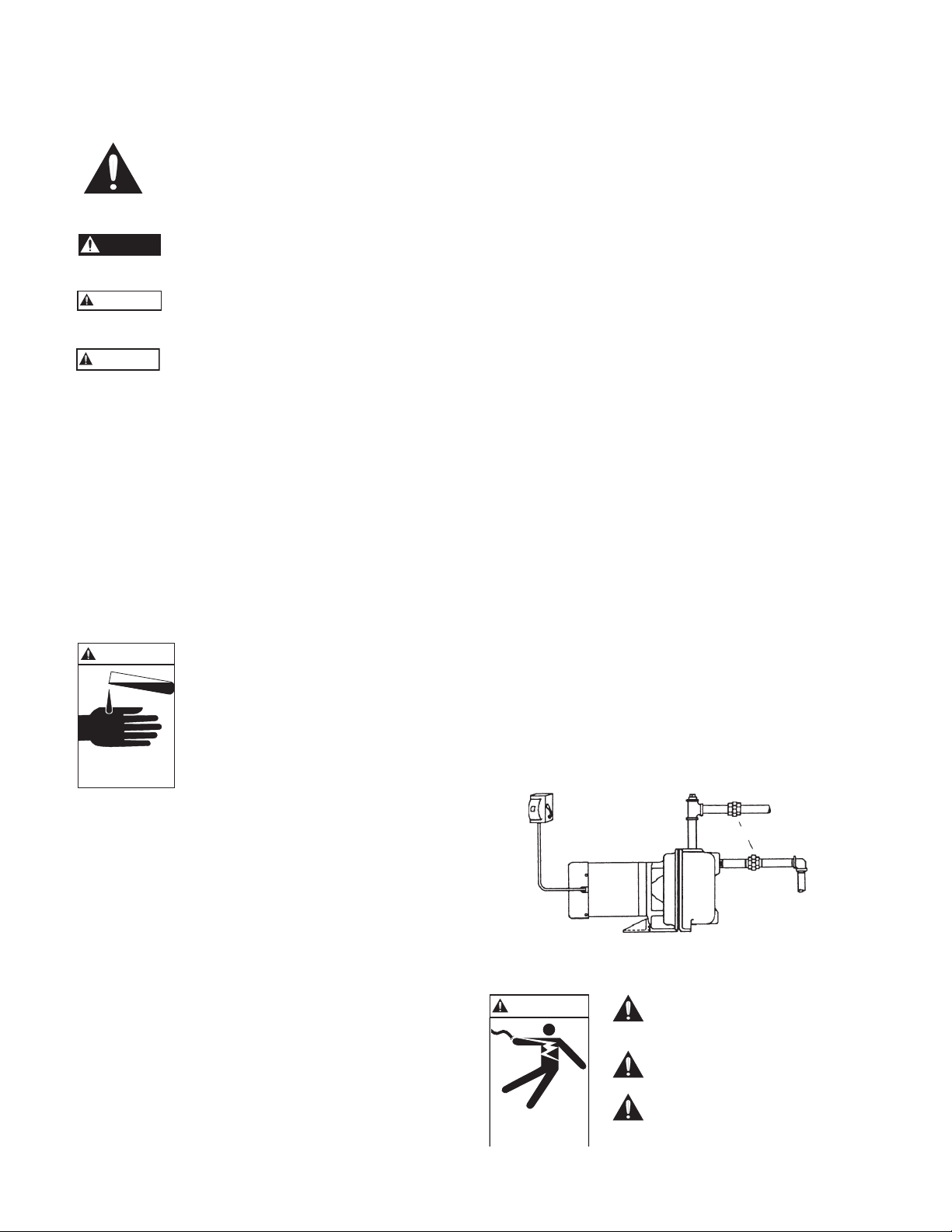

pump. See Figure 1.

• Installation of a foot valve at liquid source is recom-

mended.

NOTICE: FOR INSTALLATIONS WITH LONG

SUCTION PIPING, BOTH A FOOT VALVE

AND A CHECK VALVE ARE

RECOMMENDED.

• To avoid air pockets, no part of the piping should be

above the pump suction connection and piping should

slope upward from liquid source.

• For installations with long suction piping, fill the suction

pipe with water before connecting to pump.

DISCHARGE

• Install a tee at the discharge connection of the pump.

The top opening of the tee is required for initial priming.

See Figure 1.

Description and Specifications

• The RJSP and RSPA are end suction, single stage,

• Casing is cast iron construction with tapped openings

• Impellers are enclosed design, glass filled Noryl

• Standard motors are NEMA standard, 3500 RPM, open

• Maximum Liquid Temperature: 140ºF (60ºC)

• Maximum Starts per Hour: 20 – evenly distributed

Description and Specifications

self-priming centrifugal pumps for lawn sprinkling,

HVAC systems, and general water transfer.

provided for vacuum gauge and casing drain.

threaded directly on motor shaft.

drip proof enclosure.

™

PRIMING OPENING

DISCONNECT SWITCH DISCHARGE

UNION

SUCTION

,

Figure 1

Wiring and Grounding

Wiring and Grounding

Install, ground and wire according to local and National Electrical Code requirements.

Install an all leg electrical power

disconnect switch near the

pump.

Disconnect electrical power before installing or servicing pump.

3

Electrical supply MUST match pump’s name-

WARN ING

Hazardous voltage

can shock, burn or

cause death.

WARNING

Extreme heat can

cause personal injury

or property damage

WARN ING

Hazardous voltage

can shock, burn or

cause death.

plate specification. Incorrect voltage can cause

fire or damage to the motor and voids warranty.

Motors without built-in protection MUST be

provided with contactors and thermal overloads

for single phase motors, or starters with heaters

for three phase motors. See motor nameplate.

• Follow motor manufacturer’s wiring diagram on the

motor nameplate or terminal cover carefully.

• Use only copper wire to motor and ground. The ground

wire MUST be at least as large as the wire to the motor.

Wires should be color coded for ease of maintenance.

RECOMMENDED MINIMUM WIRE SIZE

Distance from Service Entrance to Motor

HP 50 Ft. (15 m) 100 Ft. (30 m) 150 Ft. (46 m) 200 Ft. (61 m)

115 V 230 V 115 V 230 V 115 V 230 V 115 V 230 V

¾ 12 14 10 14 8 14 6 12

1 12 14 8 14 8 12 6 12

1½ 10 14 8 14 – 12 – 10

2 10 14 8 14 – 12 – 10

3 – 12 – 12 – 10 – 10

WARNING

Hazardous

voltage

FAILURE TO PERMANENTLY

GROUND THE PUMP, MOTOR AND

CONTROLS BEFORE CONNECTING TO ELECTRICAL POWER CAN

CAUSE SHOCK, BURNS, OR DEATH.

Maintenance – All Models

Maintenance – All Models

FAILURE TO DISCONNECT

ELECTRICAL POWER BEFORE

ATTEMPTING ANY MAINTENANCE

CAN CAUSE SHOCK, BURNS OR

DEATH.

• No lubrication is required on pump.

For motor lubrication, refer to and

follow manufacturer’s instructions.

SEASONAL SERVICE

• To REMOVE pump from service, turn power off,

remove all drain plugs and drain all piping.

• To RETURN pump to service, replace all drain plugs

using Teflon™ tape or equivalent.

• Reconnect suction line if removed, examine union and

repair if necessary.

• Reprime and operate pump following all instructions

and warnings in the “OPERATION” section of manual.

Disassembly – RJSP

Disassembly – RJSP

FAILURE TO DISCONNECT

ELECTRICAL POWER BEFORE

ATTEMPTING ANY MAINTENANCE

CAN CAUSE SHOCK, BURNS OR

DEATH.

Rotation

Rotation

NOTICE: INCORRECT ROTATION MAY CAUSE

DAMAGE TO THE PUMP AND VOIDS THE

WARRANTY.

• Correct rotation is right hand, CLOCKWISE when

Operation

Operation

• Prime pump by filling pump and piping through

• Install pipe plug in top of tee using Teflon

NOTICE: IF PUMP IS DRAINED OR SHUT OFF

DURING PRIMING PERIOD, CASING

MUST BE REFILLED BEFORE

RESTARTING PUMP.

• Start the pump and partially open discharge valve and

viewed from the motor end.

OPERATION WITHOUT PRIME, OR

AGAINST A CLOSED DISCHARGE

VALVE, CAN GENERATE HOT WATER OR STEAM CAUSING INJURY

OR PROPERTY DAMAGE.

NOTICE: DO NOT OPERATE PUMP

WITHOUT PRIME OR SEAL

DAMAGE WILL RESULT.

opening in top of tee with clean water. See Figure 1.

™

tape or

equivalent.

wait for system pressure to stabilize. If system pressure is

surging, or prolonged pressure drop is experienced, the

system may not be completely primed.

1. Remove foot bolt (10).

2. Remove casing bolts (12).

3. Remove back pull-out assembly from casing (2).

4. Remove guidevane seal ring (3) and diaphragm (4).

5. Remove guidevane screws (5) from adapter (11).

6. Remove motor end plug or cover.

7. Restrain motor shaft from rotation by utilization of

the screwdriver slot, or 7⁄16" shaft flats, accessible at the

motor shaft end.

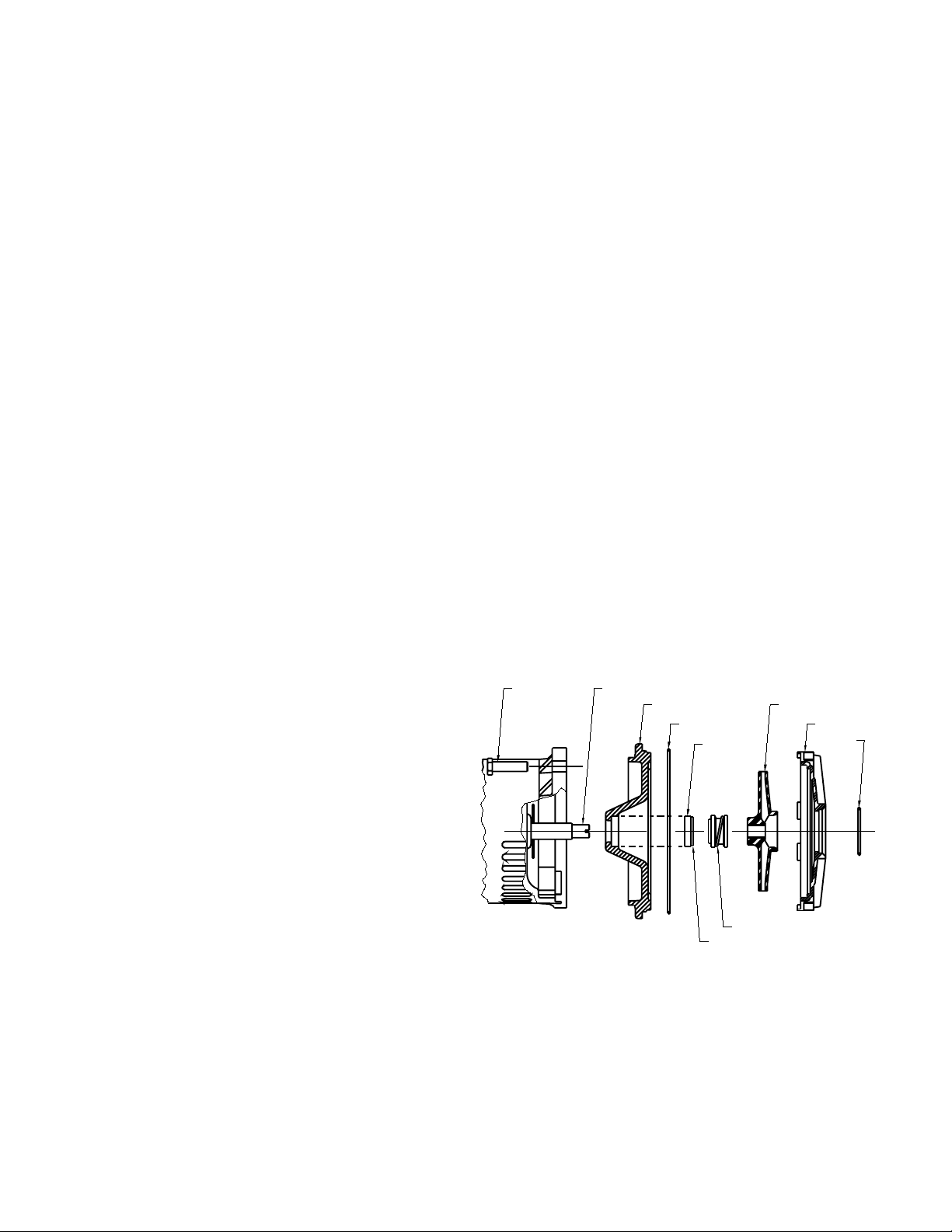

8. Remove impeller (7), turning COUNTER-

CLOCKWISE.

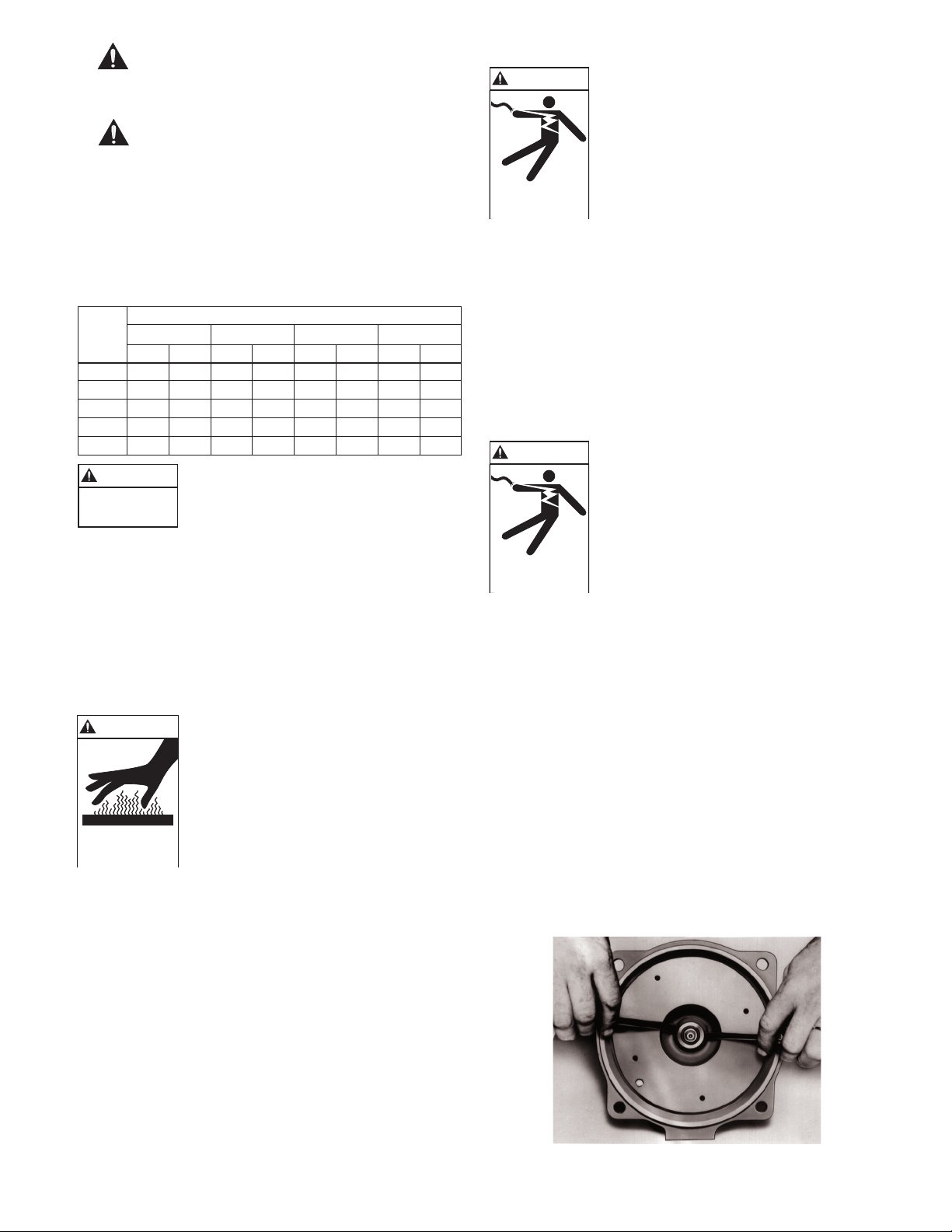

9. Using two screwdrivers, pry off rotary section of

mechanical seal (8). Discard. See Figure 2.

10. Remove motor adapter bolts (13) and remove motor

adapter from motor.

11. Push stationary seat of mechanical seal out of

motor adapter. Discard seal seat.

4

Figure 2

WARN ING

Hazardous voltage

can shock, burn or

cause death.

Reassembly – RJSP

Reassembly – RJSP

• Clean and inspect all parts before reassembly.

1. Inspect seal seat bore for wear and debris, clean and

replace as necessary.

NOTICE: MECHANICAL SEAL MUST BE REPLACED

WHENEVER SEAL HAS BEEN REMOVED.

FOLLOW SEAL MANUFACTURER’S

INSTRUCTIONS CAREFULLY.

2. If necessary, seat ring may be lubricated with water or

glycerin to aid in installation. DO NOT contaminate

the seal face. Fully and squarely install the stationary seat into the adapter. With a clean, lint free cloth,

CAREFULLY wipe the seat face clean of debris. DO

NOT damage the seal seat face.

3. Reinstall the motor adapter on the motor, making sure

that the motor shaft does not dislocate or damage the

stationary seal seat.

4. Fully and squarely install the seal rotary assembly

against the stationary seat. Be sure rotating seal face

does not drop out of holding collar and DO NOT

damage seal face.

5. On three phase units, impeller MUST be installed with

LOCTITE® “Purple”. Hold shaft from rotating, as

explained in the “DISASSEMBLY” section of the

manual, and install impeller by turning CLOCKWISE

until tight against motor shaft shoulder.

6. Replace guidevane. Align to prevent impeller rub.

7. Install new diaphragm and new guidevane seal ring.

8. Install motor and liquid end into casing.

9. Check impeller for binding by rotating the motor

shaft. If binding occurs, loosen casing bolts, readjust

guidevane until impeller hub turns freely. Retighten

casing bolts in a crossing pattern.

10. Replace all drain plugs and motor end components.

11. Reprime and operate according to instructions in the

“OPERATION” section of this manual.

Troubleshooting – All

Troubleshooting – All

FAILURE TO DISCONNECT

ELECTRICAL POWER BEFORE

ATTEMPTING ANY MAINTENANCE

CAN CAUSE SHOCK, BURNS OR

DEATH.

SYMPTOM

MOTOR NOT RUNNING:

See Probable Causes 1 through 5.

LITTLE OR NO WATER DELIVERED:

See Probable Causes 3, 4, 6 through 12, 15.

EXCESSIVE NOISE AND VIBRATION:

See Probable Causes 3, 6, 7, 10, 12, 13, 14.

PROBABLE CAUSES

1. Motor thermal protector tripped.

2. Open circuit breaker or blown fuse.

3. Impeller binding.

4. Motor improperly wired.

5. Defective motor.

6. Pump is not primed, air or gases in pumpage.

7. Discharge, suction plugged or valve closed.

8. Incorrect rotation. (3 phase only)

9. Low voltage or phase loss.

10. Impeller worn or plugged.

11. System head too high.

12. NPSHA too low – excessive suction lift or loss.

13. Discharge head too low – excessive flow rates.

14. Pump, motor or piping loose.

15. End of suction piping not submerged.

5

Electrical Data – All Models

Electrical Data – All Models

HP Voltage Full Load Amps Circuit Breaker Ph/Hz

¾ 115/230 25/15 1/60

1 115/230 25/15 1/60

1½ 115/230 See Motor Nameplate 35/20 1/60

2 230 25 1/60

3 230 30 1/60

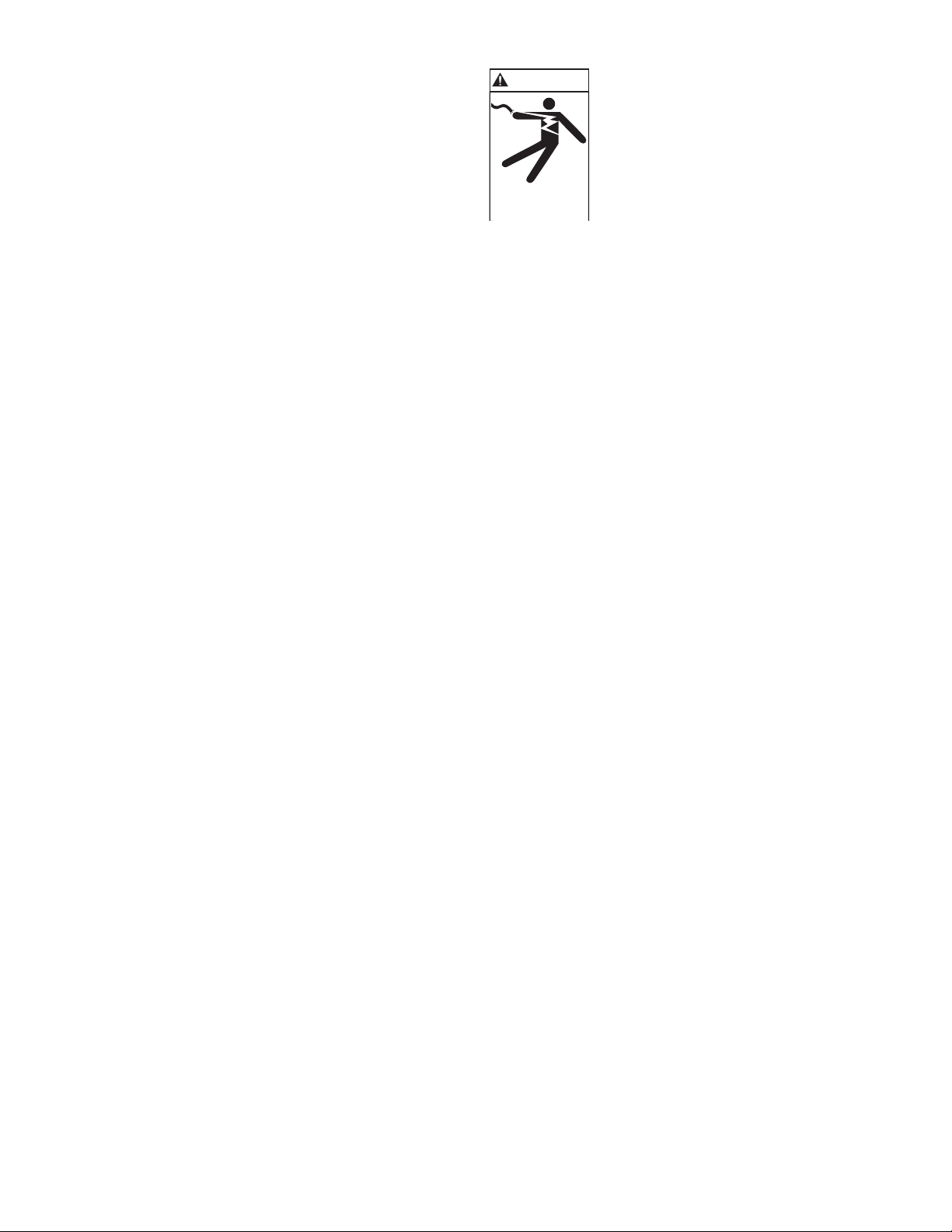

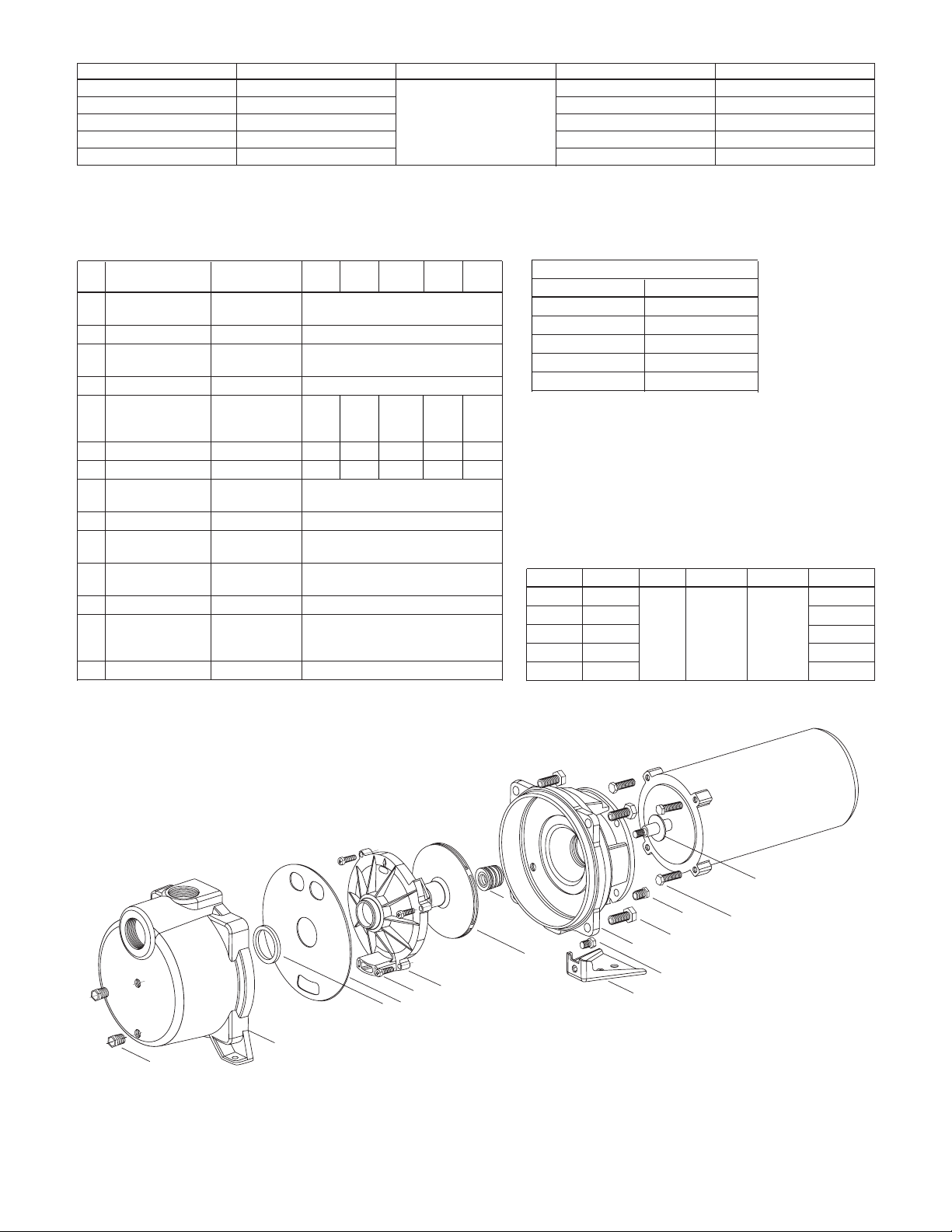

Repair Parts List – RJSP

Repair Parts List – RJSP

Item

Description Material

No. RJSP RJSP RJSP RJSP RJSP

1 ¼" NPT Pipe Plug Plated Steel 6K2

2 Casing Cast Iron 1K449

3

Guidevane Seal Ring

4 Diaphragm Neoprene 5K256

Fillister Head

5 Stainless Steel 13K4 13K4 13K2 13K2 13K2

Machine Screw

6 Guidevane Lexan® 10% G.F. 3K72 3K71 3K70 3K70 3K69

7 Impeller Noryl® 20% G.F. 2K715 2K716 2K714 2K713 2K712

Carbon/Ceramic/

8 Mechanical Seal 10K10

BUNA

9 Pump Foot Steel 4K529

10 Pump Foot Bolt Steel 13K252

11 Motor Adapter Cast Iron 1K450

12 Casing Bolt Steel 13K102

13 Motor Adapter Bolt Steel 13K89

14 Deflector BUNA 5K7

BUNA 5K231

75 100 150 200 300

RJSP Motor Codes

HP 1Ø – ODP

.75 J05853LA

1.0 J06853LA

1.5 J07858LA

2.0 J08854LA

3.0 J09853A

Engineering Data

Engineering Data

Model HP Ph/Hz Suction Discharge Wt. lbs.

75RJSP ¾ 48

100RJSP 1 52

150RJSP 1½ 1/60 1½" NPT 1½" NPT 60

200RJSP 2 65

300RJSP 3 76

14

8

7

6

5

4

3

2

1

6

11

9

1

13

12

10

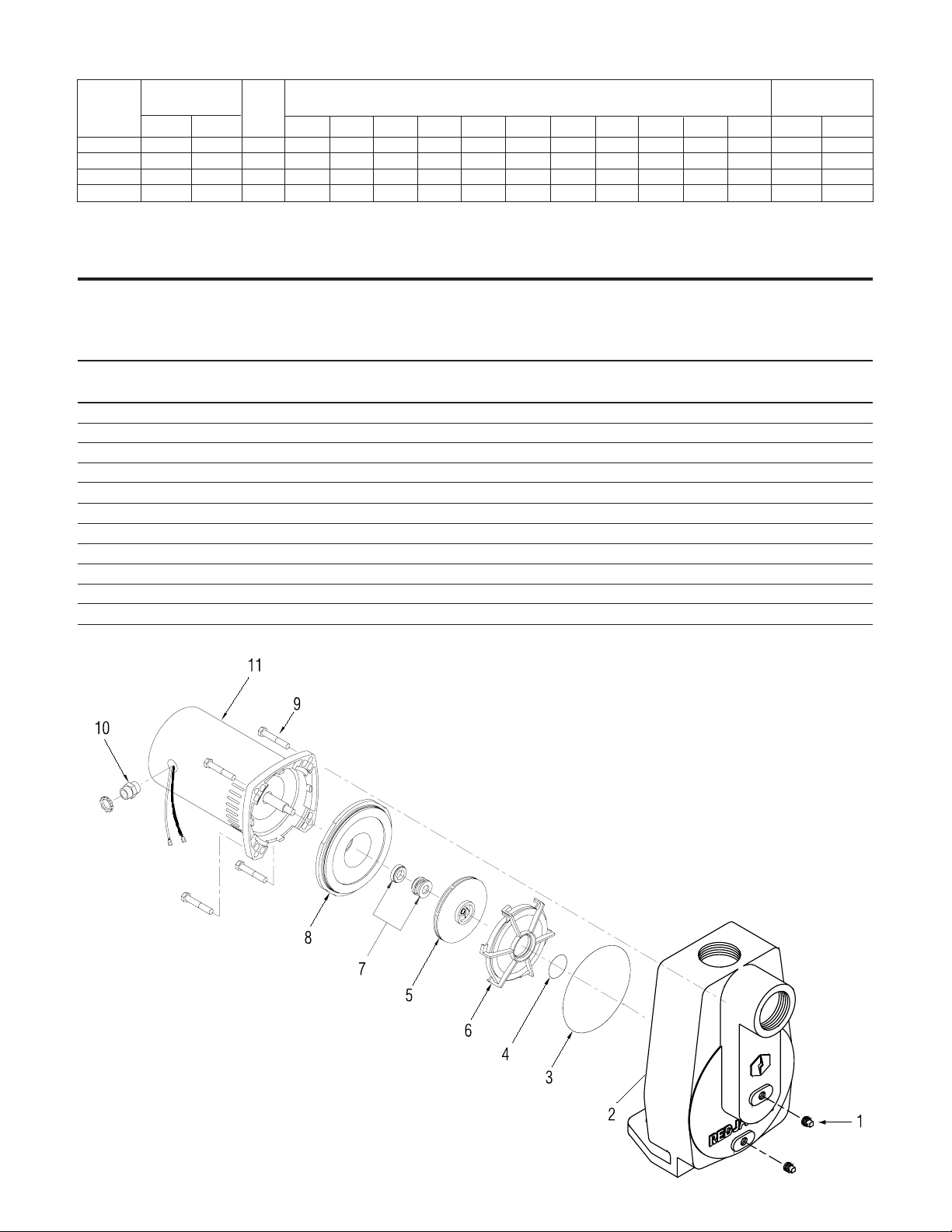

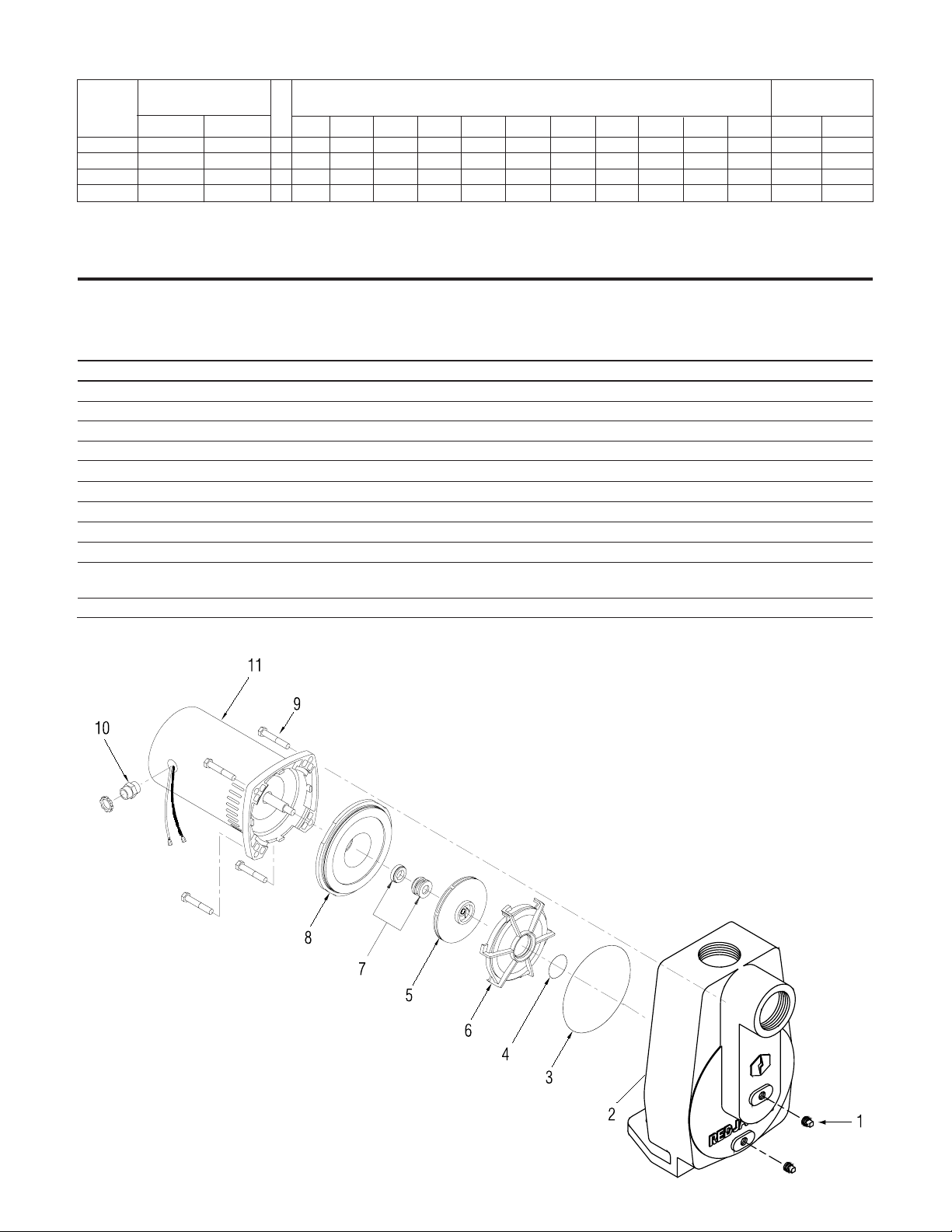

Maintenance – RSPA

Maintenance – RSPA

LUBRICATION:

1. The pump requires no lubrication.

2. For the electric motor, refer to instructions provided by

the motor manufacturer.

SEAL REMOVAL:

1. Disconnect electrical service to pump.

2. Relieve system pressure by opening a faucet or drain

valve until water stops flowing.

3. Disconnect pressure switch tubing at the barbed fitting

on the pump case. If tubing does not slide off barbed

fitting easily, cut it as close to the fitting as possible.

4. Remove four cap screws which hold down the pump

seal plate and motor to the pump case. Piping need not

be disturbed.

5. Remove the pumping assembly, as one piece, (motor,

seal plate, diffuser and impeller) by carefully prying

them apart from the pump case. Exercise care as not to

damage impeller.

6. Remove the diffuser from the seal plate, exposing

the impeller.

7. Insert regular slotted screwdriver into the slot in the

motor shaft.

8. While holding the motor shaft with the screwdriver,

unscrew the impeller by turning counterclockwise.

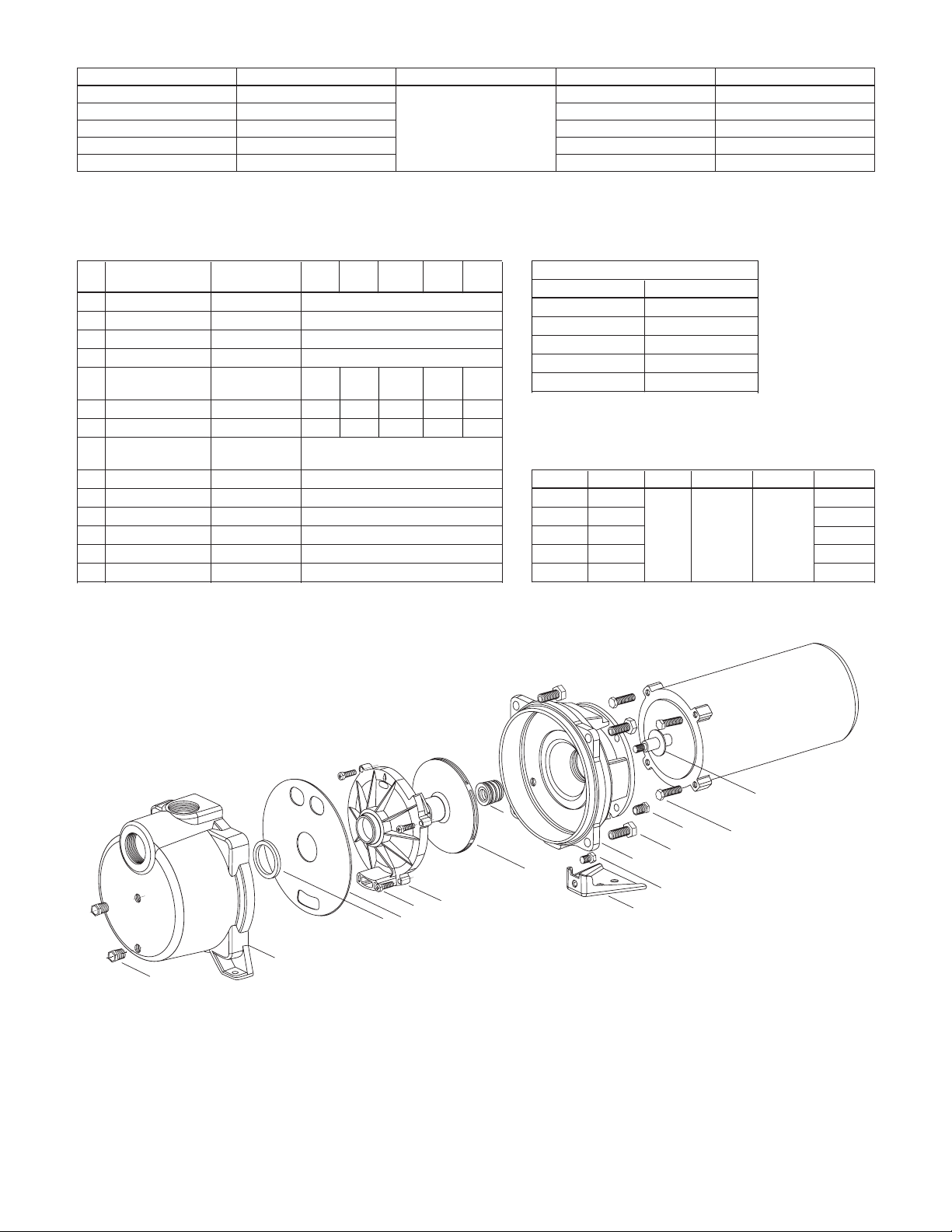

9. Slide rotating part of seal assembly from shaft (as

shown in Figure 3). Separate seal plate from motor.

10. Remove stationary part of seal assembly (including

rubber seal boot) from seal plate.

NEW SEAL INSTALLATION:

1. Clean polished surface of stationary seal with a clean

cloth.

2. Wet the outer edge of the rubber seal boot with a

soapy solution.

3. Insert rubber seal boot and ceramic seal (polished side

exposed) into seal plate. Make a cardboard washer to

cover the ceramic seal surface to be used while pressing

seal into position. Cardboard washer is used to avoid

scratching ceramic surface. Discard cardboard washer

after ceramic seal installation.

4. Reposition seal plate onto motor and slide rotating seal

assembly onto motor shaft with carbon sealing face first

until rubber end ring slides over shaft shoulder.

5. Screw impeller clockwise onto motor shaft using

screwdriver in shaft end slot to hold the shaft.

6. Reattach diffuser to seal plate and carefully reposition

the pumping assembly to the pump case. Attach with

the four cap screws through motor bracket to case.

7. Connect the pressure tubing by pressing on to barb

fitting on pump case until tubing shoulders against stop

edge of fitting. If tubing was cut off, carefully remove

excess tubing from barb fitting with a knife, taking care

not to scratch the fitting.

MOTOR REMOVAL:

1. Follow Steps 1 - 10 of “Seal Removal” in this section.

MOTOR REPLACEMENT:

1. Follow Steps 1 - 7 of “New Seal Installation” in

this section.

CASE BOLT

FIGURE 3

MOTOR SHAFT

SEAL PLATE

O-RING

SEAL BOOT

ROTATING SEAL

CERAMIC SEAL

IMPELLER

DIFFUSER

O-RING

7

Performance Chart RSPA

Pump Size Gallons Per Minute Against Total Head In Feet

Model Suct. Disch. HP 20' 30' 40' 50' 60' 70' 80' 90' 100' 110' 120' Feet PSI

75 RSPA 2" 2" ¾ 50 49 48 45 41 35 25 88 38

100 RSPA 2" 2" 1 53 52 51 49 46 42 35 25 101 44

150 RSPA 2" 2" 1½ 53 53 52 51 51 49 44 39 32 20 115 50

200 RSPA 2" 2" 2 52 52 51 51 50 49 49 46 40 33 21 123 53

NOTE: All performance based upon 15 ft. suction lift.

Maximum

Shut-Off Head

REPAIR PARTS

MODELS: 75RSPA, 100RSPA, 150RSPA, 150FSPA, 200RSPA

KEY NO.

NO. DESCRIPTION USED 75RSPA 100RSPA 150RSPA 150FSPA 200RSPA

1 Pipe Plug (¼" NPT) 3 6K2 6K2 6K2 6K2 6K2

2 Case 1 147953 147953 147953 147953 147953

3 O-Ring (67⁄16 x 6¼ x 3⁄32) 1 5K341 5K341 5K341 5K341 5K341

4 O-Ring (17⁄8 x 11⁄16 x 3⁄32) 1 5K340 5K340 5K340 5K340 5K340

5 Impeller 1 1414404 1414414 1414424 1414304 1414304

6 Diffuser 1 175561 175561 175571 175571 175571

7 Seal (5⁄8") 1 1760371 1760371 1760371 1760371 1760371

8 Seal Plate 1 671143 671143 671153 671153 671153

9 Case Bolt (3⁄8-16 x 1½) 4 13K337 13K337 13K337 13K337 13K337

10 Nipple (½" NPT x 1) with Locknut 1 6K24 6K24 6K24 6K24 6K24

11 Motor 1 1531761 1531771 1531781 1531781 1531791

8

RED JACKET WATER PRODUCTS LIMITED WARRANTY

This warranty applies to all water systems pumps manufactured by Red Jacket Water Products.

Any part or parts found to be defective within the warranty period shall be replaced at no charge to the dealer during the warranty period. The

warranty period shall exist for a period of twelve (12) months from date of installation or eighteen (18) months from date of manufacture, whichever

period is shorter.

A dealer who believes that a warranty claim exists must contact the authorized Red Jacket Water Products distributor from whom the pump was

purchased and furnish complete details regarding the claim. The distributor is authorized to adjust any warranty claims utilizing the Red Jacket Water

Products Customer Service Department.

The warranty excludes:

(a) Labor, transportation and related costs incurred by the dealer;

(b) Reinstallation costs of repaired equipment;

(c) Reinstallation costs of replacement equipment;

(d) Consequential damages of any kind; and,

(e) Reimbursement for loss caused by interruption of service.

For purposes of this warranty, the following terms have these definitions:

(1) “Distributor” means any individual, partnership, corporation, association, or other legal relationship that stands between Red Jacket Water

Products and the dealer in purchases, consignments or contracts for sale of the subject pumps.

(2) “Dealer” means any individual, partnership, corporation, association, or other legal relationship which engages in the business of selling or leasing

pumps to customers.

(3) “Customer” means any entity who buys or leases the subject pumps from a dealer. The “customer” may mean an individual, partnership,

corporation, limited liability company, association or other legal entity which may engage in any type of business.

THIS WARRANTY EXTENDS TO THE DEALER ONLY.

Xylem, Inc.

2881 East Bayard Street Ext., Suite A

Seneca Falls, NY 13148

Phone: (866) 325-4210

Fax: (888) 322-5877

www.xyleminc.com/brands/redjacketwaterproducts

Red Jacket Water Products is a trademark of Xylem Inc. or one of its subsidiaries.

© 2012 Xylem Inc. IM132 Revision Number 2 July 2012

9

MANUAL DE INSTRUCCIÓN

IM132

RSPA (FSPA) Y RJSP

Bombas centrífugas de

centrífugas de autocebado

INSTRUCCIONES DE INSTALACIÓN, FUNCIONAMIENTO Y MANTENIMIENTO

10

Índice

Índice

TEMA PÁGINA

Instrucciones de seguridad ......................................................................................................................................... 12

Descripción y especificaciones ...................................................................................................................................12

Tuberías Succión .......................................................................................................................................................12

Descarga .....................................................................................................................................................12

Alambrado y conexión a tierra ..................................................................................................................................13

Rotación .................................................................................................................................................................... 13

Operación .................................................................................................................................................................13

Mantenimiento ..........................................................................................................................................................13

Desensamblaje ................................................................................................................................................... 13 y 16

Reensamblaje .....................................................................................................................................................14 y 16

Identificación y resolución de problemas ...................................................................................................................14

Datos eléctricos ......................................................................................................................................................... 15

Lista de partes de repuesto ................................................................................................................................ 15 y 17

Datos de ingeniería .................................................................................................................................................... 15

Garantía limitada de Red Jacket Water Products ........................................................................................................ 18

11

ADVERTENCIA

Los fluidos peligrosos

pueden causar

incendios, quemaduras

o la muerte.

Instrucciones de seguridad

DANGER

ADVERTENCIA

PRECAUCIÓN

Instrucciones de seguridad

PARA EVITAR LESIONES PERSONALES GRAVES O

AÚN FATALES Y SERIOS DAÑOS MATERIALES, LEA Y

SIGA TODAS LAS INSTRUCCIONES DE SEGURIDAD

EN EL MANUAL Y EN LA BOMBA.

Éste es un SÍMBOLO DE ALERTA DE

SEGURIDAD. Cuando vea este símbolo

en la bomba o en el manual, busque una de

las siguientes palabras de señal y esté alerta

a la probabilidad de lesiones personales o

daños materiales.

Advierte los peligros que CAUSARÁN graves

lesiones personales, la muerte o daños materiales mayores.

Advierte los peligros que PUEDEN causar

graves lesiones personales, la muerte o daños

materiales mayores.

Advierte los peligros que PUEDEN causar

lesiones personales o daños materiales.

AVISO: Indica instrucciones especiales que son muy

importantes y que se deben seguir.

ESTE MANUAL HA SIDO CREADO COMO UNA GUÍA

PARA LA INSTALACIÓN Y OPERACIÓN DE ESTA UNIDAD Y SE DEBE CONSERVAR JUNTO A LA BOMBA.

EXAMINE BIEN TODAS LAS INSTRUCCIONES Y

ADVERTENCIAS ANTES DE REALIZAR CUALQUIER

TRABAJO EN ESTA BOMBA.

MANTENGA TODAS LAS CALCOMANÍAS DE

SEGURIDAD.

AVISO: INSPECCIONE LA UNIDAD PARA VER SI

TIENE DAÑOS Y NOTIFIQUE

INMEDIATAMENTE TODO DAÑO AL

TRANSPORTISTA O AL AGENTE. NO USE

LA BOMBA SI SOSPECHA QUE ESTÁ

DAÑADA.

LAS UNIDADES NO ESTÁN

DISEÑADAS PARA EL USO CON

LÍQUIDOS PELIGROSOS O GASES

INFLAMABLES.

Descripción y especificaciones

Descripción y especificaciones

• Los Modelos RJSP y RSPA son bombas centrífugas de

autocebado, de una etapa, de succión de extremo para

aspersores de césped, sistemas de calefacción, ventilación y

aire acondicionado y para la transferencia general de agua.

• La carcasa es de hierro fundido con oricios roscados

para el medidor de vacío y el drenaje de la carcasa.

• Los impulsores son de diseño encerrado, Noryl™ lleno

con vidrio, roscados directamente sobre el eje del motor.

• Los motores estándar tienen una cubierta NEMA estándar

a prueba de explosión y operan a una velocidad de 3500

RPM.

• Temperatura máxima del líquido: 160°F (71°C)

• Arranques máximos por hora: 20 – distribuidos uniforme-

mente

Tuberías

Tuberías

• La bomba DEBE instalarse horizontal sobre una superficie

plana sólida, con la descarga en el extremo superior.

• Deje un espacio adecuado para el mantenimiento y la

ventilación. Proteja la unidad contra los daños causados

por el mal tiempo y el agua de lluvia, inundación o las

temperaturas bajo cero.

• La tubería no debe ser más pequeña que las conexiones

de succión y descarga y debe mantenerse lo más corta

posible, evitando los accesorios innecesarios para reducir

al mínimo las pérdidas por fricción.

• Todas las tuberías DEBEN estar apoyadas en forma

independiente y NO DEBE aplicarse ninguna carga de las

tuberías sobre la bomba.

AVISO: NO FUERCE LA TUBERÍA A SU POSICIÓN

EN LAS CONEXIONES DE SUCCIÓN O

DESCARGA DE LA BOMBA.

• Todas las juntas de tuberías DEBEN ser herméticas.

• Se recomienda usar cinta Teon™ o su equivalente en

TODAS las juntas de tuberías.

SUCCIÓN

• La elevación de succión total, incluso la elevación y la

pérdida por fricción del tubo, no debe sobrepasar 25 pies

de altura.

• Instale una unión hermética en la línea de succión cerca

de la bomba. Ver la figura 1.

• Se recomienda instalar una válvula de aspiración en la

fuente de líquido.

AVISO: PARA LAS INSTALACIONES CON TUBERÍA

DE SUCCIÓN LARGA, SE RECOMIENDA

INSTALAR UNA VÁLVULA DE ASPIRACIÓN Y

UNA VÁLVULA DE RETENCIÓN.

• Para evitar las bolsas de aire, ninguna parte de la tubería

debe estar sobre la conexión de succión de la bomba y la

tubería debe tener una inclinación hacia arriba de la fuente

de líquido.

• Para instalaciones con tubería de succión larga, llene la tu-

bería de succión con agua antes de conectarla a la bomba.

DESCARGA

• Instale una T en la conexión de descarga de la bomba. Se

requiere la apertura del extremo superior de la T para el

cebado inicial. Ver la figura 1.

ABERTURA DE CEBADO

DESCONEXIÓN

UNIÓN

DESCARGA

SUCCIÓN

Figura 1

12

ADVERTENCIA

Un voltaje peligroso puede

producir golpes eléctricos,

quemaduras o la muerte.

ADVERTENCIA

El calor extremo

puede causar lesiones

personales o daños

materiales.

ADVERTENCIA

Un voltaje peligroso puede

producir golpes eléctricos,

quemaduras o la muerte.

ADVERTENCIA

Tensión

peligrosa

Alambrado y conexión a tierra

ADVERTENCIA

Un voltaje peligroso puede

producir golpes eléctricos,

quemaduras o la muerte.

Alambrado y conexión a tierra

• Siga cuidadosamente el diagrama de alambrado del fabri-

• Use únicamente alambre de cobre para el motor y la

TAMAÑO MÍNIMO RECOMENDADO DEL ALAMBRE

TAMAÑO MÍNIMO RECOMENDADO DEL ALAMBRE

Distancia desde la entrada de servicio al motor

HP 50 Pies (15 m) 100 Pies (30 m) 150 Pies (46 m) 200 Pies (61 m)

115 V 230 V 115 V 230 V 115 V 230 V 115 V 230 V

¾ 12 14 10 14 8 14 6 12

1 12 14 8 14 8 12 6 12

1½ 10 14 8 14 – 12 – 10

2 10 14 8 14 – 12 – 10

3 – 12 – 12 – 10 – 10

Rotación

Rotación

AVISO: LA ROTACIÓN INCORRECTA PUEDE CAU-

SAR DAÑO A LA BOMBA Y ANULAR LA GARANTÍA.

• La rotación correcta es hacia la derecha, EN EL

• La rotación trifásica puede vericarse quitando la tapa o

Operación

Operación

Instale, conecte a tierra y alambre

de acuerdo con los requerimientos del Código Eléctrico Nacional

o local.

Instale un desconectador de todos

los circuitos, cerca de la bomba.

Desconecte la corriente eléctrica

antes de instalar o dar servicio a

la bomba.

El suministro eléctrico DEBE coincidir con

la especificación de la placa del fabricante de

la bomba. La tensión incorrecta puede causar

incendios, daños al motor y anular la garantía.

Los motores sin protección incorporada DEBEN

estar equipados con contactadores y sobrecargas

térmicas para motores monofásicos, o arrancadores con calentadores para motores trifásicos. Ver

la placa del fabricante del motor.

cante del motor en placa o en la cubierta de los terminales

del motor.

conexión a tierra. El alambre de conexión a tierra DEBE

ser al menos del mismo tamaño que el alambre al motor.

Los alambres deben codificarse con colores para facilitar

el mantenimiento.

LA FALLA DE CONECTAR A TIERRA

PERMANENTEMENTE LA BOMBA,

EL MOTOR Y LOS CONTROLES, ANTES DE CONECTAR LA CORRIENTE

ELÉCTRICA, PUEDE CAUSAR ELECTROCHOQUE, QUEMADURAS O LA

MUERTE.

SENTIDO DE LAS AGUJAS DEL RELOJ cuando se

mira desde el extremo del motor.

tapón del extremo del motor y observando la rotación del

eje del motor. Para invertir la rotación, intercambie dos

conductores eléctricos cualesquiera de los tres conductores del motor.

LA OPERACIÓN SIN CEBAR O CON

UNA VÁLVULA DE DESCARGA CERRADA PUEDE GENERAR AGUA CALIENTE O VAPOR QUE PUEDE CAUSAR

LESIONES O DAÑOS MATERIALES.

AVISO: NO OPERE LA BOMBA SIN CEBARLA O SE

DAÑARÁ EL SELLO.

• Cebe la bomba llenando con agua limpia la bomba y la

tubería a través del orificio en el extremo superior de la T.

Ver la figura 1.

• Instale el tapón del tubo en el extremo superior de la T

empleando cinta Teflon™ o su equivalente.

AVISO: SI LA BOMBA SE DRENA O SE APAGA

DURANTE EL PERÍODO DE CEBADO, HAY

QUE LLENAR NUEVAMENTE LA CARCASA

ANTES DE REARRANCAR LA BOMBA.

• Arranque la bomba y abra parcialmente la válvula de

descarga y espere a que la presión del sistema se estabilice.

Si la presión del sistema varía repentinamente o se observa

una caída de presión prolongada, no se ha completado el

cebado del sistema.

Mantenimiento – todos los Modelos

Mantenimiento – todos los Modelos

LA FALLA DE DESCONECTAR LA

CORRIENTE ELÉCTRICA ANTES DE

INTENTAR CUALQUIER MANTENIMIENTO, PUEDE CAUSAR ELECTROCHOQUE, QUEMADURAS O LA

MUERTE.

• La bomba no requiere lubricación.

Consulte y siga las instrucciones del

fabricante para lubricar el motor.

SERVICIO DE TEMPORADA

• Para RETIRAR la bomba del servicio, quite todos los

tapones de drenaje y drene todas las tuberías.

• Para PONER OTRA VEZ en servicio la bomba, reinstale

todos los tapones de drenaje empleando una cinta Teflon™ o su equivalente.

• Reconecte la línea de succión si se había desconectado,

examine la unión y repárela si es necesario.

• Vuelva a cebar y opere la bomba siguiendo todas las

instrucciones y advertencias en la sección de “OPERACIÓN” del manual.

Desmontaje – RJSP

Desmontaje – RJSP

LA FALLA DE DESCONECTAR

LA CORRIENTE ELÉCTRICA

ANTES DE INTENTAR CUALQUIER

MANTENIMIENTO, PUEDE CAUSAR

ELECTROCHOQUE, QUEMADURAS

O LA MUERTE.

1. Quite el perno de la base (10).

2. Quite los pernos de la carcasa (12).

3. Retire el conjunto de desmontaje trasero de

la carcasa (2).

4. Retire el anillo de sello del álabe de guía (3) y

el diafragma (4).

5. Quite los tornillos (5) del adaptador (11) del álabe de guía.

6. Quite el tapón o la cubierta del extremo del motor.

7. Utilice la ranura para destornillador o las secciones

planas del eje de 7-16 pulg. accesibles en el extremo del

eje del motor para restringir la rotación de dicho eje.

8. Retire el impulsor (7) girando en SENTIDO

CONTRARIO A LAS AGUJAS DEL RELOJ.

13

ADVERTENCIA

Un voltaje peligroso puede

producir golpes eléctricos,

quemaduras o la muerte.

9. Con dos destornilladores retire la sección giratoria del

sello mecánico (8). Deséchela. Ver la gura 2.

10. Quite los pernos del adaptador del motor (13) y retire

el adaptador.

11. Empuje el asiento estacionario del sello mecánico fuera

del adaptador del motor. Deseche el asiento del sello.

Rearmado – RJSP

Rearmado – RJSP

• Limpie e inspeccione todas las partes antes de reensamb-

1. Inspeccione el agujero del asiento del sello para ver si

está gastado o sucio, límpielo si es necesario.

AVISO: ES NECESARIO REEMPLAZAR EL SELLO

MECÁNICO CADA VEZ QUE SE HAYA

RETIRADO. SIGA CUIDADOSAMENTE

LAS INSTRUCCIONES DEL FABRICANTE

DEL SELLO.

2. Si es necesario, el anillo del asiento puede lubricarse

con agua o glicerina para facilitar la instalación. NO

contamine la cara del sello. Instale el asiento

estacionario en forma completa y encuadrada en el

adaptador. Con un paño limpio y sin pelusas, quite

CUIDADOSAMENTE todos los residuos de la cara

del asiento. NO dañe la cara del asiento del sello.

3. Reinstale el adaptador del motor sobre el motor,

asegurándose de que el eje del motor no desplace o

dañe el asiento del sello estacionario.

4. Instale el conjunto giratorio del sello en forma

completa y encuadrada contra el asiento estacionario.

Asegúrese de que la cara del sello giratorio no se caiga

fuera del collar de retención y NO dañe la cara del

sello.

lar.

Figura 2

5. En las unidades trifásicas, el impulsor DEBE instalarse

con LOCTITE® “Purple”. Sujete el eje para que no

gire, tal como se explicó en la sección de

“DESMONTAJE” del manual, e instale el impulsor

girándolo en SENTIDO DE LAS AGUJAS DEL

RELOJ hasta que quede ajustado contra el reborde del

eje del motor.

6. Reinstale el álabe de guía. Alinéelo para evitar que roce

con el impulsor.

7. Instale el nuevo diafragma y el nuevo anillo de sello del

álabe de guía.

8. Instale el motor y el extremo del líquido en la carcasa.

9. Revise el impulsor para ver si roza girando el eje del

motor. Si hay roce, afloje los pernos de la carcasa;

reajuste el álabe de guía hasta que el cubo del impulsor

gire libremente. Apriete nuevamente los pernos de la

carcasa en configuración cruzada.

10. Reinstale todos los tapones de drenaje y los

componentes del extremo del motor.

11. Cebe nuevamente y opere de acuerdo con las

instrucciones en la sección de “OPERACIÓN” de

este manual.

Identificación y resolución de problemas – Todos

Identificación y resolución de problemas – Todos

los modelos

los modelos

LA FALLA DE DESCONECTAR LA

CORRIENTE ELÉCTRICA ANTES DE

INTENTAR CUALQUIER MANTENIMIENTO, PUEDE CAUSAR ELECTROCHOQUE, QUEMADURAS O LA

MUERTE.

SÍNTOMA

El motor no funciona:

Ver las causas probables 1 a 5.

Se entrega poco o nada de agua:

Ver las causas probables 3, 4, 6 a 12, 15.

Ruido y vibración excesivos:

Ver las causas probables 3, 6, 7, 10, 12, 13, 14.

CAUSAS PROBABLES

1. Se disparó el protector térmico del motor.

2. Cortacircuitos abierto o fusible quemado.

3. Roce del impulsor.

4. Cableado incorrecto del motor.

5. Motor defectuoso.

6. La bomba no está cebada, hay aire o gases en el agua

bombeada.

7. Descarga o succión taponada o válvula cerrada.

8. Rotación incorrecta. (motor trifásico solamente)

9. Baja tensión o pérdida de fase.

10. Impulsor gastado o taponado.

11. Carga del sistema muy alta.

12. NPSHA demasiado baja – elevación o pérdida de suc-

ción excesiva.

13. Carga de descarga demasiado baja - velocidades de flujo

excesivas.

14. La bomba, el motor o la tubería está suelta.

15. El extremo de la tubería de succión no está sumergido.

14

Datos eléctricos – Todos los Modelos

Datos eléctricos – Todos los Modelos

HP Tensión Corriente a plena carga De retardo Fase/Hz

¾ 115/230 25/15 1/60

1 115/230 30/15 1/60

1½ 115/230 35/20 1/60

2 230 25 1/60

3 230 30 1/60

Lista de partes de repuesto – RJSP

Lista de partes de repuesto – RJSP

Art.

Descripción Material

Nº. RJSP RJSP RJSP RJSP RJSP

1 Tapón de tubo Acero

NPT de ¼ pulg. enchapado

2 Carcasa Hierro fundido 1K449

3 Anillo de sello del BUNA

álabe guía

4 Diafragma Neopreno 5K256

Tornillo para Acero

5 metales de cabeza inoxidable 13K4 13K4 13K2 13K2 13K2

cilíndrica ranurada

6 Álabe guía Lexan 3K72 3K71 3K70 3K70 3K69

7 Impulsor Noryl 2K715 2K716 2K714 2K713 2K712

8 Sello mecánico Carbón/ 10K10

Cerámica/BUNA

9 Base de la bomba Acero 4K529

10 Perno de la base Acero 13K252

de la bomba

11 Adaptador Hierro fundido 1K450

del motor

12 Perno de la carcasa Acero 13K102

Perno del

13 adaptador Acero 13K89

del motor

14 Deflector BUNA 5K7

75 100 150 200 300

Placa de identificación

del motor

6K2

5K231

Códigos de motores – RJSP

HP 1Ø – ODP

.75 J05853LA

1.0 J06853LA

1.5 J07858LA

2.0 J08854LA

3.0 J09853A

Datos de ingeniería

Datos de ingeniería

Modelo HP Fase/Hz Succión Descarga Peso libras

75RJSP ¾ 48

100RJSP 1 52

150RJSP 1½ 1/60 1½" NPT 1½" NPT 60

200RJSP 2 65

300RJSP 3 76

14

8

7

6

5

4

3

2

1

11

9

1

13

12

10

15

Mantenimiento – RSPA

Mantenimiento – RSPA

LUBRICACIÓN:

1. La bomba no requiere lubricación.

2. Para el motor eléctrico, consulte las instrucciones

proporcionadas por el fabricante del motor.

RETIRO DEL SELLO:

1. Desconecte el servicio eléctrico a la bomba.

2. Alivie la presión del sistema abriendo una llave o

válvula de drenaje hasta que ya no uya agua.

3. Desconecte el tubo del interruptor de presión en el

accesorio arponado en la carcasa de la bomba. Si el

tubo no se desliza hacia afuera del accesorio arponado

con facilidad, córtelo lo más cerca posible a dicho

accesorio.

4. Quite los cuatro tornillos de cabeza cuadrada que

mantienen sujeta la placa del sello y el motor de la

bomba a la carcasa de la misma. No es necesario

perturbar el tubo.

5. Retire el conjunto de bombeo, en una pieza (motor,

placa de sello, difusor e impulsor) haciendo palanca

cuidadosamente y separándolo de la carcasa de la

bomba. Tenga cuidado para no dañar el impulsor.

6. Retire el difusor de la placa de sello, dejando al

descubierto el impulsor.

7. Introduzca un destornillador ranurado regular en la

ranura en el eje del motor.

8. Sujetando el eje del motor con el destornillador,

destornille el impulsor girándolo en sentido

contrahorario.

9. Deslice la parte rotatoria del conjunto del sello y

retírela del eje (tal como se muestra en la Figura 3).

Separe la placa de sello del motor.

10. Retire la parte estacionaria del conjunto del sello

(incluso la bota del sello de goma) de la placa de sello.

INSTALACIÓN DEL SELLO NUEVO:

1. Limpie la superficie pulida del sello estacionario con

un paño limpio.

2. Moje el borde exterior de la bota del sello de goma con

una solución jabonosa.

3. Introduzca la bota del sello de goma y el sello de

cerámica (lado pulido expuesto) en la placa de sello.

Fabrique una arandela de carbón para cubrir la

supercie del sello de cerámica, para usar mientras

presiona el sello en posición. La arandela de cartón se

utiliza para no rayar la supercie de cerámica. Deseche

la arandela de cartón después de haber instalado el sello

de cerámica.

4. Reposicione la placa de sello sobre el motor y deslice el

conjunto de sello rotatorio en el eje del motor, con la

cara de sellado de carbón primero hasta que el anillo de

extremo de goma se deslice sobre el reborde del eje.

5. Atornille el impulsor en sentido horario sobre el eje del

motor, colocando el destornillador en la ranura del

extremo del eje para sujetar este último.

6. Reconecte el difusor a la placa de sello y reposicione

cuidadosamente el conjunto de bombeo en la carcasa de

la bomba. Sujételo con los cuatro tornillos de cabeza

cuadrada a través del soporte del motor a la carcasa.

7. Conecte el tubo de presión empujándolo sobre el

accesorio arponado en la carcasa de la bomba, hasta

que los rebordes del tubo hagan contacto con el borde

de tope del accesorio. Si se cortó el tubo, quite con

cuidado el exceso de tubo del accesorio arponado con

un cuchillo, asegurándose de no rayar el accesorio.

RETIRO DEL MOTOR:

1. Siga los pasos 1 a 10 de “Retiro del sello” en

esta sección.

REEMPLAZO DEL MOTOR:

1. Siga los pasos 1 a 7 de “Instalación del sello nuevo”

en esta sección.

16

PERNO DE

LA CARCASA

FIGURA 3

EJE DEL MOTOR

PLACA DE SELLO

ANILLO EN O

IMPULSOR

BOTA DEL

SELLO

SELLO GIRATORIO

SELLO DE CERÁMICA

DIFUSOR

ANILLO

EN O

C de R – RSPA

Tamaño

Modelo

Succión Descarga 20' 30' 40' 50' 60' 70' 80' 90' 100' 110' 120' Pies LBS./

PULG.

CUADR.

75 RSPA 2" 2" ¾ 50 49 48 45 41 35 25 88 38

100 RSPA 2" 2" 1 53 52 51 49 46 42 35 25 101 44

150 RSPA 2" 2" 1½ 53 53 52 51 51 49 44 39 32 20 115 50

200 RSPA 2" 2" 2 52 52 51 51 50 49 49 46 40 33 21 123 53

NOTA: Todos los datos de rendimiento se basan en 15 pies de elevación de succión.

de la bomba

Caballos

de fuerza

Galones por minuto contra carga total en pies

Máxima carga

de cierre

PARTES DE REPUESTO

MODELOS: 75RSPA, 100RSPA, 150RSPA, 150FSPA, 200RSPA

CLAVE Nº

Nº DESCRIPCIÓN UTILIZADO 75RSPA 100RSPA 150RSPA 150FSPA 200RSPA

1 Tapón para tubo (NPT de ¼ pulg.) 3 6K2 6K2 6K2 6K2 6K2

2 Carcasa 1 147953 147953 147953 147953 147953

3 Anillo en O (67⁄16 x 6¼ x 3⁄32) 1 5K341 5K341 5K341 5K341 5K341

4 Anillo en O (17⁄8 x 11⁄16 x 3⁄32) 1 5K340 5K340 5K340 5K340 5K340

5 Impulsor 1 1414404 1414414 1414424 1414304 1414304

6 Difusor 1 175561 175561 175571 175571 175571

7 Sello (5⁄8") 1 1760371 1760371 1760371 1760371 1760371

8 Placa de sello 1 671143 671143 671153 671153 671153

9 Perno de la carcasa (3⁄8-16 x 1½) 4 13K337 13K337 13K337 13K337 13K337

Niple (NPT de ½ pulg. x 1)

10

con contratuerca

11 Motor 1 1531761 1531771 1531781 1531781 1531791

1 6K24 6K24 6K24 6K24 6K24

17

GARANTÍA LIMITADA DE RED JACKET WATER PRODUCTS

Esta garantía es aplicable a todas las bombas para sistemas de agua fabricadas por Red Jacket Water Products.

Toda parte o partes que resultaren defectuosas dentro del período de garantía serán reemplazadas durante dicho período de garantía sin cargo para el

comerciante. Tal período de garantía se extiende por doce (12) meses a partir de la fecha de instalación, o dieciocho (18) meses a partir de la fecha de

fabricación, la que se cumpla primero.

El comerciante que considere que existe lugar a un reclamo de garantía deberá ponerse en contacto con el distribuidor autorizado de Red Jacket Water

Products del cual adquiriera la bomba y brindar información detallada con respecto al reclamo. El distribuidor está autorizado a liquidar todos los

reclamos por garantía a través del Departamento de Servicios a Clientes de Red Jacket Water Products.

La presente garantía excluye:

(a) La mano de obra, el transporte y los costos relacionados en los que incurra el comerciante;

(b) los costos de reinstalación del equipo reparado;

(c) los costos de reinstalación del equipo reemplazado;

(d) daños emergentes de cualquier naturaleza; y

(e) el reembolso de cualquier pérdida causada por la interrupción del servicio.

A los fines de esta garantía, los términos “Distribuidor”, “Comerciante” y “Cliente” se definen como sigue:

(1) “Distribuidor” es aquel individuo, sociedad, corporación, asociación u otra entidad jurídica que opera entre Red Jacket Water Products y el

comerciante para la compra, consignación o contratos de venta de las bombas en cuestión.

(2) “Comerciante” es todo individuo, sociedad, corporación asociación u otra entidad jurídica que realiza negocios de venta o alquiler-venta (leasing)

de bombas a los clientes.

(3) “Cliente” es toda entidad que compra o adquiere bajo la modalidad de leasing las bombas en cuestión de un comerciante. El término “cliente”

puede significar un individuo, sociedad, corporación, sociedad de responsabilidad limitada, asociación o cualquier otra entidad jurídica con

actividades en cualquier tipo de negocios.

LA PRESENTE GARANTÍA SE EXTIENDE AL COMERCIANTE ÚNICAMENTE.

Xylem, Inc.

2881 East Bayard Street Ext., Suite A

Seneca Falls, NY 13148

Teléfono: (866) 325-4210

Fax: (888) 322-5877

www.xyleminc.com/brands/redjacketwaterproducts

Red Jacket Water Products son una marca registrada de Xylem Inc. o una de sus filiales.

© 2012 Xylem Inc. IM132 Revisión Número 2 Julio 2012

MANUEL D'UTILISATION

IM132

RSPA (FSPA) ET RJSP

Pompes centrifuges autoamorçantes

DIRECTIVES D’INSTALLATION, D’UTILISATION ET D’ENTRETIEN

Table des matières

Table des matières

SUJET PAGE

Consignes de sécurité ................................................................................................................................................21

Description et caractéristiques ................................................................................................................................... 21

Installation ................................................................................................................................................................21

Tuyauterie d’aspiration .............................................................................................................................................. 21

Tuyauterie de refoulement ......................................................................................................................................... 22

Câblage et mise à la terre ........................................................................................................................................... 22

Sens de rotation .........................................................................................................................................................22

Utilisation ..................................................................................................................................................................22

Entretien — tous les modèles ............................................................................................................................22 et 25

Démontage — RJSP...................................................................................................................................................23

Remontage — RJSP ................................................................................................................................................... 23

Diagnostic des anomalies — tous les modèles ............................................................................................................ 23

Données sur l’alimentation électrique — tous les modèles .........................................................................................24

Liste de pièces de rechange — RJSP, RSPA et FSPA ........................................................................................... 24 et 26

Données techniques ................................................................................................................................................... 24

Table de performances — RSPA ................................................................................................................................. 26

Garantie limitée de Red Jacket Water Products .......................................................................................................... 28

20

DANGER

AVERTISSEMENT

PELIGRO

AVERTISSEMENT

Les fluides dangereux

peuvent causer un

incendie, des brûlures

et la mort.

Consignes de sécurité

Consignes de sécurité

AFIN DE PRÉVENIR LES BLESSURES GRAVES OU

MORTELLES ET LES DOMMAGES MATÉRIELS

IMPORTANTS, LIRE ET SUIVRE TOUTES LES CONSIGNES DE SÉCURITÉ FIGURANT DANS LE MANUEL

ET SUR LA POMPE.

Le symbole ci-contre est un SYMBOLE DE

SÉCURITÉ employé pour signaler les mots-

indicateurs dont on trouvera la description cidessous. Sa présence sert à attirer l’attention

afin d’éviter les blessures et les dommages

matériels.

Prévient des risques qui VONT causer des

blessures graves, la mort ou des dommages

matériels importants.

Prévient des risques qui PEUVENT causer

des blessures graves, la mort ou des dommages matériels importants.

Prévient des risques qui PEUVENT causer

des blessures ou des dommages matériels.

AVIS : Sert à énoncer les directives spéciales de grande

importance que l’on doit suivre.

LE PRÉSENT MANUEL A POUR BUT DE FACILITER

L’INSTALLATION ET L’UTILISATION DE LA POMPE

ET DOIT ÊTRE CONSERVÉ PRÈS DE CELLE-CI.

LIRE SOIGNEUSEMENT CHAQUE DIRECTIVE ET

AVERTISSEMENT AVANT D’EFFECTUER TOUT

TRAVAIL SUR LA POMPE.

N’ENLEVER AUCUNE DÉCALCOMANIE DE

SÉCURITÉ.

AVIS : INSPECTER L’APPAREIL ET SIGNALER

IMMÉDIATEMENT TOUT DOMMAGE AU

TRANSPORTEUR OU AU DÉTAILLANT. NE

PAS UTILISER L’APPAREIL SI L’ON

SOUPÇONNE QU’IL EST ENDOMMAGÉ.

APPAREIL NON CONÇU POUR LES

LIQUIDES DANGEREUX NI POUR

LES GAZ INFLAMMABLES.

Installation

Installation

• On DOIT installer la pompe sur une surface plane, hori-

zontale et solide, l’orifice de refoulement vers le haut.

• Laisser sufsamment d’espace pour l’entretien et

l’aération. Protéger l’appareil contre les intempéries, les

inondations et le gel.

• An de réduire les pertes de charge (par frottement) au

minimum, maintenir la tuyauterie aussi courte que possible, ne pas employer un calibre de tuyau inférieur à celui

des raccords d’aspiration et de refoulement ni utiliser

d’accessoires ou de raccords de tuyauterie superflus.

• Tous les tuyaux DOIVENT posséder leurs propres sup-

ports. Ils NE DOIVENT appliquer AUCUNE contrainte

sur la pompe.

AVIS : LA TUYAUTERIE NE DOIT PAS APPLIQUER

DE CONTRAINTES SUR LES RACCORDS

D’ASPIRATION ET DE REFOULEMENT DE

LA POMPE.

• Chaque joint de tuyauterie DOIT être étanche.

• L’emploi de ruban de TéonMC ou l’équivalent est re-

commandé pour TOUS les joints de tuyauterie.

TUYAUTERIE D’ASPIRATION

• La hauteur d’aspiration ne devrait pas dépasser 25 pi en

tenant compte de l’élévation et de la perte de charge.

• Poser un raccord union étanche sur le tuyau d’aspiration,

près de la pompe (v. fig. 1).

• Il est recommandé de xer un clapet de pied à l’entrée

du tuyau d’aspiration.

AVIS : POUR LES LONGS TUYAUX D’ASPIRATION,

LA POSE D’UN CLAPET DE PIED ET D’UN

CLAPET DE NON-RETOUR EST

RECOMMANDÉE.

• An de prévenir les poches d’air, aucun élément de la

tuyauterie d’aspiration ne devrait être plus haut que le

raccord d’aspiration de la pompe. Incliner la tuyauterie

vers le haut à partir de la source de liquide.

• Si le tuyau d’aspiration est de longueur importante, le

remplir d’eau avant de le raccorder à la pompe.

Description et caractéristiques

Description et caractéristiques

• Les RSPA et RJSP sont des pompes centrifuges

• Le corps de pompe est en fonte et comporte des orices

• La roue est du type fermé en NorylMC chargé de fibre de

• Les moteurs standard sont du type abrité, conforme

• Température maximale du liquide : 60 ºC (140 ºF)

• Démarrages par heure : maximum de 20, répartis

autoamorçantes, à un étage et à aspiration en bout,

servant à l’arrosage des pelouses, aux systèmes CVCA

(chauffage, ventilation et conditionnement d’air) et au

transfert d’eau de nature générale.

taraudés pour la vidange et pour la pose d’un vacuomètre.

verre et est vissée sur l’arbre de moteur.

à la NEMA et ont une vitesse de rotation de 3 500 r/min.

uniformément

21

AVERTISSEMENT

Les tensions dangereuses

peuvent causer un choc

électrique, des brûlures

et la mort.

Les hautes températures

peuvent causer des

blessures et des

dommages matériels.

AVERTISSEMENT

AVERTISSEMENT

Les tensions dangereuses

peuvent causer un choc

électrique, des brûlures

et la mort.

AVERTISSEMENT

Tension

dangereuse

TUYAUTERIE DE REFOULEMENT

TUYAUTERIE DE REFOULEMENT

• Poser au-dessus de l’orice de refoulement un té dont une

branche sera orientée vers le haut pour servir au premier

amorçage de la pompe (v. fig. 1).

ORIFICE D’AMORÇAGE

DISJONCTEUR

RACCORDS UNIONS

REFOULEMENT

ASPIRATION

Figure 1

Câblage et mise à la terre

Câblage et mise à la terre

Poser le fil de terre et les autres

fils suivant les prescriptions du

code provincial ou national de

l’électricité.

Poser un sectionneur tout conducteur près de la pompe.

Couper le courant avant de

procéder à l’installation ou à

l’entretien de la pompe.

L’alimentation électrique DOIT être conforme

aux spécifications de la plaque signalétique. Une

tension inappropriée peut causer un incendie ou

des dommages au moteur et annule la garantie.

Les moteurs monophasés non protégés DOI-

VENT être munis de contacteurs et de dispositifs

de protection contre les surcharges thermiques, et

les moteurs triphasés, de démarreurs à dispositif

de protection contre la surcharge. Consulter la

plaque signalétique du moteur.

• Suivre soigneusement le schéma de câblage sur la plaque

signalétique ou le cache-bornes du moteur.

• N’utiliser que du l de cuivre pour la mise à la terre et

l’alimentation du moteur. Le calibre du fil de terre DOIT

être au moins égal à celui des fils d’alimentation, et les fils

devraient tous être chromocodés pour faciliter l’entretien.

CALIBRE DE FIL MINIMAL RECOMMANDÉ

Sens de rotation

Sens de rotation

AVIS : LA ROTATION DANS LE MAUVAIS SENS

PEUT ENDOMMAGER LA POMPE ET

ANNULE LA GARANTIE.

• La rotation appropriée est en SENS HORAIRE (vers

la droite), vue du côté moteur.

Utilisation

Utilisation

L’UTILISATION D’UNE POMPE

DÉSAMORCÉE OU DONT LE ROBINET DE REFOULEMENT EST FERMÉ

PEUT PROVOQUER UN ÉCHAUFFEMENT, TRANSFORMER AINSI L’EAU

EN VAPEUR ET CAUSER DES BLESSURES ET DES DOMMAGES MATÉRIELS.

AVIS : NE PAS UTILISER UNE POMPE

DÉSAMORCÉE AFIN DE NE PAS EN

ENDOMMAGER LES DISPOSITIFS

D’ÉTANCHÉITÉ.

• Amorcer la pompe en remplissant cette dernière et la

tuyauterie d’eau propre par l’orifice supérieur du té

(v. fig. 1).

• Recouvrir les lets du bouchon d’amorçage de ruban de

TéflonMC ou l’équivalent et visser le bouchon sur le té.

AVIS : SI LA POMPE SE VIDE OU S’ARRÊTE

PENDANT L’AMORÇAGE, ON DOIT

LA REMPLIR DE NOUVEAU, PUIS

LA REMETTRE EN MARCHE.

• Mettre la pompe en marche, entrouvrir le robinet de

refoulement et attendre que la pression se stabilise. Des

à-coups de pression ou une chute de pression prolongée

indiquent un amorçage incorrect.

Entretien — tous les modèles

Entretien — tous les modèles

OMETTRE DE COUPER LE COURANT AVANT TOUT TRAVAIL

D’ENTRETIEN PEUT CAUSER UN

CHOC ÉLECTRIQUE, DES BRÛLURES

OU LA MORT.

• La pompe ne nécessite aucune

lubrification. Quant au moteur,

consulter et suivre les directives du

fabricant.

Distance entre l’entrée de service et le moteur

hp 15 m (50 pi) 30 m (100 pi) 46 m (150 pi) 61 m (200 pi)

115 V 230 V 115 V 230 V 115 V 230 V 115 V 230 V

¾ 12 14 10 14 8 14 6 12

1 12 14 8 14 8 12 6 12

1½ 10 14 8 14 12 10

2 10 14 8 14 12 10

3 12 12 10 10

22

OMETTRE LA MISE À LA TERRE

PERMANENTE DE LA POMPE, DU

MOTEUR ET DES COMMANDES

AVANT LE BRANCHEMENT À

LA SOURCE DE COURANT PEUT

CAUSER UN CHOC ÉLECTRIQUE,

DES BRÛLURES OU LA MORT.

USAGE SAISONNIER

• Pour la MISE HORS SERVICE, déposer tous les

bouchons de vidange et vider tous les tuyaux.

• Pour la REMISE EN SERVICE, reposer tous les bouchons

de vidange après en avoir recouvert les filets de ruban de

TéflonMC ou l’équivalent.

• Raccorder le tuyau d’aspiration à la pompe s’il a été

désaccouplé, examiner le raccord union et effectuer les

réparations nécessaires.

• Réamorcer et faire fonctionner la pompe suivant les directives et les avertissements de la section

« UTILISATION » ci-dessus.

AVERTISSEMENT

Les tensions dangereuses

peuvent causer un choc

électrique, des brûlures

et la mort.

AVERTISSEMENT

Les tensions dangereuses

peuvent causer un choc

électrique, des brûlures

et la mort.

Démontage — RJSP

Démontage — RJSP

OMETTRE DE COUPER LE

COURANT AVANT TOUT TRAVAIL

D’ENTRETIEN PEUT CAUSER UN

CHOC ÉLECTRIQUE, DES BRÛLURES

OU LA MORT.

1. Enlever la vis (10) de la patte de pompe (v. page suivante).

2. Déposer les vis (12) du corps de pompe (2).

3. Écarter l’ensemble d’entraînement de la roue d’avec

le corps de pompe.

4. Enlever la bague d’étanchéité (3) du diffuseur (6) ainsi

que la membrane (4).

5. Ôter les vis de fixation (5) du diffuseur à

l’adaptateur (11).

6. Déposer l’obturateur ou le couvercle d’extrémité du

moteur.

7. Immobiliser l’arbre de moteur au moyen de la fente ou

des méplats de blocage de 7⁄16 po situés à l’extrémité de

l’arbre.

8. Dévisser (SENS ANTIHORAIRE) et enlever

la roue (7).

9. Employer deux tournevis en guise de leviers et extraire

l’élément mobile de la garniture mécanique (8), puis le

jeter (v. fig. 2).

10. Enlever les vis (13) de l’adaptateur et déposer celui-ci.

11. Pousser l’élément fixe de la garniture mécanique hors de

l’adaptateur et le jeter.

3. Poser l’adaptateur sur le moteur en s’assurant que

l’arbre de moteur ne déloge ni n’endommage le siège de

l’élément fixe.

4. Pousser l’ensemble élément mobile à fond et à angle

droit contre l’élément fixe. S’assurer que l’élément mobile est bien maintenu en place par son collet de retenue.

NE PAS endommager la garniture mécanique.

5. Dans le cas des moteurs triphasés, on DOIT employer

du LOCTITEMD violet (« Purple ») pour poser la roue.

Bloquer l’arbre (v. section « DÉMONTAGE ») et visser

la roue à fond sur l’arbre en SENS HORAIRE.

6. Reposer le diffuseur tout en l’alignant pour empêcher la

roue de frotter.

7. Poser une membrane et une bague d’étanchéité (du dif-

fuseur) neuves.

8. Réinsérer l’ensemble d’entraînement de la roue dans le

corps de pompe.

9. Faire tourner l’arbre de moteur pour vérifier si la roue

est grippée. Si elle l’est, desserrer les vis du corps de

pompe, déplacer le diffuseur jusqu’à ce que la roue

tourne librement, puis resserrer les vis, en croix.

10. Remettre chaque bouchon de vidange et composant côté

moteur en place.

11. Réamorcer et faire fonctionner la pompe suivant les

directives de la section « UTILISATION » ci-dessus.

Diagnostic des anomalies — tous les modèles

Diagnostic des anomalies — tous les modèles

OMETTRE DE COUPER LE COURANT AVANT TOUT TRAVAIL

D’ENTRETIEN PEUT CAUSER UN

CHOC ÉLECTRIQUE, DES BRÛLURES

OU LA MORT.

Remontage — RJSP

Remontage — RJSP

• Nettoyer et inspecter chaque pièce avant le remontage.

1. Vérifier s’il y a présence de résidus ou d’usure sur

AVIS : ON DOIT CHANGER LA GARNITURE

MÉCANIQUE CHAQUE FOIS QU’ON

L’ENLÈVE. SUIVRE LES DIRECTIVES DU

FABRICANT DE LA GARNITURE AVEC

SOIN.

2. Au besoin, mouiller ou glycériner l’élément fixe de

Figure 2

le siège de garniture mécanique. Le nettoyer ou le

remplacer au besoin.

la garniture mécanique pour en faciliter la pose. NE

PAS le contaminer. Le pousser à fond et à angle droit

dans son siège, sur l’adaptateur. Avec un linge propre

non pelucheux, le nettoyer AVEC SOIN. NE PAS

l’endommager.

ANOMALIE

Non-fonctionnement du moteur

(V. causes probables 1 à 5)

Débit de refoulement faible ou nul

(V. causes probables 3, 4, 6 à 12 et 15)

Vibration et bruit excessifs

(V. causes probables 3, 6, 7, 10, 12, 13 et 14)

CAUSE PROBABLE

1. Protecteur thermique du moteur déclenché

2. Disjoncteur ouvert ou fusible sauté

3. Roue grippée

4. Moteur mal connecté

5. Moteur défectueux

6. Pompe non amorcée, air ou gaz présent dans le liquide

pompé

7. Tuyau d’aspiration ou de refoulement obstrué ou robinet

fermé

8. Mauvais sens de rotation (moteurs triphasés seulement)

9. Basse tension électrique ou perte de phase

10. Roue usée ou engorgée

11. Hauteur de charge du système trop élevée

12. Hauteur nette d’aspiration disponible (NPSHA) trop

faible – hauteur ou perte d’aspiration excessives

13. Hauteur de refoulement trop faible – débit excessif

14. Pompe, moteur ou tuyauterie mal assujettis

15. Entrée du tuyau d’aspiration non immergée

23

Données sur l’alimentation électrique — tous les modèles

Données sur l’alimentation électrique — tous les modèles

hp Tension (V) Courant (A) à pleine charge Disjoncteur PH/Hz

¾ 115/230 25/15 1/60

1 115/230 25/15 1/60

1½ 115/230

2 230

3 230 30 1/60

Liste de pièces de rechange — RJSP

Liste de pièces de rechange — RJSP

Nº

Description Matériau

d’art. RJSP RJSP RJSP RJSP RJSP

1 Bouchon, ¼ po, Acier galvanisé 6K2

NPT

2 Corps de pompe Fonte 1K449

Bague

3 d’étanchéité Buna 5K231

(diffuseur)

4 Membrane Néoprène 5K256

Vis à métaux à

5 tête cylindrique Inox 13K4 13K4 13K2 13K2 13K2

bombée

6 Diffuseur Lexan + 3K72 3K71 3K70 3K70 3K69

FV (10 %)

7 Roue Noryl + 2K715 2K716 2K714 2K713 2K712

FV (20 %)

Garniture Carbone,

8 mécanique céramique, 10K10

buna

9 Patte de pompe Acier 4K529

10 Vis Acier 13K252

(patte de pompe)

11 Adaptateur Fonte 1K450

(moteur)

12 Vis Acier 13K102

(corps de pompe)

13 Vis (adaptateur) Acier 13K89

14 Déflecteur Buna 5K7

FV = fibre de verre

75 100 150 200 300

(voir la plaque signalétique

du moteur)

25 1/60

hp 1 Ø, abrité

0,75 J05853LA

1,0 J06853LA

1,5 J07858LA

2,0 J08854LA

3,0 J09853A

Données techniques

Données techniques

Modèle hp PH/Hz Aspiration Refoulement Poids

(lb)

75RJSP ¾ 48

100RJSP 1 52

150RJSP 1½ 1/60 1½ po, NPT 1½ po, NPT 60

200RJSP 2 65

300RJSP 3 76

35/20 1/60

Codes de moteur — RJSP

24

14

8

7

6

5

4

3

2

1

11

9

1

13

12

10

Entretien — RSPA

Entretien — RSPA

LUBRIFICATION

1. Aucune lubrification n’est requise pour la pompe.

2. Consulter les directives du fabricant du moteur.

DÉPOSE DE LA GARNITURE MÉCANIQUE

1. Couper l’alimentation électrique de la pompe.

2. Éliminer la pression à l’intérieur du système : ouvrir un

robinet jusqu’à ce que l’eau arrête de couler.

3. Séparer le tube du pressostat d’avec le raccord à

barbillons du corps de pompe. Si l’on n’y parvient pas,

couper le tube aussi près que possible du raccord.

4. Déposer les quatre vis de fixation du corps de pompe

(fig. 3). On n’a pas à détacher la tuyauterie.

5. Avec un levier, séparer délicatement l’organe de

pompage (moteur, logement de garniture mécanique,

roue et diffuseur) du corps de pompe. Prendre garde de

ne pas endommager la roue.

6. Ôter le diffuseur du logement de garniture pour

pouvoir accéder à la roue.

7. Insérer un tournevis à pointe plate dans la fente du bout

d’arbre de moteur.

8. Immobiliser l’arbre avec le tournevis, puis dévisser (sens

antihoraire) la roue.

9. Retirer l’élément de garniture mobile de l’arbre, puis le

logement de garniture.

10. Extraire du logement l’élément de garniture fixe, y

compris l’élément en caoutchouc.

POSE D’UNE GARNITURE MÉCANIQUE NEUVE

1. Nettoyer la face polie de l’élément de garniture fixe

avec un linge propre.

2. Mouiller le pourtour de l’élément en caoutchouc avec

une solution savonneuse.

3. Insérer les éléments en caoutchouc et en céramique (la

face polie en dernier) dans le logement de garniture,

mais découper d’abord une rondelle de carton et la

placer contre l’élément en céramique pour protéger

celui-ci des éraflures pendant son insertion sous

pression. Jeter ensuite la rondelle.

4. Reposer le logement de garniture sur le moteur. Enfiler

l’élément mobile sur l’arbre, la surface d’étanchéité en

carbone en premier, jusqu’à ce que l’anneau en

caoutchouc de l’élément affleure le collet d’arbre.

5. Revisser (sens horaire) la roue sur l’arbre, que l’on

immobilisera avec un tournevis à pointe plate inséré

dans la fente du bout d’arbre.

6. Replacer le diffuseur sur le logement de garniture, puis

réunir l’organe de pompage et le corps de pompe avec

précaution. Assujettir l’organe de pompage au corps de

pompe avec les quatre vis de fixation.

7. Enfiler le tube du pressostat sur le raccord à barbillons

jusqu’à ce que le tube atteigne l’épaulement du raccord.

Si l’on a coupé le tube pour le détacher, enlever le bout

laissé sur le raccord avec un couteau, en prenant soin de

ne pas érafler le raccord.

DÉPOSE DU MOTEUR

1. Suivre les étapes 1-10 de la section « Dépose de la

garniture mécanique ».

REMPLACEMENT DU MOTEUR

1. Suivre les étapes 1-7 de la section « Pose d’une garniture

mécanique neuve ».

VIS DE

FIXATION

DU CORPS

DE POMPE

FIGURE 3

ARBRE

DE

MOTEUR

LOGEMENT DE GARNITURE

MÉCANIQUE

JOINT TORIQUE

ÉLÉMENT DE

GARNITURE EN

CAOUTCHOUC

ÉLÉMENT DE GARNITURE MOBILE

ÉLÉMENT DE GARNITURE EN CÉRAMIQUE

ROUE

DIFFUSEUR

JOINT

TORIQUE

25

TABLE DE PERFORMANCES — RSPA

Diamètre des ori-

fices de la pompe

Débit (gal US/min) selon la hauteur manométrique totale

Modèle Aspir. Refoul. hp 20 pi 30 pi 40 pi 50 pi 60 pi 70 pi 80 pi 90 pi 100 pi 110 pi 120 pi Pieds lbf/po

75 RSPA 2 po 2 po ¾ 50 49 48 45 41 35 25 88 38

100 RSPA 2 po 2 po 1 53 52 51 49 46 42 35 25 101 44

150 RSPA 2 po 2 po 1½ 53 53 52 51 51 49 44 39 32 20 115 50

200 RSPA 2 po 2 po 2 52 52 51 51 50 49 49 46 40 33 21 123 53

Hauteur à

débit nul

2

NOTA : les performances sont basées sur une hauteur d’aspiration de 15 pi.

LISTE DE PIÈCES DE RECHANGE DES MODÈLES

75RSPA, 100RSPA, 150RSPA, 150FSPA ET 200RSPA

Nº DESCRIPTION QUANTITÉ 75RSPA 100RSPA 150RSPA 150FSPA 200RSPA

1 Bouchon de tuyau, ¼ po, NPT 3 6K2 6K2 6K2 6K2 6K2

2 Corps de pompe 1 147953 147953 147953 147953 147953

3 Joint torique (67⁄16 po x 6¼ po x 3⁄32 po) 1 5K341 5K341 5K341 5K341 5K341

4 Joint torique (17⁄8 po x 11⁄16 po x 3⁄32 po) 1 5K340 5K340 5K340 5K340 5K340

5 Roue 1 1414404 1414414 1414424 1414304 1414304

6 Diffuseur 1 175561 175561 175571 175571 175571

7 Garniture mécanique (5⁄8 po) 1 1760371 1760371 1760371 1760371 1760371

8 Logement de garniture mécanique 1 671143 671143 671153 671153 671153

9 Vis du corps de pompe (16 x 3⁄8 po x 1½ po) 4 13K337 13K337 13K337 13K337 13K337

10 Manchon fileté (1 po x ½ po, NPT) 1 6K24 6K24 6K24 6K24 6K24

et écrou freiné

11 Moteur 1 1531761 1531771 1531781 1531781 1531791

26

NOTES / NOTAS

27

GARANTIE LIMITÉE DE RED JACKET WATER PRODUCTS

La présente garantie s’applique à chaque pompe de système d’alimentation en eau fabriquée par Red Jacket Water Products.

Toute pièce se révélant défectueuse sera remplacée sans frais pour le détaillant durant la période de garantie suivante expirant la première : douze (12)

mois à compter de la date d’installation ou dix-huit (18) mois à partir de la date de fabrication.

Le détaillant qui, aux termes de cette garantie, désire effectuer une demande de règlement doit s’adresser au distributeur Red Jacket Water Products agréé

chez lequel la pompe a été achetée et fournir tous les détails à l’appui de sa demande. Le distributeur est autorisé à régler toute demande par le biais du

service à la clientèle de Red Jacket Water Products.

La garantie ne couvre pas :

a) les frais de main-d’œuvre ni de transport ni les frais connexes encourus par le détaillant ;

b) les frais de réinstallation de l’équipement réparé ;

c) les frais de réinstallation de l’équipement de remplacement ;

d) les dommages indirects de quelque nature que ce soit ;

e) ni les pertes découlant de la panne.

Aux fins de la présente garantie, les termes ci-dessous sont définis comme suit :

1) « Distributeur » signifie une personne, une société de personnes, une société de capitaux, une association ou autre entité juridique servant

d’intermédiaire entre Red Jacket Water Products et le détaillant pour les achats, les consignations ou les contrats de vente des pompes en question.

2) « Détaillant » veut dire une personne, une société de personnes, une société de capitaux, une association ou autre entité juridique dont les activités

commerciales sont la vente ou la location de pompes à des clients.

3) « Client » signifie une entité qui achète ou loue les pompes en question chez un détaillant. Le « client » peut être une personne, une société de

personnes, une société de capitaux, une société à responsabilité limitée, une association ou autre entité juridique se livrant à quelque activité que ce

soit.

CETTE GARANTIE SE RAPPORTE AU DÉTAILLANT SEULEMENT.

Xylem, Inc.

2881 East Bayard Street Ext., Suite A

Seneca Falls, NY 13148

Téléphone: (866) 325-4210

Télécopie: (888) 322-5877

www.xyleminc.com/brands/redjacketwaterproducts

Red Jacket Water Products est une marque déposée de Xylem Inc. ou d'une de ses filiales.

© 2012, Xylem Inc. IM132 Révision numéro 2 Juillet 2012

Loading...

Loading...