INSTRUCTION MANUAL

IM078

Retain Manual for Reference

Marlow Series 20EVP

INSTALLATION, OPERATION AND MAINTENANCE INSTRUCTIONS

SUBJECT PAGE

Recommended Precautions ............................................................................................................................................ 3

Operating Instructions ................................................................................................................................................... 3

Operating ...................................................................................................................................................................... 4

Priming ...................................................................................................................................................................... 4

Rotation.....................................................................................................................................................................4

Winter Storage ........................................................................................................................................................... 4

Lubrication ................................................................................................................................................................ 4

Maintenance .............................................................................................................................................................. 4

Warning ..................................................................................................................................................................... 4

Caution......................................................................................................................................................................4

Instructions for Licensed Electricians ......................................................................................................................... 4

Troubleshooting Guide .................................................................................................................................................. 5

Repair Parts ................................................................................................................................................................... 6

Limited Warranty ..........................................................................................................................................................8

Owner’s Information

Owner’s Information

Please fill in data from your pump nameplate.

Warranty information is on page 8.

Pump Model:

Serial Number:

Dealer:

Dealer’s Phone Number:

Date of Purchase:

Installation Date:

2

CAUTION

CONGRATULATIONS

You are now the owner of a Goulds Water Technology

pump. This pump was carefully inspected and subjected

to final tests before releasing for shipment. In order to

assure maximum performance, please follow the simple

instructions in this manual.

RECOMMENDED PRECAUTIONS

1. Avoid system pressures that may exceed the maxi-

mum working pressure of the pump.

2. Should the fluid temperature rise more than 50ºF.

above ambient, expansion joints must be installed on

both the suction and discharge ports to relieve any

stress on the pump casing.

3. All electrical wiring of the pump installation must be

done by a licensed electrician who will observe all

national and local electrical codes. All motors require

a magnetic starter with current overload protection.

4. No modifications, additions or deletions should be

made to the pump, without prior approval of the

factory.

5. In systems where shock wave pressures may be gener-

ated, protective devices such as check valves/gate

valves, etc., must be installed on the discharge line

to prevent shock pressures from entering the pump

casing.

6. In systems containing discharge check valves, gate

valves, etc., the pump will not prime against a closed

valve. Check the discharge valves making sure they

are open before attempting to prime the pump. If

there is a possibility of air being entrapped in the

pump casing, install an automatic venting device to

bleed off the air.

7. This pump is designed primarily for water use. Before

pumping other liquids, read carefully the CAUTION

below.

8. Overheated pumps are dangerous. Burns or explosion

could occur due to steam pressure. Operating pumps

with suction and discharge closed is one cause of severe overheating. If overheating of the pump occurs:

1. Stop pump immediately, 2. Allow pump to cool, 3.

Slowly and cautiously vent pump.

9. Drain casing completely when servicing pumps handling volatile or harmful liquids.

10. Do not use in a combustible atmosphere.

11. Make daily checks of the tightness of suction and

discharge pipe, drain, filter plug and pump gaskets.

Operation should not proceed until all of the above

items have been checked and are tight.

12. After servicing the pump, always install the coupling

guards, belt guards and other safety devices as originally found prior to disassembly.

The performance of Goulds Water

Technology are based upon clear, cold,

fresh water with suction conditions as shown on the

performance curve. If used to pump other liquids, pump

performance may differ from rated performance based

on the different specific gravity, temperature, viscosity,

etc. of the liquid being pumped. A standard pump may

not be safe for pumping all types of liquids, such as toxic,

volatile or chemical liquids, or liquids under extreme

temperatures or pressures. Please consult your Goulds

Water Tehcnology catalog as well as local codes and

general references to determine the appropriate pumps

for your particular application. Since it is impossible

for us to anticipate every application of a Goulds Water

Tehcnology pump, if you plan to use the pump for a

non-water application, consult Goulds Water Tehcnology

beforehand to determine whether such application may

be proper or safe under the circumstances. Failure to do

so could result in property damage or personal injury.

OPERATING INSTRUCTIONS

GENERAL

• Our shipping container has been specically designed

to prevent transit damage. However, any indications

of damage or shortage should be carefully noted on

the delivery ticket and a claim filed promptly with the

carrier.

PROPER LOCATION

• By placing your pump on a rm, level foundation or

between firmly supported pipelines, you reduce harmful vibrations and unnecessary noises.

• While EV series pumps are self-priming and may be

located above the source of liquid supply, best pump

operation is obtained by locating the pump as close as

possible to the liquid being handled, keeping in mind a

pump can push liquid more effectively than it can pull

or draw liquid. Provide the necessary space around the

pump for future inspection and servicing of the unit.

PIPING

• All piping should be independently supported to eliminate excessive strain on the pump. Avoid unnecessary

friction losses. Keep your piping as short as possible

and use the fewest possible elbows and fittings. Pipe

joint compound that will not dissolve in the liquid

being pumped should be used on all joints. Gate valves

combined with unions or flanges, on both sides of the

pump, will facilitate pump removal without disturbing

the piping. It is occasionally advantageous to use suction pipe one size larger than that for which the pipe

is fitted. Eccentric reducers should be used to change

pipe sizes.

STRAINER ADVISABLE

• Protect your investment. Install a strainer on the suc-

tion line. This will eliminate clogging of the pump,

poor performance and excessive wear. A 16 mesh

strainer submerged one foot below the liquid level is

adequate for EV series pumps. In-line strainers are

available from your Goulds Water Technology dealer.

Piping that has a continuous rise will facilitate draining

the system.

VALVES

• Install a check valve on the discharge side of the pump.

This will prevent high surge back pressures from

damaging the pump. If the pump is disconnected this

check valve will prevent the liquid from draining the

discharge line.

• Some installations may require the throttling of the

pump. Gate valves may be used on the discharge side.

Place the check valve between pump and gate valve.

3

• If the pump is operated against a low discharge pres-

WARNING

CAUTION

sure, it may be noisy. Throttle down the discharge gate

valve until the noise is eliminated. This restriction will

not cause any appreciable loss in capacity.

OPERATING

PRIMING

• Fill the pump tank with liquid before starting. This

may be done through the elbow on the side of the tank.

Use pipe compound when replacing the plug in the

side elbow. These Goulds Water Technology prime and

reprime themselves providing the pump tank is filled

with liquid. Should you lose this liquid from the tank

accidentally or by draining purposely, it will be necessary to refill it with liquid before starting. High suction

lifts, or long suction lines, require additional time and

reduce the performance of the pump. Should you have

difficulty, refer to the Troubleshooting Guide.

• Always keep liquid in the pump tank. No further

lubrication of the pump end is necessary including the

seal assembly. If flow does not start within five minutes,

stop the motor and determine cause (see Trouble-shooting Guide). Be sure all suction and discharge valves are

open when the pump is priming. Operating the pump

with a closed valve in the system can cause pump damage.

ROTATION

• Your pump is specically designed to rotate as indicated

by the arrow on the pump tank. Three phase motors

can rotate in either direction. Check the rotation. Interchanging any two leads of a three phase motor will

reverse the rotation, if this is found necessary.

Some motors are equipped with built-

in thermal over-loads to shut off the

motor in the event the temperature becomes excessive

(as a result of mechanical or electrical problems; such

as low voltage, poor ventilation, overloaded lines, etc.).

These motors will restart automatically as the motor

cools down. For safety sake, do not work on any motor,

without first shutting off the electricity at the source as

outlined above in the “Warning”. Also all three phase

motors are not thermal protected and motor starters are

recommended.

INSTRUCTIONS FOR LICENSED ELECTRICIANS:

INSTRUCTIONS FOR LICENSED ELECTRICIANS:

TURN POWER OFF

1. Determine the voltage of the power supply line to

motor. Voltage, phase, ampere draw, and cycles are

given on the motor nameplate.

The wire used to supply power to the motor must be

large enough to carry the amperes for the required

length without excessive voltage drop. The following table is meant to be a guide only to the minimum

proper wire size selection. Always consult local electrical codes.

Typical AWG Wire Size for Single Phase Jet Pump Motors

50 Ft. Wire Length 100 Ft. Wire Length

HP

115 V 230 V 115 V 230 V

1

⁄3 14 – 12 –

½ 14 14 10 14

¾ 12 14 10 14

1 12 14 8 14

1½ 10 14 8 12

2 8 12 8 12

WINTER STORAGE

• During freezing weather, it is especially important to

drain all of the liquid from the pump tank. This will

prevent ice from cracking the tank or internal parts.

• To maintain the excellent performance of the pump, follow the motor manufacturer’s storage instructions.

LUBRICATION

• The latest engineering advancements have been in-

corporated into our self-lubricating shaft seal. The liquid

being pumped cools and lubricates the seal, therefore

the pump should never be run dry. A seal well vent has

been provided to protect the electric motor from liquid

damage should the seal leak. DO NOT plug this vent. If

leakage becomes excessive, replace the seal assembly.

MAINTENANCE

• If your pump is not used for a few days, drain the liquid

completely. This will prevent aggravating costly rust

formations.

All electrical work MUST be done by

a licensed electrician. Before working

on motors be certain that the electrical power is off at

the main junction box. Disconnect the fuse or circuit

breaker and have the main switch tagged “Do Not Energize This Switch, Personnel Working on Equipment”.

4

TROUBLESHOOTING GUIDE

The following are some common causes of problems that may arise.

SYMPTOMS PROBABLE CAUSE RECOMMENDED ACTION

Will Not Prime No liquid Fill tank with liquid.

Air leak in suction line Tighten all joints or remake using new

compound.

Blocked suction line Clean strainer or suction line.

Worn seal Install new seal.

Suddenly Stops Clogged strainer or impeller Clean debris.

Pumping

Slowly Stops Clogged impeller, diffuser, lines or loose Clean debris and use strainer. Tighten filler

Pumping filler plug plug.

Excessive Leakage Worn seal Replace seal.

From Seal Well Vent

Will Not Worn seal Replace seal.

Hold Prime

Air leak in suction line Fix leak.

Missing or broken impeller key Replace.

Suction lift too high Relocate pump closer to supply.

Performance Poor Worn impeller or seal Replace with new impeller or seal.

Suction lift too high Relocate pump closer to supply.

Low Flow Motor not up to speed, low voltage Larger lead wires.

Or Pressure

compound.

Blocked line Clean strainer or suction line.

Worn seal Install new seal.

Incorrect rotation (three phase motor) Interchange any two leads to reverse the

rotation.

Noisy Operation Worn motor bearings Replace.

Low discharge head Throttle discharge.

Debris lodged in impeller Disassemble pump and clean out.

Cavitation Improve suction conditions.

Air leak Tighten all joints or remake using new

5

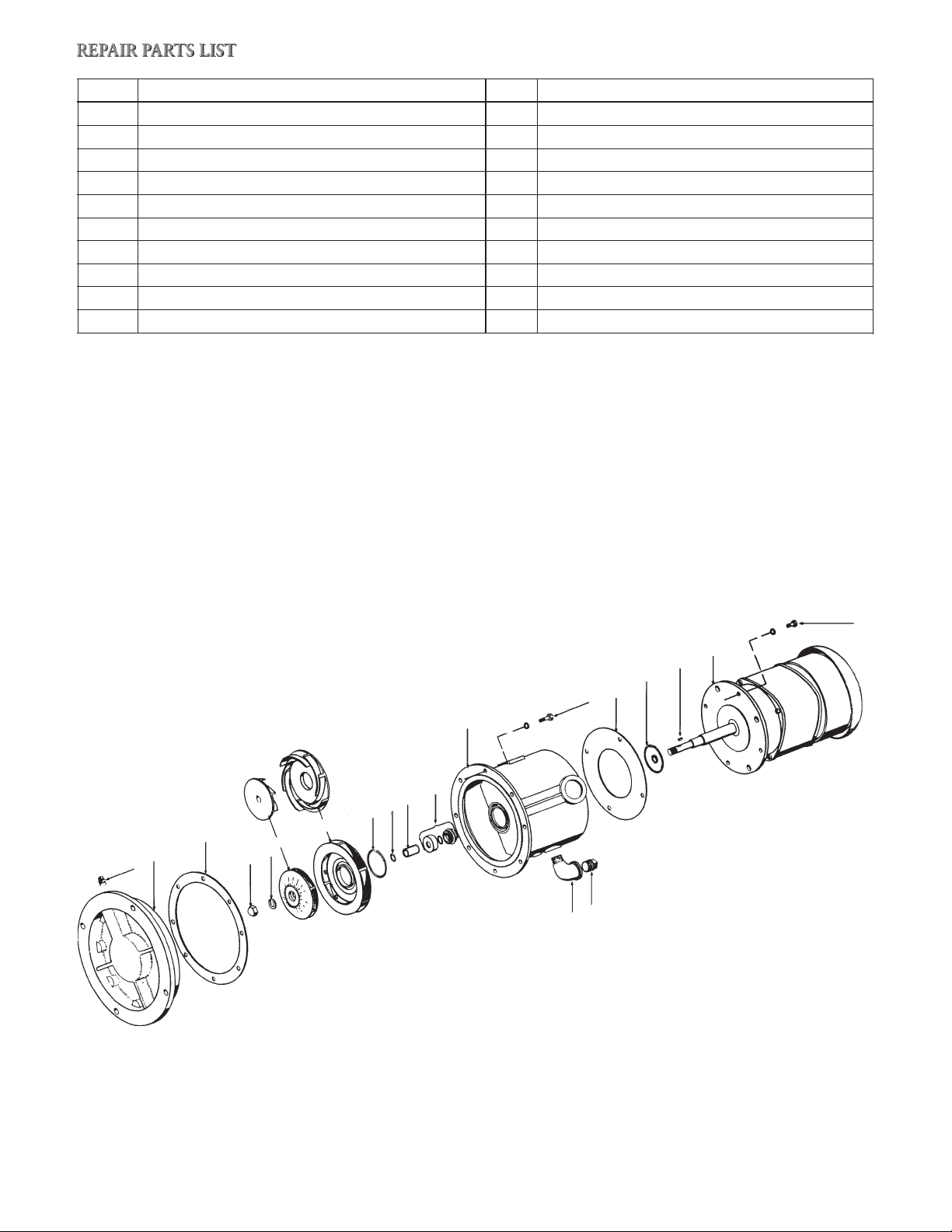

REPAIR PARTS LIST

Key Description Key Description

1 Drain plug 11➀ Seal assembly

2 Cover 12 Tank

3➀ Gasket, cover 13➀ Shim, motor

4➀ Impeller nut 14➀ Impeller key

5➀ Impeller washer 15 Cap screw

6➁ Impeller 16 Cap screw

7➁ Diffuser 17➀ Slinger

8➀ Gasket, diffuser 18 Elbow

9➀ Impeller, shim 19 Filler plug

10➀ Impeller spacer 20 Motor

➀ Recommended spare parts

➁ Recommended distributor stock, export spares and critical service.

IMPORTANT:

How to use the drawing to order parts:

The above grouping of parts illustrations cover many different Goulds Water Technology models, including your

own pump. The table on the left page indicates the name of each part. Should you need a replacement, refer to

the drawing - locate the part that matches your pump part. Contact your local Goulds Water Technology dealer

and supply him with the key number and description of the parts required, along with your pump model number

and serial number, which are located on the pump nameplate.

16

20

14

17

13

15

12

11

10

9

8

3

2

1

5

4

7

6

19

18

6

NOTES

7

GOULDS WATER TECHNOLOGY LIMITED WARRANTY

This warranty applies to all water systems pumps manufactured by Goulds Water Technology.

Any part or parts found to be defective within the warranty period shall be replaced at no charge to the dealer during the warranty period. The warranty period shall exist for a

period of twelve (12) months from date of installation or eighteen (18) months from date of manufacture, whichever period is shorter.

A dealer who believes that a warranty claim exists must contact the authorized Goulds Water Technology distributor from whom the pump was purchased and furnish complete

details regarding the claim. The distributor is authorized to adjust any warranty claims utilizing the Goulds Water Technology Customer Service Department.

The warranty excludes:

(a) Labor, transportation and related costs incurred by the dealer;

(b) Reinstallation costs of repaired equipment;

(c) Reinstallation costs of replacement equipment;

(d) Consequential damages of any kind; and,

(e) Reimbursement for loss caused by interruption of service.

For purposes of this warranty, the following terms have these definitions:

(1) “Distributor” means any individual, partnership, corporation, association, or other legal relationship that stands between Goulds Water Technology and the dealer in

purchases, consignments or contracts for sale of the subject pumps.

(2) “Dealer” means any individual, partnership, corporation, association, or other legal relationship which engages in the business of selling or leasing pumps to customers.

(3) “Customer” means any entity who buys or leases the subject pumps from a dealer. The “customer” may mean an individual, partnership, corporation, limited liability company,

association or other legal entity which may engage in any type of business.

THIS WARRANTY EXTENDS TO THE DEALER ONLY.

Xylem, Inc.

2881 East Bayard Street Ext., Suite A

Seneca Falls, NY 13148

Phone: (800) 453-6777

Fax: (888) 322-5877

www.xyleminc.com/brands/gouldswatertechnology

Goulds is a registered trademark of Goulds Pumps, Inc. and is used under license.

© 2012 Xylem Inc. IM078 Revision Number 4 March 2012

MANUAL DE INSTRUCCIÓN

IM078

Mantenga este manual para consultas

Serie Marlow 20EVP

INSTRUCCIONES DE INSTALACIÓN OPERACIÓN Y MANTENIMIENTO

Índice

Índice

TEMA PAGINA

Precauciones recomendadas .........................................................................................................................................11

Instrucciones de operación .......................................................................................................................................... 11

Operación ................................................................................................................................................................... 12

Cebado .................................................................................................................................................................... 12

Rotación .................................................................................................................................................................. 12

Almacenamiento de invierno .................................................................................................................................... 12

Lubricación .............................................................................................................................................................. 12

Mantenimiento ........................................................................................................................................................ 12

Advertencia ..............................................................................................................................................................12

Precaución ............................................................................................................................................................... 12

Instrucciones para electricistas con licencia .............................................................................................................. 12

Guía de solución de fallas ............................................................................................................................................ 13

Refacciones .................................................................................................................................................................14

Garantía limitada ......................................................................................................................................................... 16

Información del propietario

Información del propietario

Favor de copiar a continuación los datos de la placa de datos

de su bomba.

La información de la garantía está en la página 16.

Número de modelo de la bomba

Número de serie

Distribuidor

Teléfono del dist.

Fecha de compra

Fecha de instalación

10

PRECAUCIÓN

FELICIDADES

Ya es usted el propietario de una bomba Goulds Water

Technology. Ésta bomba se inspeccionó cuidadosamente

y se sujetó a las pruebas finales antes de liberarla para

su embarque. Para asegurar un desempeño máximo, por

favor sigua las instrucciones de este manual.

PRECAUCIONES RECOMENDADAS

PRECAUCIONES RECOMENDADAS

1. Evite presiones en el sistema que excedan la presión

máxima de trabajo de la bomba.

2. Si la temperatura del fluido se eleva a más de 50°F

por encima de la temperatura ambiente, se deben

instalar las juntas de expansión tanto en el puerto de

succión como en el de descarga para liberar cualquier

tensión de la carcasa de la bomba

3. Un electricista autorizado deberá realizar todo el

cableado eléctrico de la instalación de la bomba de

conformidad con todos los códigos nacionales y

locales de electricidad. Todos los motores eléctricos

requieren de un arrancador magnético con protección de sobre carga de corriente.

4. No se deben hacer modificaciones, añadiduras ni

omisiones a la bomba sin la aprobación previa de la

fábrica.

5. En los sistemas en los que pueda generarse una pre-

sión de ondas de choque, se deben instalar dispositivos de protección en la línea de descarga tales como

válvulas de retención/ válvulas de compuertas, etc.,

para evitar que las presiones de choque entren a la

carcasa de la bomba.

6. En los sistemas que contienen válvulas de retención

de descarga, válvulas de compuerta, etc., la bomba

no se cebará contra una válvula cerrada. Verique

que las válvulas de descarga estén abiertas antes de

intentar cebar la bomba. Si existe la posibilidad de

que quede aire atrapado en la carcasa de la bomba,

instale un dispositivo de ventilación automático para

purgar el aire.

7. Esta bomba ha sido diseñada principalmente para

manejar agua. Antes de bombear otros líquidos, lea

cuidadosamente la siguiente PRECAUCIÓN.

8. Las bombas sobrecalentadas son peligrosas. La

presión del vapor podría ocasionar quemaduras o

explosión. Una causa de sobrecalentamiento grave en

las bombas es la operación de las mismas con las tuberías de succión y descarga cerradas. En caso de que

la carcasa de la bomba se sobrecaliente: 1. Detenga

la bomba de inmediato. 2. Permita que se enfríe. 3.

Ventílela despacio y con cuidado.

9. Drene completamente la carcasa de la bomba cuando

maneja líquidos volátiles o peligrosos.

10. No la use en atmósferas inflamables.

11. Haga revisiones diarias de la hermeticidad de los

tubos de descarga y de succión, drenaje, tapones de

filtro y juntas de la bomba. No se deberá proceder

con la operación hasta que todos los puntos anteriores se hayan revisado y estén correctos.

12. Después de dar servicio a la bomba, siempre instale

las guardas de acoplamiento, guardas de bandas y

otros dispositivos de seguridad como se encontraban

originalmente antes del desensamble.

El desempeño nominal de las bombas

Goulds Water Technology se basa en

el bombeo de agua fresca, fría y transparente con las

condiciones de succión que se muestran en la curva

de desempeño. Si usa la bomba para otros líquidos, el

desempeño de la misma puede diferir del nominal en

base a la diferencia de gravedad, temperatura, viscosidad,

etc. Puede ser que una bomba estándar no sea segura

para bombear todos los tipos de líquidos, como tóxicos,

volátiles o químicos, o líquidos bajo temperaturas o presiones extremas. Por favor consulte el catalogo de Goulds

Water Technology así como códigos locales y referencias

generales para determinar las bombas apropiadas para su

aplicación en particular.

Ya que es imposible para nosotros anticipar cada aplicación de una bomba Goulds, si usted planea usarla para

una aplicación que no sea agua, consulte previamente a

Goulds Water Technology para determinar si dicha aplicación puede ser apropiada o segura según las circunstancias. No hacerlo puede resultar en daños a la propiedad o

lesiones al personal.

INSTRUCCIONES DE OPERACIÓN

INSTRUCCIONES DE OPERACIÓN

GENERALIDADES

• Nuestro contenedor de embarque se diseñó especícamente para evitar daños de transporte. Sin embargo,

cualquier indicación de daño o faltantes debe anotarse

detalladamente en la nota de entrega y se debe enviarle de inmediato una reclamación correspondiente al

transportista.

UBICACIÓN APROPIADA

• Al colocar su bomba Goulds en una cimentación rme

y nivelada o entre tuberías firmemente soportadas, se

reducen las vibraciones peligrosas y los ruidos innecesarios.

• Las bombas de la serie EV son de autocebadura y

pueden colocarse por encima de la fuente de abastecimiento de líquido; sin embargo, el mejor funcionamiento de la bomba se obtiene colocando la bomba tan

cerca como sea posible del líquido que se va a manejar,

teniendo en cuenta que la bomba es más efectiva en

empujar un líquido que en succionarlo. Considere el

espacio necesario alrededor de la bomba para permitir

inspeccionar y darle mantenimiento a la unidad.

TUBERÍA

• Todas las tuberías se deben soportar de manera independiente para eliminar cualquier exceso de tensión en

la bomba, evitar las pérdidas de fricción innecesarias,

mantener sus tuberías tan cortas como sea posible y

minimizar el uso de codos y conexiones. En todas las

juntas se debe usar un compuesto que no se disuelva en

el líquido que se bombea. Las válvulas de compuerta

combinadas con uniones o bridas en ambos lados de la

bomba, facilitaran la remoción de la misma sin alterar

la tubería. El algunas ocasiones, resulta ventajoso usar

un tubo de succión de un tamaño más grande que el

ancho del tubo al que se va a conectar. Se deben usar

reductores excéntricos para los cambios de diámetro de

la tubería.

FILTRO RECOMENDABLE

• Proteja su inversión; instale un ltro en la línea de

succión. Esto evitará que la bomba se atasque, que el

rendimiento baje y que se produzca un desgaste excesivo. Un colador de malla 16 sumergido un pie debajo

del nivel del líquido es adecuado para las bombas de

la Serie EV. Puede conseguir coladores en-línea con

11

su distribuidor de Goulds Water Technology. La tu-

ADVERTENCIA

PRECAUCIÓN

bería con una pendiente continua facilita el drenaje del

sistema.

VÁLVULAS

• Instale una válvula de retención en el lado de descarga

de la bomba para evitar que ésta se dañe por altas contrapresiones repentinas. Si la bomba está desconectada,

está válvula de retención evitará que se drene la línea de

descarga.

• Algunas instalaciones pueden necesitar que se reduzca

el flujo a través de la bomba. Para tal fin se pueden

usar válvulas de compuerta en el lado de descarga. La

válvula de retención deberá colocarse entre la bomba y

la válvula de compuerta.

• Si la bomba opera con una presión de descarga baja,

puede producir mucho ruido. Incremente la presión por

medio de la válvula de compuerta de descarga hasta que

se elimine el ruido. Esta restricción no causará ninguna

pérdida apreciable de capacidad.

OPERACIÓN

OPERACIÓN

CEBADURA

• Llene el tanque de la bomba con líquido antes del arranque; para tal efecto puede usar el codo del lado del

tanque. Utilice un compuesto para tubería cuando coloca de nuevo el tapón en el codo lateral. Estas bombas

Goulds se ceban de manera automática siempre que el

tanque de la bomba esté lleno de líquido. Si perdiera el

líquido del tanque de manera accidental o por drenarlo

a propósito, será necesario rellenarlo con líquido antes

de arrancar la bomba. Las elevaciones de succión altas

o líneas de succión largas, requieren tiempo adicional y

reducen el desempeño de la bomba. Si tiene dificultades,

consulte la Guía de Investigación y Solución de Fallas.

• Siempre mantenga con líquido el tanque de la bomba.

No es necesaria más lubricación en el extremo de la

bomba y en el sello. Si el flujo no inicia dentro de los

primeros cinco minutos, detenga el motor y determine

la causa, (vea la Guía de Investigación y Solución de

Fallas). Asegúrese de que todas las válvulas de descarga

y de succión estén abiertas cuando la bomba se está

cebando. La operación de la bomba con una válvula

cerrada en el sistema la puede dañar.

ROTACIÓN

• Su bomba ha sido diseñada especícamente para girar

como lo indica la flecha en el tanque de la bomba. Los

motores trifásicos pueden girar en cualquier dirección;

por lo tanto, verifique la rotación. Puede invertir la rotación al intercambiar cualquier par de cables del motor

trifásico, si fuera necesario.

ALMACENAMIENTO DE INVIERNO

• Con temperaturas ambientales bajo cero, es especialmente importante drenar todo el líquido del tanque de

la bomba. Esto evitará que el hielo que se puede formar

rompa el tanque o partes internas.

• Para mantener un desempeño excelente de la bomba,

siga las instrucciones de almacenamiento del fabricante

del motor.

LUBRICACIÓN

• Nuestro sello de eje autolubricante lleva los últimos

avances de la ingeniería. El líquido que se va a bombear

enfría y lubrica el sello; por lo tanto, la bomba nunca

deberá operarse en seco. Se ha proporcionado un sello

bien ventilado para proteger el motor eléctrico de daños

por el líquido que se pudiera fugar del sello. NO TAPE

esta ventilación. Si la fuga es excesiva, reemplace el

conjunto del sello.

MANTENIMIENTO

• Si la bomba no se va a usar por unos días, drene totalmente el líquido; esto evitará la oxidación, la cual es

grave y costosa.

Todo el trabajo eléctrico lo debe hacer

un electricista calificado. Antes de trabajar en los motores, se debe tener la certeza de que el

suministro de energía está desconectado en la caja principal de conexiones. Desconecte el fusible o interruptor

de circuito y ponga una etiqueta al interruptor principal

con la leyenda “No energizar este interruptor, Personal

trabajando en el equipo”.

Algunos motores están equipados con

sobrecargas térmicas integradas para

apagar el motor en el caso de un exceso de temperatura

(que puede resultar de problemas eléctricos o mecánicos,

como voltaje bajo, mala ventilación, líneas con exceso de

carga, etc.) Estos motores arrancarán de nuevo de manera

automática cuando su temperatura baje a cierto valor. Por

seguridad, no trabaje en el motor sin primero desconectar

el suministro eléctrico de la fuente mencionada antes en

la ADVERTENCIA. También, todos los motores trifásicos

no tienen protección térmica y se recomienda poner arrancadores de motor.

INSTRUCCIONES PARA ELECTRICISTAS CON

INSTRUCCIONES PARA ELECTRICISTAS CON

LICENCIA

LICENCIA

APAGAR

1. Determine el voltaje de la línea de alimentación

eléctrica al motor. El voltaje, fase, salida de amperes y

ciclos se indican en la placa de datos del motor.

El cable que se usa para alimentar al motor debe

ser lo suficientemente grueso para los amperes y la

longitud que se requiere, sin que se produzca una

caída excesiva de voltaje. La siguiente tabla pretende

ser sólo una guía para la selección de los tamaños

mínimos apropiados de cable. Consulte siempre los

códigos eléctricos locales.

Tamaños típicos de cable AWG para motores monofásicos de bombas

Longitud del cable 50 pies Longitud del cable 100 pies

HP

115 V 230 V 115 V 230 V

1

⁄3 14 – 12 –

½ 14 14 10 14

¾ 12 14 10 14

1 12 14 8 14

1½ 10 14 8 12

2 8 12 8 12

12

GUÍA DE SOLUCIÓN DE FALLAS

GUÍA DE SOLUCIÓN DE FALLAS

Las siguientes son algunas causas comunes de problemas que pueden surgir.

SÍNTOMAS CAUSA PROBABLE ACCION QUE SE RECOMIENDA

No se ceba No hay líquido Llene el tanque con líquido

Hay fuga de aire en la línea de succión Apriete todas las juntas o colóquelas de

nuevo usando un compuesto nuevo

Línea de succión obstruida Limpie el colador o la línea de succión

Sello gastado Instale un sello nuevo

Deja de bombear Colador o impulsor atorado Quite la basura

repentinamente

Deja de bombear Impulsor, difusor o líneas obstruidas o Quite la basura y use un colador, apriete

paulatinamente tapón de relleno suelto el tapón de relleno

Fuga excesiva en el Sello gastado Reemplace el sello

sello de la

ventilación del pozo

No mantiene la Sello gastado Reemplace el sello

bomba cebada

Fuga de aire en la línea de succión Escape del arreglo

Chaveta del impulsor perdida o rota Reemplace

Elevación de succión muy alta Reubique la bomba más cerca del suministro

Pobre desempeño Sello o impulsor gastado Reemplace el sello o impulsor por uno nuevo

Elevación de succión muy alta Reubique la bomba más cerca del suministro

Flujo o presión bajos El motor no alcanza la velocidad, voltaje bajo Alambres conductores más largos

usando compuestos nuevos

Línea obstruida Limpie el colador o la línea de succión

Sello gastado Instale un sello nuevo

Rotación incorrecta (motor trifásico) Intercambie cualquier par de conductores

para invertir la rotación

Operación ruidosa Cojinetes del motor gastados Reemplace

Presión estática de descarga baja Reducir el flujo descarga

Basura atorada en el impulsor Desensamble la bomba y límpiela

Cavitación Mejore las condiciones de succión.

Fuga de aire Apriete todas las juntas o reinstálelas

13

LISTA DE PARTES DE REPUESTO

LISTA DE PARTES DE REPUESTO

Clave Descripción Clave Descripción

1 Tapón de drenaje 11➀ Conjunto de sello

2 Cubierta 12 Tanque

3➀ Junta, cubierta 13➀ Calza, motor

4➀ Tuerca del impulsor 14➀ Chaveta del impulsor

5➀ Arandela del impulsor 15 Tornillo

6➁ Impulsor 16 Tornillo

7➁ Difusor 17➀ Eslingador

8➀ Junta , difusor 18 Codo

9➀ Impulsor, calza 19 Tapón del filtro

10➀ Impulsor, espaciador 20 Motor

➀ Partes de repuesto recomendadas

➁ Partes que se le recomienda al distribuidor tener en existencia, partes de exportación y partes críticas para el servicio

IMPORTANTE:

Cómo usar el dibujo para solicitar partes de repuesto:

Las ilustraciones anteriores de grupos de partes cubren diferentes modelos de Goulds Water Technology,

incluyendo la bomba de usted. La tabla en la página izquierda indica el nombre de cada parte. Si necesitara

cambiar una de ellas, consulte el dibujo y localice la parte que coincida con la parte de su bomba. Contacte a su

distribuidor local de Goulds Water Technology y déle el número de clave y descripción de las partes que requiera, junto con el número de modelo y número de serie de su bomba, que se localizan en la placa de datos de la

misma.

16

20

14

17

13

15

12

11

10

9

8

3

2

1

5

4

7

6

19

18

14

NOTAS

NOTAS

15

GARANTÍA LIMITADA DE GOULDS WATER TECHNOLOGY

Esta garantía es aplicable a todas las bombas para sistemas de agua fabricadas por Goulds Water Technology.

Toda parte o partes que resultaren defectuosas dentro del período de garantía serán reemplazadas durante dicho período de garantía sin cargo para el comerciante. Tal período de

garantía se extiende por doce (12) meses a partir de la fecha de instalación, o dieciocho (18) meses a partir de la fecha de fabricación, la que se cumpla primero.

El comerciante que considere que existe lugar a un reclamo de garantía deberá ponerse en contacto con el distribuidor autorizado de Goulds Water Technology del cual adquiriera

la bomba y brindar información detallada con respecto al reclamo. El distribuidor está autorizado a liquidar todos los reclamos por garantía a través del Departamento de Servicios

a Clientes de Goulds Water Technology.

La presente garantía excluye:

(a) La mano de obra, el transporte y los costos relacionados en los que incurra el comerciante;

(b) los costos de reinstalación del equipo reparado;

(c) los costos de reinstalación del equipo reemplazado;

(d) daños emergentes de cualquier naturaleza; y

(e) el reembolso de cualquier pérdida causada por la interrupción del servicio.

A los fines de esta garantía, los términos “Distribuidor”, “Comerciante” y “Cliente” se definen como sigue:

(1) “Distribuidor” es aquel individuo, sociedad, corporación, asociación u otra entidad jurídica que opera entre Goulds Water Technology y el comerciante para la compra, consig-

nación o contratos de venta de las bombas en cuestión.

(2) “Comerciante” es todo individuo, sociedad, corporación asociación u otra entidad jurídica que realiza negocios de venta o alquiler-venta (leasing) de bombas a los clientes.

(3) “Cliente” es toda entidad que compra o adquiere bajo la modalidad de leasing las bombas en cuestión de un comerciante. El término “cliente” puede significar un individuo,

sociedad, corporación, sociedad de responsabilidad limitada, asociación o cualquier otra entidad jurídica con actividades en cualquier tipo de negocios.

LA PRESENTE GARANTÍA SE EXTIENDE AL COMERCIANTE ÚNICAMENTE.

Xylem, Inc.

2881 East Bayard Street Ext., Suite A

Seneca Falls, NY 13148

Teléfono: (800) 453-6777

Fax: (888) 322-5877

www.xyleminc.com/brands/gouldswatertechnology

Goulds es una marca registrada de Goulds Pumps, Inc. y se utiliza bajo licencia.

© 2012 Xylem Inc. IM078 Revisión Número 4 Marzo 2012

MANUEL D'UTILISATION

IM078

À conserver à titre consultatif

Marlow, série 20EVP

DIRECTIVES D’INSTALLATION, D’UTILISATION ET D’ENTRETIEN

Table des matières

Table des matières

SUJET PAGE

Précautions recommandées .......................................................................................................................................... 19

Directives d'utilisation ................................................................................................................................................. 19

Utilisation .................................................................................................................................................................... 20

Amorçage ................................................................................................................................................................ 20

Sens de rotation ....................................................................................................................................................... 20

Entreposage hivernal................................................................................................................................................20

Lubrification ............................................................................................................................................................ 20

Entretien .................................................................................................................................................................. 20

Directives pour les électriciens ..................................................................................................................................... 20

Diagnostic des anomalies ............................................................................................................................................. 21

Liste de pièces de rechange .......................................................................................................................................... 22

Garantie limitée ........................................................................................................................................................... 24

Informations pour le propriétaire

Informations pour le propriétaire

Inscrire ci-dessous les informations pertinentes indiquées sur

la plaque signalétique de la pompe. La garantie se trouve en

page 24.

No de modèle de la pompe :

No de série de la pompe :

Détaillant :

No de tél. du détaillant :

Date d’achat :

Date d’installation :

18

ATTENTION

FÉLICITATIONS !

Vous êtes maintenant propriétaire d’une pompe Goulds

Water Technology, soigneusement inspectée et soumise

aux derniers essais avant de recevoir l’autorisation

d’expédition. Pour en maximiser les performances, suivre

les directives du présent manuel.

PRÉCAUTIONS RECOMMANDÉES

PRÉCAUTIONS RECOMMANDÉES

1. S’assurer que la pression du système ne dépasse pas la

pression de service maximale de la pompe.

2. Si la température du liquide devait excéder la tempé-

rature ambiante de plus de 50 °F, poser un joint de dilatation sur les orifices d’aspiration et de refoulement

de la pompe pour protéger celle-ci des contraintes.

3. Tout le matériel électrique doit être connecté par un

électricien selon le code provincial ou national de

l’électricité pertinent et les règlements locaux. Tous

les moteurs nécessitent un démarreur magnétique

avec protection contre les surcharges.

4. On ne peut modifier la pompe, y ajouter des éléments

ni en enlever sans avoir obtenu l’approbation de

l’usine à cette fin.

5. Si des ondes de choc peuvent se propager dans le

système, on doit poser des protections (clapets de

non-retour, robinets-vannes, etc.) sur le tuyau de

refoulement pour empêcher les coups de bélier de

parvenir au corps de pompe.

6. On ne peut amorcer une pompe dont le tuyau de

refoulement est bloqué par des appareils fermés du

genre clapet de non-retour, robinet-vanne, etc. Voir à

ce que ces appareils soient ouverts avant l’amorçage.

Si de l’air peut s’accumuler dans le corps de pompe,

poser un purgeur d’air automatique.

7. Les 20EVP sont conçues principalement pour le

pompage de l’eau. Avant de les utiliser pour d’autres

liquides, lire attentivement la mise en garde (« !

ATTENTION ») ci-dessous.

8. La surchauffe de la pompe est surtout due à l’arrêt de

la circulation du liquide dans les tuyaux (aspiration et

refoulement). Elle est dangereuse : elle peut générer

de la vapeur, causer des brûlures et provoquer une

explosion. S’il y a surchauffe, 1) arrêter la pompe ; 2)

la laisser refroidir ; 3) en purger la vapeur lentement

et avec précaution.

9. Si la pompe contient des liquides volatiles ou dange-

reux, la vidanger avant d’en effectuer l’entretien.

10. Ne pas utiliser la pompe en milieu combustible.

11. Vérier journellement l’étanchéité de la tuyauterie,

des bouchons de vidange, de l’évent à filtre et des

joints de la pompe. Ne pas mettre celle-ci en marche tant que la vérification en question n’a pas été

effectuée.

12. Après l’entretien de la pompe, il faut reposer le carter

d’accouplement, le protège-courroie et les autres protections d’origine installés avant le démontage.

Les performances des pompes Goulds sont

basées sur le pompage d’eau douce, limpide et froide dans les conditions d’aspiration figurant

dans les courbes de performances. Avec les autres

liquides, les performances peuvent varier, compte

tenu de la densité, de la température et de la viscosité

du liquide. L’usage d’une pompe standard peut être

risqué si le liquide est très chaud, toxique, volatile,

d’origine chimique ou sous une très forte pression.

Il vaut mieux consulter le catalogue Goulds Water

Technology ainsi que les codes locaux et les ouvrages

de référence généraux pour sélectionner la pompe

convenant à un usage particulier. Goulds Water

Technology ne peut prévoir tous les usages faits de

ses pompes. Il est donc recommandé de s’adresser à

Goulds Water Technology si l’on prévoit utiliser une

pompe pour un liquide autre que l’eau, et ce, afin de

savoir s’il y a risque ou non. L’inobservation de cette

recommandation pourrait entraîner des blessures et

des dommages matériels.

DIRECTIVES D’UTILISATION

DIRECTIVES D’UTILISATION

GÉNÉRALITÉS

Notre emballage est conçu pour prévenir les dommages

durant le transport. Toutefois, il faut noter toute indication d’endommagement avec soin sur le bordereau de

livraison et effectuer une demande de règlement sans

tarder auprès du transporteur.

LIEU D’INSTALLATION APPROPRIÉ

• La pose de la pompe Goulds sur un massif de béton

solide et de niveau ou entre deux conduites solidement

supportées réduira les vibrations nuisibles et le bruit

excessif.

• Bien que la pompe autoamorçante de la série EV

puisse être placée plus haut que la source de liquide,

on obtiendra les meilleurs résultats en l'installant aussi

près que possible du liquide à pomper, car elle refoule

le liquide plus efficacement qu'elle l'aspire. On prévoira

suffisamment d'espace autour de la pompe pour les

inspections et l'entretien de cette dernière.

TUYAUTERIE

• La tuyauterie devrait posséder ses propres supports

afin d'éliminer les contraintes excessives sur la pompe.

Prévenir les pertes de charge (par frottement) inutiles. Garder la tuyauterie aussi courte que possible

et pourvue du minimum de coudes, de raccords et

d'accessoires. Utiliser de la pâte à joint que le liquide à

pomper ne pourra dissoudre. L'usage de robinets-vannes et de raccords unions ou de brides de chaque côté

de la pompe facilitera la dépose de celle-ci, et ce, sans

déplacer la tuyauterie. Il est parfois avantageux d'employer un tuyau d'aspiration du calibre immédiatement

supérieur à celui de l'orifice d'aspiration de la pompe.

Utiliser un raccord réducteur excentré pour changer le

calibre de la tuyauterie.

CRÉPINE (RECOMMANDÉE)

• Protéger son investissement en installant une crépine à

l'entrée du tuyau d'aspiration. On évitera ainsi l'engorgement, le rendement médiocre et l'usure excessive de

la pompe. Une crépine de 16 mailles par pouce, immergée à un pied de profondeur, convient aux pompes

de la série EV. On peut se procurer les crépines chez

le détaillant Goulds Water Technology. La tuyauterie

inclinée graduellement vers le haut à partir de la source

de liquide facilite la vidange du système.

APPAREILS DE ROBINETTERIE

• Poser un clapet de non-retour du côté refoulement de

la pompe pour empêcher les coups de bélier d'endommager la pompe et empêcher aussi la tuyauterie de

refoulement de se vider durant la dépose de la pompe.

19

• Certaines installations peuvent nécessiter l'étrangle-

ATTENTION

AVERTISSEMENT

ment de la section de passage du côté refoulement de la

pompe. On peut employer des robinets-vannes à cette

fin. En pareil cas, poser le clapet de non-retour entre la

pompe et le robinet-vanne.

• Une pression de refoulement faible peut faire augmenter le bruit de la pompe. Fermer alors graduellement le

robinet-vanne du tuyau de refoulement jusqu'à ce que

le bruit excessif disparaisse. Cette restriction ne causera

pas de perte de débit appréciable.

UTILISATION

UTILISATION

AMORÇAGE

• Remplir le corps de pompe de liquide avant la mise en

marche. Le bouchon du coude fixé au corps de pompe

sert à cela. Enduire les filets du bouchon avec de la

pâte à joint avant de le visser sur le coude. La pompe

autoamorçante Goulds s'amorce d'elle-même si elle

est remplie de liquide. En cas de vidange accidentelle

ou intentionnelle de la pompe, la remplir avant de la

remettre en marche. Une hauteur d'aspiration et une

tuyauterie d'aspiration de grande dimension requièrent

un temps d'amorçage plus long et réduisent le rendement de la pompe. En cas de problème, voir Diagnostic

des anomalies.

• Veiller à ce qu'il y ait toujours du liquide dans la pompe

pour en assurer la lubrification et celle de la garniture

mécanique. Aucune autre forme de lubrification n'est

nécessaire. Si le débit ne devient pas régulier après cinq

minutes d'essai d'amorçage, consulter le Diagnostic des

anomalies. S'assurer que les robinets d'aspiration et de

refoulement sont ouverts durant l'amorçage, et ce, afin

de ne pas endommager la pompe.

SENS DE ROTATION

• La pompe est conçue pour tourner dans le sens indiqué

sur le corps de pompe. Comme les moteurs triphasés

peuvent tourner dans les deux sens, vérifier leur sens de

rotation et, au besoin, l'inverser en intervertissant deux

des fils de moteur.

ENTREPOSAGE HIVERNAL

• Par temps de gel, il est particulièrement important que

le corps de pompe soit entièrement vidangé pour en

prévenir l'endommagement et celui des pièces internes.

• An de maintenir l'excellent rendement de la pompe,

suivre les directives du fabricant du moteur quant à

l'entreposage.

LUBRIFICATION

• La garniture mécanique autolubriante est le fruit des

derniers progrès techniques. Étant donné que le liquide

pompé refroidit et lubrifie la garniture, la pompe ne

doit jamais fonctionner à sec. L'orifice de fuite du

logement de garniture protégera le moteur électrique

du liquide s'il y a fuite de la garniture. NE PAS boucher

l’orifice. Si la garniture fuit trop, la remplacer.

ENTRETIEN

• Si la pompe n'est pas employée pendant quelques jours,

la vidanger pour prévenir la formation de rouille,

aggravante et coûteuse.

Un électricien doit réaliser tout le mon-

tage électrique. S’assurer que le courant

est coupé à la boîte de jonction secteur avant de travailler sur la pompe ou le moteur. Mettre le fusible ou le

disjoncteur hors circuit et poser sur l’interrupteur secteur

une étiquette disant : « Ne pas rétablir le courant — travaux en cours sur le matériel ».

Certains moteurs sont protégés contre

les surcharges thermiques et s’arrêtent

lorsqu’il y a surchauffe d’origine mécanique ou électrique telle qu’une mauvaise ventilation, une basse tension,

un câblage surchargé, etc. Ils redémarrent inopinément

quand ils se refroidissent. Pour des raisons de sécurité,

ne travailler sur aucun moteur sans que le courant soit

d’abord coupé à la source. Procéder alors selon l’« AVERTISSEMENT » précédent. Les moteurs triphasés n’ont

pas de protection thermique. Un démarreur est recommandé dans leur cas.

DIRECTIVES POUR LES ÉLECTRICIENS

DIRECTIVES POUR LES ÉLECTRICIENS

COUPER LE COURANT.

1. Déterminer la tension sur les fils d’alimentation du

moteur. Tension, nombre de phases, débit en ampères

et fréquence du courant figurent sur la plaque signalétique du moteur.

Le calibre des ls d’alimentation du moteur doit être

suffisamment gros pour transporter le courant sur

la longueur de câble requise sans chute de tension

excessive. La table suivante sert de guide uniquement

pour le choix du calibre de fil minimal approprié. Il

faut toujours consulter le code provincial ou national

de l’électricité pertinent et les règlements locaux.

Calibre de fil AWG type des moteurs de pompe à jet monophasés

Longueur de fil de 50 pi Longueur de fil de 100 pi

hp

115 V 230 V 115 V 230 V

1

⁄3 14 12

½ 14 14 10 14

¾ 12 14 10 14

1 12 14 8 14

1½ 10 14 8 12

2 8 12 8 12

20

DIAGNOSTIC DES ANOMALIES

DIAGNOSTIC DES ANOMALIES

Ci-dessous, on trouvera certaines causes d'anomalies communes.

ANOMALIES CAUSES PROBABLES CORRECTIFS RECOMMANDÉS

La pompe ne s'amorce Liquide absent du corps de pompe Remplir la pompe de liquide.

pas.

Air entrant dans la tuyauterie d'aspiration Serrer tous les joints ou les refaire avec de la

pâte à joint neuve.

Tuyauterie d'aspiration bouchée Nettoyer la crépine ou la tuyauterie

d'aspiration.

Garniture mécanique usée Remplacer la garniture.

Le liquide s'arrête sou- Crépine ou roue engorgée Enlever les résidus.

dainement de s'écouler.

Le liquide s'arrête Roue, diffuseur ou conduites engorgés, Enlever les résidus, utiliser une crépine,

lentement de circuler. bouchon de remplissage mal serré resserrer le bouchon.

Trop de liquide sort Garniture mécanique usée Remplacer la garniture.

par l'orifice de fuite.

La pompe se Garniture mécanique usée Remplacer la garniture.

désamorce.

Air entrant dans la tuyauterie d'aspiration Colmater la fuite.

Hauteur d'aspiration excessive Rapprocher la pompe de sa source de liquide.

Clavette de roue manquante ou brisée Poser ou remplacer la clavette.

Le rendement est Roue ou garniture mécanique usée Poser une roue ou une garniture neuve.

faible.

Hauteur d'aspiration excessive Rapprocher la pompe de sa source de liquide.

Le débit ou la pression Moteur trop lent (basse tension) Employer un calibre de fil d'alimentation plus

est faible. gros.

pâte à joint neuve.

Conduite engorgée Nettoyer la crépine ou la tuyauterie

d'aspiration.

Garniture mécanique usée Remplacer la garniture.

Mauvais sens de rotation (moteur triphasé) Intervertir deux des fils d'alimentation du

moteur.

Le bruit de Roulements ou coussinets de moteur usés Les remplacer.

fonctionnement est

élevé.

refoulement.

Résidus accumulés dans la roue Démonter et nettoyer la pompe.

Cavitation Améliorer les conditions nécessaires pour

l'aspiration.

Air aspiré dans les conduites Serrer tous les joints ou les refaire avec de la

Hauteur de refoulement faible Étrangler la section de passage du tuyau de

21

LISTE DE PIÈCES DE RECHANGE

LISTE DE PIÈCES DE RECHANGE

No Description No Description

1 Bouchon de vidange 11➀ Garniture mécanique

2 Couvercle (corps de pompe) 12 Corps de pompe

3➀ Joint d'étanchéité (couvercle) 13➀ Cale (moteur)

4➀ Écrou de roue 14➀ Clavette (roue)

5➀ Rondelle de roue 15 Vis d'assemblage

6➁ Roue 16 Vis d'assemblage

7➁ Diffuseur 17➀ Déflecteur de liquide

8➀ Joint d'étanchéité (diffuseur) 18 Coude

9➀ Cale (roue) 19 Bouchon de remplissage

10➀ Entretoise (roue) 20 Moteur

➀ Pièces de rechange recommandées

➁ Service critique, pièces de rechange pour l'exportation et stocks du distributeur recommandés

IMPORTANT :

Mode de commande des pièces

La liste de pièces et le dessin figurant dans la présente page s'appliquent à divers modèles de pompes Goulds

Water Technology, y compris la 20EVP. Au besoin, se servir de la liste et du dessin pour trouver le numéro et le

nom d'une pièce à remplacer, puis les indiquer au détaillant Goulds Water Technology, ainsi que les numéros de

modèle et de série de la pompe, mentionnés sur la plaque signalétique de cette dernière.

16

20

14

17

13

15

12

11

10

9

8

3

2

1

5

4

7

6

19

18

22

NOTES

23

GARANTIE LIMITÉE DE GOULDS WATER TECHNOLOGY

La présente garantie s’applique à chaque pompe de système d’alimentation en eau fabriquée par Goulds Water Technology.

Toute pièce se révélant défectueuse sera remplacée sans frais pour le détaillant durant la période de garantie suivante expirant la première : douze (12) mois à compter de la date

d’installation ou dix-huit (18) mois à partir de la date de fabrication.

Le détaillant qui, aux termes de la présente garantie, désire effectuer une demande de règlement doit s’adresser au distributeur Goulds Water Technology agréé chez lequel la pompe a

été achetée et fournir tous les détails à l’appui de sa demande. Le distributeur est autorisé à régler toute demande par le biais du service à la clientèle de Goulds Water Technology.

La garantie ne couvre pas :

a) les frais de main-d’œuvre ni de transport ni les frais connexes encourus par le détaillant ;

b) les frais de réinstallation du matériel réparé ;

c) les frais de réinstallation du matériel de remplacement ;

d) les dommages indirects de quelque nature que ce soit ;

e) ni les pertes découlant de la panne.

Aux fins de la garantie, les termes ci-dessous sont définis comme suit :

1) « Distributeur » signifi e une personne, une société de personnes, une société de capitaux, une association ou autre entité juridique servant d’intermédiaire entre Goulds Water Tech-« Distributeur » signifie une personne, une société de personnes, une société de capitaux, une association ou autre entité juridique servant d’intermédiaire entre Goulds Water Technology et le détaillant pour les achats, les consignations ou les contrats de vente des pompes en question.

2) « Détaillant » veut dire une personne, une société de personnes, une société de capitaux, une association ou autre entité juridique dont les activités commerciales sont la vente ou la

location de pompes à des clients.

3) « Client » désigne une entité qui achète ou loue les pompes en question chez un détaillant. Le « client » peut être une personne, une société de personnes, une société de capitaux,

une société à responsabilité limitée, une association ou autre entité juridique se livrant à quelque activité que ce soit.

LA PRÉSENTE GARANTIE SE RAPPORTE AU DÉTAILLANT SEULEMENT.

Xylem, Inc.

2881 East Bayard Street Ext., Suite A

Seneca Falls, NY 13148

Téléphone: (800) 453-6777

Télécopie: (888) 322-5877

www.xyleminc.com/brands/gouldswatertechnology

Goulds est une marque déposée de Goulds Pumps, Inc. et est utilisé sous le permis.

© 2012, Xylem Inc. IM078 Révision numéro 4 Mars 2012

Loading...

Loading...