INSTRUCTION MANUAL

IM203R01

Model SSV Cartridge Seal

Modèle SSV / Modelo SSV

INSTALLATION INSTRUCTIONS / DIRECTIVES D’INSTALLATION / INSTRUCCIONES DE INSTALACIÓN

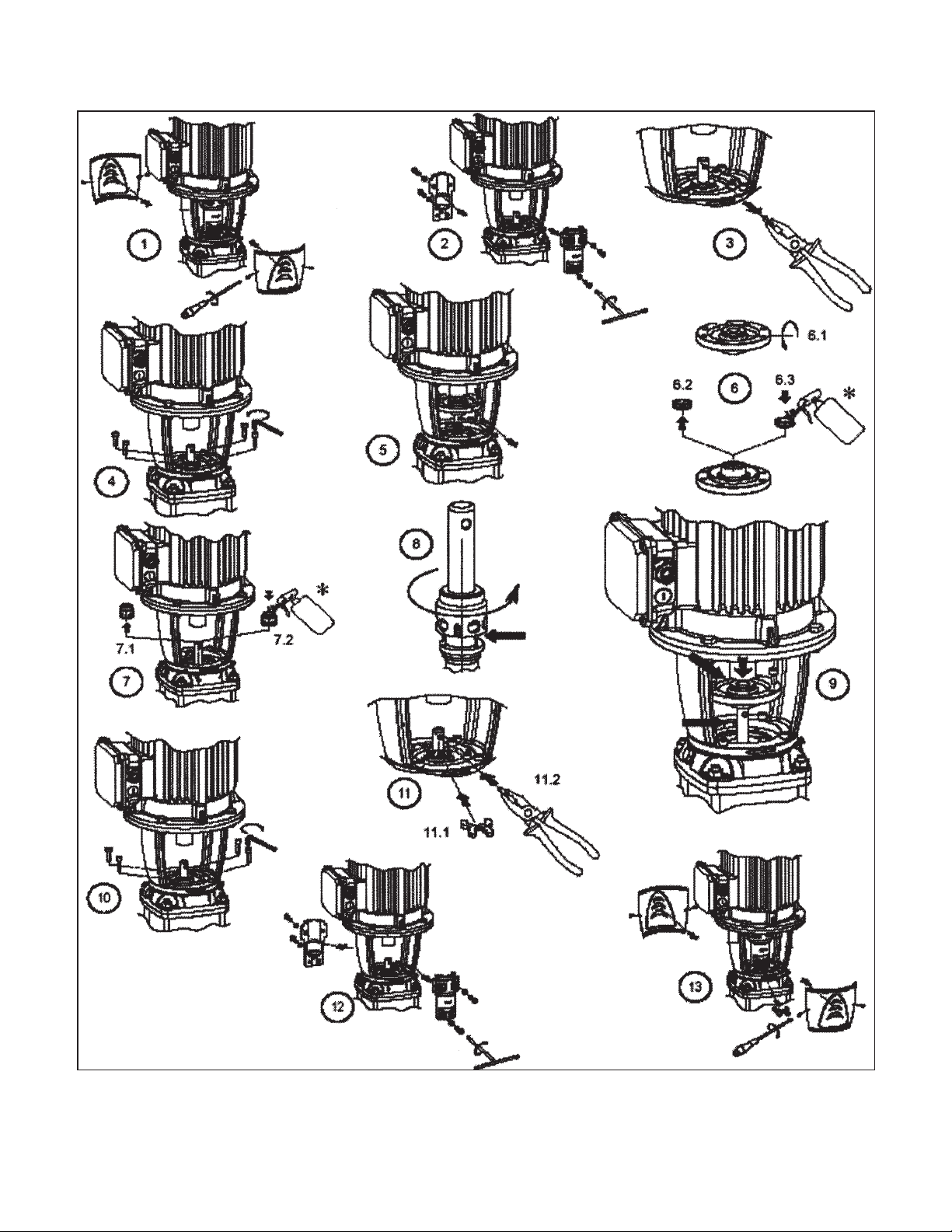

Figure 5

Page 2

SSV CARTRIDGE SEAL INSTALLATION

CAUTION

CARTRIDGE TYPE SEAL INSTALLATION

1. Close all necessary suction and discharge valves to

isolate the pump from the system.

2. Drain the liquid from the pump by removing the

drain plug and opening the needle valve on the

vent plug.

3. Remove the coupling guards, the 4 coupling hex

cap screws, the coupling and coupling drive pin.

4. Remove the 4 motor hex cap screws (inner screws)

on the seal housing.

5. Loosen the 4 set screws located around the ID of

the pump shaft.

6. Remove the cartridge seal using the two tapped

holes provided on the gland of the cartridge seal

by threading two of the hex cap screws into these

holes and evenly tightening these screws. Lift and

remove the cartridge seal between the pump and

motor shaft.

7. Inspect the pump shaft for any burrs or debris. Any

burrs should be ground smooth with (fine grit)

emery paper.

8. Install a new o-ring on the turned fit of the new

cartridge seal. Lubricate the o-ring located in the

ID of the cartridge seal. Use a lubricant compatible

with the seal elastomers to hold the o-ring.

9. Install the new cartridge seal on the pump by carefully sliding it between the pump and motor shaft

and then sliding it into position

10. Reinstall the coupling pin and locate the space

shim on the shaft on the seal housing. If the shim

is not available, a 5 mm spacer can be used. See

step 11 in Figure 5.

11. Reinstall the coupling halves and evenly tighten

the coupling bolts and torque them to 37 lbs ft (50

Nm) for 184TC frame motors and torque coupling

bolts to 48 lbs ft (65 Nm) for all larger frame sizes.

Remove the spacer shim and save for future use.

See step 12 in Figure 5.

12. Rotate the shaft by hand to insure that the pump

and motor rotate freely. Reinstall the coupling

guard.

13. The pump and system should be vented prior to

starting the pump. For sizes 33SV-92SV the vent

plug is supplied with an internal needle valve, so

it is not necessary to remove the vent plug. Simply

unscrew the needle valve half way to open the

valve to allow air to escape. (For sizes 33SV-92SV, if

the pump is supplied with a cartridge seal, remove

the vent plug located on the gland plate beneath

the coupling.)

NOTE: Place a loose rag over the open vent port

to prevent large amounts of liquid from being

sprayed on the pump and adjacent equipment.

Care should be exercised if you are

pumping hot water or chemicals to

avoid personal injury.

14. After installing the coupling, tighten the four set

screws located in the collar of the cartridge seal to

secure the seal to the pump shaft.

15. Rotate the shaft by hand to insure that the pump

and motor rotate freely. Reinstall the coupling

guard.

16. Use vent connections on cartridge seal for proper

venting.

Page 3

SSV CARTRIDGE SEAL INSTALLATION

REMPLACEMENT DE LA CARTOUCHE D’ETANCHEITE (33SV A 92SV)

1. Fermer les robinets d’aspiration et de refoulement

nécessaires pour isoler la pompe du système.

2. Enlever le bouchon de vidange, dévisser le pointeau de mise à l’air libre et laisser la pompe se

vider.

3. Enlever les carters d’accouplement, les 4 vis

d’assemblage des demi-accouplements, ces derniers et la goupille de liaison (v. fi g. 5, nos 1 à 3).

4. Enlever les 4 vis de fi xation intérieures de la

plaque-logement de garniture.

5. Desserrer les 4 vis de pression du collet de la car

touche d’étanchéité.

6. Poser deux (2) des vis de fi xation (à tête hexagonale) dans les orifi ces taraudés du fouloir de la

cartouche et les visser uniformément pour dégager

la cartouche. Lever la cartouche et la retirer par

l’espace libre entre les deux arbres.

7. Inspecter l’arbre de pompe pour s’assurer qu’il n’a

ni arêtes vives ni corps étrangers. Les arêtes vives

devraient être lissées avec une toile d’émeri fi ne.

8. Utiliser un lubrifi ant convenant aux élastomères

de la cartouche pour poser un joint torique neuf

sur le guide (usiné) de la cartouche neuve. En

appliquer aussi sur le joint torique du pourtour

intérieur de la cartouche.

9. Placer la cartouche neuve entre l’arbre de moteur

et l’arbre de pompe et enfi ler la cartouche sur ce

dernier avec précaution.

10. Insérer la goupille de liaison de l’arbre de pompe

dans son orifi ce et placer la cale de réglage de

position sur la saillie centrale de la plaque-logement (v. 11, fi g. 5). À défaut, on peut employer

une cale de 5 mm (0,203 po) d’épaisseur.

11. Réinstaller les moitiés d’accouplement et serrer

également les boulons d’accouplement et les

serrer à la clé dynamométrique à 37 lbs ft (50 Nm)

pour des moteurs de l’armature 184TC et des boulons d’accouplement de couple à 48 lbs ft (65 Nm)

pour toutes les plus grandes tailles d’armature.

Enlever la cale d’entretoise et économiser pour le

futur usage. Voir l’étape 12 sur le schéma 5.

12. Tourner l’arbre à la main pour s’assurer que la

pompe et le moteur ne sont pas grippés, puis

poser les carters d’accouplement (v. 13, fi g. 5).

13. La pompe et le système devraient être mis à l’air

libre avant la mise en service de la pompe (v.

AMORÇAGE ET MISE À L’AIR LIBRE). Le bouchon

de mise à l’air libre des 33SV à 92SV est muni

d’un pointeau (aiguille), que l’on dévisse simplement à moitié pour évacuer l’air, sans avoir à ôter

le bouchon. Quant aux 33SV à 92SV à cartouche

d’étanchéité, on doit dévisser le bouchon de mise

à l’air libre situé sur la plaque de fi xation du fouloir

de cartouche, sous l’accouplement.

NOTA: placer un chiffon sur l’orifi ce de mise à l’air

libre pour empêcher l’éclaboussement du liquide

sous pression.

ATTENTION

pompé est chaud ou corrosif.

14. Mettre l’accouplement en place, puis serrer les 4

vis de pression du collet de la cartouche pour assujettir cette dernière à l’arbre de pompe.

15. Tourner l’arbre à la main pour s’assurer que la

pompe et le moteur ne sont pas grippés, puis

poser les carters d’accouplement.

16. Utiliser le bouchon de la plaque de fi xation du

fouloir de cartouche pour mettre la pompe à l’air

libre de manière adéquate.

On doit agir avec précaution pour

prévenir les blessures si le liquide

Page 4

SSV CARTRIDGE SEAL INSTALLATION

RECAMBIO DE LA JUNTA HERMETICA MECANICA (TAMANOS 33SV-92SV)

EQUIPADASCON JUNTAS DE CARTUCHOS

1. Cierre todas las válvulas de succión y de descarga

necesarias para aislar la bomba del sistema.

2. Drene el líquido de la bomba quitando el tapón

de drenaje y abriendo la válvula cónica sobre el

tapón de cierre.

3. Quite las protecciones de acoplamiento, los 4

tornillos de acoplamiento de cabeza hexagonal,

el acoplamiento y el dedo de arrastre de acoplamiento. Vea los pasos 1-3.

4. Quite los 4 tornillos de cabeza hexagonal del

motor (tornillos internos) en la cubierta de la junta

hermética. Vea el paso 4.

5. Afl oje los 4 tornillos ubicados alrededor del ID del

eje de la bomba.

6. Quite la junta de cartucho utilizando los dos agujeros roscados suministrados en el casquillo de la

junta de cartucho, enroscando dos de los tornillos

de cabeza hexagonal dentro de estos orifi cios

y ajustando los tornillos en forma pareja. Eleve y

extraiga la junta de cartucho entre la bomba y el

eje del motor.

7. Controle que el eje de la bomba no tenga ninguna

rebaba o suciedad. Cualquier rebaba debe ser

pulida con papel de esmeril (arenado fi no).

8. Instale un nuevo aro tórico sobre el montaje

torneado de la nueva junta de cartucho. Lubrique

el aro tórico ubicado en el diámetro inferior de la

junta de cartucho. Utilice un lubricante compatible

con los elastómeros de la junta para retener el aro

tórico.

9. Instale la nueva junta de cartucho sobre la bomba

desplazándola con cuidado entre la bomba y el

eje del motor y desplazándola luego hasta lograr

la posición.

10. Reinstale el vástago de acoplamiento y coloque el

compensador de espacio del eje sobre la cubierta

de la junta. Si la cuña no está disponible, puede

utilizarse un separador de 5 mm. Vea el paso 11

en la Figura 5.

11. Reinstalar las mitades de acoplador y apretar uniformemente los pernos del acoplador y apretarlos

a 37 libras de pie (50 nanómetro) para los motores

del marco 184TC y los pernos del acoplador del

es fuerzo de torsión a 48 libras de pie (65 nanómetro) para todos los tamaños más grandes del

marco. Quitar la calza del espaciador y excepto

para el uso futuro. Ver el paso 12 en el cuadro 5.

12. Rote el eje manualmente para asegurarse que la

bomba y el motor roten sin difi cultad. Reinstale el

protector de acoplamiento.

13. La bomba y el sistema deben ventilarse antes de

arrancar la bomba. Vea la Sección 3, página 8,

para conocer los procedimientos de ventilación.

Para los tamaños 33SV-92SV el tapón de cierre de

la tubería de ventilación se proporciona con una

válvula cónica interna, por lo tanto no es necesario quitarlo. Simplemente destornille la válvula

cónica a la mitad para abrirla y permitir el escape

de aire. (Para los tamaños 33SV-92SV, si la bomba

se suministra con una junta hermética de cartucho,

quite el tapón de cierre de la tubería de ventilación ubicado sobre la placa del collarín detrás

del acoplamiento).

AVISO: Coloque una faja suelta sobre el orifi cio

de ventilación para evitar que la bomba y los equipos adyacentes sufran salpicaduras como consecuencia de la gran cantidad de líquido.

PRECAUCIÓN

para evitar lesiones personales.

14. Después de instalar el acoplamiento, ajuste los

cuatro de tornillos de fi jación ubicados en el collarín de la junta de cartucho para asegurar la junta

al eje de la bomba.

15. Rote el eje manualmente para asegurarse que la

bomba y el motor rotan sin difi cultad. Reinstale el

protector de acoplamiento.

16. Utilice las conexiones de ventilación sobre la junta

del cartucho para una correcta ventilación.

Si se bombea agua caliente o químicos, debe ponerse especial cuidado

Page 5

Declaration of Conformity

Declaration of Conformity

We at,

Goulds Water Technology / Xylem Inc.

1 Goulds Drive

Auburn, NY 13021

Declare that the following products: NPE, MCS, MCC, 3656, 3656 SP, GB, e-SV, SVI, NPO, Prime Line SP, HB, HMS,

LC, NPV, LB, LBS comply with Machine Directive 06/42/EC. This equipment is intended to be incorporated with

machinery covered by this directive, but must not be put into service until the machinery into which it is to be incorporated has been declared in conformity with the actual provisions of the directive.

Declaración de Conformidad

Declaración de Conformidad

Nosotros en

Goulds Water Technology / Xylem Inc.

1 Goulds Drive

Auburn, NY 13021

Declaramos que los siguientes productos: NPE, MCS, MCC, 3656, 3656 SP, GB, e-SV, SVI, NPO, Prime Line SP, HB,

HMS, LC, NPV, LB, LBS cumplen con las Directivas para Maquinarias 06/42/EC. Este equipo ha sido diseñado para ser

incorporado a la maquinaria cubierta por esta directiva pero no debe ponerse en funcionamiento hasta que se declare

que la maquinaria en la que será incorporado cumple con las disposiciones reales de la directiva.

Déclaration de Conformité

Déclaration de Conformité

Nous, à

Goulds Water Technology, Xylem Inc.

1 Goulds Drive

Auburn, NY, U.S.A. 13021,

déclarons que les produits NPE, MCS, MCC, 3656, 3656 SP, GB, e-SV, SVI, NPO, Prime Line SP, HB, HMS, LC, NPV,

LB et LBS sont conformes à la directive 06/42/EC (législation relative aux machines). Ils sont destinés à être intégrés

dans la machinerie faisant l’objet de ladite directive, mais ne doivent pas être mis en service tant que la machinerie en

question ne sera pas déclarée conforme aux stipulations de la directive.

Page 6

GOULDS WATER TECHNOLOGY LIMITED WARRANTY

This warranty applies to all water systems pumps manufactured by Goulds Water Technology.

Any part or parts found to be defective within the warranty period shall be replaced at no charge to the dealer during the warranty period. The warranty period shall

exist for a period of twelve (12) months from date of installation or eighteen (18) months from date of manufacture, whichever period is shorter.

A dealer who believes that a warranty claim exists must contact the authorized Goulds Water Technology distributor from whom the pump was purchased and furnish

complete details regarding the claim. The distributor is authorized to adjust any warranty claims utilizing the Goulds Water Technology Customer Service Department.

The warranty excludes:

(a) Labor, transportation and related costs incurred by the dealer;

(b) Reinstallation costs of repaired equipment;

(c) Reinstallation costs of replacement equipment;

(d) Consequential damages of any kind; and,

(e) Reimbursement for loss caused by interruption of service.

For purposes of this warranty, the following terms have these definitions:

(1) “Distributor” means any individual, partnership, corporation, association, or other legal relationship that stands between Goulds Water Technology and

the dealer in purchases, consignments or contracts for sale of the subject pumps.

(2) “Dealer” means any individual, partnership, corporation, association, or other legal relationship which engages in the business of selling or leasing

pumps to customers.

(3) “Customer” means any entity who buys or leases the subject pumps from a dealer. The “customer” may mean an individual, partnership, corporation,

limited liability company, association or other legal entity which may engage in any type of business.

THIS WARRANTY EXTENDS TO THE DEALER ONLY.

GARANTÍA LIMITADA DE GOULDS WATER TECHNOLOGY

Esta garantía es aplicable a todas las bombas para sistemas de agua fabricadas por Goulds Water Technology.

Toda parte o partes que resultaren defectuosas dentro del período de garantía serán reemplazadas durante dicho período de garantía sin cargo para el comerciante.

Tal período de garantía se extiende por doce (12) meses a partir de la fecha de instalación, o dieciocho (18) meses a partir de la fecha de fabricación, la que se cumpla

primero.

El comerciante que considere que existe lugar a un reclamo de garantía deberá ponerse en contacto con el distribuidor autorizado de Goulds Water Technology del

cual adquiriera la bomba y brindar información detallada con respecto al reclamo. El distribuidor está autorizado a liquidar todos los reclamos por garantía a través del

Departamento de Servicios a Clientes de Goulds Water Technology.

La presente garantía excluye:

(a) La mano de obra, el transporte y los costos relacionados en los que incurra el comerciante;

(b) los costos de reinstalación del equipo reparado;

(c) los costos de reinstalación del equipo reemplazado;

(d) daños emergentes de cualquier naturaleza; y

(e) el reembolso de cualquier pérdida causada por la interrupción del servicio.

A los fines de esta garantía, los términos “Distribuidor”, “Comerciante” y “Cliente” se definen como sigue:

(1) “Distribuidor” es aquel individuo, sociedad, corporación, asociación u otra entidad jurídica que opera entre Goulds Water Technology y el comerciante para la

compra, consignación o contratos de venta de las bombas en cuestión.

(2) “Comerciante” es todo individuo, sociedad, corporación asociación u otra entidad jurídica que realiza negocios de venta o alquiler-venta (leasing) de bombas a los

clientes.

(3) “Cliente” es toda entidad que compra o adquiere bajo la modalidad de leasing las bombas en cuestión de un comerciante. El término “cliente” puede significar un

individuo, sociedad, corporación, sociedad de responsabilidad limitada, asociación o cualquier otra entidad jurídica con actividades en cualquier tipo de negocios.

LA PRESENTE GARANTÍA SE EXTIENDE AL COMERCIANTE ÚNICAMENTE.

GARANTIE LIMITÉE DE GOULDS WATER TECHNOLOGY

La présente garantie s’applique à chaque pompe de système d'alimentation en eau fabriquée par Goulds Water Technology.

Toute pièce se révélant défectueuse sera remplacée sans frais pour le détaillant durant la période de garantie suivante expirant la première : douze (12) mois à compter

de la date d’installation ou dix-huit (18) mois à partir de la date de fabrication.

Le détaillant qui, aux termes de la présente garantie, désire effectuer une demande de règlement doit s’adresser au distributeur Goulds Water Technology agréé

chez lequel la pompe a été achetée et fournir tous les détails à l’appui de sa demande. Le distributeur est autorisé à régler toute demande par le biais du service à la

clientèle de Goulds Water Technology.

La garantie ne couvre pas :

a) les frais de main-d’œuvre ni de transport ni les frais connexes encourus par le détaillant ;

b) les frais de réinstallation du matériel réparé ;

c) les frais de réinstallation du matériel de remplacement ;

d) les dommages indirects de quelque nature que ce soit ;

e) ni les pertes découlant de la panne.

Aux fins de la garantie, les termes ci-dessous sont définis comme suit :

« Distributeur » signifie une personne, une société de personnes, une société de capitaux, une association ou autre entité juridique servant d'intermédiaire entre

1)

Goulds Water Technology et le détaillant pour les achats, les consignations ou les contrats de vente des pompes en question.

« Détaillant » veut dire une personne, une société de personnes, une société de capitaux, une association ou autre entité juridique dont les activités commerciales

2)

sont la vente ou la location de pompes à des clients.

« Client » désigne une entité qui achète ou loue les pompes en question chez un détaillant. Le « client » peut être une personne, une société de personnes, une

3)

société de capitaux, une société à responsabilité limitée, une association ou autre entité juridique se livrant à quelque activité que ce soit.

LA PRÉSENTE GARANTIE SE RAPPORTE AU DÉTAILLANT SEULEMENT.

Page 7

Xylem, Inc.

2881 East Bayard Street Ext., Suite A

Seneca Falls, NY 13148

Phone/Teléfono/Téléphone: (800) 453-6777

Fax/Télécopie: (888) 322-5877

www.xyleminc.com/brands/gouldswatertechnology

Goulds is a registered trademark of Goulds Pumps, Inc. and is used under license.

Goulds es una marca registrada de Goulds Pumps, Inc. y se utiliza bajo licencia.

Goulds est une marque déposée de Goulds Pumps, Inc. et est utilisé sous le permis.

© 2012 Xylem Inc. IM203 Revision Number 1 November/Noviembre/Novembre 2012

Loading...

Loading...